1. Introduction

The whole automotive sector has been facing huge challenges in recent years. CO2-and other harmful gas emissions of internal combustion engines have to be reduced drastically and the COVID-19 virus situation also influences the daily life of many researcher and development institutes. To reach the emission goals, the continuous development of the internal combustion engines and the lubricants inside them is crucial. Of course, electric vehicles are becoming more and more popular, but the production of electricity also has its CO2 emission until it will be made from 100% CO2 neutral and renewable resources.

Lubricants used in internal combustion engines are very complex liquids, containing several additives for different purposes, e.g., viscosity modifiers, antiwear additives such as ZDDP (zinc dialkyldithiophosphate) [

1] or PTFE (poly(tetrafluoroethene)) [

2,

3], defoamers such as silicone oils, etc. To take advantage of the maximum potential of the lubricants, the additives must be compatible with each other. However, several additives can act differently in the presence of non-metallic surface materials (e.g., ceramic-containing coatings), which means the elements of the whole tribosystem have to be optimized. During the combustion phase in the cylinders of the engines, the lubricant attached to the cylinder wall can be burned, the protective oil film can be removed from there and the harmful emission gases can damage the surface of the cylinder liner. These burned additive molecules can influence the operating conditions of the exhaust gas after-treatment systems (particle filters [

4], catalysts [

5]) as well, so these properties also influence the applicability of the lubricant additives.

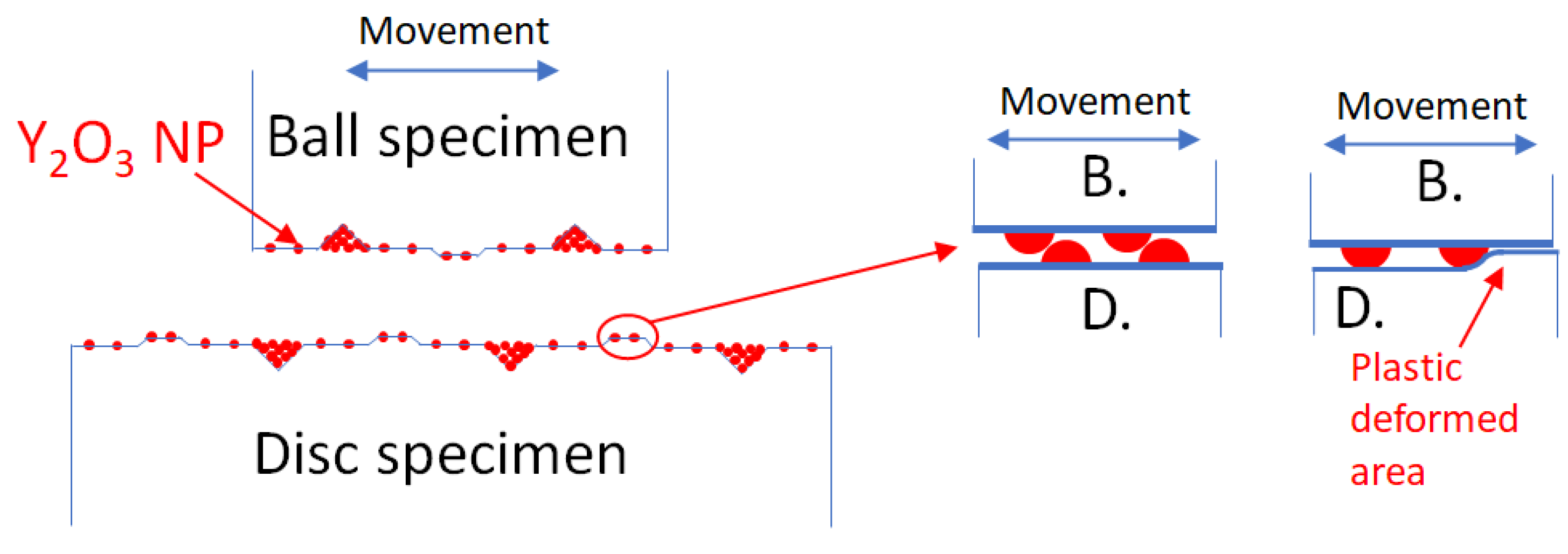

Nanoparticles (average particle size is between 1 and 100 nm [

6]) as lubricant additives can be the solution for the previously presented challenges. Several mechanisms were published [

7] to explain the possible working procedures of the nanoparticles: rolling (

Figure 1a), mending (

Figure 1b), polishing (

Figure 1c) and protective film mechanism (

Figure 1d). However, before the common application, the tribological effects of nanoparticles must be experimentally analyzed. For this purpose, researchers usually use tribometers with different specimens (e.g., ball-on-disc). For the measurement of the wear on the surfaces, different microscopes are usually used (e.g., digital microscope or scanning electron microscope).

The homogenization of the lubricant samples to be measured is a crucial part of the experiments. Akl et al. [

9] presented two commonly used preparation methods to homogenize nanoparticle containing lubricants. In the single-step method, the nanoparticles, the dispersing agent and the base fluid are prepared simultaneously, meanwhile in the two-step method, the nanoparticles are mixed with the dispersing agent separately and later this mixture is homogenized into the base fluid. The single-step method is rarely used due to its higher cost and small-scale production rates. The usage of the two-step method is much more common because this method also enables to produce nanolubricants with higher volumes effectively.

The particle size of the used ceramic additives has to be suited to the roughness of the contacting surfaces. Peña-Parás et al. [

10] has proved that only the nanoparticles with an initial diameter smaller than the average surface roughness can decrease the friction and wear losses of a tribosystem. However, if the initial diameter of the nanoparticles is too small, they can form larger micron-scale clusters and the tribological losses cannot continue to decrease.

Numerous research papers exist which investigate the tribological properties and working mechanisms of different nanoscale particles as lubricant additives. These nanoscale additives can be categorized into metal-oxides (TiO

2, CuO, Fe

3O

4, ZnO, Co

3O

4, Al

2O

3, etc.), metal-sulfides (MoS

2, WS

2, FeS, etc.), nanocomposites (Cu/CeO

2, Al

2O

3/SiO

2, ZrO

2/SiO

2, etc.) and rare earth compounds (CeVO

4, Y

2O

3, La(OH)

3, LaF

3, etc.) [

11].

The yttrium-oxide (Y2O3) nanoparticle is one of the additives those tribological properties have not investigated and published on yet. This paper aims to experimentally analyze the friction and wear behavior of the yttria nanoparticles as lubricant additives and to investigate their applicability in internal combustion engine lubricants.

