High-Temperature Wear and Frictional Performance of Plasma-Nitrided AISI H13 Die Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Die Steel Selection and Pin Preparation

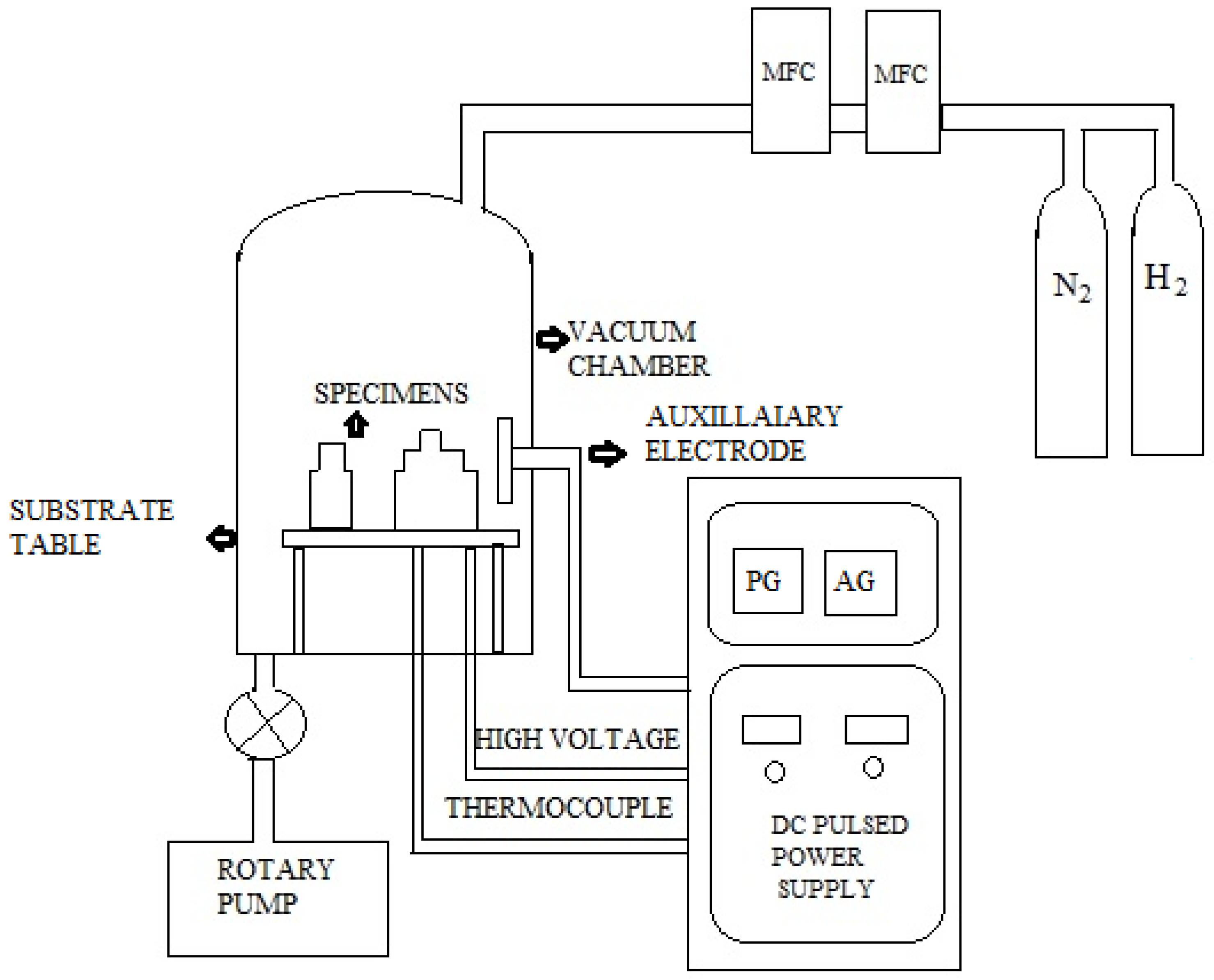

2.2. Plasma Nitriding

