A Review of the Friction and Wear Behavior of Particle-Reinforced Aluminum Matrix Composites

Abstract

:1. Introduction

2. Typical Preparation Technology of Composites

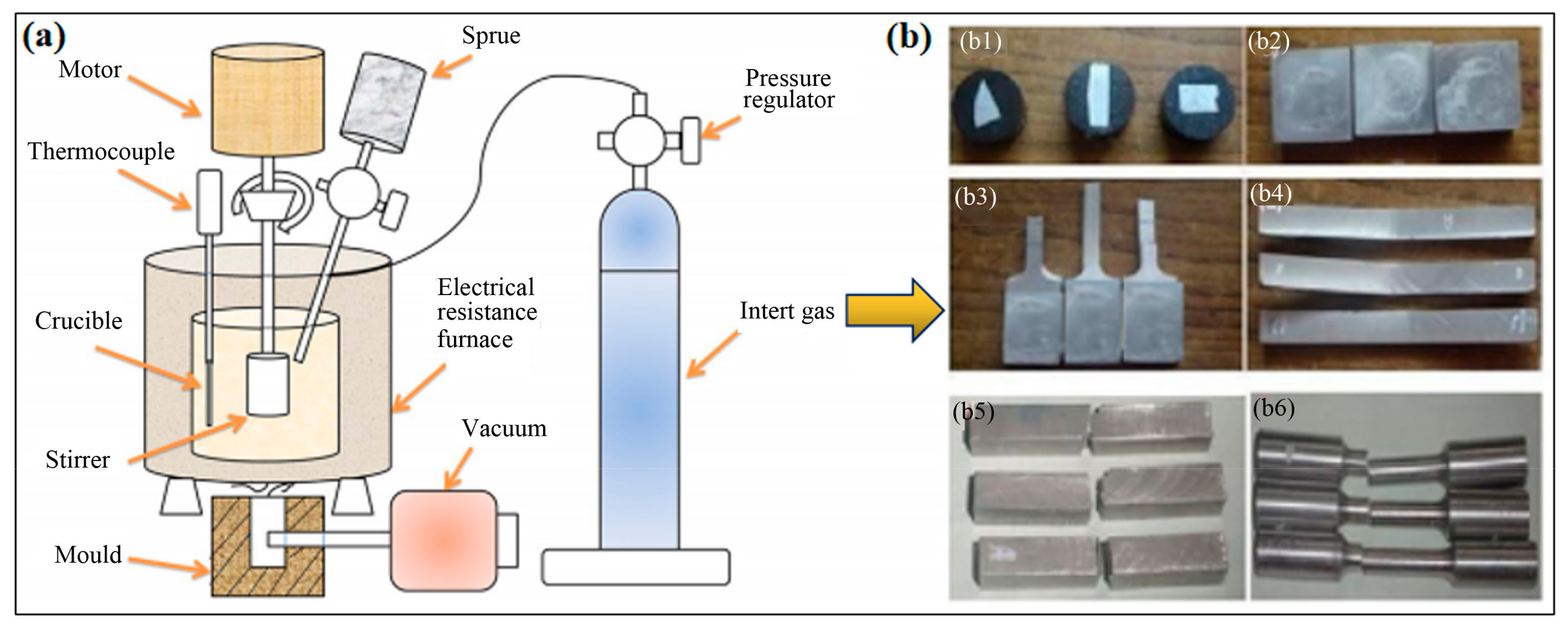

2.1. Stir Casting

2.2. Powder Metallurgy

2.3. Spray Deposition

2.4. High-Energy Ultrasound Assisted

3. Friction and Wear Behavior of Composites

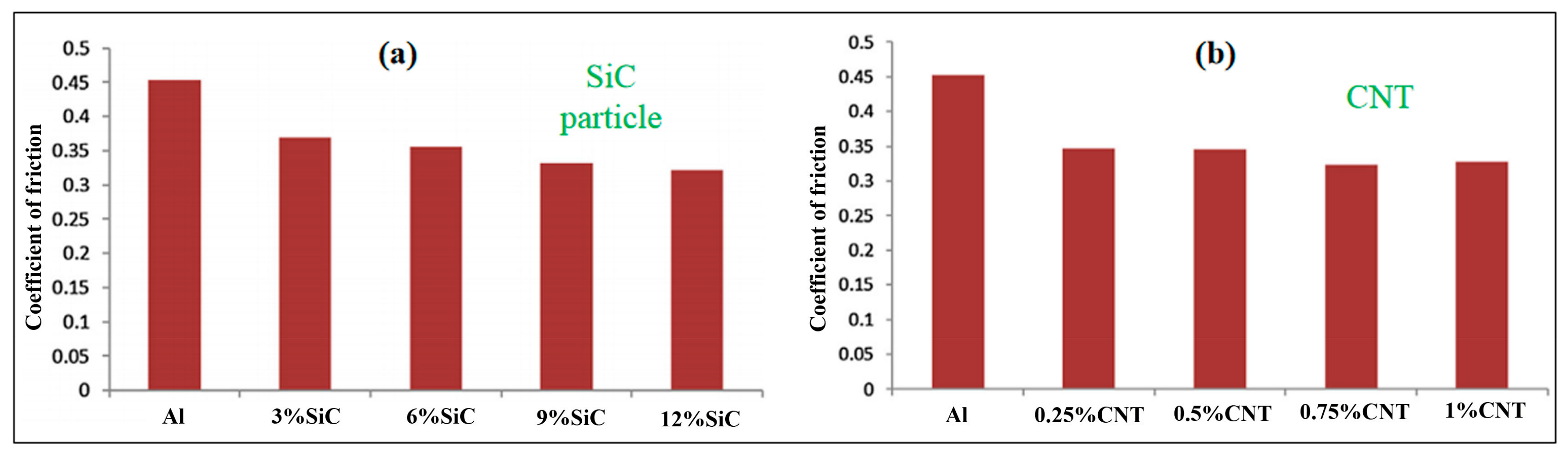