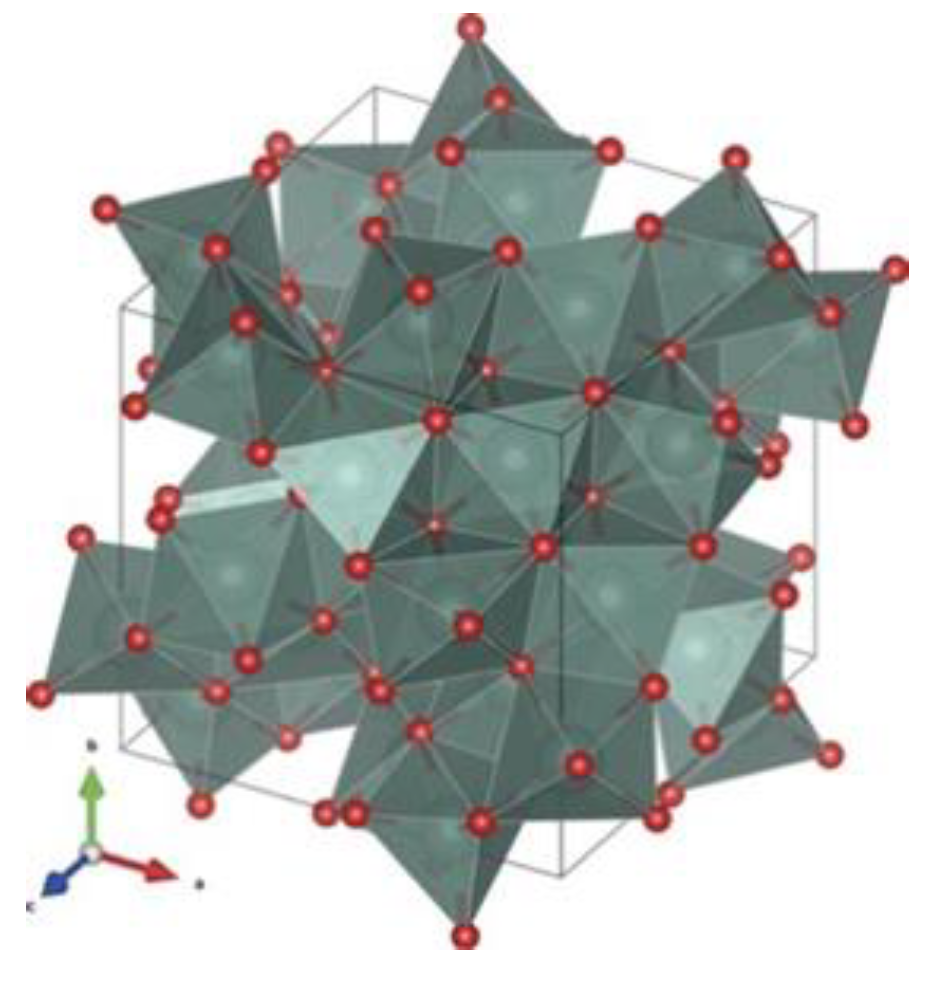

Yttrium oxide is an air-stable, white, solid crystalline oxide of yttrium transition metal. Yttria closely resembles lanthanide oxides in most of its properties. Generally, yttria is produced by the calcination of yttrium containing compounds and ores such as samarskite-(Y) and yttrobetafite-(Y). The other industrial production possibility is solvent extraction from ores that also contain heavier lanthanides. Yttria occurs naturally in its own mineral, known as yttrialite-(Y). In nature, yttria appears with a body-centered cubic crystalline structure (

Figure 2) [

12].

Yttria particles are commonly used as a lapping–polishing agent because of their physical properties (their hardness is between 2200 and 2800 HV) [

13]. From a tribological point of view, yttria can be used as a stabilizer material for zirconia to strengthen its properties. Pandian et al. [

14] investigated the friction and wear properties of yttria stabilized zirconia nanolubricants in a ball-on-disc rotational tribosystem. They defined a significant amount of friction and wear reduction with the YSZ-doped lubricant, and they also underlined the importance of the formation and the effective spreading of the YSZ lubricating film.

He et al. [

15] reported that sheet-like 2D yttrium-oxide nanoparticles have been shown to improve the mechanical and flow phenomena of various fluids. Non-Einstein-like reductions in the viscosity of 0.1 wt% nano yttrium oxide doped mineral oil are reported. The experimental results, along with general smoothed-particle hydrodynamic simulations, provide insight into the mechanism of fluid shear stress reduction. The orderly tilt of these two-dimensional nanoparticle additives significantly improves the lubricating properties of the mineral oil, ultimately reduces friction, and provides an opportunity to design and understand next-generation lubricants. As an additive, the yttrium nanoparticle can reduce friction and viscosity by up to 40% and 5%, respectively, on a pin-on-disc tribometer.

2. Investigation Methods and Materials

For the investigation, nano-scale yttrium oxide particles (CAS-number: 1314-36-9, Reanal Laborvegyszer Kereskedelmi Kft., Budapest, Hungary) were used. The exact data of the used yttria nanoparticles are presented in

Table 1. The yttria nanoparticles (see in

Figure 3) are used in their original form, their properties were not changed during the tribological measurements

The homogenization of the yttria nanoparticles into the used liquid is crucial to produce nanolubricants with positive tribological properties. For the experiments neat Group III base oil with 4 cSt kinematic viscosity (provided by MOL-LUB Ltd., Almásfüzitő, Hungary) was used to prevent any collision between different lubricant additives. The yttria nanoparticles were doped in the base oil and the mixtures were homogenized with a magnetic stirrer and ultrasonic homogenizer for 3 min at 1000 rpm and 30 min on 50 °C, respectively. After the ultrasonic homogenization, the samples were stirred magnetically again until the lubrication pipes were filled up with the sample.