2.3. Characterization of Plasma-Nitrided Specimens

2.4. Tribological Tests

3. Results and Discussion

3.1. Characterization of Plasma-Nitrided Specimens

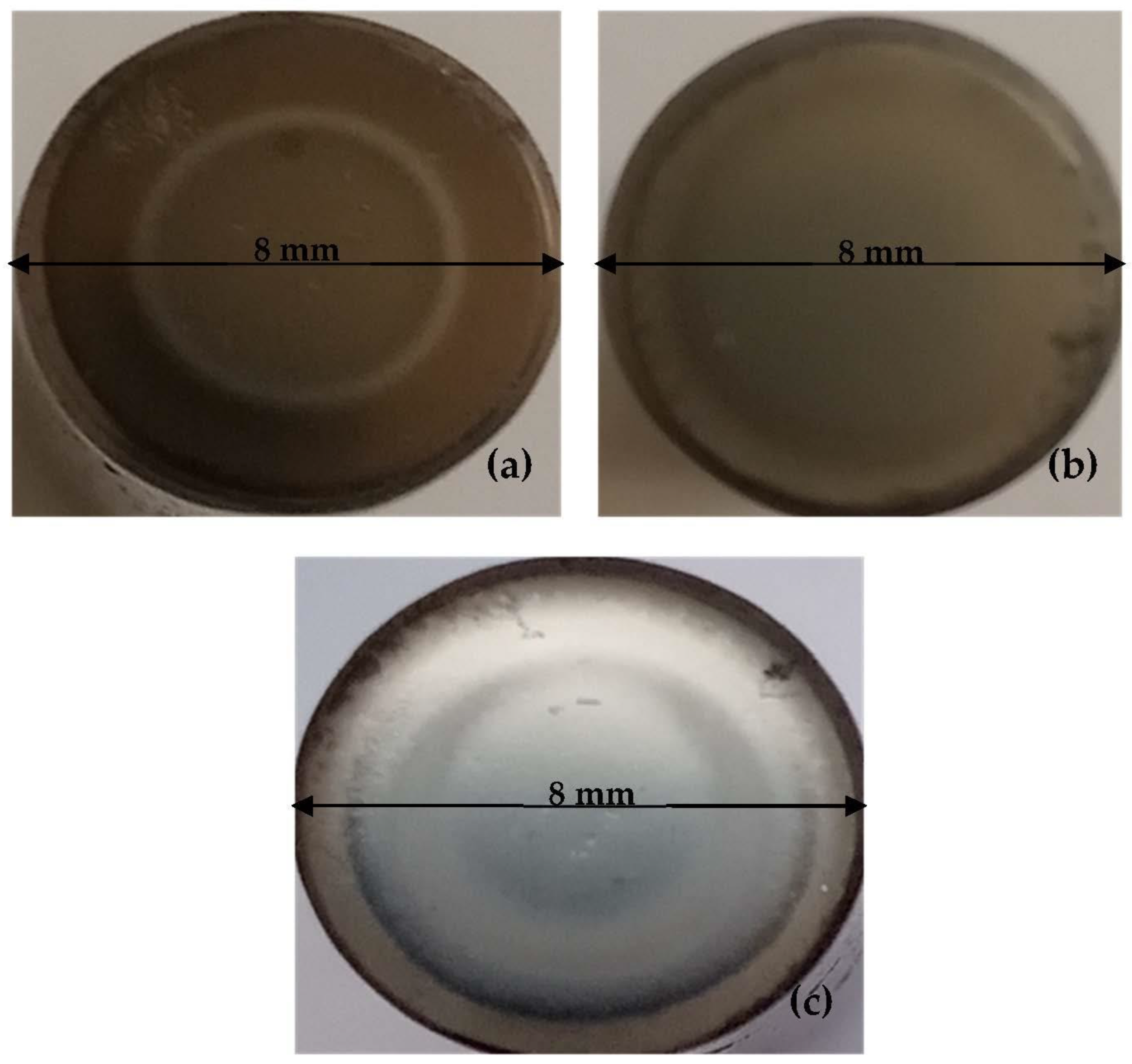

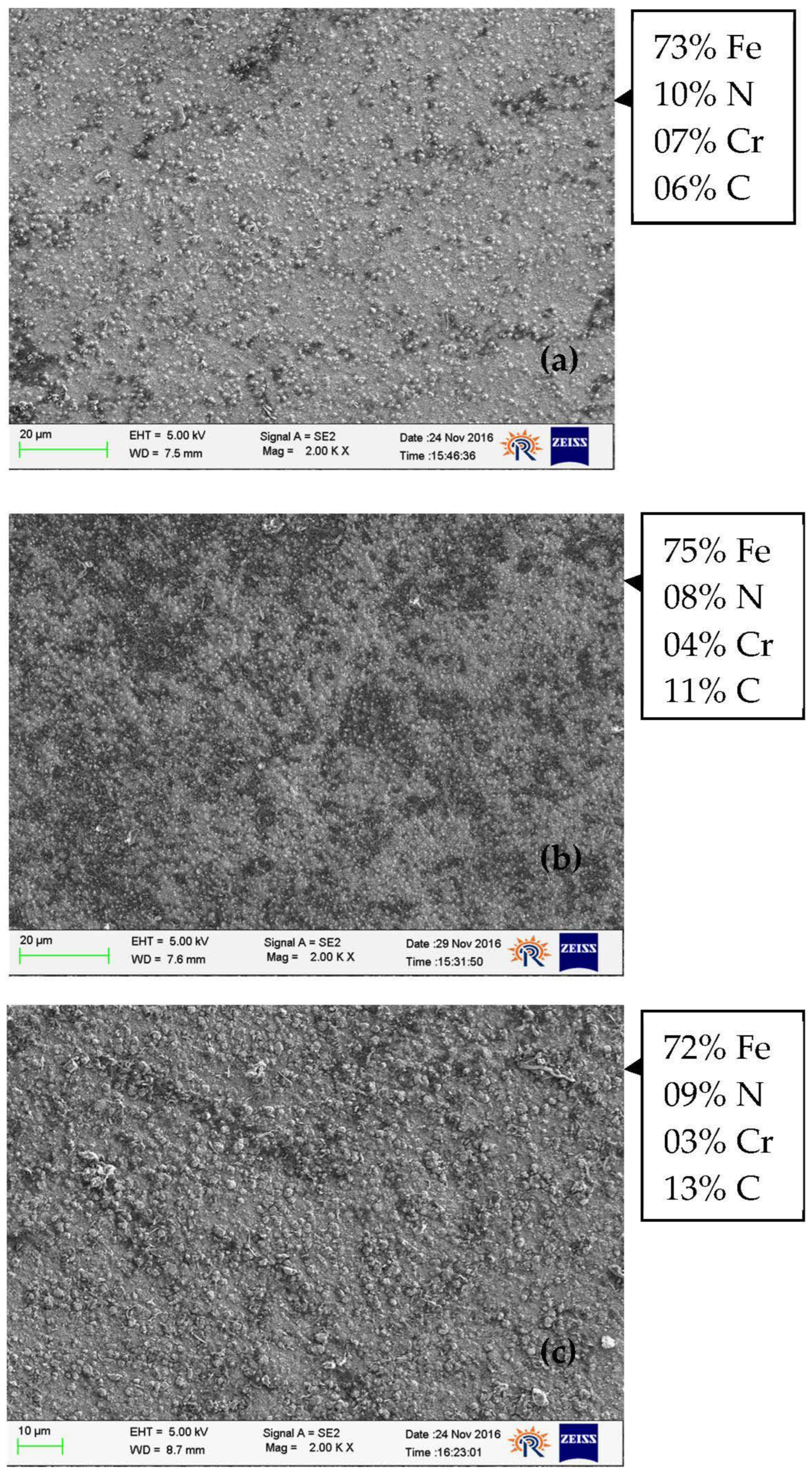

3.1.1. Visual Examination, Ra Values, and Microstructure Analysis

