Abstract

Surface engineering is required to improve the poor lubrication performance of titanium alloys in many applications. In this study, an oxide coating with high-hardness was created on TC4 titanium alloy by using plasma electrolytic oxidation (PEO). The composition and structure of the PEO coatings were analyzed by scanning electron microscopy (SEM), X-ray diffraction (XRD), and Raman spectroscopy. The tribological properties of the PEO-treated TC4 were investigated in the presence of a polyalphaolefin (PAO) base oil with addition of molybdenum dialkyldithiocarbamate (MoDTC). The results show that the PEO-treated TC4 exhibits excellent lubrication performance in the presence of MoDTC. The oxide coating on the PEO-treated TC4 sample shows a tribo-induced catalysis effect enabling the decomposition of MoDTC to forms an effective lubricating film containing MoS2, resulting in reduced friction and wear.

1. Introduction

Since nearly 20% of the global annual energy is consumed by transportation vehicles, it is urgent to achieve lower friction and wear to improve fuel efficiency [1,2,3]. Most efforts have focused on developing lubricants with low base oil viscosity and more effective additives, such as anti-wear additives, detergents, viscosity modifiers, dispersants, corrosion inhibitors, extreme pressure additives, and friction modifiers [4]. Molybdenum dialkyldithiocarbamate (MoDTC) is widely used as a friction modifier in lubricating oils to reduce friction by forming a tribofilm containing MoS2 in the sliding contact [5,6,7,8,9,10,11,12,13]. Some recent studies have shown that different tribochemical reactions may happen when MoDTC is employed with other materials, which leads to different tribological performance [14,15,16,17,18,19,20]. In diamond-like carbon (DLC)/steel contact, MoDTC presents a pro-wear effect, which is due to the formation of an abrasive material MoO3 from the incomplete decomposition of MoDTC during the sliding [14,15,16,17,18]. In contrast, the friction and wear were significantly reduced when MoDTC was employed with TiO2 coatings [19,20]. In this case, MoDTC completely decomposes to MoS2 with the help of the tribocatalytic effect of TiO2. Similar efforts have been recently observed for TiN coatings [21].

Titanium and its alloy are widely used in aeronautical fields and have been entered into automobile manufacturing for their outstanding mechanical properties with low density [22]. Poor wear protection performance is the main drawback of titanium alloy [23,24,25]. Thus, surface engineering is widely used to enhance the wear protection properties of titanium alloys [26,27,28,29,30,31,32]. Plasma electrolytic oxidation (PEO) is a simple and friendly method for the improved mechanical performance of the surface of titanium [33], magnesium [34,35,36], aluminum [37,38], and other valve metals. Ceramic coatings can be directly grown on the surface, substantially improving their hardness, wear resistance, and corrosion resistance [39,40,41]. However, the tribological performance of PEO-treated titanium has been primarily evaluated under non-lubrication conditions [42,43,44,45,46,47,48,49,50]. Due to the promising application prospect of titanium alloys in automobile engine, it is of great significance to investigate the tribological interaction between PEO-treated titanium alloys and MoDTC. These studies are important for the appropriate selection or design of lubricant additives for titanium alloys. Thus, in this manuscript, the tribological interaction between a PEO-treated TC4 titanium alloy and MoDTC was evaluated to elucidate the lubrication mechanism of MoDTC.

2. Experimental

2.1. Materials

All reagents were purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). The multi-walled carbon nanotubes (MCNT) were obtained from Nanjing XFNANO Materials Tech Co., Ltd., Nanjing, China and used without pretreatment. The MCNT has an average outer diameter of 8~15 nm and a length of ~12 μm with a purity of 95 wt.%, provided by the supplier.

TC4 alloy samples, commercially obtained from Boti International Metal Co. Ltd., Baoji, China, were successively polished by 400, 800, and 1200 grade sandpaper until surface roughness Ra = 0.1 μm. They were ultrasonically cleaned in absolute ethyl alcohol and deionized water, each for 10 min.

2.2. Preparation of PEO Coatings

The PEO coatings were deposited on TC4 in the air by employing a DC power supply at the constant current mode as reported in our previous manuscript [51]. Table 1 summarized the base electrolytes solution used. During the PEO process, the TC4 samples were used as the anode and a cylindrical 304 stainless steel as the cathode. The compositions and the process conditions of the PEO experiment are given in Table 1.

Table 1.

Electrolyte composition used in the experiment.

The phase composition of the PEO coating was characterized by X-ray diffraction (XRD). The surface and cross-section microstructure of the PEO coatings was analyzed by the scanning electron microscope (SEM). TR200 roughness meter was used to measure the surface roughness of the bare TC4 and PEO-treated coating. Each sample was measured three times and the average value was taken to obtain the surface roughness.

2.3. Tribological Tests

A ball-on-disk machine was used to evaluate the lubricating performance of the PEO-treated TC4 in the presence of PAO base oil (viscosity: 31.7 mPa.s at 20 °C) containing MoDTC at a concentration of 0.3%, 0.5%, 1%, and 2% by weight. MoDTC was commercially obtained and used without pretreatment. Table 2 lists the testing conditions. 50 μL fresh lubricants were needed each time. The test was repeated three times and the averaged value were reported. The lambda ratio (λ) was computed to be about 0.082~0.086, suggesting that the experiments were operated in the regime of boundary lubrication.