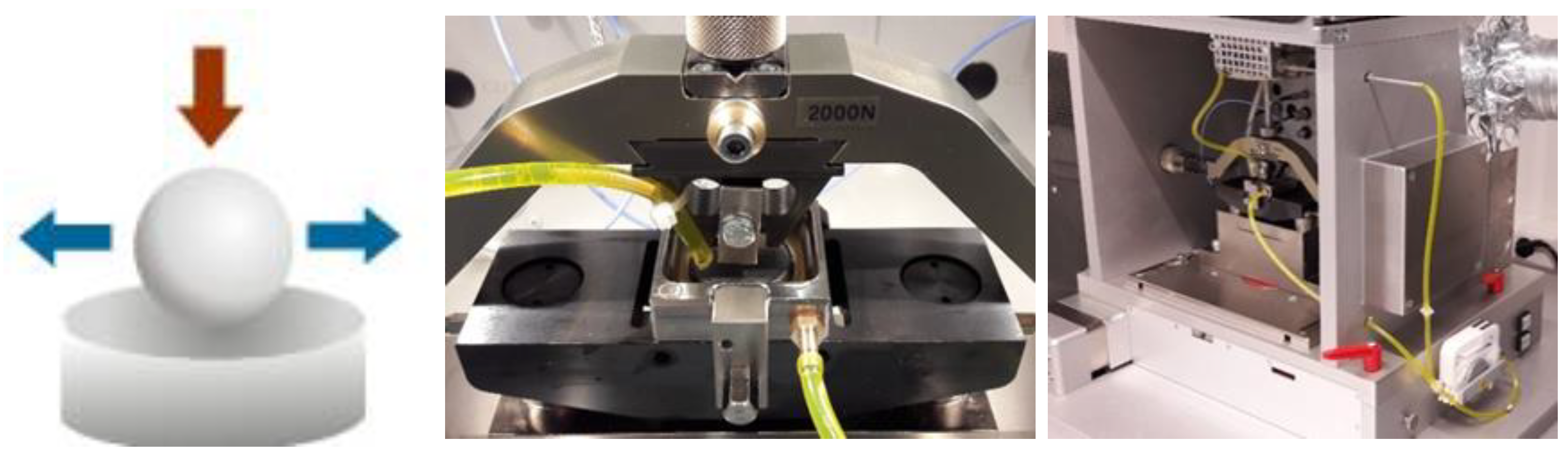

For the experimental investigations, an Optimol SRV

®5 type tribometer (Munich, Bavaria, Germany) was used with the specimens of ball and disc. The specification of used specimens is in correlation with the standard of ISO 19291:2016 [

16]. A self-developed testing method [

17] was used for the experiments with a supplementary oil circuit with an oil flow rate of 225 mL/h. The ball specimen was moved on the flat surface of the disc with a 1 mm stroke and 50 Hz frequency oscillation movement pattern. Both the specimens and the lubricant were heated up to 100 °C temperature separately; 50 N loading force was applied between the surfaces for 30 s and then increased to 100 N for 2 h [

18]. The applied testing machine with the realized oil circuit is presented in

Figure 4.

For the evaluation of the results, two different friction coefficient values were used, which were recorded with 1 s frequency:

COF (coefficient of friction) value: the maximum friction coefficient value during one stroke, which arises usually from the dead centers of the oscillation movement, representing the property of the system under boundary lubrication condition;

FAI (friction absolute integral) value: an average value calculated from the area under the friction coefficient values recorded with high frequency, representing the property of the system under mixed and hydrodynamic lubrication regimes. The calculating equation can be observed in (1).

where s is the applied stroke and µ is the measured friction coefficient. The difference between the two measured friction coefficient values is illustrated in

Figure 5.

The friction measurements were supported with wide microscopic analysis to quantify and investigate the wear on the surfaces of the specimens. A digital microscope (Keyence VHX-1000, Mechlin, Belgium) was used to measure the wear scar diameter (WSD) on the ball specimen in the directions of parallel and perpendicular to the sliding motion, according to standard ISO 19291:2016 [

16]. Further confocal microscope measurements (Leica DCM 3D, Wetzlar, Germany) were carried out to measure the wear volume on the surface of the disc specimen. The signs of the wear mechanism and the presence of yttria on the worn surface were determined with a high-magnitude scanning electron microscope with an EDX sensor (Hirox SEM-4000M, Limonest, France) [

10]. High resolution EDX element mapping was carried out with a ThermoFisher Helios G4 PFIB CXe scanning electron microscope (Waltham, MA, USA, acceleration voltage 20 kV, beam current 13 nA).

3. Experimental Results and Discussion

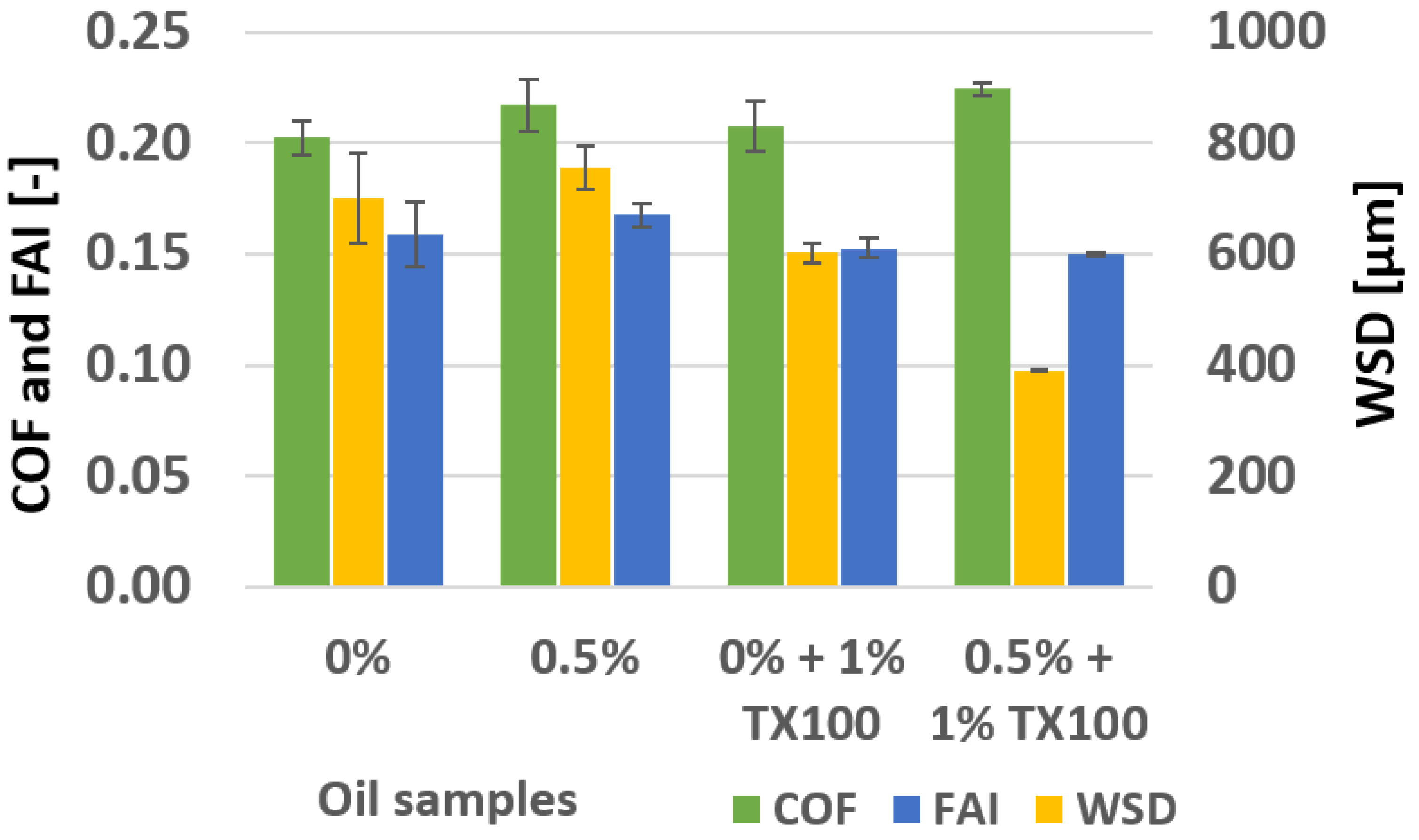

Firstly, the necessity of extra surface-active detergent additive was analyzed. For this, four different lubricant samples were prepared: neat Group III base oil as the reference, GIII doped with 0.5 wt% Y

2O

3, GIII with 1 wt% Triton X-100, and GIII doped with 1 wt% TX100 and 0.5 wt% Y

2O

3. The results of this comparison are shown in

Figure 6. The results are obvious: yttria without triton in the applied base oil significantly increased the tribological losses, but the nanoparticles supplemented with the detergent TX100 have provided positive tribological values. Both the integral friction coefficient value and the diameter of the wear scar on the ball specimens were remarkably reduced.

