An Experimental Investigation on the Effects of the Base Fluid of External Fluid and Voltage on the Milling Performance of Nanofluid Composite Electrostatic Spraying

Abstract

:1. Introduction

2. Materials and Methods

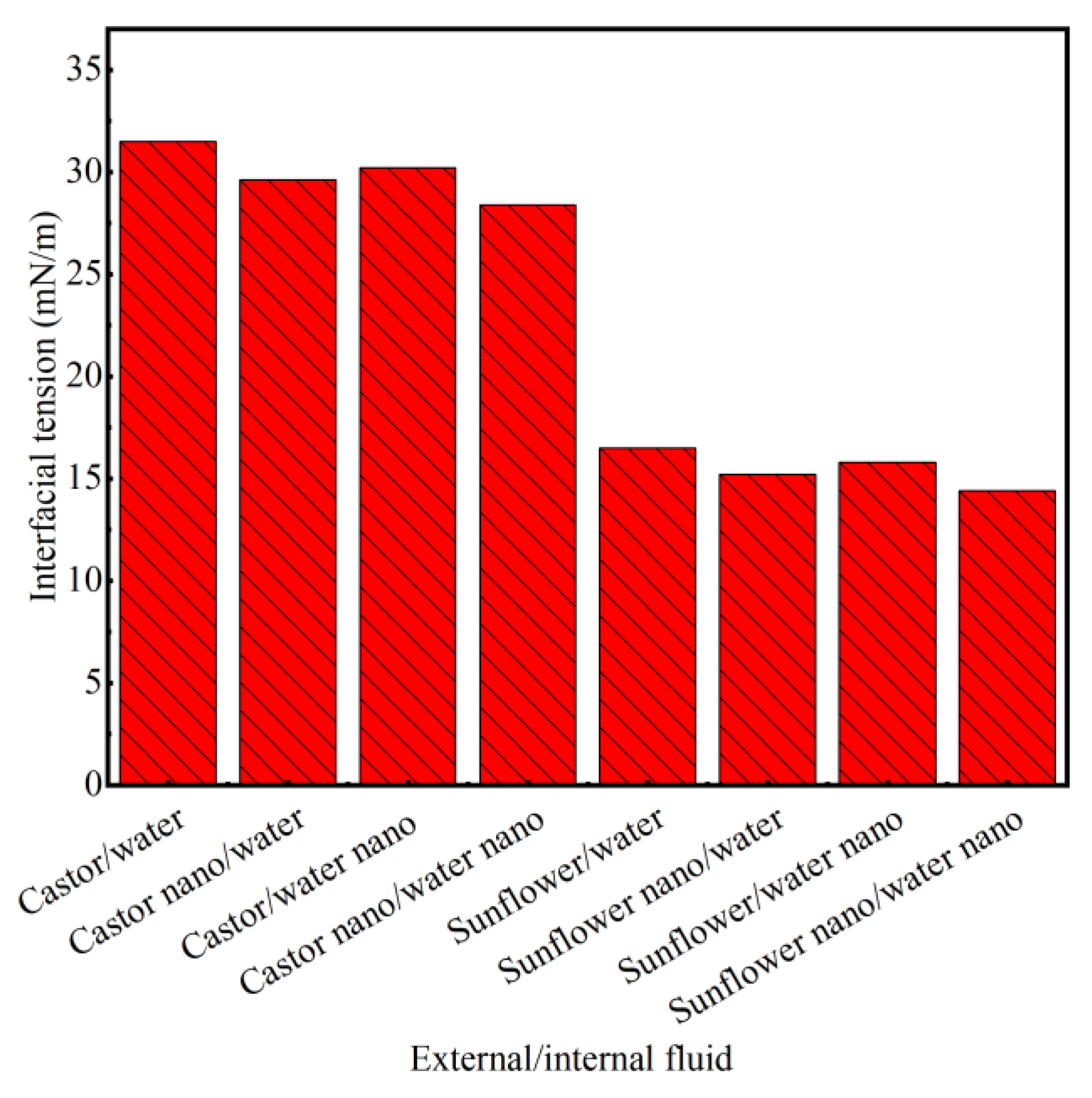

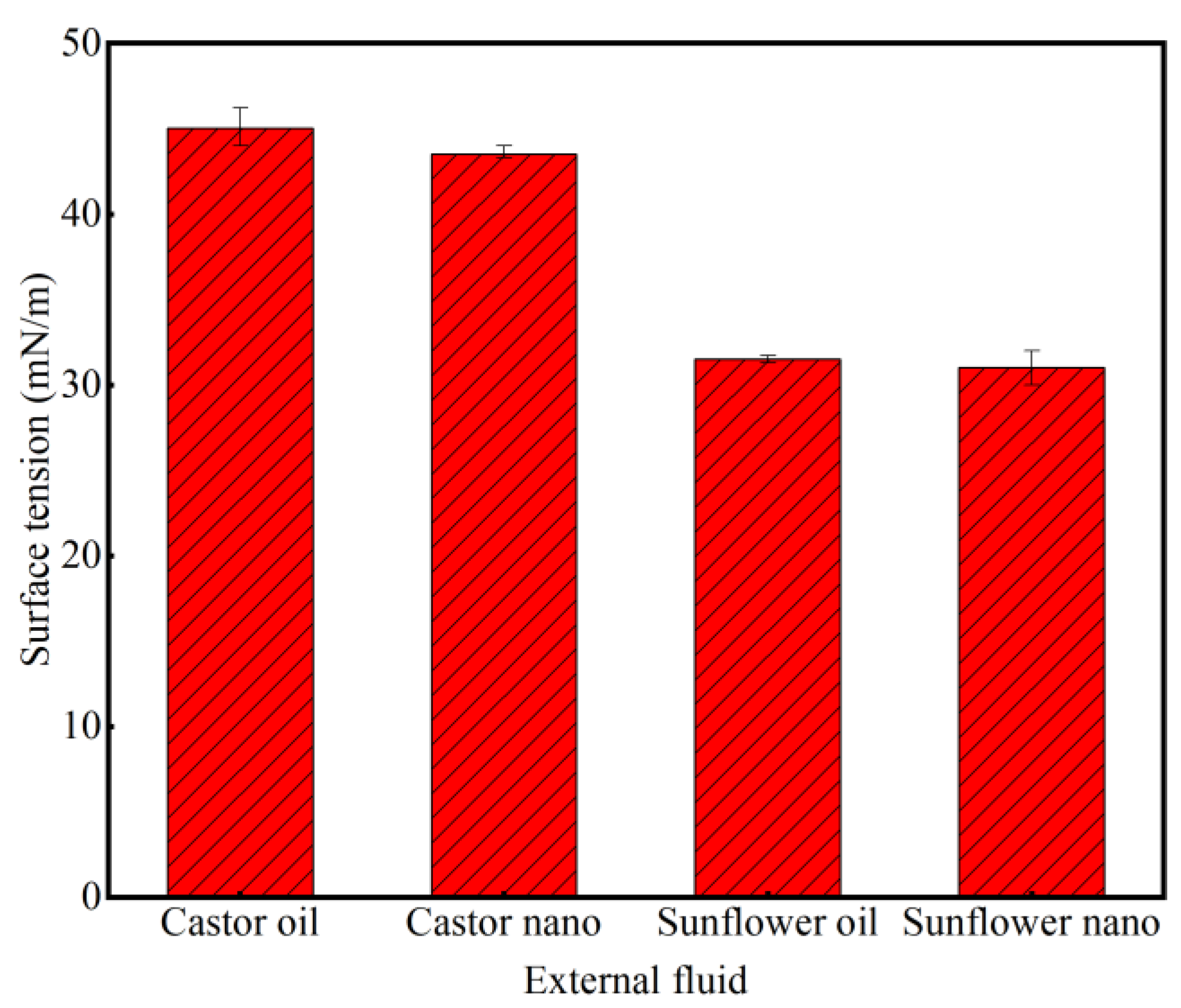

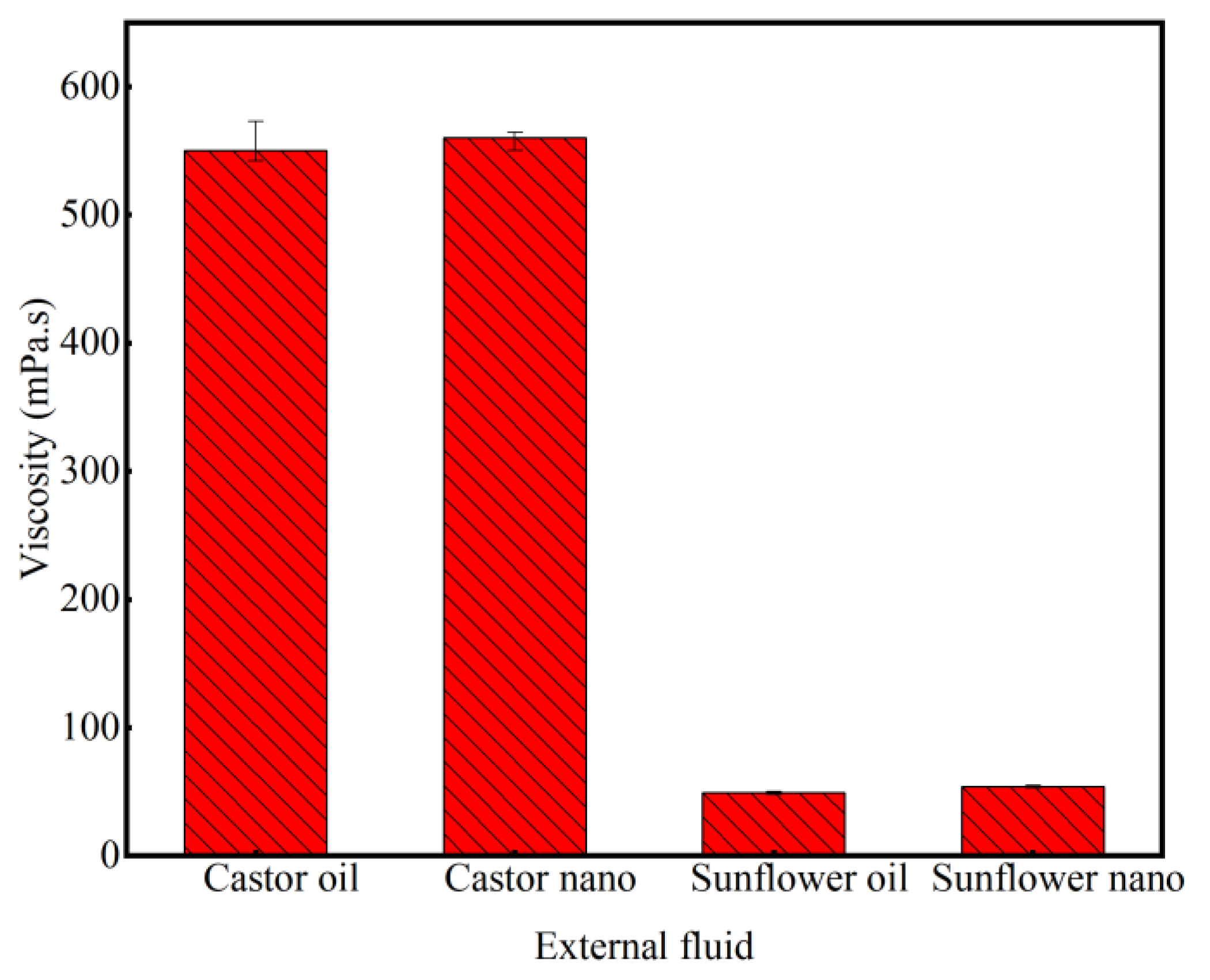

2.1. Nanofluid Preparation and Physical Property Testing

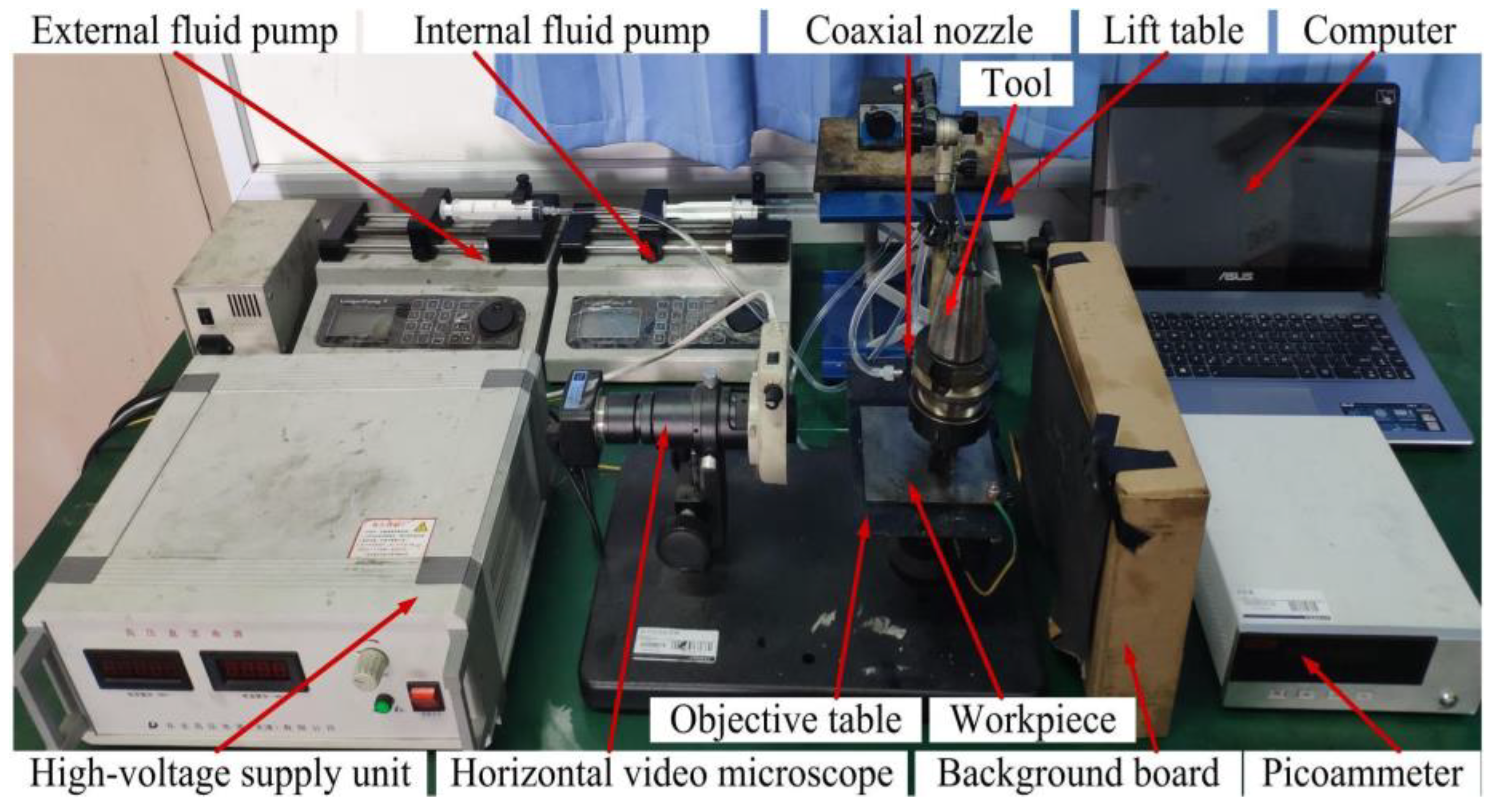

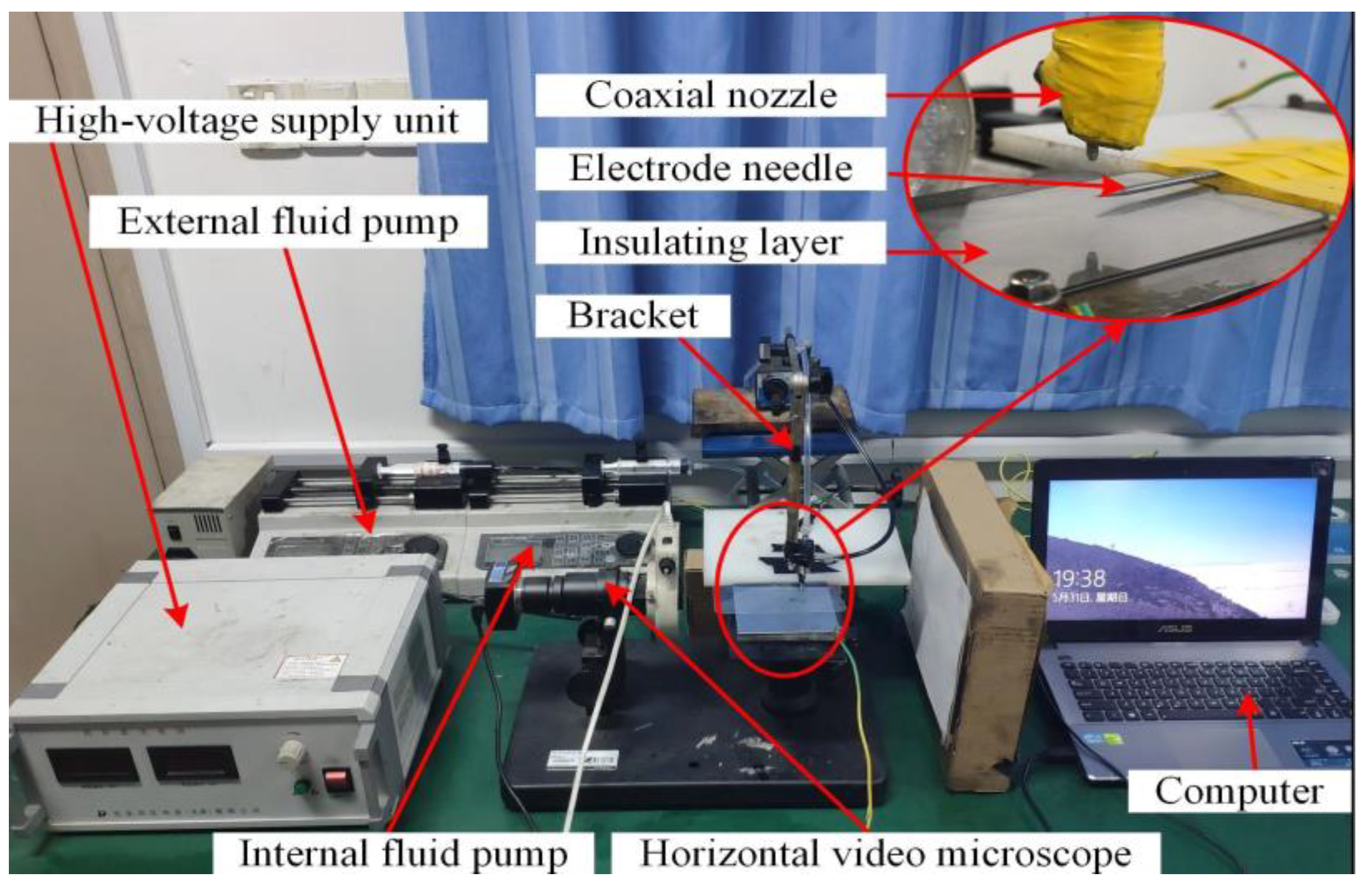