3.1. Friction Coefficient

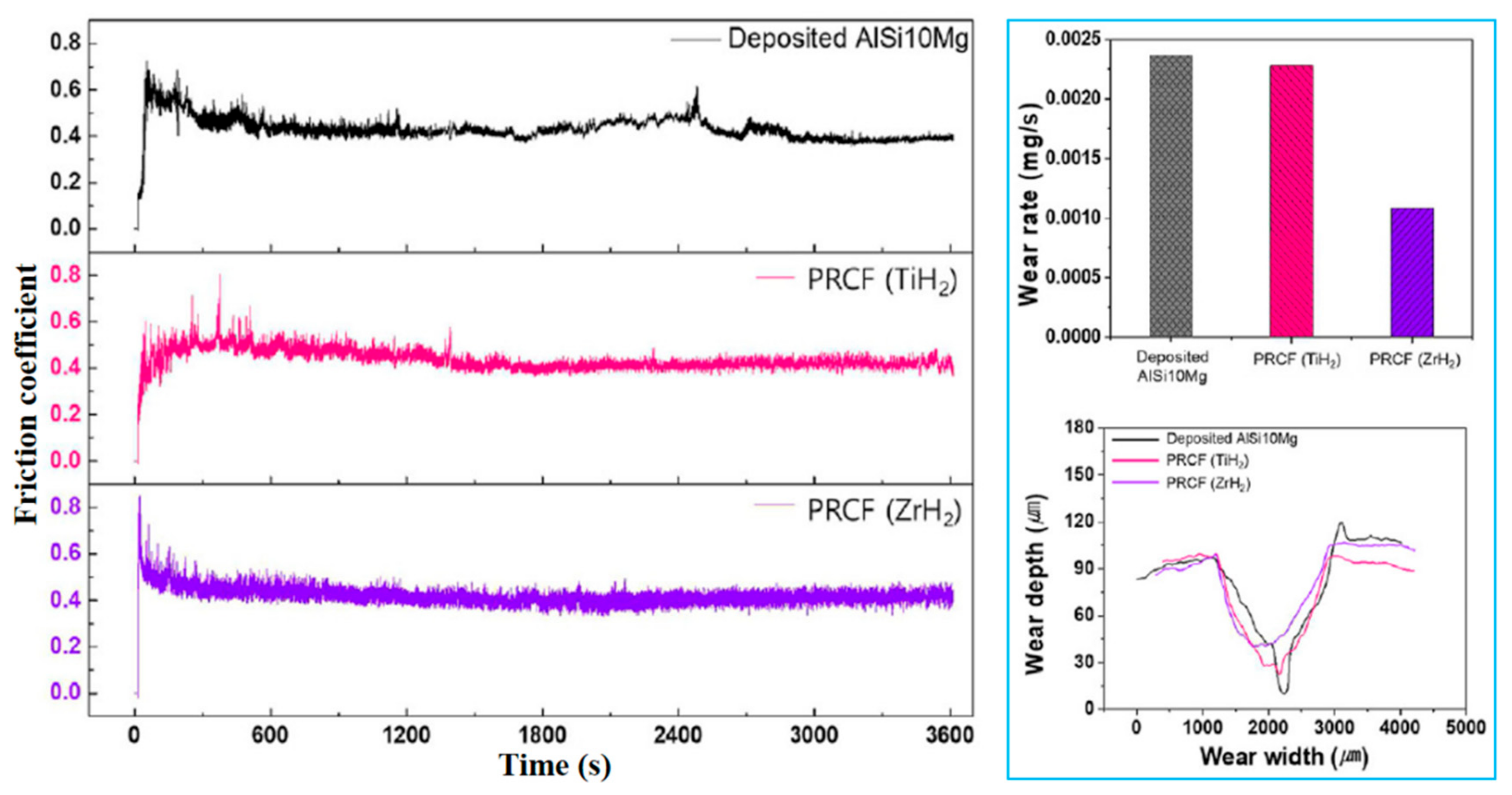

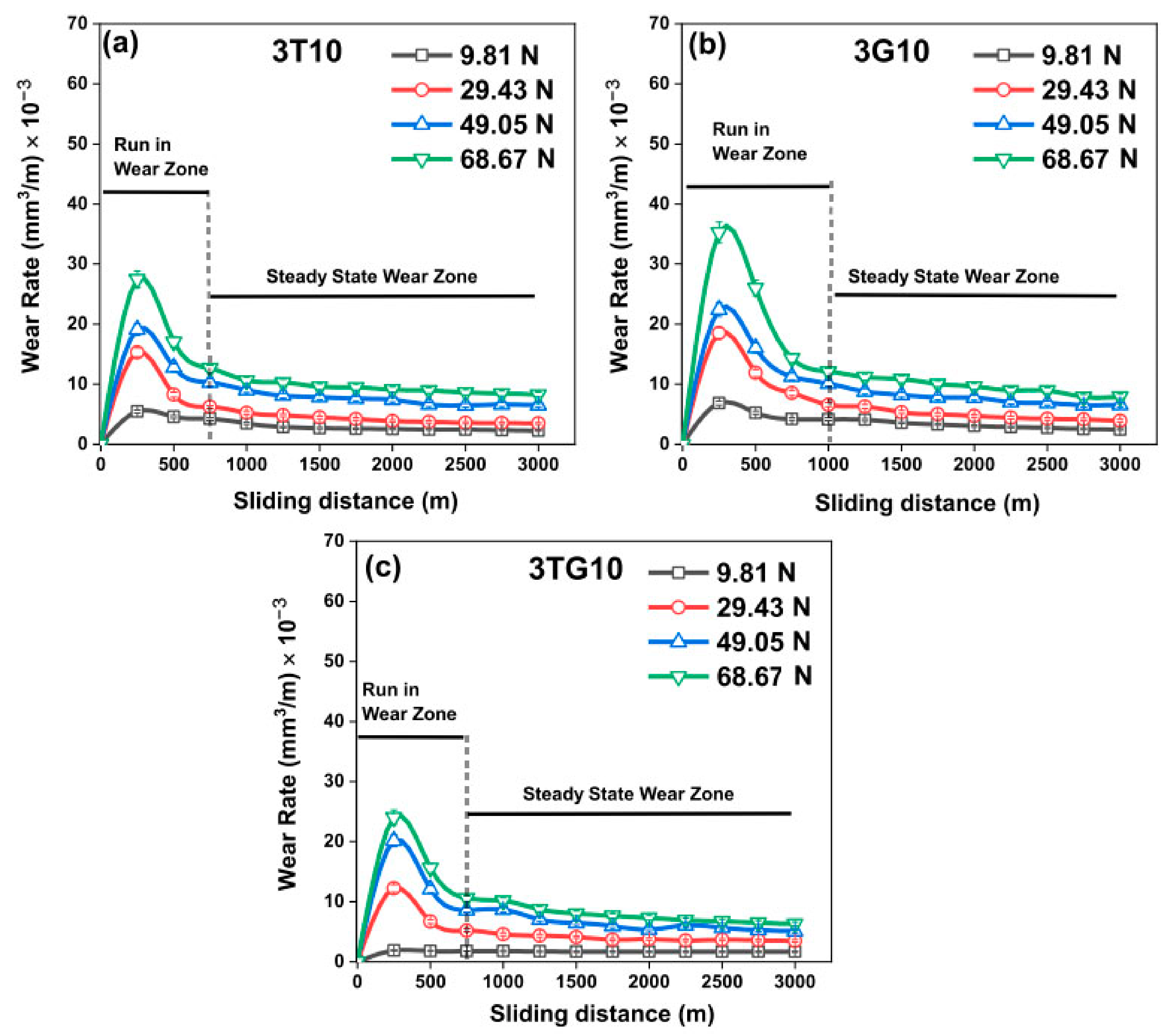

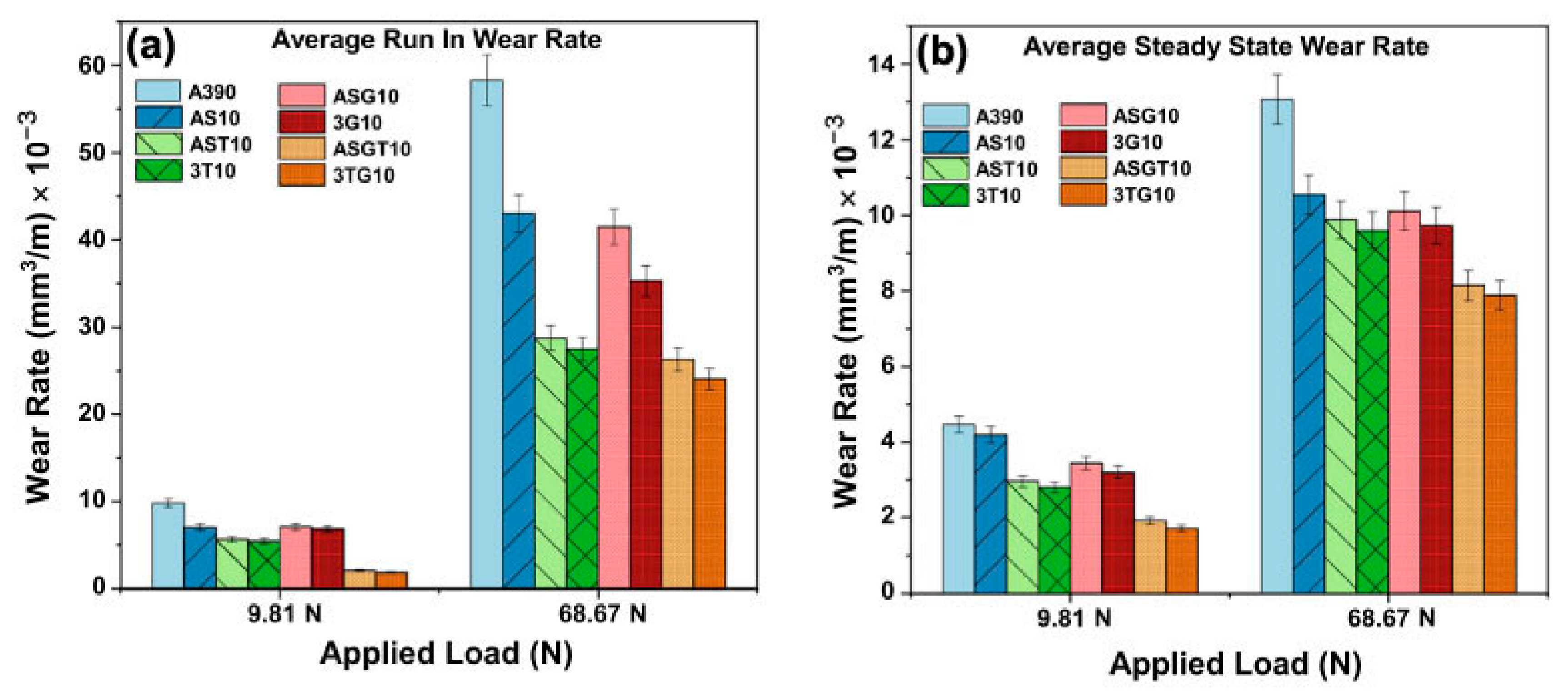

3.2. Wear Rate

3.3. Aluminum Matrix Surface

4. Effect of Factors on Friction and Wear Behavior of Composites

4.1. Internal Factors

4.1.1. Microstructure Characteristics of Matrix Materials

4.1.2. State of Reinforced Particles

4.2. External Factors