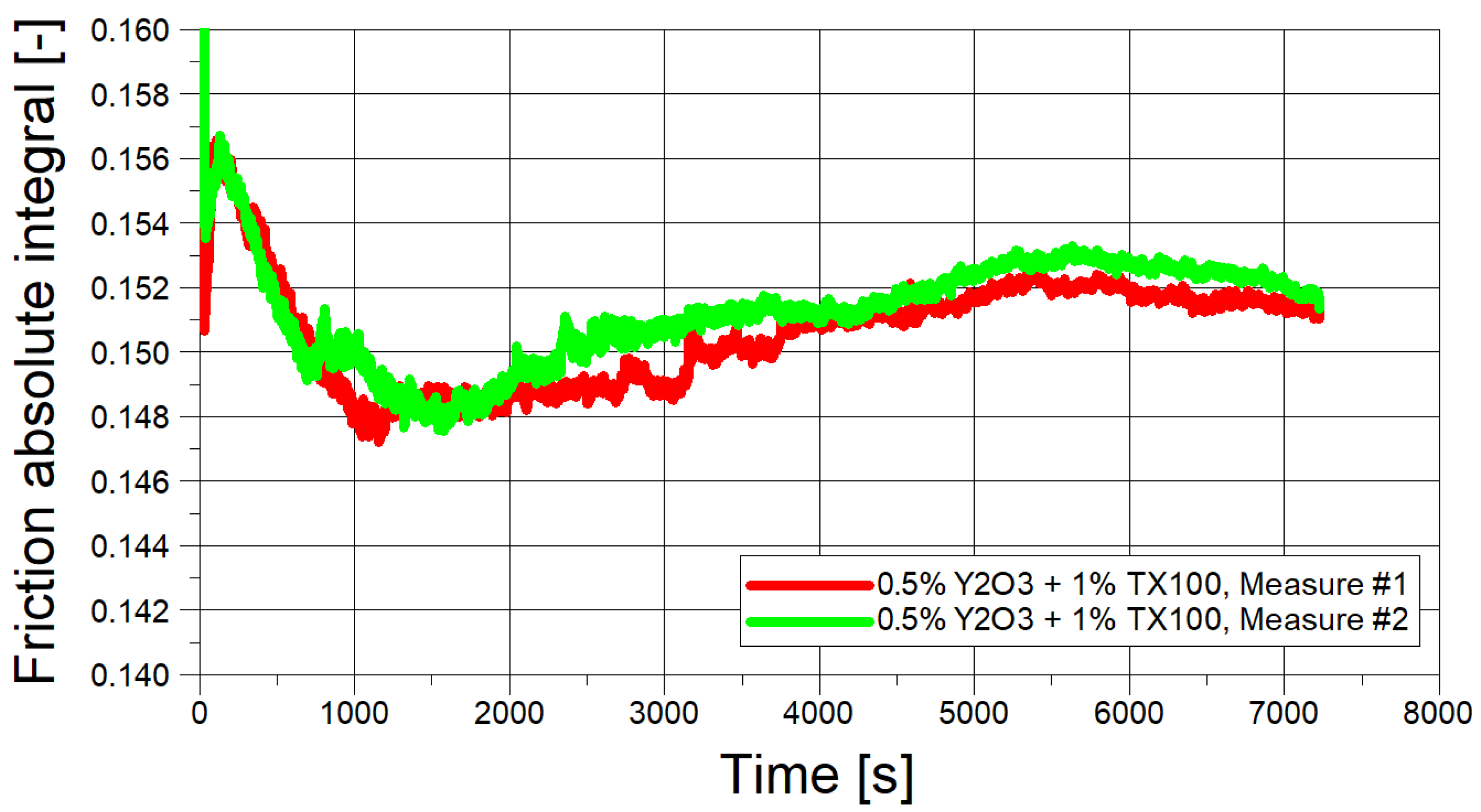

Figure 7 demonstrates the time dependence of the measured friction coefficient values during the frictional tests and the comparison of two independent measurements with the same nanoparticle concentration. The two measured friction coefficient curves are smooth and nearly linear, which strengthens the statement that the yttria nanoparticles require the presence of triton detergent to provide positive tribological properties. The reproducibility of the measurements is also excellent.

