Influence of Ball Burnishing on Lubricated Fretting of the Titanium Alloy Ti6Al4V

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

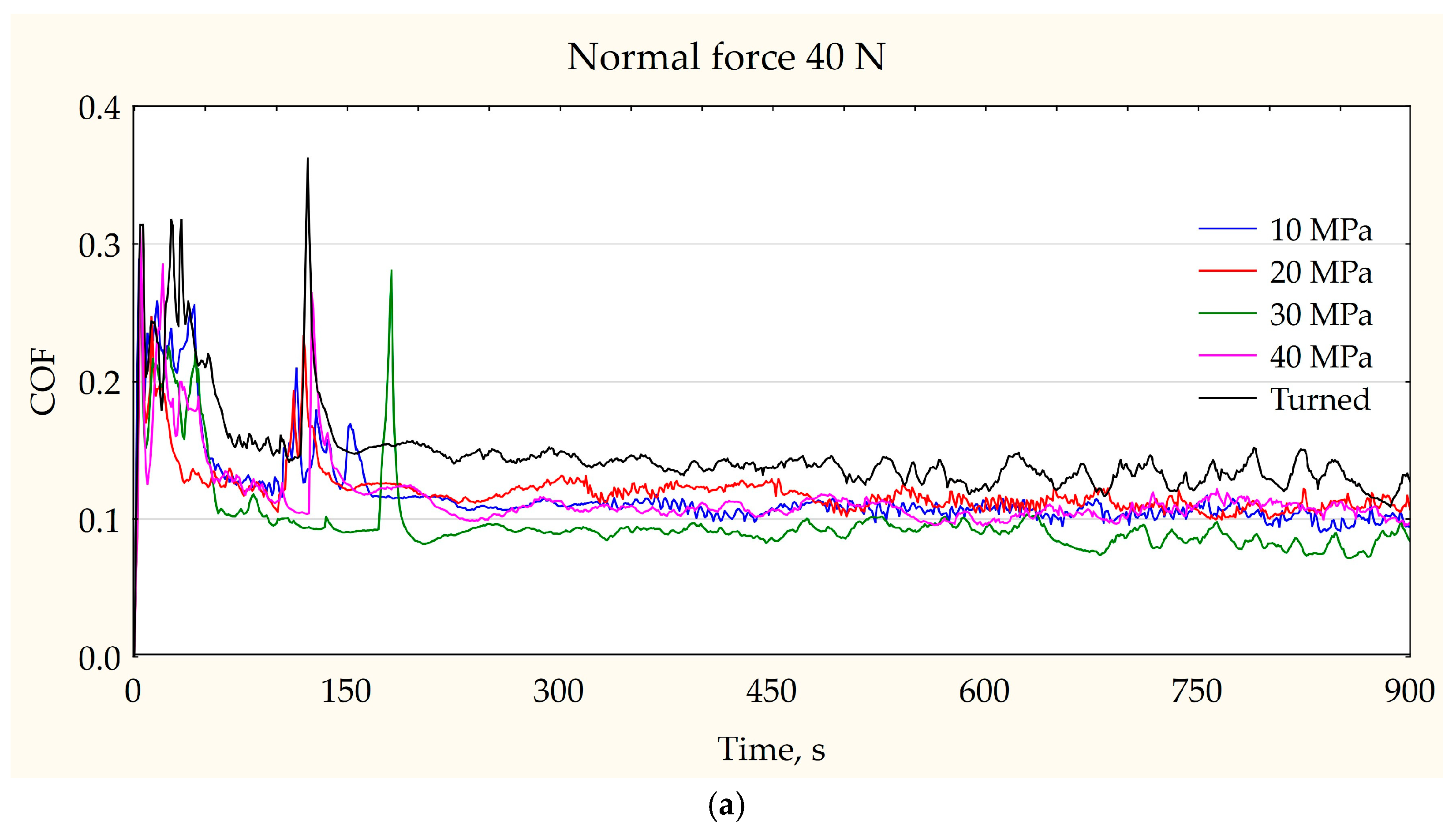

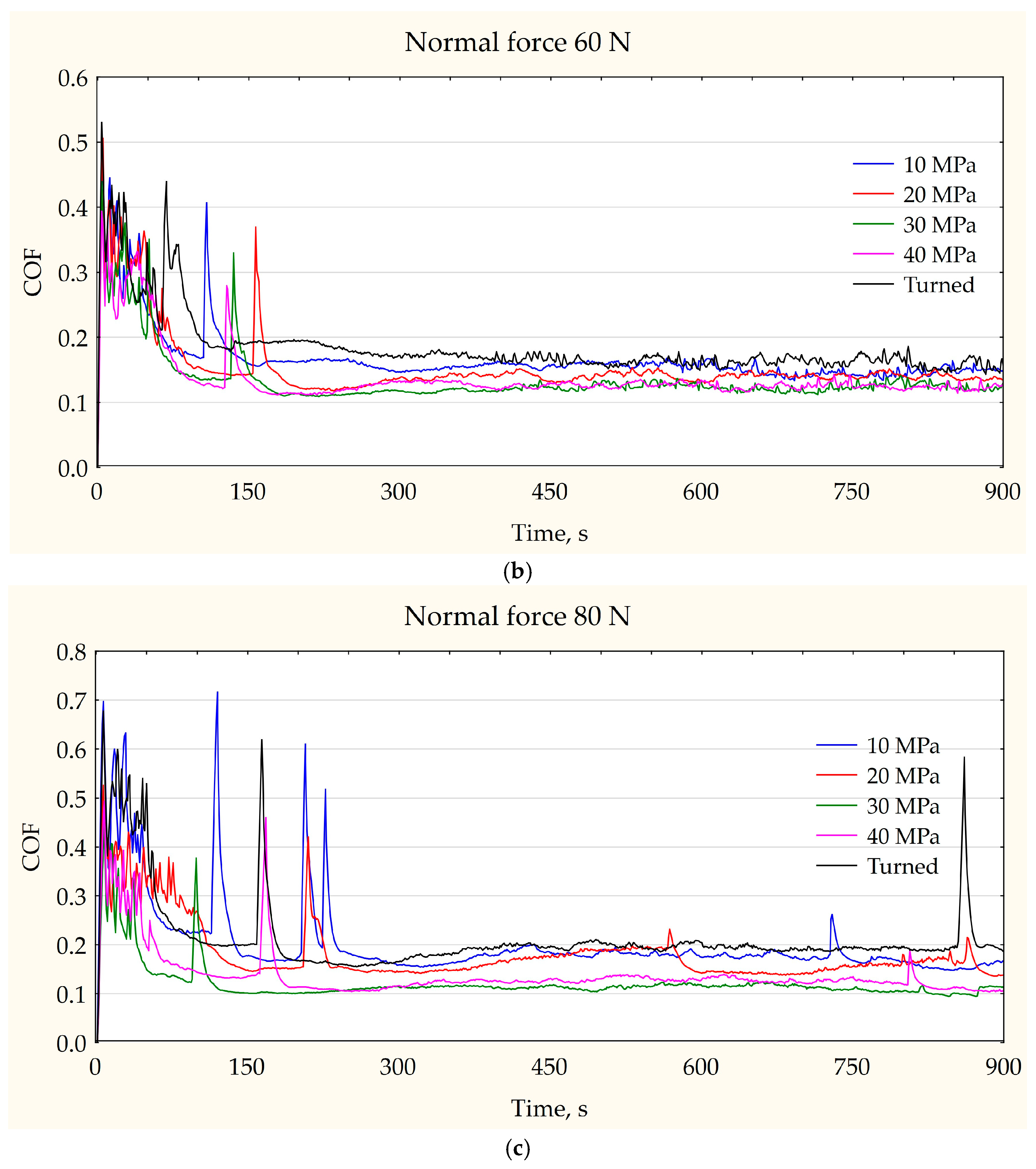

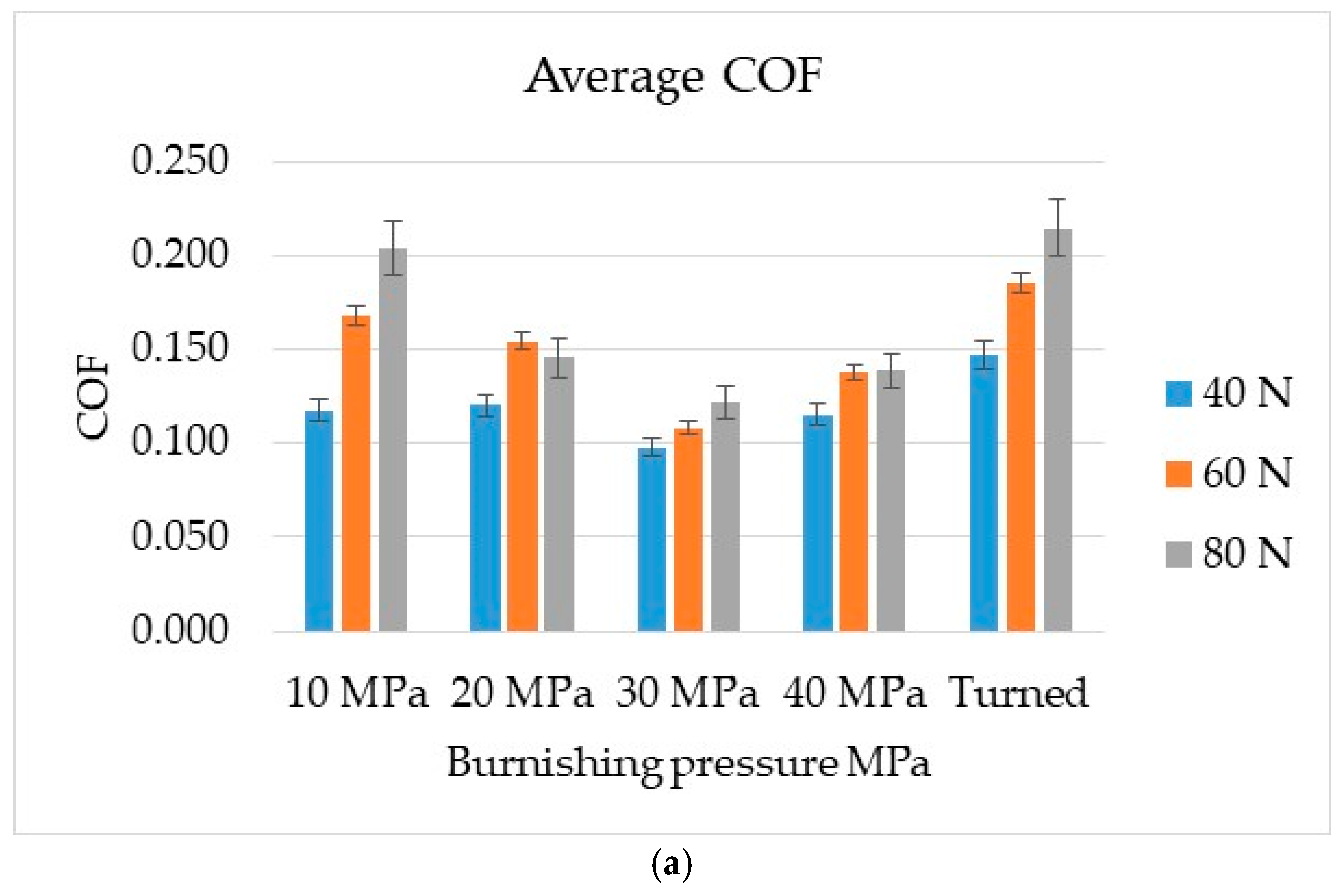

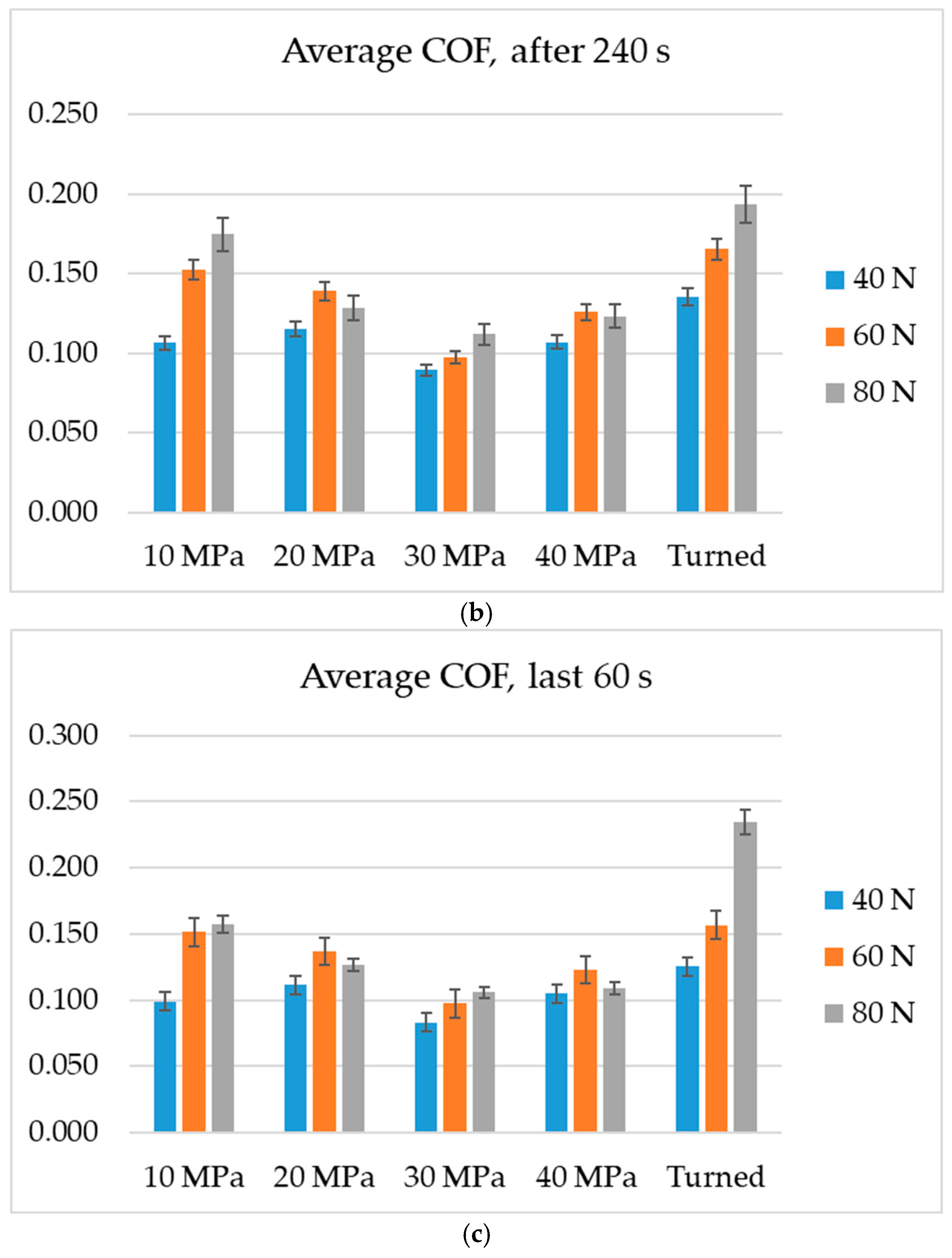