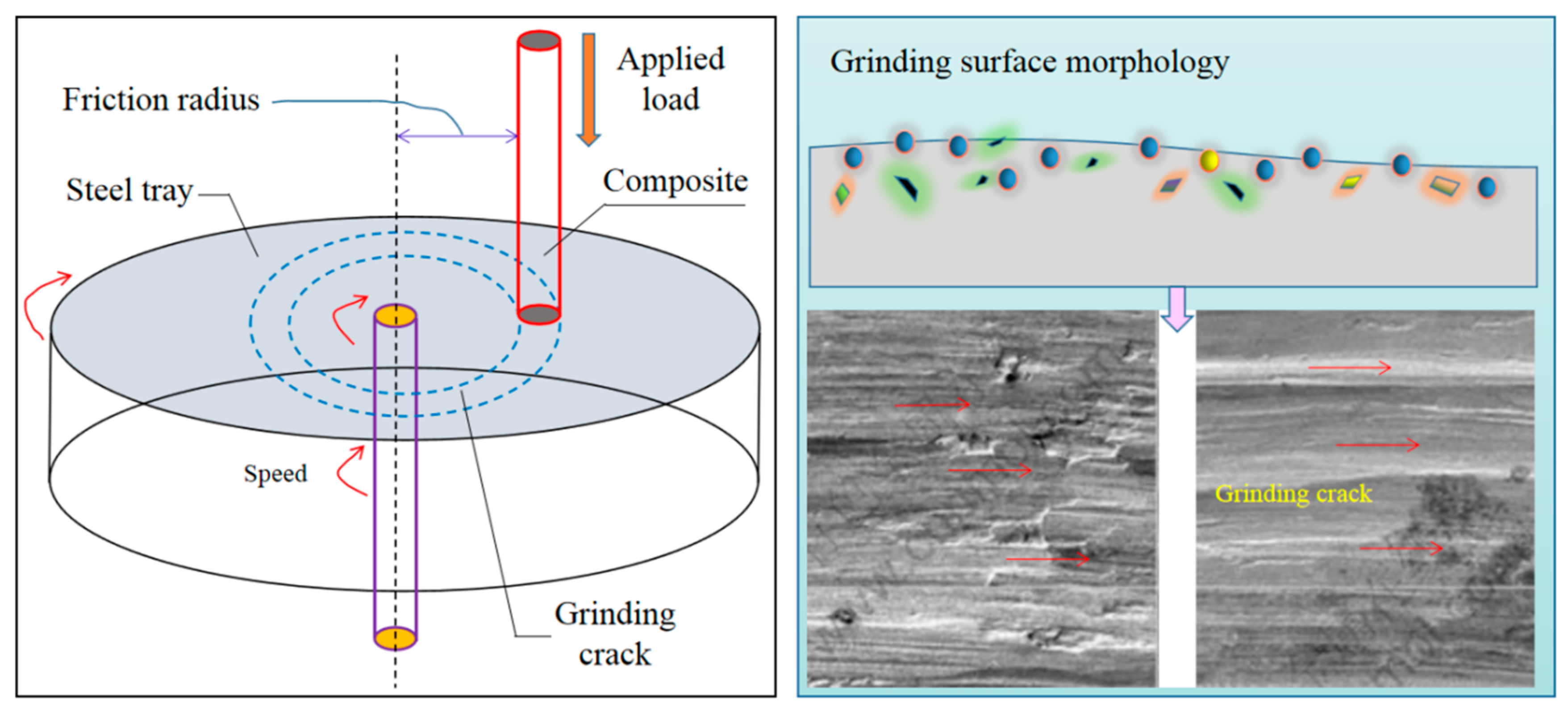

4.2.1. Wear Pattern

4.2.2. Applied Load

4.2.3. Sliding Speed

4.2.4. Thermal Treatment

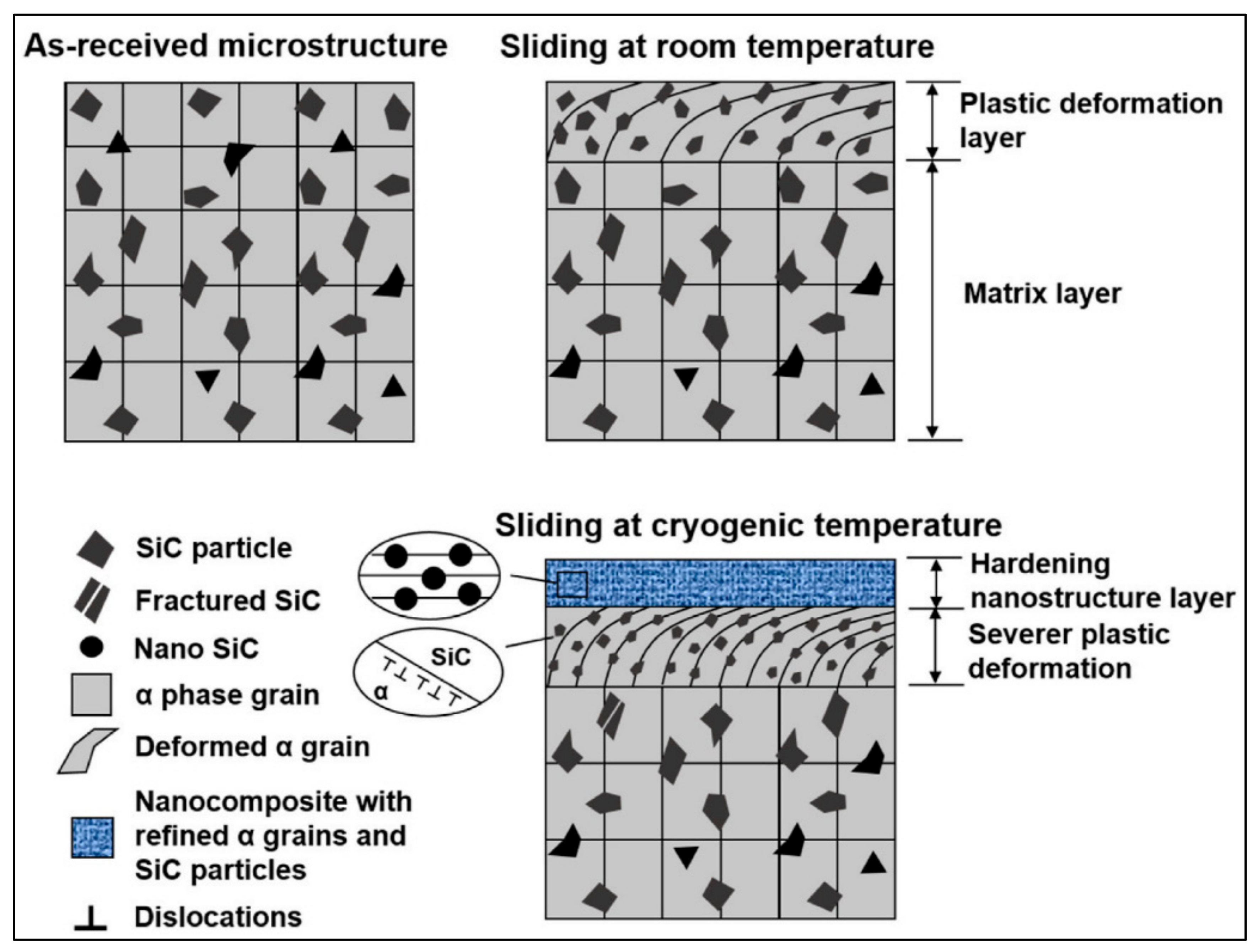

4.2.5. Temperature

5. Wear Mechanisms

6. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, J.; Wang, J.; Lin, Y.; Zheng, K.; Tian, Z.; Han, P. The influence of particle surface oxidation treatment on microstructure and mechanical behavior of 3D-SiCp/A356 interpenetrating composites fabricated by pressure infiltration technique. J. Mater. Res. Technol. 2023, 24, 8984–8996. [Google Scholar] [CrossRef]

- Morsi, K.; Esawi, A.M.K.; Borah, P.; Lanka, S.; Sayed, A.; Taher, M. Properties of single and dual matrix aluminum–carbon nanotube composites processed via spark plasma extrusion (SPE). Mater. Sci. Eng. A 2010, 527, 5686–5690. [Google Scholar] [CrossRef]

