Abstract

In recent years, reduced graphene oxide (rGO) received considerable interest as a lubricant nano-additive for enhancing sliding and rolling contacts. This paper investigates the tribological and dynamic behavior of ball bearings lubricated by lithium grease at different weight percentages of rGO. Full bearing tests were conducted for experimental modal analysis, vibration analysis, ultrasonic analysis, and infrared thermography. Modal analysis indicated considerable improvements of the damping ratio values up to 50% for the bearings with rGO nano-additives. These findings were confirmed by the corresponding reductions in vibrations and ultrasound levels. The steady-state temperatures of bearings running with lithium grease reached 64 °C, whereas the temperature of bearings lubricated by grease with 2 wt.% rGO measured only 27 °C. A Timken Load test was conducted on grease samples with and without rGO additives. Grease samples having 2, 3.5, and 5 wt.% rGO showed the highest OK load with an increase of 25%, 50%, and 100% as compared to values of lithium grease. For comparison, all tests were conducted on samples of the same grease blended with graphite and MWCNTs’ nano-additives. The results proved the superiority of graphene in enhancing the load-carrying capacity and damping of grease in rolling bearings.

1. Introduction

Rolling element bearings (REBs) are critical components in rotating machinery for various mechanical systems in wind turbines, aerospace, and automotive industries. It is reported that around 10 billion bearings are manufactured worldwide every year [1], and this bearing market is expected to grow in size from about USD 118.7 billion in 2020 with a compound annual growth rate (CAGR) of 8.5% from 2021 to 2028 [2].

Unexpected failures of REBs present a crucial impact on the performance of machinery and may cause a catastrophic failure of the assets and losses of lives [3]. A review analysis by Vencl et al. [4] classified the most frequent bearing failures according to wear mechanisms while reporting that bearings fail prematurely due to improper bearing selection, incorrect bearing handling and mounting, and inappropriate operating conditions. More than one-third of the failed bearings are attributed to inadequate lubrication, including improper lubricant viscosity, overdose/underdose lubrication, and wrong lubrication intervals. By combining lubricant contamination from the harsh surrounding environment and worn-out sealing, this ratio is increased to about 80%. Harris [5] classified lubricant deficiency as one of the main failure mechanisms of rolling bearings. For example, if the lubricant is insufficient at the Hertzian contact zone (i.e., lubricant starvation case), an adhesion wear mechanism takes place where the contacting surfaces weld together; then, they get torn apart as the rolling action follows [5,6].

During operation, lubricant migration from the contact zone in bearings is a common cause of lubricant starvation [7,8]. Different theoretical and experimental approaches for controlling oil migration considering the thermal gradient factor, surface texture, and chemical surface properties were discussed by Grützmacher et al. [9]. One advanced approach presented multi-scale surface patterning using two techniques in journal bearings as a countermeasure for oil migration [10]. It proved highly efficient in reducing lubricant migration and wear reduction. A further study in the same direction considered the effect of thermal gradient on the oil spreading (migration) on single and multi-scale surface patterned stainless steel samples [11].

Oil and grease are mainly employed in REBs to prevent metal-to-metal contact between the rubbing surfaces of the inner race, rolling elements, and outer race [12]. Their purpose is to minimize friction and wear in REBs during operation; hence, they significantly contribute to reducing energy losses and maintaining high reliability of power transmission systems [13]. Grease is preferred over oil lubricants for REBs as it shows superior performance in resisting the washing action of water, preventing any leakage, operating without frequent relubrication, showing good vibration damping capacities, and increasing the sealing efficiency against any contaminants [14,15].

Grease lubrication consists of a thickener (such as lithium soap, calcium soap, polyurea), 70–97% base oil (synthetic or mineral oil), and 3% additives. The prominent role of the additives is to introduce or enhance specific properties, such as extreme pressure (EP) additives, anti-wear (AW) agents, oxidation inhibitors, and lubricity additives [16].