Table 2.

The ball-on-flat reciprocating tribotest conditions.

The samples after the testing were carefully rinsed with heptane before performing surface analysis. XPS analysis and Raman spectroscopy was performed to characterize the tribofilms on TiO2 coatings. An XPS experiment was conducted using an Al Kα X-ray source at 12 kV. The energy spectrum calibration was achieved by using C1s binding energy at 284.8 eV. Raman spectra were carried out with a laser with 532 nm wavelength. Scanning electron microscopies (SEM) were performed with the operating voltage of 20 kV.

3. Results and Discussion

3.1. Characterization of PEO Coatings

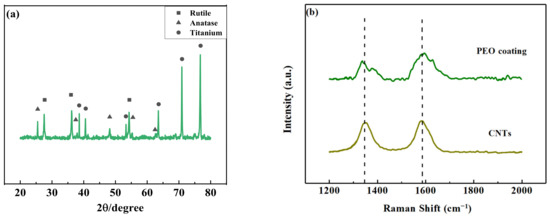

As shown in Figure 1a for the XRD patterns, the PEO-treated TC4 exhibits peaks of anatase (JCPDS No. 21-1272) and rutile (JCPDS No. 21-1276), indicating that PEO coating consists of titanium oxide in the form of anatase and rutile [52]. Moreover, it is interesting to note the peaks of titanium (JCPDS No. 1-1198) in the XRD pattern [53]. The reason is that the porosity of the PEO coating could have contributed to letting X-rays penetrate the PEO coatings to reach the TC4 substrates [54]. However, no peak of carbon was observed in the XRD spectra of the PEO-treated TC4 samples. The likely reason is that the PEO coatings contained such a low amount of MCNT that they were not detected by XRD [55]. Thus, Raman spectroscopy was employed to determine the presence of the MCNT materials in the PEO coatings. The peaks around 1585 cm−1 (G band) and 1353 cm−1 (D band) were found in Raman spectrum in Figure 1b, suggesting the presence of MCNT in the PEO coating. These observations are in agreement with previous studies [56,57].

Figure 1.

(a) XRD spectra of PEO coating and (b) Raman spectra of PEO coating and WCNT.

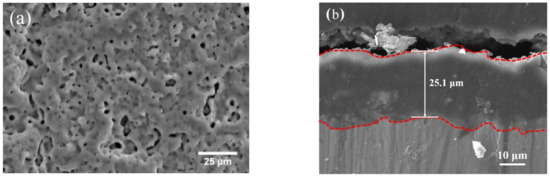

As shown in Figure 2a, the PEO-treated TC4 substrate is shown by the usual surface features after PEO treatment [58,59,60], which leads to higher surface roughness (Ra = 1.99 μm) when compared with the bare TC4 (Ra = 0.10 μm). The surface roughness data were measured by the above roughness meter. Figure 2b shows the cross-sectional SEM images of the PEO coatings. No discontinuity zone existed between the substrate and the PEO coatings, suggesting the PEO coatings were well adhered to the substrate. The Vickers hardness of the surfaces of the PEO coatings was measured to be 672 HV, which was almost two times larger than the value of the uncoated substrate (383 HV).

Figure 2.

SEM surface (a) and cross-section (b) images of PEO coatings.

3.2. Lubrication Performance

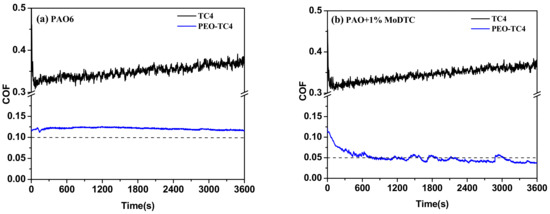

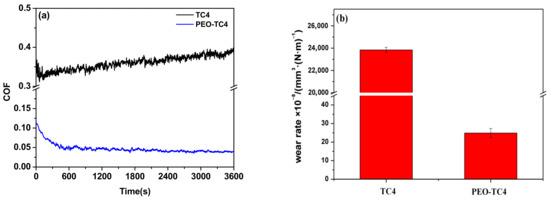

Figure 3 plots the coefficient of friction (COF) versus the sliding time for the bare and PEO-treated TC4 under the lubrication of a PAO base oil with and without MoDTC. The initial COF of the bare TC4 sample lubricated with base oil is 0.33; the value increases slowly with the sliding time, and the final COF is 0.37. The addition of 1% MoDTC to the base oil does not significantly change the friction performance, suggesting that MoDTC, which is commonly used as a friction modifier in iron-based materials, is not effective in reducing the COF for the bare TC4. However, this is not the case for the TC4 sample after the PEO treatment. Specifically, the COF of the PEO-treated sample lubricated with the base oil is stable at 0.11 during the entire sliding period. After the addition of 1% MoDTC to the base oil, the COF is further reduced to ~0.05 after a short running-in period, matching the performance of the MoDTC with the surface oxide coatings.

Figure 3.

The evolution of COF with sliding time for various TC4 samples under the lubrication of (a) PAO base oil and (b) PAO + 1% MoDTC oil.

