Experimental Study on the Influence of Stearic Acid Additive on the Elastohydrodynamic Lubrication of Mineral Oil 2137

Abstract

:1. Introduction

2. Experimental

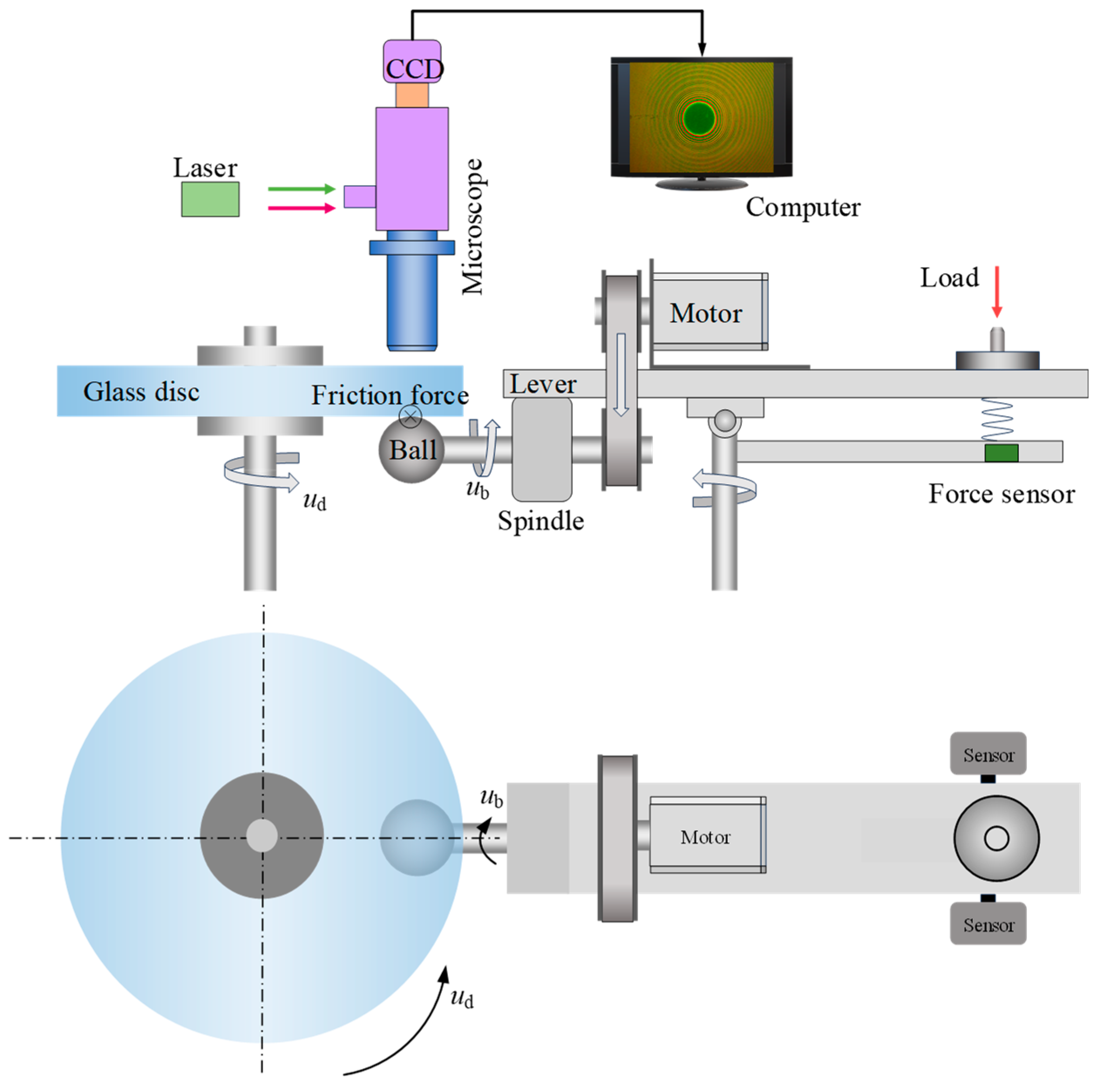

2.1. Experimental Apparatus and Scheme

