Experimental Investigation on the Effect of Velocity Anisotropy on Oil Film State under Different Surface Wettability Interface

Abstract

:1. Introduction

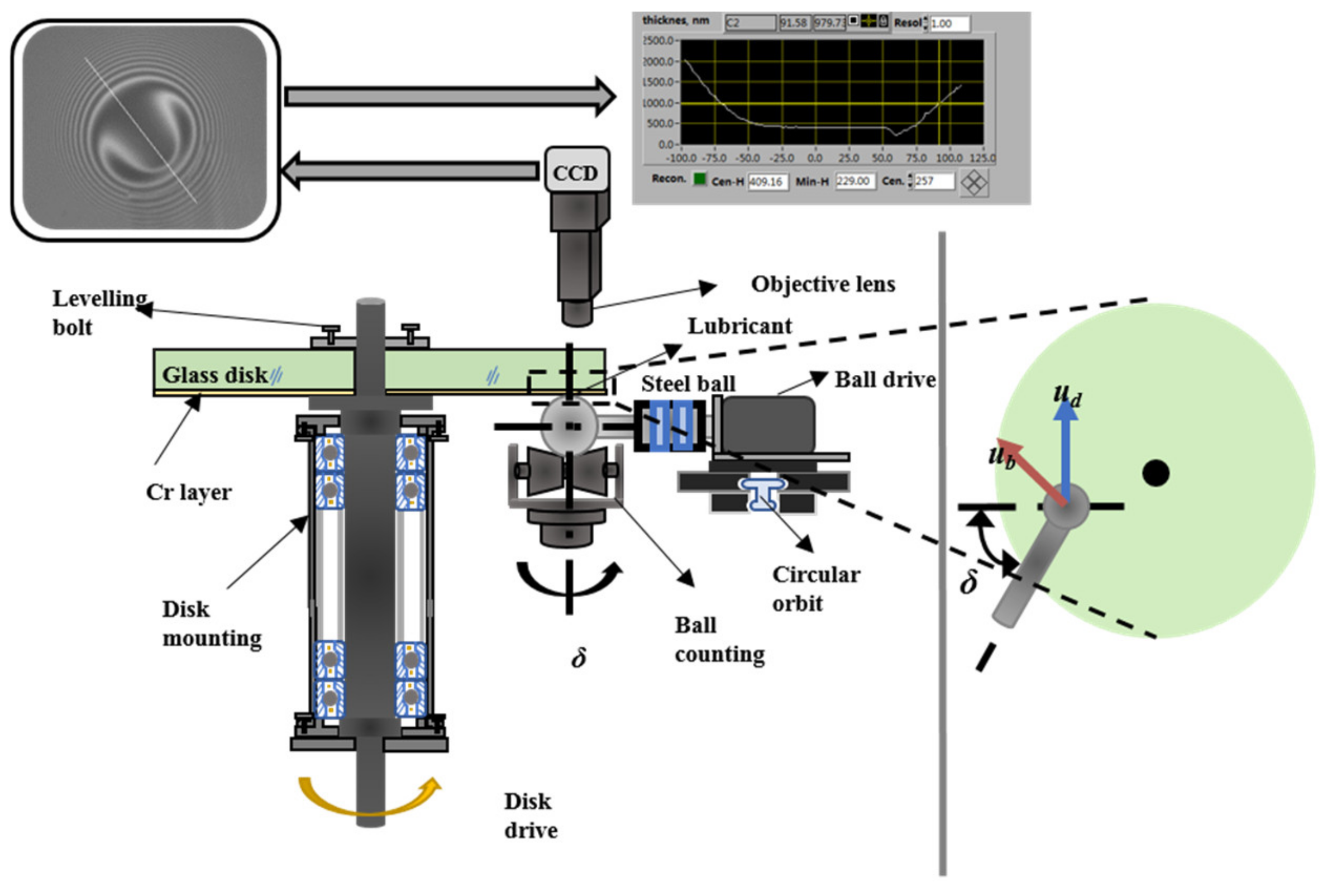

2. Materials and Methods

2.1. Test Device

2.2. Experimental Model

2.3. Experimental Protocol

3. Results and Discussion

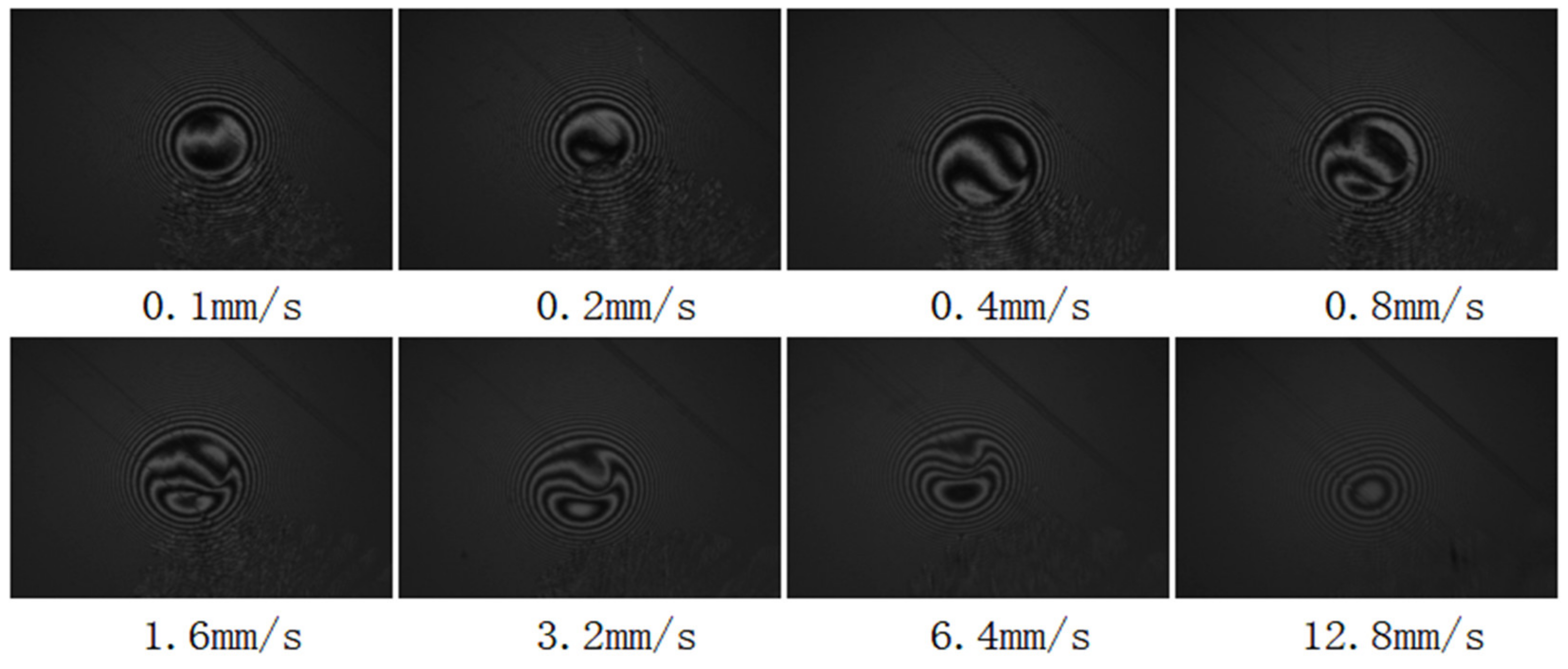

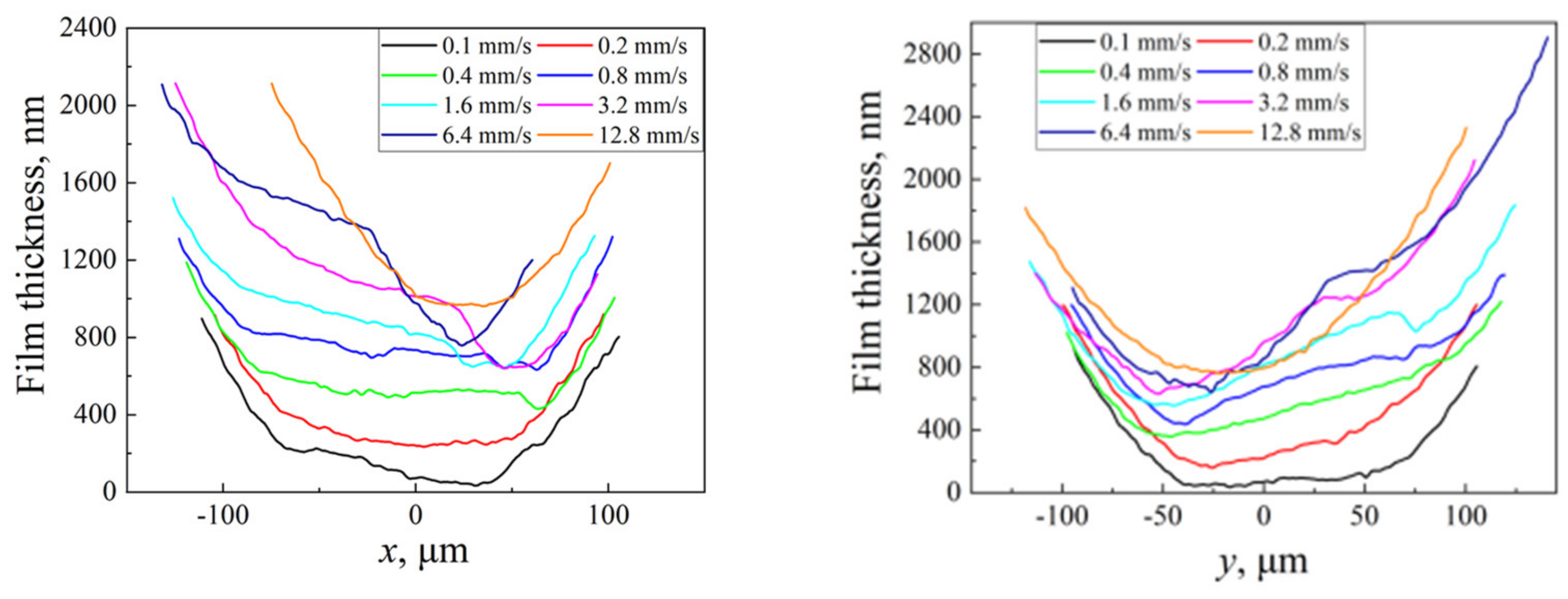

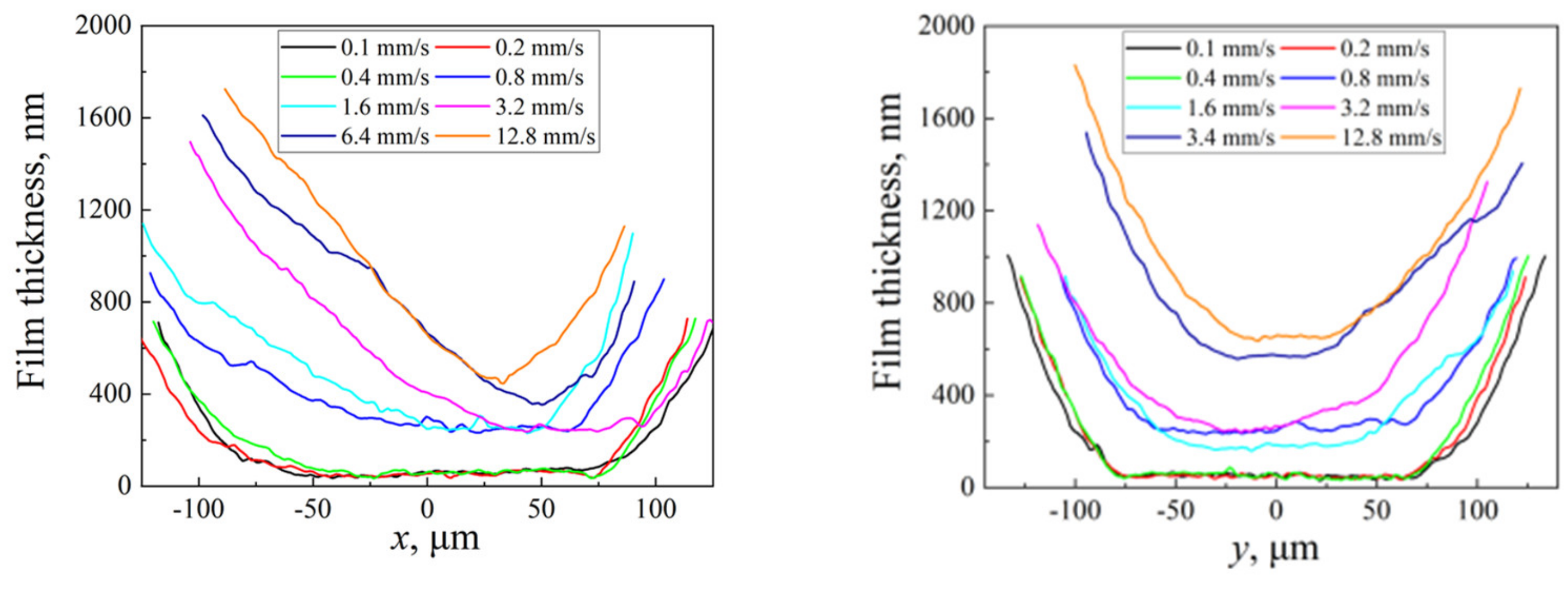

3.1. Effect of Velocity Change on Oil Film State

3.1.1. Surface Velocity Angle (0–90°)

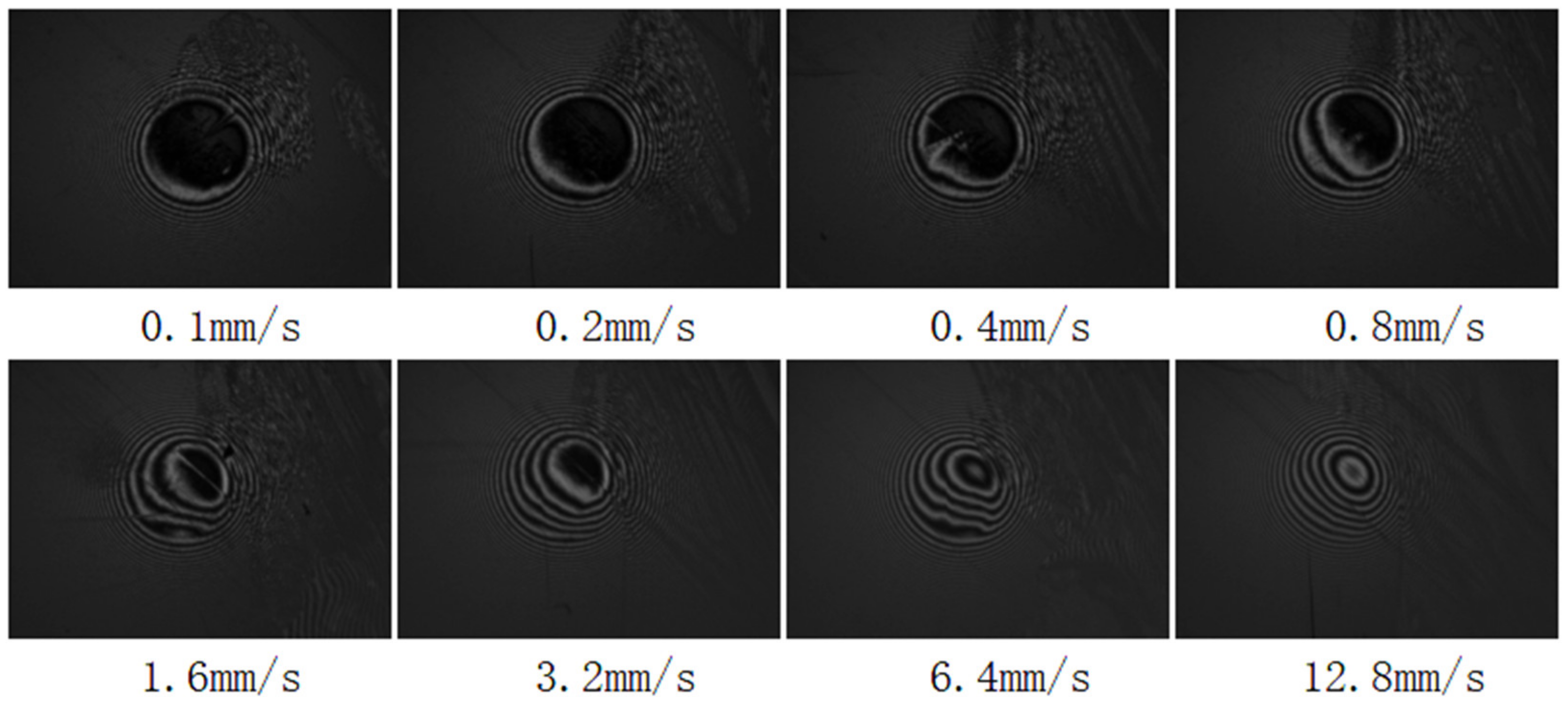

