Wear Resistance of In Situ NbC-Reinforced Laser Cladding Ni45 Coatings

Abstract

1. Introduction

2. Experiment

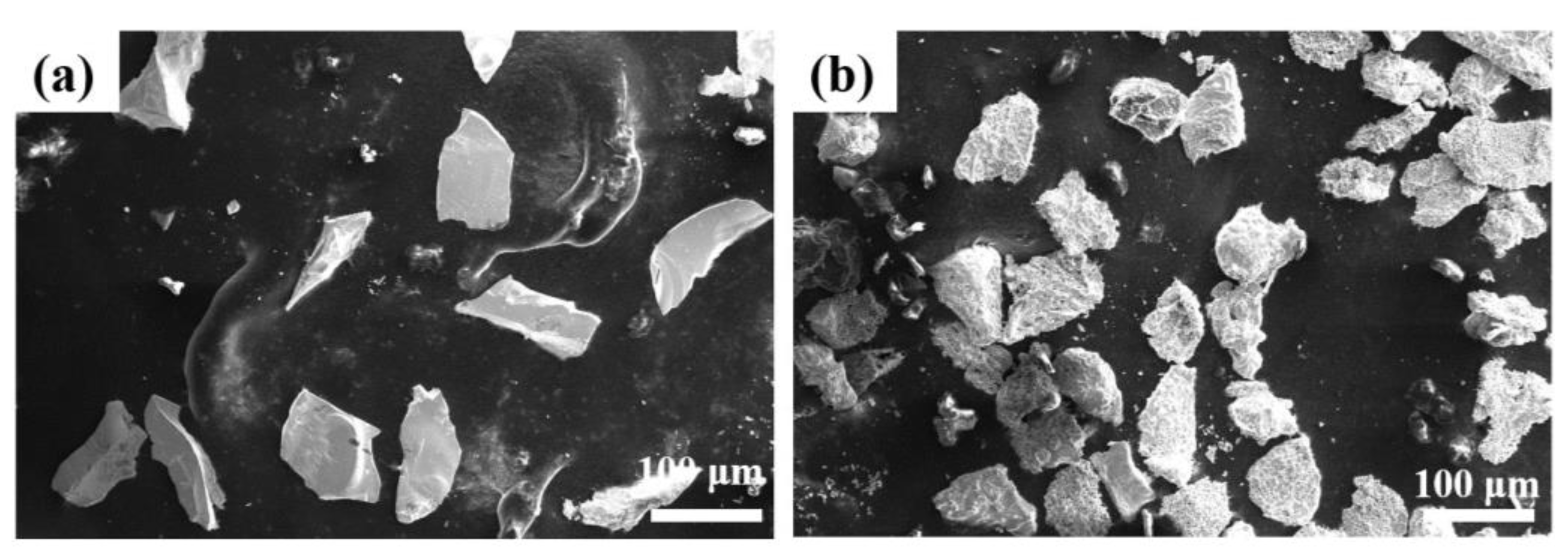

2.1. Materials

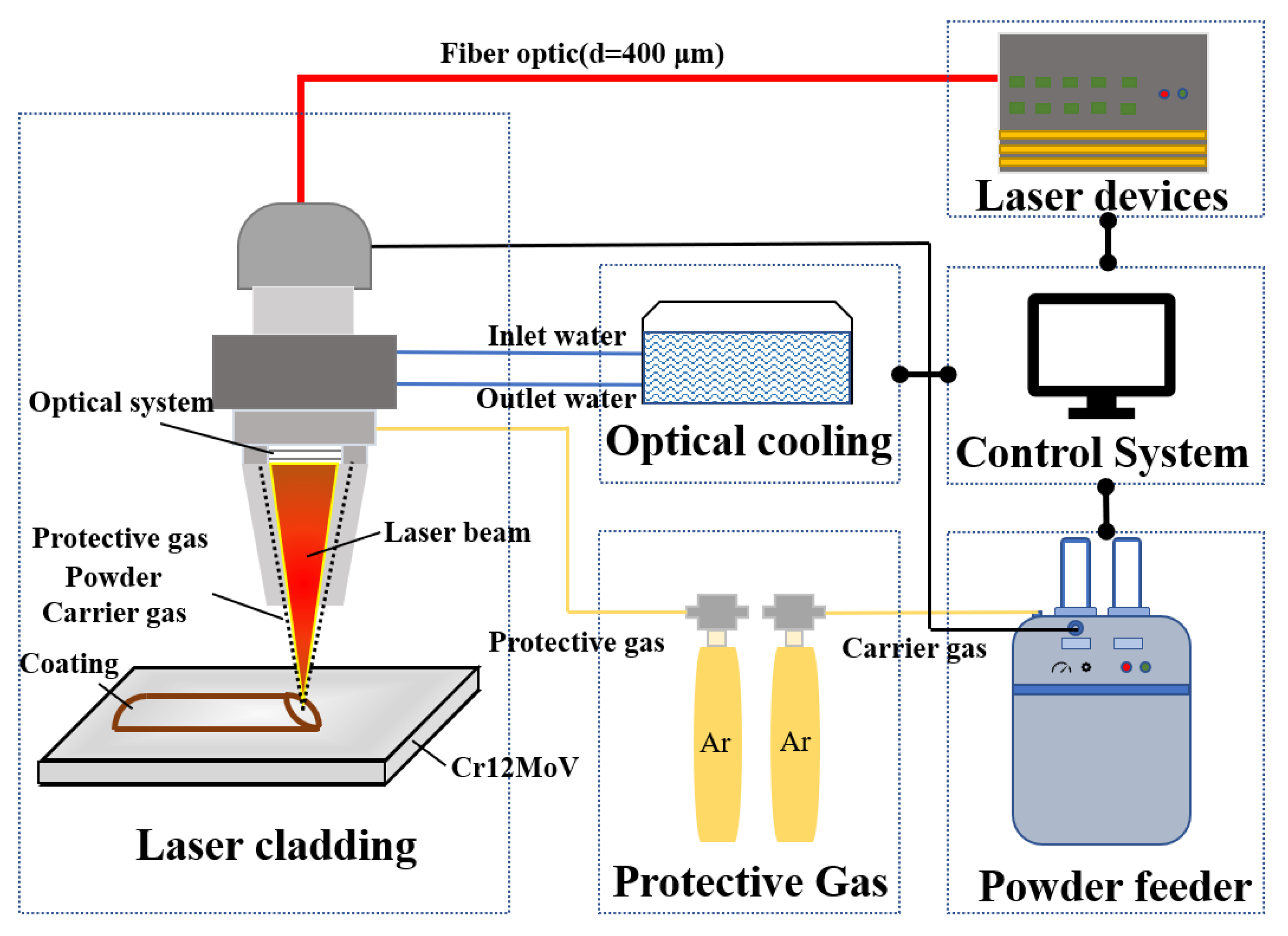