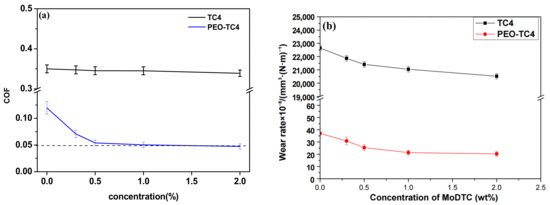

The effect of the MoDTC concentration in the PAO base oil on the tribological properties was evaluated. As shown in Figure 4a, the COF of the bare TC4 sample remains around 0.35, regardless of whether or not MoDTC is added to the base oil. In contrast, the COF decreases with the increasing MoDTC concentration for the PEO-treated TC4 samples. The COF remains stable at 0.05 when MoDTC concentration in the base oil exceeds 0.5%.

Figure 4.

The effort of MoDTC concentration in PAO base oil on (a) COF and (b) wear rate of various samples.

As shown in Figure 4b, the wear rate of the bare TC4 sample lubricated by the base oil is 2.3 × 10−4 mm3/(Nm) and decreases slightly with increasing MoDTC concentrations in the base oil. The wear rate of the bare TC4 sample is still high (2.1 × 10−4 mm3/(Nm) even under lubrication of PAO + 2% MoDTC oil. In contrast, the wear rate of the bare TC4 is reduced significantly after the PEO treatment and decreases with increasing MoDTC concentrations. The wear rate of the PEO-treated sample lubricated by the base oil is only 37 × 10−8 mm3/(Nm). At an MoDTC concentration of 2%, the wear rate is 20 × 10−8 mm3/(Nm), which is three orders of magnitude lower than that of the bare TC4 sample.

Figure 5 shows the tribological properties of the samples lubricated with PAO + 1% MoDTC at a load of 50 N. The bare TC4 sample shows a 13.3% increase in the wear rate with a slight increase in the COF with the increasing load from 27 N to 50 N (Figure 4a vs. Figure 5a). However, after the PEO treatment, the COF of the TC4 samples remains unchanged with an increase in the load from 27 N to 50 N. The increase in the wear rate of the PEO-treated TC4 is lower as compared with the bare TC4, indicating that the PEO-treated TC4 samples still maintain good lubrication performance in the presence of MoDTC, even under a high load.

Figure 5.

(a) COF and (b) wear rate under lubrication of PAO + 1%MoDTC oil at load of 50 N.

3.3. SEM Analysis

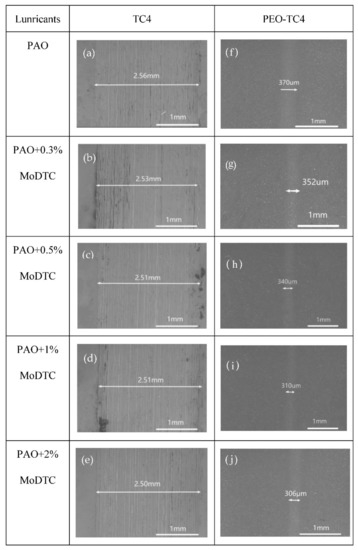

SEM was used to characterize the surface morphology of the wear track after the sliding test. As shown in Figure 6a, the worn surface of the bare TC4 was covered in furrows in the sliding direction when lubricated with the base oil. Significant plastic deformation also occurred at the edge of the contacting area, indicating extensive adhesive metallic wear. After adding MoDTC to the PAO base oil, the morphology of the worn surface did not change significantly (Figure 6b–e), except that the wear scar width slightly decreased with an increase in the MoDTC concentration in the base oil. However, the PEO-treated TC4 samples had a relatively smooth surface with no furrows when lubricated with the base oil. The width of the wear track decreased with increasing MoDTC concentrations (Figure 6f–j). At a MoDTC concentration of 2%, the wear scar width of the PEO-treated sample was only 306 μm (Figure 6j), which was only 12.2% of the wear scar width of the bare TC4 sample.

Figure 6.

SEM images of the wear track.

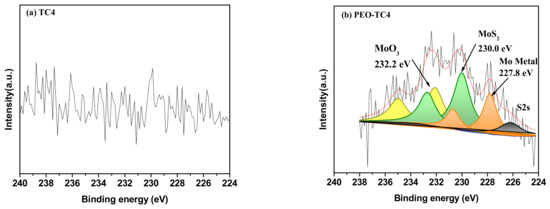

3.4. XPS and Raman Analysis

The wear tracks of the bare and PEO-treated TC4 lubricated with base oil containing 1% MoDTC were characterized by XPS to clarify the tribochemical reaction of the MoDTC film. As shown in Figure 7a, for the bare TC4 sample, no significant peaks were observed in the Mo3d spectra, suggesting no tribofilm existed in the contact area. It agrees with the observation of similar friction behavior of the TC4 sample lubricated by the base oil with and without MoDTC. However, for PEO-treated TC4, surface chemistries of the tribofilm were totally different. As shown in Figure 7b for the Mo 3d spectra, there is a strong peak at the position of 230.0 eV for MoS2, along with the contribution of MoO3 at 232.2 eV and metallic Mo at 227.8eV [19,20,21].

Figure 7.

Mo3d XPS spectra inside wear track for (a) the bare TC4 and (b) PEO-treated coating lubricated by PAO + 1% MoDTC oil.

