On the Wear Behaviour of Bush Drive Chains: Part II—Performance Screening of Pin Materials and Lubricant Effects

Abstract

1. Introduction

- Comparative friction and wear characterization of two chromium-based bush chain pin coatings, namely, CrN and a new Cr-based multilayer coating.

- Characterization of lubricant-related effects, such as oil variation and specific influence of carbon black and fuel dilution, on friction and wear phenomena in a pin/bush-plate model contact.

2. Experimental Method and Materials

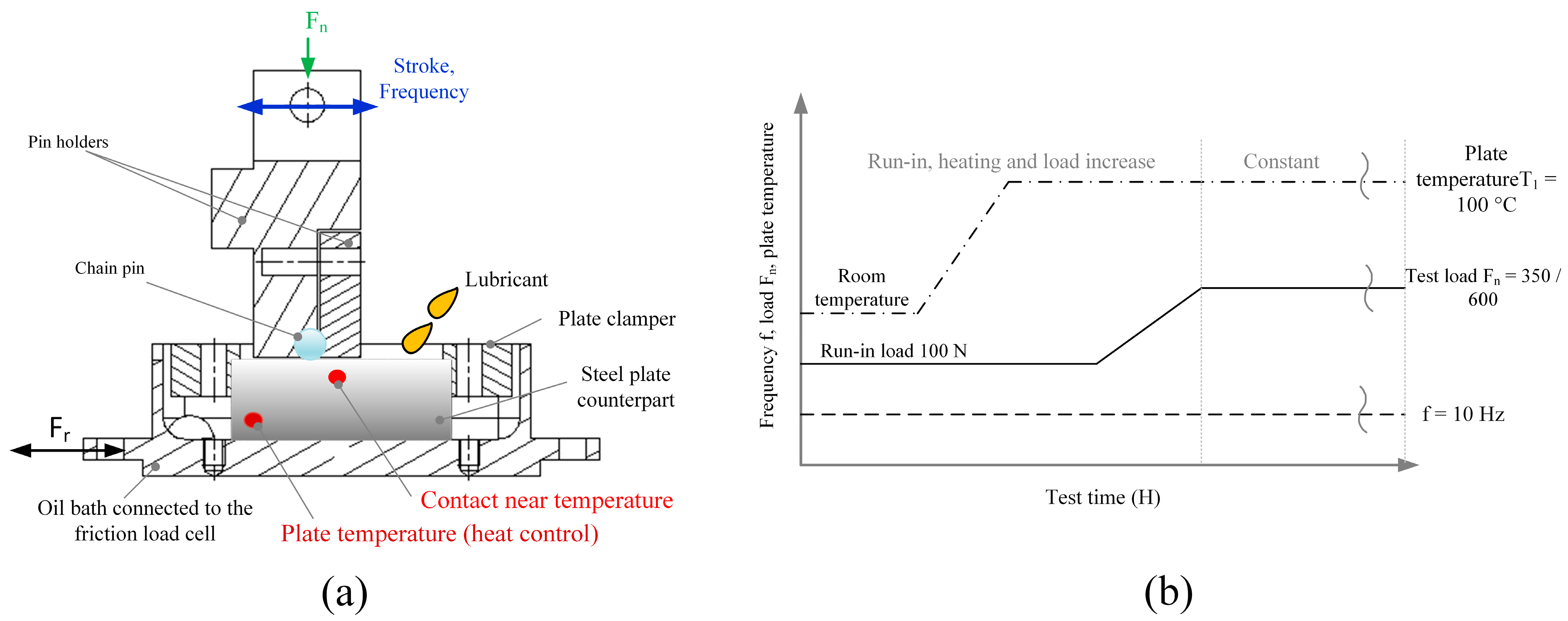

2.1. Test Method and Test Strategy

2.2. Lubricants