- Karbalaei Akbari, M.; Baharvandi, H.R.; Mirzaee, O. Fabrication of nano-sized Al2O3 reinforced casting aluminum composite focusing on preparation process of reinforcement powders and evaluation of its properties. Compos. Part. B-Eng. 2013, 55, 426–432. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, Y. Microstructure and mechanical properties of the rheoformed cylindrical part of 7075 aluminum matrix composite reinforced with nano-sized SiC particles. Mater. Des. 2015, 79, 32–41. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Dora, T.L. A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites. J. Manuf. Process. 2020, 56, 1059–1074. [Google Scholar] [CrossRef]

- Gill, R.S.; Samra, P.S.; Kumar, A. Effect of different types of reinforcement on tribological properties of aluminium metal matrix composites (MMCs)—A review of recent studies. Mater. Today Proc. 2022, 56, 3094–3101. [Google Scholar] [CrossRef]

- Okokpujie, I.P.; Tartibu, L.K.; Babaremu, K.; Akinfaye, C.; Ogundipe, A.T.; Akinlabi, E.T. Study of the corrosion, electrical, and mechanical properties of aluminium metal composite reinforced with coconut rice and eggshell for wind turbine blade development. Clean. Eng. Technol. 2023, 13, 100627. [Google Scholar] [CrossRef]

- Zeng, M.; Ling, Y.; Zhang, P.; Dong, X.; Li, K.; Yan, H. Improvement of interfacial interaction and mechanical properties in aluminum matrix composites reinforced with Cu-coated carbon nanotubes. Mater. Sci. Eng. A 2023, 870, 144918. [Google Scholar] [CrossRef]

- Charan Theja, P.; Suresh, R.; Chandra Sekhara Reddy, M. A review on-fabrication and testing methods of aluminium metal matrix nano composites for various applications. Mater. Today Proc. 2022, 56, 1137–1142. [Google Scholar] [CrossRef]

- Li, P.; Peng, K.; Wu, B.; Huang, H.; Zhang, Y.; Gao, M. Mechanical properties of Al-Si matrix composites synergistically reinforced by high-entropy alloy and SiC nanoparticles. J. Alloys Compd. 2023, 939, 168762. [Google Scholar] [CrossRef]

- Wang, Z.; Song, M.; Sun, C.; Xiao, D.; He, Y. Effect of extrusion and particle volume fraction on the mechanical properties of SiC reinforced Al–Cu alloy composites. Mater. Sci. Eng. A 2010, 527, 6537–6542. [Google Scholar] [CrossRef]

- Tosun, G.; Kurt, M. The porosity, microstructure, and hardness of Al-Mg composites reinforced with micro particle SiC/Al2O3 produced using powder metallurgy. Compos. B Eng. 2019, 174, 106965. [Google Scholar] [CrossRef]

- Tu, T.A.; Phuc, N.H.H. Preparation of MgO–SiO2–Al2O3 composite particle by electrostatic adsorption method and its transformation to cordierite. Ceram. Int. 2023, 49, 23591–23597. [Google Scholar]

- He, E.; Wang, S.; Li, Y.; Wang, Q. Enhanced tribological properties of polymer composites by incorporation of nano-SiO2 particles: A molecular dynamics simulation study. Comp. Mater. Sci. 2017, 134, 93–99. [Google Scholar] [CrossRef]

- Sun, H.; Ma, A.; Jiang, J.; Li, Y.; Xu, Q. Revealing the tensile creep behavior and mechanism of SiC particles reinforced AZ31 composite fabricated by liquid metallurgy. Mater. Sci. Eng. A 2023, 862, 144325. [Google Scholar] [CrossRef]

- Subramani, K.; Arunkumar, T.; Mohanavel, V.; Kolappan, S.; Kailasanathan, C.; Boopathi Rathinam, B.; Subbiah, R.; Suresh Kumar, S. Investigation on wear characteristics of Al2219/Si3N4/Coal bottom ash MMC. Mater. Today Proc. 2022, 62, 5514–5518. [Google Scholar] [CrossRef]

- Sahoo, B.P.; Das, D.; Rath, P.; Chakrabarty, S.; Roy, S.; Mohanta, K. Improving reinforcement properties of CNTs in aluminium matrix composites: A case of surface modification through AlN nano-particle grafting. Surf. Interfaces 2023, 36, 102571. [Google Scholar] [CrossRef]

- Zhao, K.; Liu, X.; Fang, Y.; Guo, E.; Kang, H.; Hao, Z.; Li, J.; Du, G.; Liu, L.; Chen, Z.; et al. Multiscale microstructures, mechanical properties and electrical conductivity of in-situ dual-size TiB2 particles reinforced 6201 aluminum matrix composites. J. Mater. Res. Technol. 2023, 23, 5459–5473. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ravichandran, M.; Suresh Kumar, S. Tribological and mechanical properties of Zirconium Di-boride (ZrB2) particles reinforced aluminium matrix composites. Mater. Today Proc. 2020, 21, 862–864. [Google Scholar] [CrossRef]

- Liu, W.; Ke, Y.; Sugio, K.; Qiu, Z.; Li, W.; Guo, Y.; Liu, X.; Sasaki, G. Effects of repeated accumulative roll bonding cycles on microstructural characteristics and tensile behaviors of Al2O3 particle reinforced aluminum-matrix composites. Mater. Lett. 2022, 320, 132386. [Google Scholar] [CrossRef]

- Santhosh, N.; Praveena, B.A.; Jain, R.; Hasan, M.A.; Islam, S.; Khan, M.A.; Razak, A.; Daniyal, M. Analysis of friction and wear of aluminium AA 5083/WC composites for building applications using advanced machine learning models. Ain Shams Eng. J. 2023, 14, 102090. [Google Scholar] [CrossRef]

- Sahin, Y. Optimization of testing parameters on the wear behaviour of metal matrix composites based on the Taguchi method. Mater. Sci. Eng. A 2005, 408, 1–8. [Google Scholar] [CrossRef]

- Santhosh, N.; Praveena, B.A.; Chandrashekar, A.; Mohanavel, V.; Raghavendra, S.; Basheer, D. Wear behaviour of aluminium alloy 5083/SiC/fly ash inoculants based functional composites–optimization studies. Mater. Res. Express 2022, 9, 076513. [Google Scholar] [CrossRef]

- Sudeep Kumar, T.; Shivashankar, G.S.; Dhotey, K.; Singh, J. Experimental study wear rate of glass fibre reinforced epoxy polymer composites filled with aluminium powder. Mater. Today Proc. 2017, 4, 10764–10768. [Google Scholar] [CrossRef]