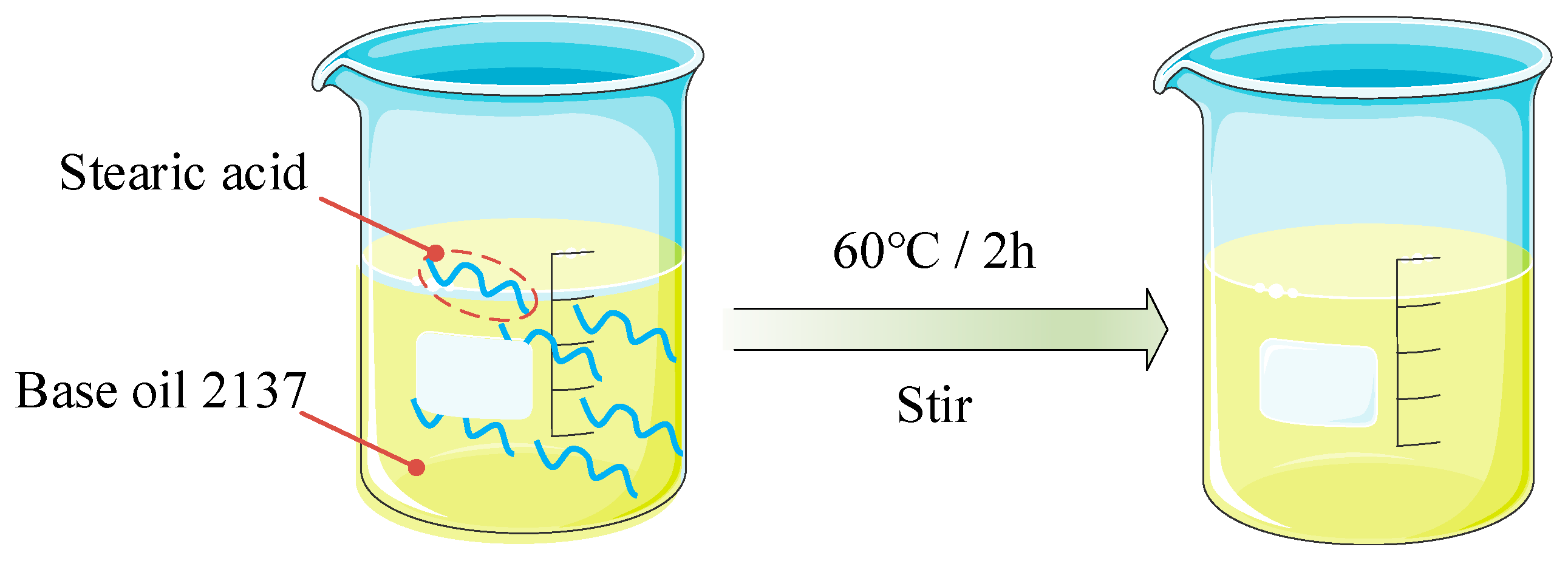

2.2. Experimental Conditions and Materials

3. Results and Discussion

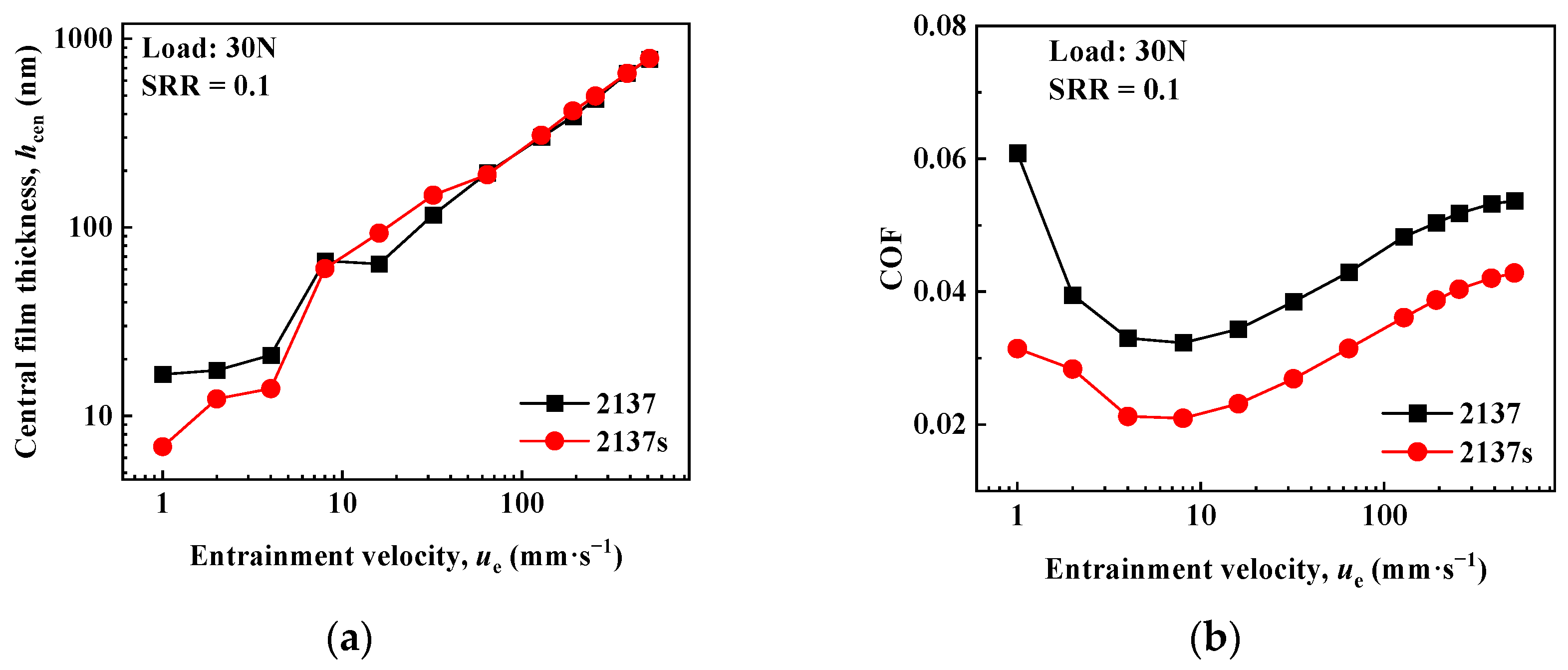

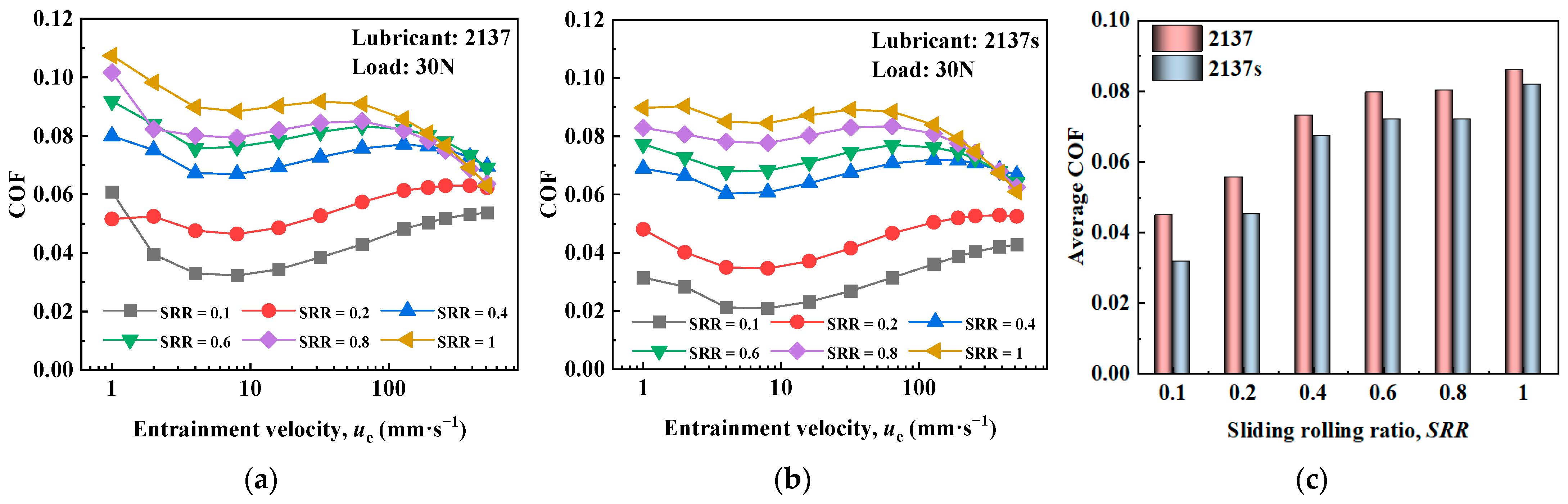

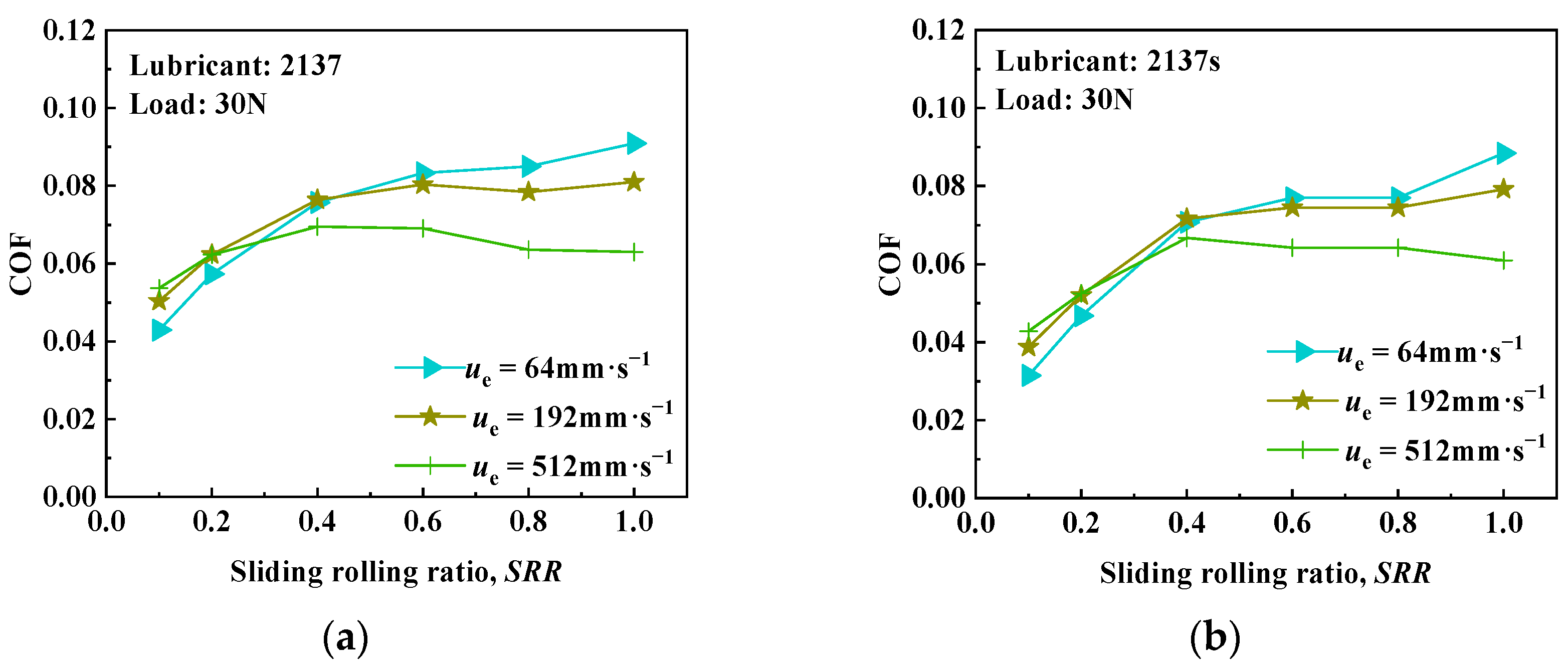

