Erosive Wear Behavior of Novel Hybrid Multicomponent Cast Alloys with Different C and B Contents

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

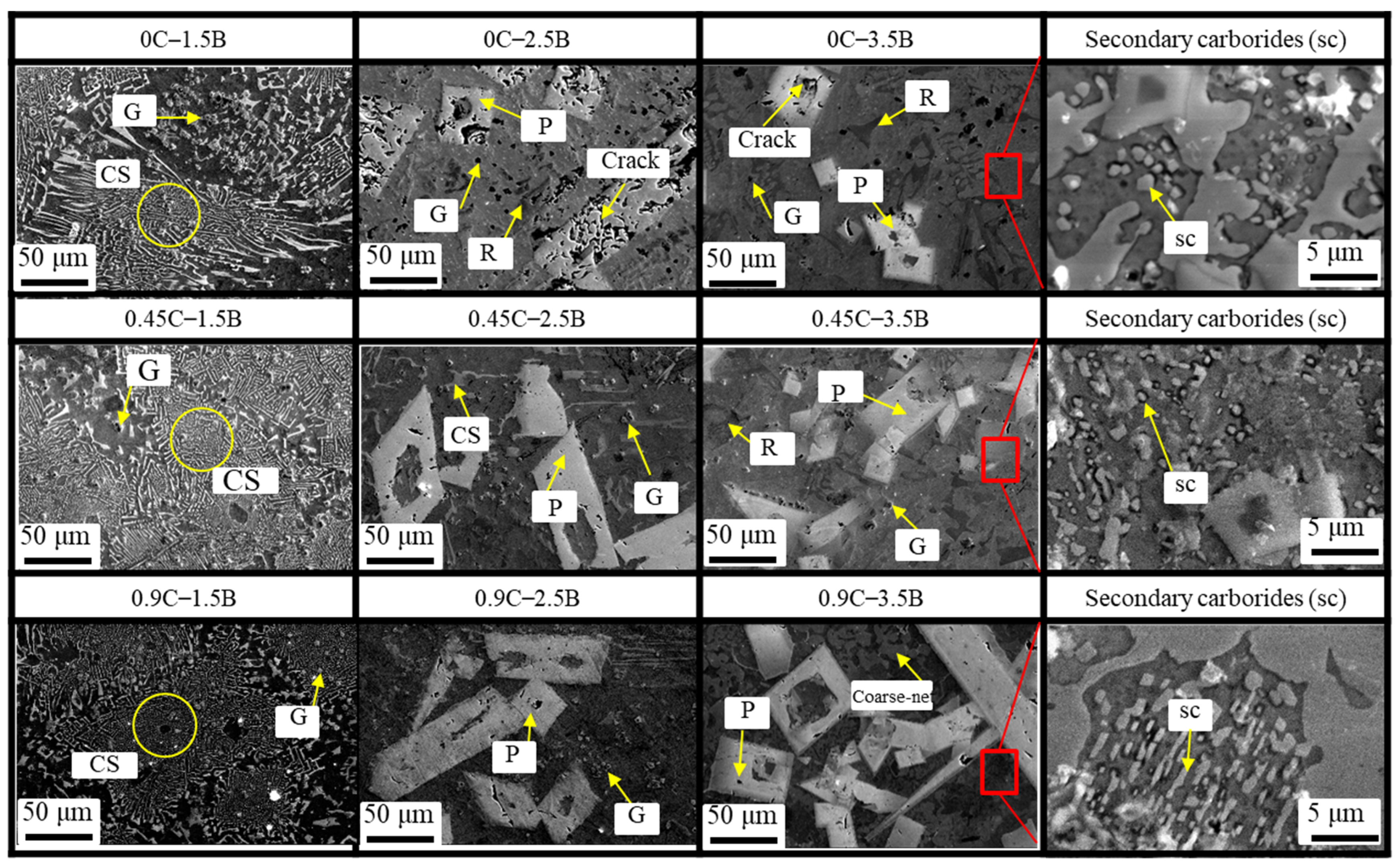

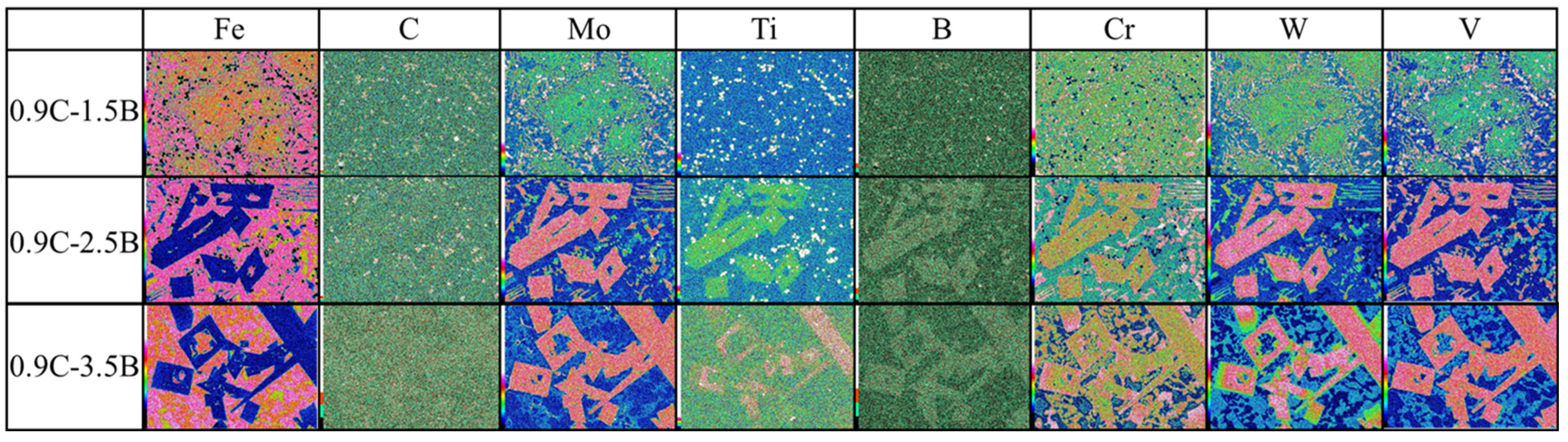

3.1. Microstructure Observation

3.2. Bulk Volume Fraction and Hardness of Alloy

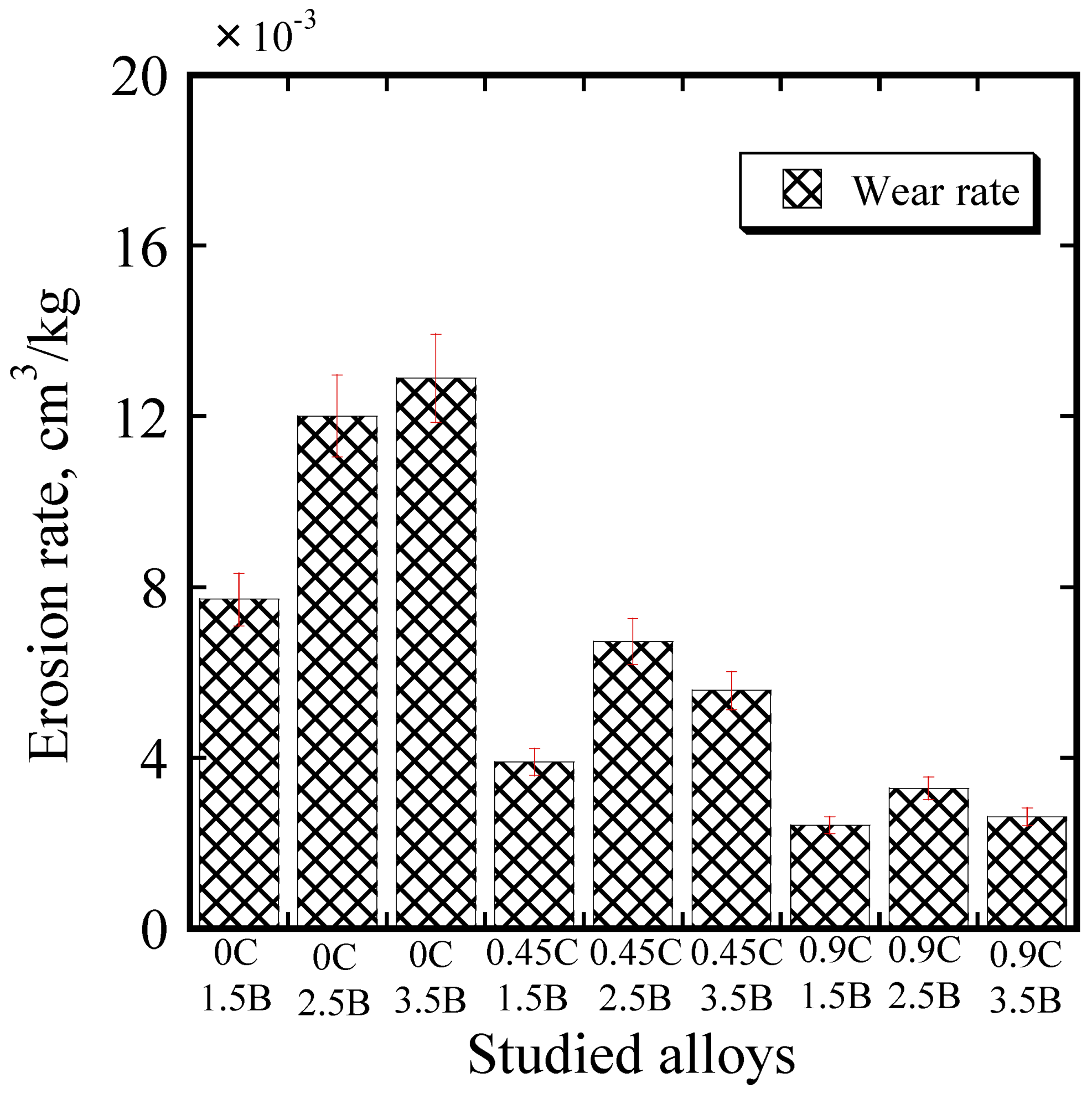