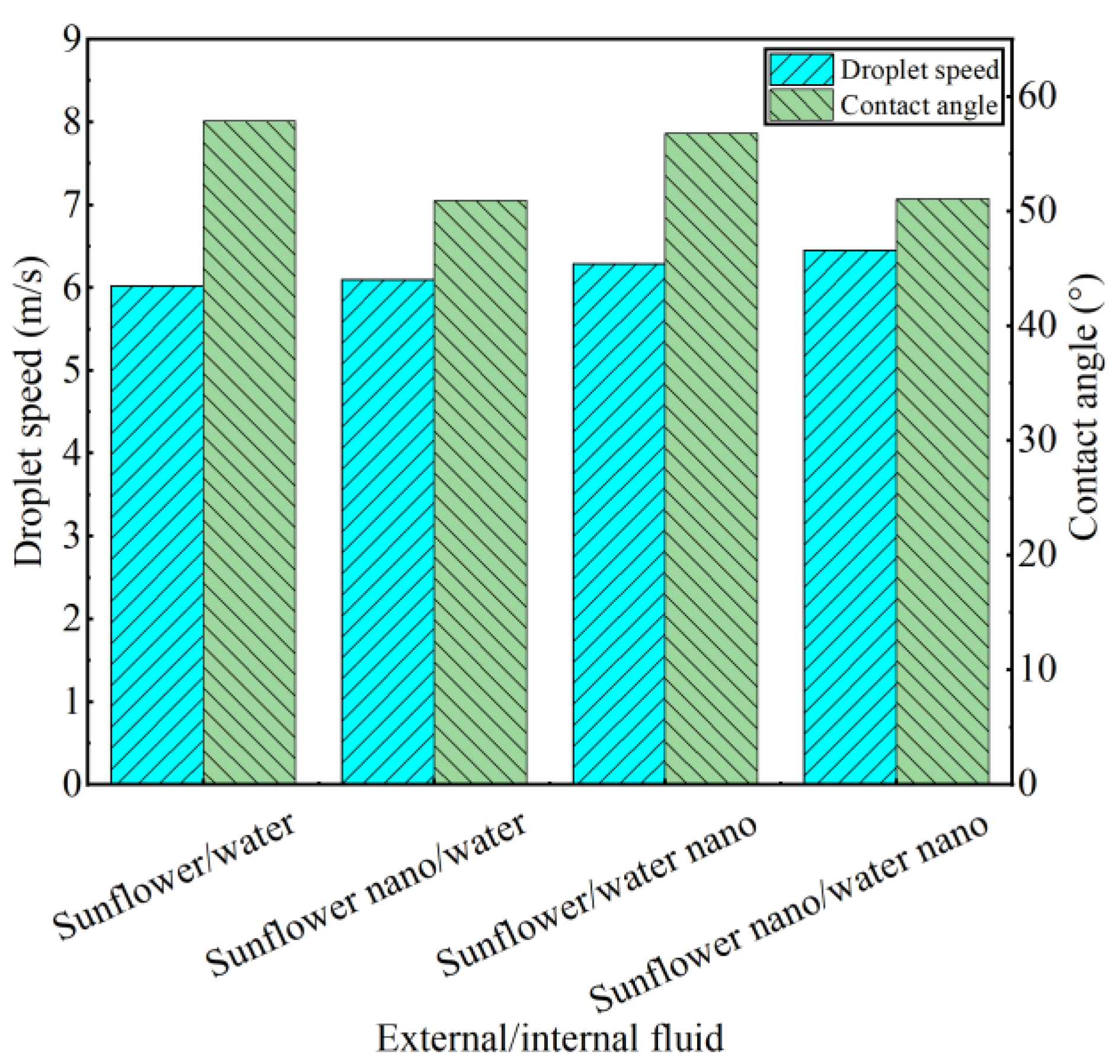

2.2. Atomization Current, Droplet Speed and Electrowetting Contact Angle Testing

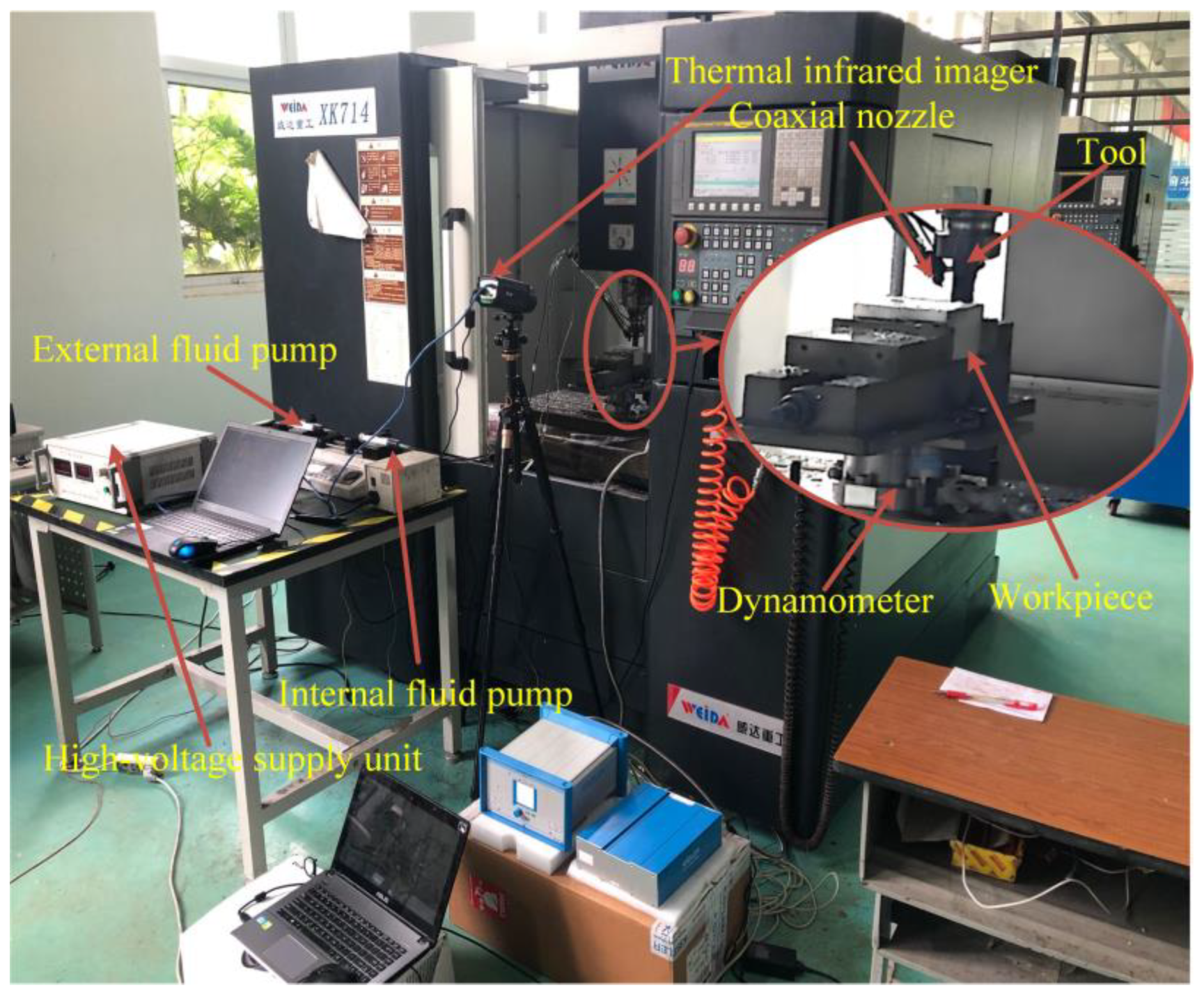

2.3. Milling Tests

3. Results and Discussion