3.1.2. Surface Velocity Angle (90–180°)

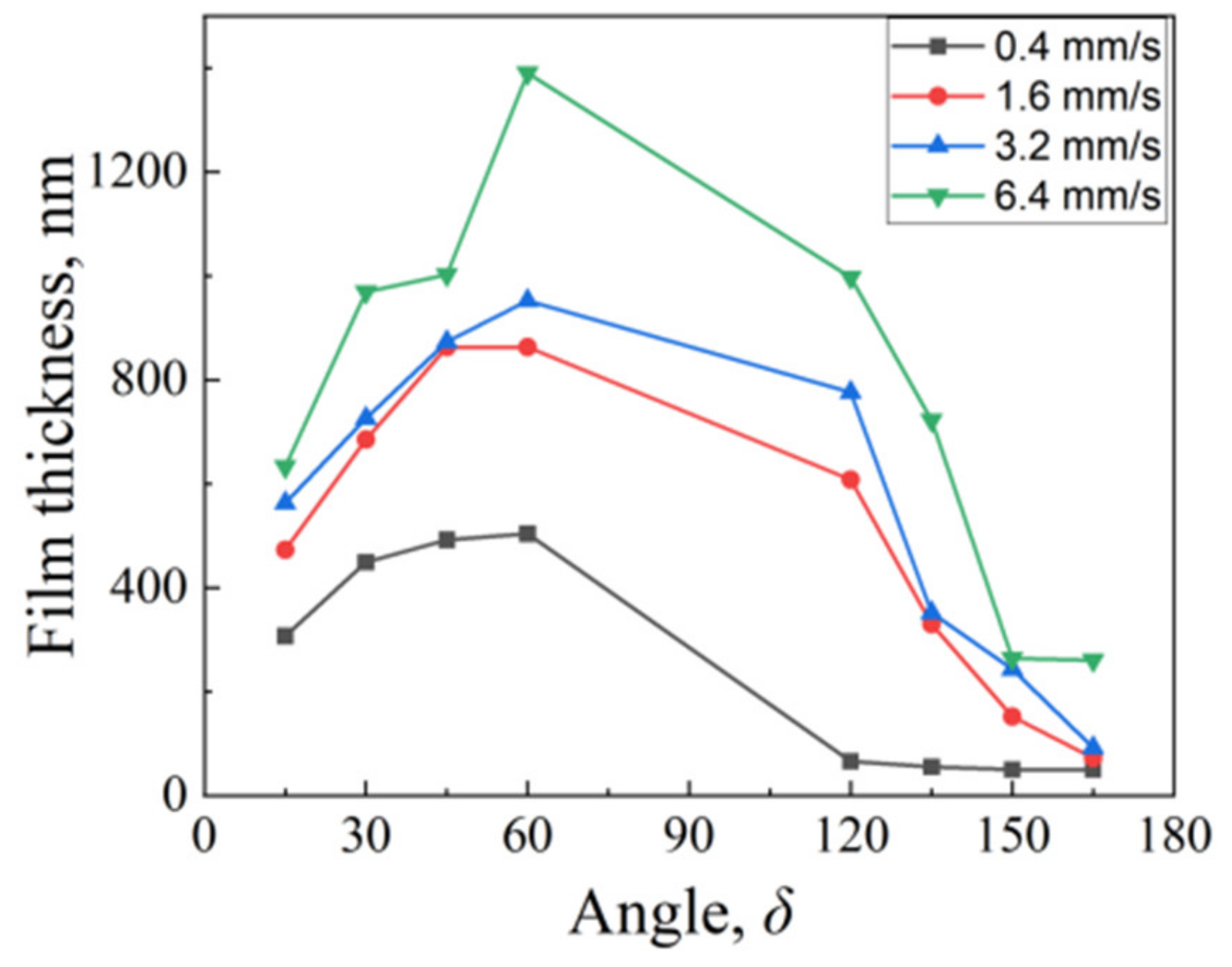

3.2. Effect of Angle Change on Oil Film State

3.2.1. Direction of Suction Speed

3.2.2. Sliding Speed Direction

3.2.3. The Central Membrane Is Thick

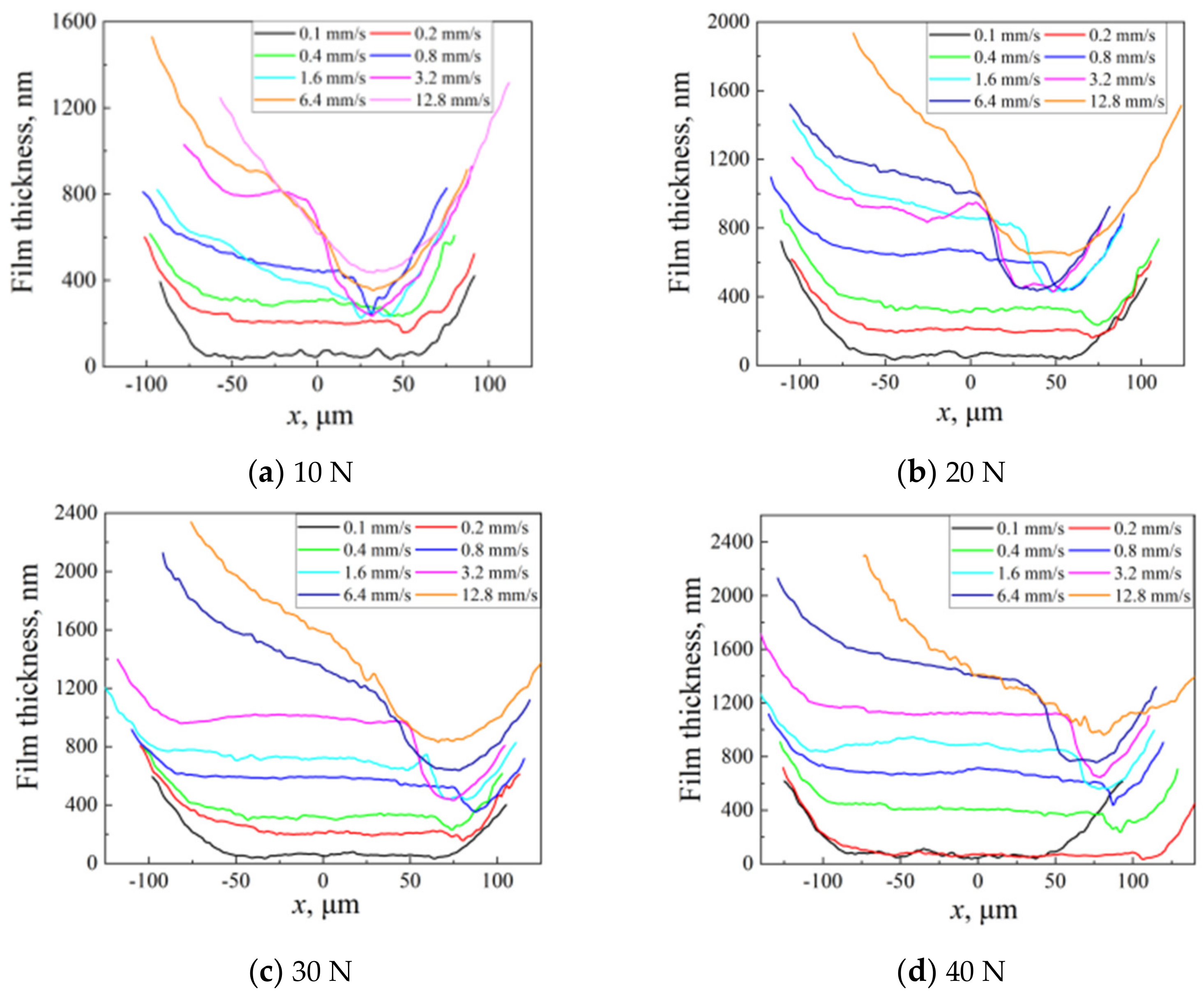

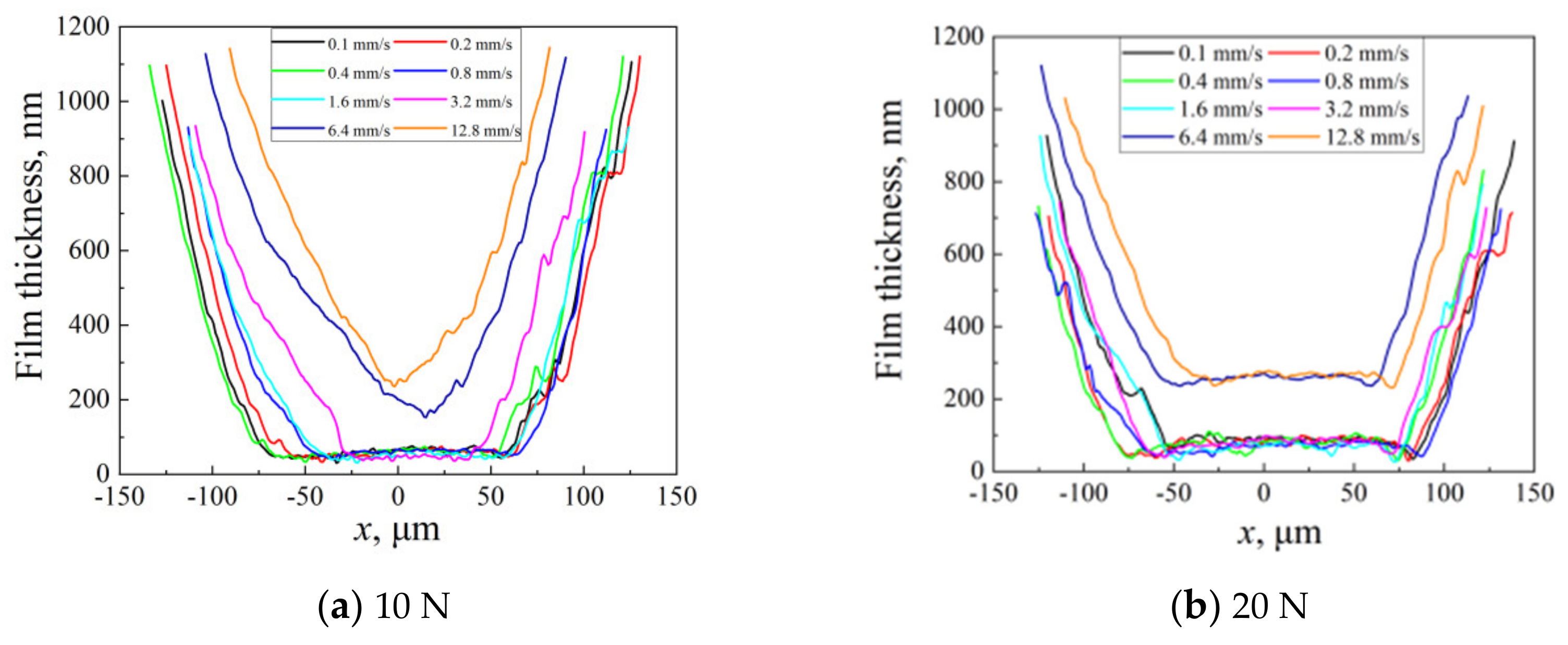

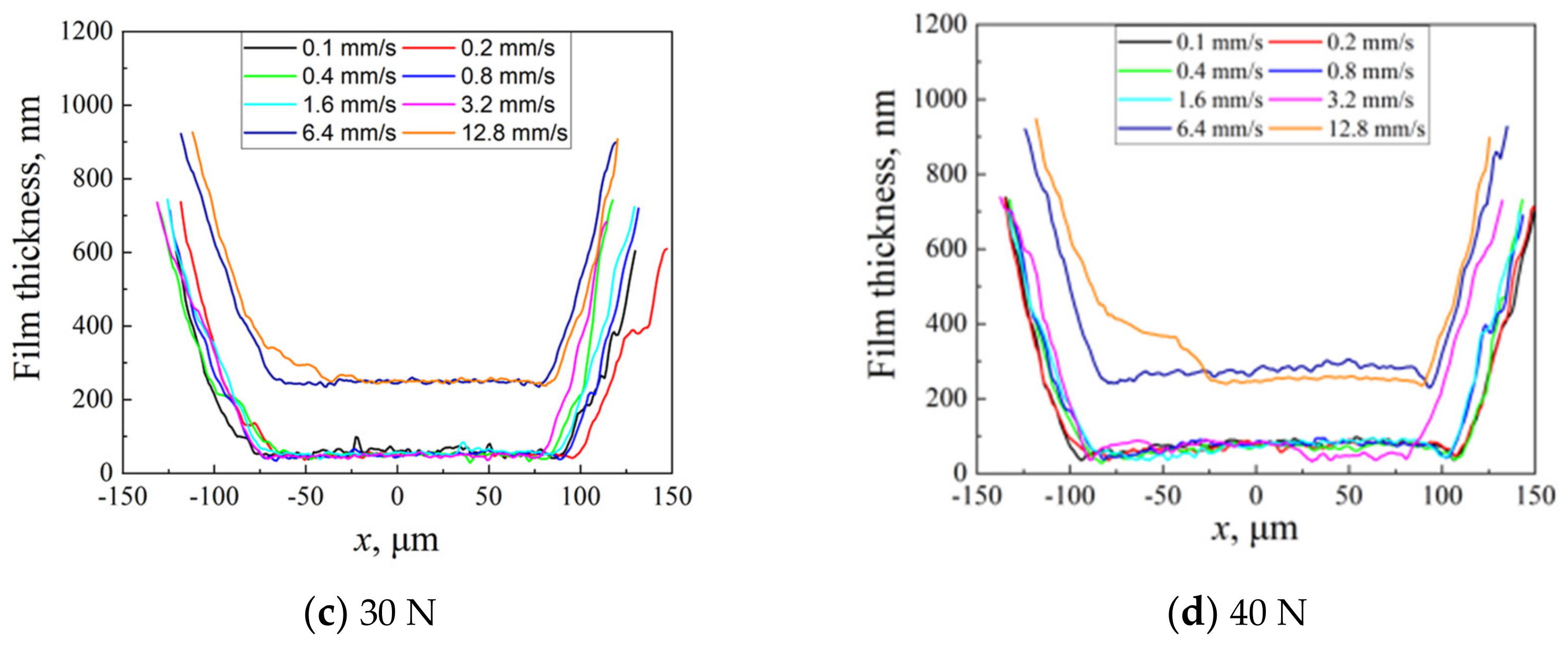

3.3. Effect of Load Variation on Oil Film State

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chiu, Y.P.; Sibley, L.B. Contact Shape and Non-Newtonian Effects in Elastohydrodynamic Point Contacts. Lubr. Eng. 1972, 28, 48–60. [Google Scholar]