3.3. Erosive Wear Behavior of Each Cast Alloy

3.4. Erosive Wear Mechanism of Each Cast Alloy

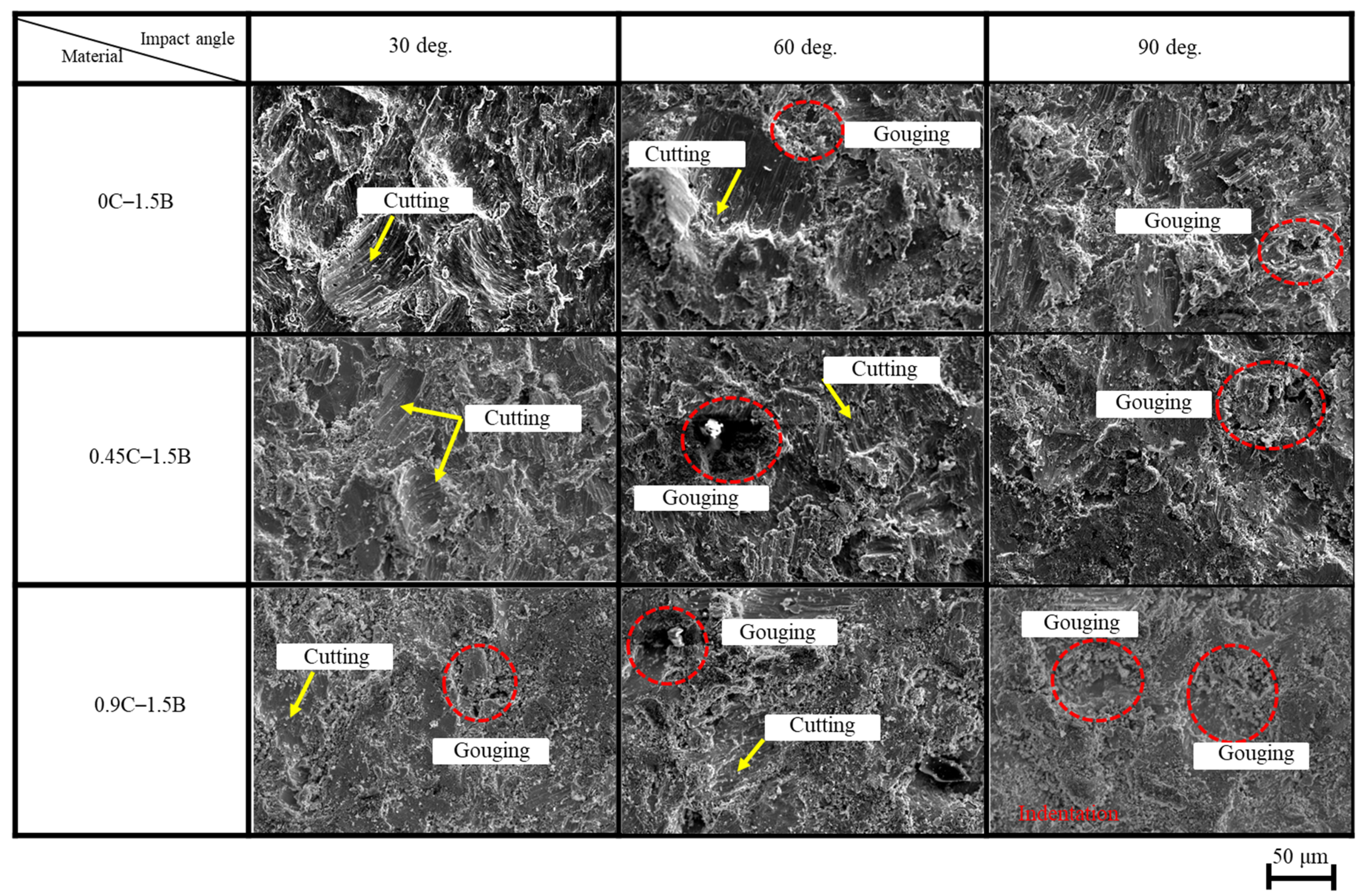

3.4.1. Worn-Surface Investigation