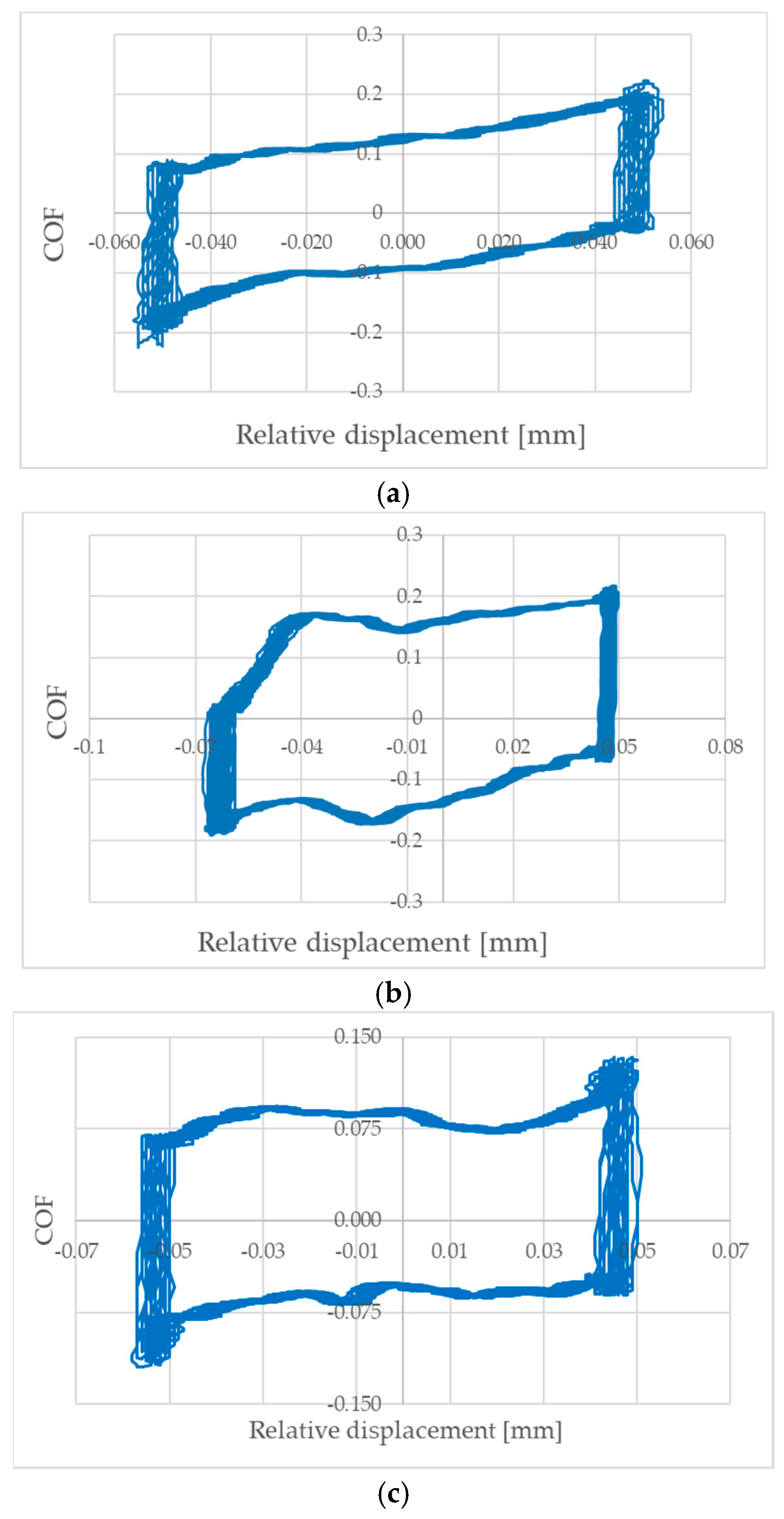

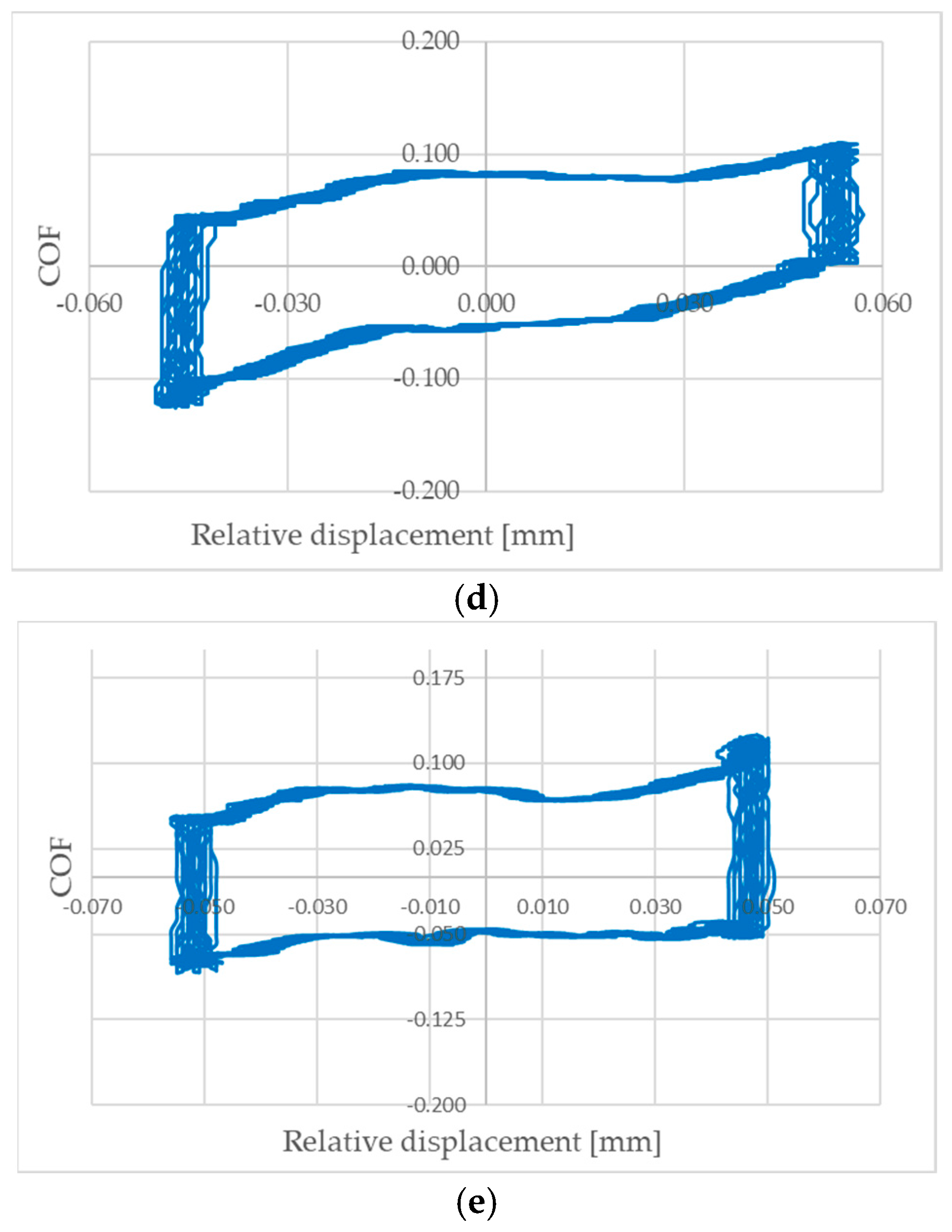

- The application of ball burnishing to discs made from the titanium alloy in contact with ceramic balls reduced the coefficient of friction up to 45% compared to the turned disc sample in lubricated gross fretting conditions. The highest friction decrease was achieved for a burnishing pressure of 30 MPa, while the lowest was obtained for the smallest pressure of 10 MPa. The greatest friction reduction was acquired for the smoothest disc sample of high microhardness.