The current increasing usage of heavy machinery and advanced mechanical systems in sectors of construction, mining, railway and aerospace, and electric vehicles’ industries requires a corresponding significant improvement in grease lubrication additives to achieve higher load-carrying capacities, better vibration damping, and minimum energy losses. Advances in synthesis and characterization of two-dimensional (2-D) materials such as molybdenum disulfide (MoS2), tungsten disulfide (WS2), hexagonal boron nitride, graphene, and other 2-D nano-materials have opened the door for their application as solid lubricants or lubricant additives in rotating machinery. A review by Rosenkranz et al. [17] summarized the directions of research work conducted on 2-D nano-materials, including their chemical properties, tribological behavior, and their potential to be applied as solid lubricants well as lubricant additives. The review also highlighted the current issues related to large-scale production and the obtained quality of each 2-D nano-material to be reasonably applied in the industry as solid lubricants. In order to efficiently incorporate 2-D nano-materials to reach a superlubricity regime on the nano- and macro-scales, different mechanisms of energy dissipation due to friction between sliding surfaces were studied and discussed in [18]. The review in [19] discussed different theoretical and experimental models describing physical mechanisms such as the interlayer sliding between single or multilayered 2-D nano-materials such as graphene and graphene oxide in comparison to graphite and how this significantly contributed to reducing the friction coefficient to the superlubricity zone. The review recommended that more studies should address the practical application of these 2-D materials in controlling friction and wear in macro- and meso-mechanical systems.

Adding carbonaceous nanomaterials such as CNTs, graphene, and reduced graphene oxide (GO) to the lubricating grease has been proposed as a popular trend to improve lubricant properties [20,21,22] significantly. Carbonaceous nanomaterials enhance the load-carrying capacity, decrease the coefficient of friction (COF) and wear scar diameter (WSD) between the mating parts [23,24], and impart new chemical, mechanical, and physical properties to grease [25]. Due to their strong in-plane bonding, weak interlayer interactions, and dangling bonds, their application in dry and boundary lubrication of machine elements such as gears and bearings was highly recommended by Berman et al. [26].

Graphene has a two-dimensional structure and small particle size, providing a large contact area sufficient to resist oxidation [27,28]. Its unique nano-scaled structure introduced high thermal and electrical conductivities, promoting it to be one of the best choices in supercapacitors and energy harvesting [29]. Due to its outstanding physical properties and self-lubricity characteristic, researchers reported that graphene enhanced the lubricity of grease and thermal conductivity as well [30,31].

Zhang et al. [20] investigated the addition of different graphene weight fractions with lithium-based grease. The results showed about 15% improvement of the COF when adding 2 wt.% graphene. Jayant et al. [30] conducted experimental trials by mixing reduced graphene oxide (rGO) with lithium-based grease. The rGO concentration of 0.4 wt.% reduced the COF by about 20% and 30% for sliding-induced rolling contact and rolling contact compared to base grease. Fu et al. [32] tried different graphene additions with calcium grease, and they found that 2 wt.% was the optimum percentage regarding the tribological properties as this percentage reduced the COF by about 15% compared to base grease. Furthermore, a reduction in the friction coefficient by up to 60% was obtained after adding 1 wt.% graphene to a semi-solid lubricant [33]. Nan et al. [34] investigated the effect of mixing different graphene percentages with attapulgite-based grease. They observed that graphene additions improve the tribological behavior of the base grease, especially at high loading conditions. It was also found that the addition of 1 wt.% graphene reduces the friction coefficient by 67% as compared to the base grease.

From the above review of literature, it was concluded that complex lithium grease is commonly used as a lubricant in REBs due to its good tribological behavior. However, there is still a need to improve the tribological properties of the REBs in rotating machinery by reducing generated friction forces and energy losses. According to a previous investigation, achieving 1% reduction in the frictional power concerning the automotive industry can save approximately billions of fuel liters [35].

Most of the research work highlighted the importance of nano-additives in general and graphene in particular in enhancing the tribological performance of grease lubricant. Extensive research work focused on determining the COF and WSD of the developed grease using standard tests, such as the four-ball wear test and ball-on-disk test. Despite the promising tribological results of graphene as a nano-additive in grease, its application in the lubrication of essential mechanical components, such as rolling bearings, remains relatively unexplored.

The literature lacks any attempts to provide an insight into the influence of adding graphene on the damping capacity of grease lubricant and how this would enhance the dynamic response of REBs during highly dynamic operations. An individual attempt in [36] found that have rolling bearings experienced the lowest frictional torque when adding 1 wt.% GNPs with the thickness of 6–8 nm as an additive to grease. It reduced the frictional torque inside the bearing by more than 60% as compared to base grease, but the investigation was limited to only 1 wt.% of graphene as an additive. A more recent investigation studied the effect of adding different rGO percentages and several other carbonaceous additives such as MWCNTs to the bearing lubrication and reported maximum power saving when 2 wt.% rGO was added to lithium grease [37].

The present research had the objective to focus on investigating important aspects of graphene grease lubricant that are still unexplored and have not received considerable research attention on rolling machinery components such as rolling bearings. Vibration damping properties, heat chilling potential, and load-carrying capacity are among the important aspects of this investigation. Full bearing tests, vibration modal analysis tests, and standard lubricant tests were conducted in this research investigation. Other prominent carbonaceous additives, namely, graphite and MWCNTs, were considered for comparison to stand upon the level of improvement when applying graphene to grease lubricant.