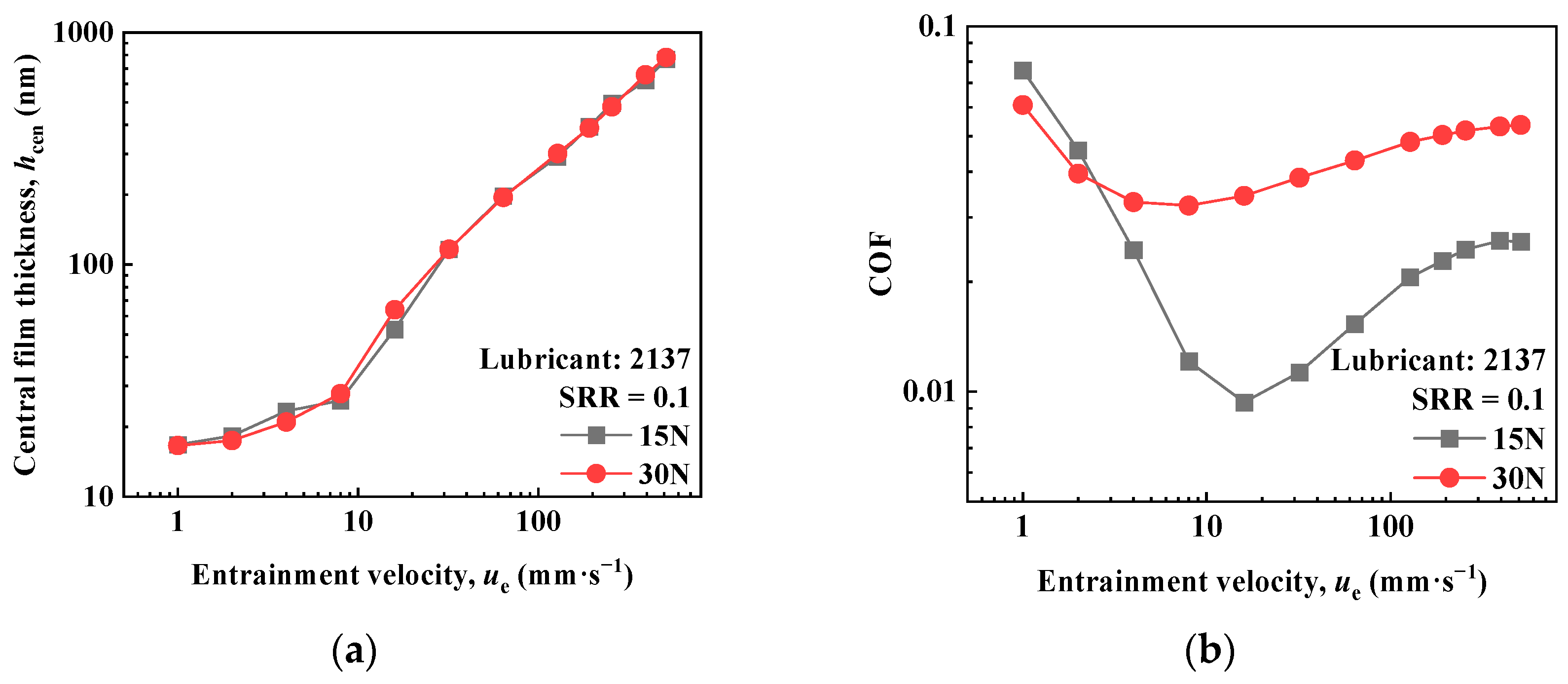

3.1. The Effect of Stearic Acid on the 2137 Mineral Oil under Fully Flooded Condition

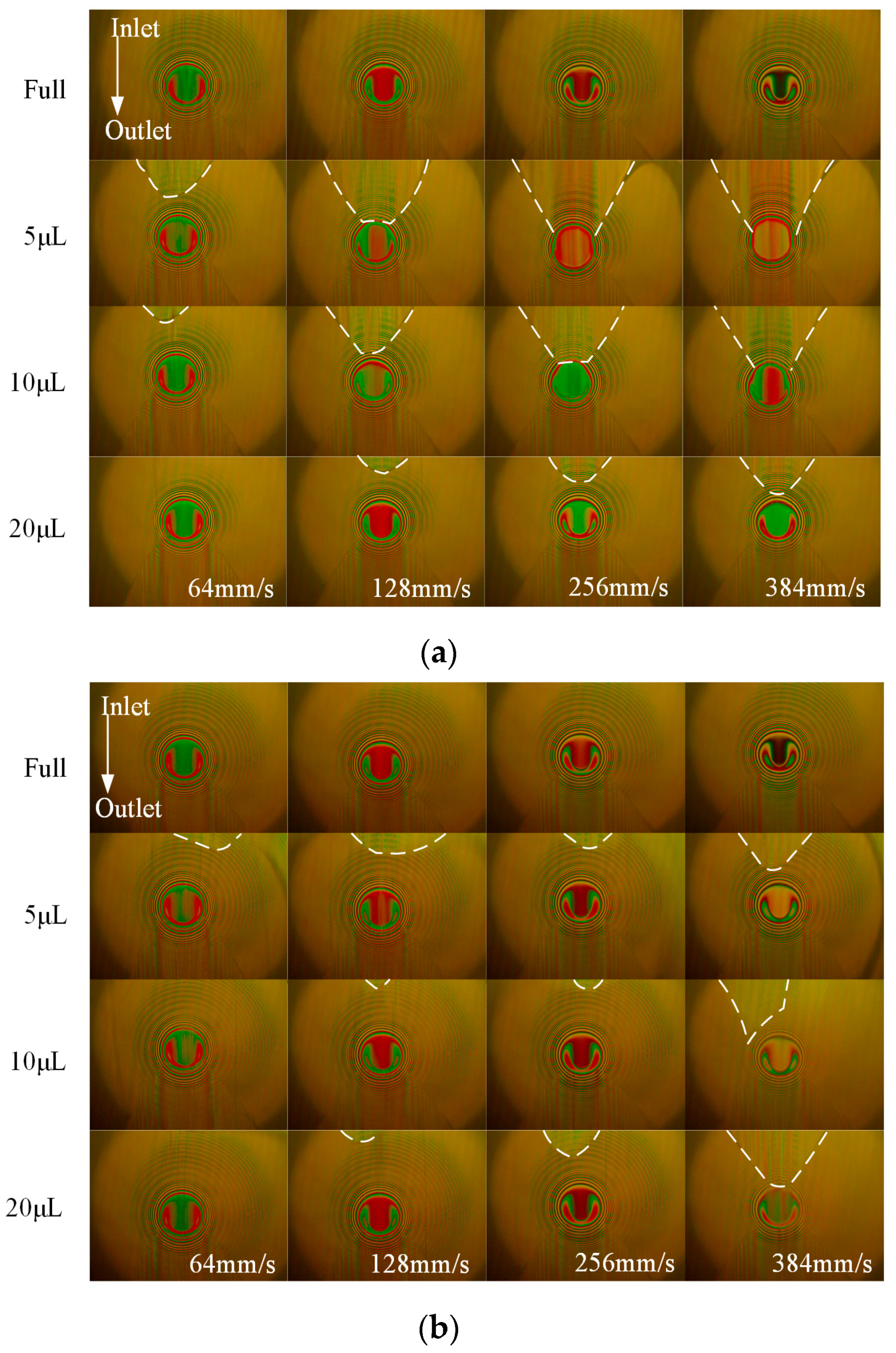

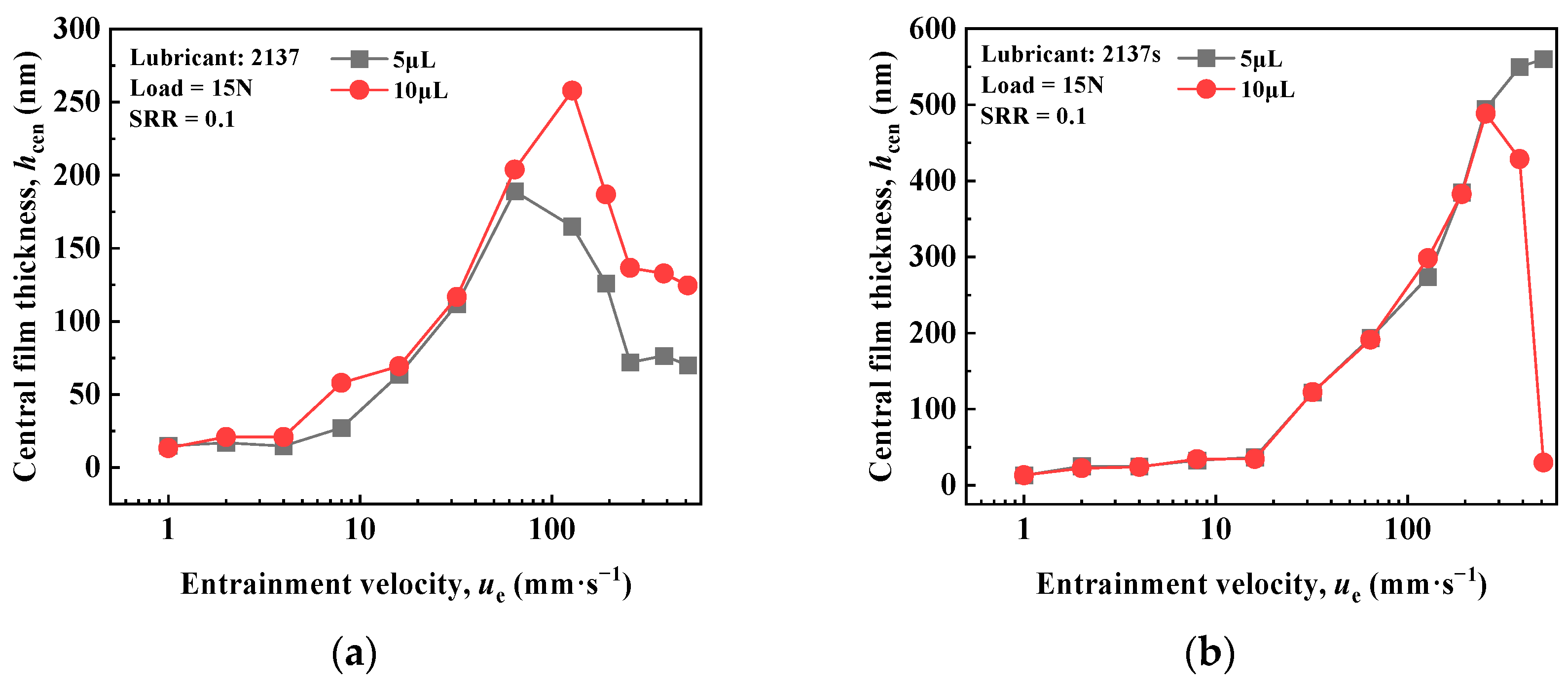