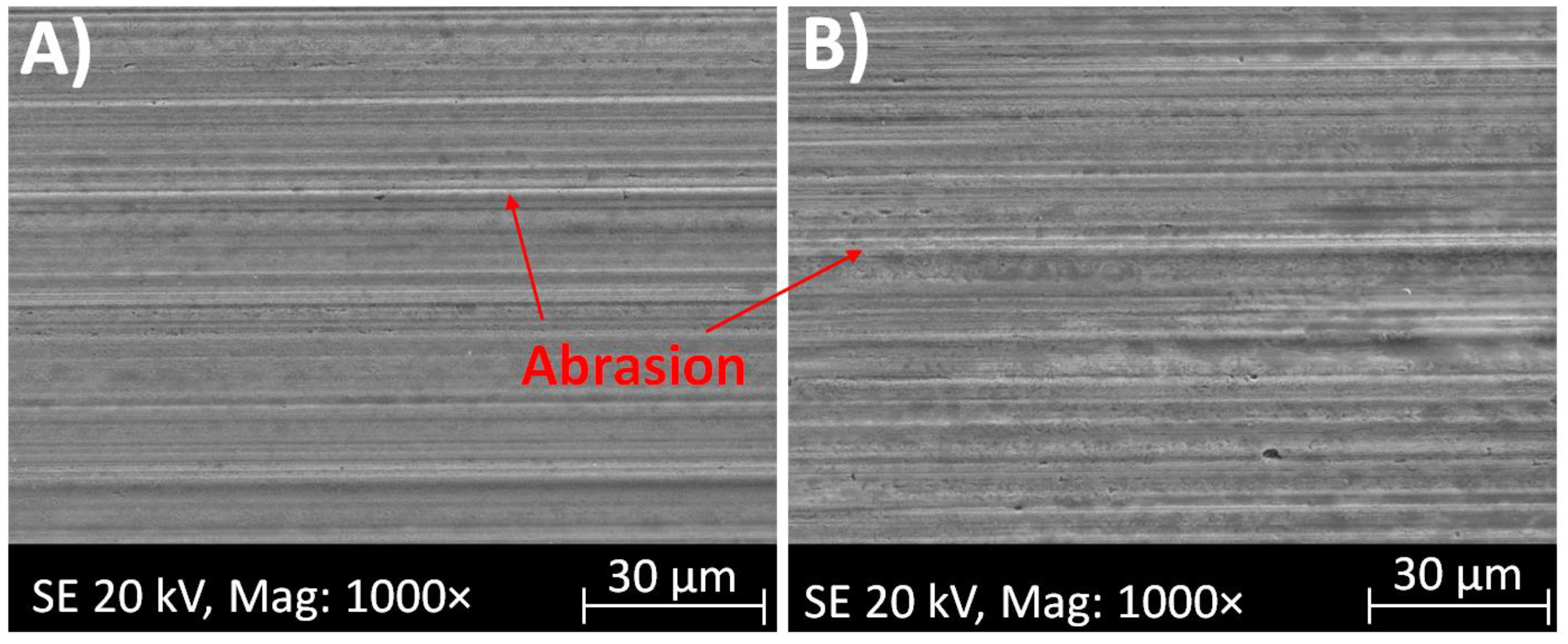

For further investigation, only lubricant samples supplemented with TX100 were used. The yttria-free, triton-doped Group III base oil measurements were considered as reference, which provided a COF-value of 0.2076 ± 0.0113, an FAI-value of 0.1528 ± 0.0046 and a WSD-value of 601.868 ± 18.629 µm. The digital microscope image of the reference measurement is demonstrated in

Figure 8 and the scanning electron microscope images in

Figure 9. Both images clearly illustrate the heavy abrasive wear mechanism occurring on the worn surface of the disc and the ball specimen.

The yttria nanoparticles were homogenized in six different concentrations (between 0.1 and 0.6 wt%). According to numerous literature sources [

2,

6,

9,

11,

19,

20,

21,

22,

23], the nanoscale ceramic particles can provide positive friction and wear reduction properties in this concentration range. Furthermore, due to the higher purchase cost of nanoscale spherical yttria (Y

2O

3: 8 EUR/g, on the other hand e.g., ZrO

2: 0.18 EUR/g), the production costs of engine lubricants containing these nanoparticles would be only profitable with lower concentration values. Additionally, a too-high yttria concentration can form larger agglomerates of yttria nanoparticles which can significantly increase the amount of three-body abrasion wear.

The tribological properties of yttria containing nanolubricants were analyzed with the previously presented ball-on-disc tribosystem. At least three independent tribometer tests were carried out with every yttria concentration including the yttria-free reference oil for the proper statistical evaluation. For the evaluation, COF and FAI values from the last 15 min of each measurement were taken, where the friction coefficient curves are already straightened. The average value and the standard distribution of these values were calculated and plotted for the graphical illustration and evaluation.

The tribological results of the yttria-doped lubricants are illustrated in

Figure 10. The bar chart clearly shows the positive antiwear properties of the investigated nanoparticles: the wear scar diameter on the ball specimens were decreased by more than 30% in the presence of the 0.5 wt% lubricant sample, compared to the GIII + 1% TX100 sample and the standard deviation between the independent experiments was also decreased significantly. This significant wear reduction was achieved without major friction modification: the average friction coefficient was decreased by less than 2%, the COF value at the dead center of the oscillation movement was increased by 8%. The optimum concentration was determined at 0.5 wt% with the highest amount of friction reduction.

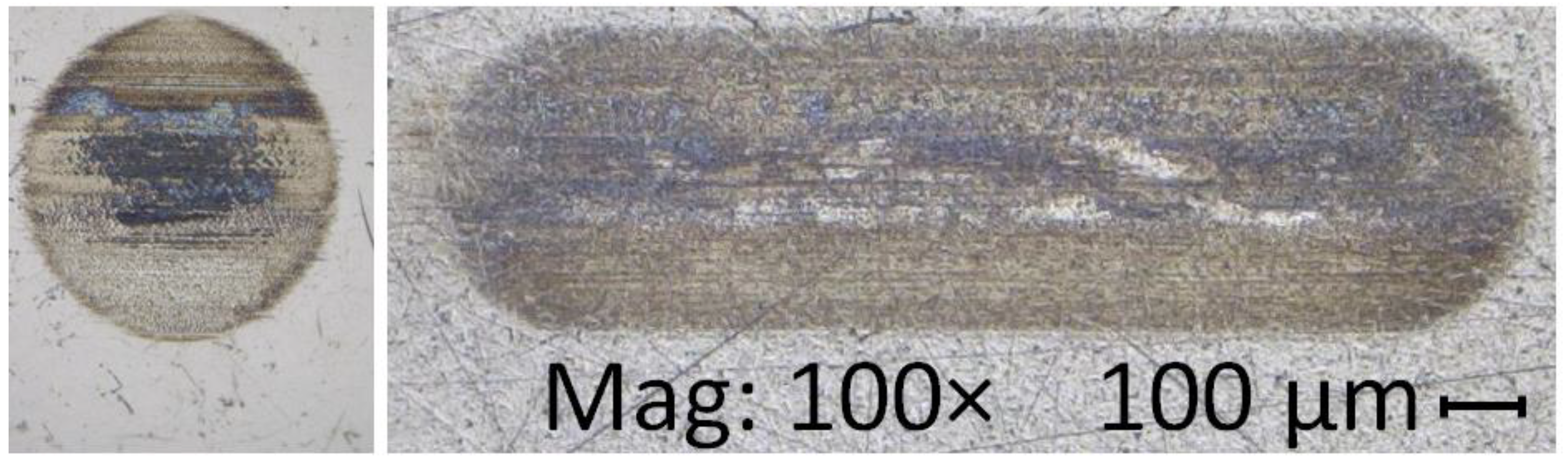

Figure 11 demonstrates the wear scars on the testing ball and disc specimens, measured with 0.5 wt% yttria nanoparticles under a digital microscope. After the comparison with the image of the reference lubricant sample, the yttria nanoparticles have significantly reduced the amount of deep abrasive wear valleys on the surface. This change of wear amount indicates the decrease of the tribological load of the surfaces. According to the digital microscope image of the disc specimen, it can be deduced, that not only the wear scar diameter but the wear depth and the wear volume have also been reduced. The amount of wear depth and wear volume can be experimentally measured with the confocal microscope analysis.

The missing volume of the surfaces represents the antiwear properties of the tribosystem more accurately. During the investigation, the wear volume of the run disc specimens was measured by a confocal microscope. Both the worn area and the original disc surface around the wear area was digitalized by the Leica confocal microscope and the results were evaluated to measure the wear volume. The worn area was enclosed, the average height value of the unworn areas was calculated and the volume under the average height is considered as the wear volume. An example of the analysis of wear volume is presented in

Figure 12.

