A Study on the Effects of Hybridized Metal Oxide and Carbonaceous Nano-Cutting Fluids in the End Milling of AA6082 Aluminum Alloy

Abstract

1. Introduction

- Preparation and characterization of metal-oxide and carbonaceous nanofluids using ultrasonicator and study of their rheological behavior at different conditions.

- Experimental investigation of the input parameters (speed, feed rate type of nanofluids) on two responses (tool wear and surface roughness) during end milling of AA6082.

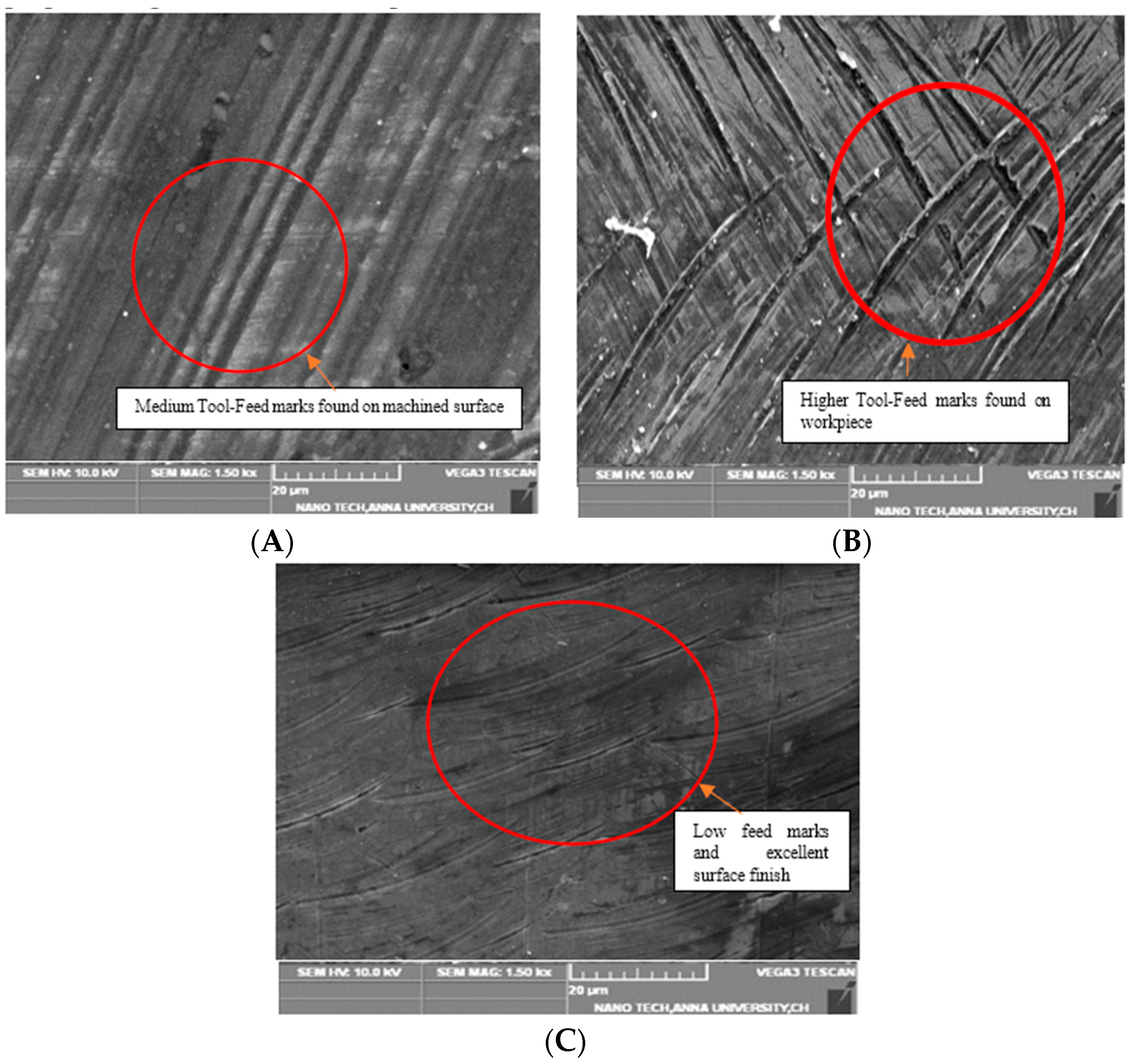

- Establishment of an ANOVA for output responses, and to further study the surface morphologies of machined specimens and tool surfaces.

