1. Introduction

AISI 4340 steel, which contains elements such as nickel, molybdenum, and chromium in different proportions, is a commercial steel known for its good corrosion resistance, hardenability, ductility, and high strength [

1]. It finds applications in various fields such as the aerospace industry, automotive industry, power plants, maritime and defense industries, petroleum and gas industry, and weapons industry, especially after undergoing different heat treatments [

2]. Considering the areas of use of this material, it is classified as a challenging alloy due to its high strength and low thermal conductivity. Consequently, excessive heating occurs in the machining zone, leading to issues such as poor surface finish and excessive tool wear. Cooling of the machining zone is of paramount importance to address the problems caused by excessive heat. Many studies have been conducted to optimize cutting parameters of AISI 4340 alloy steel and improve the quality of the machined surface [

3,

4,

5,

6]. In these studies, researchers have focused on reducing surface roughness to ensure the integrity of the machined surface, minimizing tool wear and the resulting increase in cutting forces, reducing power consumption, enhancing machining efficiency, optimizing cutting parameters such as cutting speed and feed rate, as well as controlling parameters such as cooling and lubrication methods, and exploring environmentally friendly green manufacturing [

7].

The limited availability of resources worldwide necessitates optimization in production and environmental aspects. However, the increasing demand for prosperity in developing societies leads to increased resource consumption. As resource consumption rises, it becomes imperative to minimize environmental pollution and harmful emissions. Similarly, in the field of metalworking, particularly in chip manufacturing, the growing importance of human health and environmental awareness necessitates new studies on the use of cutting fluids [

8]. Compared to traditional methods, the cost of lubricating/cooling cutting fluids is estimated to be around 17% of the total production costs within machining. Besides the high cost, the environmental and health hazards associated with these fluids have prompted researchers to explore new cooling techniques [

9,

10].

Traditionally, abundant cutting fluid is used when machining certain materials. However, this approach increases component costs and energy consumption. Therefore, researchers have found this a compelling reason to explore alternative lubrication–cooling strategies to enhance cutting performance. In a study by Gong et al. [

11], machining of Inconel 718 alloy was carried out under cryo, dry, wet, MQL, and nanofluid MQL conditions. Minimum quantity lubrication (MQL) refers to the mixture of pressurized air in the form of fine droplets that atomize and create a spray of a small quantity of lubricating liquid in the cutting zone. The intensity and quantity of the aerosol cloud can be controlled using various valves [

12]. The application of MQL in machining operations has demonstrated various benefits, including limited environmental impact compared to the abundant use of traditional cutting fluids, reduced production costs, and increased worker safety. However, MQL has its limitations in terms of cooling function due to the inability to completely limit heat generation in both primary and secondary machining zones, mainly because of the lower oil flow rate. Hence, there is a need to enhance cutting performance in MQL processes, and hybrid nanofluid-assisted MQL applications have recently become important research trends to improve MQL efficiency [

13,

14]. For a lubrication system using MQL and nano-MQL to be effective in cutting, the quantity of liquid delivered to the work zone per minute and the air pressure, as well as the type and quantity of nano material added to the cutting fluid, are important parameters. Patole and Kulkarni optimized cutting parameters by adding 0.02% MWCNT to the cutting fluid during the turning of AISI 4340 steel. The results indicated that the nano-fluid coolant was highly dependent on the parameters, with flow rate and pressure following suit. The optimal values for these parameters were determined to be 5 bars of pressure and a flow rate of 140 mL/min. They claimed that using MWCNT-doped nano-MQL systems could reduce tool wear and achieve good surface roughness [

15]. Palanisamy et al. investigated the effect of applying high-pressure cutting fluid to the cutting zone during the machining of titanium alloys. They achieved better surface quality on the machined material and a longer tool life. The study also revealed that cooling fluids at different pressures caused significant changes in chip morphology [

16]. In a study by Ramanan et al., nano fluids with higher thermal conductivity compared to traditional cutting fluids were used in the MQL system to investigate their effect on cutting parameters [

17].

Studies on cooling fluids with minimal environmental impact and workplace safety concerns continue from the perspective of operators [

18]. In this regard, Chetan et al. compared Al

2O

3 nano particle-based nMQL with cryogenic cooling during the turning of Nimonic 90 alloy [

19].

Modern machining industries primarily prioritize factors such as workpiece dimensional accuracy, surface finish, cutting temperature, high production rates, extended cutting tool lifespan, cost savings, occupational health, machining performance, and energy consumption reduction, especially with a focus on environmental concerns. Surface roughness and noise pollution are crucial factors, and various studies in the literature have demonstrated that machining under minimum quantity lubrication (MQL) and nano-MQL conditions leads to improvements in energy consumption, surface roughness, sound intensity and cutting forces [

20,

21,

22].

Recently, numerous researchers have investigated the balance between cutting quality and power consumption during machining operations [

23]. The continuous rise in energy demand and the constraints associated with increasing carbon emissions have exerted significant pressure on manufacturing industries to save energy. In one study, Abbas et al. explored the surface roughness and power consumption of AISI 1045 steel when machined in a nanofluidized MQL environment [

24].

Sound levels during machining processes are parameters of particular concern for occupational health and safety. In the machinery manufacturing industry, especially in large facilities with numerous machine tools in close proximity, machine operators are exposed to high levels of noise. It is essential to mitigate noise levels in this context. Svenningsson and Tatar investigated sound generation using different cutting methods and inserts in a study on AISI 4340 material. Through their analysis and measurements, they proposed that the source of the sound is related to the vibration mode of the chip. Chip segmentation influences cutting forces, thereby increasing the current [

25]. Albayrak et al. investigated the effects of cutting parameters, including feed rate, spindle speed, and chip depth, at three levels, on the sound level and surface roughness during the turning of SAE 4140 alloy steel [

26]. In a study by Downey et al., the machining precision, tool wear performance, and surface roughness of AISI 4340 material were experimentally compared using the Acoustic Signals (AS) method with a high-speed steel (HSS) cutting tool and a physical vapor deposition (PVD) titanium carbon nitride (TiCN) insert. It was reported that as tool wear progressed over time, the emitted sound changed, and a unique sound signature characterizing wear was observed for each wear phase [

27].

As a result of the literature studies conducted, it has been observed that there is a notable lack of research on various aspects of AISI4340 alloy steel machining, including the cooling/lubrication conditions during machining, environmental consciousness in conjunction with green production, the impact of noise generated during work on both human health and cutting parameters, wear, surface roughness, and energy consumption. This study aims to contribute to previous research by statistically evaluating the reciprocal effects of dry, MQL, and nano-MQL cooling under different machining conditions, focusing on chip morphology. The study employs the Taguchi signal-to-noise (S/N) method to optimize tool wear, power consumption, sound level reduction, and surface roughness.