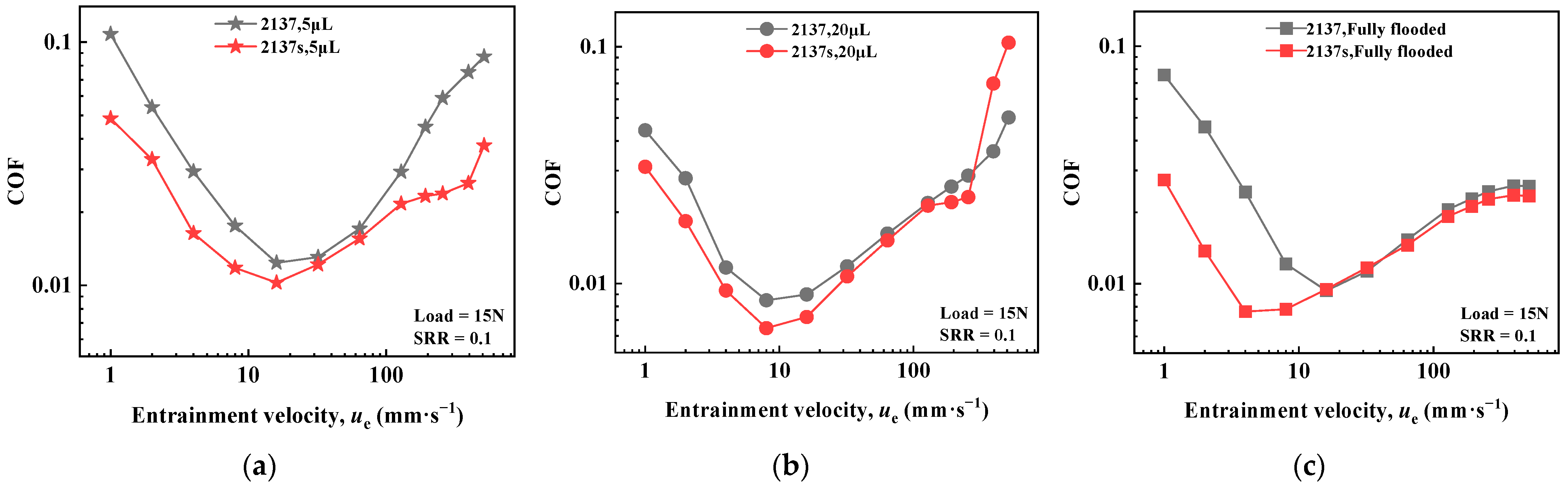

3.2. Influence of Stearic Acid under Limited Lubricant Supply Conditions

3.3. Lubrication Mechanism Analysis

4. Conclusions

- (1)

- Under conditions of sufficient oil supply, 2137 and 2137s achieve similar oil film thickness, but the COF of 2137s is significantly lower than that of 2137, indicating a weak affinity at the oil film/adsorption layer interface. Overall, the average COF of 2137s is 13.3% smaller than that of 2137.

- (2)

- Under conditions of sufficient oil supply, the SRR has an important influence on the lubricating performance. At a high SRR and high entrainment velocity, the lubricant is prone to thermal thinning, resulting in a significant decrease in COF.

- (3)