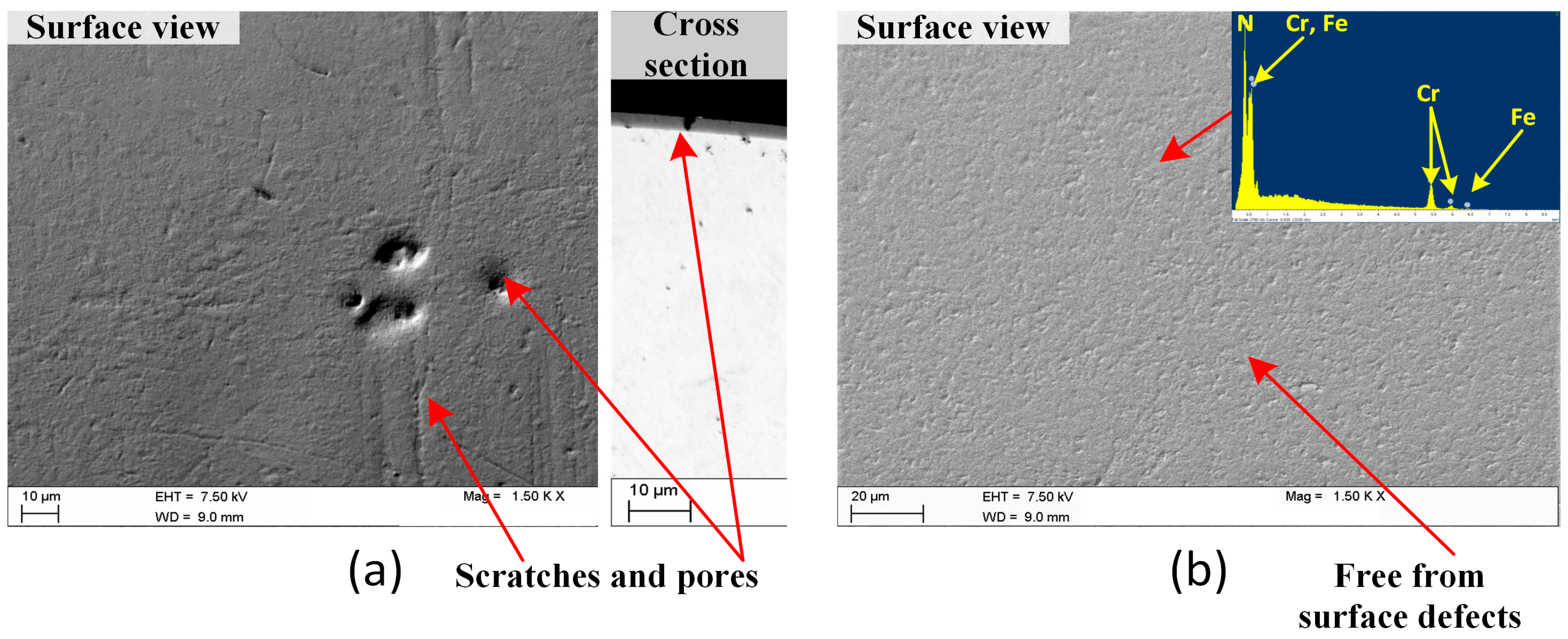

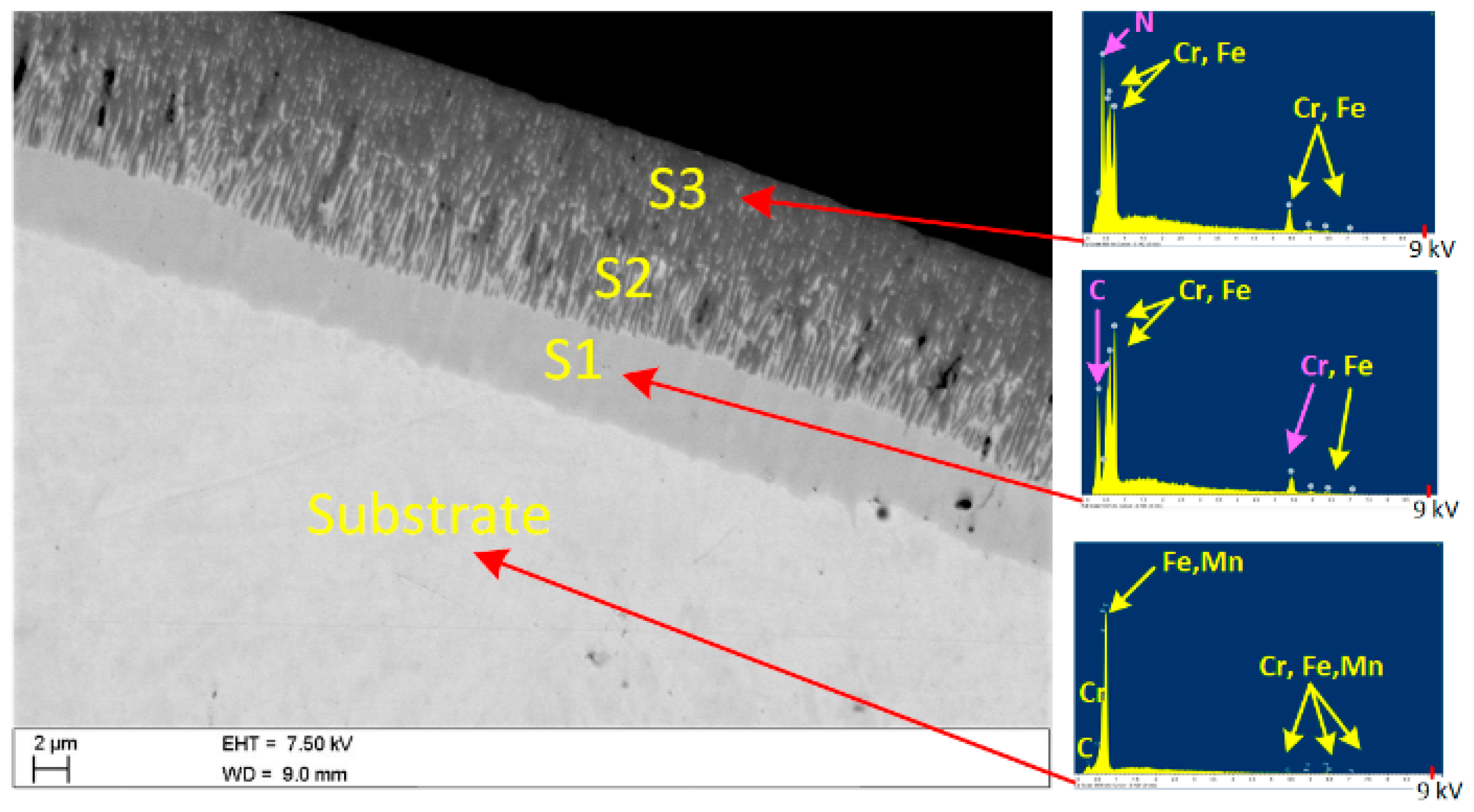

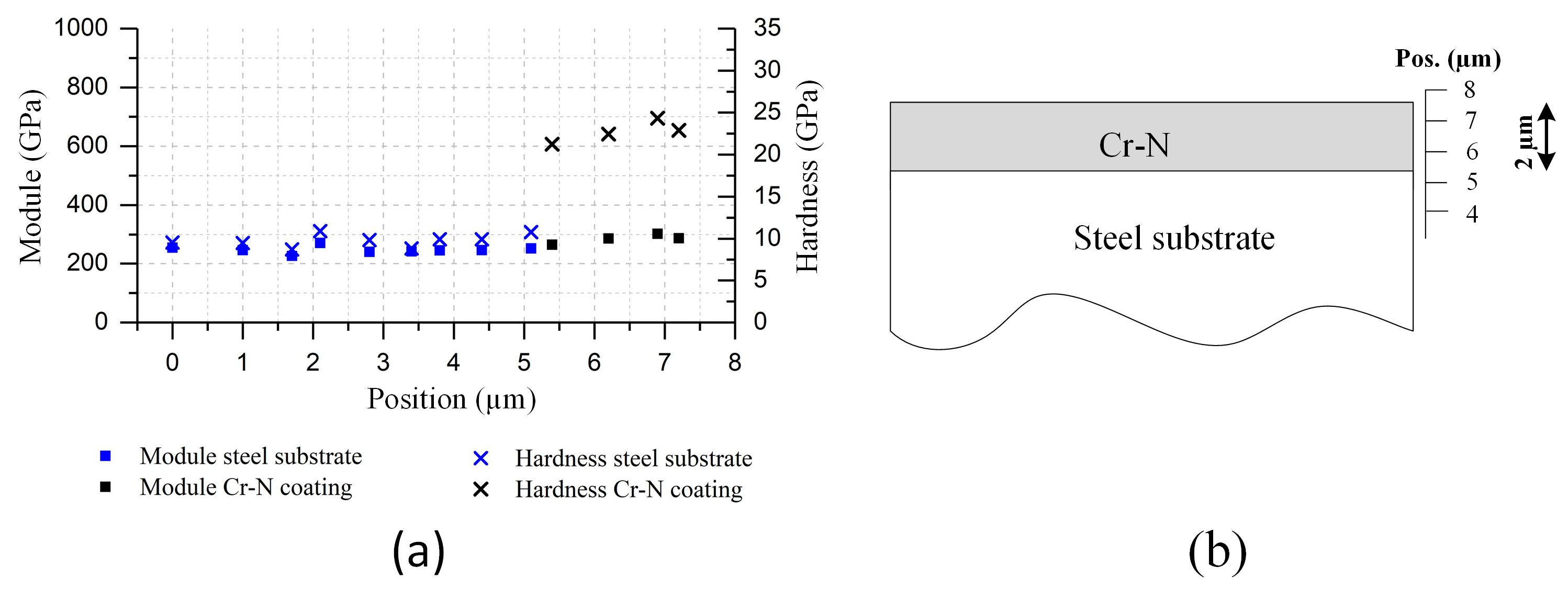

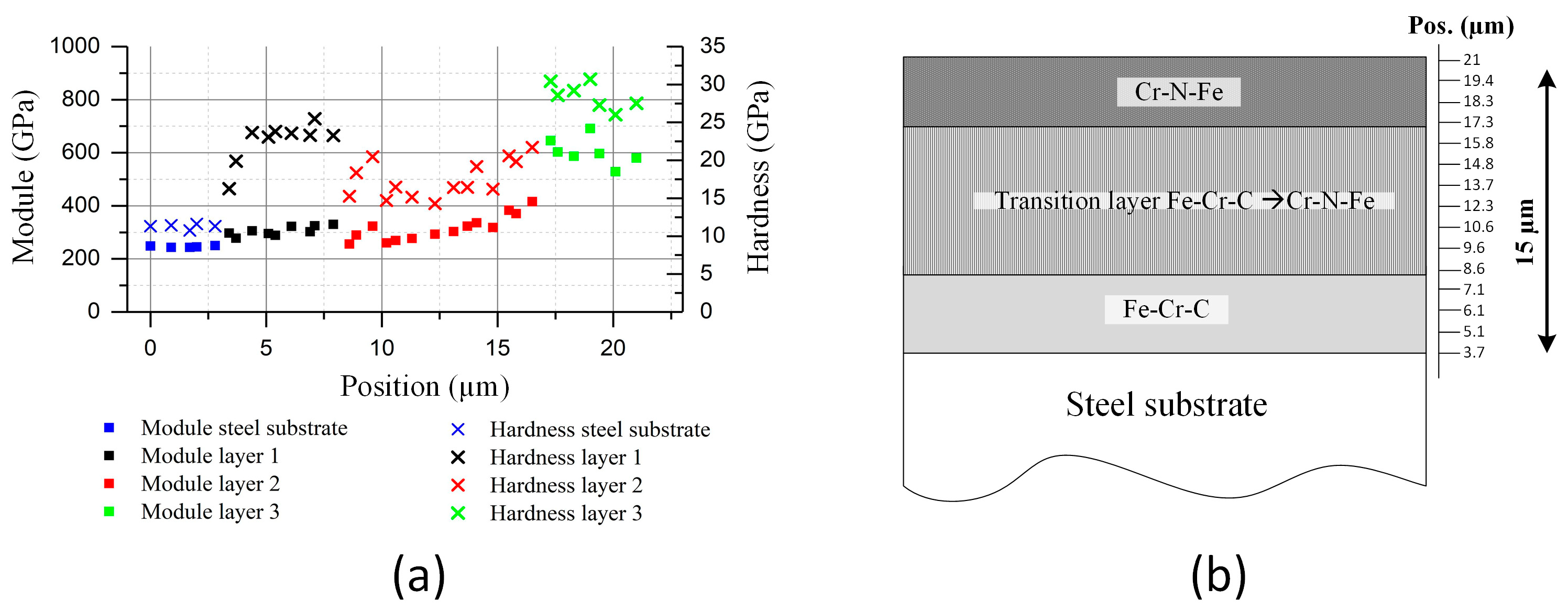

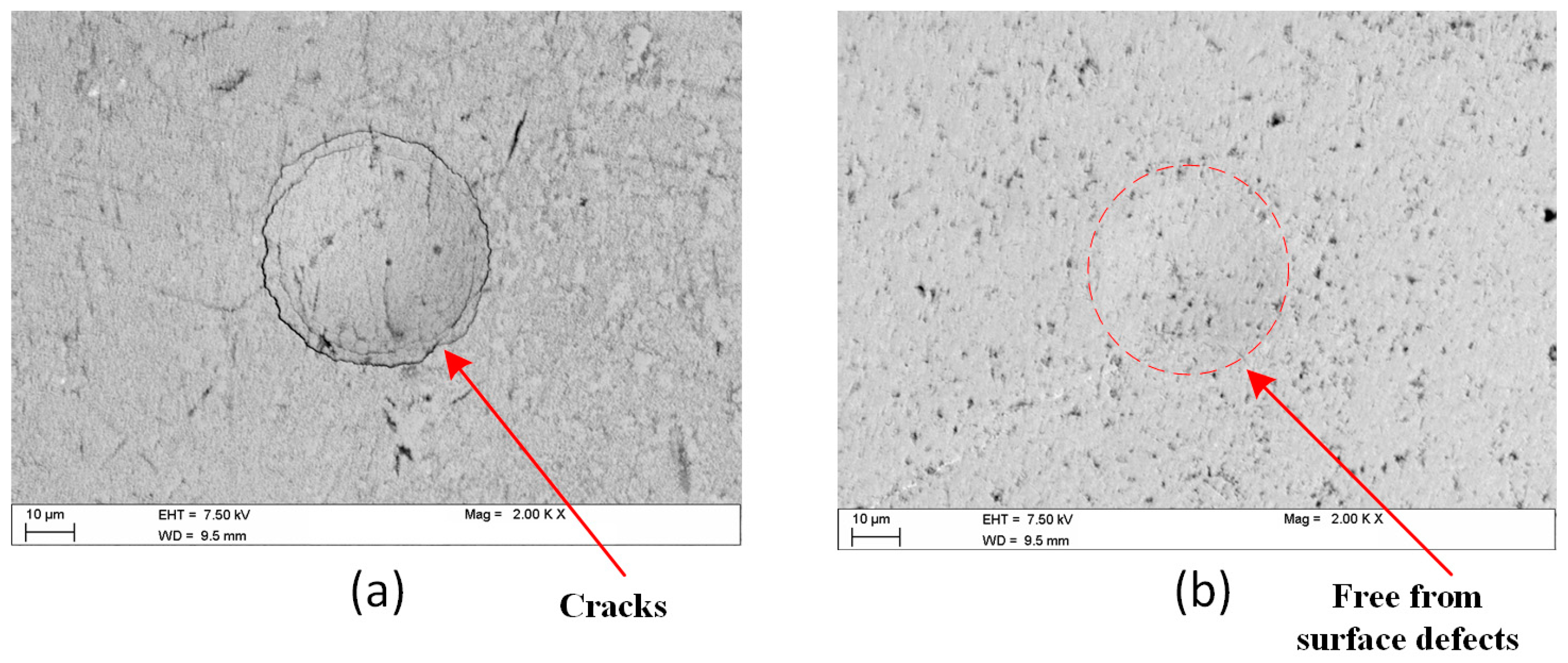

2.3. Pin Materials and Counterparts

3. Experimental Results

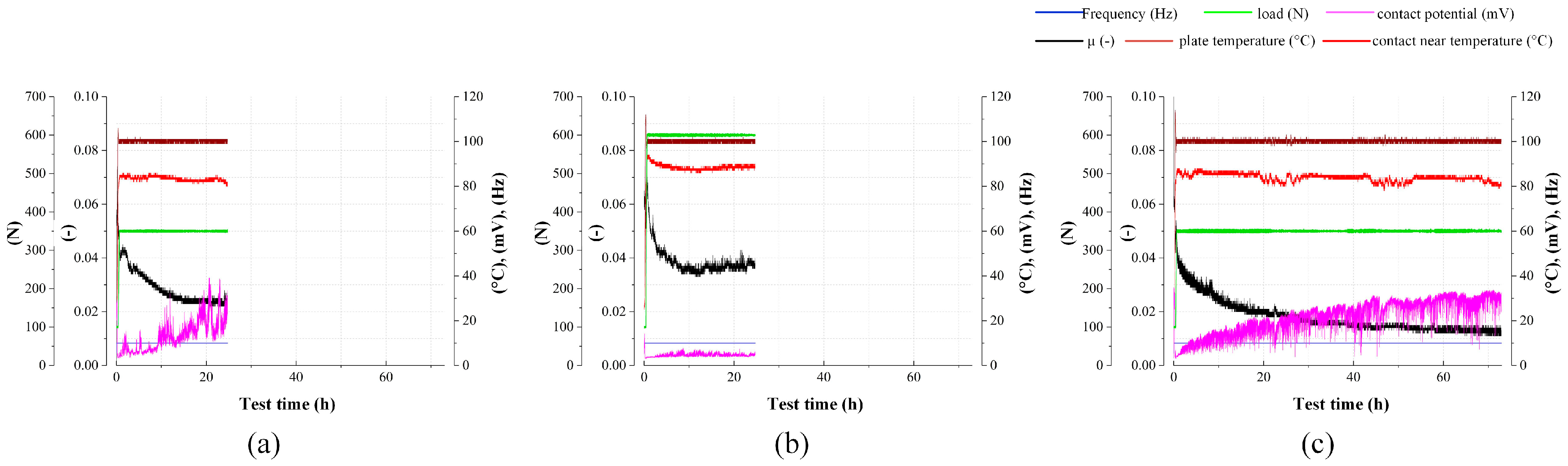

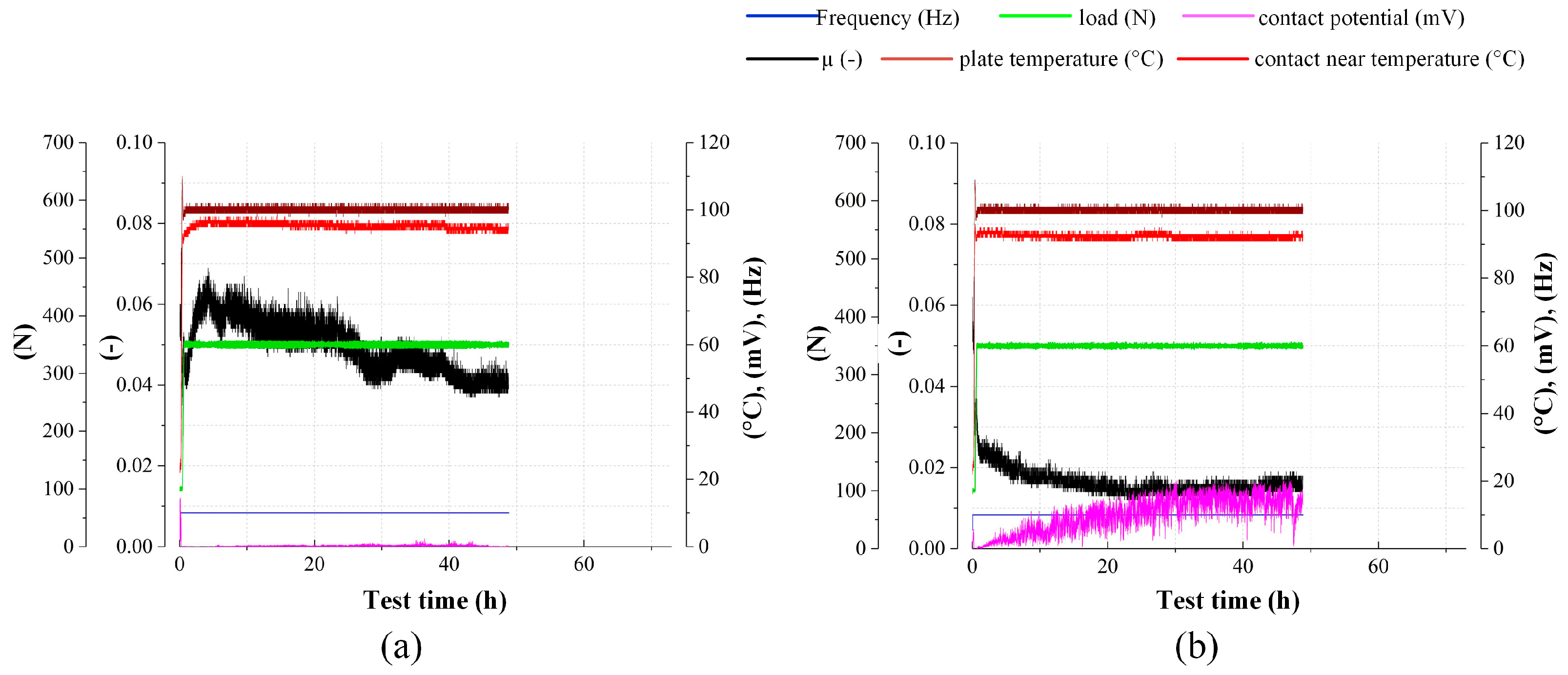

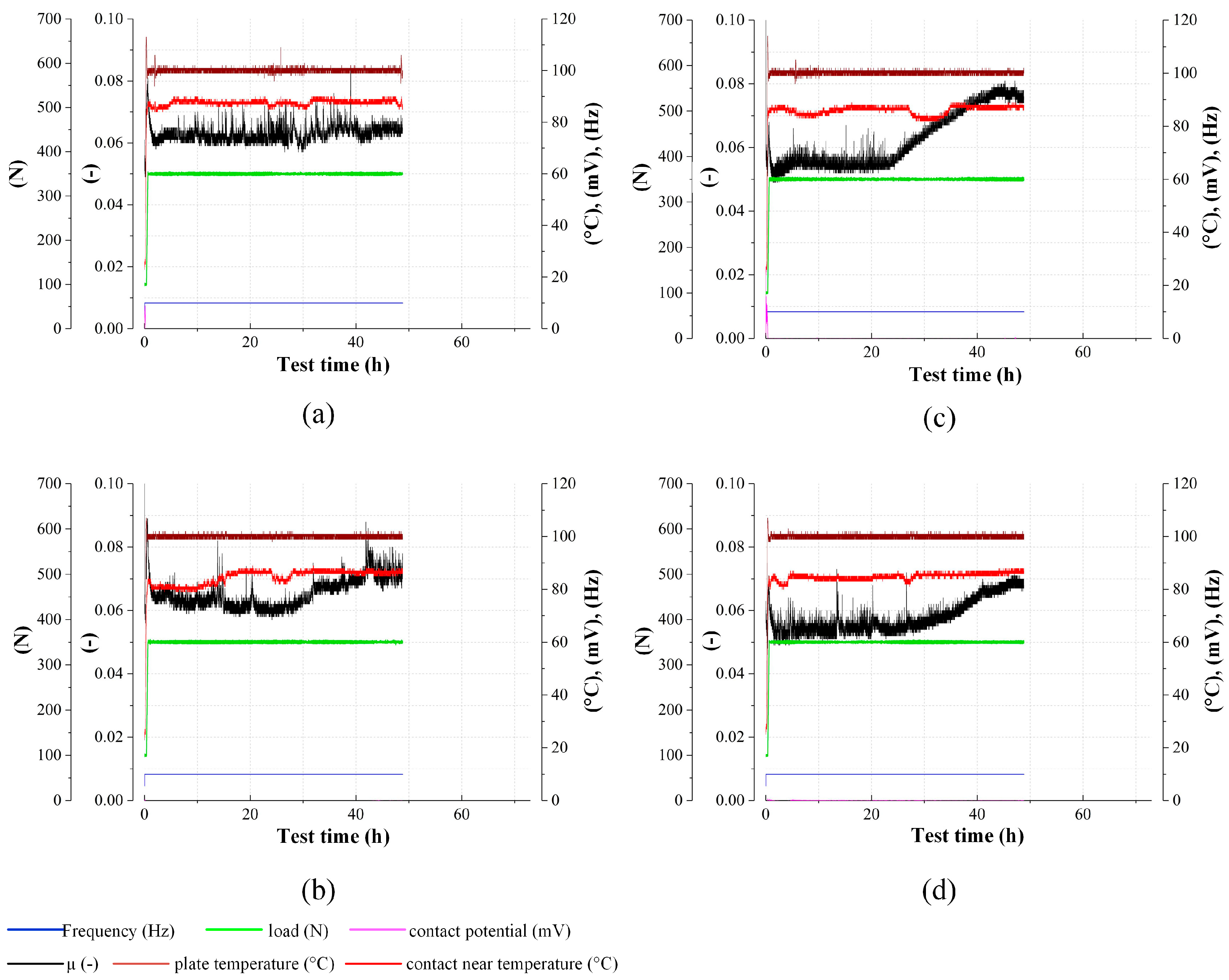

3.1. Comparison of Pin Material Performance for Used Engine Oil EO1

3.2. Comparison of Pin Material Performance for Used Engine Oil EO2

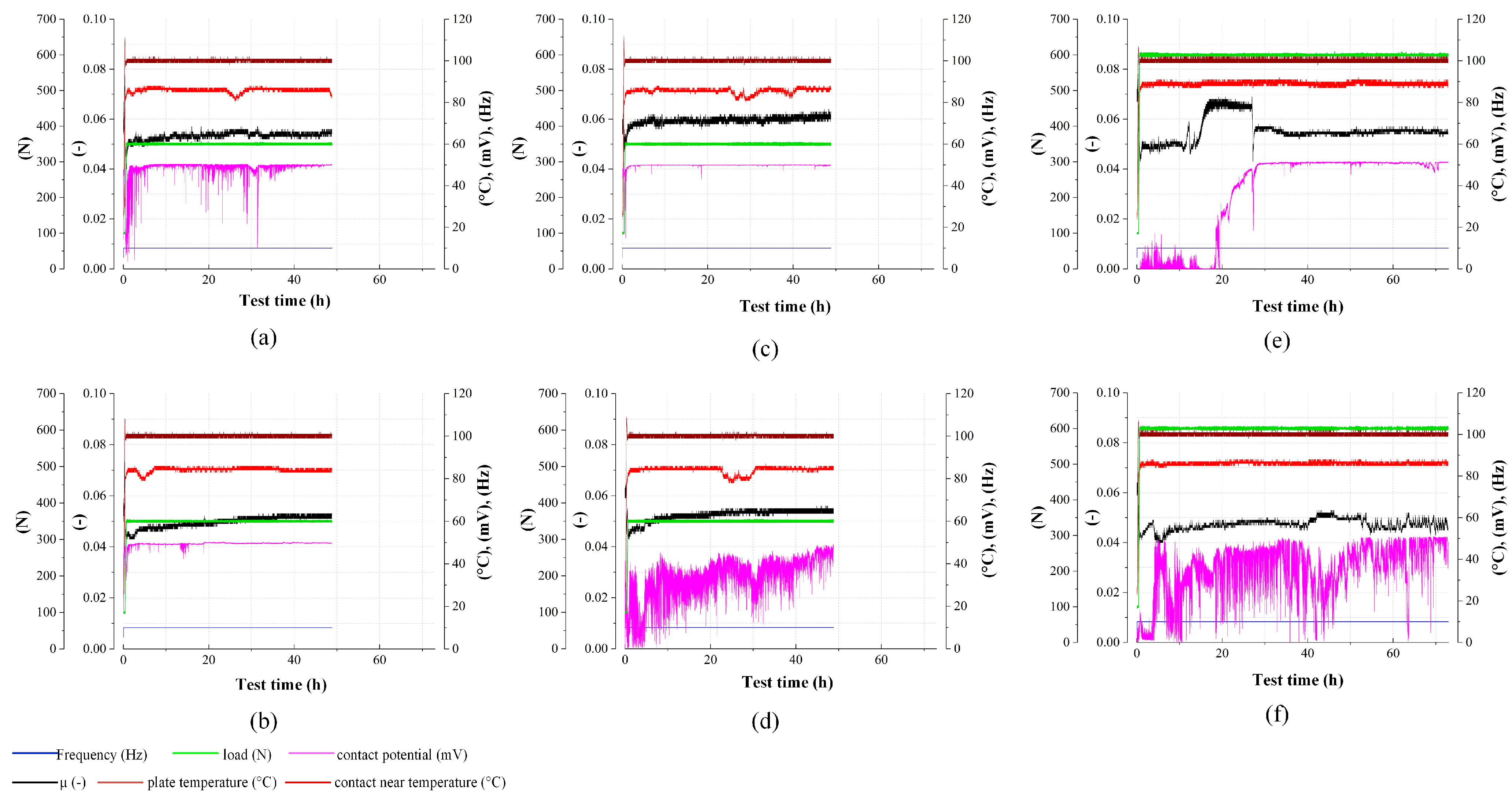