2. Materials and Methods

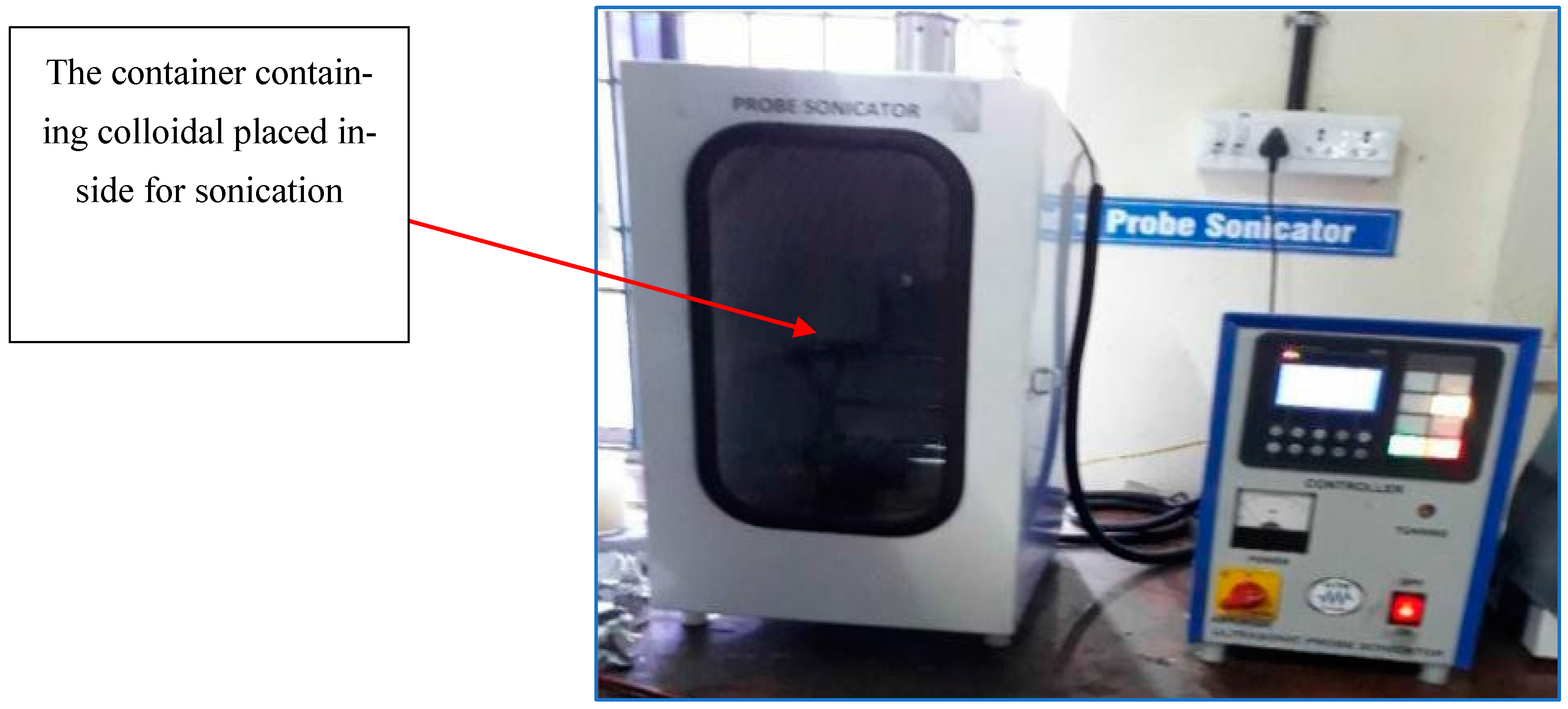

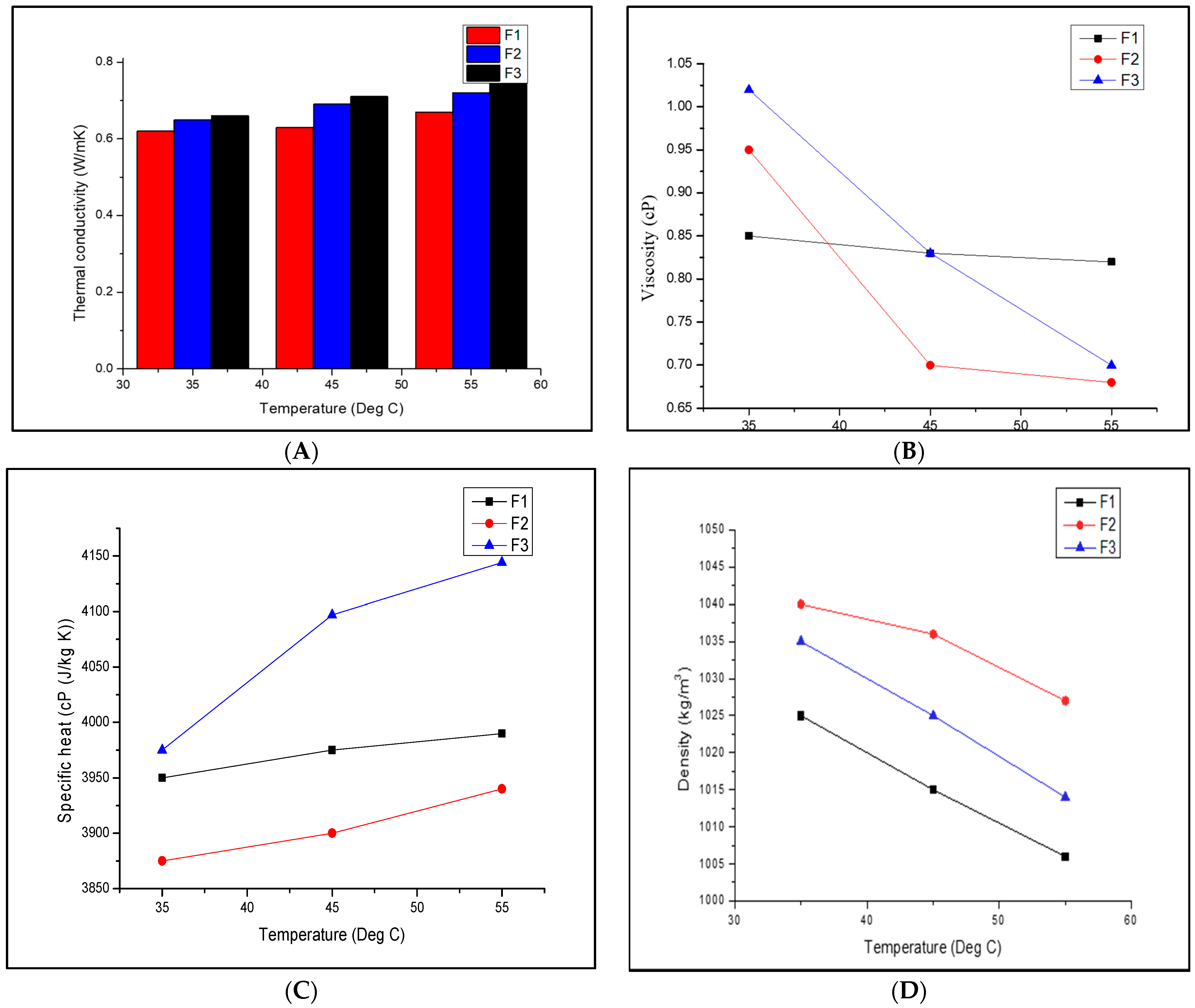

2.1. Preparation and Characteristic Study of Prepared Nanofluids

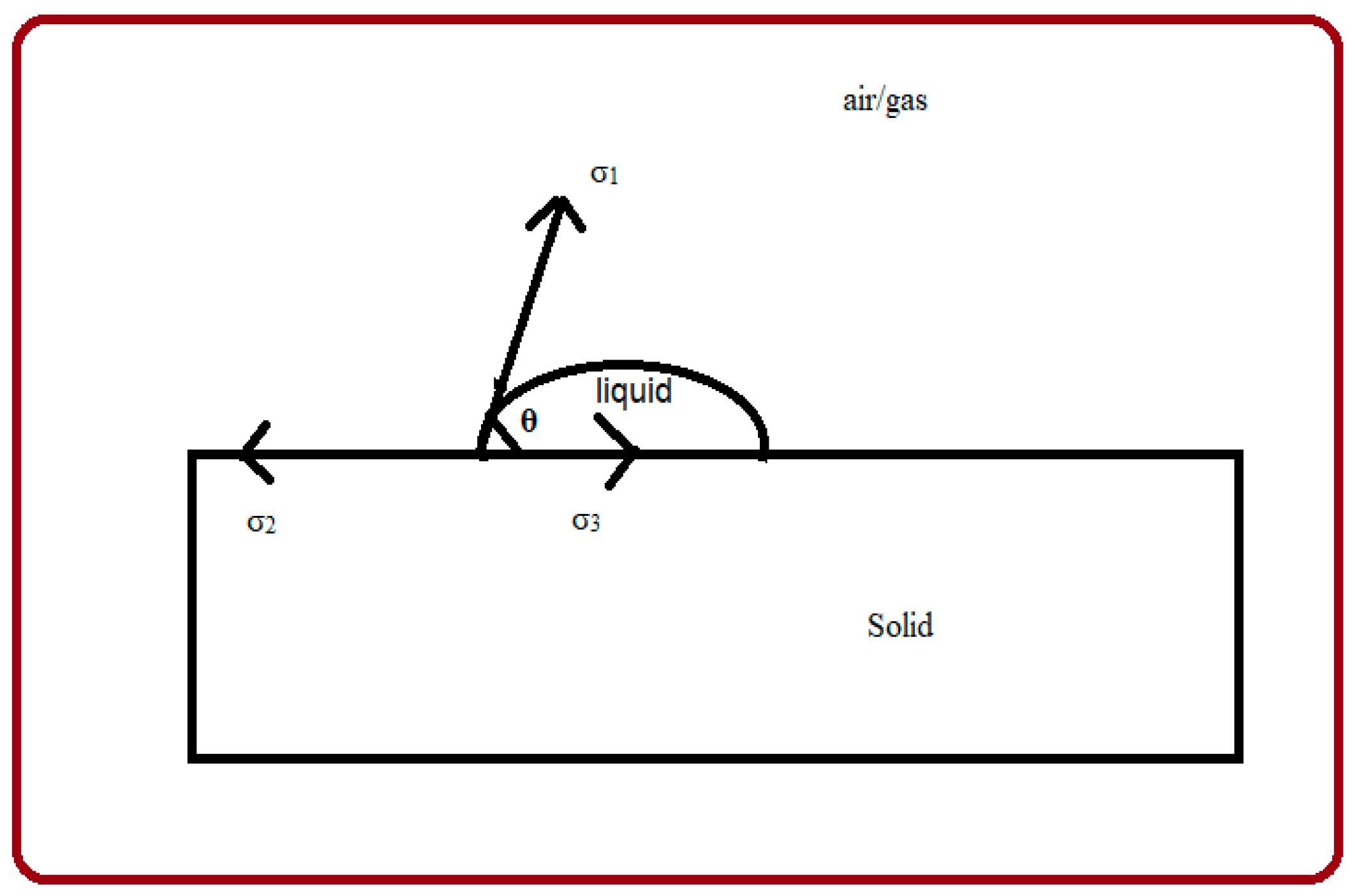

2.2. Contact Angle and Its Effects