2. Materials and Methods

2.1. CNC Lathe, Workpiece and Cutting Tool

For the turning experiments of AISI 4340 steel, workability criteria such as surface roughness, tool wear, sound intensity, and the current during machining were measured. The experiments were conducted using a Yunnan Cy-K360n CNC Lathe with a maximum of 10,000 rpm and a 7.5 kW main motor power. Commercial AISI 4340 (DIN 34CrNiMo6) steel, in its as-received condition without any physical or chemical treatments (e.g., heat treatment, etc.), was used as the workpiece material. The round bar-shaped AISI 4340 (DIN 34CrNiMo6) steel was cut using a band saw with a cooling fluid to obtain dimensions of 360 mm in length and Ø135 mm in diameter. The chemical properties of the AISI 4340 alloy steel used in the experiments are provided in

Table 1, while the mechanical properties are given in

Table 2 [

28]. The cut workpiece was prepared for the experiments by performing surface and face turning to remove surface impurities and oxide layers, ensuring that the workpiece was clean before commencing the experiments. All experiments involved the machining of a Ø135 diameter. The CNC lathe machine and the workpiece used in the experiments are depicted in

Figure 1.

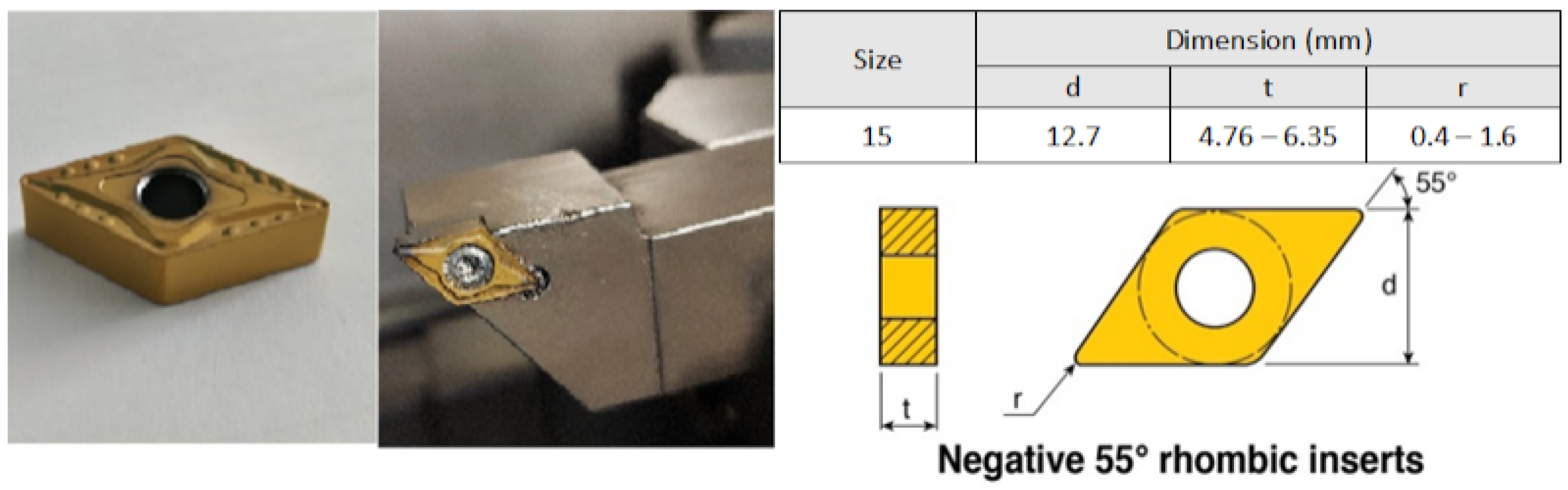

In the experiments, PVD-coated cutting inserts of TaeguTec brand, DNMG 150608 TT5080 type, were used. For each experiment, one face of the cutting insert was utilized and recorded for wear measurement. The cutting insert has approximate dimensions of 15 mm in width, 6 mm in thickness, and a corner radius of 0.8 mm. The dimensions and appearance of the cutting insert are provided in

Figure 2.

2.2. MQL System and Preparation of Nano Fluid

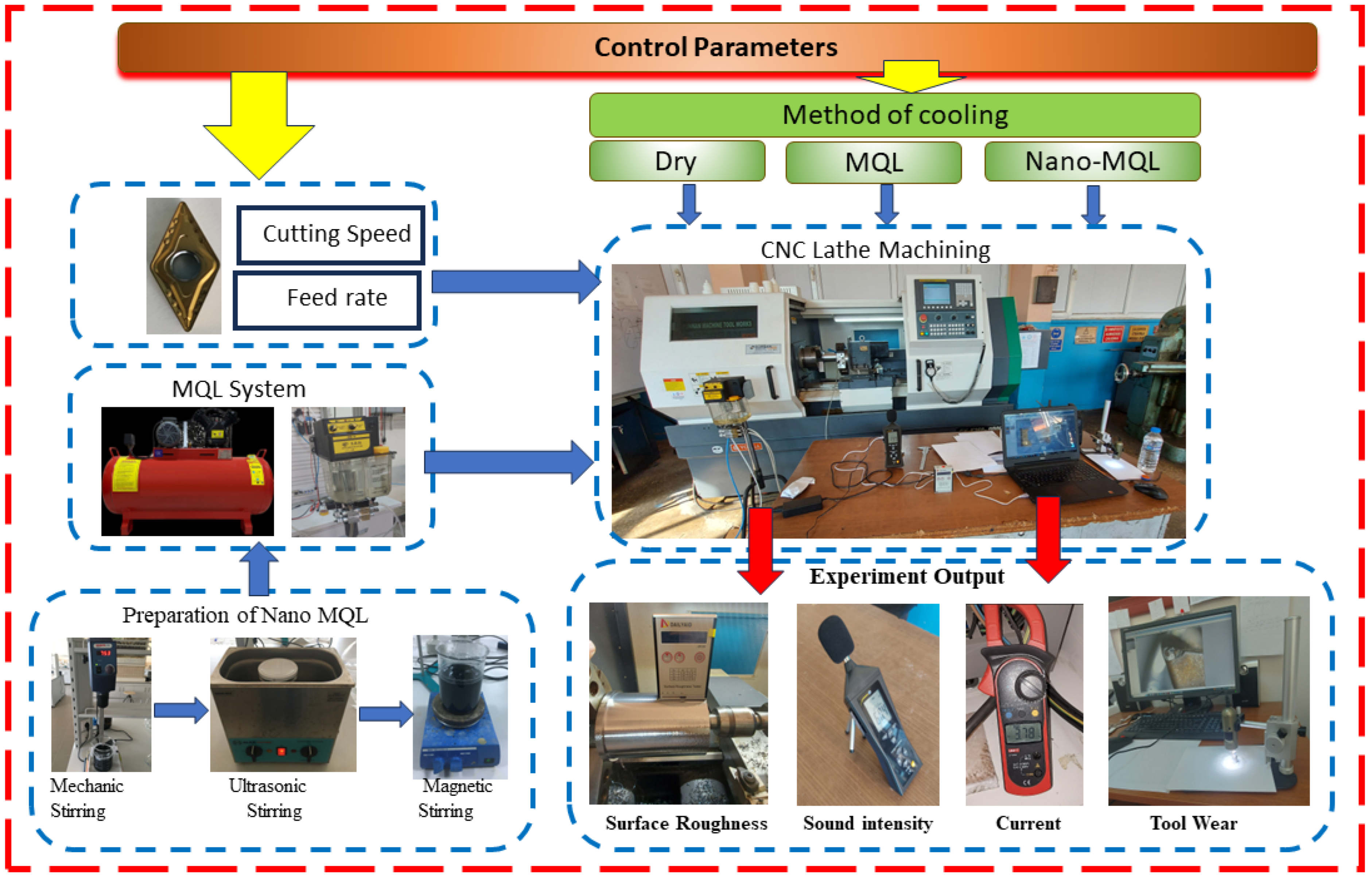

The primary objective of the MQL (minimum quantity lubrication) system is to achieve optimal chip removal from the workpiece under environmentally friendly conditions, taking into consideration factors such as cost, health, and the environment. In this process, water-based biodegradable lubricants, which are environmentally friendly, are atomized and sprayed into the cutting area under high pressure, reducing the heat generated between the chip and the tool and carrying it away from the cutting zone. In the experiments, the S.B.H. STN 15 MQL system, which operates within a range of 4–6 bar air pressure as shown in the schematic representation in