- Kaneta, M.; Nishikawa, H.; Kameishi, K. Effects of Elastic Moduli of Contact Surfaces in Elastohydrodynamic Lubrication. J. Tribol. 1992, 114, 75–80. [Google Scholar] [CrossRef]

- Ehret, P.; Dowson, D.; Taylor, C.M. On Lubricant Transport Conditions in Elastohydrodynamic Conjuctions. Proc. R. Soc. Lond. A 1998, 454, 763–787. [Google Scholar] [CrossRef]

- Qu, S.; Yang, P.; Guo, F. Theoretical Investigation on the Dimple Occurrence in the Thermal EHL of Simple Sliding Steel-Glass Circular Contacts. Tribol. Int. 2000, 33, 59–65. [Google Scholar] [CrossRef]

- Yang, P.; Qu, S.; Chang, Q. On the Theory of Thermal Elastohydrodynamic Lubrication at High Slide-Roll Ratios: Line Contact Solution. J. Tribol. 2001, 123, 36–41. [Google Scholar] [CrossRef]

- Cameron, A. The Viscosity Wedge. ASLE Trans. 1958, 1, 248–253. [Google Scholar] [CrossRef]

- Murch, L.E.; Wilson, W.R.D. A Thermal Elastohydrodynamic Inlet Zone Analysis. J. Lubr. Tech. 1975, 97, 212–216. [Google Scholar] [CrossRef]

- Wilson, W.R.D.; Sheu, S. Effect of Inlet Shear Heating due to Sliding on Elastohydrodynamic Film Thickness. Trans. ASME J. Lubric. Technol 1983, 105, 187–188. [Google Scholar] [CrossRef]