3. Results and Discussion

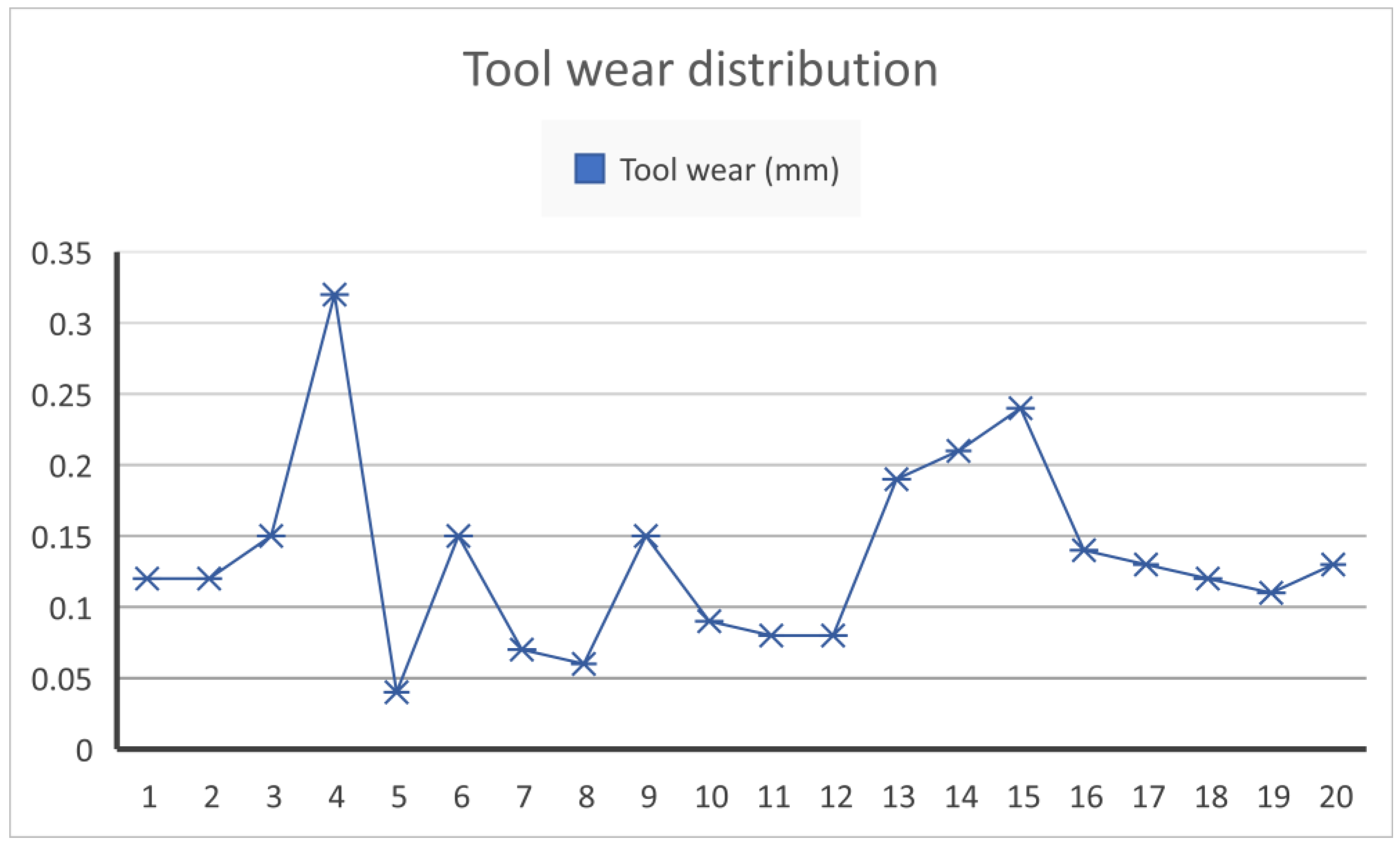

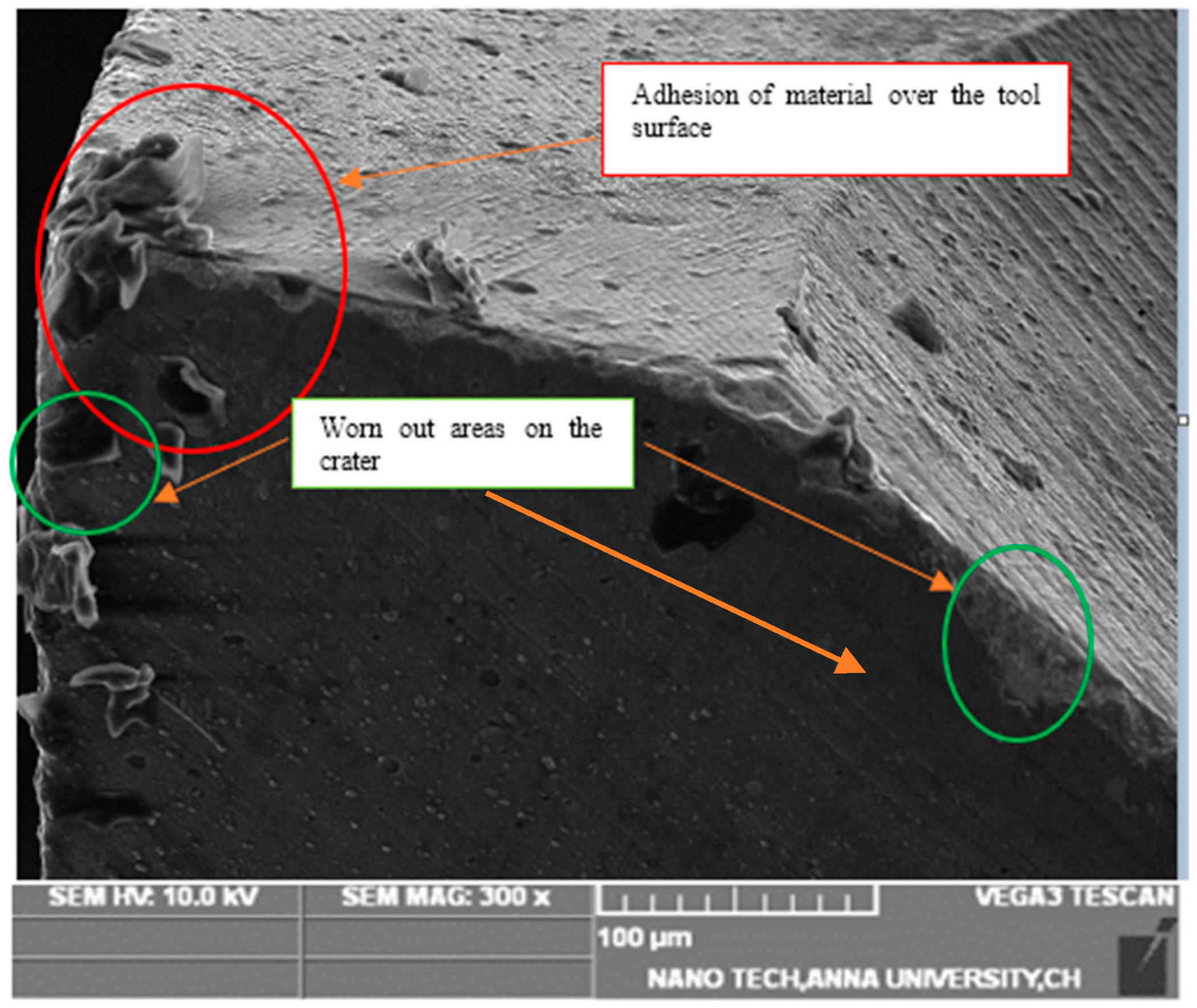

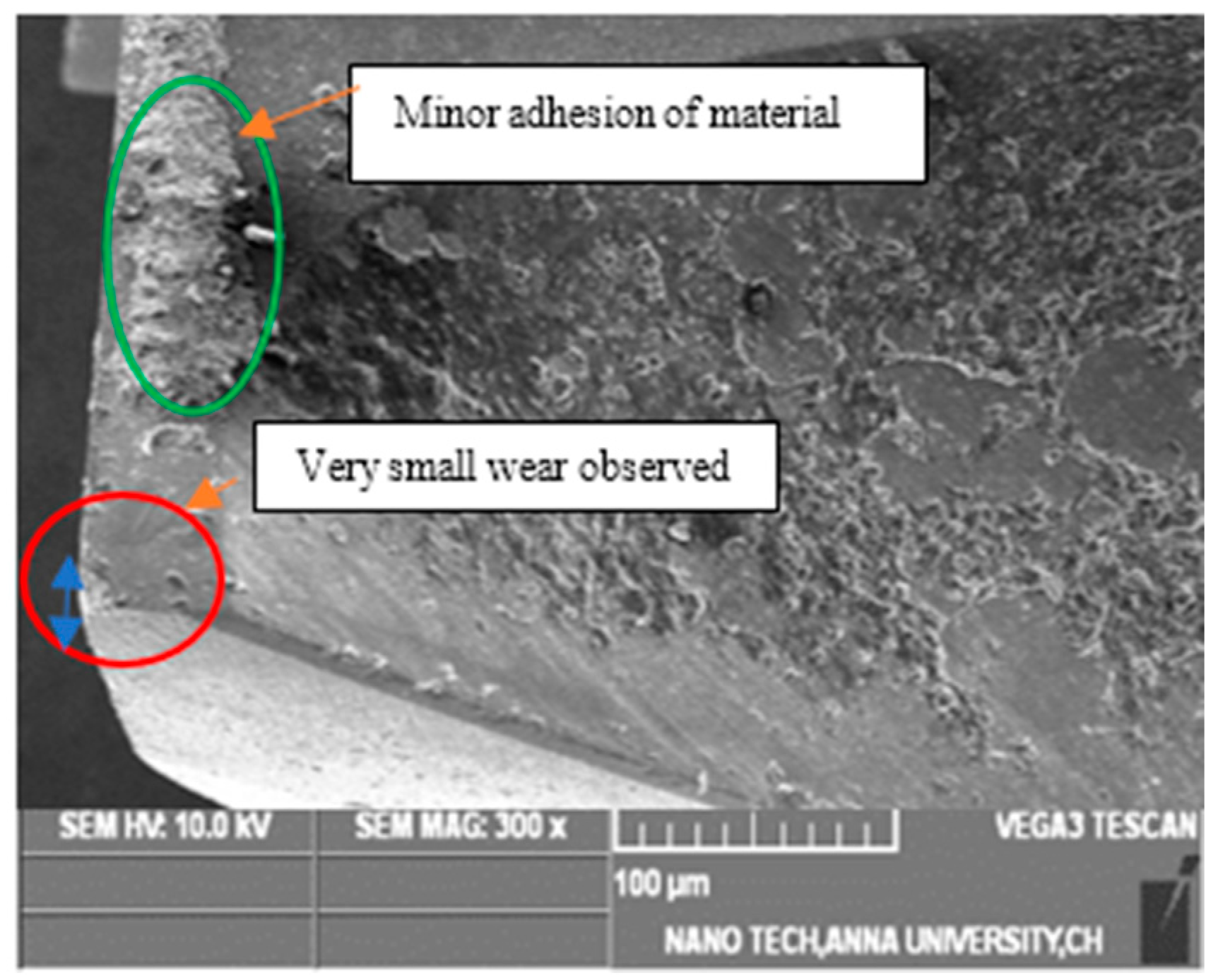

3.1. Tool Wear

- (1)

- When the temperature in the tool increases, the softening of the material occurs due to higher temperature, and the material that is being removed penetrates in between the tool face and the specimen.

- (2)

- Additionally, due to thermal stiffness on the tool face, layer removal on the tool occurs, which leads to cavitation as seen.