- Singh, H.; Bhowmick, H. Lubrication characteristics and wear mechanism mapping for hybrid aluminium metal matrix composite sliding under surfactant functionalized MWCNT-oil. Tribol. Int. 2020, 145, 106152. [Google Scholar] [CrossRef]

- Ramkumar, K.R.; Sivasankaran, S.; Al-Mufadi, F.A.; Siddharth, S.; Raghu, R. Investigations on microstructure, mechanical, and tribological behaviour of AA 7075–x wt.% TiC composites for aerospace applications. Arch. Civ. Mech. Eng. 2019, 19, 428–438. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Wang, J.; Hu, D.; Li, J. Microstructure and wear resistance of direct laser-deposited TiC-enhanced aluminum-based composite coating for brake discs. Surf. Coat. Technol. 2023, 455, 129193. [Google Scholar] [CrossRef]

- Khorsand, A.; Majidian, H.; Farvizi, M. Wear behavior and microstructure of alumina-mullite-zirconia composites prepared by a novel method: Coating of zircon powder by aluminum alkoxide. Ceram. Int. 2022, 48, 33594–33603. [Google Scholar] [CrossRef]

- Bai, M.; Xue, Q. Investigation of wear mechanism of SiC particulate-reinforced Al-20Si-3Cu-1Mg aluminium matrix composites under dry sliding and water lubrication. Tribol. Int. 1997, 30, 261–269. [Google Scholar] [CrossRef]

- Tharanikumar, L.; Mohan, B.; Anbuchezhiyan, G. Enhancing the microstructure and mechanical properties of Si3N4–BN strengthened Al–Zn–Mg alloy hybrid nano composites using vacuum assisted stir casting method. J. Mater. Res. Technol. 2022, 20, 3646–3655. [Google Scholar] [CrossRef]

- Yamamoto, T.; Kato, K.; Komarov, S.V.; Ueno, Y.; Hayashi, M.; Ishiwata, Y. Investigation of melt stirring in aluminum melting furnace through Water model. J. Mater. Process. Technol. 2018, 259, 409–415. [Google Scholar] [CrossRef]

- Sharma, S.; Nanda, T.; Pandey, O.P. Effect of particle size on dry sliding wear behaviour of sillimanite reinforced aluminium matrix composites. Ceram. Int. 2018, 44, 104–114. [Google Scholar] [CrossRef]

- Herzallah, H.; Elsayd, A.; Shasha, A.; Adly, M. Effect of carbon nanotubes (CNTs) and silicon carbide (SiC) on mechanical properties of pure Al manufactured by powder metallurgy. J. Mater. Res. Technol. 2020, 9, 1948–1954. [Google Scholar] [CrossRef]

- Woo, D.J.; Heer, F.C.; Brewer, L.N.; Hooper, J.P.; Osswald, S. Synthesis of nanodiamond-reinforced aluminum metal matrix composites using cold-spray deposition. Carbon 2015, 86, 15–25. [Google Scholar] [CrossRef]

- Cheng, N.P.; Zeng, S.M.; Liu, Z.Y. Preparation, microstructures and deformation behavior of SiCp/6066Al composites produced by PM route. J. Mater. Process. Technol. 2008, 202, 27–40. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, B.; Kang, H.; Guo, E.; Li, J.; Du, G.; Chen, Z.; Wang, T. Ultrasound-assisted dispersion of TiB2 nanoparticles in 7075 matrix hybrid composites. Mater. Sci. Eng. A 2022, 840, 142958. [Google Scholar] [CrossRef]

- Li, G.; Qu, Y.; Yang, Y.; Zhou, Q.; Liu, X.; Li, R. Improved multi-orientation dispersion of short carbon fibers in aluminum matrix composites prepared with square crucible by mechanical stirring. J. Mater. Sci. Technol. 2020, 40, 81–87. [Google Scholar] [CrossRef]

- Venkatesh, V.S.S.; Rao, G.P.; Patnaik, L.; Gupta, N.; Kumar, S.; Saxena, K.K.; Sunil, B.D.Y.; Eldin, S.M.; Al-kafaji, F.H.K. Processing and evaluation of nano SiC reinforced aluminium composite synthesized through ultrasonically assisted stir casting process. J. Mater. Res. Technol. 2023, 24, 7394–7408. [Google Scholar] [CrossRef]

- Li, G.; Jiang, W.; Guan, F.; Zhu, J.; Yu, Y.; Fan, Z. Improving mechanical properties of AZ91D magnesium/A356 aluminum bimetal prepared by compound casting via a high velocity oxygen fuel sprayed Ni coating. J. Magnes. Alloy. 2022, 10, 1075–1085. [Google Scholar] [CrossRef]

- Yang, Z.; Ye, S.; Wang, Z.; Li, Z.; Li, W. Experimental and simulation study on braking noise characteristics and noise reduction strategies of the friction pair between the SiCp/A356 brake disc and the synthetic pad. Eng. Fail. Anal. 2023, 145, 107017. [Google Scholar] [CrossRef]

- Xie, X.; Li, Z.; Domblesky, J.P.; Yang, Z.; Liu, X.; Li, W.; Han, J. Analysis of deep crack formation and propagation in railway brake discs. Eng. Fail. Anal. 2021, 128, 105600. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Zhao, Y.; Tian, W.; Bian, H.; He, J. Sliding wear behaviors of in situ alumina/aluminum titanate ceramic composites. Wear 2009, 266, 1051–1057. [Google Scholar] [CrossRef]

- Ma, S.; Xu, E.; Zhu, Z.; Liu, Q.; Yu, S.; Liu, J.; Zhong, H.; Jiang, Y. Mechanical and wear performances of aluminum/sintered-carbon composites produced by pressure infiltration for pantograph sliders. Powder Technol. 2018, 326, 54–61. [Google Scholar] [CrossRef]

- Li, W.; Yang, X.; Wang, S.; Xiao, J.; Hou, Q. Research and prospect of ceramics for automotive disc-brakes. Ceram. Int. 2021, 47, 10442–10463. [Google Scholar] [CrossRef]

- Bowden, P.B. The effect of hydrostatic pressure on the fibre-matrix bond in a steel—Resin model composite. J. Mater. Sci. 1970, 1, 318–319. [Google Scholar]

- Wang, F.; Cheng, L.; Liang, S. Study on the internal friction mechanism of C/SiC composites in different corrosion stage. Vacuum 2019, 168, 108833. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Liang, A. Friction and wear behaviors of Ta-based nanocrystalline composite coating under extreme sliding conditions. Surf. Coat. Technol. 2023, 465, 129607. [Google Scholar] [CrossRef]