2.2. Laser Parameters

2.3. Microstructure Observation

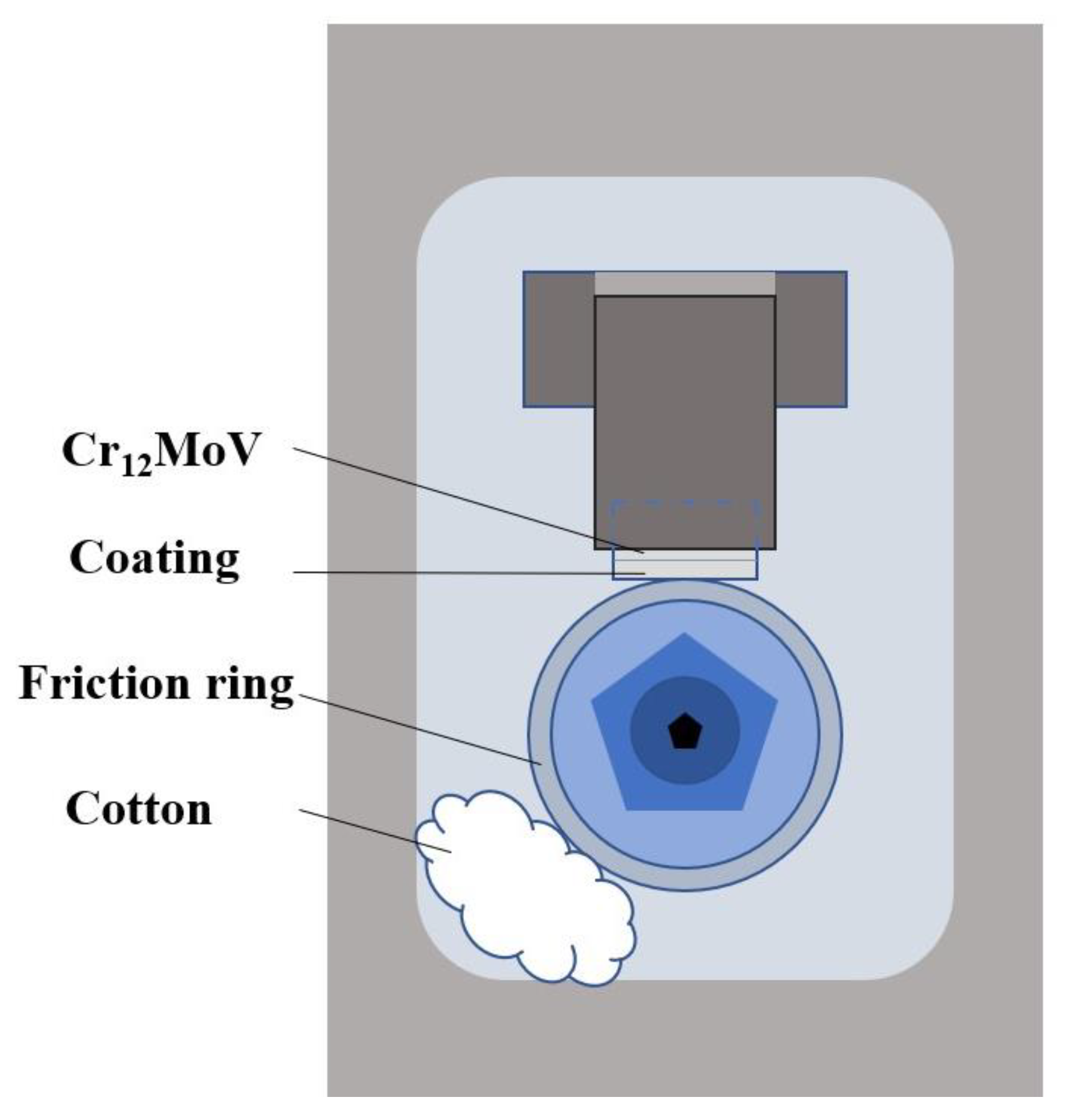

2.4. Microhardness and Wear Resistance

3. Results and Discussion

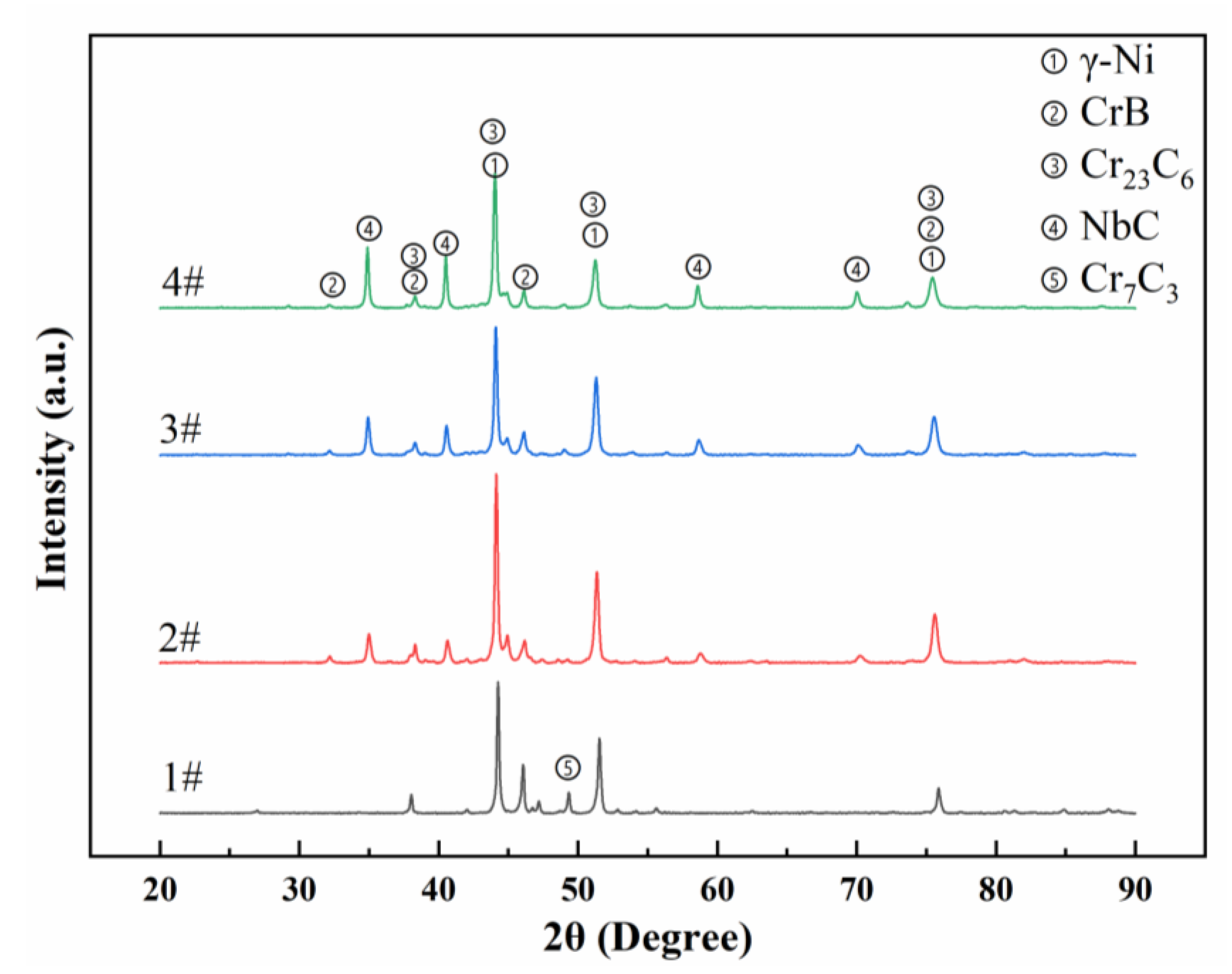

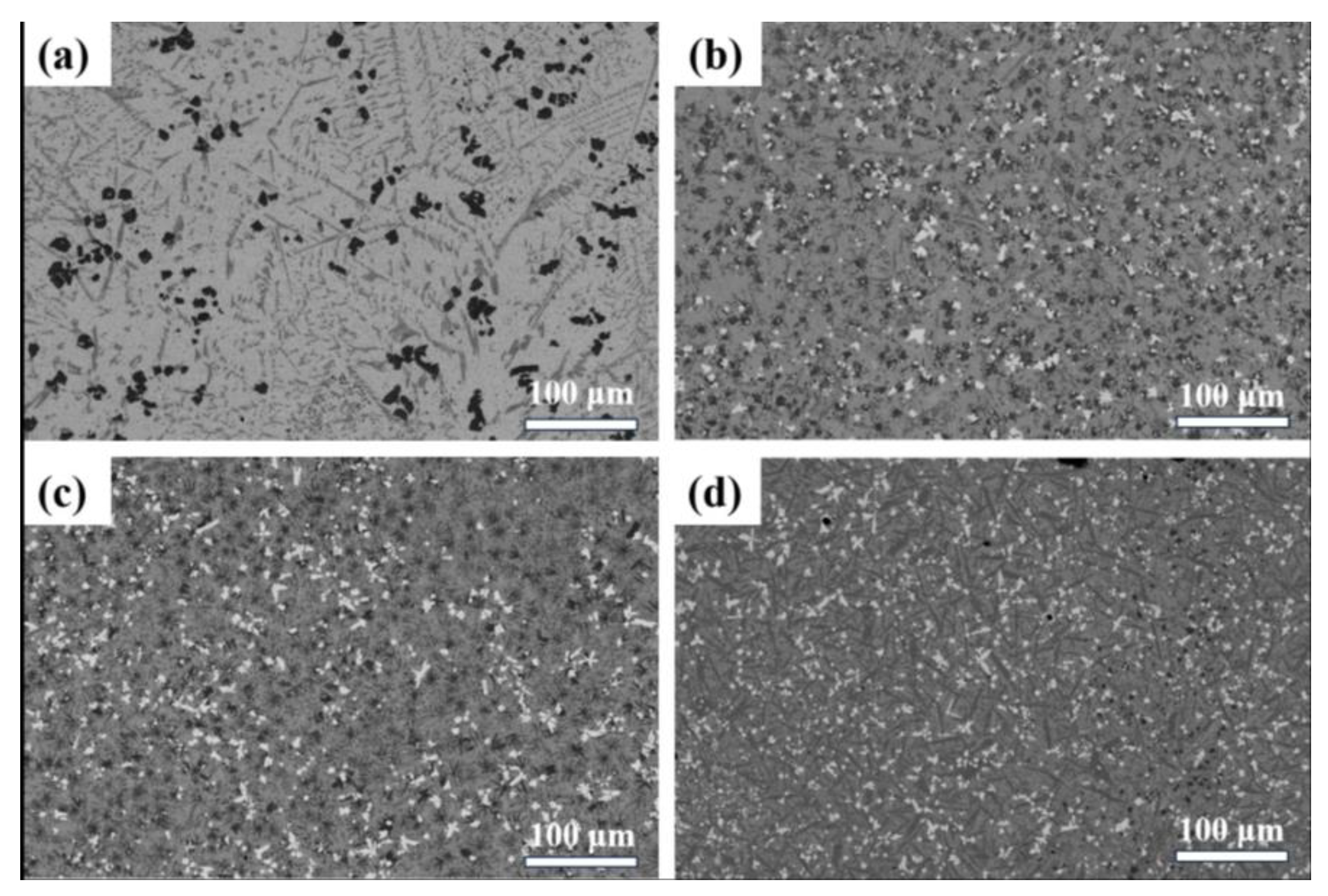