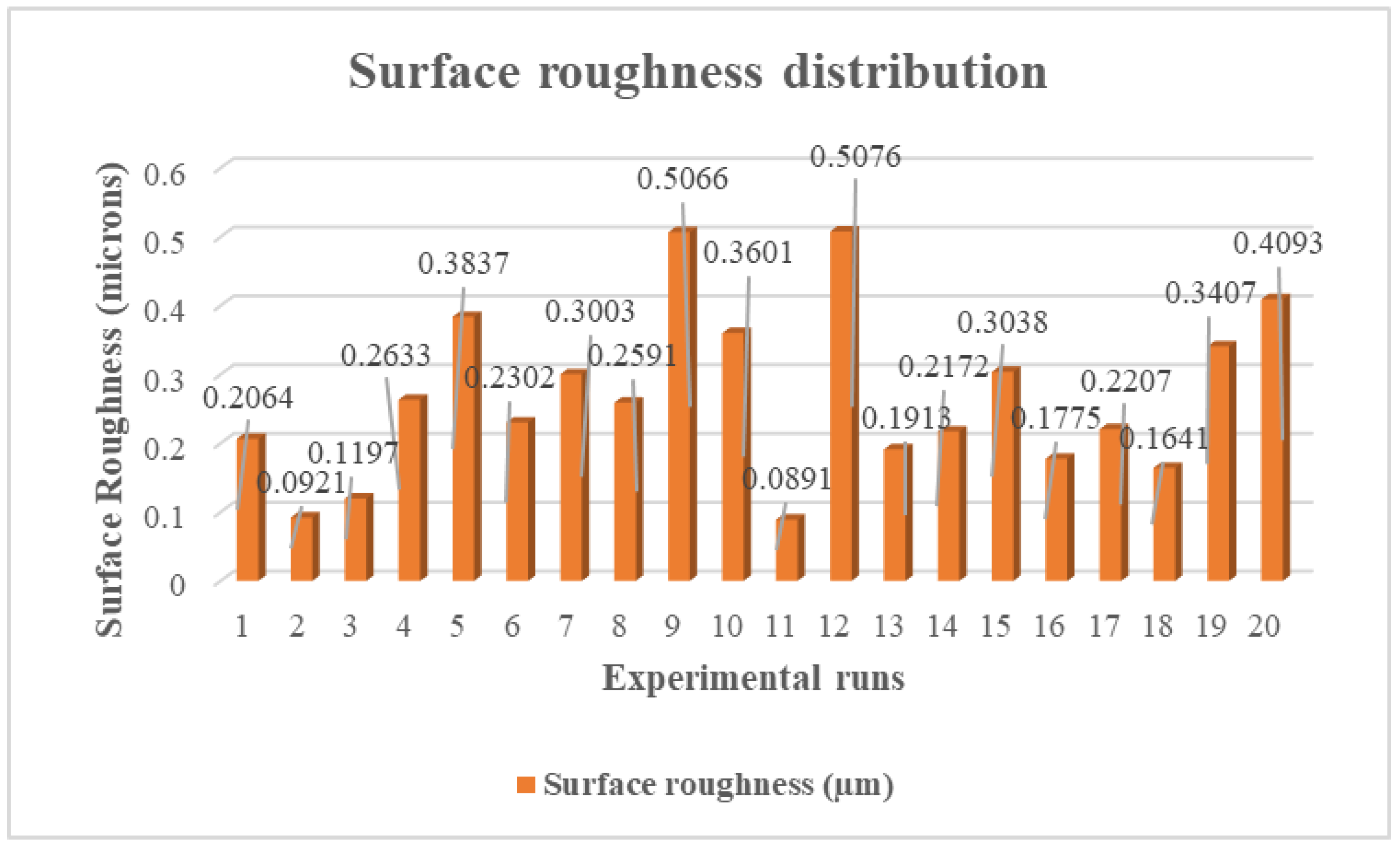

3.2. Surface Roughness (Ra) and Adaptive Behaviour

4. Conclusions

- The machining was found to be smooth and cost-effective, as only a minimum quantity of nanoparticles were utilized during machining using the nanoparticle mist technique (NPMT), and the synergistic effect of metal oxide & carbonaceous was found to be good.

- The surface finish in terms of surface roughness on the workpiece was found to be better in hybrid fluid, and with help of analysis of variance, the most influencing parameter was found to be the type of fluid followed by feed rate.

- The optimized input parameters for obtaining minimum surface finish were found to be N = 125 m/min, feed rate = 0.015 mm/tooth with F3 (hybrid) fluid.

- The tool life in terms of minimal tool wear was found to be better in both hybrid fluid and alumina. An ANOVA reveals that the most influencing parameter is the type of fluid and equal importance to be given during the selection of speed and feed rates.

- The optimized input parameters for obtaining minimum tool wear were found to be N = 75 m/min, feed rate = 0.015 mm/tooth with F3 (hybrid)/F2 fluid (alumina).

- Researchers thus far have given more attention to nanofluids containing a mono nanoparticle. This study was an attempt to investigate the effect of the hybridization of two different families of nanoparticles in a fixed volumetric ratio. The results of this study will be beneficial for researchers and industry people working on hybrid nanofluids.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Abbreviations

| BUE | Built-up edge |

| BUL | Built-up layer |

| dc | Depth of cut in mm |

| F | Feed rate in mm/rev |

| CNT | Carbon nanotubes |

| ANOVA | Analysis of variance |

| SS | Sum of squares |

| MS | Mean of squares |

| MQL | Minimum quantity lubrication |

| N | Speed of spindle in rpm |

| Ra | Surface roughness |

| RSM | Response surface methodology |

| SEM | Scanning electron microscope |

References

- Davoodi, B.; Tazehkandi, A.H. Experimental investigation and optimization of cutting parameters in dry and wet machining of aluminum alloy 5083 in order to remove cutting fluid. J. Clean. Prod. 2014, 68, 234–242. [Google Scholar] [CrossRef]

- Musavi, S.H.; Davoodi, B.; Niknam, S.A. Environmental-friendly turning of A286 superalloy. J. Manuf. Process. 2018, 32, 734–743. [Google Scholar] [CrossRef]

- Khanna, N.; Rodríguez, A.; Shah, P.; Pereira, O.; Rubio-Mateos, A.; de Lacalle, L.N.L.; Ostra, T. Comparison of dry and liquid carbon dioxide cutting conditions based on machining performance and life cycle assessment for end milling GFRP. Int. J. Adv. Manuf. Technol. 2022, 122, 821–833. [Google Scholar] [CrossRef]

- Iya Nouzil, I.; Eltaggaz, A.; Pervaiz, S.; Deiab, I. Toxicity Analysis of Nano-Minimum Quantity Lubrication Machining—A Review. Lubricants 2022, 10, 176. [Google Scholar] [CrossRef]

- Zhang, S.; Li, J.F.; Wang, Y.W. Tool life and forces in end milling Inconel 718 under dry and minimum quantity cooling lubrication cutting conditions. J. Clean. Prod. 2012, 32, 81–87. [Google Scholar] [CrossRef]

- Sharma, A.K.; Singh, R.K.; Dixit, A.R.; Tiwari, A.K. Novel uses of alumina-MoS2 hybrid nanoparticle enriched cutting fluid in hard turning of AISI 304 steel. J. Manuf. Process. 2017, 30, 467–482. [Google Scholar] [CrossRef]