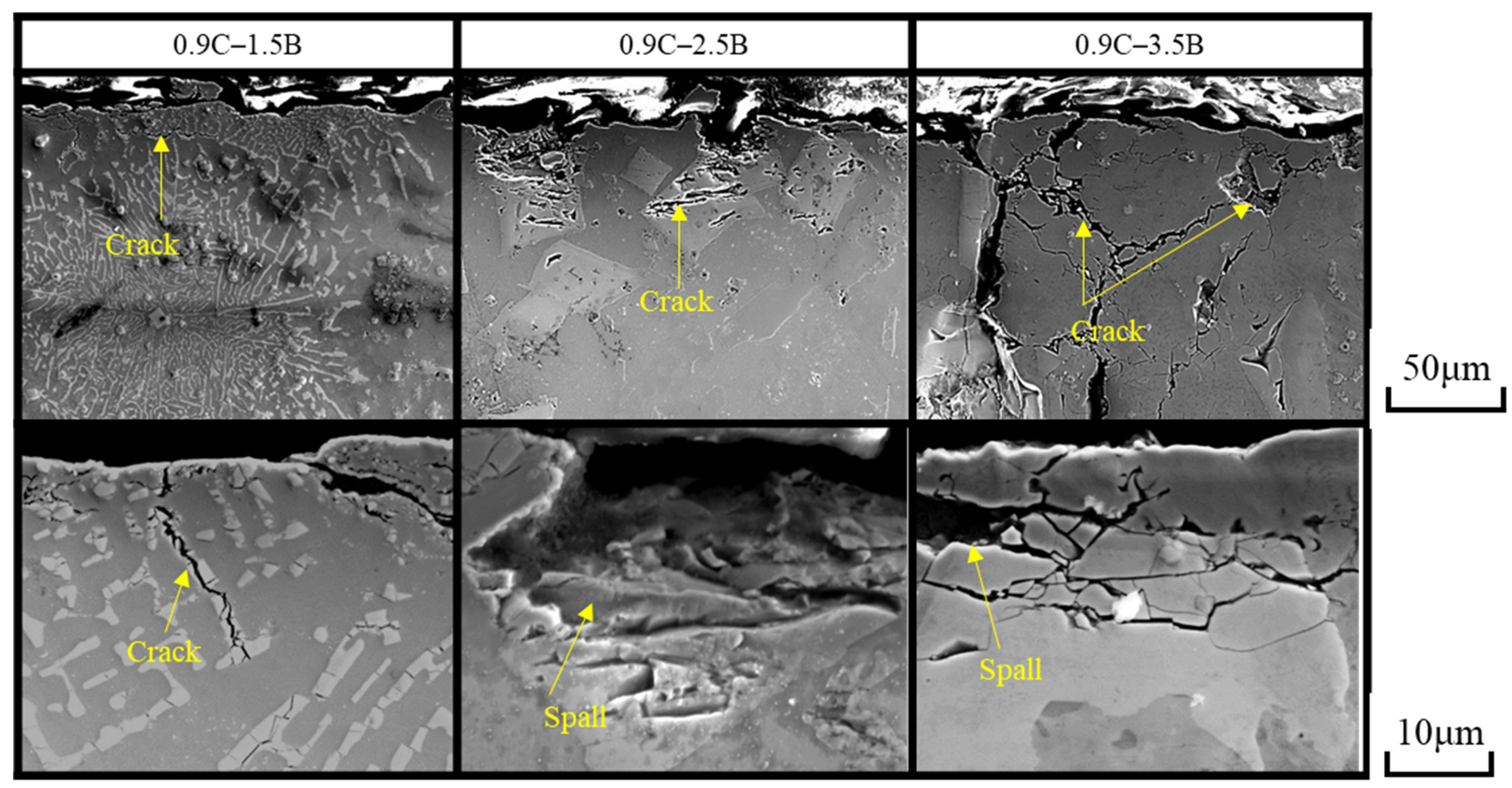

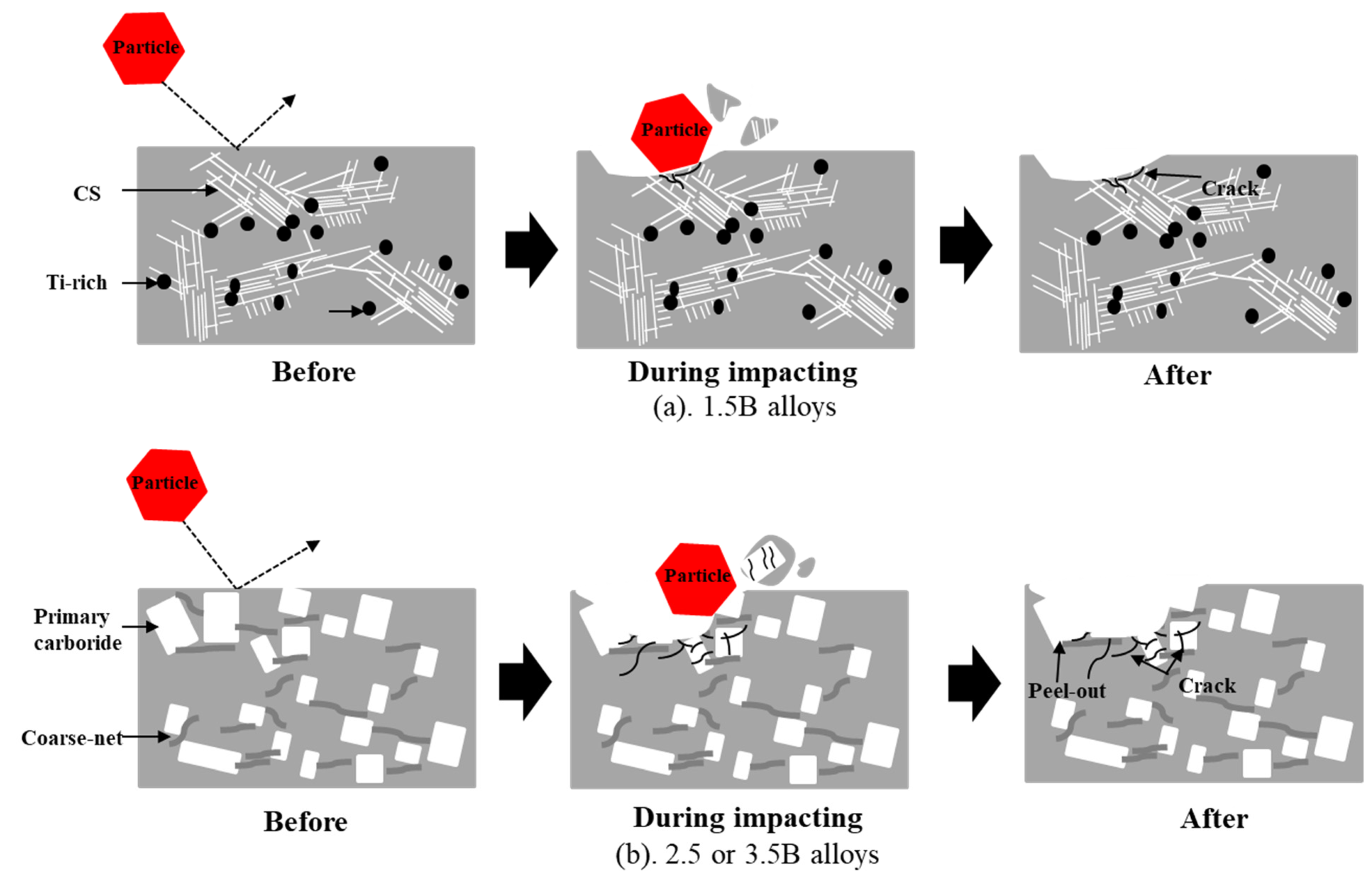

3.4.2. Cross-Section Investigation

4. Conclusions

- The hardness of the alloy was not directly dependent on the change in BVF. Instead, it was affected by the amount of C or B added. Alloys with more C or B will definitely have a higher hardness.