3.1.2. Microhardness Analysis

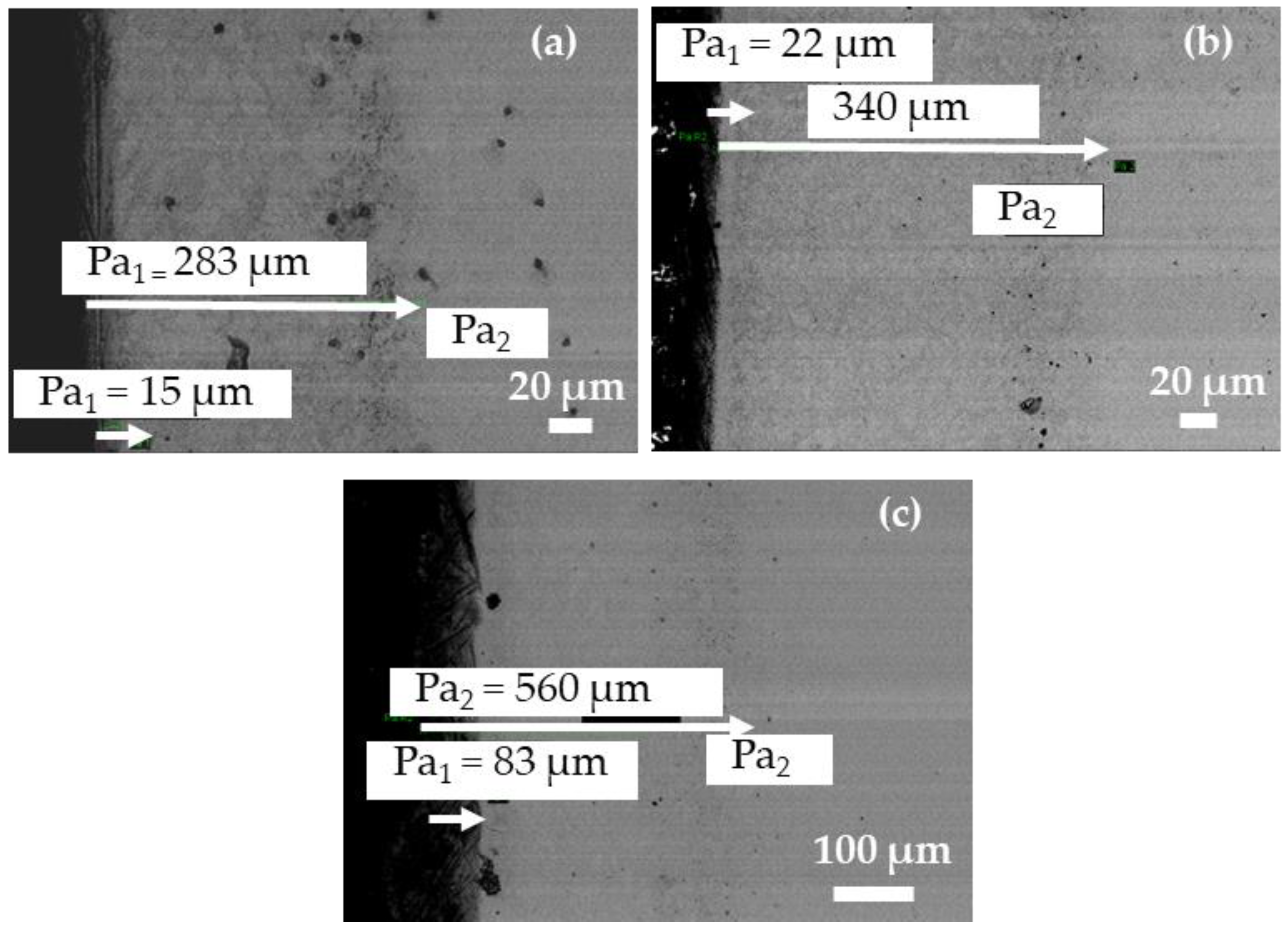

3.1.3. Cross-Sectional SEM Analysis

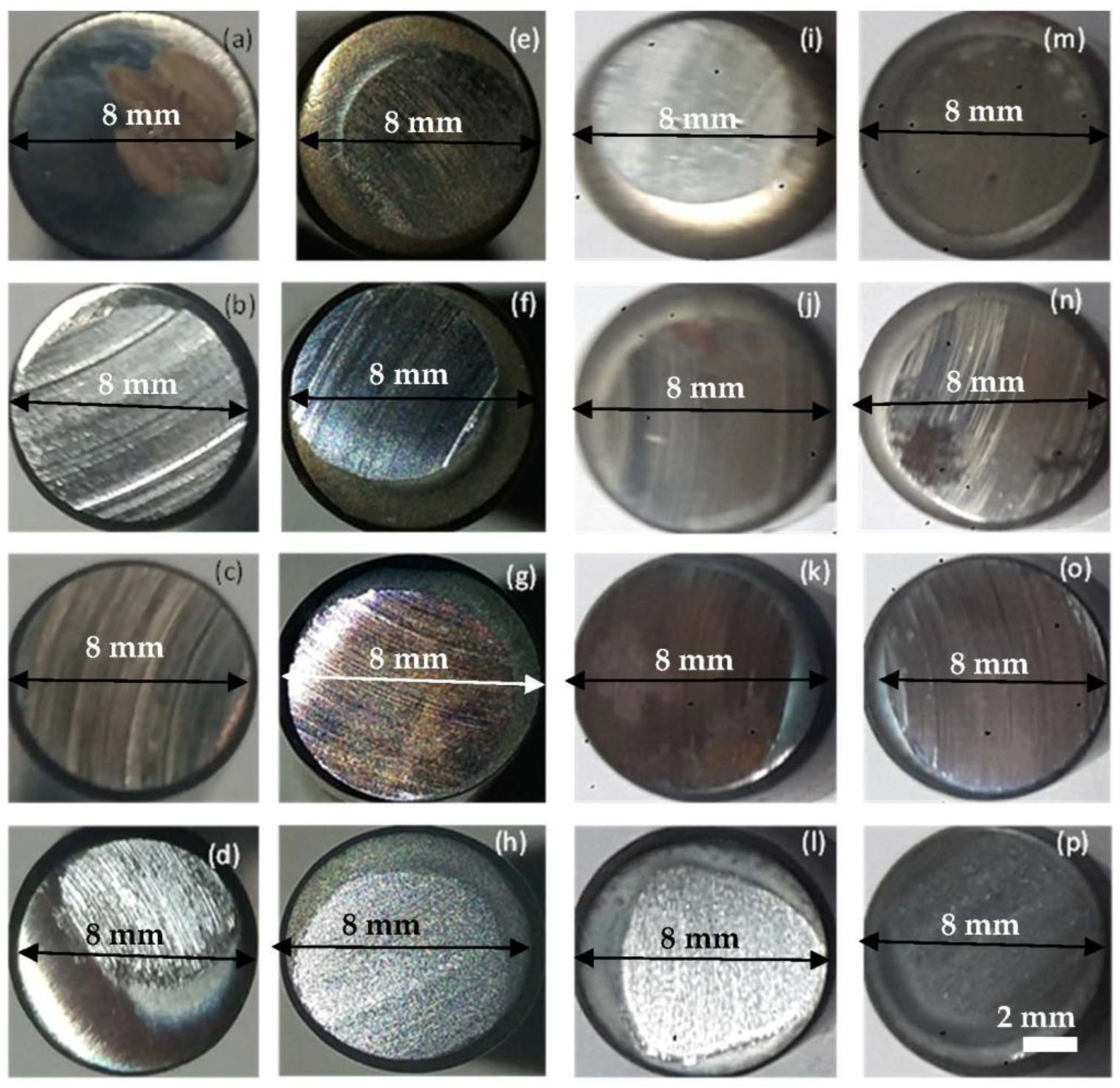

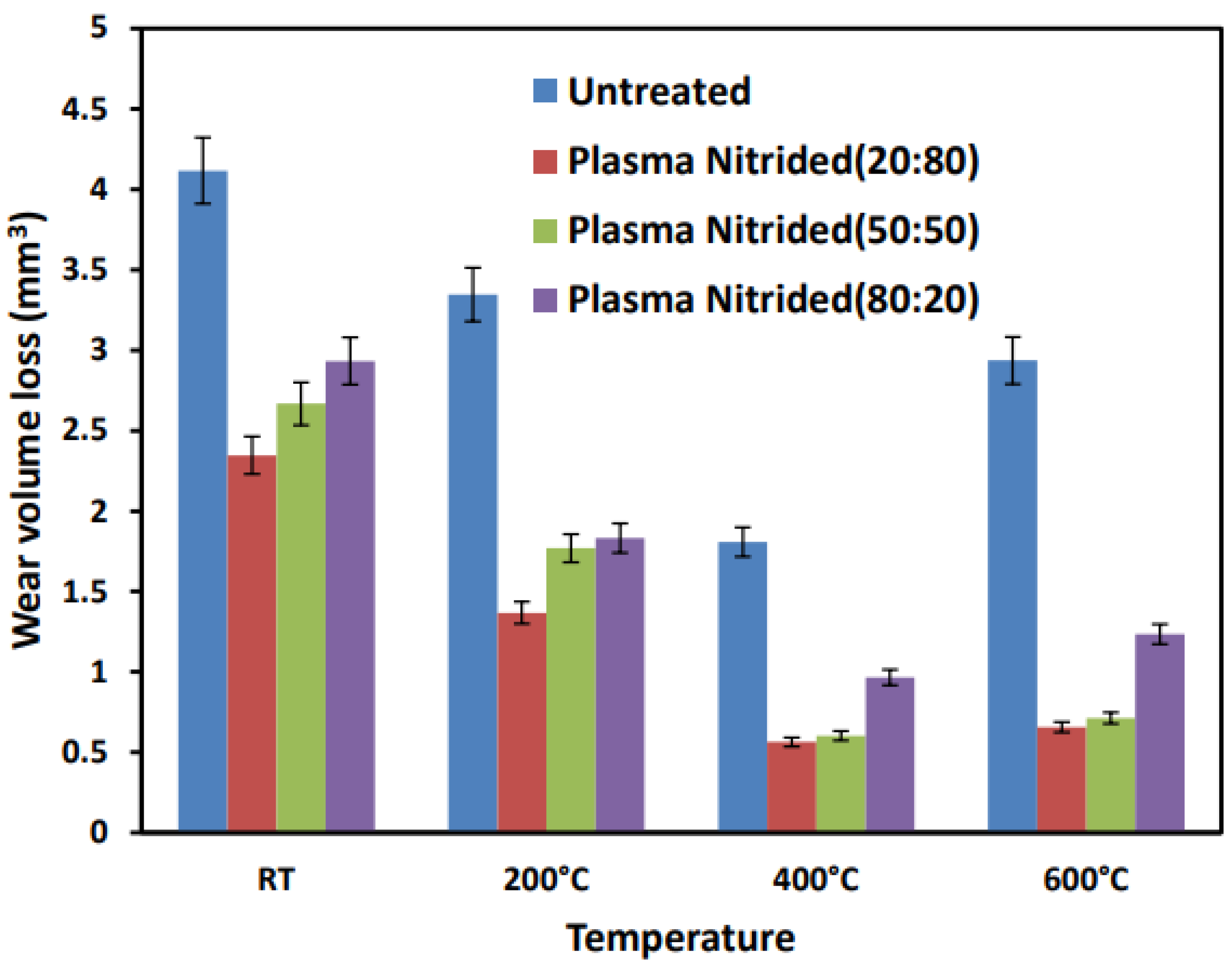

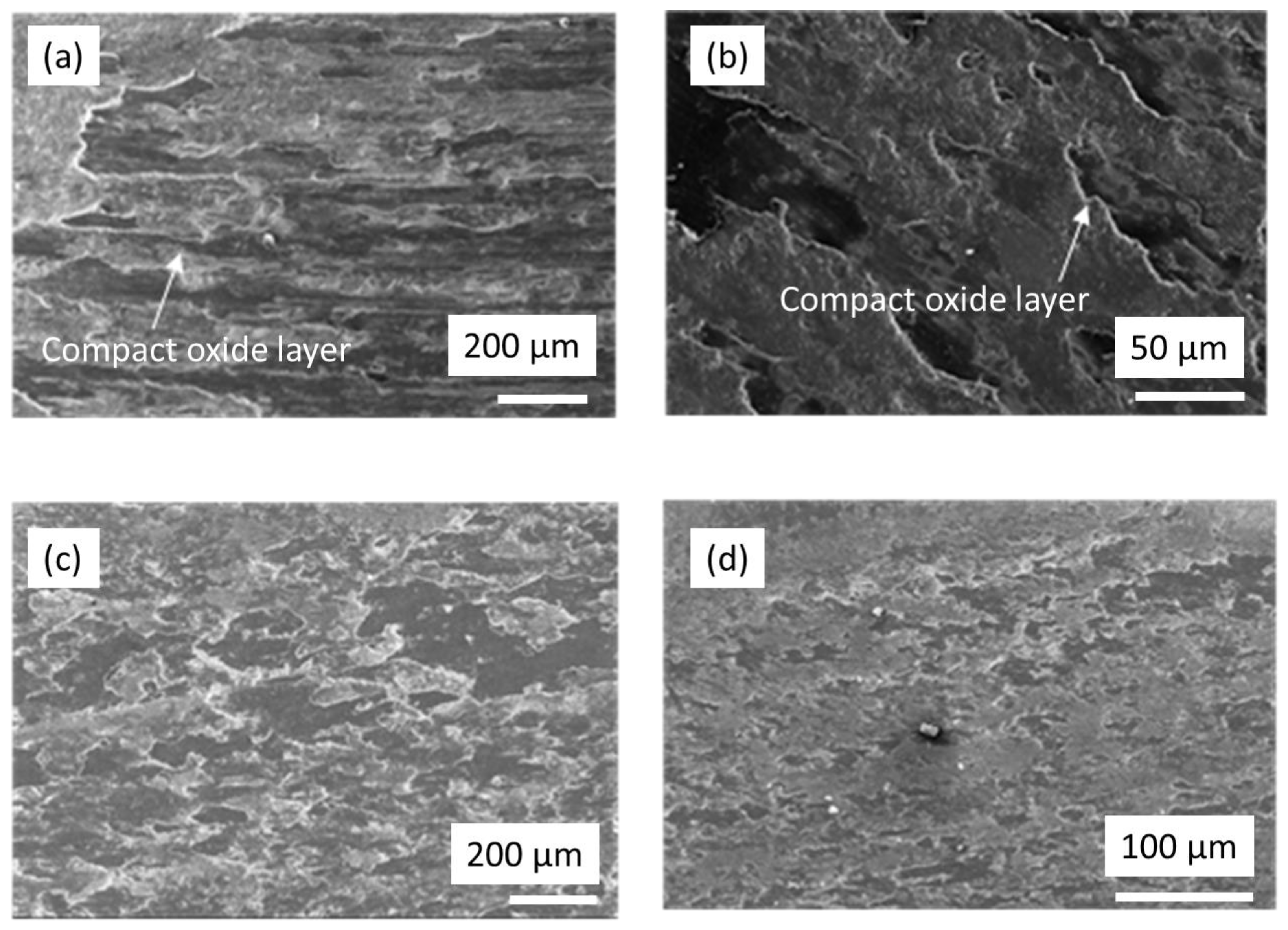