2. Materials and Methods

2.1. Test Setup

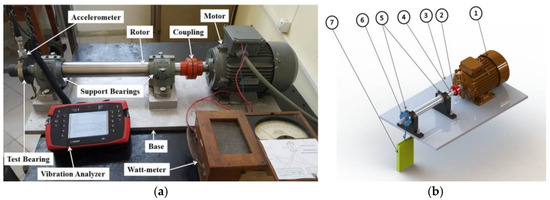

A customized test rig was designed and manufactured to conduct a full bearing test, as shown in Figure 1. It was used to evaluate the effect of each nano-additive in lithium grease lubricant on the vibrational response, ultrasound emissions, and heat generation of rolling element bearings (REBs) [37]. The test rig previously designed by Nassef [37] consisted of seven main components: (1) the electric motor, (2) coupling, (3) base, (4) shaft, (5) two support bearings, (6) test bearing, and (7) the applied radial load. The specifications of each component are listed in Table 1, whereas the detailed design of the rig is described elsewhere [37].

Figure 1.

(a) Test rig setup, and (b) Assembly model of the test showing: (1) an electric motor with (2) a suitable coupling, (3) base, (4) shaft, (5) two support bearings and their housings, (6) test bearing with a specially designed housing, and (7) the applied radial load.

Table 1.

Specifications of test rig components.

The test bearing was a deep-groove ball bearing 6006 zz, whose specifications are summarized in Table 2 as provided by NSK bearing manufacturer. The test bearing was fitted to its special housing, which was assembled in an interference to the rotor. The motor ran at 1400 RPM while a set of dead weights between 2050 N and 2250 N were separately attached to the bearing housing through a suitable hook.

Table 2.

Specifications of the test bearing (6006 zz) provided by NSK manufacturer.

2.2. Material Preparation and Characterization

The nano-additive material under investigation in this work was graphene nano-sheets supplied, by Nanogate Company, Cairo, Egypt, in the form of reduced graphene oxide (rGO) from the local market, which was prepared via the Modified Hummer’s Method [38,39,40]. X-ray diffraction (XRD) (Empyrean Malver panalytical, Almelo city, The Netherlands) was used to obtain the average grain size, % crystallinity, and d-spacing of graphene nano-sheets. XRD analysis operated at 30 mA and 40 keV with an angular range of 0.08–80 degrees and Cu-Kα1 radiation of 0.154-nm wavelength.

A transmission electron microscope (TEM) (JEOL JEM-2100, JOEL Ltd., Tokyo, Japan) was used to obtain the shape and number of layers. The sample was first immersed in ethanol, and the suspended solution was then sonicated for around 5 min. Then, a 5-µm sample from the suspension was drop cast on a carbon-coated copper grid. The TEM results were further confirmed using Raman spectroscopy (WITec alpha 300 R confocal Raman microscope, WITec Company, Ulm, Germany) at room temperature through the exposure of the rGO sample to a 532-nm laser. The Raman spectrum was recorded using a WITec alpha 300 R confocal Raman microscope (Germany) with 50× magnification objective. The sample was excited using a 532-nm laser line and 3-mW power impinging on the sample. Finally, the Raman spectrum was collected with 20-s detector time and five accumulations.

Moreover, Fourier transform infrared (FTIR) spectroscopy (Bruker Vertex 70 with a wave-number range of 400–4000 cm−1, Bruker Company, Billerica, MA, USA) was used to obtain information about the functional groups attached to the graphene structure to assess its quality. MWCNTs were characterized using TEM to confirm their shape and size, whereas a scanning electron microscope (SEM) (JSM-IT200) was used to investigate the graphite structure.

The rGO weight percentages of 0.5, 1, 2, 3.5, and 5 wt.% were separately mixed with the appropriate quantity of commercial, heavy-duty, lithium-based grease (4 g). The blending process was performed using a commercial mixer of 150 kW. The stirring process was completed after the grease color became uniformly dark. The exact mixing conditions were applied for mixing constant MWCNTs’ percentage of 1 wt.% and graphite percentages of 2, 3.5, and 5 wt.% with grease to compare their tribological behavior with rGO. The blended grease and nano-additives were then used to lubricate the test bearings according to the SKF formula shown in Equation (1).

where Gq is the amount of grease used to re-lubricate the bearing in ounces, (D) is the outer diameter of the bearing, and (B) is the bearing width.