3.3. Performance Assessment for Artificial Lubricants without Soot (AO1 and AO3)

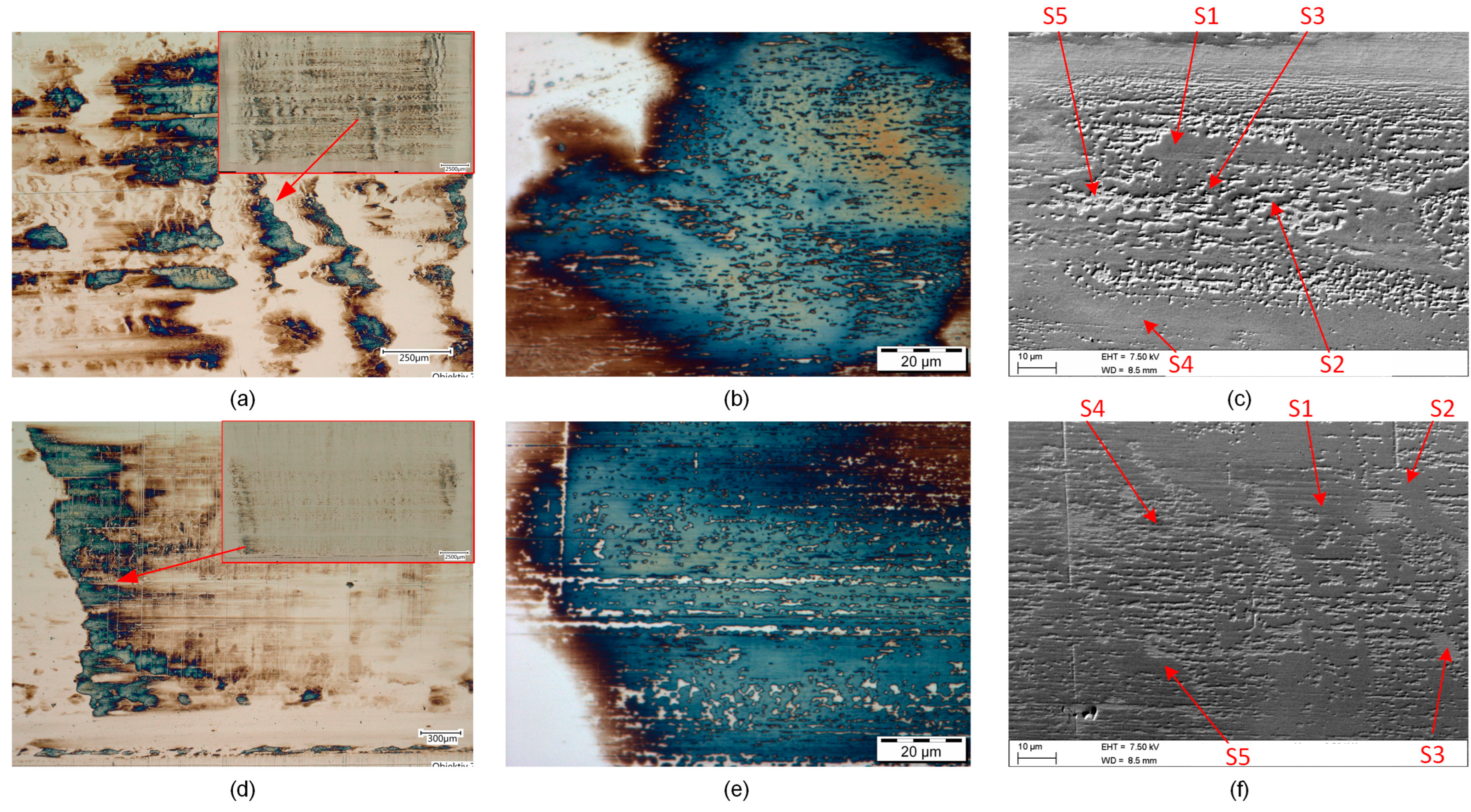

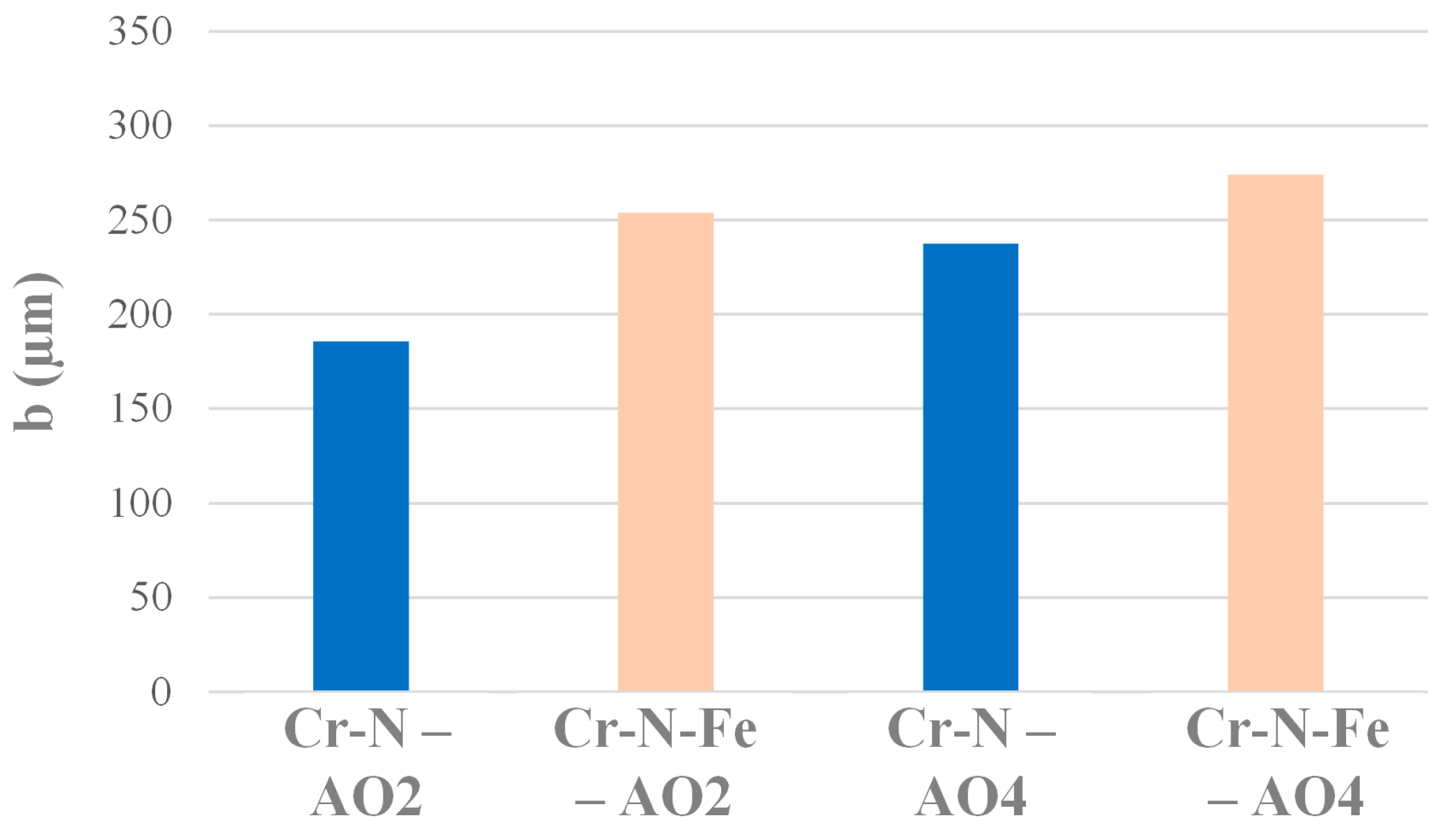

3.4. Performance Assessment for Artificial Lubricants with Soot (AO2 and AO4)

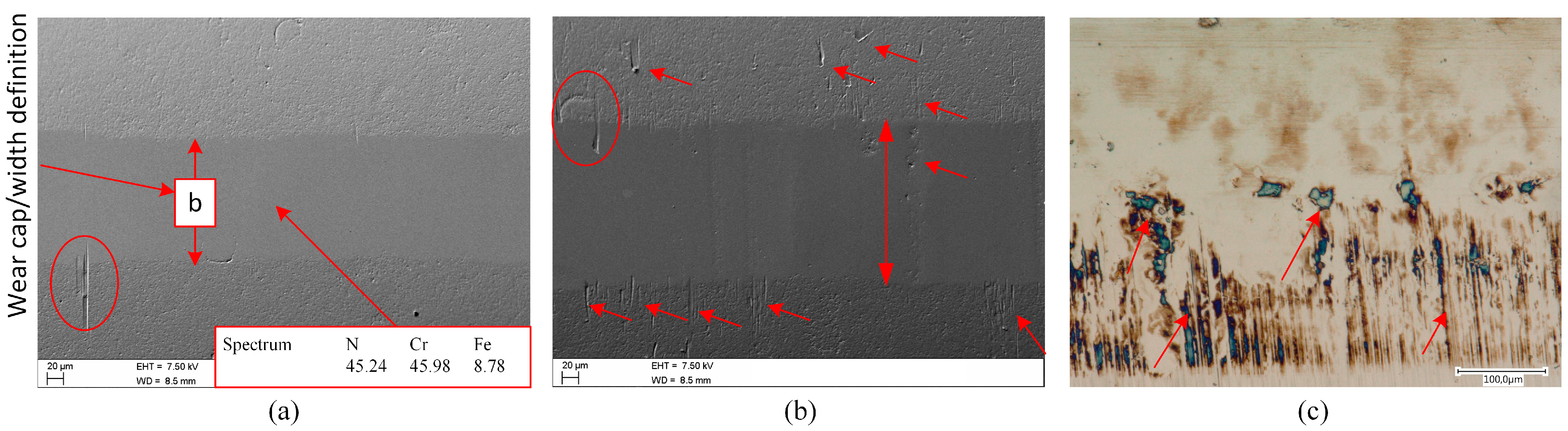

4. Discussion

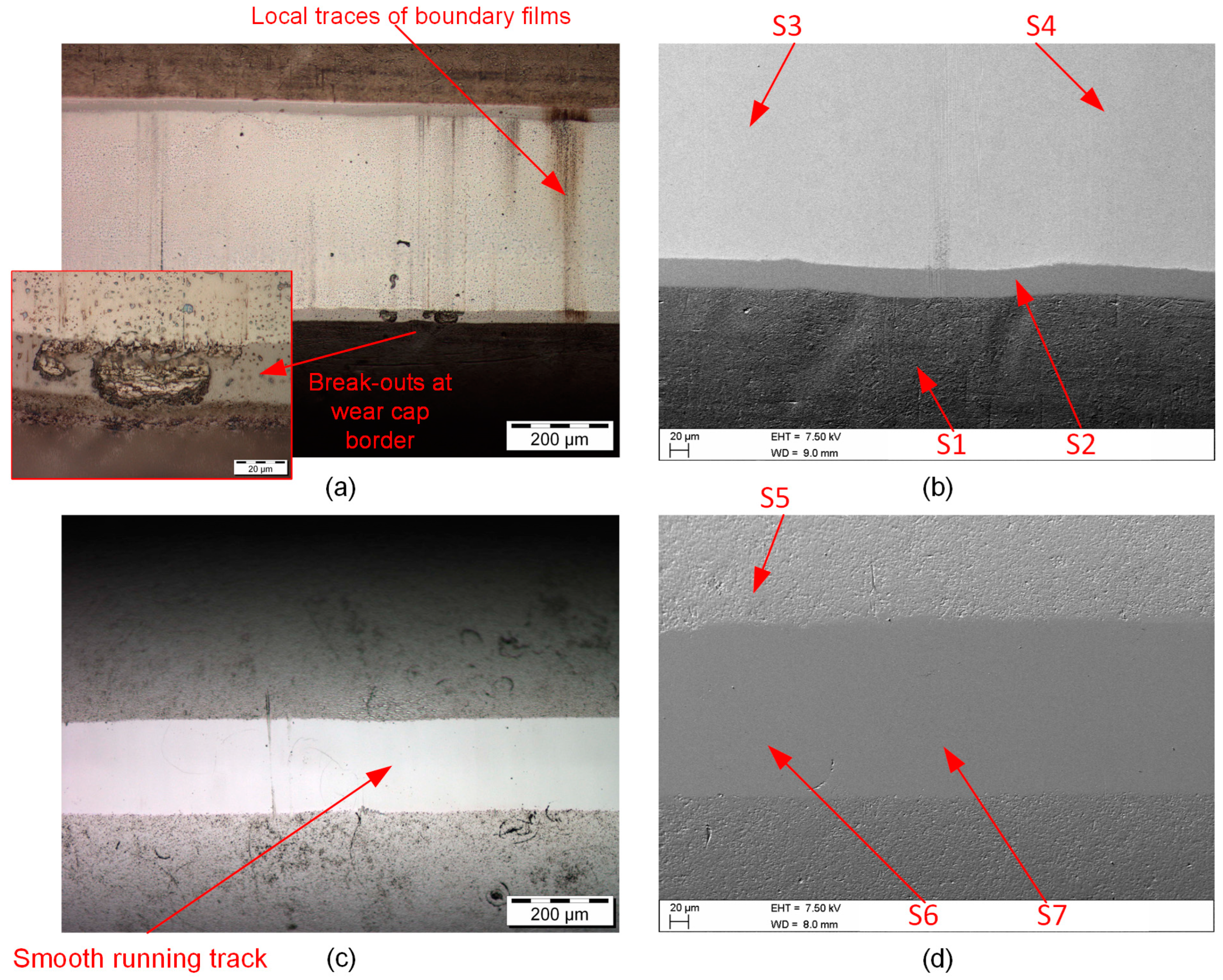

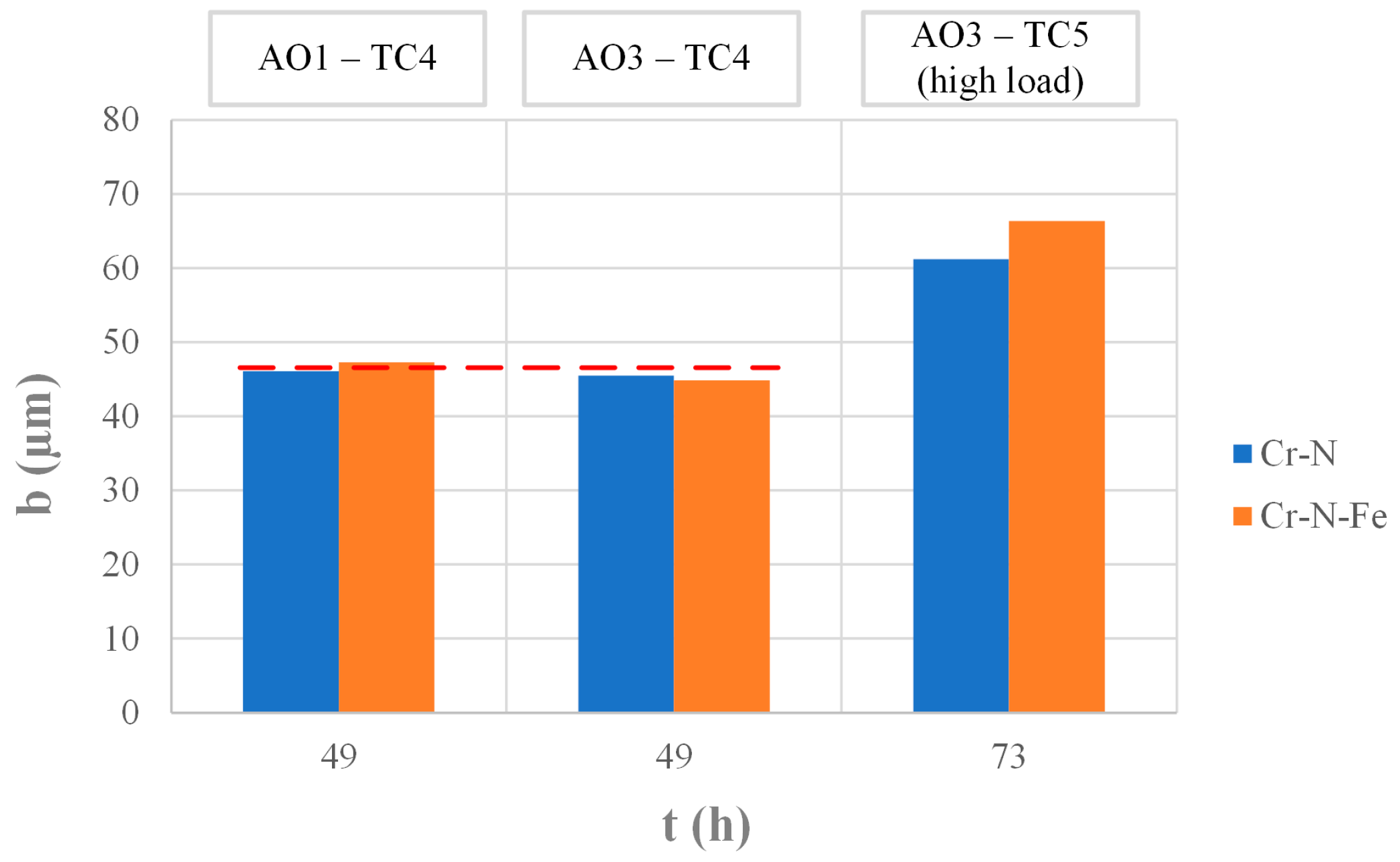

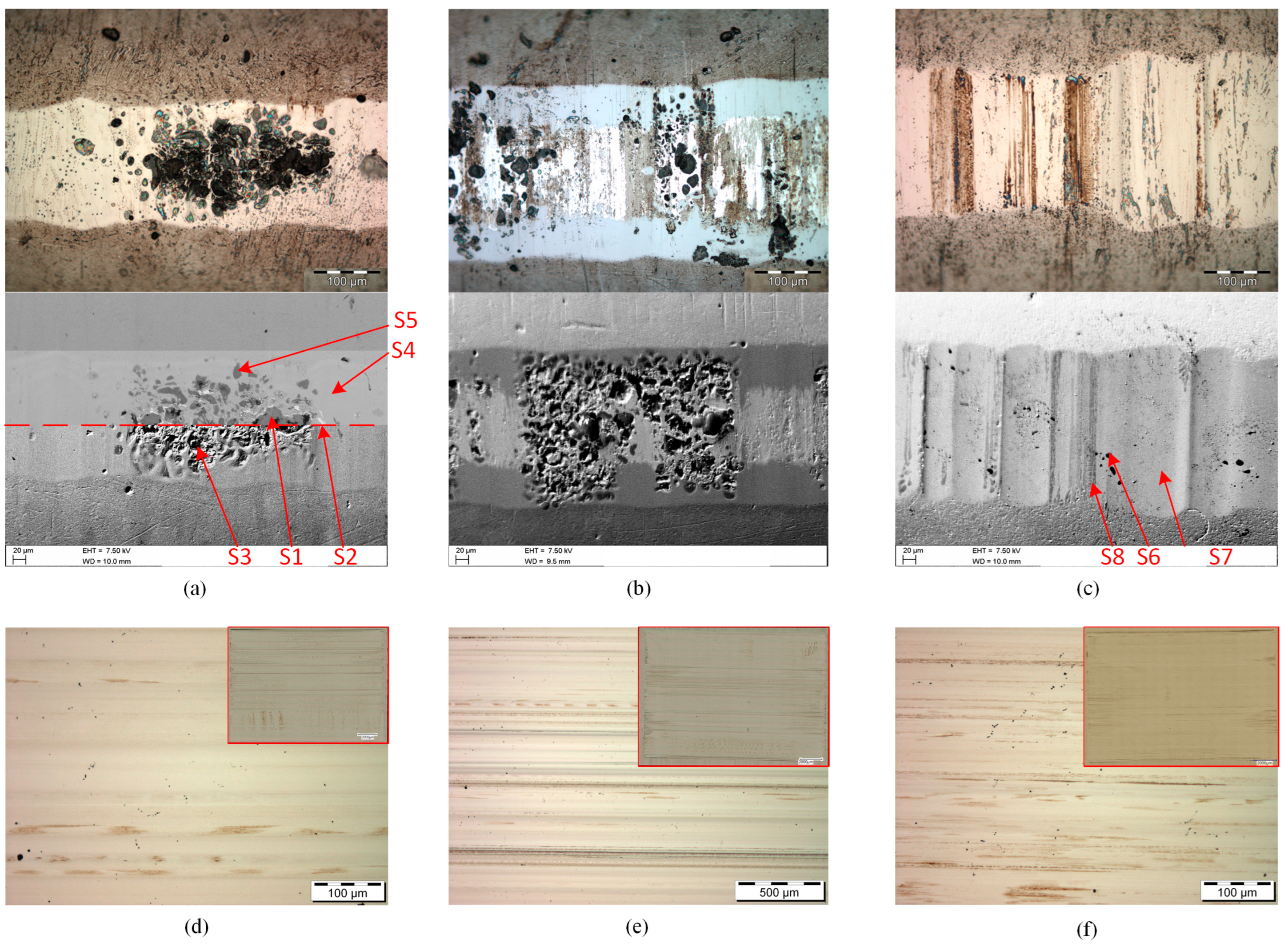

4.1. Oils without Engine Soot or Carbon Black

4.2. Oils from Engine Test Run

4.3. Oils with Carbon Black Added

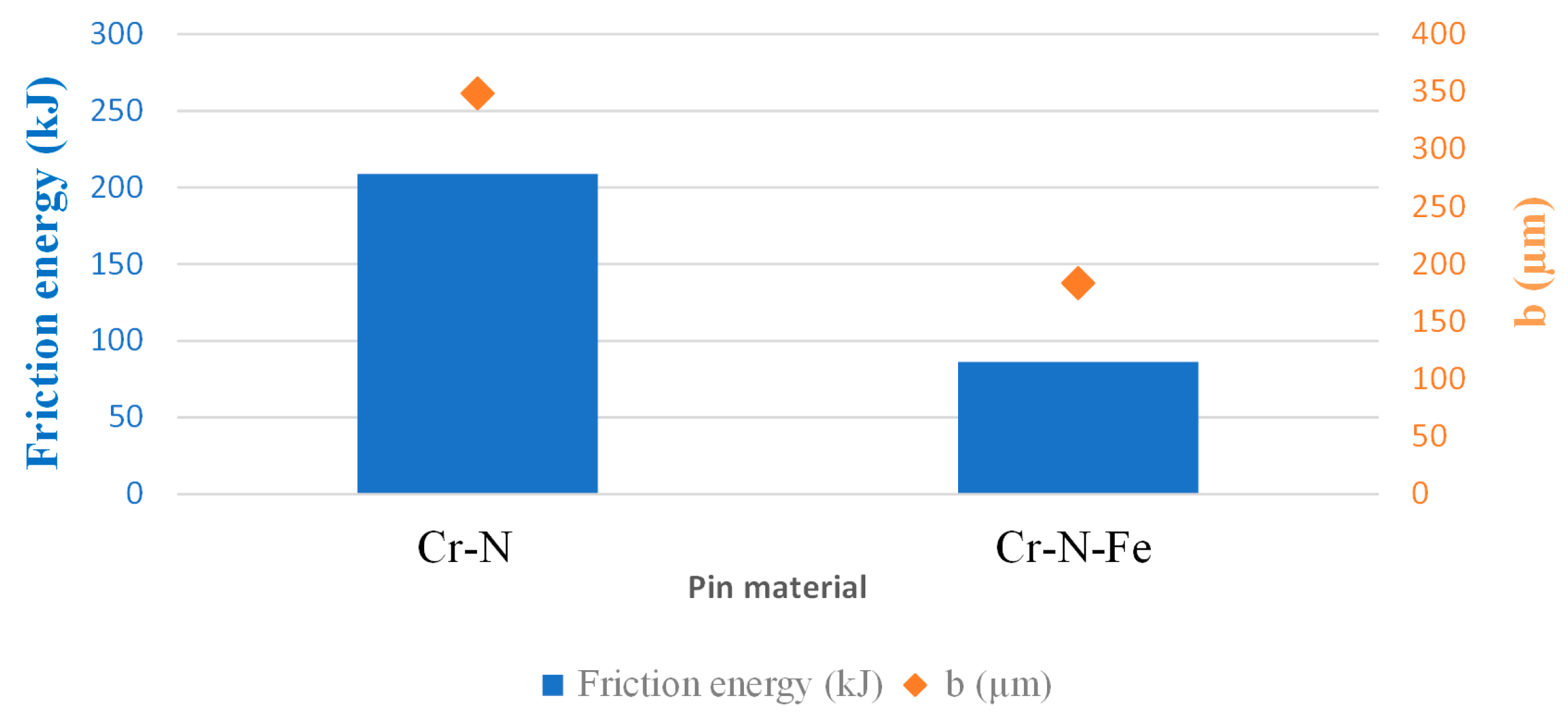

4.4. Pin Material Variation

5. Conclusions