3.2. Tribological Behaviour

4. Conclusions

- Plasma nitriding with N2:H2 ratios of 20:80, 50:50 and 80:20 was successfully applied to the AISI H13 steel. The nitride layer was thick and evenly distributed. There were no visible cracks.

- The hardness of steel improved considerably after plasma nitriding. The plasma-nitrided steels showed higher hardness, with an increase of about a factor of two, compared to the untreated die steels. This indicates that the steels perform better in hot-forming applications.

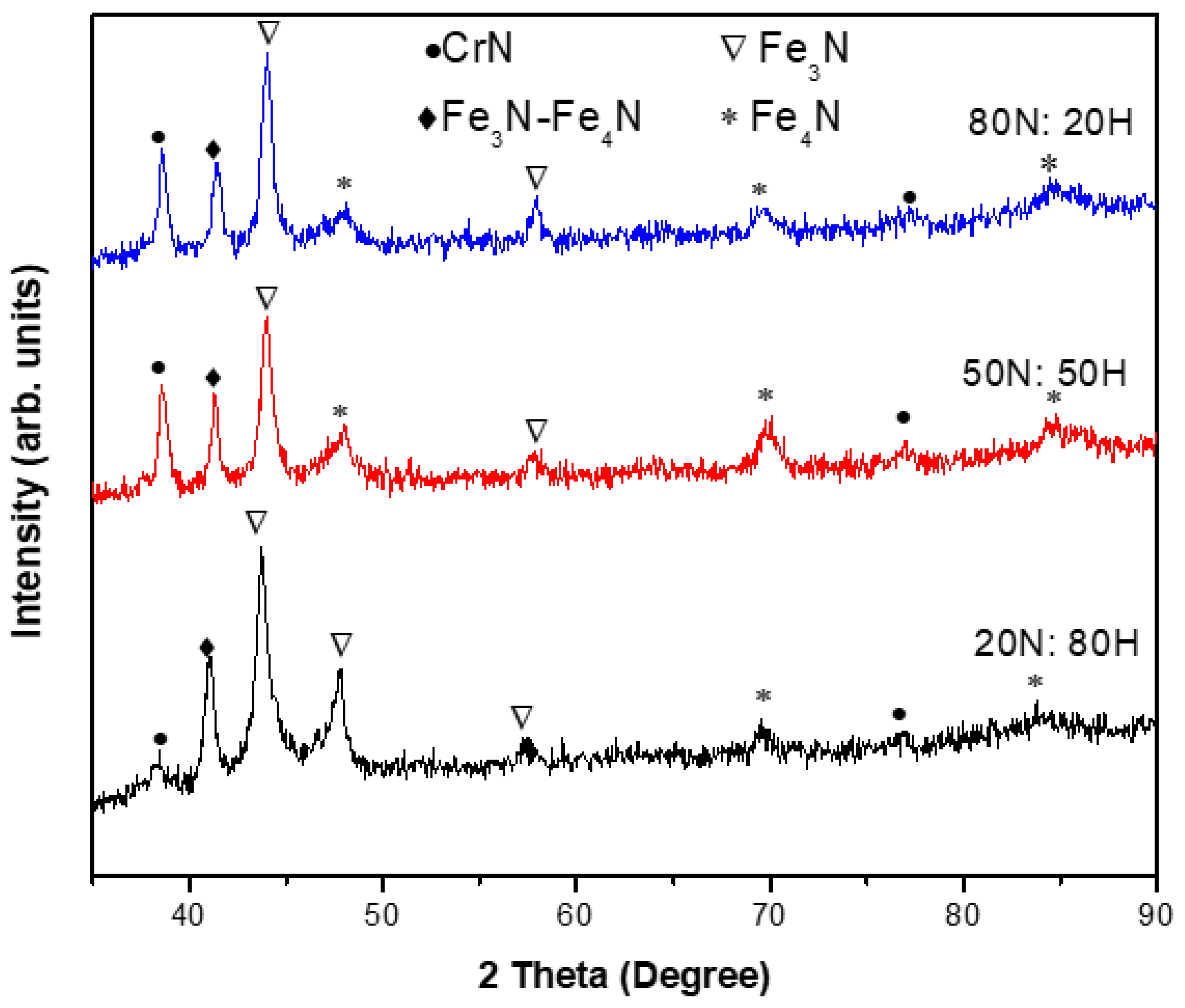

- The SEM image of the plasma-nitrided surface show evenly distributed micro-particles (nitrides). The XRD analysis of the plasma-nitrided specimens showed the presence of Fe3N, Fe3N-Fe4N, Fe4N and CrN phases in the nitriding layer.