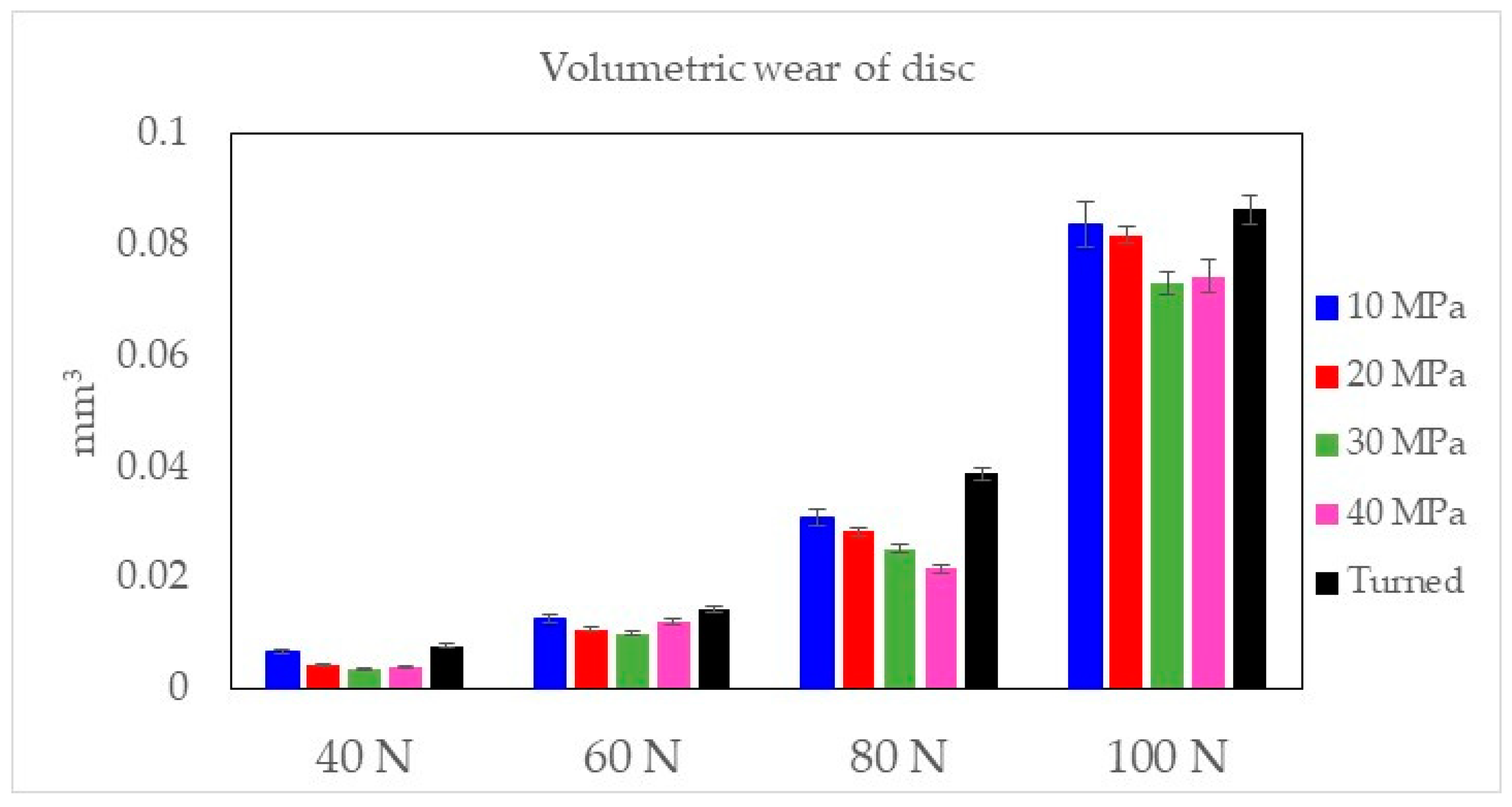

- Ball burnishing of the discs also led to a reduction in disc volume loss up to 50% compared to the turned sample. For normal forces of 40 N and 60 N, the highest reductions were achieved for a specimen burnished with a pressure of 30 MPa. For the highest normal force of 80 N, the increase in burnishing pressure caused a decrease in the disc’s volumetric wear.