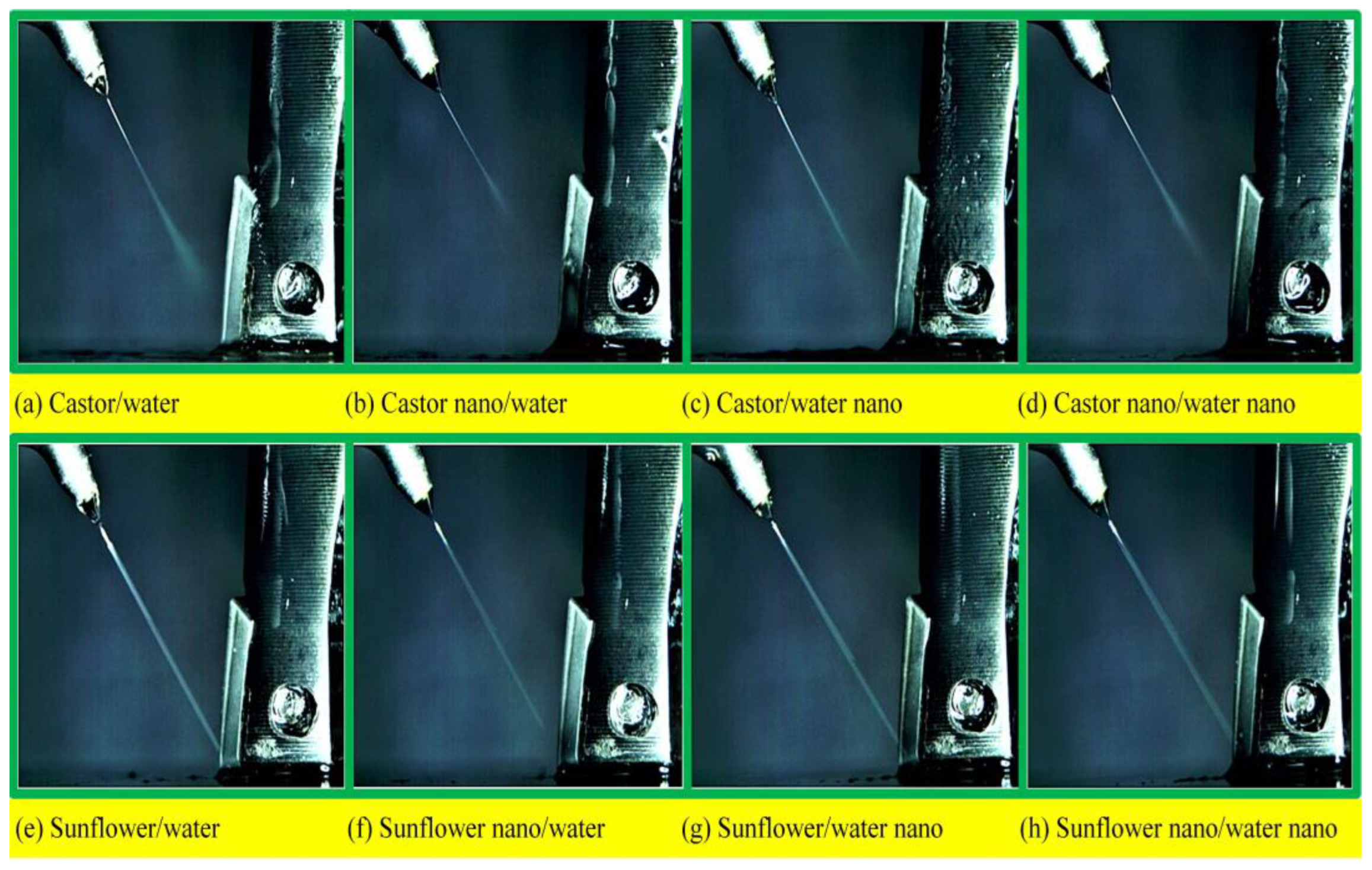

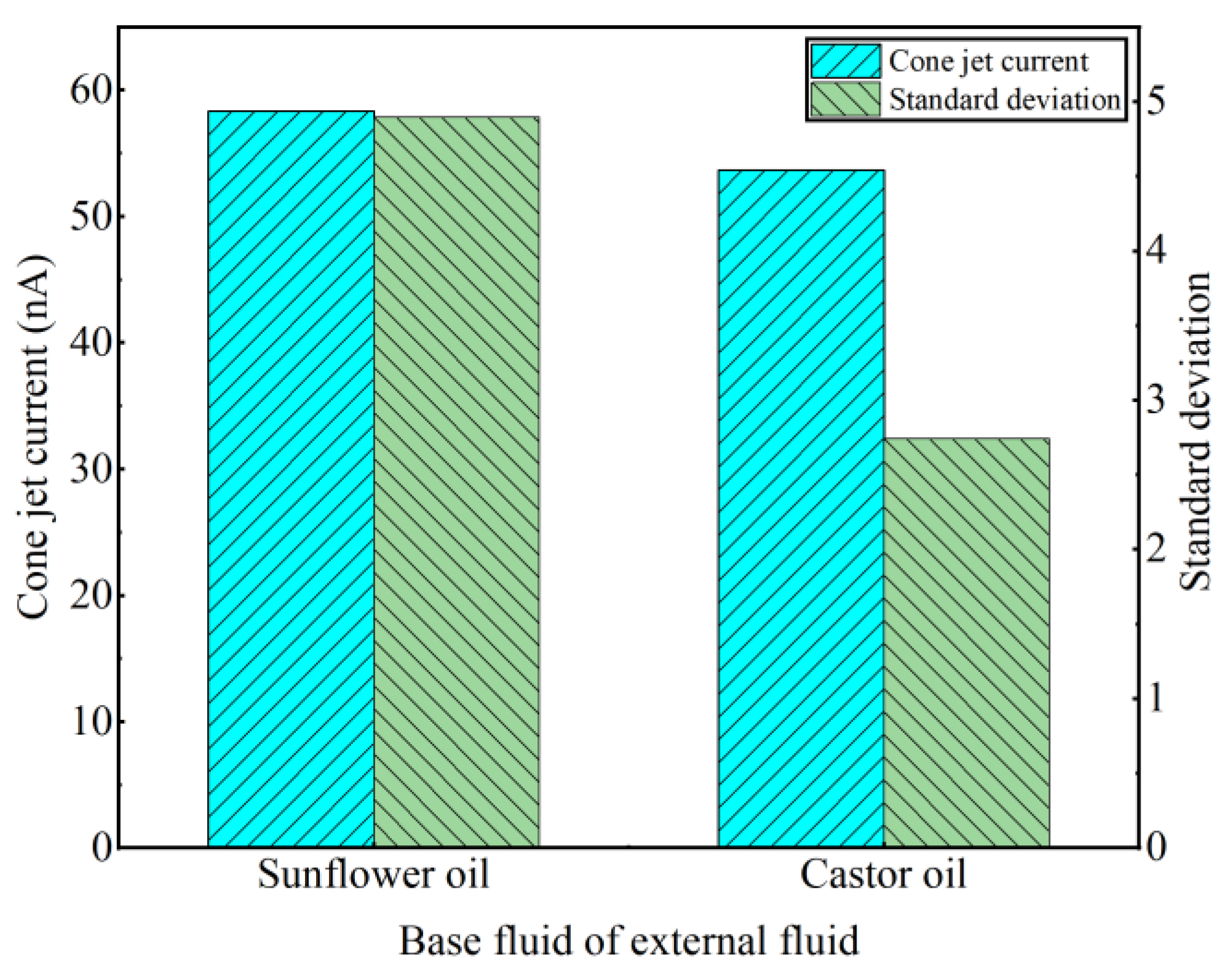

3.1. Cone Jet Morphology and Current

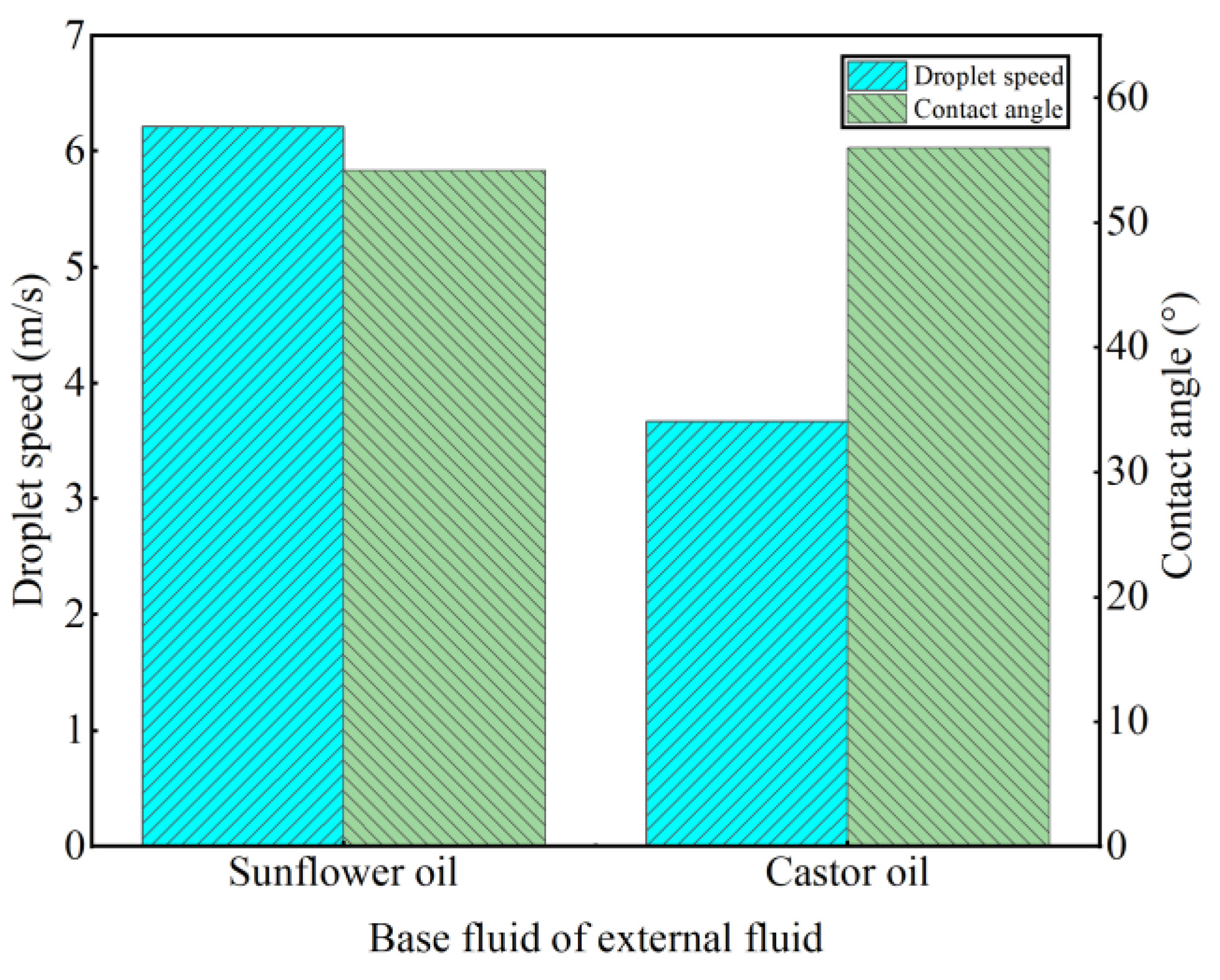

3.2. Droplet Speed and Electrowetting Contact Angle

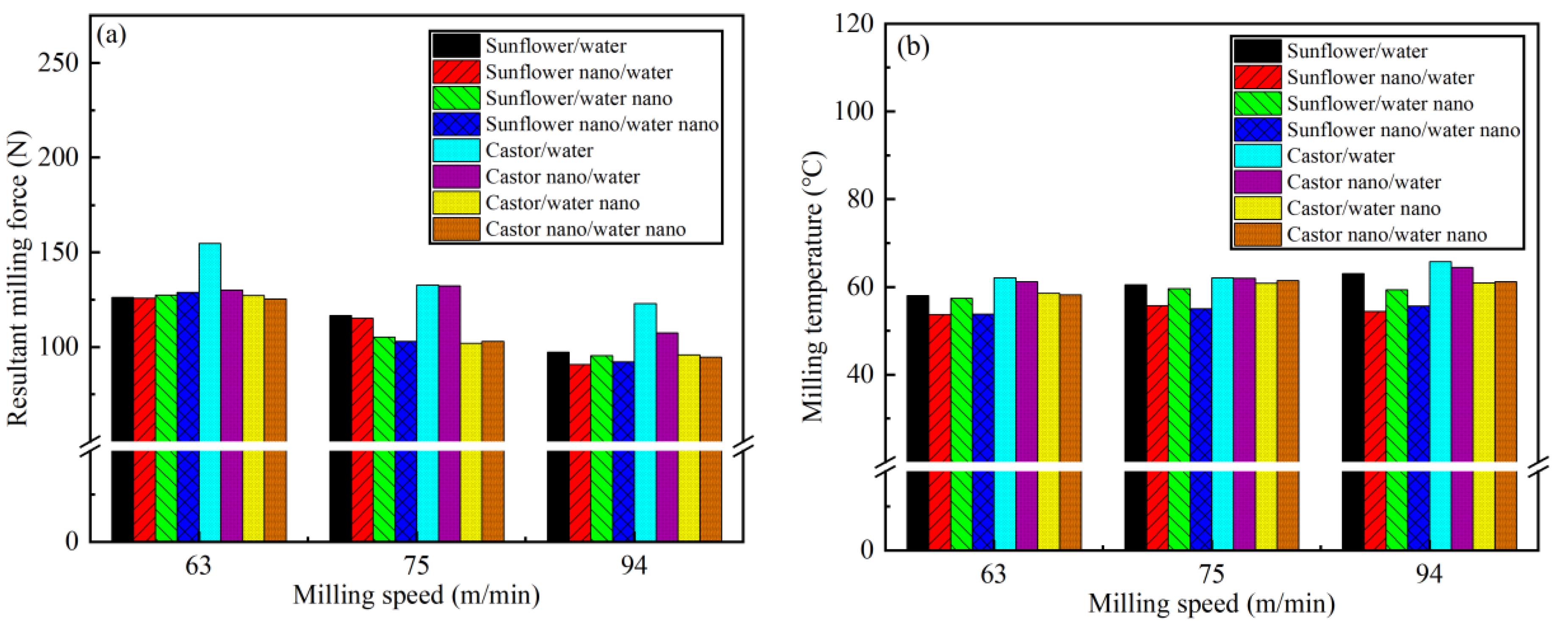