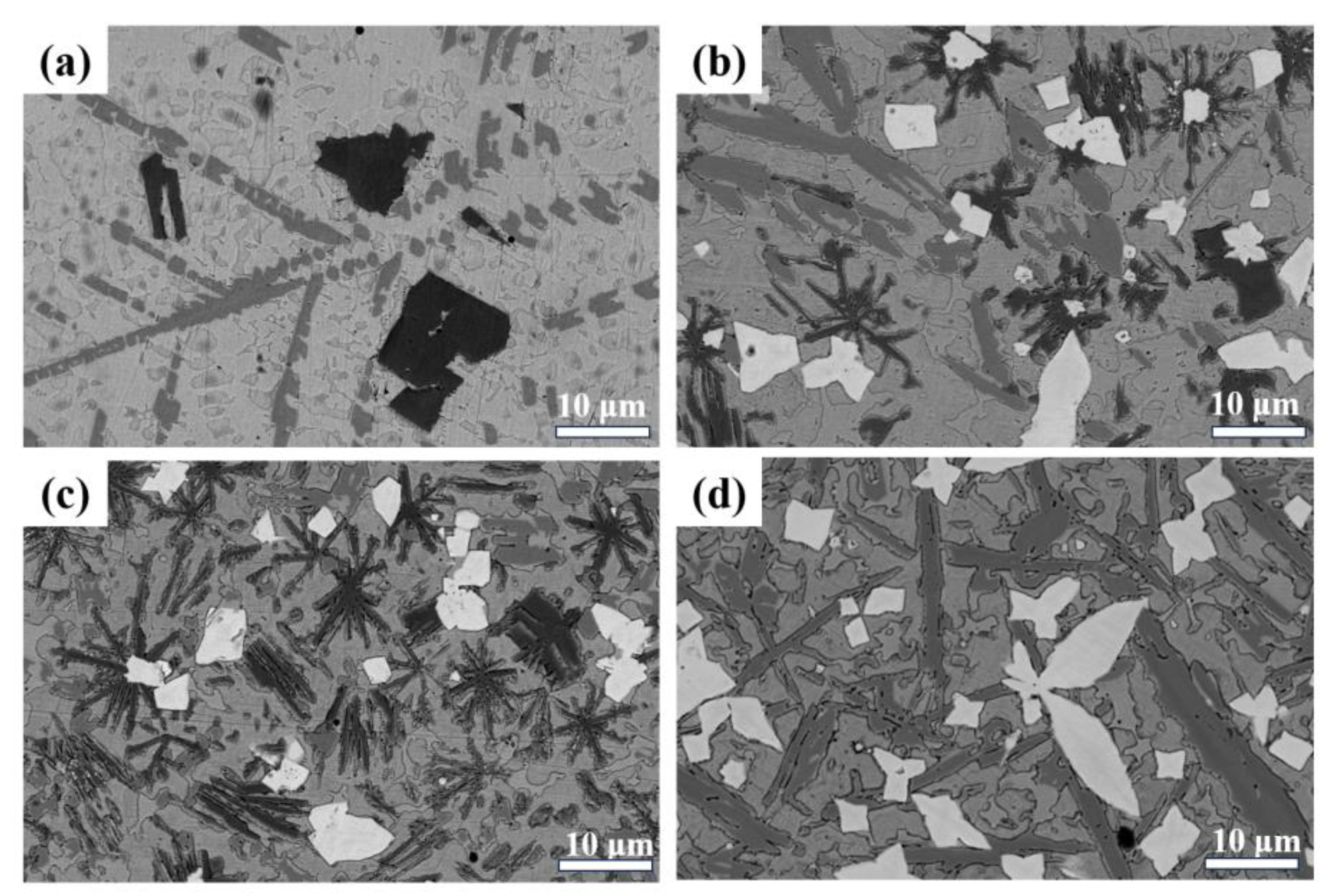

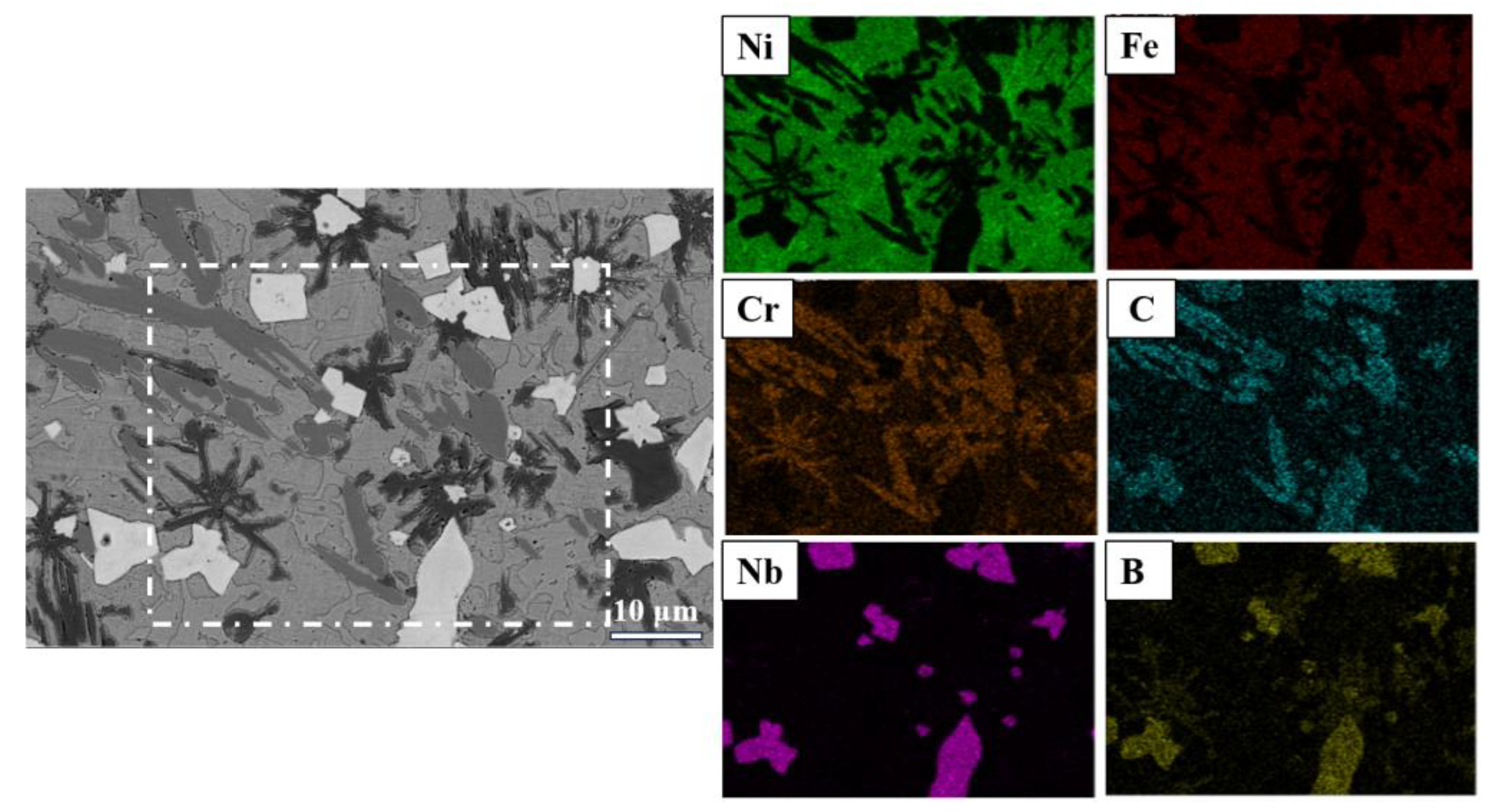

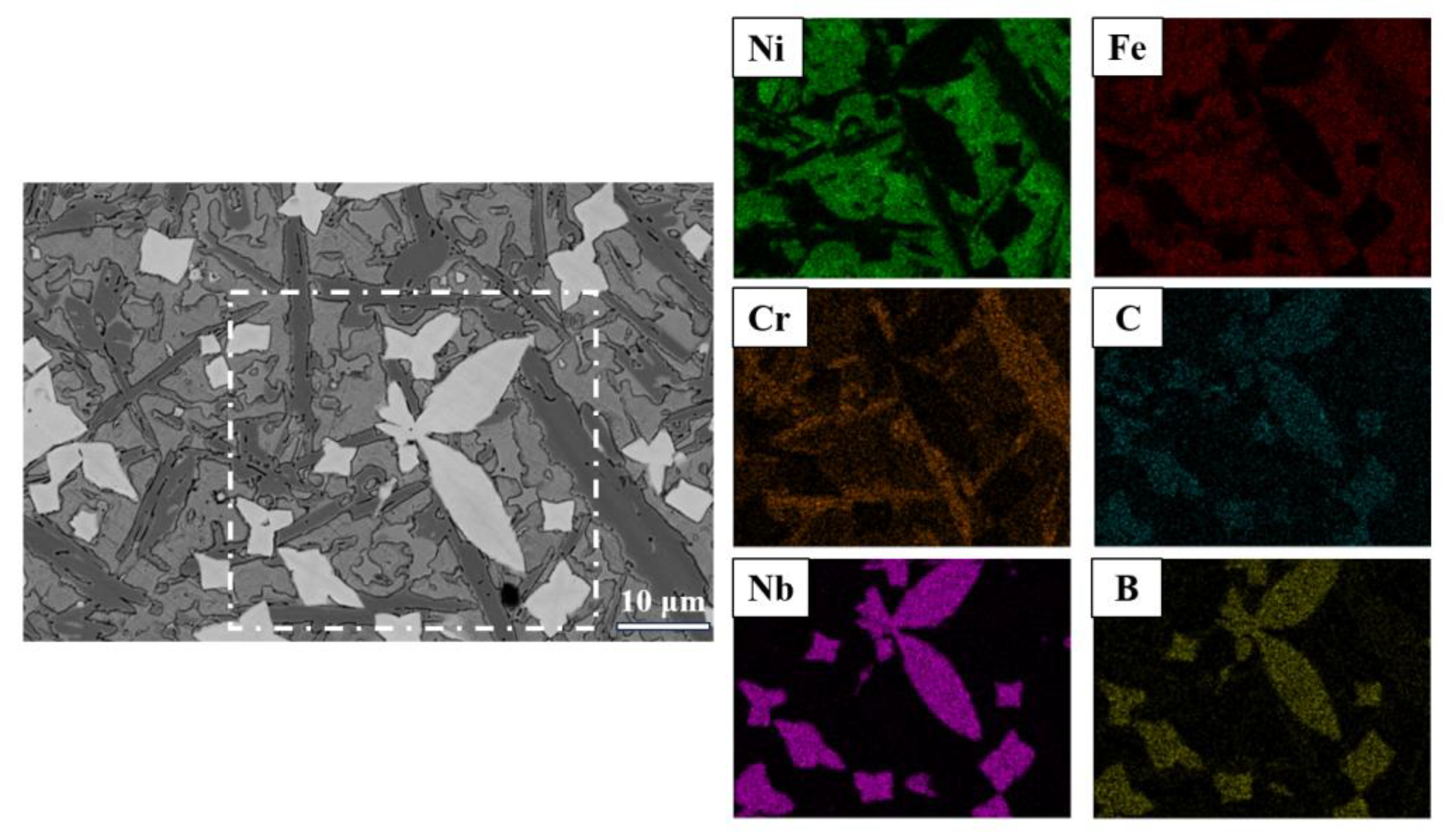

3.1. Microstructure Analysis

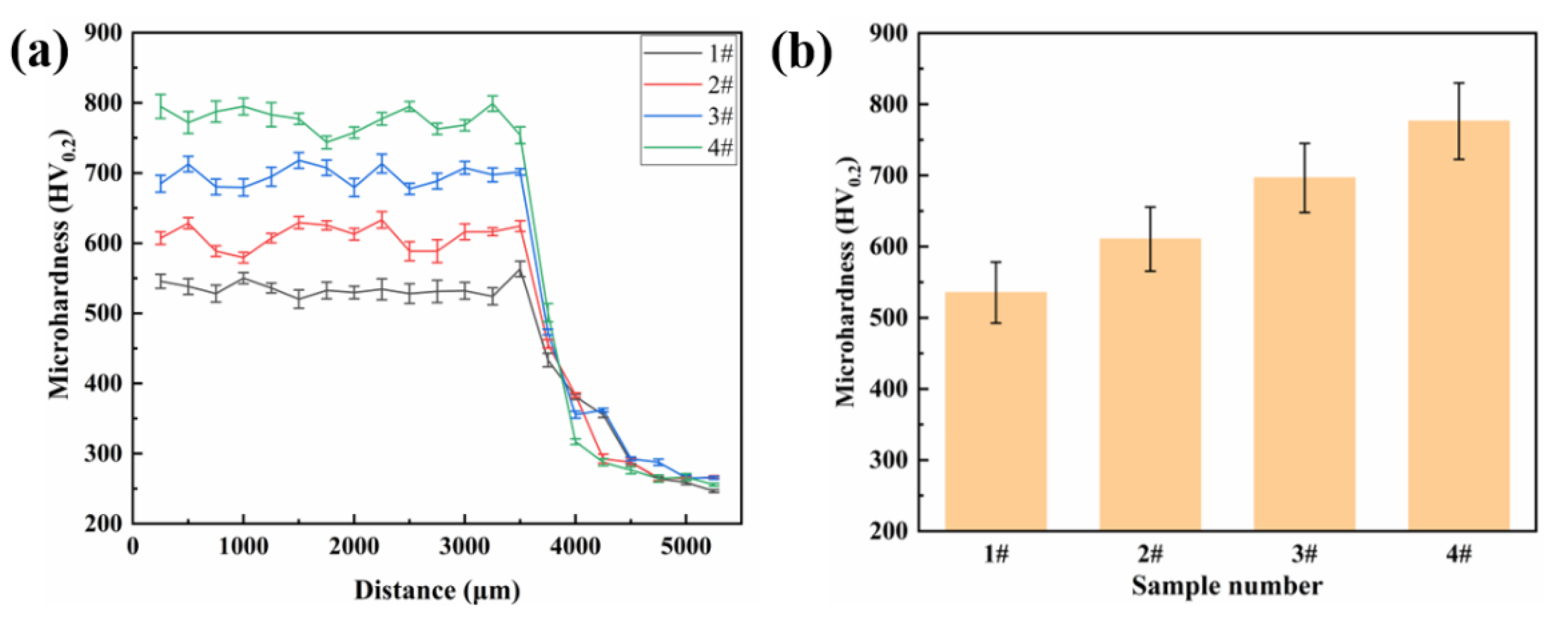