Gq = 0.114(D)(B)

2.3. Experimental Modal Analysis

Experimental modal analysis technique was conducted on the test bearings to obtain their dynamic characteristics in terms of natural frequencies and damping, according to ISO 7626-5:2019 [41]. The purpose of this test was to evaluate the effect of added nano-additives with a lithium grease lubricant on the dynamic response of a test bearing. A customized setup was used for supporting each rolling bearing. Each test bearing was suspended from the support using elastic cords to reach approximate free boundary conditions. This was an essential step to obtain the flexible body modes of the bearing structure while ignoring the effect of the rigid body modes.

An impact hammer was used to induce a low to moderate force impulse in a very short time in the time domain, which excited a wide (theoretically infinite) range of frequencies, including the natural frequencies of the test bearing itself. The transient impulsive signals were measured using a piezoelectric force transducer attached to the hammer. Meanwhile, the vibrational response of the bearing to the impulsive shock was measured using a piezoelectric triaxial accelerometer mounted using wax on the outer ring of the bearing (in the opposite direction to the force signal). The accelerometer was carefully selected so that its weight was less than one-tenth the weight of the test bearing.

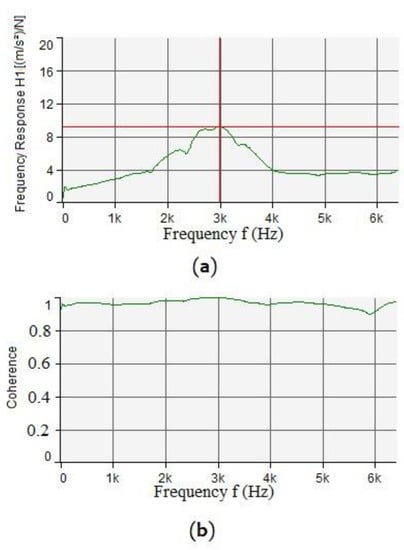

Both force and response signals were detected and recorded by a multi-channel signal analyzer unit. The signals were then conditioned and processed in PULSE labshop© software to calculate the frequency response function (FRF) of each bearing as the ratio between response to force signal. An arithmetic average of four impulse signals was determined for each bearing to ensure the high repeatability of results. The FRF and coherence function for each test bearing were determined. The first fundamental mode of vibration (first resonant mode) was selected for further analysis. Hence, the natural frequency (fn), damping ratio (ξ), FRF amplitude (H), and corresponding coherence value at the first resonant mode of vibration were recorded. Only resonant modes with high coherence values were considered during the selection of bearing modes. This was essential to ensure high autocorrelation and cross-correlation between response and force signals.

For proper signal conditioning, transient and exponential windowing functions were selected for excitation and response signals, respectively. The frequency range of interest for the tested bearing fell between 0–4000 Hz. An anti-aliasing filter and proper least-squares curve were used to avoid aliasing and truncations of signals. To ensure the consistency of results, the same locations were considered for the impact force, vibration response, and fixation points of the elastic cords during testing for all test bearings.

2.4. Vibration Analysis

Vibration measurements and analysis in the time domain and spectrum were conducted to investigate the influence of rGO nano-additives on the vibration performance of each bearing during operation. The vibration measurements were performed on each test bearing mounted to the test rig under a radial load of 2250 N. SPM Lenova Diamond vibration analyzer (SPM, Strängnäs, Sweden) was used for condition monitoring of the test REBs according to ISO 10816 part 7 [42].

Test bearing vibrations were measured using an accelerometer attached to the housing of the test bearing in the radial vertical and horizontal directions via magnet. The measured signals were directly fed into the data analyzer, which conducted signal conditioning and processing using anti-aliasing filtering, amplifiers, and integrators. Vibration measurements were taken in terms of acceleration (g) and velocity (mm/s). In the analysis part, the root mean square (RMS) was selected as a vibration amplitude indicator and was calculated for all signals to detect any abnormal behavior of rolling bearings due to localized faults or improper lubrication. RMS results were used for comparison between grease types as it was directly proportional to the energy consumption in bearings due to vibration.

2.5. Ultrasound Analysis

Ultrasonic testing is a commonly applied technique for condition monitoring and early detection of localized faults in rolling bearings. It is effectively used to measure the ultrasonic energy generated by friction forces and identify the lubrication status, whether it is normal or improper lubrication, such as over lubrication or lack of lubrication. Ultrasound technique operates in the spectrum range between 20 kHz to 100 kHz. In this work, an SDT 340 ultrasound device (STD Ultrasound Solutions, Brussels, Belgium) was employed to measure and analyze dynamic signals in time and frequency domains for each test bearing. The aim was to detect changes in the high-frequency ultrasonic signatures of the test bearings caused by changing the tested lubrication type according to ISO 29821:2018 [43].