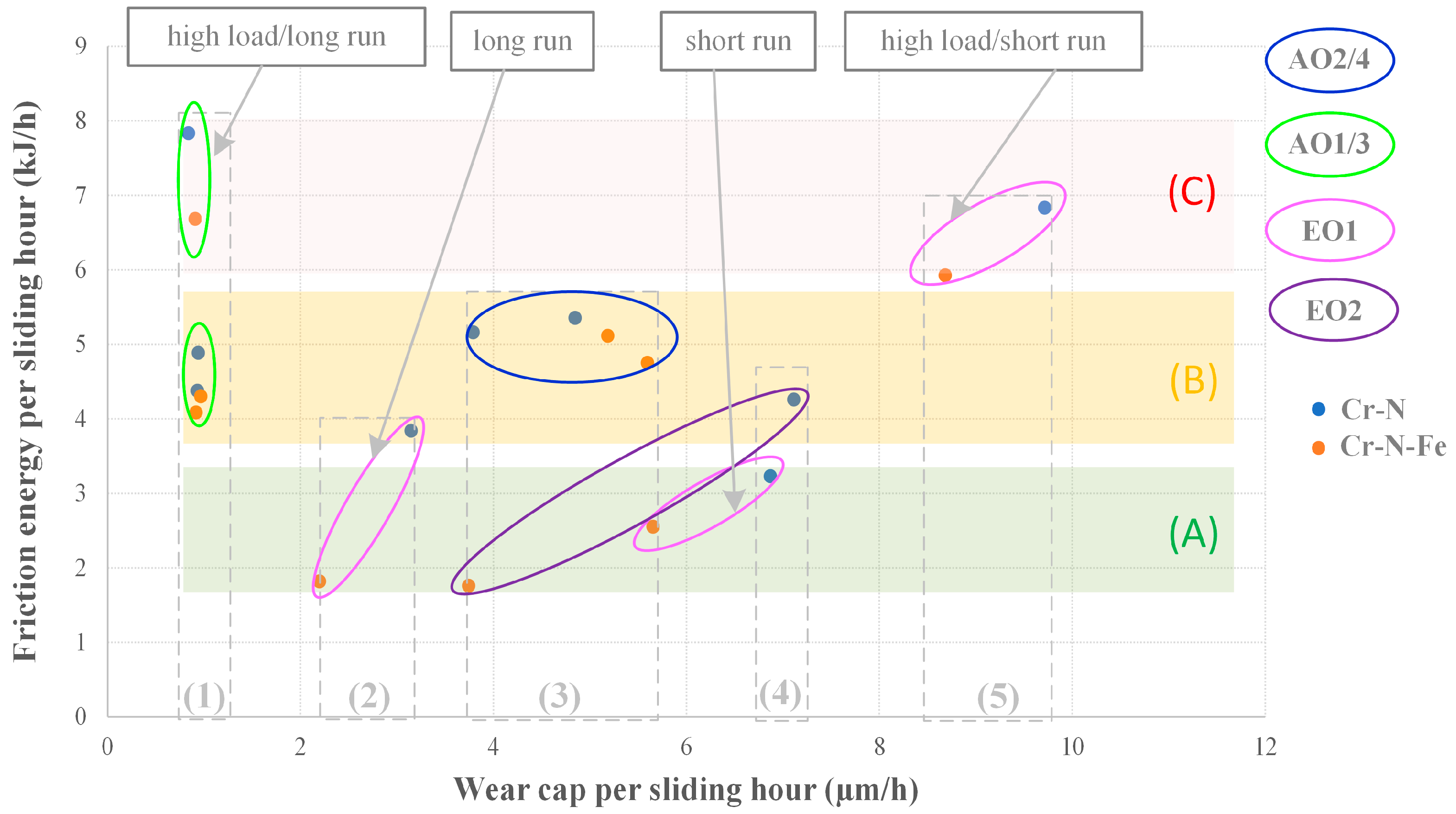

- The used test methodology was well suited to investigate and rank the different tribological systems (pin materials, lubricant, etc.). In this regard, the same oil performance ranking was achieved compared to an engine test run in terms of wear assessment when comparing two oils EO1 (acceptable chain elongation) and EO2 (high/non-acceptable chain elongation).

- The results show that engine soot and carbon black both have a wear-promoting effect for all tested tribological systems in this study. With an increased amount of the soot surrogate carbon black from 2 wt% to 4.5 wt%, the