Figure 3, was used. The MQL flow rate varies in the literature between 60 and 300 mL/h. Several studies have reported improved surface roughness at higher flow rates [

29]. In accordance with the literature [

30], a flow rate of 100 mL/h was used in the experimental study.

2.3. Preparation of MQL System and Nano Fluid

Nano-fluids are a new class of fluids obtained by mixing nano-sized materials into the coolant fluid. In this study, multi-walled carbon nanotubes (MWCNT) with a diameter of 7 nm and a length of 5 μm were mixed with the cutting fluid. Triethanolamine was used as the cutting fluid. Triethanolamine is an environmentally friendly choice as it is a water-based chemical compound. Mixing was carried out by adding 1% by weight of MWCNT to 1 L of cutting fluid. The mixing process of the nanomaterial into the cutting fluid occurred in three stages (

Figure 4). In the first stage, the nanomaterial was weighed and then introduced into the cooling fluid, followed by mechanical stirring at 750 rpm for 1 h. This step was aimed at preventing the clumping of the nanomaterial within the liquid. In the second stage, ultrasonic mixing was performed for 1 h, and in the third stage, magnetic stirring was carried out at 1500 rpm for 2 h to prevent the settling of the nanomaterial. The mixed nanomaterial was directly used in the experiments to prevent any settling.

2.4. Measurement of Experimental Outputs

Surface roughness is one of the essential factors in machining operations on metals. The quality of the machined surface is significantly represented by surface roughness. In this study, ‘Ra’ was considered as the roughness parameter. Surface roughness values were measured using the Dailyaid DR100 model roughness measurement device. For these values, the arithmetic average of measurements taken from three different points immediately after the machining experiment was calculated. The samples were thoroughly cleaned with air before measurements. The measurement device was axially placed on the workpiece. To reduce measurement errors, three different points were selected along the same axis for all experiments. Sampling length and evaluation length for surface roughness values were set at 0.8 mm and 4 mm, respectively.

Sound is a significant factor in terms of environmental pollution. Therefore, in the experiments, the sound generated by the machine and during cutting was selected as a parameter. To obtain reliable data during measurements, ambient sounds were isolated. Initially, the CNC lathe was run without any cutting to determine the background noise level, and values above this level were identified as cutting sound data. PCE brand and 322A model sound measurement devices were used for measurements. The device has a measurement capacity within the frequency range of 30–130 dB and can capture data in the range of 1 s to 125 milliseconds.

The current value was measured using a UNI-T brand and UT202 model clamp ammeter. The device allows high-precision measurements with an extended current frequency. It has a 4000-count display and data-holding function, facilitating the analysis of measurement data. Due to its design, the clamp ammeter can only measure a single-phase current. Therefore, the phase going to the main spindle of the lathe was identified, and the clamp ammeter was mounted on this cable. During the experiment, the average of the varying current values was calculated.

The measurement of the cutting tool wear amounts was performed using a Dino-Lite digital microscope. After a specific length of cutting operation, the cutting tool was removed, and photographs of the worn surfaces of the cutting tools were taken with the microscope to measure the side wear amounts.

Detailed images of the control parameters and outputs for the CNC used in the experiments are provided in

Figure 4.

2.5. Cutting Condition and Design of Experiment

During chip removal operations, a significant amount of electrical energy is primarily consumed, depending on various cutting parameters. In this study, the impact of input parameters was investigated with a focus on environmental consciousness and minimizing power consumption during machining. Particularly, as outputs of an environmentally friendly machining operation, surface roughness, tool wear, and, current, sound intensity—a crucial factor for the environment—were selected as output parameters in the optimization of control parameters. The control parameters selected included cooling of method (MOC) cutting speed and feed rate, taking into account the influence of environmental factors on methods for cooling the cutting zone. The levels of the fundamental cutting parameters were chosen in accordance with the recommendations of the tool manufacturer and existing literature. Preliminary experiments were conducted to test the interaction between the machine, cutting tool, and workpiece. The selected parameters and levels are shown in

Table 3.

Experimental design is a method used to plan and conduct experiments. The Taguchi orthogonal array is a widely used statistical method for the analysis of process and product improvements. With this method, the best factors for obtaining the most optimal results with a small number of experiments can be determined. The Taguchi method has significant potential for the cost-effective analysis of experiments. Therefore, experiments were conducted using Taguchi’s L9 orthogonal array(

Table 4), which uses three factors at three levels, in order to achieve the best results from a series of experiments [

31,

32]. The impact levels of variables on the outputs were determined by applying variance analysis (ANOVA) to the experimental results with a 95% confidence interval. The experimental design and statistical analyses, according to the Taguchi method, were carried out using Minitab 20 software.