- Lord, J.; Larsson, R. Effects of Slide-roll Ratio and Lubricant Properties on Elastohydrodynamic Lubrication Film Thickness and Traction. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2001, 215, 301–308. [Google Scholar] [CrossRef]

- Omasta, M.; Krupka, I.; Hartl, M. Effect of Surface Velocity Directions on Elastohydrodynamic Film Shape. Tribol. Trans. 2013, 56, 301–309. [Google Scholar] [CrossRef]

- Omasta, M.; Krupka, I.; Hartl, M. Study of Elastohydrodynamic Film Shape Under Different Directions of Velocity Vectors. In Proceeding of ASME/STLE 2011 International Joint Tribology Conference, Los Angeles, CA, USA, 24–26 October 2011; pp. 401–403. [Google Scholar]

- Omasta, M.; Krupka, I.; Hartl, M. Effect of sliding direction on EHL film shape under high sliding conditions. Tribol. Trans. 2016, 60, 87–94. [Google Scholar] [CrossRef]

- Yagi, K.; Vergne, P.; Nakahara, T. In Situ Pressure Measurements in Dimples Elastohydrodynamic Sliding Contacts by Raman Microspectroscopy. Tribol. Int. 2009, 42, 724–730. [Google Scholar] [CrossRef]

- Guo, F.; Wong, P.L. Experimental Observation of a Dimple-wedge Elastohydrodynamic Lubricating Film. Tribol. Int. 2004, 37, 119–127. [Google Scholar] [CrossRef]

- Kaneta, M.; Yang, P. Effects of the Thermal Conductivity of Contact Materials on Elastohydrodynamic Lubrication Characteristics. J. Mech. Eng. Sci. 2010, 224, 257787. [Google Scholar] [CrossRef]

- Bruyere, V.; Fillon, N.; Morales, G.E.; Vergne, P. Computational Fluid Dynamics and Full Elasticity Model for Sliding Line Thermal Elastohydrodynamic Contacts. Tribol. Int. 2012, 46, 3–13. [Google Scholar] [CrossRef]