- Amongst the plasma-nitrided specimens, the specimens nitrided with an N2:H2 ratio of 20:80 showed the highest wear resistance at all temperatures and under a 50 N load.

- The wear mechanism for the untreated plasma-nitrided specimens at room temperature and 200 °C was predominantly adhesive in nature. At 400 °C, the mode of wear was a combination of oxidative, adhesive and abrasive wear. At 600 °C the mode of wear was observed as oxidative and adhesive.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Vergne, C.; Boher, C.; Gras, R. Influence of oxides on friction in hot rolling: Experimental investigations and tribological modelling. Wear 2006, 260, 957–975. [Google Scholar] [CrossRef]

- Winkelmann, H.; Badisch, E.; Kirchgassner, M.; Danninger, H. Wear mechanisms at high temperatures-part 1 Wear mechanisms of different Fe-based alloys at elevated temperatures. Tribol. Lett. 2009, 34, 155–166. [Google Scholar] [CrossRef]

- Tomala, A.; Hernandez, S.; Rodriguez Ripoll, M.; Badisch, E.; Prakash, B. Tribological performance of some solid lubricants for hot forming through laboratory simulative tests. Tribol. Int. 2014, 74, 164–173. [Google Scholar] [CrossRef]

- Kumar, S. Influence of processing conditions on the mechanical, tribological and fatigue performance of cold spray coating: A Review. Surf. Eng. 2022, 38, 324–365. [Google Scholar] [CrossRef]

- Prchlik, L.; Sampath, S. Effect of the microstructure of thermally sprayed coatings on friction and wear response under lubricated and dry sliding conditions. Wear 2007, 262, 11–23. [Google Scholar] [CrossRef]

- Singh, S.; Singh, H.; Buddu, R.K. Microstructural investigations on bonding mechanisms of cold-sprayed copper with SS316L steel. Surf. Eng. 2020, 36, 1067–1080. [Google Scholar] [CrossRef]

- Lenhard, A.; Damasio, S.; Milke, A.; Schaeffer, L. Method to Estimate Workpiece-Die Heat Transfer Coefficient on Precision Warm Forging Process. In Proceedings of the 4th JSTP International Seminar on Precision Forging March, Nara, Japan, 21–24 March 2006. [Google Scholar]

- Deshpande, M.; Altan, T. Selection of Die Materials and Surface Treatments for Increasing Die Life in Hot and Warm Forging; FIA Tech Conference Paper No 644; Forging Industry Association: Independence, OH, USA, 2011. [Google Scholar]

- Phakatkar, H.H.; Ghorpade, R.R. Tribology, 2nd ed.; Nirali Prakashan (Maharashtra): Pune, India, 2009. [Google Scholar]

- Castaños, B.; Peña-Parás, L.; Maldonado-Cortés, D.; Kitala, M.; Sliwa, S.; Węglarz, M.; Mierzwiński, D. Increasing the tool life of forging die inserts. Int. J. Mod. Manuf. Technol. 2020, XII, 16–21. [Google Scholar]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Singh, S.; Ghai, V.; Agrawal, A.; Singh, H. Effect of machining parameters on cutting force during micro-turning of a brass rod. Mater. Manuf. Process. 2019, 34, 1816–1823. [Google Scholar] [CrossRef]

- Gronostajski, Z.; Hawryluk, M.; Widomski, P.; Kaszuba, M.; Nowak, B.; Polak, S.; Rychlik, M.; Ziemba, J.; Zwierzchowski, M. Selected effective methods of increasing the durability of forging tools in hot forging processes. Procedia Manuf. 2019, 27, 124–129. [Google Scholar] [CrossRef]

- Peng, T.; Zhao, X.; Chen, Y.; Tang, L.; Wei, K.; Hu, J. Improvement of stamping performance of H13 steel by compound-layer free plasma nitriding. Surf. Eng. 2019, 36, 492–497. [Google Scholar] [CrossRef]

- Kaba, M.; Altay, M.; Akyildiz, E.; Muhaffel, F.; Ozkurt, S.; Atar, E.; Baydogan, M.; Cimenoglu, H. Surface degradation of nitrided hot work tool steels under repeated impact-sliding contacts: Effect of compound layer. Wear 2022, 498–499, 204300. [Google Scholar] [CrossRef]

- Karami, M. An investigation of the properties and wear behaviour of plasma nitrided hot-working steel (H13). Wear 1991, 150, 331–342. [Google Scholar] [CrossRef]

- Sun, Y.; Bell, T.; Wood, G. Wear behaviour of plasma nitrided martensitic stainless steel. Wear 1994, 178, 131–138. [Google Scholar] [CrossRef]

- Kumar, A.; Kaur, M.; Joseph, A.; Jhala, G. Surface engineering analysis of plasma-nitrided die steels. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 917–931. [Google Scholar] [CrossRef]

- Kumar, A.; Kaur, M.; Singh, S.; Joseph, A.; Jhala, G.; Bhandari, S. High-temperature tribological studies of plasma-nitrided tool steels. Surf. Eng. 2018, 34, 620–633. [Google Scholar] [CrossRef]