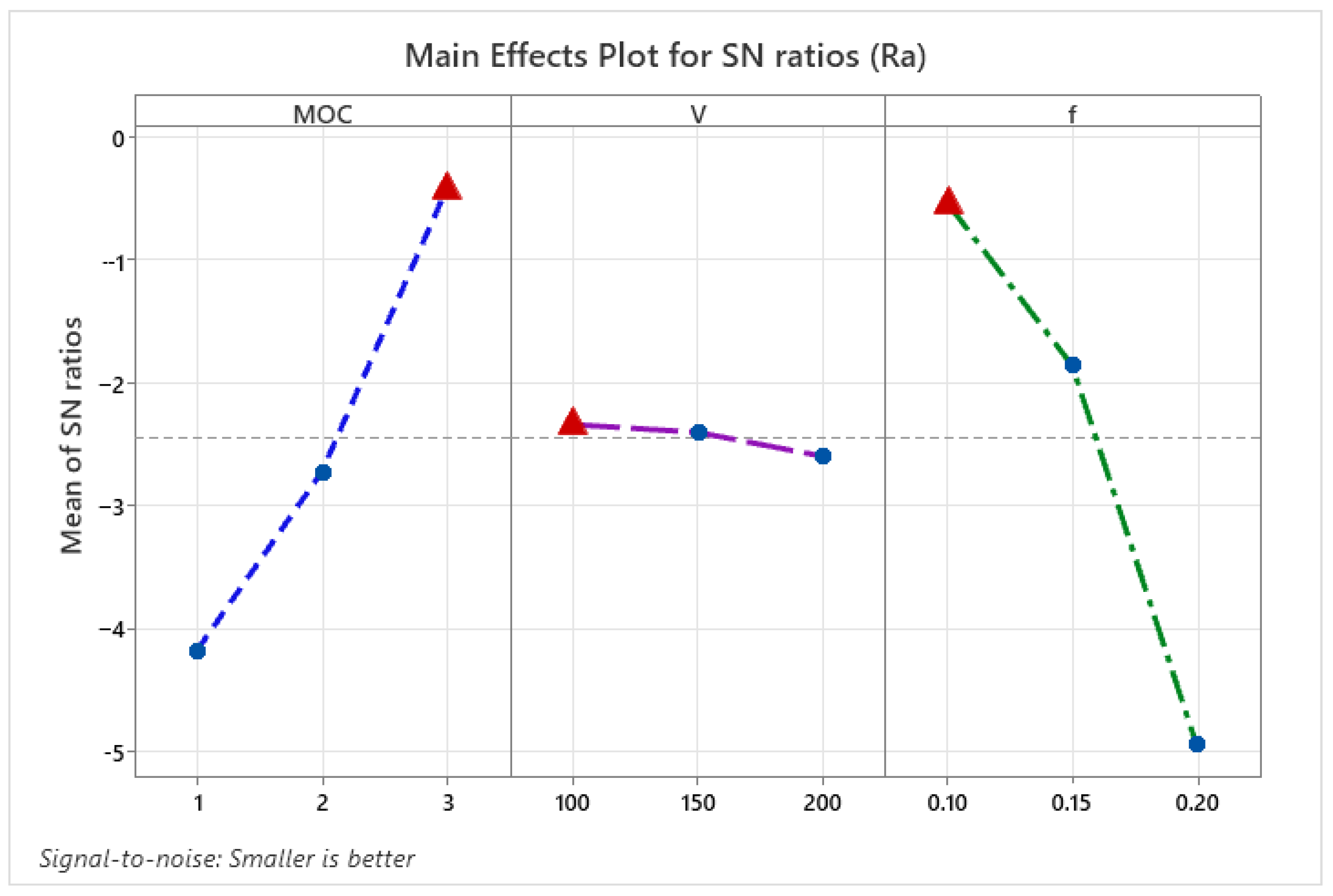

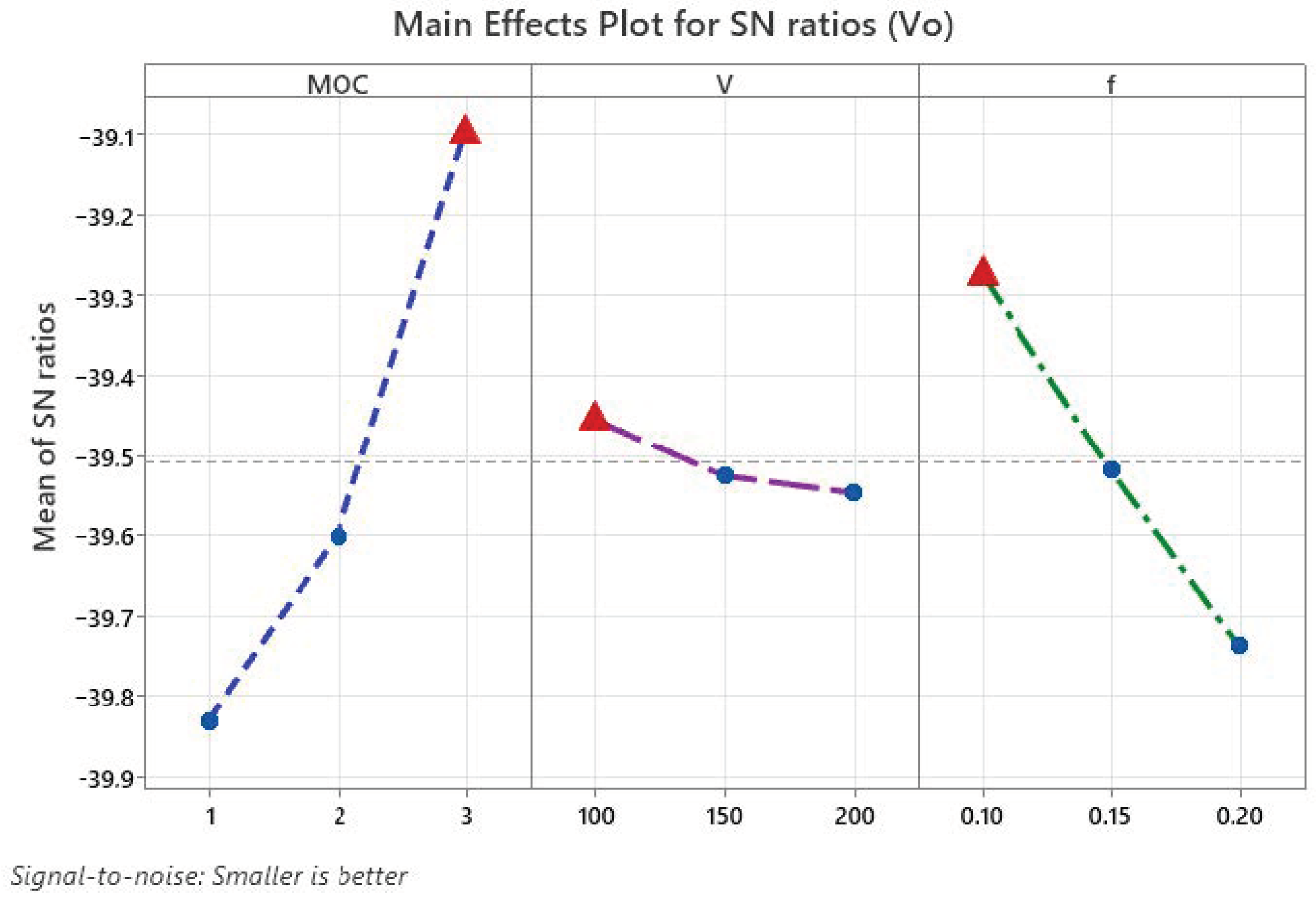

In this method, a statistical performance measure known as the signal-to-noise (S/N) ratio is used to analyze the results. The results obtained from the experiments are converted into signal-to-noise (S/N) ratios for evaluation. In the calculation of S/N ratios, three different methods, known as larger-the-better, smaller-the-better, and nominal-the-best, are used depending on the characteristic type. In determining the S/N values in this study, it was desired to minimize the SI values for sound intensity, minimize the (Ra) surface roughness for machining efficiency, minimize tool wear (Vb), and minimize power consumption represented by I (A). Therefore, the formula corresponding to the “smaller-the-better” principle given in Equation (1) was used [

33].