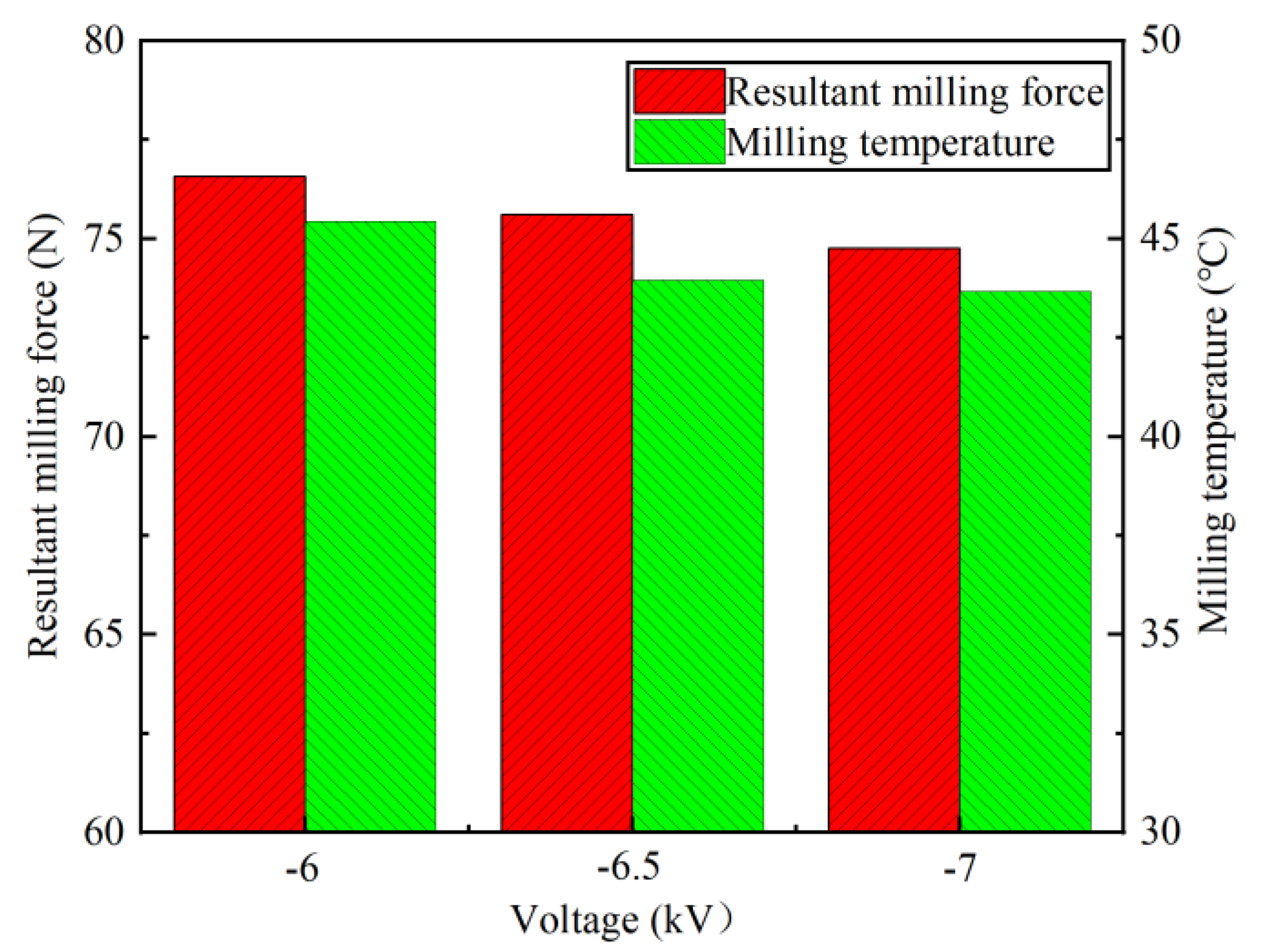

3.3. Milling Force and Milling Temperature

4. Conclusions

- As the base fluid, castor oil presented better end dispersibility of the cone jet than sunflower oil, which contributed to composite droplets better covering the machining zone. Moreover, compared to sunflower oil, the use of castor oil as the base fluid decreased the standard deviation of the cone jet current by 44%, showing higher stability of the cone jet.