The ultrasound detector consisted of a transducer mounted on the bearing support, which dynamically detected the signal, i.e., each measurement on each test bearing was recorded as a signal for 10 s. The data were then converted by a heterodyne circuit board into an audible signal (<20 kHz). This processed signal was furtherly conditioned by an audio amplifier to be heard using standard headphones. The heterodyned signals were analyzed in the time domain and frequency domain. The root mean square (RMS) was used for analyzing each measured signal in the time domain.

2.6. Infrared Thermographic Analysis

Infrared thermography (IRT) was conducted in this work using a FLIR E8 Thermal Camera (Teledyne FLIR LCC, Wilsonville, OR, USA) as a non-contact and non-invasive condition monitoring technique to measure the surface temperature and its distribution on test bearing according to the ISO18434-1:2008 [44]. It is commonly used in maintenance activities to record infrared radiation emitted by the bearing and indicate any abnormal friction due to improper lubrication during operation [45]. Considering the fact that the intensity of the emitted infrared radiation from the bearing is proportional to its temperature, it presents a relevant indicator for the impact of lubricant additives on the lubricity and generated rolling friction during operation and on the resultant temperature [46,47].

Proper calibration of the test setup of the IRT camera is essential to obtain accurate temperature recordings [48]. Since the test bearing is the main source of heat during operation, the passive IRT technique was adopted, i.e., no external heat source was used for each test. It should be noted that IRT measurements were conducted in a controlled environment. Therefore, the effect of humidity, wind, and solar radiations were ignored. Two main parameters were considered during IRT calibration: emissivity and reflected temperature measurement. The test bearing material had low emissivity; therefore, a high emissivity electrical tape was placed on the outer ring of the bearing to measure the apparent temperature accurately. The tape had high emissivity, which was set to be 0.95. The IR camera was located at a distance of 500 mm from the test bearing to fit within the region of interest (ROI).

The bearing surface temperature, i.e., the environmental temperature, was recorded at the beginning of each test. Then, the test bearing ran at 1400 rpm supporting a 2250-N radial load. The transient temperature was monitored every 2 min until reaching a steady state after 10 min. After being transformed into equivalent electric signals, the measured infrared radiations were revealed as visible images (thermograms) of different colored energy levels.

2.7. Timken Load Test

The load-carrying capacity of each test grease aggregate was determined using the Timken load test method, according to ASTM D 2509 [49]. The Timken OK load is described as the maximum load that can be applied before the lubricant film’s breakdown and the roller element’s seizure. It is used to characterize the extreme pressure (EP) of each test grease. The duration of the test is around 10 min. The test procedure starts by installing a bearing roller element with a 15-mm width and 11-mm diameter in contact with the inner race. The material of both the inner race and the roller element was made from GCr15 bearing steel (SAE 52100). A sample of 10 gm from the test grease was applied to the inner race and the roller element.

During Timken load tests, the temperature was maintained at 25 °C before the start of the test. The load was increased by a constant rate until the load broke the lubricant film, separating a rolling element and the inner raceway, leading to scoring and motor seizure. The number of used unit loads was recorded in each test (each unit load weighed 497 g). After each test, the Timken OK load was recorded and the corresponding roller element scar area was inspected and measured for each test grease using the Stereo microscope (Zeiss Company, Jena, Germany).

3. Results and Discussion

3.1. Nano-Additive Material Characterization

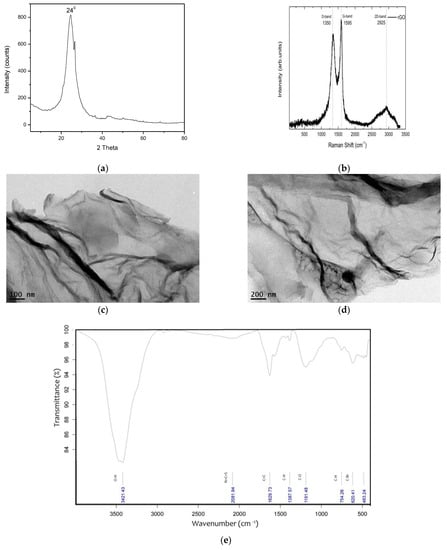

Figure 2a shows the XRD pattern of graphene, which reveals a broad (near sharp) characteristic peak at 2ϴ = 24.65 °C, referring to the basal plane (002) with about 54% crystallinity. The broad peak indicates the randomly arranged crystal phase due to the formation of a few layers of rGO after the reduction process [50,51,52]. Additionally, the average grain size was estimated from Scherrer’s formula to be 1.66 nm, and the interlayer spacing (d) (FWHM = 5.11) accounted for 0.37 nm according to Bragg’s law, which confirmed the removal of oxygen functional groups during the fabrication process [53,54].