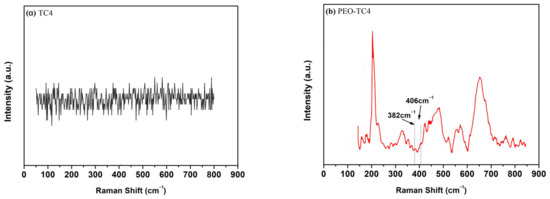

Raman microscopy was also used to confirm the presence of MoS2 in the tribofilm for the PEO-treated TC4. Two peaks at 406 and 382 cm−1 were found in the Raman diagram of Figure 8, which were assigned to the A1g and E2g modes of MoS2, respectively [10].

Figure 8.

Raman diagram inside the wear scar for (a) the bare TC4 and (b) PEO treated coating lubricated by PAO + 1% MoDTC oil.

Thus, both XPS and Raman observations strongly indicate that MoDTC molecules decomposed to MoS2 on the PEO-treated TC4 in the sliding process. The findings were in agreement with the experimental observation of the lower friction and wear of the PEO-treated TC4. The presence of MoS2 in the tribofilm could be the major reason for lower COF for the PEO-treated TC4. On the contrary, no such tribochemical reaction occurred in the case of the bare TC4 one, leading to the high COF (Figure 2a).

3.5. Mechanism of MoDTC

Some investigations in the past have been conducted to illustrate how lower COF was achieved on iron-based materials by MoDTC [6,7,8,9,10,11,12,13,14,15,16,17,18,19,20]. It is strongly suggested that the formation of MoS2-containing tribofilm from the decomposition of MoDTC during sliding is the major reason [7,8]. The complete decomposition reaction of MoDTC to MoS2 is determined by several factors, such as the concentration of MoDTC, the Hertzian contact pressure, the testing temperature, the humidity, and the slide-to-roll ratio [19,20]. The surface chemical properties of contacting material are also important. Here, it was found that PEO-treated TC4 presents lower COF and wear rate than the bare TC4 under lubrication of PAO base oil with addition of MoDTC. The Raman and XPS analysis suggested the creation of tribofilm which consists of MoS2, MoO3, and a small amount of metallic molybdenum. The results suggest that MoDTC completely decomposed to MoS2 during sliding in the PEO-treated TC4. However, no such a decomposition reaction was observed for the bare TC4. Thus, the surface PEO oxide coating presents a catalytic effect for the decomposition reaction of MoDTC during the contacting process. As shown in Figure 1a, the XRD spectra indicates the existence of a TiO2 layer on the surface of the PEO-treated samples. It was recently observed that TiO2 is helpful in inducing the decomposition reaction of MoDTC to MoS2 [19,20]. Qu et al. [24] also reported that oxides coated with thermally oxidized TC4 reacted more easily with a lubricating additive of zinc dialkyldithiophosphate (ZDDP) than metallic titanium. TiO2 materials are n-type semiconductors, emitting more negatively charged particles than conductive metallic materials [61,62]. This behavior is more pronounced when the materials are sliding under boundary lubrication conditions. Moreover, some theoretical studies have proven that the formation of MoS2 from the decomposition of MoDTC is accelerated in the presence of a reducing agent [10]. These results have been further corroborated by the experimental results of Grossiord et al. [6] and De Barros et al. [12], who found that Mo+6 (MoDTC) was reduced to Mo+4 (MoS2) via electron transfer. Thus, for the PEO-treated TC4 samples, it is posited that the sliding process provides more energy for the release of negatively charged particles, facilitating the complete decomposition of MoDTC via a tribo-induced catalytic process on the PEO-treated samples, leading to the formation of MoS2 inside the tribofilm and reduced friction and wear. This tribo-induced catalytic effect is likely enhanced by MCNT in the PEO coating. Since MCNT possess a highly complex structure with rolled-up graphene layers [63], they have been considered as effective catalysts to support various reactions, such as hydrogenation [64] and hydrocarbon decomposition [65]. MCNT have been also investigated for enhancing tribological applications as lubricant additives [66,67,68] or reinforcements for various materials [69,70,71]. Moreover, a synergistic effect was observed when WCNT were used with MoS2 as a nanocomposite solid lubricant [72] or nanofluid [73].

Thus, the oxide coating on the PEO-treated TC4 sample exhibits a tribo-induced catalytic effect that enables the complete decomposition of MoDTC to form an effective lubricating film containing MoS2, resulting in reduced friction and wear. However, this tribo-induced catalytic effect was not observed in the bare TC4 samples. A natural oxide film exists on the surface of the bare TC4 sample. However, this film is very thin (10 nm or less) and is easily removed after several early sliding passes. In this case, the bare TC4 sample did not effectively catalyze the degradation of MoDTC molecules to form a tribofilm in the sliding process. As a result, no MoS2 was observed in the contacting zone of the bare TC4 in the XPS and Raman analyses. In this case, similar tribological performances were observed for the bare TC4 with or without the addition of MoDTC to the base oil.

Plasma electrolytic oxidation is an efficient method to enhance the wear resistance of TC4 significantly due to the formation of a hard oxide film. The present study demonstrated that this oxide film facilitated the creation of an effective lubricating film containing MoS2 to decrease COF and wear rate in the presence of MoDTC. Our findings are expected to promote the wider use of titanium alloys in energy-efficient engine systems.