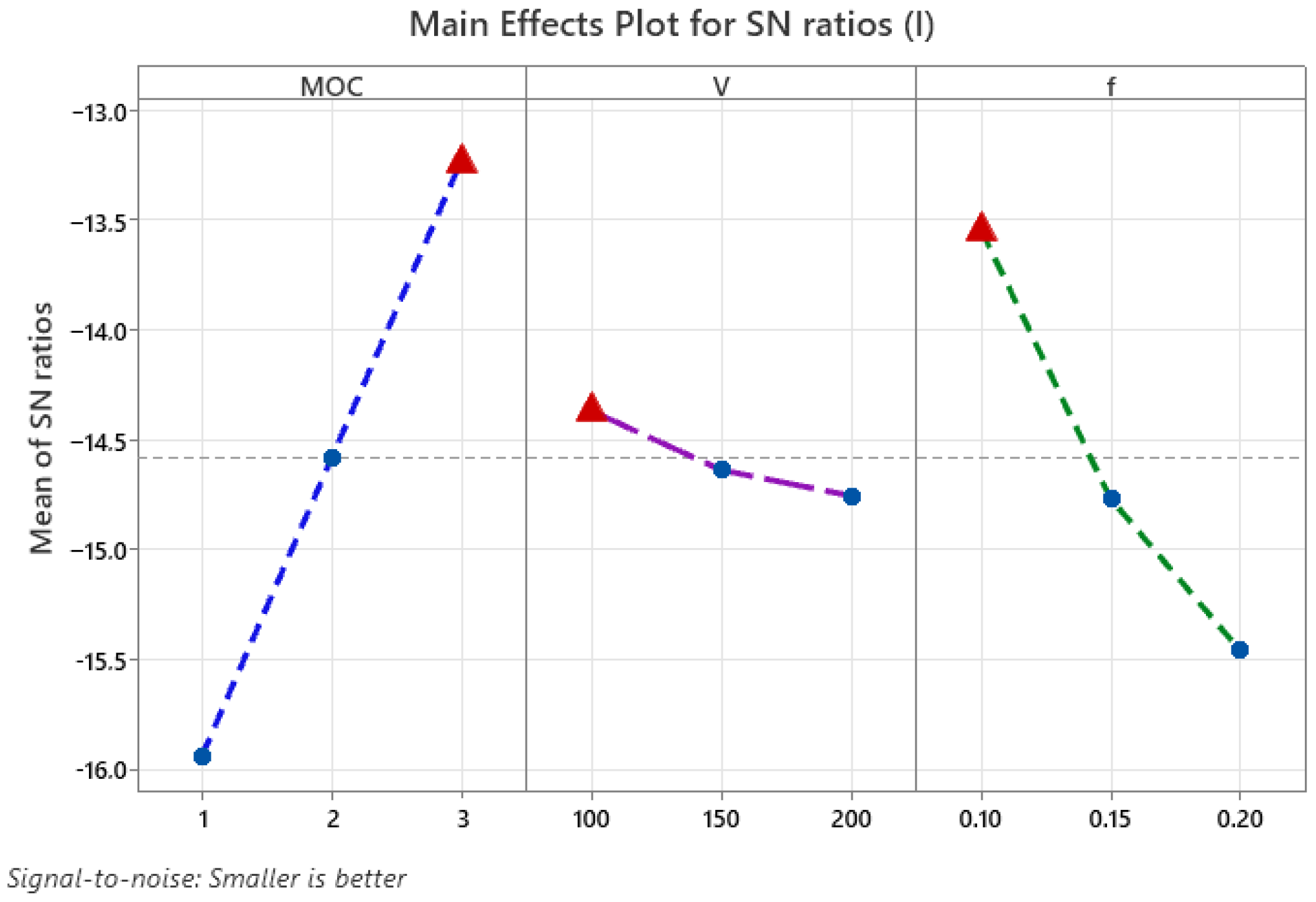

The objective here is to minimize the noise function, in other words, maximize the S/N ratio. Therefore, in the evaluations, the level with the highest S/N ratio among the calculated average S/N ratios for each parameter is used to determine the best result.

4. Conclusions

In this study, AISI 4340 alloy steel was subjected to turning under different cooling conditions using PVD-coated tools. Cutting parameters’ effects on tool wear, surface roughness, the current by the CNC, and ambient sound intensity were investigated in dry, MQL, and nano-MQL cutting processes.

The results obtained from the experiments can be summarized as follows:

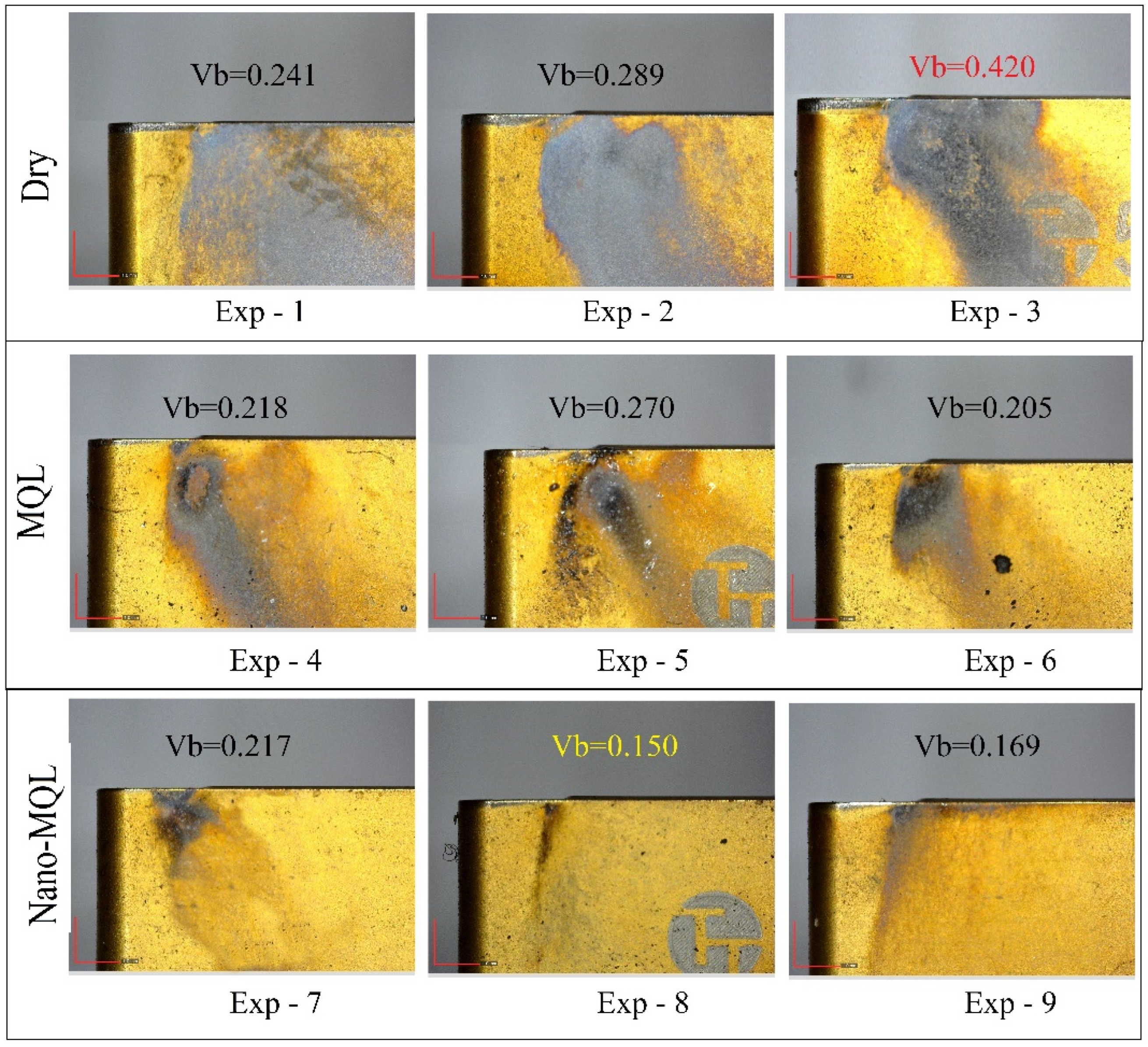

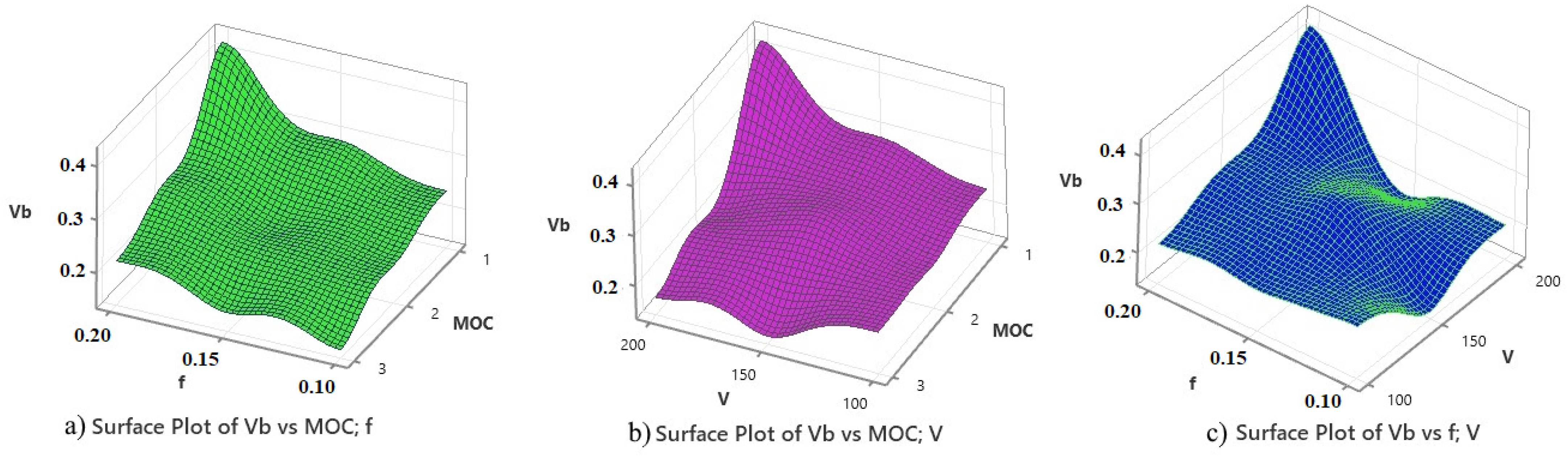

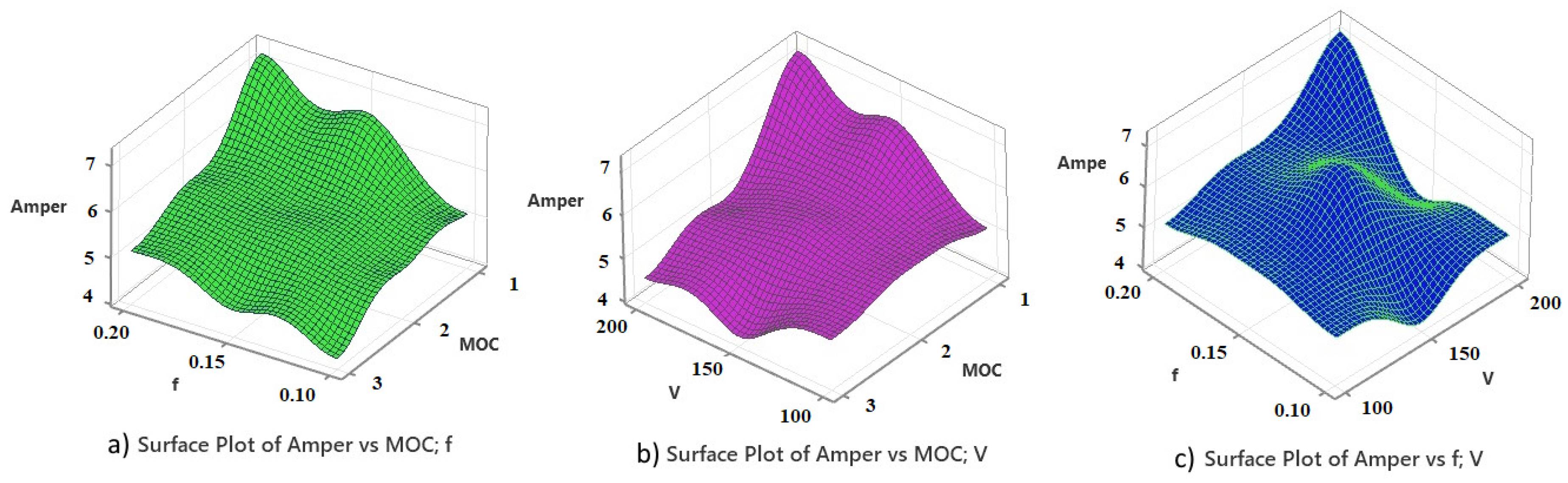

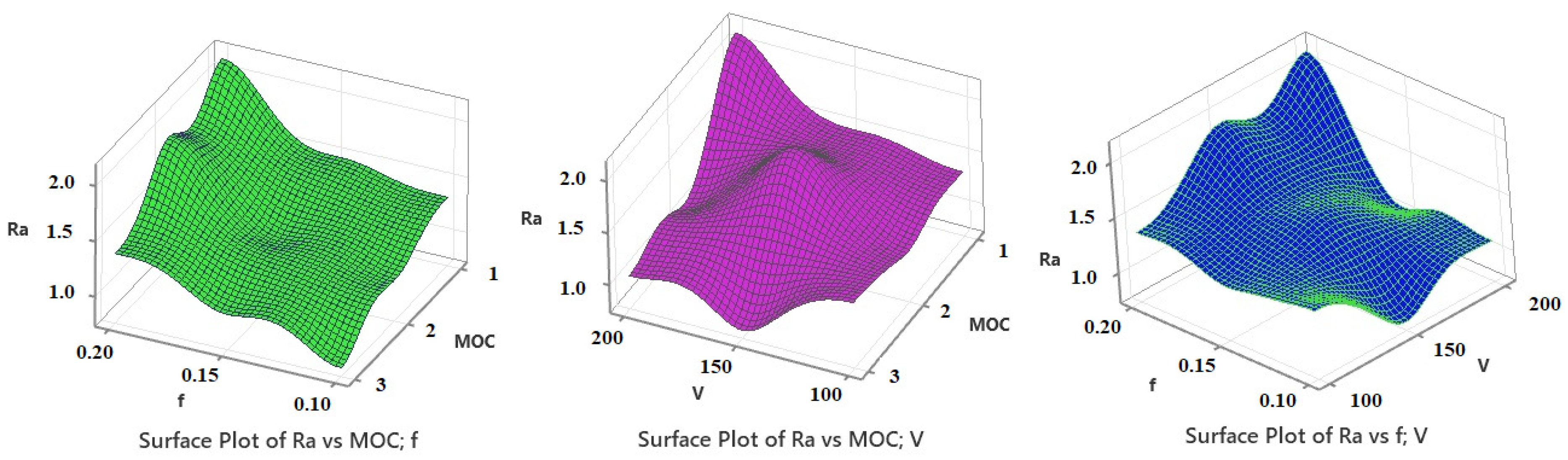

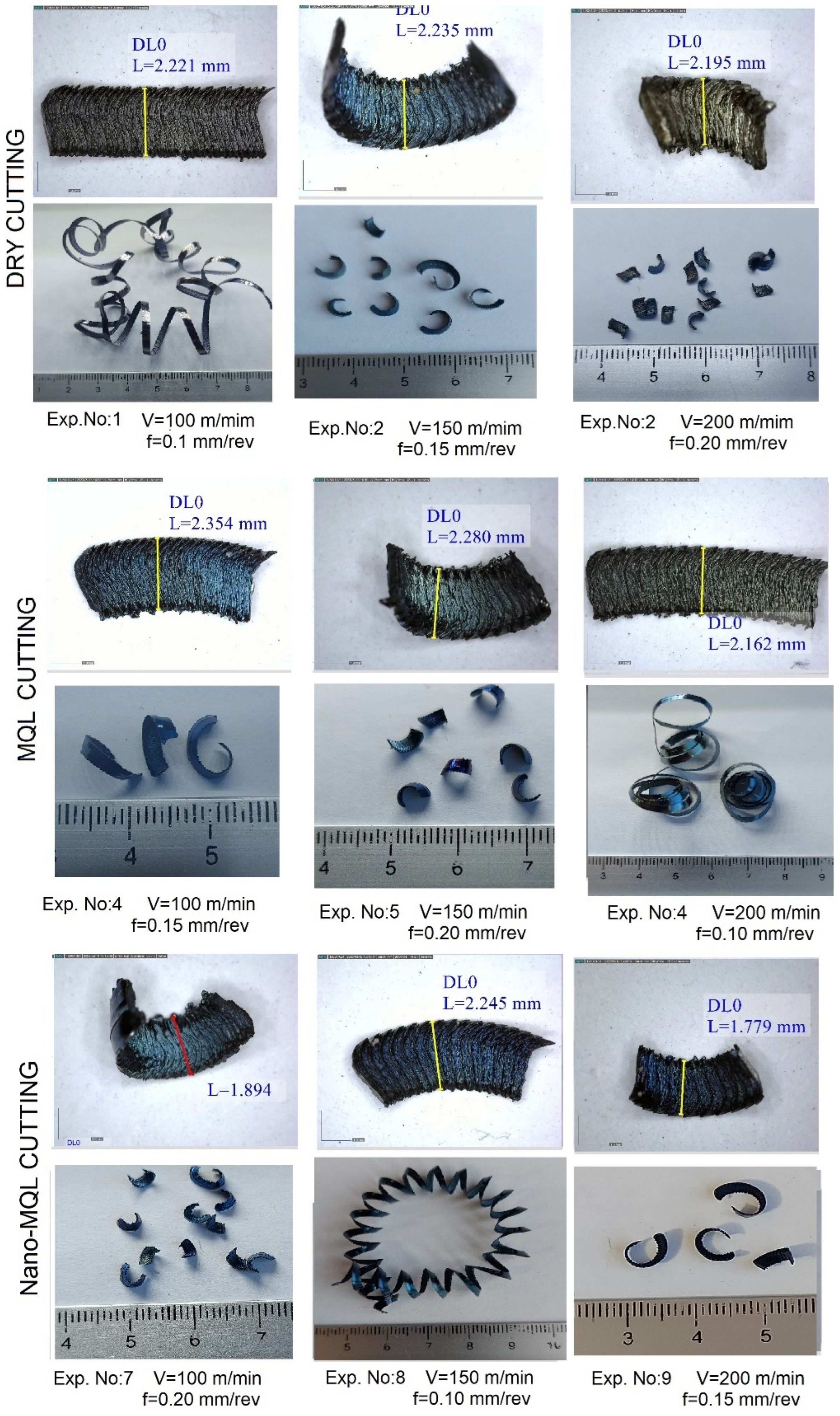

(1) The best values for all output parameters were achieved in experiment number 8 under the A3B2C1 conditions, with Vb = 0.15 mm, Ra = 0.81 µm, sound intensity of 88.1 dB, and a current value of I = 4.18 A;