- A 8.7% increase in cone jet current, a 69.3% increase in droplet speed, and a 33% decrease in electrowetting contact angle were achieved using sunflower oil as the base fluid compared with castor oil. Therefore, using sunflower oil as the base fluid provided better permeability of composite droplets.

- Sunflower oil was considered to be the suitable base fluid for NCES lubrication, owing to its suitable physical properties and fatty acid composition. The use of sunflower oil as the base fluid lowered the milling force and temperature by 5.4–10.8% and 6.3–7.9%, respectively, compared with the use of castor oil as the base fluid.

- Within the voltage range of the cone jet, raising the voltage brought about a 2.4% and 3.9% reduction in milling force and temperature, respectively, due to the improved charging performance and electrowetting property.

Author Contributions

Funding

Conflicts of Interest

References

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production—A review. J. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Sankaranarayanan, R.; Rajesh Jesudoss Hynes, N.; Senthil Kumar, J.; Krolczyk, G.M. A comprehensive review on research developments of vegetable-oil based cutting fluids for sustainable machining challenges. J. Manuf. Process. 2021, 67, 286–313. [Google Scholar]

- Tang, L.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Cao, H.; Liu, B.; Zhang, N.; Said, Z.; et al. Biological stability of water-based cutting fluids: Progress and application. Chin. J. Mech. Eng. 2022, 35, 3. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Krolczyk, G.M.; Mandal, U.K.; Mondal, S.P. Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 8, 249–280. [Google Scholar] [CrossRef]

- Boswell, B.; Islam, M.N.; Davies, I.J.; Ginting, Y.R.; Ong, A.K. A review identifying the effectiveness of minimum quantity lubrication (MQL) during conventional machining. Int. J. Adv. Manuf. Technol. 2017, 92, 321–340. [Google Scholar] [CrossRef]

- Chetan; Ghosh, S.; Venkateswara Rao, P. Application of sustainable techniques in metal cutting for enhanced machinability: A review. J. Clean. Prod. 2015, 100, 17–34. [Google Scholar] [CrossRef]

- An, Q.; Cai, C.; Zou, F.; Liang, X.; Chen, M. Tool wear and machined surface characteristics in side milling Ti6Al4V under dry and supercritical CO2 with MQL conditions. Tribol. Int. 2020, 151, 106511. [Google Scholar] [CrossRef]

- Cai, C.; Liang, X.; An, Q.; Tao, Z.; Ming, W.; Chen, M. Cooling/lubrication performance of dry and supercritical CO2-based minimum quantity lubrication in peripheral milling Ti-6Al-4V. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 405–421. [Google Scholar] [CrossRef]

- Wickramasinghe, K.C.; Sasahara, H.; Rahim, E.A.; Perera, G.I.P. Recent advances on high performance machining of aerospace materials and composites using vegetable oil-based metal working fluids. J. Clean. Prod. 2021, 310, 127459. [Google Scholar] [CrossRef]

- Shah, R.; Shirvani, K.A.; Przyborowski, A.; Pai, N.; Mosleh, M. Role of nanofluid minimum quantity lubrication (NMQL) in machining application. Lubricants 2022, 10, 266. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, A.K.; Katiyar, J.K. State-of-the-art in sustainable machining of different materials using nano minimum quality lubrication (NMQL). Lubricants 2023, 11, 64. [Google Scholar] [CrossRef]

- Chatha, S.S.; Pal, A.; Singh, T. Performance evaluation of aluminium 6063 drilling under the influence of nanofluid minimum quantity lubrication. J. Clean. Prod. 2016, 137, 537–545. [Google Scholar] [CrossRef]

- Pal, A.; Chatha, S.S.; Sidhu, H.S. Experimental investigation on the performance of MQL drilling of AISI 321 stainless steel using nano-graphene enhanced vegetable-oil-based cutting fluid. Tribol. Int. 2020, 151, 106508. [Google Scholar] [CrossRef]

- Li, M.; Yu, T.; Zhang, R.; Yang, L.; Li, H.; Wang, W. MQL milling of TC4 alloy by dispersing graphene into vegetable oil-based cutting fluid. Int. J. Adv. Manuf. Technol. 2018, 99, 1735–1753. [Google Scholar] [CrossRef]

- Huang, W.T.; Wu, D.H.; Lin, S.P.; Liu, W.S. A combined minimum quantity lubrication and MWCNT cutting fluid approach for SKD 11 end milling. Int. J. Adv. Manuf. Technol. 2016, 84, 1697–1704. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Yang, M.; Jia, D.; Wang, Y.; Li, B.; Hou, Y.; Zhang, N.; Wu, Q. Experimental evaluation of cooling performance by friction coefficient and specific friction energy in nanofluid minimum quantity lubrication grinding with different types of vegetable oil. J. Clean. Prod. 2016, 139, 685–705. [Google Scholar] [CrossRef]

- Gupta, M.K.; Sood, P.K.; Sharma, V.S. Optimization of machining parameters and cutting fluids during nano-fluid based minimum quantity lubrication turning of titanium alloy by using evolutionary techniques. J. Clean. Prod. 2016, 135, 1276–1288. [Google Scholar] [CrossRef]

- Su, Y.; Gong, L.; Li, B.; Liu, Z.; Chen, D. Performance evaluation of nanofluid MQL with vegetable-based oil and ester oil as base fluids in turning. Int. J. Adv. Manuf. Technol. 2016, 83, 2083–2089. [Google Scholar] [CrossRef]

- Xu, W.; Li, C.; Zhang, Y.; Ali, H.M.; Sharma, S.; Li, R.; Yang, M.; Gao, T.; Liu, M.; Wang, X.; et al. Electrostatic atomization minimum quantity lubrication machining: From mechanism to application. Int. J. Extrem. Manuf. 2022, 4, 042003. [Google Scholar] [CrossRef]

- Maski, D.; Durairaj, D. Effects of electrode voltage, liquid flow rate, and liquid properties on spray chargeability of an air-assisted electrostatic-induction spray-charging system. J. Electrost. 2010, 68, 152–158. [Google Scholar] [CrossRef]

- Reddy, N.S.K.; Nouari, M.; Yang, M. Development of electrostatic solid lubrication system for improvement in machining process performance. Int. J. Mach. Tools Manuf. 2010, 50, 789–797. [Google Scholar] [CrossRef]

- Reddy, N.S.K.; Yang, M. Development of an electro static lubrication system for drilling of SCM 440 steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2010, 224, 217–224. [Google Scholar] [CrossRef]

- Su, Y.; Lu, Q.; Yu, T.; Liu, Z.; Zhang, C. Machining and environmental effects of electrostatic atomization lubrication in milling operation. Int. J. Adv. Manuf. Technol. 2019, 104, 2773–2782. [Google Scholar] [CrossRef]