- Based on impact angle, the highest wear rate in 0C and 0.45C with 1.5–3.5% B occurred at an impact angle of 60° due to gouging and indentation mechanisms occurring simultaneously. However, different results occurred in the case of 0.9C with the same amount of B, where the wear rate increased with increasing impact angle due to brittleness.

- Based on the chemical composition, the wear resistance of the alloy increased with increasing C content due to higher hardness values. However, the reverse performance occurred when the addition of B exceeded the threshold (more than 1.5 wt.%) despite the higher hardness. This fact is due to the susceptibility to carbide cracking as the amount of B increases.

- Overall, the alloy with the best erosion resistance was 0.9C–1.5B because it was more resistant to cracking and had appropriate hardness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, cost and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Kosel, T.H. Solid particle erosion. In Friction, Lubrication, and Wear Technology; ASM International: Materials Park, OH, USA, 1992; Volume 18, pp. 199–213. [Google Scholar]

- Murakami, T. Reducing Wear Through Material Selection and Geometric Design with Actual Lubrication Mode. In Biotribology of Natural and Artificial Joints; Elsevier: Amsterdam, The Netherlands, 2023; pp. 1–27. [Google Scholar] [CrossRef]

- Shimizu, K.; Xinba, Y.; Ishida, M.; Kato, T. High temperature erosion characteristic of surface treated SUS410 stainless steel. Wear 2011, 271, 1349–1356. [Google Scholar] [CrossRef]

- Yaer, X.; Shimizu, K.; Qu, J.; Wen, B.; Cao, X.; Kusumoto, K. Surface deformation micromechanics of erosion damage at different angles and velocities for aero-engine hot-end components. Wear 2019, 426–427, 527–538. [Google Scholar] [CrossRef]

- Verma, P.; Tyagi, R.; Mohan, S. Effect of microstructure, impact velocity and angle on erosive wear of medium carbon, dual phase and fully martensitic steels. Wear 2023, 518, 204645. [Google Scholar] [CrossRef]

- Sapate, S.G.; Ramarao, A.V. Erosive wear behaviour of weld hardfacing high chromium cast irons: Effect of erodent particles. Tribol. Int. 2006, 39, 206–212. [Google Scholar] [CrossRef]

- Walker, A.I.; Hambe, M. Effect of particles shape on slurry wear of white iron. Wear 2015, 332–333, 1021–1027. [Google Scholar] [CrossRef]

- Babu, P.S.; Basu, B.; Sundararajan, G. The influence of erodent hardness on the erosion behavior of detonation sprayed WC-12Co coatings. Wear 2011, 270, 903–913. [Google Scholar] [CrossRef]

- Ahmed, D.A.; Yerramalli, C.S. Experimental and computational analysis of the erosion behaviour of unidirectional glass fiber epoxy composites. Wear 2020, 462–463, 203525. [Google Scholar] [CrossRef]

- Divakar, M.; Agarwal, V.K.; Singh, S.N. Effect of material surface hardness on the erosion of AISI316. Wear 2005, 259, 110–117. [Google Scholar] [CrossRef]

- Bergami, L.B.; Lima, A.O.; Venturelli, B.N.; Machado, I.F.; Albertin, E.; Souza, R.M. Effect of carbide orientation during single scratch test in directionally solidified and heat-treated high chromium cast irons. Wear 2023, 523, 204823. [Google Scholar] [CrossRef]

- Shimizu, K.; Purba, R.H.; Kusumoto, K.; Year, X.; Ito, J.; Kasuga, H.; Gaqi, Y. Microstructural evaluation and high-temperature erosion characteristic of high chromium cast irons. Wear 2019, 426–427, 420–427. [Google Scholar] [CrossRef]