Figure 2.

(a) XRD pattern of reduced graphene oxide, (b) Raman spectrum of rGO sample, (c) TEM analysis of rGO structure with a resolution of 100 nm, (d) TEM analysis of rGO structure with a resolution of 200 nm, and (e) FTIR analysis results of rGO sample.

From Raman spectroscopy results, three characteristic peaks attributed to rGO, are shown in Figure 2b. The first one, which is the D-band, appeared at 1350 cm−1 and this peak was mainly responsible for the structural disorders and defects [55], while the second (G-band) and third (2-D-band) peaks were observed at 1595 and 2925 cm−1, respectively. The G-band characterized the graphene symmetry and order [56], while the stacking of carbon atoms was deduced from the 2-D-band [57]. The intensity ratio of 2-D/G was estimated to be 0.91, and this ratio was essential to evaluate the number of graphene layers, which accounted for four layers, confirming the TEM results [58]. Turning to the D-band, it strongly appeared in the spectrum, reflecting a significant distortion in the symmetry of the graphite structure [59,60]. The intensity ratio of D/G showed a great importance in the detection of the structural defects and disorders. By calculating the ratio, it was found that ID/IG was 0.98, which indicated a remarkable density of defects represented in edge defects obtained from the reduction of the C=C bond [61].

In Figure 2c,d, TEM images reveal a nanosheet-layered structure of graphene with four stacked layers and dimensions of up to 3 μm in length and 5 nm in thickness, respectively. Additionally, the graphene structure had fewer wrinkles and folds at different TEM resolutions. Figure 2e reveals the spectrum obtained from FTIR analysis of rGO. It was found that there was a strong and broad stretching band at 3421.43 cm−1, which was attributed to the intermolecular bonded O-H function group. The weak presence of the C-O function group at 1191.48 cm−1 indicated the insufficiency of oxidizing substances to break covalent bonds at the basal plane, reducing structural defects and distortions. Another medium stretching band of C=C appeared at 1629.73 cm−1, indicating the stability and integrity of the graphene structure. Moreover, weak peaks were observed at 1387.57 and 754.26 cm−1, which belonged to C-H bending, revealing the small amounts of hydrogen species, which were functionalized with carbon atoms [61].

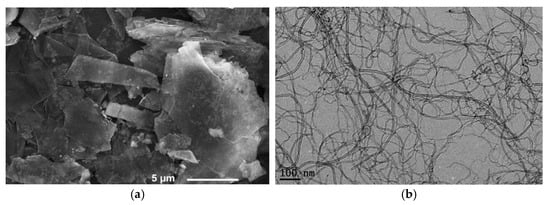

Both graphite and MWCNTs were used in this study and were characterized using SEM for the former and TEM for the latter. The SEM micrograph of the graphite structure revealed a sheet-like structure with a flake size of about 27 μm, as shown in Figure 3a, while for MWCNTs, TEM images confirmed the nanotube structure with an average external diameter of about 17.5 nm, as revealed in Figure 3b.

Figure 3.

(a) Microstructural analysis of graphite using SEM with 5-µm resolution and (b) microstructural analysis of MWCNTs using SEM with 100-nm resolution.

3.2. Modal Analysis Results

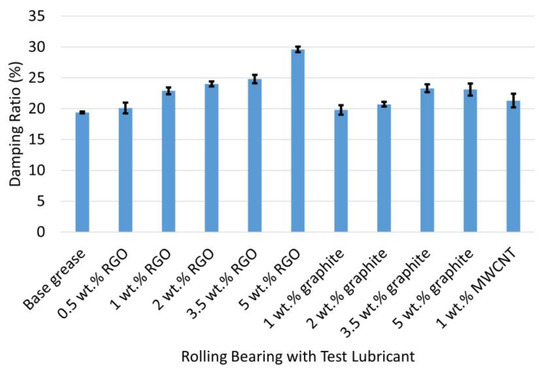

Figure 4 shows an example of the FRF plot, including the first mode of vibration for bearing from impact excitation of bearing and the corresponding coherence function to the first dominant mode. The damping ratio values for the test rolling bearings were calculated from their individual FRF plots and are illustrated as shown in Figure 5.

Figure 4.

Modal test results of bearing with base grease lubrication in the form of: (a) frequency response function (FRF) and (b) coherence function.

Figure 5.

Damping ratio values for rolling bearings with each test lubricant.