The calculated wear volume values measured for each yttria-concentration are demonstrated on a bar chart in

Figure 13. It is clearly visible that both a low concentration (0.1 wt%) and higher concentrations (0.5 and 0.6 wt%) cause very low wear volume on the surface. The optimum concentration according to the wear volume analysis can be established at 0.5 wt%, which resulted in a 90% wear volume reduction. To understand the positive wear reduction properties of yttria nanoparticles, further SEM analysis was carried out which will be introduced in the following paragraphs.

Cross-section diagrams can be produced from the digitalized surface data as well. These cross-section diagrams enable us to analyze the wear depth in specific areas.

Figure 14 represents the results of cross-sections at three different yttria concentrations compared to the reference, yttria-free measurement. The 0.5 wt% result clearly proves the positive antiwear properties of yttria, because both the wear volume and the wear depth was significantly reduced, compared with the reference.

The positive tribological properties of the nanoscale yttria particles are obvious, according to the executed investigations. To understand the mechanism of how the yttria nanoparticle can work, further investigation must be accomplished. The scanning electron microscope analysis with different magnitudes is an excellent possibility for this purpose. The scanning electron microscopes are usually equipped with EDX (energy-dispersive X-ray spectroscopy) sensors to analyze the element distribution on the surface of the specimens.

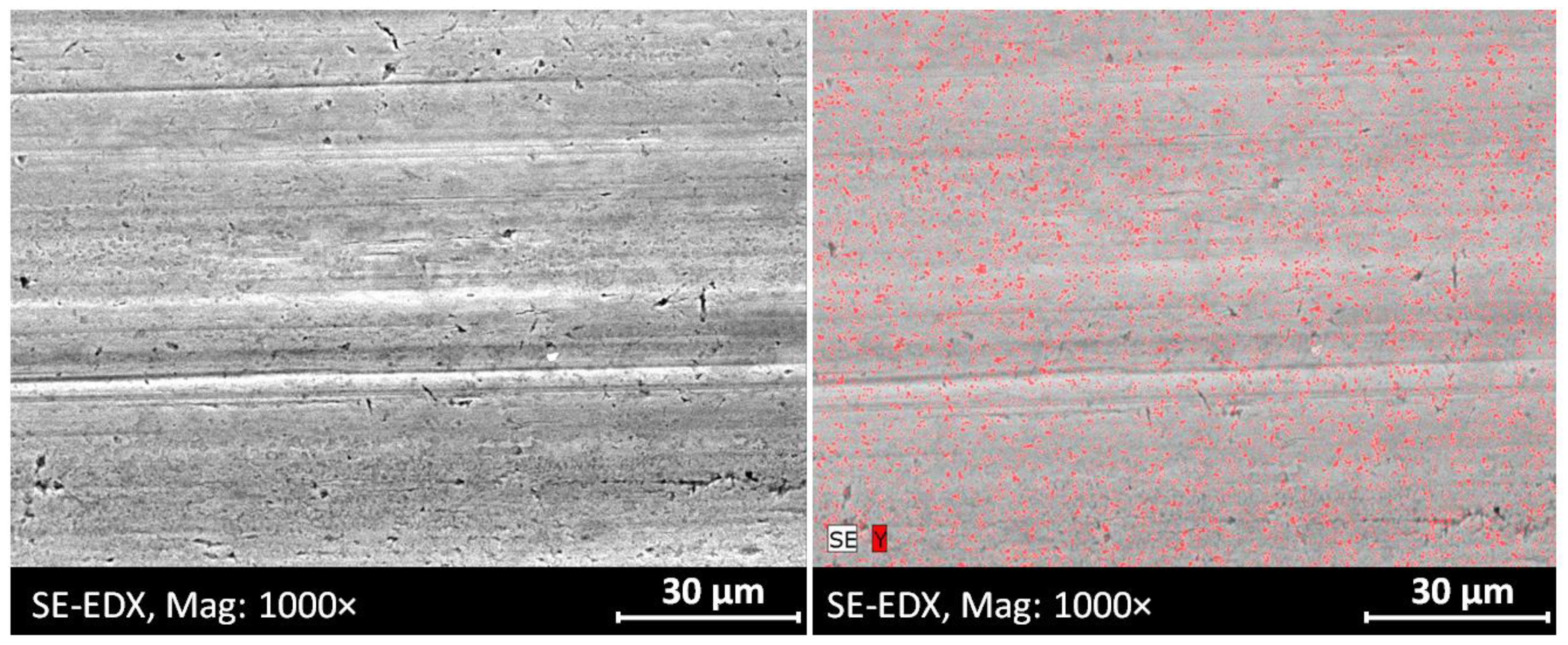

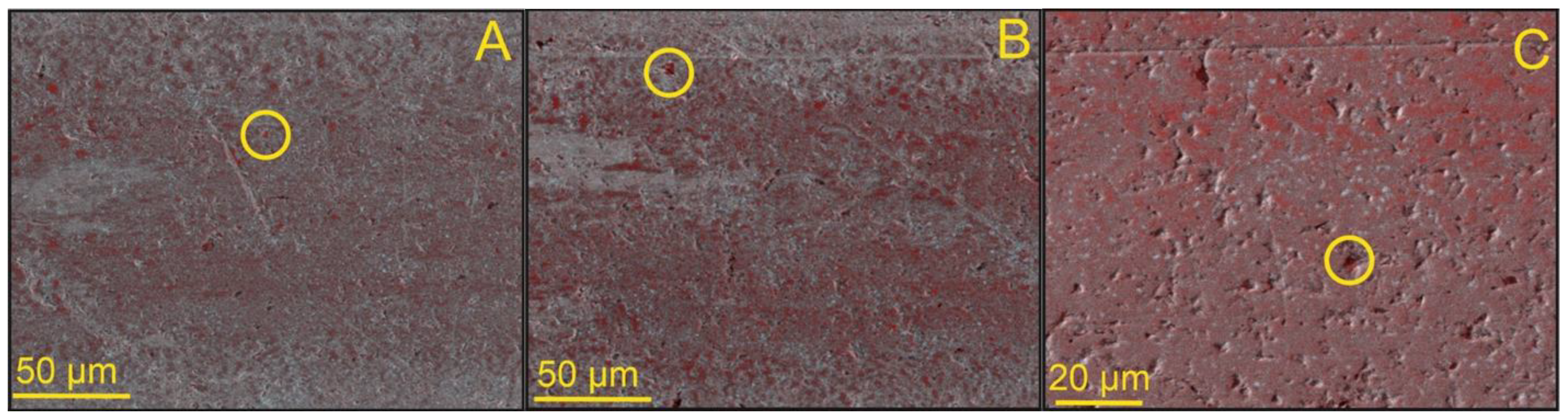

The wear surface of the disc specimen with optimum concentration is analyzed by a Hirox SEM-4000M microscope (Limonest, France) at the Department of Internal Combustion Engines and Propulsion Technology in the Széchenyi István University of Győr. The acquired SEM images including yttrium distribution about the 0.1 wt% yttria-doped measurement are illustrated in

Figure 15. A significant amount of yttrium was found on the surface which represents the presence of the nanoparticles on the worn surface after multi-stage thorough ultrasonic cleaning of the specimen. The yttria nanoparticles can be observed alongside the whole worn surface.