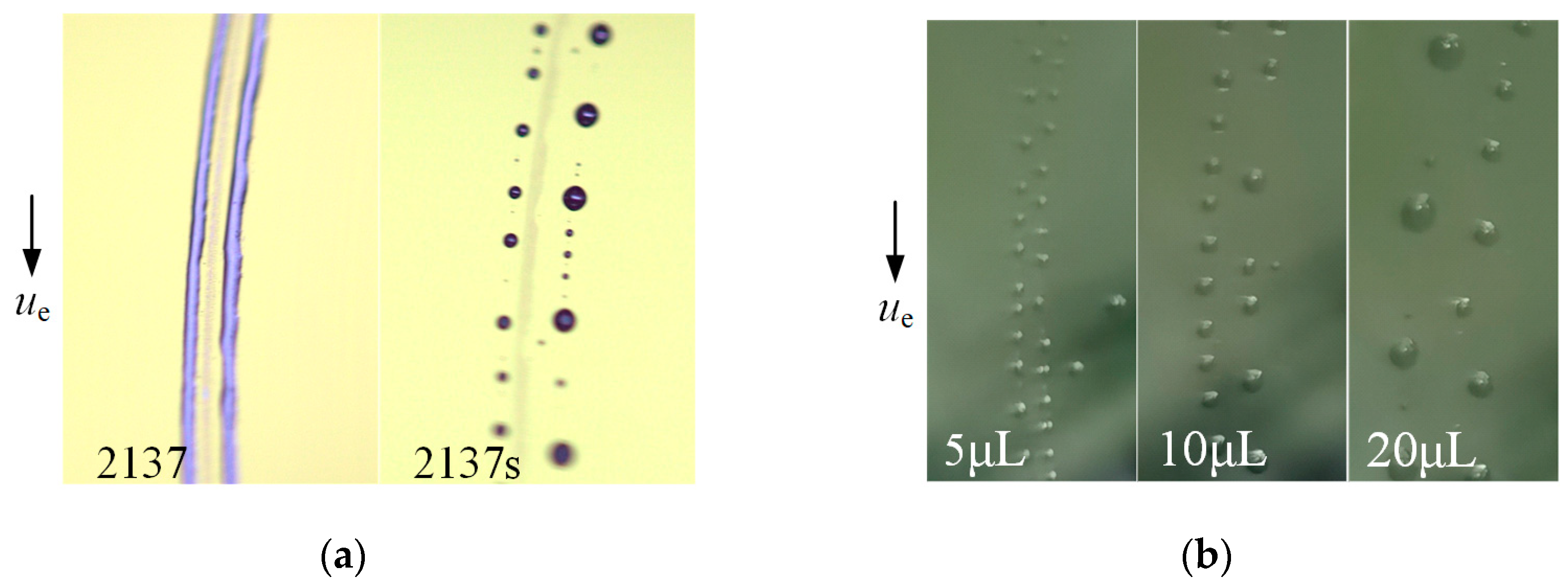

- Under conditions of limited lubricant supply, 2137 base oil is prone to oil starvation as the entrainment velocity increases, and the less the oil supply, the earlier the occurrence of oil starvation. Compared to 2137, 2137s significantly improves the oil starvation phenomenon, which is related to the discrete oil distribution due to adsorption of stearic acid on the contact surface.

- (4)

- The adsorption film formed by 2137s on the glass disc surface reduces surface energy, and the lubricating oil with a discrete droplet distribution on the lubricating track due to “dewetting” is beneficial for early load-bearing at the entrance of the contact area, thereby reducing the COF.

- (5)

- With increase in the disc speed, it is interesting to find that less 2137s supply quantity can produce higher film thickness, which can be explained by the fact that a smaller 2137s supply quantity generates droplets with a smaller size, and presents oil with more resistance to the centrifugal force to leave the lubrication track.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, P.R. Numerical Analysis of Fluid Lubrication; Beijing National Defense Industry Press: Beijing, China, 1998. [Google Scholar]

- Cai, X.J.; Liu, Z.Q.; Chen, M.; An, Q.L. An experimental investigation on effects of minimum quantity lubrication oil supply rate in high-speed end milling of Ti–6Al–4V. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 1784–1792. [Google Scholar] [CrossRef]

- Van der Kruk, W.M.; Smit, S.A.; Segers, T.J.; Li, X.M.; Venner, C.H. Drop-on-demand printing as novel method of oil supply in elastohydrodynamic lubrication. Tribol. Lett. 2019, 67, 95. [Google Scholar] [CrossRef]

- Wedeven, L.D.; Evans, D.; Cameron, A. Optical analysis of ball bearing starvation. J. Tribol. 1971, 93, 349–361. [Google Scholar] [CrossRef]

- Guangteng, G.; Cann, P.M.; Spikes, H.A. A study of parched lubrication. Wear 1992, 153, 91–105. [Google Scholar] [CrossRef]

- Kingsbury, E.; Schritz, B.; Prahl, J. Parched Elasto Hydrodynamic Lubrication Film Thickness Measurement in an Instrument Ball Bearing. Tribol. Trans. 1990, 33, 11–14. [Google Scholar] [CrossRef]

- Fischer, D.; Jacobs, G.; Stratmann, A.; Burghardt, G. Effect of base oil type in grease composition on the lubricating film formation in EHD contacts. Lubricants 2018, 6, 32. [Google Scholar] [CrossRef]

- Cann, P.M.E.; Damiens, B.; Lubrecht, A.A. The transition between fully flooded and starved regimes in EHL. Tribol. Int. 2004, 37, 859–864. [Google Scholar] [CrossRef]

- Maruyama, T.; Saitoh, T. Relationship between supplied oil flow rates and oil film thicknesses under starved elastohydrodynamic lubrication. Lubricants 2015, 3, 365–380. [Google Scholar] [CrossRef]

- Ebner, M.; Yilmaz, M.; Lohner, T.; Michaelis, K.; Höhn, B.-R.; Stahl, K. On the effect of starved lubrication on elastohydrodynamic (EHL) line contacts. Tribol. Int. 2018, 118, 515–523. [Google Scholar] [CrossRef]

- Niu, Y.; Pang, X.; Yue, S.; Shangguan, B.; Zhang, Y. The friction and wear behavior of Laser Textured Surfaces in non-conformal contact under Starved Lubrication. Wear 2021, 476, 203723. [Google Scholar] [CrossRef]

- Matthew, H.; Matthew, S.; Ramin, R.; Nekouie-Esfahani, R. Effect of surface texture positioning in grease lubricated contacts. Tribol. Int. 2023, 185, 108523. [Google Scholar]

- Hirayama, T.; Ikeda, M.; Suzuki, T.; Matsuoka, T.; Sawada, H.; Kawahara, K. Effect of nanotexturing on increase in elastohydrodynamic lubrication oil film thickness. J. Tribol. 2014, 136, 031501. [Google Scholar] [CrossRef]

- Li, X.; Guo, F.; Wong, P.; Zhao, Y. Regulation of lubricant supply by wettability gradient in rolling EHL contacts. Tribol. Int. 2018, 120, 565–574. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L.; Xue, Q. Influence of micro/nano-textures and chemical modification on the nanotribological property of Au surface. Colloids Surf. A Physicochem. Eng. Asp. 2010, 366, 191–196. [Google Scholar] [CrossRef]

- Wen, S.Z.; Huang, P.; Tian, Y.; Ma, L.R. Principles of Tribology, 5th ed.; Tsinghua University Press: Beijing, China, 2018. [Google Scholar]