Test rolling bearings of the same type and size, same material, same manufacturer, and same interference fit with the shaft showed various dynamic characteristics. This was potentially attributed to variations in the lubricant characteristics of the tested rolling bearings. The damping ratio values for bearings lubricated by the addition of 1, 2, 3.5, and 5 wt.% rGO were increased by 18, 24, 28, and 52% when compared to bearings with base grease lubrication. While the damping ratio values of bearings with 1 wt.% rGO grease fell in the same range as those for 1 wt.% graphite and 1 wt.% MWCNTs, increasing the contribution of rGO to the grease to 2 wt.% and up to 5 wt.% improved the damping ratios by 15% and 28% when compared to 2 wt.% and 5 wt.% graphite.

For a typical ball bearing, the damping capacity originates from three mechanisms [62]. The first damping mechanism is the material damping due to internal friction within the material structure during the material dynamic deformation, while the second damping contributor is the dry friction at the contact points between rolling elements and raceways. The third and the most effective mechanism of damping is the viscous damping originated from the oil full film lubricant at the elastohydrodynamic lubrication zone (EHL). Other possible sources for damping are the contact surfaces between the outer ring to the housing and the inner ring to the shaft. Since bearings are assembled with the shaft in interference, the contact areas between the bearing rings and the housing possess high stiffness and barely contribute to the damping mechanisms of REBs. This is because damping can only be effective in the case of relative motion between REB elements [62,63]. As REBs suffer from low damping characteristics compared to other bearing types, enhancement of oil film damping characteristics contributes to a corresponding improvement in reliability of bearings during service [63].

On the nanoscale level, interfaces between stacked layers of graphene are significantly weaker than grease–graphene interfaces [64]. The addition of graphene to grease increases the viscosity of grease, which in turn increases its shear strength, while weak Van der Waal bonding between graphene layers reduces their interface shear strength [65]. Thus, lower shear forces are sufficient to cause slippage of graphene layers with respect to each other during operation. This latter action would contribute to damping enhancement. The larger surface area of 2-D graphene nanosheets makes it more compliant than 1-D CNTs, especially when subjected to small shear forces resulting in easier activation of damping mechanisms.

3.3. Vibration Analysis Results

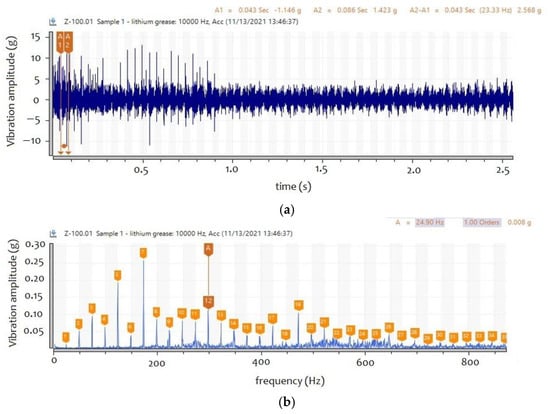

For each test bearing, vibrations were measured and analyzed in radial vertical and horizontal directions [66]. Time waveform and frequency spectrum for test bearings lubricated with base grease are shown in Figure 6. Among all results, test bearings lubricated with base grease showed the maximum vibration velocity levels, reaching 3.31 mm/s and 3.93 mm/s in the vertical and horizontal directions, respectively. These levels comply with the maximum permissible levels in ISO 10816-7:2009 [67].

Figure 6.

(a) Time waveform and (b) frequency spectrum of rolling bearings lubricated with base grease.

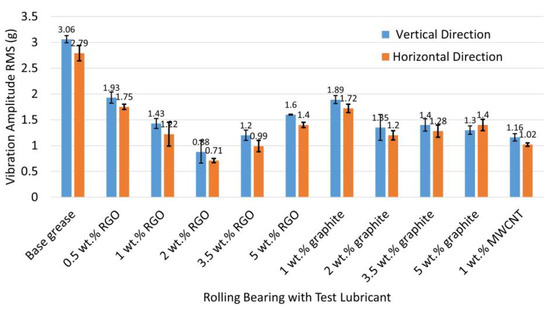

Vibration acceleration values (RMS) were calculated from the frequency domain for all test bearings, as shown in Figure 7. It can be seen that test bearings with nano-additives’ lubricant demonstrated significantly lower vibration values than a base lithium grease condition. Furthermore, increasing the weight percentage of rGO nano-additive in grease resulted in a corresponding reduction in the calculated vibration RMS levels until reaching its lowest at 0.71 g and 0.88 g in the horizontal and vertical directions, respectively, which was lower by around 70% and 34% when compared to base grease results. Increasing the aggregate rGO in grease to 3.5 and 5 wt.% caused an increase in vibration levels by 40% and 80%, respectively. This is attributed to the agglomeration effect of graphene in the grease, which resulted in more resistance to the flow of lubricant between the rolling element and raceway, causing more friction and vibrations. A similar trend took place in the case of graphite nano-additives. Grease with 1 wt.% MWCNTs’ nano-additives showed similar vibration levels to the 1 wt.% rGO case and is lower by 38% than the 1 wt.% graphite results.