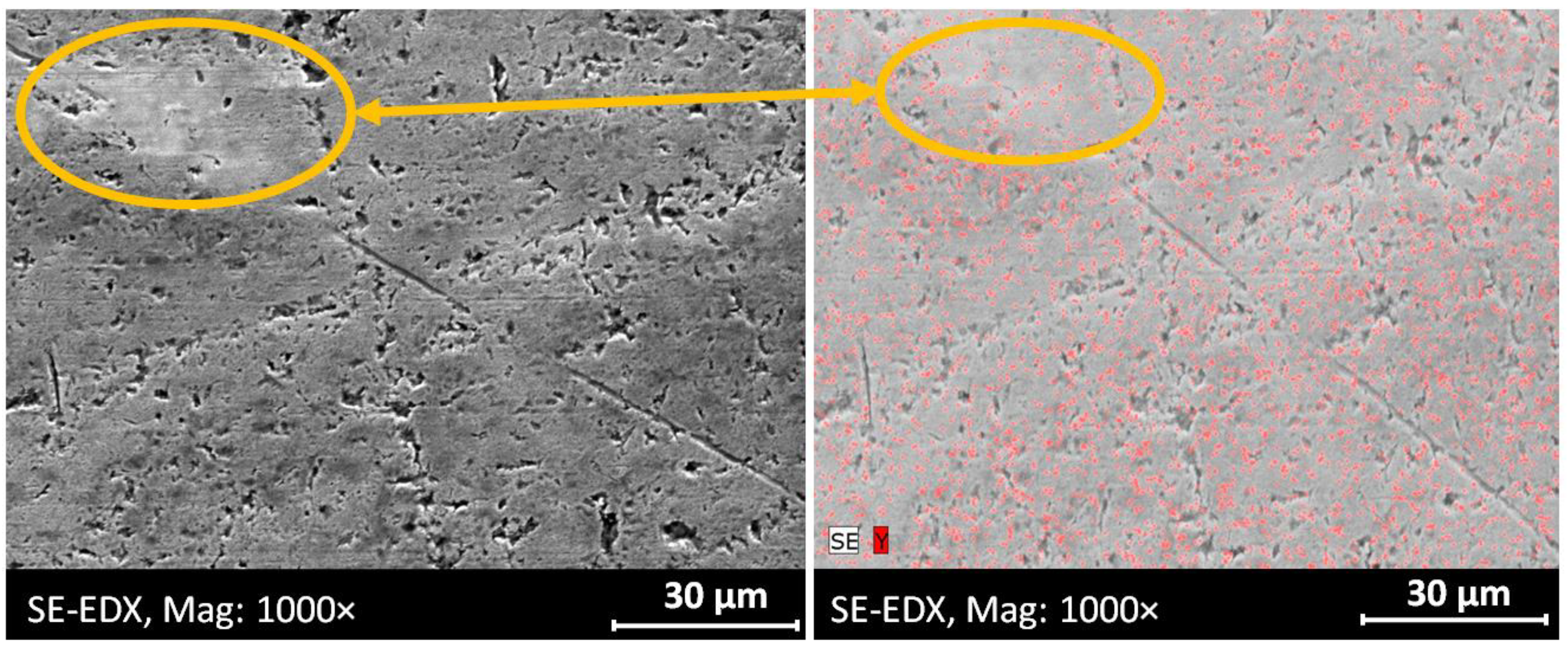

Figure 16 represents the results of the SEM-EDX analysis of the worn surface of the disc specimen with 0.5 wt% yttria-doped lubricant sample. The acquired SEM image clearly illustrates the low wear status: the original disc surface structure can be observed in the SEM images as well. This low wear rate correlates with the acquired cross-section profiles (

Figure 14, 0.5 wt%) too, where the mean wear depth was significantly below 1 µm. On the worn surface, a significant amount of yttrium element was found, which represents the presence of yttria nanoparticles attached to the surface. However, the SEM-EDX analysis also reveals several tiny areas with significantly lower yttrium distribution, such as the orange-marked area in

Figure 16.

Quantitative element analysis was also carried out on the worn surface of the disc specimens with 0.5 wt% yttria-doped nanolubricant to define the amount of Y

2O

3. The element distribution on the worn surface of the disc with the reference oil sample was also measured. The results of the EDX analysis of the worn surfaces are presented in

Table 2. The results of the quantitative element analysis clearly show the increase of the yttrium, oxygen, and carbon element on the surface. The increased carbon (8% increase) represents the hydrocarbon molecules of the used Group III base oil, which could not be removed by the thorough ultrasonic cleaning process of the specimens. The rise of yttrium (1.78%) and oxygen (8.02% increase) elements indicates the presence of the investigated nanoparticles on the surface. The oxygen may also show the increased corrosion of the outer layers of the surface, which also has to be kept in mind.

The increased amount of yttrium on the worn surface refers to the deduction, that the tribologically analyzed yttria nanoparticles have attached to the worn surface and this attaching bond could not be dissolved with an ultrasonic cleaner and brake cleaner liquid, even after multiple thorough cleaning processes. The only difference between the reference oil sample and the oil sample with optimum yttria concentration is the presence of the Y2O3 nanoparticles, which led to the astonishing 90% wear volume decrease. To explain how the yttria nanoparticles resulted in this wear-reducing effect, further scanning electron microscope analysis with higher magnitude was carried out. During this high-magnitude investigation, both the condition of the contacting surface areas and the details of yttrium distribution should be analyzed to understand how the yttria nanoparticles act during the tribological tests.

Multiple high-resolution SEM images including EDX element analysis were recorded to receive further detailed information about the distribution of the yttria on the worn surface of the disc specimen.

Figure 17 represents the recorded BSE images; the yttrium signals were marked with red color. It can be clearly stated that the distribution or the yttrium element on the surface is quite homogenous; however, several areas show yttrium enrichments. These areas were marked on the images, and they were further analyzed.

The BSE images were supplemented with quantitative EDX element analysis, both area and point element analysis were carried out at the marked areas. The results are shown in

Table 3 and

Table 4. The data in

Table 3 indicate an average amount of yttrium on the surface, which is 0.6–0.7%. This amount of yttrium was attached to the contacting surfaces during the tribological test. The analysis of yttrium-enriched areas indicates a 2–3 times higher yttrium concentration compared with the average value. The results of the EDX element analysis support the element mapping results.