4. Conclusions

The tribological interaction between a MoDTC additive in the PAO base oil and the micro-arc oxidized TC4 was investigated. Unlike the bare TC4, the PEO-treated TC4 showed excellent tribological properties when lubricated with the base oil containing MoDTC. The friction coefficient of the PEO-treated TC4 sample was 87% lower and the wear rate was three orders of magnitude lower than that of the bare sample. The XPS and Raman analyses provided evidence for the formation of MoS2 from the complete decomposition of MoDTC for the PEO-treated TC4. It is suggested that the oxide coating on the PEO-treated TC4 sample exhibited a tribo-induced effect that enabled the decomposition of MoDTC to form an effective lubricating film containing MoS2, resulting in reduced friction and wear.

Author Contributions

Conceptualization, H.S., Y.W. and C.W.; Methodology, H.S., S.Z. and J.L.; Formal analysis, H.S. and J.L.; Investigation, H.S. and Y.W.; Writing-original draft preparation, H.S.; Writing-review and editing, H.S., S.Z., J.L. and C.W.; Funding acquisition, H.S., S.Z. and J.L.; Validation, J.L.; Data curation, L.S. and J.L.; Software, Y.W.; Project administration, C.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Natural Science Foundation of Shandong Province, China (Grant No. ZR2019MEE016).

Data Availability Statement

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Erdemir, A.; Ramirez, G.; Eryilmaz, O.L.; Narayanan, B.; Liao, Y.; Kamath, G.; Sankaranarayanan, S.K.R.S. Carbon-based tribofilms from lubricating oils. Nature 2016, 536, 67–71. [Google Scholar] [CrossRef] [PubMed]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Zhang, J.; Spikes, H. On the Mechanism of ZDDP Antiwear Film Formation. Tribol. Lett. 2016, 63, 1–15. [Google Scholar] [CrossRef]

- Spikes, H. Friction Modifier Additives. Tribol. Lett. 2015, 60, 1–26. [Google Scholar] [CrossRef]

- Grossiord, C.; Varlot, K.; Martin, J.-M.; Le Mogne, T.; Esnouf, C.; Inoue, K. MoS2 single sheet lubrication by molybdenum dithiocarbamate. Tribol. Int. 1998, 31, 737–743. [Google Scholar] [CrossRef]

- Garcia, C.E.; Ueda, M.; Spikes, H.; Wong, J.S.S. Temperature dependence of molybdenum dialkyl dithiocarbamate (MoDTC) tribofilms via time-resolved Raman spectroscopy. Sci. Rep. 2021, 11, 3621. [Google Scholar] [CrossRef]

- Vaitkunaite, G.; Espejo, C.; Wang, C.; Thiébaut, B.; Charrin, C.; Neville, A.; Morina, A. MoS2 tribofilm distribution from low viscosity lubricants and its effect on friction. Tribol. Int. 2020, 151, 106531. [Google Scholar] [CrossRef]

- Jose, D.; De Feo, M.; Minfray, C.; Cobian, M. Computational studies of reaction mechanism of MoDTC, Leeds- Lyon. Symp. Tribol. 2015, 2, 92–100. [Google Scholar]

- Espejo, C.; Wang, C.; Thiébaut, B.; Charrin, C.; Neville, A.; Morina, A. The role of MoDTC tribochemistry in engine tribology performance. A Raman microscopy investigation. Tribol. Int. 2020, 150, 106366. [Google Scholar] [CrossRef]

- Komaba, M.; Kondo, S.; Suzuki, A.; Kurihara, K.; Mori, S. Kinetic Study on Lubricity of MoDTC as a Friction Modifier. Tribol. Online 2019, 14, 220–225. [Google Scholar] [CrossRef]

- Bouchet, M.D.B.; Martin, J.; Le Mogne, T.; Bilas, P.; Vacher, B.; Yamada, Y. Mechanisms of MoS2 formation by MoDTC in presence of ZnDTP: Effect of oxidative degradation. Wear 2005, 258, 1643–1650. [Google Scholar] [CrossRef]

- Balarini, R.; Diniz, G.; Profito, F.; Souza, R. Comparison of unidirectional and reciprocating tribometers in tests with MoDTC-containing oils under boundary lubrication. Tribol. Int. 2020, 149, 105686. [Google Scholar] [CrossRef]

- Kosarieh, S.; Morina, A.; Flemming, J.; Lainé, E.; Neville, A. Wear Mechanisms of Hydrogenated DLC in Oils Containing MoDTC. Tribol. Lett. 2016, 64, 4. [Google Scholar] [CrossRef]

- De Feo, M.; Bouchet, M.D.B.; Minfray, C.; Le Mogne, T.; Meunier, F.; Yang, L.; Thiebaut, B.; Martin, J. MoDTC lubrication of DLC-involving contacts. Impact of MoDTC degradation. Wear 2016, 348–349, 116–125. [Google Scholar] [CrossRef]

- Kosarieh, S.; Morina, A.; Lainé, E.; Flemming, J.; Neville, A. The effect of MoDTC-type friction modifier on the wear performance of a hydrogenated DLC coating. Wear 2013, 302, 890–898. [Google Scholar] [CrossRef]

- Vengudusamy, B.; Green, J.H.; Lamb, G.D.; Spikes, H.A. Behaviour of MoDTC in DLC/DLC and DLC/steel contacts. Tribol. Int. 2012, 54, 68–76. [Google Scholar] [CrossRef]