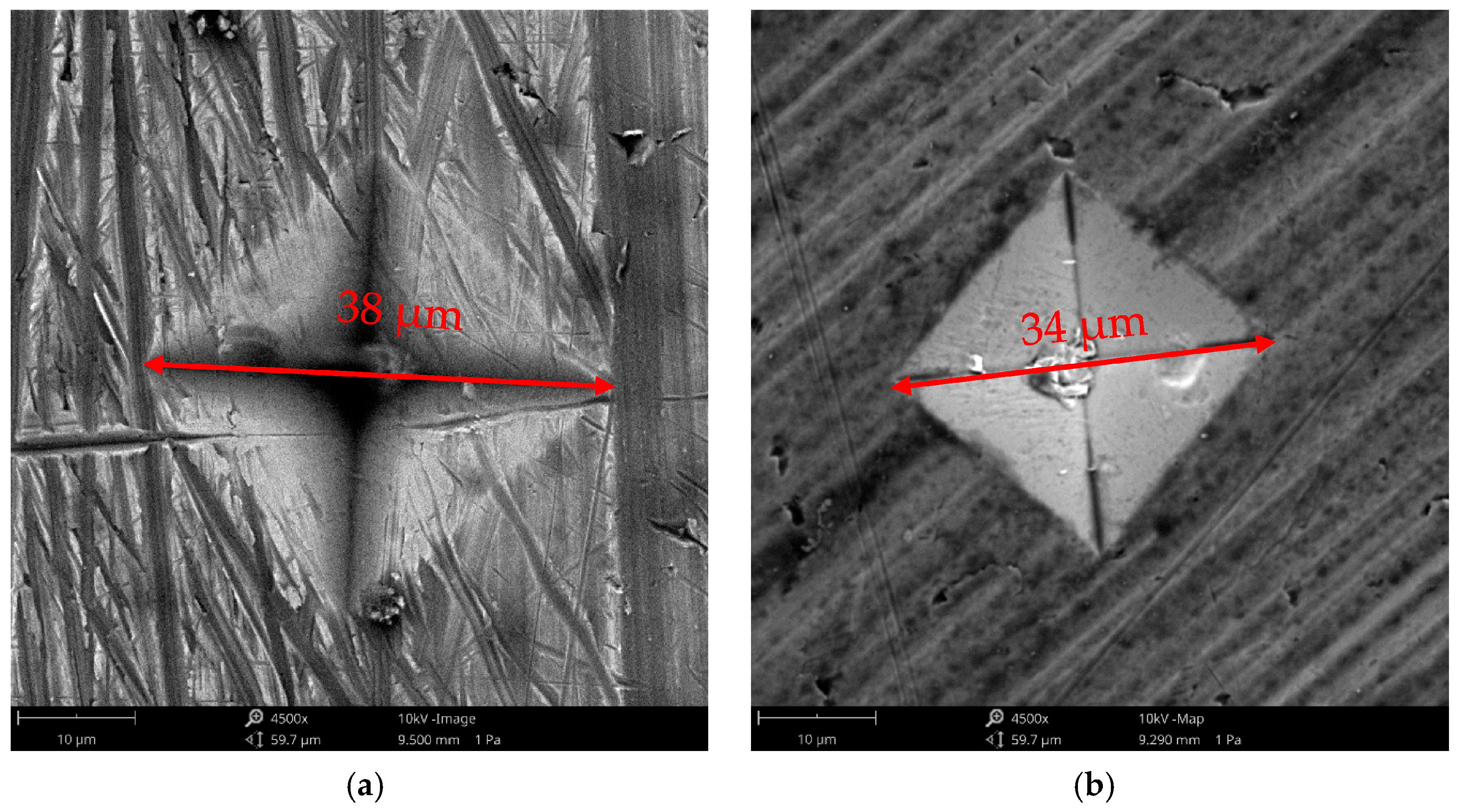

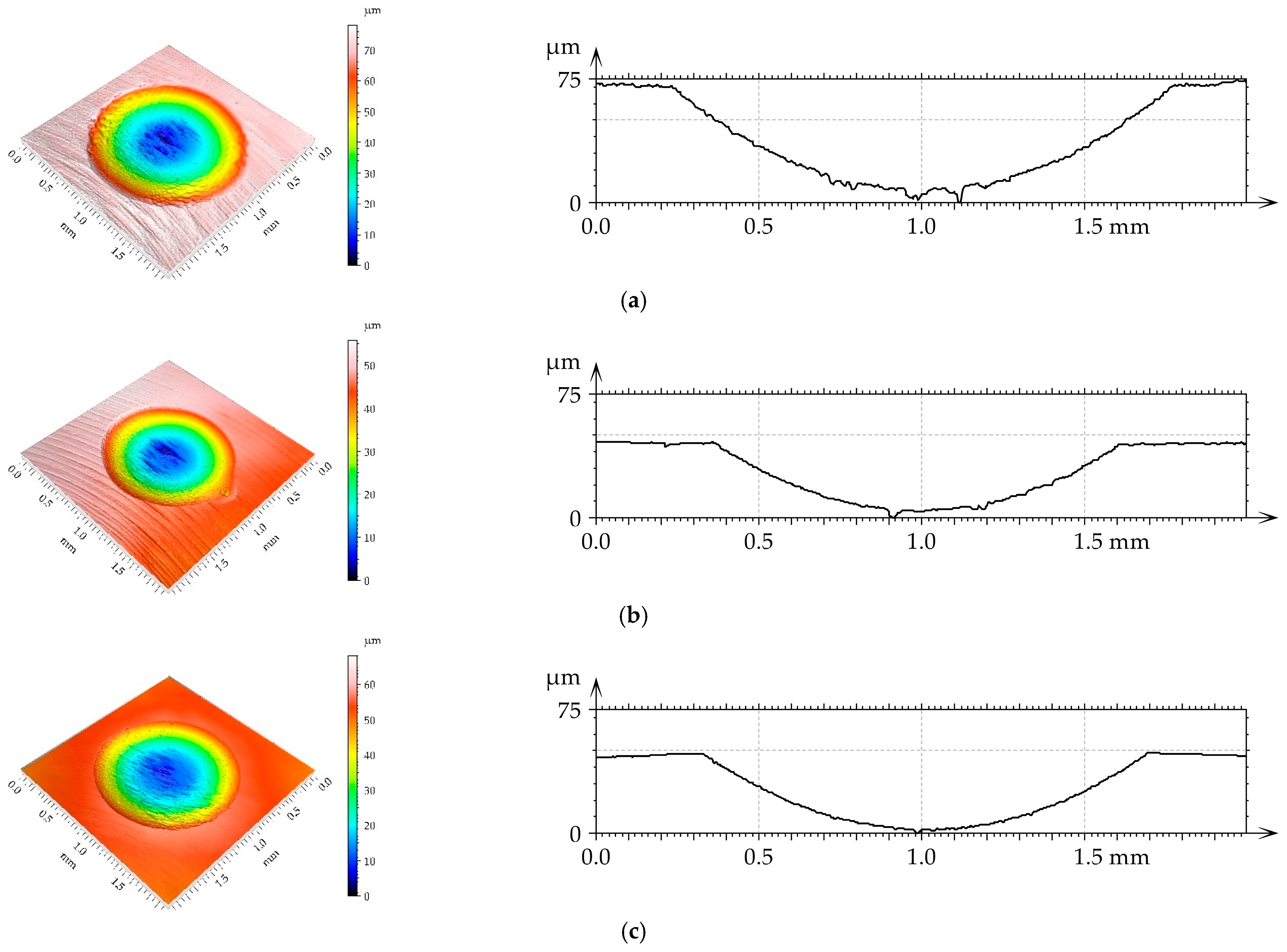

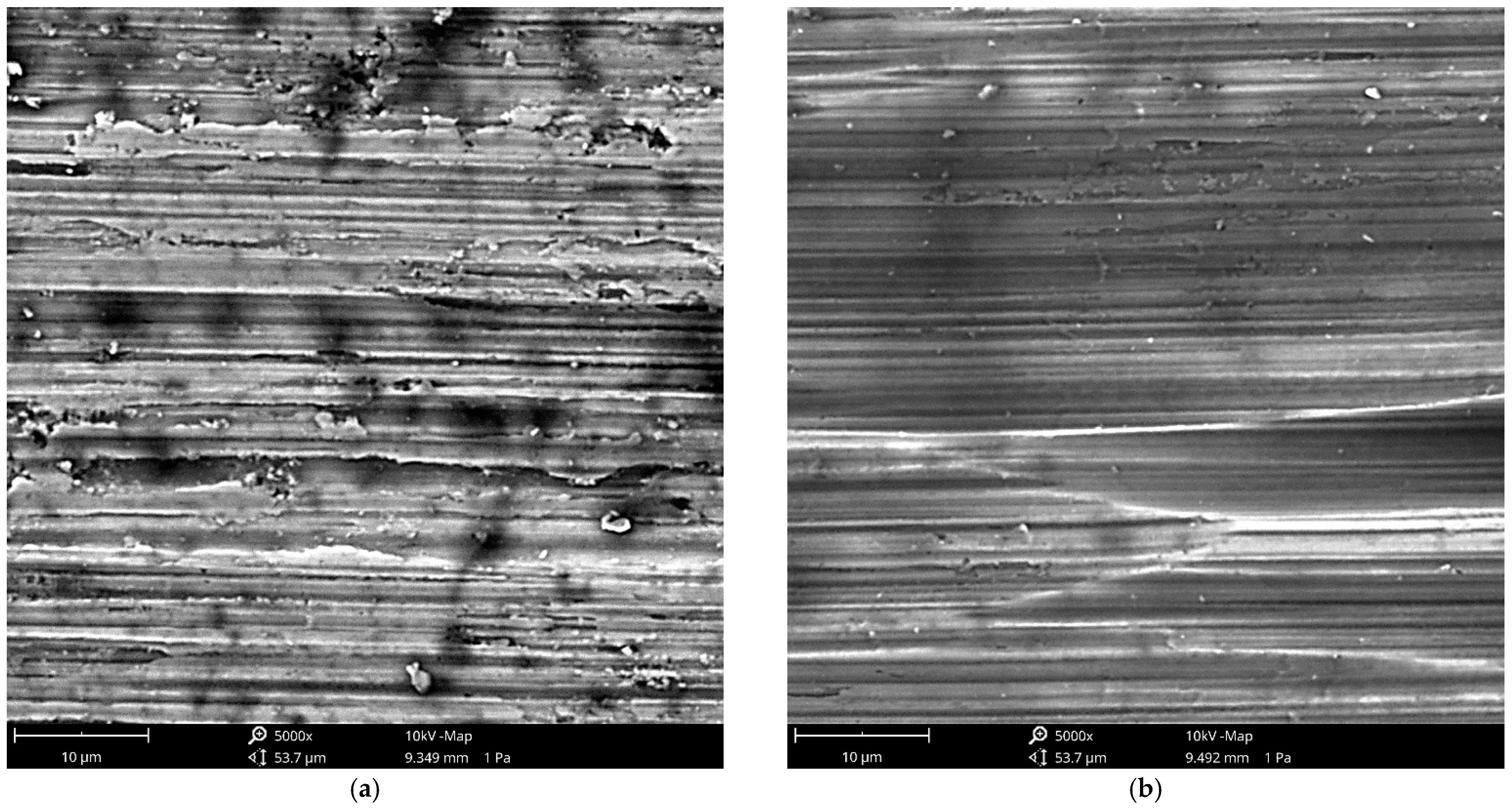

- The wear of the disc had an abrasive character with the presence of delamination, which corresponds to larger wear losses. The wear levels of balls made from WC ceramic were negligible due to the large difference between the hardness values of the balls and discs. Co-action between the disc and ball during the tests occurred in non-conformal conditions.