- Kui, G.W.A.; Islam, S.; Reddy, M.M.; Khandoker, N.; Chen, V.L.C. Recent progress and evolution of coolant usages in conventional machining methods: A comprehensive review. Int. J. Adv. Manuf. Technol. 2022, 119, 3–40. [Google Scholar] [CrossRef]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S.; Jamil, M.; Pimenov, D.Y.; Khanna, N. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Process. 2020, 62, 179–201. [Google Scholar] [CrossRef]

- Roy, R.; Ghosh, S.K.; Kaisar, T.I.; Ahmed, T.; Hossain, S.; Aslam, M.; Kaseem, M.; Rahman, M.M. Multi-Response Optimization of Surface Grinding Process Parameters of AISI 4140 Alloy Steel Using Response Surface Methodology and Desirability Function under Dry and Wet Conditions. Coatings 2022, 12, 104. [Google Scholar] [CrossRef]

- Amrita, M.; Shariq, S.; Manoj; Gopal, C. Experimental investigation on application of emulsifier oil based nano cutting fluids in metal cutting process. Procedia Eng. 2014, 97, 115–124. [Google Scholar] [CrossRef]

- Vignesh, S.; Iqbal, U.M. Application of tri-hybridized carbonaceous nanocutting fluids in an end milling operation by the minimum quantity lubrication technique. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 837–855. [Google Scholar] [CrossRef]

- Alberts, M.; Kalaitzidou, K.; Melkote, S. An investigation of graphite nanoplatelets as lubricant in grinding. Int. J. Mach. Tools Manuf. 2009, 49, 966–970. [Google Scholar] [CrossRef]

- Murshed, S.; Leong, K.; Yang, C. A combined model for the effective thermal conductivity of nanofluids. Appl. Therm. Eng. 2009, 29, 2477–2483. [Google Scholar] [CrossRef]

- Chetan; Behera, B.C.; Ghosh, S.; Rao, P.V. Application of Nanofluids during minimum quantity lubrication; A case study in turning process. Tribol. Int. 2016, 101, 234–246. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, J.; Bhaumik, S. Influence of alumina/MWCNT hybrid nanoparticles additives of lubricants in turning operations. Friction 2017, 7, 153–168. [Google Scholar] [CrossRef]

- Vignesh, S.; Mohammed Iqbal, U. Effect of tri-hybridized metallic nano cutting fluids in end milling of AA7075 in minimum quantity lubrication environment. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 1458–1468. [Google Scholar] [CrossRef]

- Selvam, C.; Irshad, E.M.; Lal, D.M.; Harish, S. Convective heat transfer characteristics of water–ethylene glycol mixture with silver nanoparticles. Exp. Therm. Fluid Sci. 2016, 77, 188–196. [Google Scholar] [CrossRef]

- Singh, R.K.; Sharma, A.K.; Dixit, A.R.; Tiwari, A.K.; Pramanik, A.; Mandal, A. Performance evaluation of alumina-graphene hybrid nano-cutting fluid in hard turning. J. Clean. Prod. 2017, 162, 830–845. [Google Scholar] [CrossRef]

- Liu, M.; Li, C.; Zhang, Y.; An, Q.; Yang, M.; Gao, T.; Mao, C.; Liu, B.; Cao, H.; Xu, X.; et al. Cryogenic minimum quantity lubrication machining: From mechanism to application. Front. Mech. Eng. 2021, 16, 649–697. [Google Scholar] [CrossRef]

- Reddy, B.S.; Kumar, J.S.; Reddy, K.V.K. Optimization of surface roughness in CNC end milling using response surface methodology and genetic algorithm. Int. J. Eng. Sci. Technol. 2011, 3, 102–108. [Google Scholar] [CrossRef]

- Sultana, N.; Dhar, N.R. A critical review on the progress of MQL in machining hardened steels. Adv. Mater. Process. Technol. 2022, 8, 3834–3858. [Google Scholar] [CrossRef]

- Vignesh, S.; Iqbal, U.M. Preparation and characterization of bio-based nano cutting fluids for tribological applications. J. Dispers. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Eltaggaz, A.; Zawada, P.; Hegab, H.A.; Deiab, I.; Kishawy, H.A. Coolant strategy influence on tool life and surface roughness when machining ADI. Int. J. Adv. Manuf. Technol. 2017, 94, 3875–3887. [Google Scholar] [CrossRef]

- Sodavadia, K.P.; Makwana, A.H. Experimental Investigation on the Performance of Coconut oil Based Nano Fluid as Lubricants during Turning of AISI 304 Austenitic Stainless Steel. Int. J. Adv. Mech. Eng. 2014, 4, 55–60. [Google Scholar]

- Polvorosa, R.; Suarez, A.; Lopez de Lacalle, L.N. Tool wear on nickel alloys with different coolant pressures: Comparison of alloy 718 and Waspaloy. J. Manuf. Process. 2017, 26, 44–56. [Google Scholar] [CrossRef]

- Manjunath, G.B.; Bharath, K.N.; Ganesh, D.B.; Raj Kumar, D.G.; Shivprakash, P.; Harsha, H.M. ANOVA and Response Surface Methodology for the Optimization of Fracture Toughness parameters on Jute Fabric-Epoxy composites using SENB specimens. Mater. Today Proc. 2017, 4, 11285–11291. [Google Scholar] [CrossRef]

- Calikskan, H.; Kucukkose, M. The effect of can/TiAlN coating on tool wear, cutting force, surface finish, and Chip morphology in face milling of Ti6Al4V superalloy. Int. J. Refract. Met. Hard Mater. 2015, 50, 304–312. [Google Scholar] [CrossRef]

- Arifuddin, A.; Redhwan, A.A.M.; Azmi, W.H.; Zawawi, N.N.M. Performance of Al2O3/TiO2 Hybrid Nano-Cutting Fluid in MQL Turning Operation via RSM Approach. Lubricants 2022, 10, 366. [Google Scholar] [CrossRef]

- Singh, R.K.; Dixit, A.R.; Mandal, A.; Sharma, A.K. Emerging application of nanoparticle enriched cutting fluid in metal removal processes: A review. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 4677–4717. [Google Scholar] [CrossRef]