- Masuko, M.; Ono, T.; Aoki, S.; Suzuki, A.; Ito, H. Friction and wear characteristics of DLC coatings with different hydrogen content lubricated with several Mo-containing compounds and their related compounds. Tribol. Int. 2015, 82, 350–357. [Google Scholar] [CrossRef]

- Deshpande, P.; Minfray, C.; Dassenoy, F.; Thiebaut, B.; Le Mogne, T.; Vacher, B.; Jarnias, F. Tribological behaviour of TiO2 Atmospheric Plasma Spray (APS) coating under mixed and boundary lubrication conditions in presence of oil containing MoDTC. Tribol. Int. 2018, 118, 273–286. [Google Scholar] [CrossRef]

- Deshpande, P.; Minfray, C.; Dassenoy, F.; Le Mogne, T.; Jose, D.; Cobian, M.; Thiebaut, B. Tribocatalytic behaviour of a TiO2 atmospheric plasma spray (APS) coating in the presence of the friction modifier MoDTC: A parametric study. RSC Adv. 2018, 8, 15056–15068. [Google Scholar] [CrossRef]

- Fu, X.; Li, Y.; Su, H.; Cao, L.; Wan, Y.; Li, R. Tribological interactions between TiN PVD coating and MoDTC under boundary lubrication conditions. Vacuum 2022, 195, 110646. [Google Scholar] [CrossRef]

- Sachdev, A.K.; Kulkarni, K.; Fang, Z.Z.; Yang, R.; Girshov, V. Titanium for Automotive Applications: Challenges and Opportunities in Materials and Processing. Jom 2012, 64, 553–565. [Google Scholar] [CrossRef]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Qu, J.; Blau, P.J.; Howe, J.Y.; Iii, H.M.M. Oxygen diffusion enables anti-wear boundary film formation on titanium surfaces in zinc-dialkyl-dithiophosphate (ZDDP)-containing lubricants. Scr. Mater. 2009, 60, 886–889. [Google Scholar] [CrossRef]

- Cao, L.; Liu, J.; Wan, Y.; Yang, S.; Gao, J.; Pu, J. Low-friction carbon-based tribofilm from poly-alpha-olefin oil on thermally oxidized Ti6Al4V. Surf. Coatings Technol. 2018, 337, 471–477. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Chen, L.-Y.; Wang, L. Surface Modification of Titanium and Titanium Alloys: Technologies, Developments, and Future Interests. Adv. Eng. Mater. 2020, 22, 1901258. [Google Scholar] [CrossRef]

- Liu, W.; Liu, S.; Wang, L. Surface Modification of Biomedical Titanium Alloy: Micromorphology, Microstructure Evolution and Biomedical Applications. Coatings 2019, 9, 249. [Google Scholar] [CrossRef]

- Liu, X.; Chu, P.K.; Ding, C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater. Sci. Eng. R Rep. 2004, 47, 49–121. [Google Scholar] [CrossRef]

- Diamanti, M.; Sebastiani, M.; Mangione, V.; Del Curto, B.; Pedeferri, M.; Bemporad, E.; Cigada, A.; Carassiti, F. Multi-step anodizing on Ti6Al4V components to improve tribomechanical performances. Surf. Coatings Technol. 2013, 227, 19–27. [Google Scholar] [CrossRef]

- Bansal, D.; Eryilmaz, O.; Blau, P. Surface engineering to improve the durability and lubricity of Ti–6Al–4V alloy. Wear 2011, 271, 2006–2015. [Google Scholar] [CrossRef]

- Aniołek, K.; Barylski, A.; Kupka, M. Friction and Wear of Oxide Scale Obtained on Pure Titanium after High-Temperature Oxidation. Materials 2021, 14, 3764. [Google Scholar] [CrossRef] [PubMed]

- Praveen, A.S.; Arjunan, A. High-temperature oxidation and erosion of HVOF sprayed NiCrSiB/Al2O3 and NiCrSiB/WC Co coatings. Appl. Surf. Sci. Adv. 2022, 7, 100191. [Google Scholar] [CrossRef]

- Aliofkhazraei, M.; Macdonald, D.; Matykina, E.; Parfenov, E.; Egorkin, V.; Curran, J.; Troughton, S.; Sinebryukhov, S.; Gnedenkov, S.; Lampke, T.; et al. Review of plasma electrolytic oxidation of titanium substrates: Mechanism, properties, applications and limitations. Appl. Surf. Sci. Adv. 2021, 5, 100121. [Google Scholar] [CrossRef]

- Barati Darband, G.; Aliofkhazraei, M.; Hamghalam, P.; Valizade, N. Plasma electrolytic oxidation of magnesium and its alloys: Mechanism, properties and applications. J. Magnes. Alloy. 2017, 5, 74–132. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, D.; Su, H.; Yu, P.; Wan, Y.; Sun, H. Improving the tribocorrosion performance of plasma electrolytic oxidized coatings on AZ31B magnesium alloy using pullulan as an electrolyte additive. Surf. Coat. Technol. 2022, 446, 128754. [Google Scholar] [CrossRef]

- Xu, L.; Fu, X.; Su, H.; Sun, H.; Li, R.; Wan, Y. Corrosion and tribocorrosion protection of AZ31B Mg alloy by a hydrothermally treated PEO/chitosan composite coating. Prog. Org. Coat. 2022, 170, 107002. [Google Scholar] [CrossRef]