- Black, D.T. Slip between a liquid and a solid: D.M. Tolstoi’s theory reconsidered. Colloids Surf. A 1990, 47, 135–145. [Google Scholar]

- Vinogradova, O. Drainage of a thin liquid film confined between hydrophobic surfaces. Langmuir 1995, 11, 2213–2220. [Google Scholar] [CrossRef]

- Xiang, G.; Yang, T.Y.; Guo, J.; Wang, J.X. Optimization transient wear and contact performances of water-lubricated bearings under fluid-solid-thermal coupling condition using profile modification. Wear 2022, 502–503, 204379. [Google Scholar] [CrossRef]

- Tretheway, D.C.; Meinhart, C.D. Apparent fluid slip at hydrophobic microchannel walls. Phys. Fluids 2002, 14, 9–12. [Google Scholar] [CrossRef]

- Choo, J.H.; Spikes, H.A.; Ratoi, M. Friction reduction in low-load hydrodynamic lubrication with a hydrophobic surface. Tribol. Int. 2007, 40, 154–159. [Google Scholar] [CrossRef]

- Piotr, W. Investigation of energy losses of the internal combustion engine taking into account the correlation of the hydrophobic and hydrophilic. Energy 2023, 264, 126002. [Google Scholar]

- Ma, J.; Liu, Y.C.; Zhang, N.; Zhang, W.J. Wettability transition and tribological properties of hydrophobic alloy surfaces prepared by one-step method. Tribol. Int. 2023, 178, 108020. [Google Scholar] [CrossRef]

- Piotr, W. Reduction of friction energy in a piston combustion engine for hydrophobic and hydrophilic multilayer nanocoatings surrounded by soot. Energy 2023, 271, 126974. [Google Scholar]

- Wang, Y.X.; Yuan, C.; Zhou, K.; Gu, Q.L.; Jing, W.H. Construction of Janus silicon carbide membranes with asymmetric wettability for enhanced antifouling in water-in-oil emulsification process. J. Membr. Sci. 2023, 671, 121389. [Google Scholar] [CrossRef]

- Lu, H.W.; Zhang, J.; Liu, C.; Guo, F. Experimental study of limited oil supply on lubrication characteristics under velocity intersection working condition. Tribology 2022, 43, 178–188. [Google Scholar]

- Li, X.M.; Zhou, G.Y.; Guo, F. Experimental Investigation into Enhancement of Lubricant Replenishment Induce by Angled Entrainment. J. Mech. Eng. 2020, 56, 225–232. [Google Scholar]

- Ni, Q.B.; Zhang, J.J.; Guo, F. Experimental investigation of effects of surface speed effect on EHL. Lubr. Eng. 2018, 43, 37–39. [Google Scholar]

- Liu, H.C.; Guo, F.; Zhao, G.L. A Dichromatic Interference Intensity Modulation Approach to Lubricating Film Thickness Measurement. Tribology 2015, 35, 282–287. [Google Scholar] [CrossRef]

- Luo, J.B.; Wen, S.Z.; Huang, P. Thin film lubrication. Part I Study on the transition between EHL and thin film lubrication using a relative optical interference intensity technique. Wear 1996, 194, 107–115. [Google Scholar] [CrossRef]

- Guo, F.; Wong, P.L.; Fu, Z. Interferometry measurement of lubricating films in slider-on-disc contacts. Tribology 2010, 39, 71–79. [Google Scholar] [CrossRef]

- Zhang, J.J. Study on Non-Collnearentrainment Speed, Thermal Viscosity Wedge and Interface Slippage of Elastohyrodynamic Lubrication; Qingdao Technology University: Qingdao, China, 2022. [Google Scholar]

| Name of the Oil | Density ρ (kg·m−3) 20 °C | Dynamic Viscosity l (Pa·s) 20 °C |

|---|---|---|

| PB1300 | 896 | 117.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Zhang, J.; Wang, S.; Wang, W.; Che, Q. Experimental Investigation on the Effect of Velocity Anisotropy on Oil Film State under Different Surface Wettability Interface. Lubricants 2023, 11, 381. https://doi.org/10.3390/lubricants11090381

Wang Z, Zhang J, Wang S, Wang W, Che Q. Experimental Investigation on the Effect of Velocity Anisotropy on Oil Film State under Different Surface Wettability Interface. Lubricants. 2023; 11(9):381. https://doi.org/10.3390/lubricants11090381

Chicago/Turabian StyleWang, Zuomin, Jianjun Zhang, Shijin Wang, Weihui Wang, and Qinglun Che. 2023. "Experimental Investigation on the Effect of Velocity Anisotropy on Oil Film State under Different Surface Wettability Interface" Lubricants 11, no. 9: 381. https://doi.org/10.3390/lubricants11090381

APA StyleWang, Z., Zhang, J., Wang, S., Wang, W., & Che, Q. (2023). Experimental Investigation on the Effect of Velocity Anisotropy on Oil Film State under Different Surface Wettability Interface. Lubricants, 11(9), 381. https://doi.org/10.3390/lubricants11090381