The significant amount of yttrium element increases on the surface and its distribution states for the working mechanism of the yttria nanoparticles: the particles can attach to the connecting surfaces forming a protective layer and fill up the roughness and wear grooves (yttrium-enriched areas were defined by the SEM-EDX images) resulting in a smoother contact between the rubbing surfaces. This mechanism is called mending (see in

Figure 1b)). Additionally, the yttria nanoparticles were also pushed into the metal matrix forming a protective tribofilm, called as tribo-sintering (see in

Figure 1d)) mechanism. The working mechanism of tribo-sintering was already proved in previous studies of researchers in case of nanoparticles from other materials (e.g., CuO, ZrO

2 and ZnO Hernandez Battez et al. [

24], and Fe

2O

3, SnO

2, CuO and Bi

2O

3 by Kato et al. [

25]).

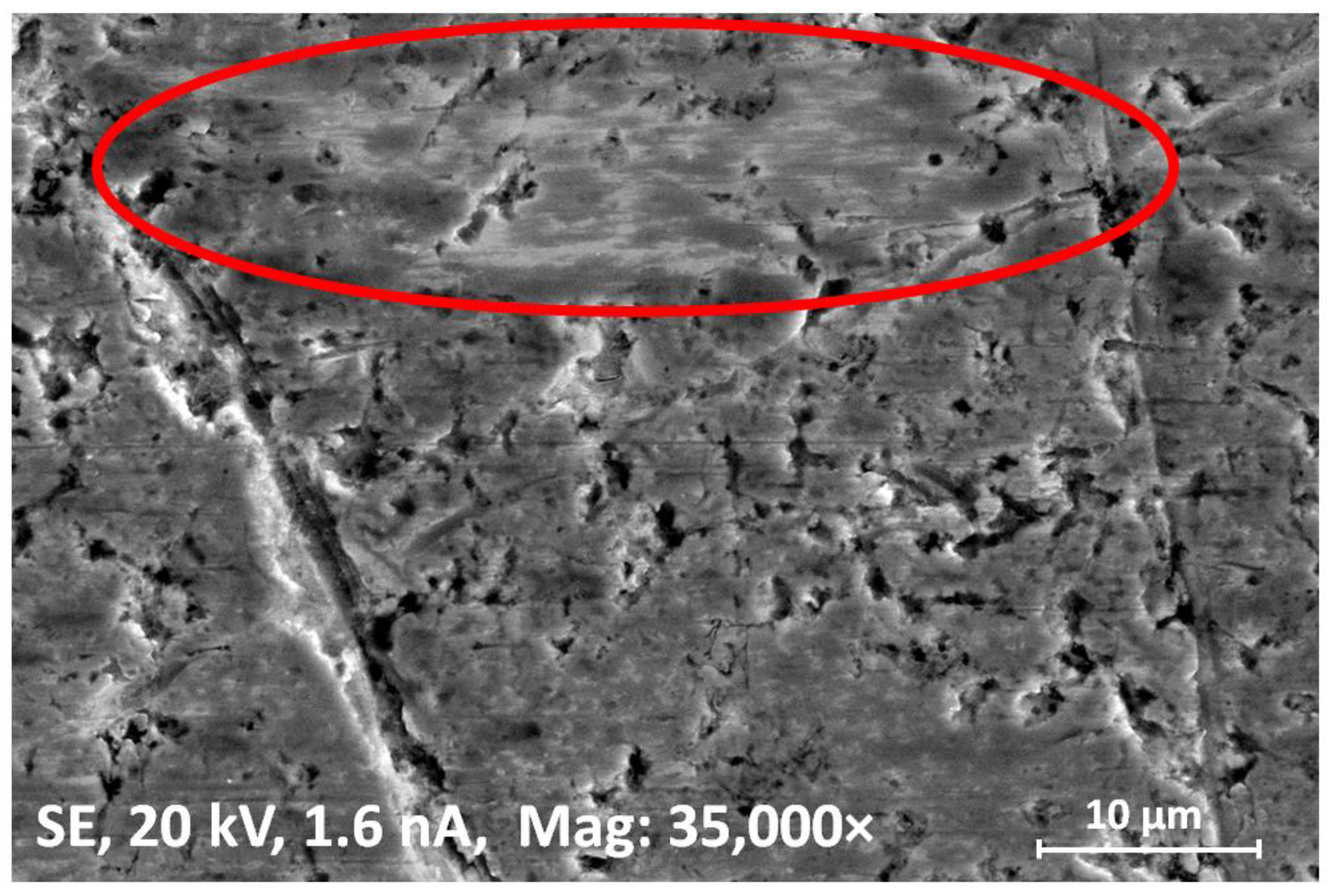

The high-magnitude SEM analysis has also revealed an interesting area which can be seen in the red circle in

Figure 18. The surface structure of the original surface cannot be observed despite the very low wear depth. According to the deeper analysis of this area, it can be established that the nanoscale yttria-doped lubricant caused microscopic plastic deformation on the surface. In the highlighted area, no sign of the original surface (grinding grooves) can be observed, which proves that it was produced during the tribotest. No porosity can be observed in the deformed areas because these pores were covered by the plastic deformed materials. The SEM analysis has also revealed that the marked area is bowl-shaped: the middle section of this area shows higher wear depth, while its edge shows lower wear depth.

This plastic deformation offered positive tribological properties to the tribological system, it increased the area of the contacting surfaces resulting in a lower surface pressure of the tribological system. Compared with previous experiments with the same tribological methodology [

18,

26] this kind of plastic deformation could not be observed in the presence of another nanoceramic doped lubricant samples.

According to the scanning electron microscope analysis, the working mechanism of the yttria nanoparticles is a mixed mechanism: by mending, the particles were collecting in the surface grooves resulting in a smoother contact surface, by tribo-sintering, the particles were attached to the connecting surfaces and they caused a microscopic plastic deformation on the top layers of the rubbing surfaces. The working mechanisms of the yttria nanoparticles are presented in

Figure 19.

The nanoscale Y2O3 particles homogenized into a neat Group III base oil has provided positive tribological properties (astonishing 90% wear volume reduction without significant friction modification). The performed microscopic analysis has revealed the working process of the yttria nanoparticles: tribo-sintering and microscopic plastic deformation of the top layer of the contacting surfaces. However, some properties of the yttria-reinforced lubricants are not known yet. The nanoparticles can only work properly if they are homogeneously distributed in the used liquids, that is why the homogenization method must be further developed in the future to produce long-life engine lubricants. Additionally, the effect of the nanoparticles to the saturation of the particle filters of the modern passenger cars are also not known. These properties of the yttria nanoparticles must be analyzed in the future. In their current status, they can be used in closed mechanical systems, which do not have emissions (e.g., transmissions of the vehicles).