- Khandekar, S.; Sankar, M.R.; Agnihotri, V.; Ramkumar, J. Nano-Cutting Fluid for Enhancement of Metal Cutting Performance. Mater. Manuf. Process. 2012, 27, 963–967. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Krolczyk, G.M.; Mandal, U.K.; Mondal, S.P. Eco-Friendly Cutting Fluids in Minimum Quantity Lubrication Assisted Machining: A Review on the Perception of Sustainable Manufacturing. Int. J. Precis. Eng. Manuf. Technol. 2019, 8, 249–280. [Google Scholar] [CrossRef]

| Composition Material | Al | Si | Mg | Mn | Fe | Zn | Ti | Cr | Cu |

|---|---|---|---|---|---|---|---|---|---|

| % | 97 | 0.8 | 0.7 | 0.35 | 0.3 | 0.15 | 0.075 | 0.1 | 0.1 |

| Specifications | Parameters | Value |

|---|---|---|

| Workpiece material: AA6082 Mechanical Property | Density | 2.70 g/cm3 |

| Thermal conductivity | 185 W/m-K | |

| Young’s modulus | 69 Gpa | |

| Brinell hardness | 91 HB | |

| Work part geometry | Dimensions | Cube of 60 × 60 × 60 mm |

| Machining area length | Length of machining area (mm) 40 | |

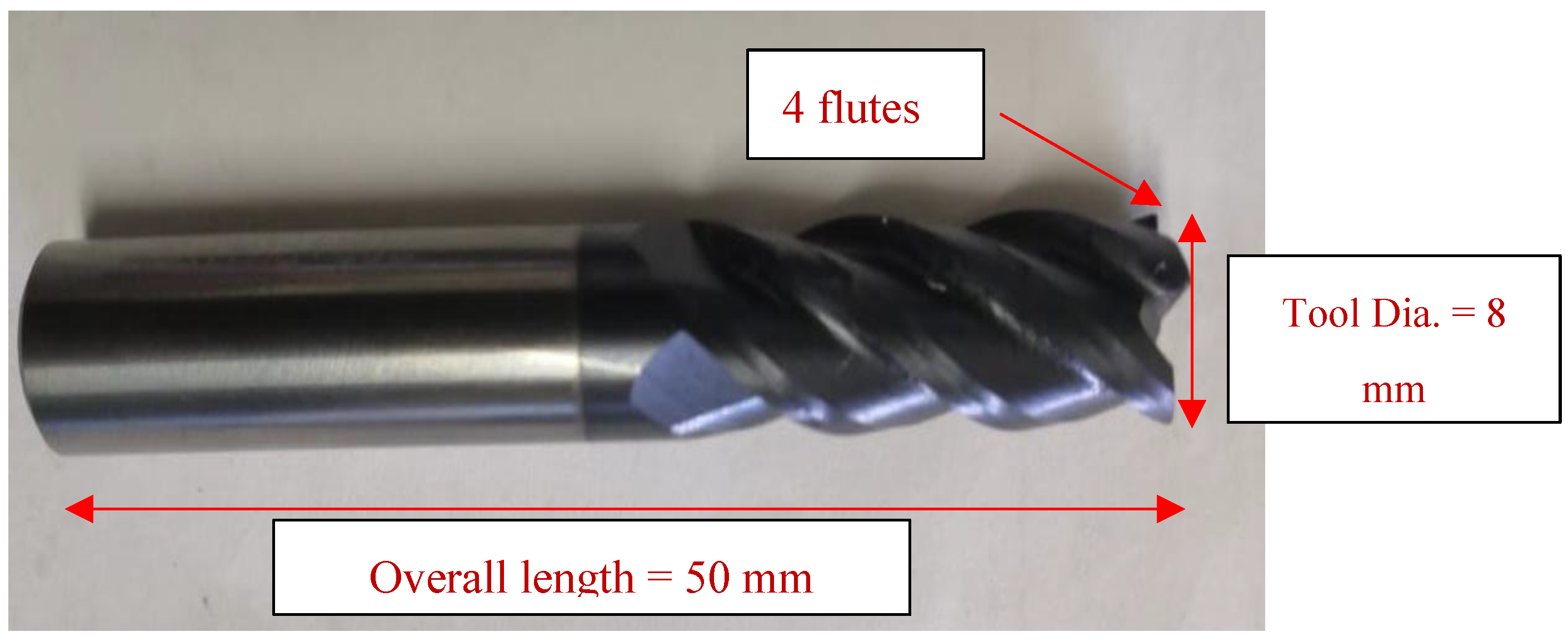

| Material | Cemented carbides coated with TiAlN | |

| Cutting tools Endmills | Dimensions | 8 mm dia × 4 flutes, Length 50 mm Tungsten carbide/Dormer-make |