wear increases accordingly. For oils from an engine test run, a friction reducing effect could be observed, but not for oils with added carbon black.

- The addition of diesel fuel alone to the fresh oil with 10 wt.% did not change the friction and wear effects of either of the various tribological systems tested.

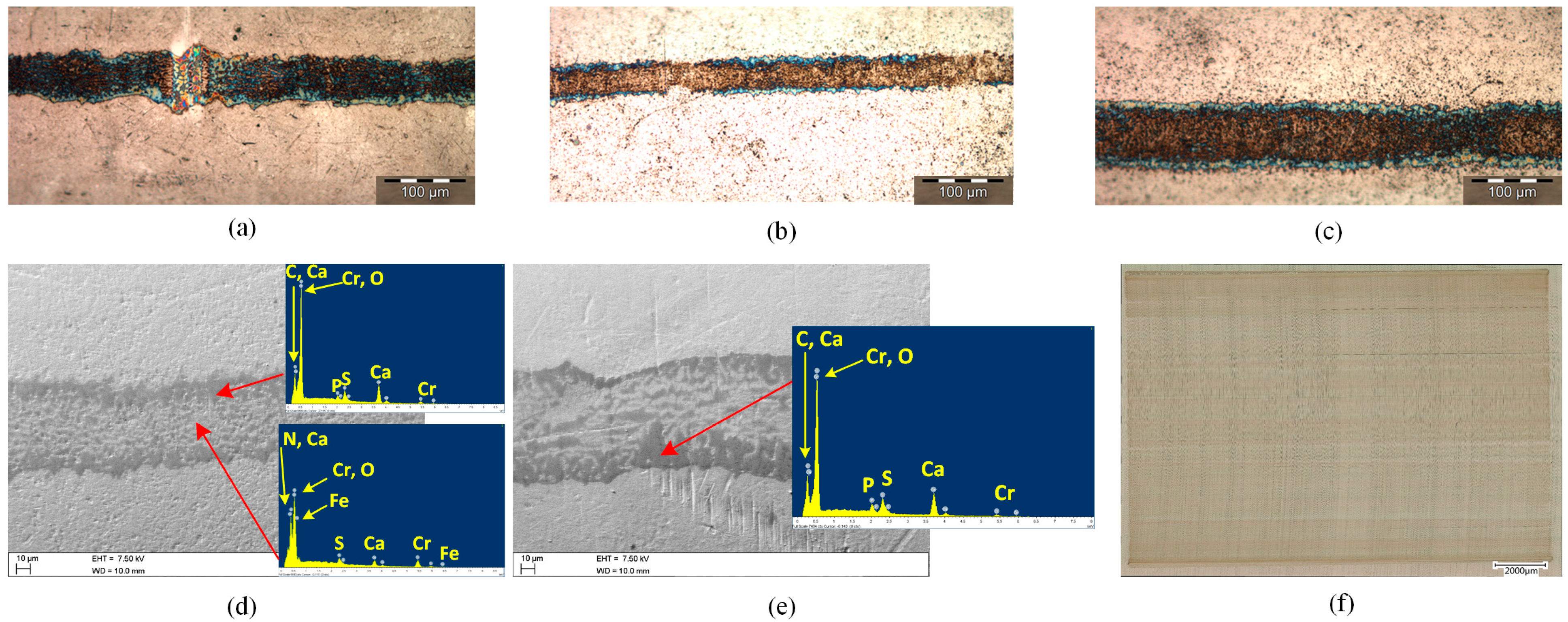

- In the case of using fresh oils, an additive layer formation with phosphorous structures and sulphur structures on the chrome-based pin surfaces formed. Under the presence of engine soot or carbon black, these layers did not form on the Cr-based coatings, which was likely to be the reason of the wear increase. In addition, the surfaces were finely polished. This leads to the assumption of a corrosive–abrasive mechanism. In contrast to tests with engine oils, artificial oils with carbon black showed signs of carbon-based agglomerations on the pin materials, and, in particular, these were pronounced for the CrN coating, which created higher friction. These differences between oils from engine test runs and carbon-black-added oils were attributed to the different structures and surface chemistry between engine soot and carbon black, which was reported in [60].