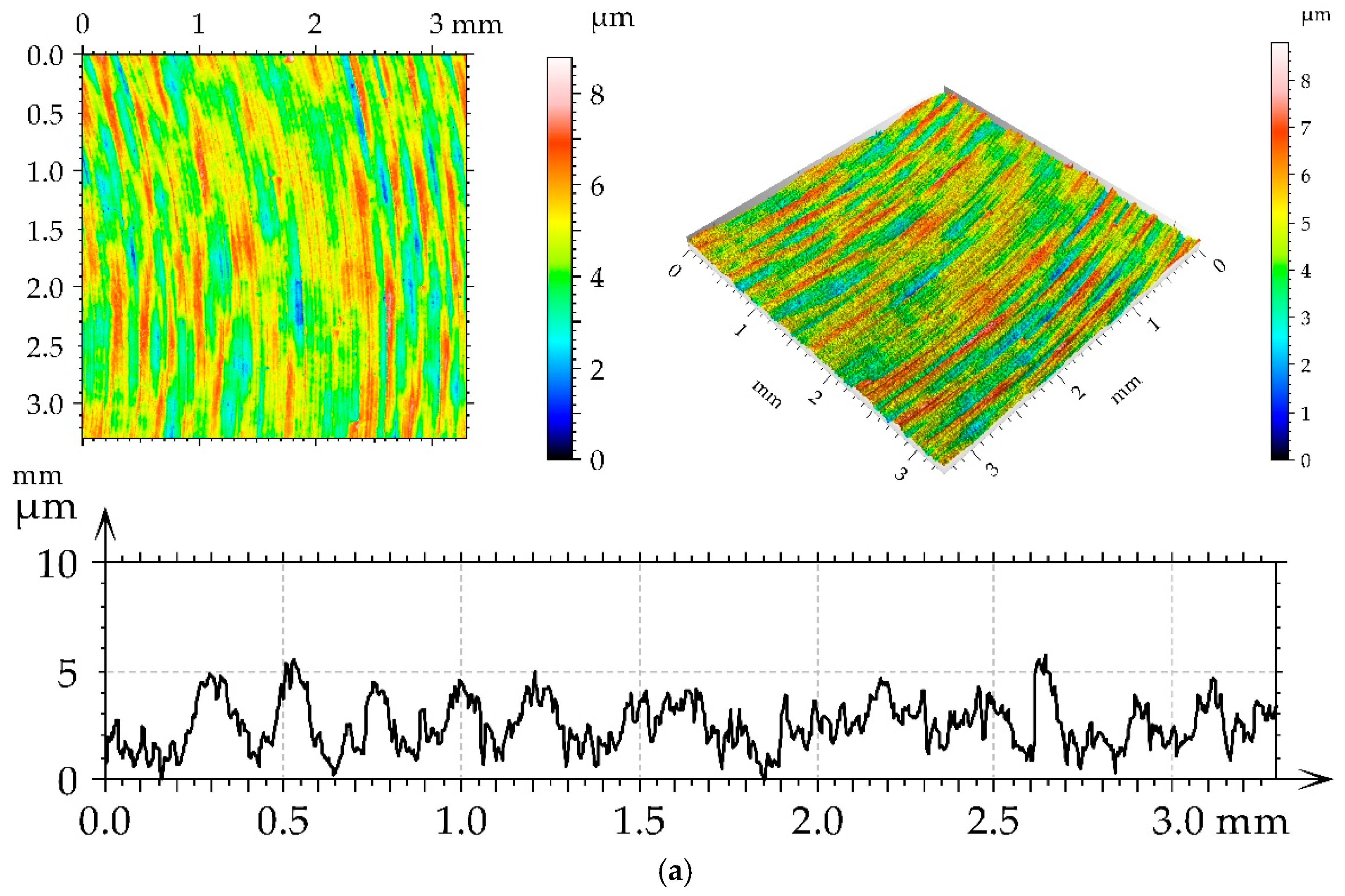

- A decrease in the height of the roughness was obtained due to ball burnishing. This decrease was the lowest for a pressure of 10 MPa, but the largest for a pressure of 30 MPa. The maximum decrease in the Sq parameter was 84%. Ball burnishing also led to reductions in the rms. slope Sdq, the development of an interfacial areal ratio Sdr, the peak density Spd and mean peak curvature Spc, and growths in the correlation length Sal, texture aspect ratio Str and kurtosis Sku.