- Singh, G.; Kaur, M. Sliding wear behaviour of plasma sprayed 65% (NiCrSiFeBC)-35% (WC-Co) coating at elevated temperatures. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 1396–1415. [Google Scholar] [CrossRef]

- Visuttipitukul, P.C.; Kuwahara, H. Charactrization of plasma nitrided AISI H13 tool steel. Acta Metall. Slovaca 2006, 12, 264–274. [Google Scholar]

- Capa, M.; Tamer, M.; Gulmez, T.; Bodur, C.T. Life enhancement of Hot-Forging Dies by Plasma-Nitriding. Turk. J. Eng. Environ. Sci. 2000, 24, 111–117. [Google Scholar]

- Pellizzari, M.; Molinar, A.; Straffelini, G. Thermal Fatigue Resistance of GAS and Plasma Nitrided 41CrAlMo7 Steel. Mater. Sci. Eng. A 2003, 352, 186–194. [Google Scholar] [CrossRef]

- Birol, Y. Analysis of wear of a gas nitrided H13 tool steel die in aluminium extrusion. Eng. Fail. Anal. 2012, 26, 203–210. [Google Scholar] [CrossRef]

- Stott, F.H. High-temperature sliding wear of metals. Tribol. Int. 2002, 35, 489–495. [Google Scholar] [CrossRef]

- Paschke, H.; Weber, M.; Braeuer, G.; Yilkiran, T.; Behrens, B.A.; Brand, H. Optimized plasma nitriding processes for efficient wear reduction of forging dies. Arch. Civil. Mech. Eng. 2012, 12, 407–412. [Google Scholar] [CrossRef]

- Leite, M.V.; Figueroa, C.A.; Gallo, S.C.; Rovani, A.C.; Basso, R.L.O.; Meid, P.R.; Baumvol, I.J.R.; Sinatora, A. Wear mechanisms and microstructure of pulsed plasma nitrided AISI H13 tool Steel. Wear 2010, 269, 466–472. [Google Scholar] [CrossRef]

- Castro, G.; Fernández, A.V.; Cid, J. Influence of the nitriding time in the wear behaviour of an AISI H13 steel during the crankshaft forging process. Wear 2007, 263, 1375–1385. [Google Scholar] [CrossRef]

- Ebrahimzadeh, I.; Ashrafizadeh, F. High-temperature wear and frictional properties of duplex-treated tool steel sliding against a two-phase brass. Ceram. Int. 2014, 40, 16429–16439. [Google Scholar] [CrossRef]

- Barrau, O.; Boher, C.; Gras, R.; Aria, F.R. Analysis of the friction and wear behaviour of hot work tool steel for forging. Wear 2003, 255, 1444–1454. [Google Scholar] [CrossRef]

- Podgornik, B.; Zuzek, B.; Kafexhiu, F.; Leskovsek, V. Effect of Si content on wear performance of hot work tool steel. Tribol. Lett. 2016, 63, 5. [Google Scholar] [CrossRef]

- Chowdhurya, M.A.; Nuruzzamanb, D.M. Experimental Investigation on Friction and Wear Properties of Different Steel Materials. Tribol. Ind. 2013, 35, 42–50. [Google Scholar]

- Kchaou, M.; Alimi, A.; Elleuch, R.; Desplanques, Y. Characterisation of oxidation and wear oxidised surfaces of H13 steel/brass in dry sliding conditions. Int. J. Microstruct. Mater. Prop. 2013, 8, 373–384. [Google Scholar] [CrossRef]

- Kashani, H.; Amadeh, A.; Ghasemi, H.M. Room and high-temperature wear behaviours of nickel and cobalt base weld overlay coatings on a hot forging die. Wear 2007, 262, 800–806. [Google Scholar] [CrossRef]

| Element | C | Mn | P | S | Si | Cr | Mo | Ni | Cu | V | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight percent (wt. %) | 0.32–0.45 | 0.20–0.50 | 0.03 | 0.03 | 0.80–1.20 | 4.75–5.50 | 1.10–1.75 | 0.03 | 0.25 | 0.8–1.2 | Bal |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, A.; Kaur, M.; Joseph, A.; Jhala, G.; Nanda, T.; Singh, S. High-Temperature Wear and Frictional Performance of Plasma-Nitrided AISI H13 Die Steel. Lubricants 2023, 11, 448. https://doi.org/10.3390/lubricants11100448

Kumar A, Kaur M, Joseph A, Jhala G, Nanda T, Singh S. High-Temperature Wear and Frictional Performance of Plasma-Nitrided AISI H13 Die Steel. Lubricants. 2023; 11(10):448. https://doi.org/10.3390/lubricants11100448

Chicago/Turabian StyleKumar, Ashish, Manpreet Kaur, Alphonsa Joseph, Ghanshyam Jhala, Tarun Nanda, and Surinder Singh. 2023. "High-Temperature Wear and Frictional Performance of Plasma-Nitrided AISI H13 Die Steel" Lubricants 11, no. 10: 448. https://doi.org/10.3390/lubricants11100448

APA StyleKumar, A., Kaur, M., Joseph, A., Jhala, G., Nanda, T., & Singh, S. (2023). High-Temperature Wear and Frictional Performance of Plasma-Nitrided AISI H13 Die Steel. Lubricants, 11(10), 448. https://doi.org/10.3390/lubricants11100448