- Uyyuru, R.K.; Surappa, M.K.; Brusethaug, S. Tribological behavior of Al–Si–SiCp composites/automobile brake pad system under dry sliding conditions. Tribol. Int. 2007, 40, 365–373. [Google Scholar] [CrossRef]

- Kim, H.-J.; Shin, G.-Y.; Lee, K.-Y.; Shim, D.-S. Wear behavior of aluminum-matrix particle (TiH2 and ZrH2)-reinforced composite foam additively manufactured using directed energy deposition. J. Mater. Res. Technol. 2023, 25, 222–230. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, Y.; Wang, Y.; Xiao, P.; Huang, X. Effects of ZrC particles, load and sliding speed on the wear behavior of the ZrC/2024Al composites. Wear 2022, 506–507, 204465. [Google Scholar] [CrossRef]

- Devaraju, A.; Kumar, A.; Kotiveerachari, B. Influence of addition of Grp/Al2O3p with SiCp on wear properties of aluminum alloy 6061-T6 hybrid composites via friction stir processing. Trans. Nonferr. Metal. Soc. 2013, 23, 1275–1280. [Google Scholar] [CrossRef]

- Rinawa, M.L.; Singh, K.; Chaudhary, V.; Ahamad, N.; Das, P.P.; Gupta, S.; Gupta, P. Simulation of bio-fiber based polymer composites for frictional and specific wear rate. Mater. Today Proc. 2022, 56, 2640–2646. [Google Scholar] [CrossRef]

- Ma, J.; Liu, Y.; Mostaghimi, J.; Zhan, X. Effect of laser-induced texture on lubrication retention and tribological properties of 40Cr alloy surfaces. Tribol. Int. 2023, 187, 108651. [Google Scholar] [CrossRef]

- Zhou, X.; Gao, Y.; Wang, Y. Wear behavior of Ni-coated carbon fiber and ZrC particles reinforced 2024Al matrix composites. Wear 2023, 528–529, 204967. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Elaya Perumal, A. Study on mechanical and wear properties of Al 7075/Al2O3/graphite hybrid composites. Compos. Part B-Eng. 2014, 56, 464–471. [Google Scholar] [CrossRef]

- Akhlaghi, F.; Lajevardi, A.; Maghanaki, H.M. Effects of casting temperature on the microstructure and wear resistance of compocast A356/SiCp composites: A comparison between SS and SL routes. J. Mater. Process. Technol. 2004, 155–156, 1874–1880. [Google Scholar] [CrossRef]

- Banerji, A.; Prasad, S.V.; Surappa, M.K.; Rohatgi, P.K. Abrasive wear of cast aluminium alloy-zircon particle composites. Wear 1982, 82, 141–151. [Google Scholar] [CrossRef]

- Zhang, C.; Yao, D.; Yin, J.; Zuo, K.; Xia, Y.; Liang, H.; Zeng, Y.-P. Effects of β-Si3N4 whiskers addition on mechanical properties and tribological behaviors of Al matrix composites. Wear 2019, 430–431, 145–156. [Google Scholar] [CrossRef]

- Singhal, V.; Gupta, A.; Pandey, O.P.; Sharma, D.; Jain, V.K. Investigate the optical and dry sliding wear behavior of solid lubricated sillimanite reinforced aluminum metal matrix composite. Mater. Today Proc. 2023, 2, 196. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, W.; Su, Z.; Xue, Y.; Wang, S.; Zhao, H.; Sun, Y.; Li, Y.; Xu, G. Improving the wear resistance of 50 wt% Si particle-reinforced Al matrix composites treated by over-modification with a Cu-P modifier. Tribol. Int. 2023, 180, 108247. [Google Scholar] [CrossRef]

- Wang, F.; Liu, H.; Ma, Y.; Jin, Y. Effect of Si content on the dry sliding wear properties of spray-deposited Al–Si alloy. Mater. Des. 2004, 25, 163–166. [Google Scholar] [CrossRef]

- Eshaghian, O.; Hoseinie, S.H.; Jazi, H.S. Effects of Ni-based composite coatings on failure mechanism and wear resistance of cutting picks on coal shearer machine. Eng. Fail. Anal. 2023, 151, 107342. [Google Scholar] [CrossRef]

- Umanath, K.; Palanikumar, K.; Selvamani, S.T. Analysis of dry sliding wear behaviour of Al6061/SiC/Al2O3 hybrid metal matrix composites. Compos. Part B-Eng. 2013, 53, 159–168. [Google Scholar] [CrossRef]

- Kang, Y.-C.; Chan, S.L.-I. Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites. Mater. Chem. Phys. 2004, 85, 438–443. [Google Scholar] [CrossRef]

- Shao, J.C.; Xiao, B.L.; Wang, Q.Z.; Ma, Z.Y.; Yang, K. An enhanced FEM model for particle size dependent flow strengthening and interface damage in particle reinforced metal matrix composites. Compos. Sci. Technol. 2011, 71, 39–45. [Google Scholar] [CrossRef]

- Tan, H.; Sun, Q.; Chen, W.; Zhu, S.; Cheng, J.; Yang, J. Tribological performance and wear mechanisms of a high-temperature wear-resistant Al-Si/SiAlON composite. Tribol. Int. 2021, 164, 107227. [Google Scholar] [CrossRef]

- Ipek, R. Adhesive wear behaviour of B4C and SiC reinforced 4147 Al matrix composites (Al/B4C–Al/SiC). J. Mater. Process. Technol. 2005, 162–163, 71–75. [Google Scholar] [CrossRef]

- Jamaati, R.; Naseri, M.; Toroghinejad, M.R. Wear behavior of nanostructured Al/Al2O3 composite fabricated via accumulative roll bonding (ARB) process. Mater. Des. 2014, 59, 540–549. [Google Scholar] [CrossRef]

- Khelge, S.; Kumar, V.; Shetty, V.; Kumaraswamy, J. Effect of reinforcement particles on the mechanical and wear properties of aluminium alloy composites: Review. Mater. Today Proc. 2022, 52, 571–576. [Google Scholar] [CrossRef]

- Ma, Z.; Bi, J.; Lu, Y.; Shen, H.; Gao, Y. Abrasive wear of discontinuous SiC reinforced aluminum alloy composites. Wear 1991, 148, 287–293. [Google Scholar] [CrossRef]