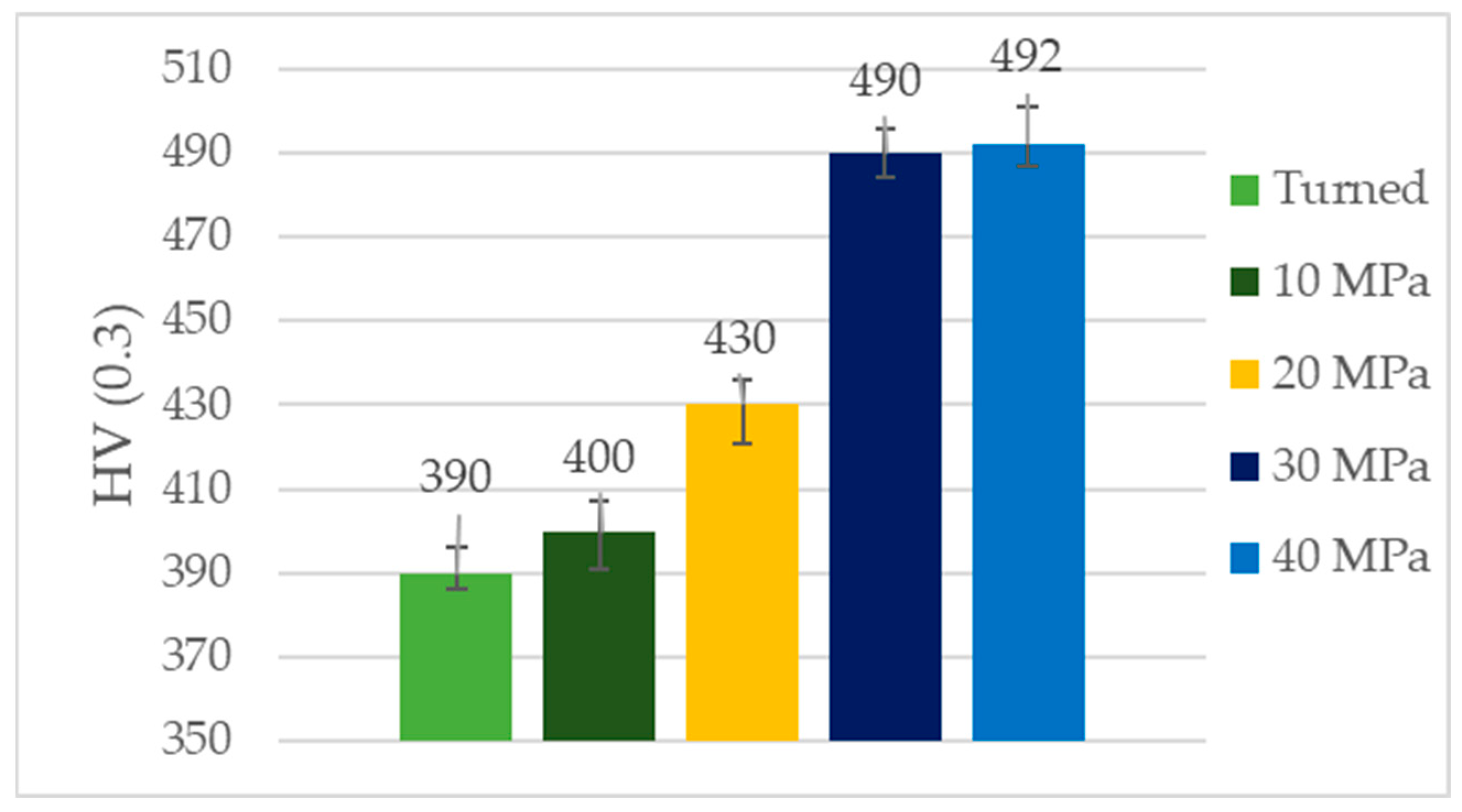

- Ball burnishing produced growth in the microhardness of the samples up to 26%. The smallest microhardness increase was acquired for the smallest burnishing pressure, while the highest was obtained for pressures of 30 and 40 MPa.

Funding

Data Availability Statement

Conflicts of Interest

References

- Saldaa-Robles, A.; Diosdado-De La Peña, J.; Balvantin-Garcia, A.; Aguilera-Gomez, E.; Plasencia-Mora, H.; Saldaña-Robles, N. Ball. burnishing process: State of the art of a technology in development. Dyna 2017, 92, 28–33. [Google Scholar] [CrossRef]

- Mahajan, D.; Tajane, R. A Review on the Ball Burnishing Process. Int. J. Sci. Res. Publ. 2013, 3–4, 1–8. [Google Scholar]

- Revankar, G.D.; Shetty, R.; Rao, S.S.; Gaitonde, V.N. Analysis. of the surface roughness and hardness in ball burnishing of titanium alloy. Measurement 2014, 58, 256–268. [Google Scholar] [CrossRef]

- Attabi, S.; Himour, A.; Laouar, L.; Motallebzadeh, A. Effect of ball burnishing on surface roughness and wear of the surface of AISI 316L SS. J. Bio-Tribo-Corros. 2020, 7, 7. [Google Scholar] [CrossRef]

- Kanovic, Z.; Vukelic, D.; Simunovic, K.; Prica, M.; Saric, T.; Tadic, B.; Simunovic, G. Modelling of Surface Roughness after the Ball Burnishing Process with a High-Stiffness Tool Using Regression Analysis, Artificial Neural Networks, and Support Vector Regression. Metals 2022, 12, 320. [Google Scholar] [CrossRef]

- Dzionk, S.; Scibiorski, B.; Przybylski, W. Surface texture analysis of Hardened Shafts after ceramic ball burning. Materials 2019, 12, 204. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Functional Importance of Surface Texture Parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef]

- Jerez-Mesa, R.; Travieso-Rodrguez, J.A.; Landon, Y.; Dessein, G.; Lluma-Fuentes, J.; Wagner, V. Comprehensive. analysis of surface integrity modification of Ti-6Al-4V surfaces through vibration-assisted ball burnishing. J. Mater. Process. Technol. 2019, 267, 230–240. [Google Scholar] [CrossRef]

- Swirad, S.; Wydrzynski, D.; Nieslony, P.; Krolczyk, G.M. Influence. of hydrostatic burnishing strategy on the surface topography of martensitic steel. Measurement 2019, 138, 590–601. [Google Scholar] [CrossRef]

- Bourebia, M.; Hamadache, H.; Lakhdar, L.; Mentouri, Z.; Kamila, D.; Tarek, H.; Ahlem, T. Effect of the ball burnishing process on the mechanical properties and impact behavior of S355JR steel. Int. J. Adv. Manuf. Technol. 2021, 116, 1373–1384. [Google Scholar] [CrossRef]

- Bourebia, M.; Bouri, A.; Hamadache, H.; Achouri, S.; Laouar, L.; Gharbi, A.; Bouhamla, K. Study of the effect of burnishing on superficial hardness and hardening of S355JR steel using experimental planning. Energy Procedia 2019, 157, 568–577. [Google Scholar] [CrossRef]

- Ye, W.; Xie, M.; Huang, Z.; Wang, H.; Zhou, Q.; Wang, L.; Chen, B.; Wang, H.; Liu, W. Microstructure and tribological properties of in-situ carbide/CoCrFeNiMn high entropy alloy composites synthesized by flake powder metallurgy. Tribol. Int. 2023, 181, 108295. [Google Scholar] [CrossRef]

- Zhang, T.; Bugtai, N.; Marinescu, I.D. Burnishing of aerospace alloy: A theoretical–experimental approach. J. Manuf. Syst. 2015, 37, 472–478. [Google Scholar] [CrossRef]

- Han, K.; Zhang, D.; Yao, C.; Zhou, Z.; Zhao, Y. Neural Network Modeling of Surface Roughness and Residual Stress Induced by Ball Burnishing. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 6–13 March 2021; p. 9438416. [Google Scholar]

- Dzierwa, A.; Pawlus, P.; Zelasko, W.; Reizer, R. The study of the tribological properties of one-process and two-process textures after vapour blasting and lapping using pin-on-disc tests. Key Eng. Mater. 2013, 527, 217–222. [Google Scholar] [CrossRef]

- Sedlacek, M.; Podgornik, B.; Vizintin, J. Correlation between standard roughness parameters skewness and kurtosis and tribological behaviour of contact surfaces. Tribol. Int. 2012, 48, 102–112. [Google Scholar] [CrossRef]

- Sedlacek, M.; Podgornik, B.; Vizintin, J. Influence of surface preparation on roughness parameters, friction and wear. Wear 2009, 266, 482–487. [Google Scholar] [CrossRef]