- Matsubara, Y.; Sasaguri, N.; Shimizu, K.; Yu, S.K. Solidification and abrasion wear of white cast irons alloyed with 20% carbide forming elements. Wear 2001, 250, 502–510. [Google Scholar] [CrossRef]

- Kusumoto, K.; Shimizu, K.; Yaer, X.; Hara, H.; Tamura, K.; Kawai, H. High erosion-oxidation performance of Fe-based Nb or V containing multicomponent alloys with Co addition at 1173 K. Mater. Des. 2015, 88, 366–374. [Google Scholar] [CrossRef]

- Zang, Y.; Shimizu, K.; Kusumoto, K.; Tamura, K.; Hara, H.; Ito, J. Effect of Co addition on high temperature erosive wear characteristics of Fe-C-Cr-Mo-W-V multi-component white cast iron. Mater. Trans. 2017, 58, 927–931. [Google Scholar] [CrossRef]

- Purba, R.H.; Shimizu, K.; Kusumoto, K.; Gaqi, Y.; Huq, M.J. A study of the three-body abrasive wear resistance of 5V/5Nb-5Cr-5Mo-5W-5Co-Fe multicomponent cast alloys with different carbon percentages. Materials 2023, 16, 3102. [Google Scholar] [CrossRef]

- Yang, H.; Wang, X.; Jin-bo, Q.U. Effect of boron on CGHAZ microstructure and toughness of high strength low alloy steels. J. Iron Steel Res. Int. 2014, 28, 787–792. [Google Scholar] [CrossRef]

- Hwang, B.; Suh, D.; Kim, S. Austenitizing temperature and hardenability of low-carbon boron steels. Scr. Mater. 2011, 64, 1118–1120. [Google Scholar] [CrossRef]

- Baker, I. Alloy phase diagrams. In ASM Handbook; ASM International: Materials Park, OH, USA, 1992; Volume 3, p. 281. [Google Scholar]

- Kulka, M.; Makuch, N.; Piasecki, A. Nanomechanical characterization and fracture toughness of FeB and Fe2B iron borides produced by gas boriding of armco iron. Surf. Coat Technol. 2017, 325, 515–532. [Google Scholar] [CrossRef]

- Lakeland, K.D.; Graham, E.; Heron, A. Mechanical Properties and Microstructures of a Series of Fe-C-B Alloys; The University of Queensland: Brisbane, Australia, 1992. [Google Scholar]

- Li, Y.X.; Liu, Z.L.; Chen, X. Development of boron white cast iron. Int. J. Cast Met. Res. 2008, 21, 67–70. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Chen, X.; Hu, K. Microstructure and mechanical properties of high boron white cast iron. Mater. Sci. Eng. A 2008, 486, 112–116. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Li, Y.; Hu, K. Effect of chromium on microstructure and properties of high boron white cast iron. Metall. Mater. Trans. A 2008, 39, 636–641. [Google Scholar] [CrossRef]

- Ren, X.; Tang, S.; Fu, H.; Xing, J. Effect of titanium modification on microstructure and impact toughness of high-boron multi-component alloy. Metals 2021, 11, 193. [Google Scholar] [CrossRef]

- Liu, Y.; Li, B.H.; Li, J. Effect of titanium on the ductilization of Fe–B alloys with high boron content. Mater. Lett. 2010, 64, 1299–1301. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Chabak, Y.G.; Shimizu, K.; Golinskyi, M.A.; Lekatou, A.G.; Petryshynets, I.; Efremenko, B.V.; Halfa, H.; Kusumoto, K.; Zurnadzhy, V.I. The novel hybrid concept on designing advanced multi-component cast irons: Effect of boron and titanium (Thermodynamic modelling, microstructure and mechanical property evaluation). Mater. Charact. 2023, 197, 112691. [Google Scholar] [CrossRef]

- Chabak, Y.G.; Shimizu, K.; Efremenko, V.G.; Golinskyi, M.A.; Kusumoto, K.; Zurnadzhy, V.I.; Efremenko, A.V. Microstructure and phase elemental distribution in high-boron multi-component cast irons. Int. J. Miner. Metall. Mater. 2022, 29, 78–87. [Google Scholar] [CrossRef]

- Chabak, Y.; Petryshynets, I.; Efremenko, V.; Golinskyi, M.; Shimizu, K.; Zurnadzhy, V.; Sili, I.; Halfa, H.; Efremenko, B.; Puchy, V. Investigations of Abrasive Wear Behaviour of Hybrid High-Boron Multi-Component Alloys: Effect of Boron and Carbon Contents by the Factorial Design Method. Materials 2023, 16, 2530. [Google Scholar] [CrossRef]