- Jadhav, P.; Bongale, A.; Kumar, S. A review of process characteristics of plasma electrolytic oxidation of aluminium alloy. J. Physics Conf. Ser. 2021, 1854, 012030. [Google Scholar] [CrossRef]

- Tong, S.; Xu, L.; Wan, Y.; Wang, Y.; Wang, J. Enhanced corrosion-resistant performance of the PEO coatings on AA7075 alloy by a sol-gel derived silica layer. Int. J. Appl. Ceram. Technol. 2022, 19, 2613–2622. [Google Scholar] [CrossRef]

- Wang, G.; Nie, X.; Tjong, J. Load and Lubricating Oil Effects on Friction of a PEO Coating at Different Sliding Velocities. SAE Tech. Pap. 2017, 1, 464. [Google Scholar] [CrossRef]

- Garcia-Cabezón, C.; Rodríguez-Méndez, M.L.; Borrás, V.A.; Bayón, R.; Salvo-Comino, C.; Garcia-Hernandez, C.; Martin-Pedrosa, F. Improvements in tribological and anticorrosion performance of porous Ti-6Al-4V via PEO coating. Friction 2021, 9, 1303–1318. [Google Scholar] [CrossRef]

- Lv, X.; Cao, L.; Wan, Y.; Xu, T. Effect of different electrolytes in micro-arc oxidation on corrosion and tribological performance of 7075 aluminum alloy. Mater. Res. Express. 2019, 6, 086421. [Google Scholar] [CrossRef]

- Friedemann, A.; Gesing, T.; Plagemann, P. Electrochemical rutile and anatase formation on PEO surfaces. Surf. Coatings Technol. 2017, 315, 139–149. [Google Scholar] [CrossRef]

- Wang, G.; Nie, X.; Tjong, J. Surface Effect of a PEO Coating on Friction at Different Sliding Velocities. SAE Tech. Pap. 2015, 1, 687. [Google Scholar] [CrossRef]

- Mortazavi, G.; Jiang, J.; Meletis, E.I. Investigation of the plasma electrolytic oxidation mechanism of titanium. Appl. Surf. Sci. 2019, 488, 370–382. [Google Scholar] [CrossRef]

- Martini, C.; Ceschini, L.; Tarterini, F.; Paillard, J.; Curran, J. PEO layers obtained from mixed aluminate–phosphate baths on Ti–6Al–4V: Dry sliding behaviour and influence of a PTFE topcoat. Wear 2010, 269, 747–756. [Google Scholar] [CrossRef]

- Demirbaş, Ç.; Ayday, A. Effect of Ag concentration on structure and wear behaviour of coatings formed by micro-arc oxidation on Ti6Al4 V Alloy. Surf. Eng. 2020, 37, 24–31. [Google Scholar] [CrossRef]

- Rafieerad, A.; Ashra, M.; Mahmoodian, R.; Bushroa, A. Surface characterization and corrosion behavior of calcium phosphate-base composite layer on titanium and its alloys via plasma electrolytic oxidation: A review paper. Mater. Sci. Eng. C 2015, 57, 397–413. [Google Scholar] [CrossRef]

- Guo, H.; Liu, Z.; Wang, Y.; Li, J. Tribological mechanism of micro-arc oxidation coatings prepared by different electrolyte systems in artificial seawater. Ceram. Int. 2020, 47, 7344–7352. [Google Scholar] [CrossRef]

- Ríos, J.; Quintero, D.; Castaño, J.; Echeverría, F.; Gómez, M. Comparison among the lubricated and unlubricated tribological behavior of coatings obtained by PEO on the Ti6Al4V alloy in alkaline solutions. Tribol. Int. 2018, 128, 1–8. [Google Scholar] [CrossRef]

- Pesode, P.; Barve, S. Surface modification of titanium and titanium alloy by plasma electrolytic oxidation process for biomedical applications: A review. Mater. Today Proc. 2021, 46, 594–602. [Google Scholar] [CrossRef]

- Guo, Y.; Xu, L.; Luan, J.; Wan, Y.; Li, R. Effect of carbon nanotubes additive on tribocorrosion performance of micro-arc oxidized coatings on Ti6Al4V alloy. Surf. Interfaces 2022, 28, 101626. [Google Scholar] [CrossRef]

- Wang, K.; Zhuo, Y.; Chen, J.; Gao, D.; Ren, Y.; Wang, C.; Qi, Z. Crystalline phase regulation of anatase–rutile TiO2 for the enhancement of photocatalytic activity. RSC Adv. 2020, 10, 43592–43598. [Google Scholar] [CrossRef] [PubMed]

- Kalyoncuoglu, U.T.; Yilmaz, B.; Gungor, S. Evaluation of the chitosan-coating effectiveness on a dental titanium alloy in terms of microbial and fibroblastic attachment and the effect of aging. Mater. Teh. 2015, 49, 925–931. [Google Scholar] [CrossRef]

- Mashtalyar, D.; Nadaraia, K.; Imshinetskiy, I.; Belov, E.; Filonina, V.; Suchkov, S.; Sinebryukhov, S.; Gnedenkov, S. Composite coatings formed on Ti by PEO and fluoropolymer treatment. Appl. Surf. Sci. 2021, 536, 147976. [Google Scholar] [CrossRef]