3.2. Microhardness Analysis

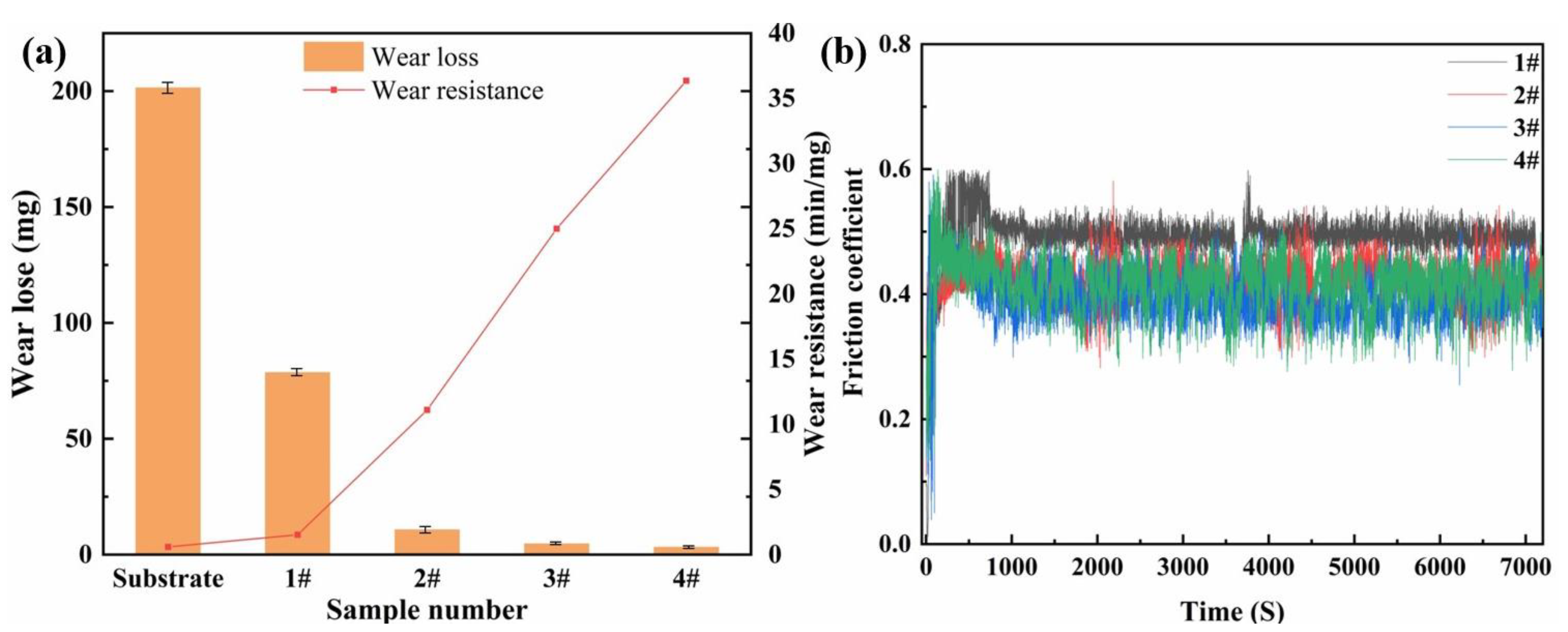

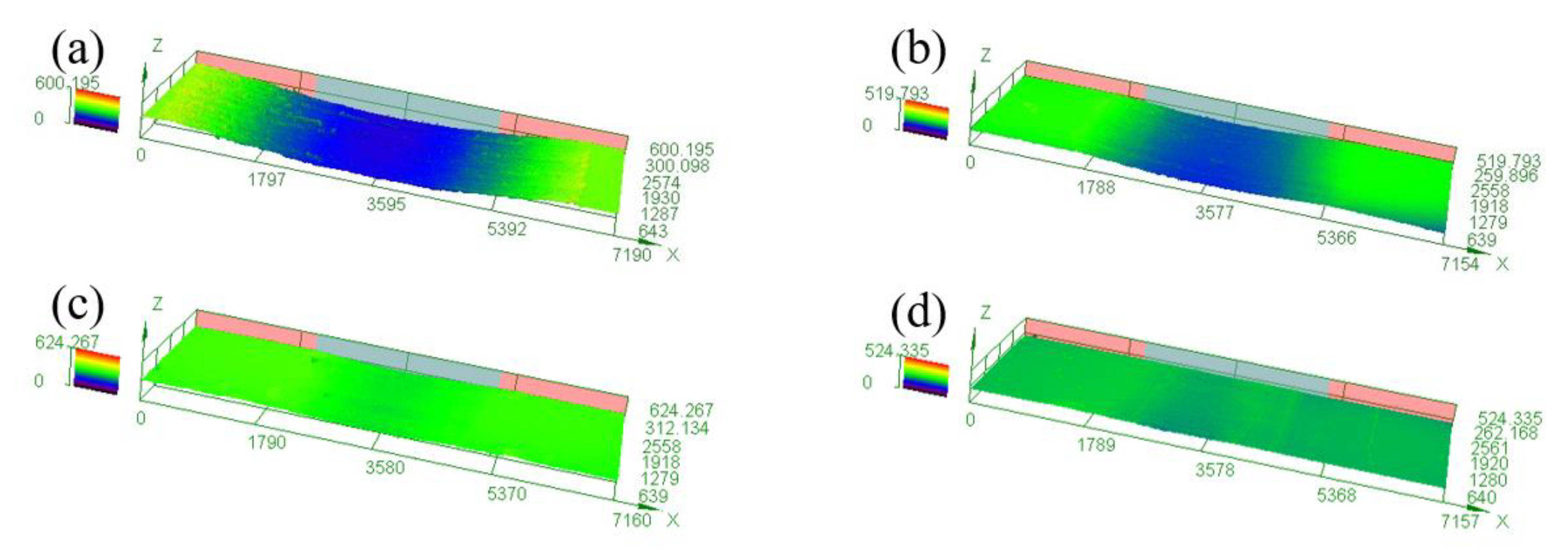

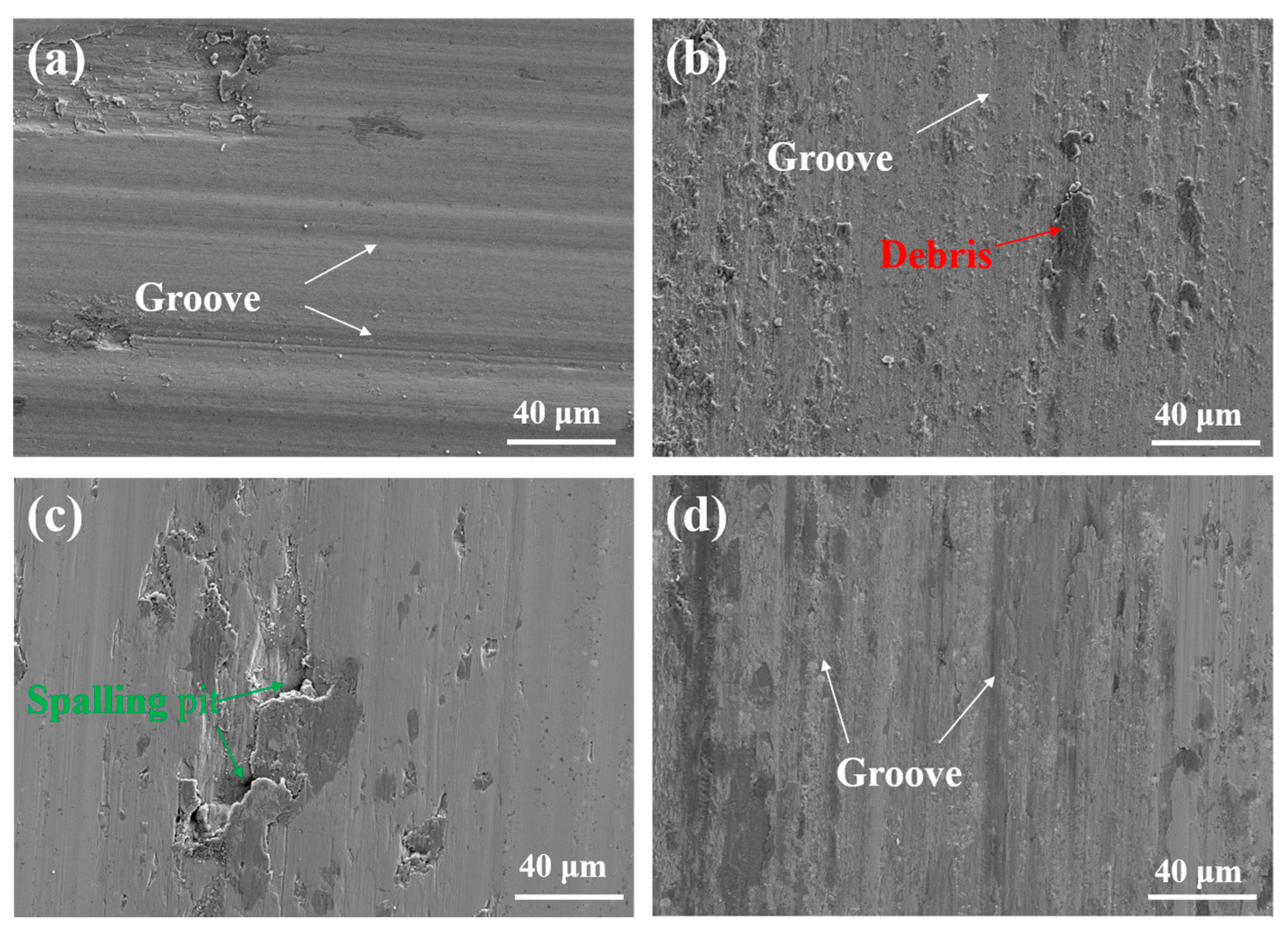

3.3. Wear Resistance Analysis

4. Conclusions

- 1.

- NbC was synthesized in situ from FeNb65 and Cr3C2, and elements such as Fe, Cr and Si diffused into the high temperature austenite phase to form a γ-Ni solid solution phase.

- 2.

- With the increase in NbC content, the microhardness of the coating increases. The microhardness of coating 4# reached 776.3 HV0.2, a 45% increase in microhardness compared to coating 1#. This is attributed to the uniform distribution of the NbC phase and Cr23C6 in the coating.

- 3.