| MQL conditions | Input pressure (MPa) | 0.2 |

| MQL flow rare (mL/h) | 60 | |

| Nozzle diameter (mm) | 2.5 | |

| Nozzle distance (mm) | 20 |

| Factors | Units | Low | High | |

|---|---|---|---|---|

| Cutting speed (N) | m/min | 75 | 125 | - |

| Feed rate (f) | mm/tooth | 0.005 | 0.015 | - |

| Nanofluids | -- | CNT | Alumina | CNT + Alumina |

| Machining time | Minutes | 30 | ||

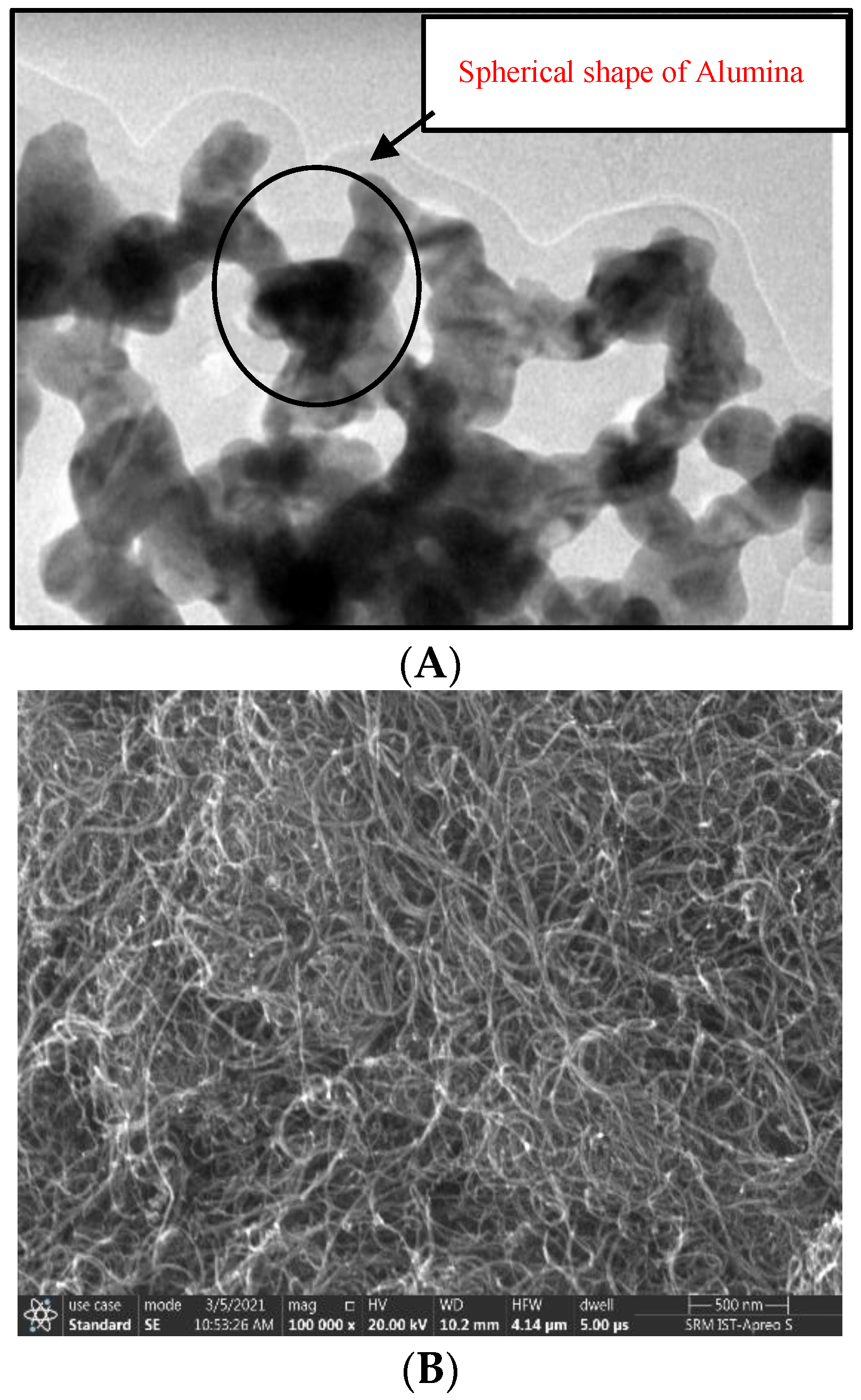

| Property | Alumina | CNT |

|---|---|---|

| Melting point (°C) | 1400 | 1550 |

| Morphology | Spherical | Tubular |

| Colour | White | Black |

| Diameter (nm) | 60–80 | 30–50 (avg.), length—40–50 microns |

| Purity (%) | 98 | 99 |

| Levels of Fluids | Composition | Weight Ratio in gms/100 mL of Base Fluid |

|---|---|---|

| F1 | CNT | 1% |

| F2 | Alumina | 1% |

| F3 | CNT + alumina | 0.5% each |

| Base Fluid (Coconut Oil) | F1 | F2 | F3 |

|---|---|---|---|

| 46 | 52 | 49 | 47 |

| Exp No. | Cutting Speed (m/min) | Feed Rate f (mm/Tooth) | Fluid | Tool Wear (mm) |

|---|---|---|---|---|

| 1 | 75 | 0.005 | 1 | 0.12 |

| 2 | 125 | 0.005 | 1 | 0.12 |

| 3 | 75 | 0.015 | 1 | 0.15 |

| 4 | 125 | 0.015 | 1 | 0.32 |

| 5 | 100 | 0.01 | 1 | 0.04 |

| 6 | 75 | 0.005 | 2 | 0.15 |

| 7 | 125 | 0.005 | 2 | 0.07 |

| 8 | 75 | 0.015 | 2 | 0.06 |

| 9 | 125 | 0.015 | 2 | 0.15 |

| 10 | 100 | 0.01 | 2 | 0.09 |

| 11 | 75 | 0.01 | 3 | 0.08 |

| 12 | 125 | 0.015 | 3 | 0.08 |

| 13 | 100 | 0.005 | 3 | 0.19 |

| 14 | 100 | 0.015 | 3 | 0.21 |

| 15 | 100 | 0.01 | 3 | 0.24 |

| 16 | 100 | 0.01 | 3 | 0.14 |

| 17 | 100 | 0.01 | 3 | 0.13 |

| 18 | 100 | 0.01 | 3 | 0.12 |

| 19 | 100 | 0.01 | 3 | 0.11 |

| 20 | 100 | 0.01 | 3 | 0.13 |

| Source | DF | SS | MS | F | P | % of Confidence Level |

|---|---|---|---|---|---|---|

| Cutting speed (m/min) | 2 | 19,021 | 9511 | 5.83 | 0.22 | 15.11 |

| Feed rate (mm/tooth) | - | 10,521 | 5261 | 3.64 | 0.395 | 25.21 |

| Type of fluid | 2 | 82,585 | 41,293 | 20.53 | 0.082 | 54.54 |

| Error | 2 | 3080 | 1540 | - | - | 5.14 |

| Total | 8 | 115,207 | 57,604 | - | - | 100 |

| Exp No. | Cutting Speed (m/min) | Feed Rate f (mm/Tooth) | Fluid | Surface Roughness (µm) |

|---|---|---|---|---|

| 1 | 75 | 0.005 | 1 | 0.2064 |

| 2 | 125 | 0.005 | 1 | 0.0921 |

| 3 | 75 | 0.015 | 1 | 0.1197 |

| 4 | 125 | 0.015 | 1 | 0.2633 |

| 5 | 100 | 0.01 | 1 | 0.3837 |

| 6 | 75 | 0.005 | 2 | 0.2302 |

| 7 | 125 | 0.005 | 2 | 0.3003 |

| 8 | 75 | 0.015 | 2 | 0.2591 |

| 9 | 125 | 0.015 | 2 | 0.5066 |

| 10 | 100 | 0.01 | 2 | 0.3601 |

| 11 | 75 | 0.01 | 3 | 0.0891 |

| 12 | 125 | 0.015 | 3 | 0.5076 |

| 13 | 100 | 0.005 | 3 | 0.1913 |

| 14 | 100 | 0.015 | 3 | 0.2172 |

| 15 | 100 | 0.01 | 3 | 0.3038 |

| 16 | 100 | 0.01 | 3 | 0.1775 |

| 17 | 100 | 0.01 | 3 | 0.2207 |

| 18 | 100 | 0.01 | 3 | 0.1641 |

| 19 | 100 | 0.01 | 3 | 0.3407 |

| 20 | 100 | 0.01 | 3 | 0.4093 |

| Source | DF | SS | MS | F | P | % of Confidence Level |

|---|---|---|---|---|---|---|

| Cutting speed (m/min) | 2 | 21,021 | 10,511 | 4.33 | 0.18 | 9.9 |

| Feed rate (mm/tooth) | - | 12,521 | 62,061 | 2.64 | 0.275 | 16.40 |

| Type of fluid | 2 | 92,585 | 46,293 | 18.42 | 0.051 | 68.81 |

| Error | 2 | 4030 | 2030 | 4.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

S, V.; U, M.I.; Ghani, J.A. A Study on the Effects of Hybridized Metal Oxide and Carbonaceous Nano-Cutting Fluids in the End Milling of AA6082 Aluminum Alloy. Lubricants 2023, 11, 87. https://doi.org/10.3390/lubricants11020087

S V, U MI, Ghani JA. A Study on the Effects of Hybridized Metal Oxide and Carbonaceous Nano-Cutting Fluids in the End Milling of AA6082 Aluminum Alloy. Lubricants. 2023; 11(2):87. https://doi.org/10.3390/lubricants11020087

Chicago/Turabian StyleS, Vignesh, Mohammed Iqbal U, and Jaharah A. Ghani. 2023. "A Study on the Effects of Hybridized Metal Oxide and Carbonaceous Nano-Cutting Fluids in the End Milling of AA6082 Aluminum Alloy" Lubricants 11, no. 2: 87. https://doi.org/10.3390/lubricants11020087

APA StyleS, V., U, M. I., & Ghani, J. A. (2023). A Study on the Effects of Hybridized Metal Oxide and Carbonaceous Nano-Cutting Fluids in the End Milling of AA6082 Aluminum Alloy. Lubricants, 11(2), 87. https://doi.org/10.3390/lubricants11020087