- Swirad, S.; Pawlus, P. The Influence of Ball Burnishing on Friction in Lubricated Sliding. Materials 2020, 13, 5027. [Google Scholar] [CrossRef] [PubMed]

- Fouvry, S.; Kapsa, P.; Vincent, L. Analysis of sliding behavior for fretting loading: Determination of transition. Wear 1995, 185, 21–46. [Google Scholar] [CrossRef]

- Vingsbo, O.; Soerberg, S. On fretting maps. Wear 1988, 126, 131–147. [Google Scholar] [CrossRef]

- Zhou, Z.R.; Nakazawa, S.; Zhu, M.H.; Maruyama, N.; Kapsa, P.; Vincent, L. Progress in fretting maps. Tribol. Criteria Int. 2006, 39, 1068–1073. [Google Scholar] [CrossRef]

- Wang, Z.A.; Zhou, Z.R. An investigation of fretting behaviour of several synthetic base oils. Wear 2009, 267, 1399–1404. [Google Scholar] [CrossRef]

- Warmuth, A.R.; Sun, W.; Shipway, P.H. The roles of contact conformity, temperature and displacement amplitude on the lubricated fretting wear of a steel-on-steel contact. R. Soc. Open Sci. 2016, 3, 150637. [Google Scholar] [CrossRef]

- Sato, J.; Shima, M.; Sugawara, T.; Tahara, A. Effect of lubricants on fretting wear of steel. Wear 1988, 125, 83–95. [Google Scholar] [CrossRef]

- Imai, M.; Teramoto, H.; Shimauchi, Y.; Tonegawa, E. Effect of oil supply on fretting wear. Wear 1986, 110, 217–225. [Google Scholar] [CrossRef]

- Okamoto, M.; Jibiki, T.; Ito, S.; Motoda, T. Role of cross-grooved type texturing in acceleration of initial running-in under lubricated fretting. Tribol. Int. 2016, 100, 126–131. [Google Scholar] [CrossRef]

- Lenart, A.; Pawlus, P.; Dzierwa, A.; Wos, S.; Reizer, R. The effect of surface texture on lubricated fretting. Materials 2020, 13, 4886. [Google Scholar] [CrossRef] [PubMed]

- Kubiak, K.J.; Mathia, T.G. Influence of roughness on contact interface in fretting under dry an boundary lubricated sliding regimes. Wear 2009, 267, 315–321. [Google Scholar] [CrossRef]

- El-Tayeb, N.S.M.; Low, K.O.; Brevern, P.V. Enhancement of surface quality and tribological properties using the ball burnishing process. Mach. Sci. Technol. 2015, 12, 234–248. [Google Scholar] [CrossRef]

- Swirad, S.; Pawlus, P. The Effect of Ball Burnishing on Tribological Performance of 42CrMo4 Steel under Dry Sliding Conditions. Materials 2020, 13, 2127. [Google Scholar] [CrossRef]

- Swirad, S.; Pawlus, P. The Effect of Ball Burnishing on Dry Fretting. Materials 2021, 14, 7073. [Google Scholar] [CrossRef]

- Yilmaz, H.; Sadeler, R. Impact wear behavior of ball-blended 316L stainless steel. Surf. Coat. Technol. 2019, 363, 369–378. [Google Scholar] [CrossRef]

- Revankar, G.D.; Shetty, R.; Rao, S.S.; Gaitonde, V.N. Improvement. in the wear resistance of titanium alloy (Ti–6Al–4V) by the ball burnishing process. J. Mater. Res. Technol. 2017, 6, 13–32. [Google Scholar] [CrossRef]

- Dzyura, V.; Maruschak, P.; Slavov, S.; Dimitrov, D.; Semehen, V.; Markov, O. Evaluating Some Functional Properties of Surfaces with Partially Regular Microreliefs Formed by Ball-Burnishing. Machines 2023, 11, 633. [Google Scholar] [CrossRef]

- Ren, Y.; Huang, Z.; Wang, Y.; Zhou, Q.; Yang, T.; Li, Q.; Jia, Q.; Wang, H. Friction-induced rapid amorphization in a wear-resistant (CoCrNi)88Mo12 dual-phase medium-entropy alloy at cryogenic temperature. Compos. Part B Eng. 2023, 263, 110833. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M.; Królczyk, G. Parametric description of one-process surface texture. Meas. J. Int. Meas. Confed. 2022, 204, 112066. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Frequency | 50 Hz |

| Humidity | 40–50% |

| Stroke | 0.1 mm |

| Normal load | 40, 60, 80 N |

| Number of cycles | 45,000 |

| Lubricant | L-AN-46 oil (0.07 mL) |

| Parameter | Value |

|---|---|

| Burnishing strategy | Spiral |

| Speed | 400 mm/min |

| Ball | 4 mm |

| Pressure | 10, 20, 30, 40 MPa |

| Parameters | Turned | 10 MPa | 20 MPa | 30 MPa | 40 MPa | |

|---|---|---|---|---|---|---|

| Height Parameters | ||||||

| Sq | µm | 1.08 | 1.01 | 0.189 | 0.178 | 0.431 |

| Ssk | −0.007 | −0.345 | 0.037 | 0.221 | −0.060 | |

| Sku | 2.79 | 2.99 | 3.24 | 3.6 | 3.63 | |

| Sp | µm | 4.2 | 3.23 | 0.947 | 1.05 | 2.78 |

| Sv | µm | 4.59 | 4.92 | 1.43 | 0.789 | 1.94 |

| Sz | µm | 8.79 | 8.15 | 2.37 | 1.84 | 4.72 |

| Sa | µm | 0.869 | 0.82 | 0.15 | 0.139 | 0.331 |

| Spatial parameters | ||||||

| Sal | mm | 0.0534 | 0.264 | 0.109 | 0.152 | 0.157 |

| Str | 0.137 | 0.133 | 0.504 | 0.502 | 0.478 | |

| Hybrid parameters | ||||||

| Sdq | 0.123 | 0.0629 | 0.0123 | 0.00354 | 0.0276 | |

| Sdr | % | 0.74 | 0.197 | 0.00756 | 0.000626 | 0.0379 |

| Feature parameters | ||||||

| Spd | 1/mm2 | 336 | 30.9 | 48.7 | 4.34 | 84.2 |

| Spc | 1/mm | 74.3 | 60.1 | 8.36 | 0.493 | 30.1 |

| Functional parameters | ||||||

| Sk | µm | 2.46 | 1.14 | 0.43 | 0.337 | 0.787 |

| Spk | µm | 0.901 | 0.298 | 0.151 | 0.138 | 0.315 |

| Svk | µm | 0.934 | 0.953 | 0.162 | 0.0993 | 0.367 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Swirad, S. Influence of Ball Burnishing on Lubricated Fretting of the Titanium Alloy Ti6Al4V. Lubricants 2023, 11, 341. https://doi.org/10.3390/lubricants11080341

Swirad S. Influence of Ball Burnishing on Lubricated Fretting of the Titanium Alloy Ti6Al4V. Lubricants. 2023; 11(8):341. https://doi.org/10.3390/lubricants11080341

Chicago/Turabian StyleSwirad, Slawomir. 2023. "Influence of Ball Burnishing on Lubricated Fretting of the Titanium Alloy Ti6Al4V" Lubricants 11, no. 8: 341. https://doi.org/10.3390/lubricants11080341

APA StyleSwirad, S. (2023). Influence of Ball Burnishing on Lubricated Fretting of the Titanium Alloy Ti6Al4V. Lubricants, 11(8), 341. https://doi.org/10.3390/lubricants11080341