- Purba, R.H.; Shimizu, K.; Kusumoto, K.; Todaka, T.; Shirai, M.; Hara, H.; Ito, J. Erosive wear characteristics of high-chromium based multi-component white cast irons. Tribol. Int. 2021, 159, 106982. [Google Scholar] [CrossRef]

- Georgatis, E.; Lekatou, A.; Karantzalis, A.E.; Petropoulos, H.; Katsamakis, S.; Poulia, A. Development of a cast Al–Mg2Si–Si in situ composite: Microstructure, heattreatment, and mechanical properties. J. Mater. Eng. Perform. 2013, 22, 729–741. [Google Scholar] [CrossRef]

- Kim, B.J.; Jung, S.S.; Hwang, J.H.; Park, Y.H.; Lee, Y.C. Effect of eutectic Mg2Si phase modification on the mechanical properties of Al–8Zn–6Si–4Mg–2Cu cast alloy. Metals 2019, 9, 32. [Google Scholar] [CrossRef]

- Purba, R.H.; Shimizu, K.; Kusumoto, K.; Gaqi, Y.; Todaka, T. Effect of boron addition on three-body abrasive wear characteristics of high chromium based multi-component white cast iron. Mater. Chem. Phys. 2022, 275, 125232. [Google Scholar] [CrossRef]

- Robert, J.K. Wood. In ASM Handbook: Friction, Lubrication, and Wear Technology; ASM International: Materials Park, OH, USA, 2017; Volume 18, pp. 266–289. [Google Scholar]

| Sample Name | C | B | Cr | V | Mo | W | Ti | Fe |

|---|---|---|---|---|---|---|---|---|

| 0C–1.5B | 0.08 | 1.51 | 9.80 | 5.21 | 4.80 | 5.01 | 2.45 | Bal. |

| 0C–2.5B | 0.07 | 2.43 | 10.10 | 5.14 | 5.02 | 4.95 | 2.37 | Bal. |

| 0C–3.5B | 0.10 | 3.56 | 10.36 | 5.07 | 4.93 | 4.86 | 2.59 | Bal. |

| 0.45C–1.5B | 0.44 | 1.47 | 10.04 | 5.04 | 4.78 | 4.79 | 2.54 | Bal. |

| 0.45C–2.5B | 0.44 | 2.38 | 10.12 | 5.01 | 5.21 | 5.01 | 2.43 | Bal. |

| 0.45C–3.5B | 0.45 | 3.35 | 10.09 | 5.31 | 5.13 | 5.01 | 2.52 | Bal. |

| 0.9C–1.5B | 0.85 | 1.56 | 9.87 | 5.04 | 5.02 | 5.03 | 2.67 | Bal. |

| 0.9C–2.5B | 0.81 | 2.51 | 9.59 | 5.10 | 5.21 | 5.05 | 2.50 | Bal. |

| 0.9C–3.5B | 0.93 | 3.33 | 10.12 | 5.05 | 5.07 | 4.85 | 2.51 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Purba, R.H.; Kusumoto, K.; Shimizu, K.; Efremenko, V. Erosive Wear Behavior of Novel Hybrid Multicomponent Cast Alloys with Different C and B Contents. Lubricants 2023, 11, 243. https://doi.org/10.3390/lubricants11060243

Purba RH, Kusumoto K, Shimizu K, Efremenko V. Erosive Wear Behavior of Novel Hybrid Multicomponent Cast Alloys with Different C and B Contents. Lubricants. 2023; 11(6):243. https://doi.org/10.3390/lubricants11060243

Chicago/Turabian StylePurba, Riki Hendra, Kenta Kusumoto, Kazumichi Shimizu, and Vasily Efremenko. 2023. "Erosive Wear Behavior of Novel Hybrid Multicomponent Cast Alloys with Different C and B Contents" Lubricants 11, no. 6: 243. https://doi.org/10.3390/lubricants11060243

APA StylePurba, R. H., Kusumoto, K., Shimizu, K., & Efremenko, V. (2023). Erosive Wear Behavior of Novel Hybrid Multicomponent Cast Alloys with Different C and B Contents. Lubricants, 11(6), 243. https://doi.org/10.3390/lubricants11060243