- In regard to the pin materials investigated, the alternative multilayer solution with a Cr-N-Fe top layer showed mostly significantly lower, but never worse, friction losses than the Cr-N reference coating under all test conditions and lubricant variants.

- In regard to wear of the different pin materials, no significant differences were observed in the absence of soot or carbon black in the lubricant. For the oils from engine test runs, the Cr-N-Fe coating showed higher wear resistance under all test conditions compared to Cr-N, which is most likely due to the higher hardness and modulus of the Cr-N-Fe coating. In the case of the artificial oils with carbon black, the trend was the opposite in regard to the wear of the pin materials. This is hypnotized due to an accumulation and growth effect in the area of breakouts of the Cr-N layer of tribofilm and carbon deposits, which could have a wear-reducing effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Summer, F.; Bergmann, P.; Grün, F. On the Wear Behavior of Bush Drive Chains: Part I—Characterization of Engine Damage Processes and Development of a Model Test Setup for Pin Wear. Lubricants 2023, 11, 85. [Google Scholar] [CrossRef]

- Fink, T.; Hirschmann, V. Kettentriebe für den Einsatz in modernen Verbrennungsmotoren. MTZ-Mot. Z. 2001, 62, 796–806. [Google Scholar] [CrossRef]

- Burgess, S.; Lodge, C. Optimisation of the chain drive system on sports motorcycles. Sport. Eng. 2004, 7, 65–73. [Google Scholar] [CrossRef]

- Sundar, M.; Kumaran, S.T.; Kurniawan, R.; Ahmed, F. Investigating the corrosion behaviour of conveyor chain pin and link. Mater. Today Proc. 2021, 50, 855–860. [Google Scholar] [CrossRef]

- Belmer, S.; Fink, T.; Lorenz, I.; Neukirchner, H. Steuertriebefür Verbrennungsmotoren. MTZ-Mot. Z. 2005, 66, 466–475. [Google Scholar] [CrossRef]

- Tung, S.C.; McMillan, M.L. Automotive tribology overview of current advances and challenges for the future. Tribol. Int. 2004, 37, 517–536. [Google Scholar] [CrossRef]

- Sappok, D.; Sauer, B. Wear Measurement on Chain Joint Components Using a Roundness Instrument. Period. Polytech. Mech. Eng. 2015, 59, 51–59. [Google Scholar] [CrossRef]

- Fink, T.; Bodenstein, H. Möglichkeiten der Reibungsreduktion in Kettentrieben. MTZ-Mot. Z. 2011, 72, 582–587. [Google Scholar] [CrossRef]

- Enomoto, Y.; Yamamoto, T. New materials in automotive tribology. Tribol. Lett. 1998, 5, 13–24. [Google Scholar] [CrossRef]

- Wan, S.; Li, D.; Zhang, G.; Tieu, A.K.; Zhang, B. Comparison of the scuffing behaviour and wear resistance of candidate engineered coatings for automotive piston rings. Tribol. Int. 2017, 106, 10–22. [Google Scholar] [CrossRef]

- Laxane, R.B.; Bhide, R.S.; Patil, A.S.; Sane, S.G. Characterisation of chromium nitride physical vapour deposition coating on diesel engine pistons. Surf. Eng. 2006, 22, 78–80. [Google Scholar] [CrossRef]

- Ferreira, R.; Carvalho, Ó.; Sobral, L.; Carvalho, S.; Silva, F. Influence of morphology and microstructure on the tribological behavior of arc deposited CrN coatings for the automotive industry. Surf. Coat. Technol. 2020, 397, 126047. [Google Scholar] [CrossRef]

- Bozyazı, E.; Ürgen, M.; Çakır, A.F. Comparison of reciprocating wear behaviour of electrolytic hard chrome and arc-PVD CrN coatings. Wear 2004, 256, 832–839. [Google Scholar] [CrossRef]

- Vera, E.; Vite, M.; Lewis, R.; Gallardo, E.; Laguna-Camacho, J. A study of the wear performance of TiN, CrN and WC/C coatings on different steel substrates. Wear 2011, 271, 2116–2124. [Google Scholar] [CrossRef]

- Tung, S.C.; Gao, H. Tribological characteristics and surface interaction between piston ring coatings and a blend of energy-conserving oils and ethanol fuels. Wear 2003, 255, 1276–1285. [Google Scholar] [CrossRef]

- Petrogalli, C.; Montesano, L.; Gelfi, M.; La Vecchia, G.; Solazzi, L. Tribological and corrosion behavior of CrN coatings: Roles of substrate and deposition defects. Surf. Coat. Technol. 2014, 258, 878–885. [Google Scholar] [CrossRef]

- Lorenzo-Martin, C.; Ajayi, O.; Erdemir, A.; Fenske, G.; Wei, R. Effect of microstructure and thickness on the friction and wear behavior of CrN coatings. Wear 2013, 302, 963–971. [Google Scholar] [CrossRef]

- Shan, L.; Zhang, Y.-R.; Wang, Y.-X.; Li, J.-L.; Jiang, X.; Chen, J.-M. Corrosion and wear behaviors of PVD CrN and CrSiN coatings in seawater. Trans. Nonferrous Met. Soc. China 2016, 26, 175–184. [Google Scholar] [CrossRef]

- Ou, Y.X.; Lin, J.; Tong, S.; Che, H.L.; Sproul, W.D.; Lei, M.K. Wear and corrosion resistance of CrN/TiN superlattice coatings deposited by a combined deep oscillation magnetron sputtering and pulsed dc magnetron sputtering. Appl. Surf. Sci. 2015, 351, 332–343. [Google Scholar] [CrossRef]

- Gilewicz, A.; Warcholinski, B. Tribological properties of CrCN/CrN multilayer coatings. Tribol. Int. 2014, 80, 34–40. [Google Scholar] [CrossRef]

- Qi, Y.; Liang, W.; Miao, Q.; Yi, J.; Lin, H.; Liu, Y.; Ma, H. Role of the nitrogen ratio on mechanical properties and wear resistance of CrN/Fe functionally graded coating produced by double glow plasma alloying. Appl. Surf. Sci. 2022, 585, 152735. [Google Scholar] [CrossRef]

- Sui, X.; Liu, J.; Zhang, S.; Yang, J.; Hao, J. Microstructure, mechanical and tribological characterization of CrN/DLC/Cr-DLC multilayer coating with improved adhesive wear resistance. Appl. Surf. Sci. 2018, 439, 24–32. [Google Scholar] [CrossRef]

- Spikes, H. The History and Mechanisms of ZDDP. Tribol. Lett. 2004, 17, 469–489. [Google Scholar] [CrossRef]

- Grün, F.; Summer, F.; Pondicherry, K.S.; Gódor, I.; Offenbecher, M.; Lainé, E. Tribological functionality of aluminium sliding materials with hard phases under lubricated conditions. Wear 2013, 298–299, 127–134. [Google Scholar] [CrossRef]

- Pereira, G.; Lachenwitzer, A.; Nicholls, M.; Kasrai, M.; Norton, P.; De Stasio, G. Chemical characterization and nanomechanical properties of antiwear films fabricated from ZDDP on a near hypereutectic Al–Si alloy. Tribol. Lett. 2005, 18, 411–427. [Google Scholar] [CrossRef]

- Pereira, G.; Lachenwitzer, A.; Munoz-Paniagua, D.; Kasrai, M.; Norton, P.R.; Abrecht, M.; Gilbert, P. The role of the cation in antiwear films formed from ZDDP on 52100 steel. Tribol. Lett. 2006, 23, 109–119. [Google Scholar] [CrossRef]

- Nicholls, M.A.; Do, T.; Norton, P.R.; Kasrai, M.; Bancroft, G. Review of the lubrication of metallic surfaces by zinc dialkyl-dithiophosphates. Tribol. Int. 2005, 38, 15–39. [Google Scholar] [CrossRef]

- Nicholls, M.A.; Norton, P.R.; Bancroft, G.M.; Kasrai, M.; Stasio, G.D.; Wiese, L.M. Spatially resolved nanoscale chemical and mechanical characterization of ZDDP antiwear films on aluminum?silicon alloys under cylinder/bore wear conditions. Tribol. Lett. 2005, 18, 261–278. [Google Scholar] [CrossRef]

- Martin, J.M. Antiwear mechanisms of zinc dithiophosphate: A chemical hardness approach. Tribol. Lett. 1999, 6, 1–8. [Google Scholar] [CrossRef]

- Ji, H.; Nicholls, M.A.; Norton, P.R.; Kasrai, M.; Capehart, T.W.; Perry, T.A.; Cheng, Y.-T. Zinc-dialkyl-dithiophosphate antiwear films: Dependence on contact pressure and sliding speed. Wear 2005, 258, 789–799. [Google Scholar] [CrossRef]

- Ng, E.; Sinha, S.K.; Satyanarayana, N.; Lim, C.; Narayan, A. Effect of ZDDP and ashless triphenyl phosphorothionate (TPPT) as lubricant additives on tribological performance of Cr–N coatings. Tribol.-Mater. Surf. Interfaces 2014, 8, 172–178. [Google Scholar] [CrossRef]

- Mandrino, D.; Podgornik, B. XPS investigations of tribofilms formed on CrN coatings. Appl. Surf. Sci. 2017, 396, 554–559. [Google Scholar] [CrossRef]

- Morina, A.; Haque, T.; Neville, A. Comparing Tribochemical Film Formation and Durability at Steel and CrN Coating Interface in Boundary Lubrication. Tribol. Online 2010, 5, 187–194. [Google Scholar] [CrossRef]

- Haque, T.; Morina, A.; Neville, A.; Kapadia, R.; Arrowsmith, S. Non-ferrous coating/lubricant interactions in tribological contacts: Assessment of tribofilms. Tribol. Int. 2007, 40, 1603–1612. [Google Scholar] [CrossRef]

- Tandler, R.; Bohn, N.; Gabbert, U.; Woschke, E. Experimental investigations of the internal friction in automotive bush chain drive systems. Tribol. Int. 2019, 140, 105871. [Google Scholar] [CrossRef]

- Mainwaring, R. Soot and Wear in Heavy Duty Diesel Engines. In SAE Transactions; SAE International: Warrendale, PA, USA, 1997. [Google Scholar] [CrossRef]