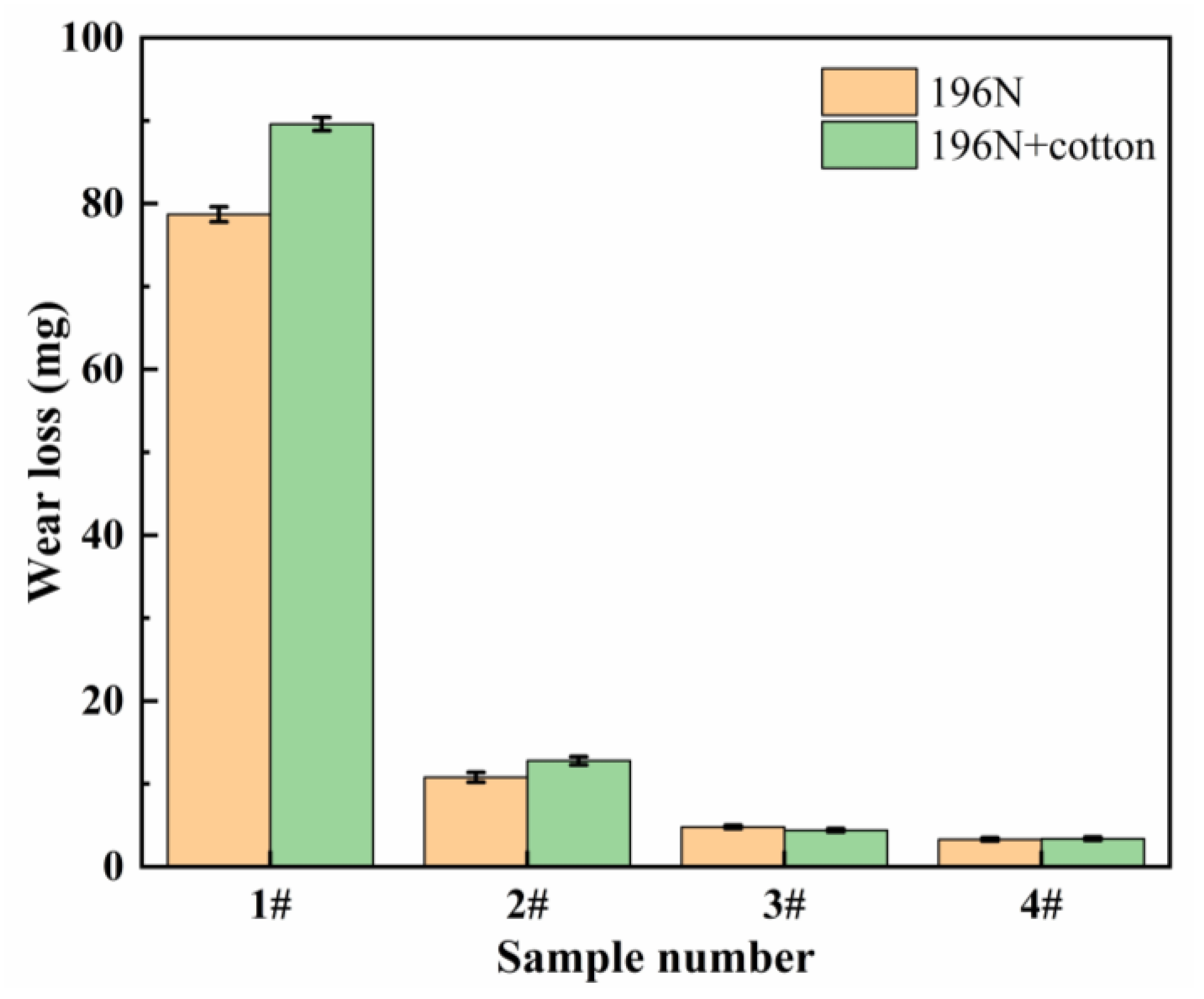

- The wear resistance of the coatings increased significantly with the increase in NbC content. Coating 4# with 25 wt.% FeNb65 + Cr3C2 showed the best wear resistance of 36.36 min/mg, an improvement of 606.0% in abrasion resistance compared to the base material and 227.6% compared to coating 1#.

- 4.

- The compacted layer formed by abrasive extrusion protects the coating surface when subjected to wear, reducing the wear of the coating.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jiang, L.; Cui, X.; Jin, G.; Tian, Z.; Wen, X.; Tian, H.; Liu, E. Design and characterization of a novel Cu2.3Al1.3Ni1.7SnCr0.3 multi-principal element alloy coating on magnesium alloy by laser cladding. J. Mater. Sci. Technol. 2023, 152, 220–236. [Google Scholar] [CrossRef]

- Zhu, Z.-X.; Liu, X.-B.; Liu, Y.-F.; Zhang, S.-Y.; Meng, Y.; Zhou, H.-B. Effects of Cu/Si on the microstructure and tribological properties of FeCoCrNi high entropy alloy coating by laser cladding. Wear 2023, 512, 204533. [Google Scholar] [CrossRef]

- Wu, S.; Liu, Z.; Gong, Y.; Liang, X.; Wu, Y.; Zhao, X. Analysis of the sequentially coupled thermal–mechanical and cladding geometry of a Ni60A-25%WC laser cladding composite coating. Opt. Laser Technol. 2023, 167, 109595. [Google Scholar] [CrossRef]

- Budde, L.; Biester, K.; Coors, T.; Faqiri, M.Y.; Lammers, M.; Hermsdorf, J.; Hassel, T.; Pape, F.; Overmeyer, L. Influence of shielding gas coverage during laser hot-wire cladding with high carbon steel. Int. J. Adv. Manuf. Technol. 2023, 127, 3195–3207. [Google Scholar] [CrossRef]

- Bhatnagar, S.; Mullick, S. A study on the influence of reinforcement particle size in laser cladding of TiC/Inconel 625 metal matrix composite. Opt. Laser Technol. 2023, 161, 109115. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.K.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufac-turing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar]

- Szost, B.A.; Terzi, S.; Martina, F.; Boisselier, D.; Prytuliak, A.; Pirling, T.; Hofmann, M.; Jarvis, D.J. A comparative study of additive manufacturing techniques: Residual stress and microstructural analysis of CLAD and WAAM printed Ti–6Al–4V components. Mater. Des. 2016, 89, 559–567. [Google Scholar] [CrossRef]

- Sun, D.; Zhu, L.; Cai, Y.; Yan, Y.; Ge, F.; Shan, M.; Tian, Y.; Han, J.; Jiang, Z. Tribology comparison of laser-cladded CrMnFeCoNi coatings reinforced by three types of ceramic (TiC/NbC/B4C). Surf. Coat. Technol. 2022, 450, 129013. [Google Scholar] [CrossRef]

- Paul, C.P.; Gandhi, B.K.; Bhargava, P.; Dwivedi, D.K.; Kukreja, L.M. Cobalt-Free Laser Cladding on AISI Type 316L Stainless Steel for Improved Cavitation and Slurry Erosion Wear Behavior. J. Mater. Eng. Perform. 2014, 23, 4463–4471. [Google Scholar] [CrossRef]

- Apolinário, L.H.R.; Torres, E.A.; Araújo, H.R.; Vicente, A.d.A.; Santos, T.F.d.A. Effect of laser cladding parameters in NbC reinforced 316L austenitic stainless steel composite depositions on a mild steel. Int. J. Adv. Manuf. Technol. 2022, 122, 3095–3113. [Google Scholar] [CrossRef]

- Jie, G.; Qingchao, M.; Yan, S.; Kangning, W.; Qiang, S.; Canming, W. Effect of Nb content on microstructure and corrosion resistance of Inconel 625 coating formed by laser cladding. Surf. Coat. Technol. 2023, 458, 129311. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Q.; Shen, W.; Liang, Z.; Chang, C.; Yang, L.; Li, J.; Huang, F. Failure Analysis of a Chromium Plating Layer on a Piston Rod Surface and the Study of Ni-Based Composite Coating with Nb Addition by Laser Cladding. Metals 2022, 12, 1194. [Google Scholar] [CrossRef]