- He, X.; Lu, J.; Desanker, M.; Invergo, A.M.; Lohr, T.L.; Ren, N.; Lockwood, F.E.; Marks, T.J.; Chung, Y.-W.; Wang, Q.J. Boundary lubrication mechanisms for high-performance friction modifiers. ACS Appl. Mater. Interfaces 2018, 10, 40203–40211. [Google Scholar] [CrossRef]

- Hu, W.-J.; Xu, Y.; Zeng, X.; Li, J.-S. Alkyl-ethylene amines as effective organic friction modifiers for the boundary lubrication regime. Langmuir 2020, 36, 6716–6727. [Google Scholar] [CrossRef]

- Somayaji, A.; Aswath, P.B. The role of antioxidants on the oxidation stability of oils with F-ZDDP and ZDDP, and chemical structure of tribofilms using XANES. Tribol. Trans. 2009, 52, 511–525. [Google Scholar] [CrossRef]

- Wang, Z.; Chang, J.; Wu, W. Synergistic effects of phosphate ionic liquids and octadecylaminen-oleoyl sarcosinate as lubricating grease additives. Lubr. Sci. 2019, 31, 127–136. [Google Scholar] [CrossRef]

- Faujdar, E.; Negi, H.; Singh, R.K.; Varshney, V. Study on Biodegradable Poly (α-Olefins–co–α-Pinene) Architectures as Pour Point Depressant and Viscosity Index Improver Additive for Lubricating Oils. J. Polym. Environ. 2020, 28, 3019–3027. [Google Scholar] [CrossRef]

- Battez, A.E.H.; González, R.; Viesca, J.L.; Blanco, D.; Asedegbega, E.; Osorio, A. Tribological behaviour of two imidazolium ionic liquids as lubricant additives for steel/steel contacts. Wear 2009, 266, 1224–1228. [Google Scholar] [CrossRef]

- Wells, H.M.; Southcombe, J.E. Theory and Practice of Lubrication. Sci. Am. 1920, 2 (Suppl. 1), 32–36. [Google Scholar] [CrossRef]

- Doig, M.; Warrens, C.P.; Camp, P.J. Structure and friction of stearic acid and oleic acid films adsorbed on iron oxide surfaces in squalane. Langmuir 2014, 30, 186–195. [Google Scholar] [CrossRef] [PubMed]

- Ewen, J.P.; Gattinoni, C.; Morgan, N.; Spikes, H.A.; Dini, D. Nonequilibrium molecular dynamics simulations of organic friction modifiers adsorbed on iron oxide surfaces. Langmuir 2016, 32, 4450–4463. [Google Scholar] [CrossRef] [PubMed]

- Fry, B.M.; Moody, G.; Spikes, H.A.; Wong, J.S.S. Adsorption of organic friction modifier additives. Langmuir 2020, 36, 1147–1155. [Google Scholar] [CrossRef] [PubMed]

- Kalin, M.; Kus, M. New strategy for reducing the EHL friction in steel contacts using additive-formed oleophobic boundary films. Friction 2021, 9, 1346–1360. [Google Scholar] [CrossRef]

- Zang, S.Y.; Guo, F.; Li, C. Influence of Surface Wettability on Lubrication by Limited Lubricant Supply. Tribology 2017, 37, 429–434. [Google Scholar]

- Li, S.Y.; Guo, F.; Wong, P.L.; Li, X. Numerical analysis of lubrication of conformal contact with discontinuous oil droplets. Tribol. Int. 2022, 173, 107632. [Google Scholar]

- Liu, H.C.; Guo, F.; Guo, L.; Wong, P.L. A dichromatic interference intensity modulation approach to measurement of lubricating film thickness. Tribol. Lett. 2015, 58, 1–11. [Google Scholar] [CrossRef]

| Lubricant | Dynamic Viscosity (mPa·s @22 °C) | Refractive Index |

|---|---|---|

| 2137 | 220.8 | 1.475 |

| 2137s | 199.8 | 1.475 |

| Condition | Value |

|---|---|

| Volume of the oil supply, V/µL | 5, 10, 20, Fully flooded (1 mL) |

| Load, w/N | 15, 30 |

| Entrainment velocity, ue/mm·s−1 | 1–512 |

| Slide-roll-ratio, SRR | 0.1, 0.2, 0.4, 0.6, 0.8, 1.0 |

| Temperature, T/°C | 22 ± 1 |

| Relative humidity, RH/% | 50 ± 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Guo, F.; Liu, C.; Ma, Z. Experimental Study on the Influence of Stearic Acid Additive on the Elastohydrodynamic Lubrication of Mineral Oil 2137. Lubricants 2023, 11, 446. https://doi.org/10.3390/lubricants11100446

Li W, Guo F, Liu C, Ma Z. Experimental Study on the Influence of Stearic Acid Additive on the Elastohydrodynamic Lubrication of Mineral Oil 2137. Lubricants. 2023; 11(10):446. https://doi.org/10.3390/lubricants11100446

Chicago/Turabian StyleLi, Wei, Feng Guo, Chenglong Liu, and Zhaoqun Ma. 2023. "Experimental Study on the Influence of Stearic Acid Additive on the Elastohydrodynamic Lubrication of Mineral Oil 2137" Lubricants 11, no. 10: 446. https://doi.org/10.3390/lubricants11100446

APA StyleLi, W., Guo, F., Liu, C., & Ma, Z. (2023). Experimental Study on the Influence of Stearic Acid Additive on the Elastohydrodynamic Lubrication of Mineral Oil 2137. Lubricants, 11(10), 446. https://doi.org/10.3390/lubricants11100446