- Salehi, F.M.; Khaemba, D.N.; Morina, A.; Neville, A. Corrosive–Abrasive Wear Induced by Soot in Boundary Lubrication Regime. Tribol. Lett. 2016, 63, 256. [Google Scholar] [CrossRef]

- Ratoi, M.; Castle, R.C.; Bovington, C.H.; Spikes, H.A. The influence of soot and dispersant on ZDDP film thickness and friction. Lubr. Sci. 2004, 17, 25–43. [Google Scholar] [CrossRef]

- Chinas-Castillo, F.; Spikes, H. The Behavior of Diluted Sooted Oils in Lubricated Contacts. Tribol. Lett. 2004, 16, 317–322. [Google Scholar] [CrossRef]

- Ryason, P.; Chan, I.; Gilmore, J. Polishing wear by soot. Wear 1990, 137, 15–24. [Google Scholar] [CrossRef]

- Vyavhare, K.; Bagi, S.; Patel, M.; Aswath, P.B. Impact of Diesel Engine Oil Additives–Soot Interactions on Physiochemical, Oxidation, and Wear Characteristics of Soot. Energy Fuels 2019, 33, 4515–4530. [Google Scholar] [CrossRef]

- Salehi, F.M.; Morina, A.; Neville, A. The effect of soot and diesel contamination on wear and friction of engine oil pump. Tribol. Int. 2017, 115, 285–296. [Google Scholar] [CrossRef]

- Salehi, F.M.; Morina, A.; Neville, A. Zinc Dialkyldithiophosphate Additive Adsorption on Carbon Black Particles. Tribol. Lett. 2018, 66, 118. [Google Scholar] [CrossRef]

- Kontou, A.; Southby, M.; Spikes, H. Effect of steel hardness on soot wear. Wear 2017, 390–391, 236–245. [Google Scholar] [CrossRef]

- Olomolehin, Y.; Kapadia, R.; Spikes, H. Antagonistic Interaction of Antiwear Additives and Carbon Black. Tribol. Lett. 2009, 37, 49–58. [Google Scholar] [CrossRef]

- Kontou, A.; Southby, M.; Morgan, N.; Spikes, H.A. Influence of Dispersant and ZDDP on Soot Wear. Tribol. Lett. 2018, 66, 157. [Google Scholar] [CrossRef]

- Paulovics, L.; Kuti, R.; Rohde-Brandenburger, J.; Tóth-Nagy, C. Development of comparative investigation method for timing chain wear analysis using oscillating tribometer. Acta Tech. Jaurinensis 2021, 14, 406–423. [Google Scholar] [CrossRef]

- Sappok, D.; Merz, R.; Sauer, B.; Kopnarski, M. Surface Analysis of Chain Joint Components after Tribological Load and Usage of Antiwear Additives. Conf. Pap. Sci. 2015, 2015, 407048. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.D.; Moore, J.J.; Lee, S.; Myers, S. High rate deposition of thick CrN and Cr2N coatings using modulated pulse power (MPP) magnetron sputtering. Surf. Coat. Technol. 2011, 205, 3226–3234. [Google Scholar] [CrossRef]

- Li, D.; Kong, N.; Zhang, B.; Zhang, B.; Li, R.; Zhang, Q. Comparative study on the effects of oil viscosity on typical coatings for automotive engine components under simulated lubrication conditions. Diam. Relat. Mater. 2020, 112, 108226. [Google Scholar] [CrossRef]

- Pondicherry, K.S.; Grün, F.; Gódor, I.; Bertram, R.; Offenbecher, M. Applicability of ring-on-disc and pin-on-plate test methods for Cu-steel and Al-steel systems for large area conformal contacts. Lubr. Sci. 2012, 25, 231–247. [Google Scholar] [CrossRef]

- Neville, A.; Morina, A.; Haque, T.; Voong, M. Compatibility between tribological surfaces and lubricant additives—How friction and wear reduction can be controlled by surface/lube synergies. Tribol. Int. 2007, 40, 1680–1695. [Google Scholar] [CrossRef]

- Taylor, L.J.; Spikes, H.A. Friction-Enhancing Properties of ZDDP Antiwear Additive: Part I—Friction and Morphology of ZDDP Reaction Films. Tribol. Trans. 2003, 46, 303–309. [Google Scholar] [CrossRef]

- Taylor, L.; Dratva, A.; Spikes, H.A. Friction and Wear Behavior of Zinc Dialkyldithiophosphate Additive. Tribol. Trans. 2000, 43, 469–479. [Google Scholar] [CrossRef]

- Morina, A.; Neville, A.; Green, J.; Priest, M. Assessing friction, wear and film formation characteristics in formulated lubricants in severe to moderate boundary lubrication conditions. In Tribological Research and Design for Engineering Systems; Dowson, D., Priest, M., Dalmaz, G., Lubrecht, A.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2003; pp. 23–33. [Google Scholar] [CrossRef]

- Kaminski, P. Experimental Investigation into the Effects of Fuel Dilution on the Change in Chemical Properties of Lubricating Oil Used in Fuel Injection Pump of Pielstick PA4 V185 Marine Diesel Engine. Lubricants 2022, 10, 162. [Google Scholar] [CrossRef]

- Peng, J.-F.; Shen, M.-X.; Cai, Z.-B. Nano Diesel Soot Particles Reduce Wear and Friction Performance Using an Oil Additive on a Laser Textured Surface. Coatings 2018, 8, 89. [Google Scholar] [CrossRef]

- Saini, V.; Seth, S.; Ramakumar, S.S.V.; Bijwe, J. Carbon Nanoparticles of Varying Shapes as Additives in Mineral Oil Assessment of Comparative Performance Potential. ACS Appl. Mater. Interfaces 2021, 13, 38844–38856. [Google Scholar] [CrossRef] [PubMed]

- Marchetto, D.; Restuccia, P.; Ballestrazzi, A.; Righi, M.; Rota, A.; Valeri, S. Surface passivation by graphene in the lubrication of iron: A comparison with bronze. Carbon 2017, 116, 375–380. [Google Scholar] [CrossRef]

- Clague, A.; Donnet, J.; Wang, T.; Peng, J. A comparison of diesel engine soot with carbon black. Carbon 1999, 37, 1553–1565. [Google Scholar] [CrossRef]

| Abbreviation | Test Load (N) | Test Time (h) | |

|---|---|---|---|

| Test category I (also Part I) | TC 1 | 350 | 25 |

| Test category II (also Part I) | TC 2 | 600 | 25 |

| Test category III (also Part I) | TC 3 | 350 | 73 |

| Test category IV | TC 4 | 350 | 49 |

| Test category V | TC 5 | 600 | 73 |

| Nomenclature | Abbreviation | Engine Test Performance | Fresh Oil (wt%) | Soot (wt%) | Diesel Fuel (wt%) |

|---|---|---|---|---|---|

| Engine oil type 1 | EO 1 | Acceptable chain elongation | - | - | - |

| Engine oil type 2 | EO 2 | High/Non-acceptable chain elongation | - | - | - |

| Artificial oil type 1 | AO 1 | - | 100 | - | - |

| Artificial oil type 2 | AO 2 | - | 97 | 3 | - |

| Artificial oil type 3 | AO 3 | - | 90 | - | 10 |

| Artificial oil type 4 | AO 4 | - | 75.5 | 4.5 | 20 |

| Spectrum | C | N | O | Cr | Fe |

|---|---|---|---|---|---|

| 1 | - | 45.0 | 6.4 | 48.5 | - |

| 2 | - | 48.3 | 2.7 | 49.0 | - |

| 3 | 5.1 | - | - | 4.5 | 90.3 |

| 4 | 5.2 | - | - | 5.4 | 89.5 |

| 5 | - | 44.0 | 3.8 | 47.0 | 5.1 |

| 6 | - | 44.3 | 2.2 | 46.3 | 7.3 |

| 7 | - | 43.6 | 2.8 | 46.6 | 7.0 |

| Spectrum | C | O | P | S | Ca | Fe | Zn |

|---|---|---|---|---|---|---|---|

| 1 | 6.5 | 45.5 | 0.8 | - | - | 47.3 | - |

| 2 | 9.9 | 39.3 | 0.7 | - | - | 50.2 | - |

| 3 | 7.4 | 44.9 | 0.8 | 0.6 | - | 46.3 | - |

| 4 | 8.6 | 24.8 | - | - | - | 66.6 | - |

| 5 | 10.4 | 3.4 | - | - | - | 86.3 | - |

| Spectrum | C | O | P | S | Ca | Fe | Zn |

|---|---|---|---|---|---|---|---|

| 1 | 7.6 | 38.5 | 2.2 | 1.0 | 2.7 | 48.0 | - |

| 2 | 7.2 | 37.2 | 1.1 | - | - | 54.5 | - |

| 3 | 7.2 | - | - | - | - | 92.8 | - |

| 4 | 25.0 | 27.8 | 1.4 | 1.0 | 2.0 | 42.9 | - |

| 5 | 7.4 | 35.9 | 2.2 | 1.5 | 2.5 | 50.5 | - |

| Spectrum | C | N | O | P | S | Ca | Cr | Fe | Zn |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 7.6 | - | 58.8 | 11.6 | 0.8 | 11.0 | - | 10.2 | - |

| 2 | 8.1 | 9.7 | - | - | - | - | 17.5 | 64.7 | - |

| 3 | 67.1 | - | 18.0 | 2.4 | 5.3 | 2.1 | - | 4.7 | 0.3 |

| 4 | - | 47.6 | - | - | - | - | 52.4 | - | - |

| 5 | 11.8 | - | 59.8 | 6.9 | 1.0 | 15.2 | - | 5.2 | - |

| 6 | 74.2 | - | 6.0 | - | 0.3 | - | 15.5 | 4.0 | - |

| 7 | - | 44.8 | - | - | - | - | 45.7 | 9.5 | - |

| 8 | 2.9 | 27.7 | 20.2 | 1.7 | - | 4.8 | 33.8 | 8.9 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Summer, F.; Bergmann, P.; Grün, F. On the Wear Behaviour of Bush Drive Chains: Part II—Performance Screening of Pin Materials and Lubricant Effects. Lubricants 2023, 11, 157. https://doi.org/10.3390/lubricants11040157

Summer F, Bergmann P, Grün F. On the Wear Behaviour of Bush Drive Chains: Part II—Performance Screening of Pin Materials and Lubricant Effects. Lubricants. 2023; 11(4):157. https://doi.org/10.3390/lubricants11040157

Chicago/Turabian StyleSummer, Florian, Philipp Bergmann, and Florian Grün. 2023. "On the Wear Behaviour of Bush Drive Chains: Part II—Performance Screening of Pin Materials and Lubricant Effects" Lubricants 11, no. 4: 157. https://doi.org/10.3390/lubricants11040157

APA StyleSummer, F., Bergmann, P., & Grün, F. (2023). On the Wear Behaviour of Bush Drive Chains: Part II—Performance Screening of Pin Materials and Lubricant Effects. Lubricants, 11(4), 157. https://doi.org/10.3390/lubricants11040157