- Arrebola, J.C.; Caballero, A.; Hernán, L.; Morales, J. Graphitized Carbons of Variable Morphology and Crystallinity: A Comparative Study of Their Performance in Lithium Cells. J. Electrochem. Soc. 2009, 156, A986. [Google Scholar] [CrossRef]

- Rao, A.M.; Richter, E.; Bandow, S.; Chase, B.; Eklund, P.C.; Williams, K.A.; Fang, S.; Subbaswamy, K.R.; Menon, M.; Thess, A.; et al. Diameter-Selective Raman Scattering from Vibrational Modes in Carbon Nanotubes. Science 1997, 275, 187–191. [Google Scholar] [CrossRef]

- Keszler, A.M.; Nemes, L.; Ahmad, S.R.; Fang, X. Characterization of carbon nanotube materials by Raman spectroscopy and microscopy—A case study of multiwalled and singlewalled samples. J. Optoelectronics. Adv. Mater. 2004, 6, 1269–1274. [Google Scholar]

- Yürektürk, Y.; Muhaffel, F.; Baydoğan, M. Characterization of micro arc oxidized 6082 aluminum alloy in an electrolyte containing carbon nanotubes. Surf. Coatings Technol. 2015, 269, 83–90. [Google Scholar] [CrossRef]

- Yazıcı, S.K.; Muhaffel, F.; Baydogan, M. Effect of incorporating carbon nanotubes into electrolyte on surface morphology of micro arc oxidized Cp-Ti. Appl. Surf. Sci. 2014, 318, 10–14. [Google Scholar] [CrossRef]

- Cheng, T.; Chen, Y.; Nie, X. Surface morphology manipulation and wear property of bioceramic oxide coatings on titanium alloy. Surf. Coatings Technol. 2013, 215, 253–259. [Google Scholar] [CrossRef]

- Nakayama, K.; Suzuki, N.; Hashimoto, H. Triboemission of charged particles and photons from solid surfaces during frictional damage. J. Phys. D Appl. Phys. 1992, 25, 303–308. [Google Scholar] [CrossRef]

- Ciniero, A.; Le Rouzic, J.; Baikie, I.; Reddyhoff, T. The origins of triboemission—Correlating wear damage with electron emission. Wear 2017, 374–375, 113–119. [Google Scholar] [CrossRef]

- Serp, P.; Corrias, M.; Kalck, P. Carbon nanotubes and nanofibers in catalysis. Appl. Catal. A Gen. 2003, 253, 337–358. [Google Scholar] [CrossRef]

- Giordano, R.; Serp, P.; Kalck, P.; Kihn, Y.; Schreiber, J.; Marhic, C.; Duvail, J. Preparation of Rhodium Catalysts Supported on Carbon Nanotubes by a Surface Mediated Organometallic Reaction. Eur. J. Inorg. Chem. 2003, 2003, 610–617. [Google Scholar] [CrossRef]

- Pham-Huu, C.; Keller, N.; Roddatis, V.V.; Mestl, G.; Schlögl, R.; Ledoux, M.J. Large scale synthesis of carbon nanofibers by catalytic decomposition of ethane on nickel nanoclusters decorating carbon nanotubes. Phys. Chem. Chem. Phys. 2002, 4, 514–521. [Google Scholar] [CrossRef]

- Cornelio, J.A.C.; Cuervo, P.A.; Hoyos-Palacio, L.M.; Lara-Romero, J.; Toro, A. Tribological properties of carbon nanotubes as lubricant additive in oil and water for a wheel–rail system. J. Mater. Res. Technol. 2016, 5, 68–76. [Google Scholar] [CrossRef]

- Chen, C.; Chen, X.; Xu, L.; Yang, Z.; Li, W. Modification of multi-walled carbon nanotubes with fatty acid and their tribological properties as lubricant additive. Carbon 2005, 43, 1660–1666. [Google Scholar] [CrossRef]

- Peng, Y.; Hu, Y.; Wang, H. Tribological behaviors of surfactant-functionalized carbon nanotubes as lubricant additive in water. Tribol. Lett. 2007, 25, 247–253. [Google Scholar] [CrossRef]

- Ahmad, I.; Kennedy, A.; Zhu, Y. Wear resistant properties of multi-walled carbon nanotubes reinforced Al2O3 nanocomposites. Wear 2010, 269, 71–78. [Google Scholar] [CrossRef]

- Shirasu, K.; Miyaura, T.; Yamamoto, G.; Suzuki, T.; Naito, K.; Hashida, T. Enhanced tribological performance of alumina composites reinforced with acid-treated carbon nanotubes under water lubrication. Diam. Relat. Mater. 2020, 101, 107657. [Google Scholar] [CrossRef]

- Arai, S.; Fujimori, A.; Murai, M.; Endo, M. Excellent solid lubrication of electrodeposited nickel-multiwalled carbon nanotube composite films. Mater. Lett. 2008, 62, 3545–3548. [Google Scholar] [CrossRef]

- Zhang, X.; Luster, B.; Church, A.; Muratore, C.; Voevodin, A.A.; Kohli, P.; Aouadi, S.; Talapatra, S. Carbon Nanotube−MoS2 Composites as Solid Lubricants. ACS Appl. Mater. Interfaces 2009, 1, 735–739. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, C.; Jia, D.; Zhang, D.; Zhang, X. Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int. J. Mach. Tools Manuf. 2015, 99, 19–33. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).