- Pizzatto, A.; Teixeira, M.F.; Rabelo, A.; Falcade, T.; Scheid, A. Microstructure and Wear Behavior of NbC-Reinforced Ni-Based Alloy Composite Coatings by Laser Cladding. Mater. Res. Ibero Am. J. Mater. 2021, 24, e20200447. [Google Scholar] [CrossRef]

- Lian, G.F.; Yue, K.; Zeng, J.Y.; Feng, M.Y.; Lan, R.Q.; Kong, L.H. Microstructures and Properties of NbC-Reinforced Ni-Based Coatings Synthesized In Situ by Ultrasonic Vibration-Assisted Laser Cladding. Materials 2023, 16, 1704. [Google Scholar] [CrossRef] [PubMed]

- Shi, B.; Huang, S.; Zhu, P.; Xu, C.; Zhang, T. Microstructure and Wear Behavior of In-Situ NbC Reinforced Composite Coatings. Materials 2020, 13, 3459. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Lei, Y.; Fu, H. Laser cladding in-situ NbC particle reinforced Fe-based composite coatings with rare earth oxide addition. Surf. Coat. Technol. 2014, 239, 102–107. [Google Scholar] [CrossRef]

- Dong, G.; Yan, B.; Deng, Q.; Yu, T. Microstructure and wear resistance of in situ NbC particles reinforced Ni-based alloy composite coating by laser cladding. J. Wuhan Univ. Technol. Sci. Ed. 2012, 27, 231–237. [Google Scholar] [CrossRef]

- Wang, K.; Du, D.; Liu, G.; Chang, B.; Ju, J.; Sun, S.; Fu, H. Microstructure and property of laser clad Fe-based composite layer containing Nb and B4C powders. J. Alloys Compd. 2019, 802, 373–384. [Google Scholar] [CrossRef]

- Chen, L.; Yu, T.; Xu, P.; Zhang, B. In-situ NbC reinforced Fe-based coating by laser cladding: Simulation and experiment. Surf. Coat. Technol. 2021, 412, 127027. [Google Scholar] [CrossRef]

- Sun, S.; Fu, H.; Ping, X.; Lin, J.; Lei, Y.; Wu, W.; Zhou, J. Reinforcing behavior and microstructure evolution of NbC in laser cladded Ni45 coating. Appl. Surf. Sci. 2018, 455, 160–170. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, H.; Zhang, P.; Yu, Z.; Lu, Q.; Guo, J. Microstructural evolution and wear behaviors of laser-clad Stellite 6/NbC/h-BN self-lubricating coatings. Surf. Coat. Technol. 2019, 372, 218–228. [Google Scholar] [CrossRef]

- Jellad, A.; Labdi, S.; Benameur, T. On the hardness and the inherent ductility of chromium carbide nanostructured coatings prepared by RF sputtering. J. Alloys Compd. 2009, 483, 464–467. [Google Scholar] [CrossRef]

- Yu, T.; Tang, H. Microstructure and high-temperature wear behavior of laser clad TaC-reinforced Ni-Al-Cr coating. Appl. Surf. Sci. 2022, 592, 153263. [Google Scholar] [CrossRef]

- Huang, L.; Zhou, J.; Xu, J.; Huo, K.; He, W.; Meng, X.; Huang, S. Microstructure and wear resistance of electromagnetic field assisted multi-layer laser clad Fe901 coating. Surf. Coat. Technol. 2020, 395, 125876. [Google Scholar] [CrossRef]

- Yan, H.; Chen, Z.F.; Zhao, J.; Zhang, P.L.; Yu, Z.S.; Lu, Q.H. Enhancing tribological properties of WS2/NbC/Co-based self-lubricating coating via laser texturing and laser cladding two-step process. J. Mater. Res. Technol. 2020, 9, 9907–9919. [Google Scholar] [CrossRef]

- Gao, Y.; Tong, Y.; Guohui, L.; Lu, P.; Zhang, D. Microstructure and Mechanical Properties of Ni-Based Alloy Composite Coating on Cr12MoV by Laser Cladding. Coatings 2022, 12, 1632. [Google Scholar] [CrossRef]

- Wu, J.Q.; Li, Z.; Luo, Y.; Li, Y.; Gao, Z.L.; Zhao, Y.B.; Wu, C.W.; Liao, Y.X.; Jin, M. The effects of double ceramic particles (B4C-SiC) on the performance, microstructure, and friction-wear mechanisms of copper-based PM. Tribol. Int. 2022, 175, 107865. [Google Scholar] [CrossRef]

- Yin, H.G.; Li, J.H.; Zhao, L.W.; Yao, F. Simulation of in-situ preheating of ni-based multi-layer and multi-pass coatings on H13 steel. J. Mech. Sci. Technol. 2022, 36, 4671–4680. [Google Scholar] [CrossRef]

- Zhu, Y.; Song, X.; Liu, M.; Jia, W.; Yin, Z.; Wang, Q.; Zhang, Y.; Jiang, D.; Song, Q.; Cui, H. Improved wear resistance of TiAl composite coatings through NbC@(Ti,Nb)2AlC core-shell structure and nanoscale precipitation strengthening. Vacuum 2023, 213, 112091. [Google Scholar] [CrossRef]

- Liu, X.; Bi, J.; Meng, Z.; Li, R.; Li, Y.; Zhang, T. Tribological behaviors of high-hardness Co-based amorphous coatings fabricated by laser cladding. Tribol. Int. 2021, 162, 107142. [Google Scholar] [CrossRef]

| Ni | Cr | B | Si | Fe | C | Mn | P | V | Mo | S | Cu | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr12MoV | 0.12 | 12.30 | - | 0.27 | Bal. | 1.44 | 0.21 | 0.02 | 0.27 | 0.55 | 0.01 | 0.13 |

| Ni45 | Bal. | 10.02 | 1.89 | 3.05 | 5.30 | 0.33 | - | - | - | - | - | - |

| Ni45 | FeNb65 + Cr3C2 | |

|---|---|---|

| 1# | 100 | 0 |

| 2# | 85 | 15 |

| 3# | 80 | 20 |

| 4# | 75 | 25 |

| 1# | 2# | 3# | 4# | |

|---|---|---|---|---|

| Width (μm) | 6489.0 | 4033.1 | 3061.8 | 3059.3 |

| Depth (μm) | 26.5 | 22.6 | 21.4 | 11.9 |

| Area (μm2) | 86,122.0 | 45,636.6 | 32,808.3 | 18,129.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Wang, K.; Fu, H.; Zong, B.; Zhang, J. Wear Resistance of In Situ NbC-Reinforced Laser Cladding Ni45 Coatings. Lubricants 2023, 11, 316. https://doi.org/10.3390/lubricants11080316

Liu Y, Wang K, Fu H, Zong B, Zhang J. Wear Resistance of In Situ NbC-Reinforced Laser Cladding Ni45 Coatings. Lubricants. 2023; 11(8):316. https://doi.org/10.3390/lubricants11080316

Chicago/Turabian StyleLiu, Yingpeng, Kaiming Wang, Hanguang Fu, Bin Zong, and Jiguang Zhang. 2023. "Wear Resistance of In Situ NbC-Reinforced Laser Cladding Ni45 Coatings" Lubricants 11, no. 8: 316. https://doi.org/10.3390/lubricants11080316

APA StyleLiu, Y., Wang, K., Fu, H., Zong, B., & Zhang, J. (2023). Wear Resistance of In Situ NbC-Reinforced Laser Cladding Ni45 Coatings. Lubricants, 11(8), 316. https://doi.org/10.3390/lubricants11080316