- López-Herrera, J.M.; Barrero, A.; López, A.; Loscertales, I.G.; Márquez, M. Coaxial jets generated from electrified Taylor cones. Scaling laws. J. Aerosol Sci. 2003, 34, 535–552. [Google Scholar] [CrossRef]

- Su, Y.; Jiang, H.; Liu, Z. A study on environment-friendly machining of titanium alloy via composite electrostatic spraying. Int. J. Adv. Manuf. Technol. 2020, 110, 1305–1317. [Google Scholar] [CrossRef]

- Su, Y.; Gao, W.; Jiang, H.; Liu, Z. Experimental investigation on the performance of composite electrostatic spraying milling using different inner/outer fluid combinations. Mach. Sci. Technol. 2021, 25, 1010–1030. [Google Scholar] [CrossRef]

- Iyappan, S.K.; Ghosh, A. Small quantity lubrication assisted end milling of aluminium using sunflower oil. Int. J. Precis. Eng. Manuf.-Green Technol. 2020, 7, 337–345. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Zhang, Y.; Yang, M.; Li, B.; Jia, D.; Hou, Y.; Mao, C. Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. J. Clean. Prod. 2016, 127, 487–499. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Ravi Sankar, M. Past and current status of eco-friendly vegetable oil based metal cutting fluids. Mater. Today Proc. 2017, 4, 3786–3795. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhang, Y.; Wang, Y.; Jia, D.; Yang, M. Grinding temperature and energy ratio coefficient in MQL grinding of high-temperature nickel-base alloy by using different vegetable oils as base oil. Chin. J. Aeronaut. 2016, 29, 1084–1095. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Spraying angle (°) | 35 |

| Spraying distance (mm) | 20 |

| Voltage (kV) | −6, −6.5, −7 |

| External fluid flow (mL/h) | 5 |

| Inner fluid flow (mL/h) | 1 |

| Milling speed (m/min) | 63, 75, 94, 157 |

| Feed per tooth (mm/z) | 0.1 |

| Axial cutting depth (mm) | 1 |

| Radial cutting depth (mm) | 0.5 |

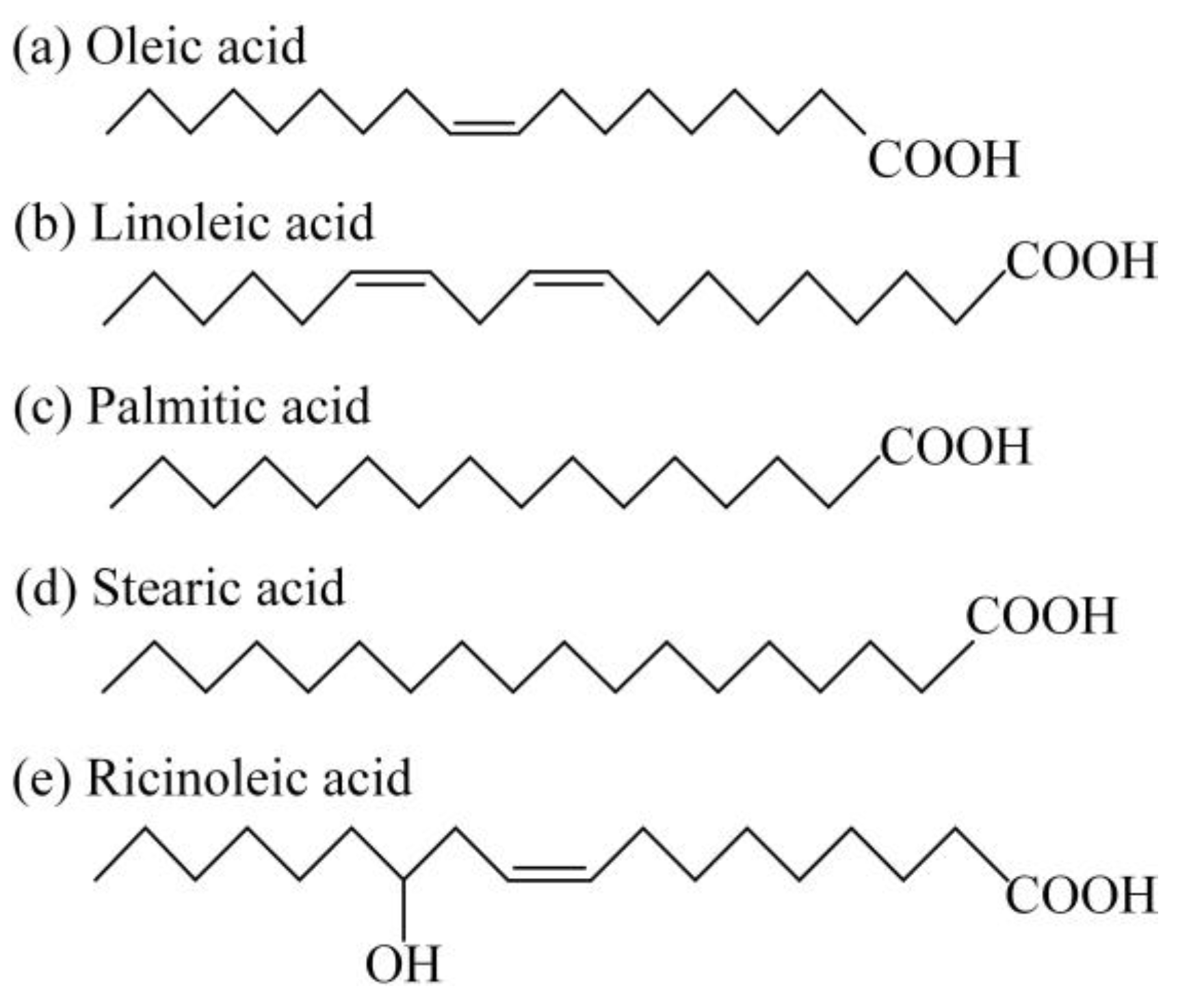

| Fatty Acid | Castor Oil (%) | Sunflower Oil (%) |

|---|---|---|

| Oleic acid | 2.82 | 28.76 |

| Linoleic acid | 3.74 | 50.48 |

| Palmitic acid | 0.72 | 11.24 |

| Stearic acid | 0.64 | 6.48 |

| Ricinoleic acid | 90.85 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, Y.; Yang, Q.; Liu, P.; You, J. An Experimental Investigation on the Effects of the Base Fluid of External Fluid and Voltage on the Milling Performance of Nanofluid Composite Electrostatic Spraying. Lubricants 2023, 11, 447. https://doi.org/10.3390/lubricants11100447

Su Y, Yang Q, Liu P, You J. An Experimental Investigation on the Effects of the Base Fluid of External Fluid and Voltage on the Milling Performance of Nanofluid Composite Electrostatic Spraying. Lubricants. 2023; 11(10):447. https://doi.org/10.3390/lubricants11100447

Chicago/Turabian StyleSu, Yu, Qingxiang Yang, Pan Liu, and Jiaxi You. 2023. "An Experimental Investigation on the Effects of the Base Fluid of External Fluid and Voltage on the Milling Performance of Nanofluid Composite Electrostatic Spraying" Lubricants 11, no. 10: 447. https://doi.org/10.3390/lubricants11100447

APA StyleSu, Y., Yang, Q., Liu, P., & You, J. (2023). An Experimental Investigation on the Effects of the Base Fluid of External Fluid and Voltage on the Milling Performance of Nanofluid Composite Electrostatic Spraying. Lubricants, 11(10), 447. https://doi.org/10.3390/lubricants11100447