- Singh, R.P. Synthesis and characterisation of Al-Mg-SiO2 particulate composite prepared by nanostructured silica from rice husk ash. Mater. Today Proc. 2021, 37, 3148–3153. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, W.; Liu, M.; Tian, J.; Xu, G. Comparison of wear performance of bainitic and martensitic structure with similar fracture toughness and hardness at different wear conditions. Wear 2023, 512–513, 204512. [Google Scholar] [CrossRef]

- Li, J.X.; Wu, B.N.; Ding, H.H.; Galas, R.; Omasta, M.; Wen, Z.F.; Guo, J.; Wang, W.J. Wear and damage behaviours of wheel and rail materials: Effects of friction modifier and environmental temperature. Wear 2023, 523, 204796. [Google Scholar] [CrossRef]

- Wang, Y.-G.; Yang, Y.; Liang, H.-E.; Tian, W.; Shao, Y.-X. Effect of Cr2O3 on the microstructure and wear resistance of coatings prepared from Cr2O3-SiC-Al composite powders. Mater. Chem. Phys. 2023, 304, 127860. [Google Scholar] [CrossRef]

- Lee, G.-S.; Bae, S.-H.; Lee, Y.-Z. The influence of formation of transfer layer on the characteristics of friction and wear mechanism between several coatings and anodized aluminum alloy. Surf. Coat. Technol. 2010, 205, S152–S157. [Google Scholar] [CrossRef]

- Paladugu, S.R.M.N.; Aparna, D.; Rama Sreekanth, P.S. Mechanical and wear analysis of Al6061-SiC/Al2O3/B4C hybrid metal matrix composites using stir casting process. Mater. Today Proc. 2022, 56, 1091–1096. [Google Scholar] [CrossRef]

- Zhang, J.; Alpas, A.T. Wear regimes and transitions in Al2O3 particulate-reinforced aluminum alloys. Mater. Sci. Eng. A 1993, 161, 273–284. [Google Scholar] [CrossRef]

- Mohamadigangaraj, J.; Nourouzi, S.; Jamshidi Aval, H. Microstructure, mechanical and tribological properties of A390/SiC composite produced by compocasting. Trans. Nonferrous Met. Soc. 2019, 29, 710–721. [Google Scholar] [CrossRef]

- Weng, Z.; Pan, R.; Liu, B.; Gu, K.; Zhang, M.; Cui, C.; Wang, J. Subsurface deformation and wear behavior of 15% SiCp/2009Al aluminum matrix composite under cryogenic sliding. Ceram. Int. 2023, 49, 17135–17147. [Google Scholar] [CrossRef]

- Prathap Singh, S.; Arun Vasantha Geethan, K.; Elilraja, D.; Prabhuram, T.; Immanuel Durairaj, J. Optimization of dry sliding wear performance of functionally graded Al6061/20% SiC metal matrix composite using Taguchi method. Mater. Today Proc. 2020, 22, 2824–2831. [Google Scholar] [CrossRef]

- Xi, K.; Wu, H.; Zhou, C.; Qi, Z.; Yang, K.; Fu, R.K.Y.; Xiao, S.; Wu, G.; Ding, K.; Chen, G.; et al. Improved corrosion and wear resistance of micro-arc oxidation coatings on the 2024 aluminum alloy by incorporation of quasi-two-dimensional sericite microplates. Appl. Surf. Sci. 2022, 585, 152693. [Google Scholar] [CrossRef]

- Lang, A.; Klüppel, M. Influences of temperature and load on the dry friction behaviour of tire tread compounds in contact with rough granite. Wear 2017, 380, 15–25. [Google Scholar] [CrossRef]

- Pinto, A.L.; Araújo, J.A.; Talemi, R. Effects of fretting wear process on fatigue crack propagation and life assessment. Tribol. Int. 2021, 156, 106787. [Google Scholar] [CrossRef]

- Elhefnawey, M.; Shuai, G.L.; Li, Z.; Nemat-Alla, M.; Zhang, D.T.; Li, L. On dry sliding wear of ECAPed Al-Mg-Zn alloy: Wear rate and coefficient of friction relationship. Alex. Eng. J. 2021, 60, 927–939. [Google Scholar] [CrossRef]

- Wilden, J.; Jahn, S.; Reich, S.; Dal-Canton, S. Cladding of aluminum substrates with iron based wear resistant materials using controlled short arc technology. Surf. Coat. Technol. 2008, 202, 4509–4514. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, Z.; Wang, Q.; Ren, M.; Jia, H. Study on wear resistance of local aluminum alloy reinforced by carbon fiber transfer membrane region. J. Mater. Res. Technol. 2023, 23, 5772–5782. [Google Scholar] [CrossRef]

- Mehta, D.S.; Masood, S.H.; Song, W.Q. Investigation of wear properties of magnesium and aluminum alloys for automotive applications. J. Mater. Process. Technol. 2004, 155–156, 1526–1531. [Google Scholar] [CrossRef]

- Previtali, B.; Pocci, D.; Taccardo, C. Application of traditional investment casting process to aluminium matrix composites. Compos. Part A-Appl. Sci. Manuf. 2008, 39, 1606–1617. [Google Scholar] [CrossRef]

- Senthil, S.; Raguraman, M.; Thamarai Manalan, D. Manufacturing processes & recent applications of aluminium metal matrix composite materials: A review. Mater. Today Proc. 2021, 45, 5934–5938. [Google Scholar]

- Garg, P.; Jamwal, A.; Kumar, D.; Sadasivuni, K.K.; Hussain, C.M.; Gupta, P. Advance research progresses in aluminium matrix composites: Manufacturing & applications. J. Mater. Res. Technol. 2019, 8, 4924–4939. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zhang, J. A Review of the Friction and Wear Behavior of Particle-Reinforced Aluminum Matrix Composites. Lubricants 2023, 11, 317. https://doi.org/10.3390/lubricants11080317

Wang Y, Zhang J. A Review of the Friction and Wear Behavior of Particle-Reinforced Aluminum Matrix Composites. Lubricants. 2023; 11(8):317. https://doi.org/10.3390/lubricants11080317

Chicago/Turabian StyleWang, Yunlei, and Jie Zhang. 2023. "A Review of the Friction and Wear Behavior of Particle-Reinforced Aluminum Matrix Composites" Lubricants 11, no. 8: 317. https://doi.org/10.3390/lubricants11080317

APA StyleWang, Y., & Zhang, J. (2023). A Review of the Friction and Wear Behavior of Particle-Reinforced Aluminum Matrix Composites. Lubricants, 11(8), 317. https://doi.org/10.3390/lubricants11080317