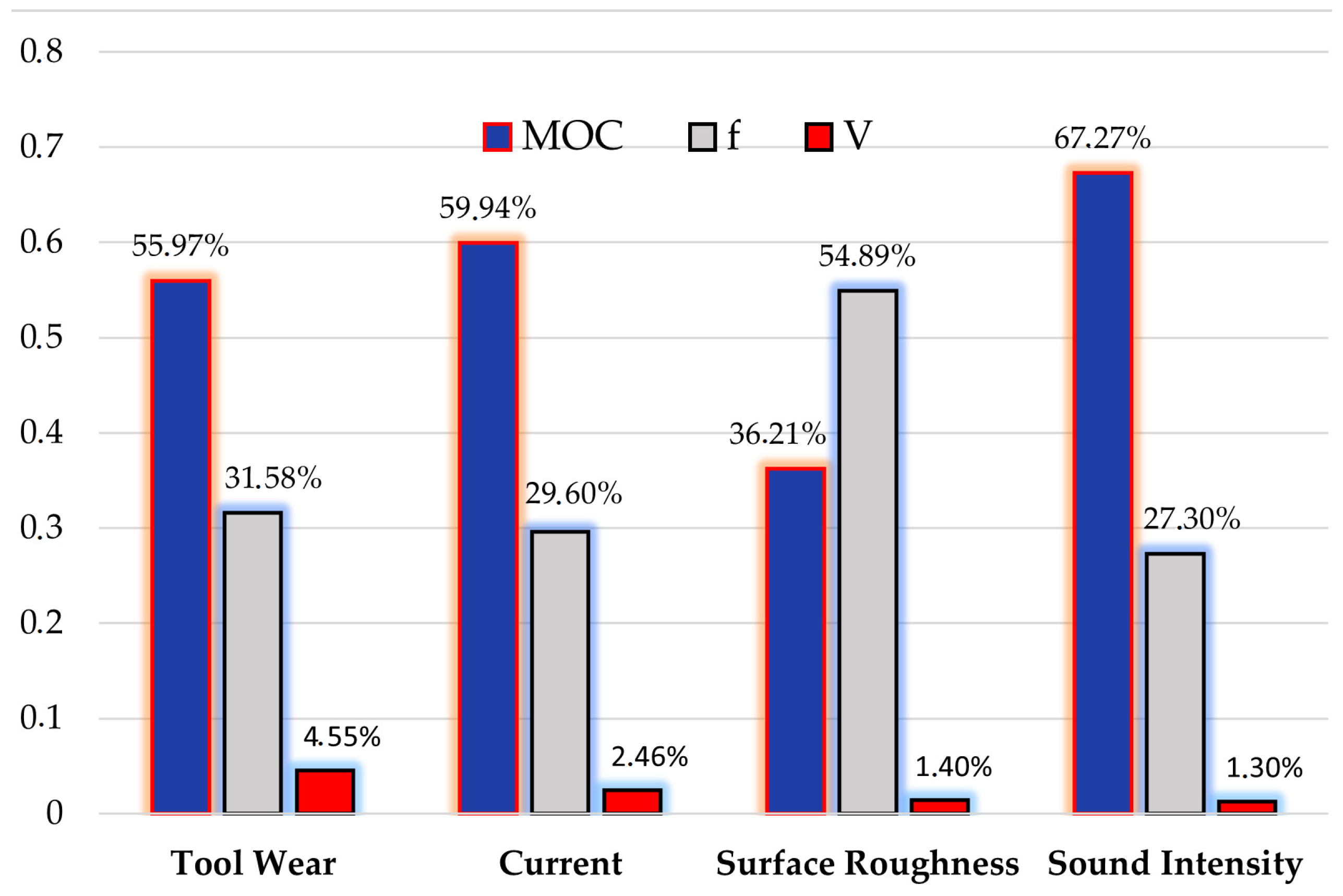

(2) The effects of cutting parameters on response variables were analyzed using the statistical method of ANOVA. The percentage contributions to the variation were as follows: MOC was the most influential factor with 55.97% for tool wear, 59.94% for current, 54.89% for surface roughness, and 67.27% for sound intensity. In this study, tool wear was modeled with an accuracy of 92.10%, current at 92.00%, surface roughness at 92.50%, and sound intensity at 95.87%;

(3) Flank wear was measured as tool wear using a microscope. Burn marks were generally observed on the cutting tools due to excessive heating. There was generally no sign of chipping or fracturing on the cutting edges, and uniform wear was observed in all tools. The highest wear occurred in experiment number 3, with Vb = 0.420 mm, under dry cutting conditions with V = 200 m/min and f = 0.2 mm/rev, while the lowest wear was observed in experiment number 8, with Vb = 0.150 mm, under nano-MQL conditions with V = 150 m/min and f = 0.1 mm/rev.

(4) Cutting parameters’ effects on tool wear, current, surface roughness, and sound intensity were determined using the Taguchi S/N ratio. According to the S/N ratio, the optimum cutting conditions were found to be A3B1C1 for all output parameters. Since these experimental conditions were not part of the L9 series, confirmation experiments were conducted under nano-MQL cooling and V = 100 m/min, f = 0.1 mm/rev cutting conditions. The results of the confirmation experiment showed an improvement of 13% in tool wear, 7% in current, 9% in surface roughness, and 8% in sound intensity compared to the normal experimental results.

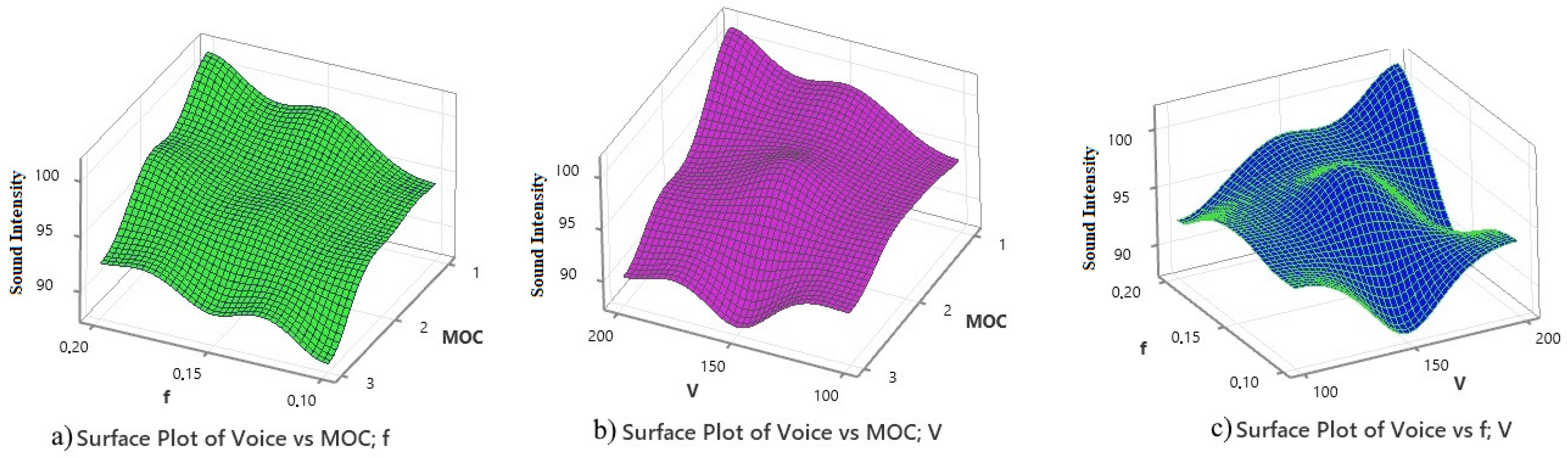

(5) When examining chip morphology, continuous chips with low feed rates and cutting conditions were obtained under dry cutting conditions, while with MQL and nano-MQL cooling, segmented chips with smaller radii were obtained at higher speeds;

(6) The use of nano-MQL coolant resulted in the lowest values for all output parameters. In dry cutting conditions with high cutting speeds and feed rates, tool wear increased due to excessive heating in the cutting zone. An increase in tool wear led to higher values for sound intensity and surface roughness. As the required cutting force increased, the current also tended to increase. There was a positive relationship between surface roughness, tool wear, sound intensity, and current. When one of these four values increased, the others also increased.

In conclusion, nano-MQL systems appear to have several advantages among the cooling/lubrication methods used in machining. However, during the experiments, it was observed that MWCNT, used as nanomaterial, had a tendency to adhere to all environments and atomize in the MQL spraying system, especially affecting the operator’s health. For the sustainability of the necessary environmental impact conditions, future studies should pay attention to these issues. Along with the resolution of such problems, it is anticipated that the nano-MQL system will contribute to environmental friendliness, cleaner production, and the improvement of desired machinability properties.

There are many studies in the literature on the optimization of tool wear and surface roughness, which form the basis of the cutting parameters of AISI 4340 steel. However, in addition to these, in terms of sustainability, energy efficiency under different cooling/lubrication conditions and reduction in sound emission (sound pollution) are important parameters in terms of green production. This study aims to analyze the effects of dry, MQL and nano-MQL conditions on the output parameters of AISI 4340 steel, which has an intensive use in dry, MQL and nano-MQL conditions, and to suggest the optimum parameters for researchers and the use of steel in industry. Again, different chip morphology outputs will also be helpful for those who will work on this subject.