Figure 7.

Vibration levels (RMS) measured in radial vertical and horizontal directions on each test bearing.

The vibration levels in the case of test bearings with rGO, MWCNTs, and graphite nano-additive lubricants proved that these additives contributed to decreasing the transmitted vibrations inside the bearing structure [68]. Adding these nano-additives to grease produced a stable tribo-film between the rolling elements, inner ring, and outer ring, which acted as spring and damper connectors. The carbonaceous nano-additives possessed high damping and elasticity properties that significantly reduced vibration signal transmissibility between bearing elements. Furthermore, the 2-D structure of rGO had a large area that covered the asperities between the mating surfaces and inhibited metal-to-metal contact in the elastohydrodynamic zone [64]. Hence, it reduced the vibration levels due to rolling friction in the ball bearings during operation.

Another aspect is that adding graphene stabilizes the fibrous structure of grease thickener to a large extent [69]. However, it weakens the cross-linking in the thickener fibrous network, which facilitates the discharge of base oil from voids to formulate full film lubrication [70]. Adding rGO also contributed to widening the voids in the fibrous structure of the lithium grease thickener. This, in turn, increased the amount of discharged base oil to the clearance gap between the rolling elements and raceways. Hence, the supplied nano-additive lubricant between the bearing elements eliminated metal-to-metal contact and acted as a good spring-damper system that reduced transmitted vibration in the bearing structure. Adding more rGO wt.% beyond 2 wt.% did not cause any further reduction in vibrations levels as the grease structure became more saturated with the graphene nano-additives.

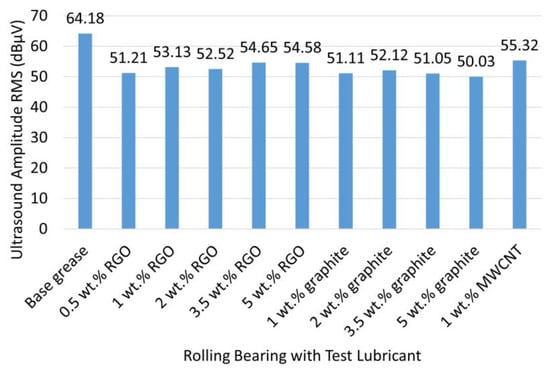

3.4. Ultrasound Results

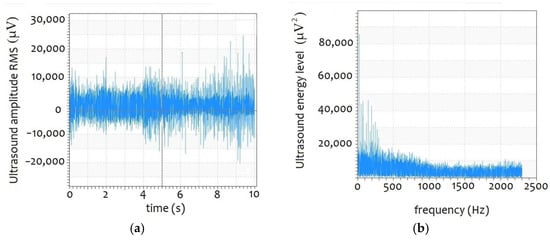

Figure 8 shows the ultrasound signal measured in the time domain and spectrum for test bearings with base grease lubrication. It can be seen that the test bearing was in a normal condition, showing ultrasound RMS value of 64.18 dBµV. The main source of this value was friction forces during operation. In comparison, test bearings with rGO, graphite, and MWCNTs’ nano-additive cases showed a lower ultrasound RMS value by around 15%–20%, as shown in Figure 9.

Figure 8.

Ultrasound signal for test bearing with base grease lubrication in (a) time domain and (b) frequency domain.

Figure 9.

Ultrasound amplitude (RMS) values for test bearings with test lubricants.

The results indicated the efficiency of rGO nano-additives in reducing frictional forces generated during operation while providing quieter operation. The obtained ultrasound values confirmed the vibration analysis results in the fact that nano-additive lubricants showed significant reduction in friction forces of rolling bearings during operation in comparison with base grease lubricant.

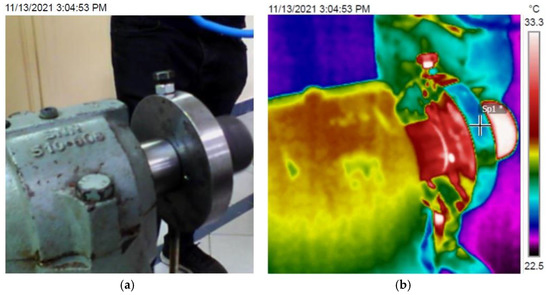

3.5. IRT Thermographic Results

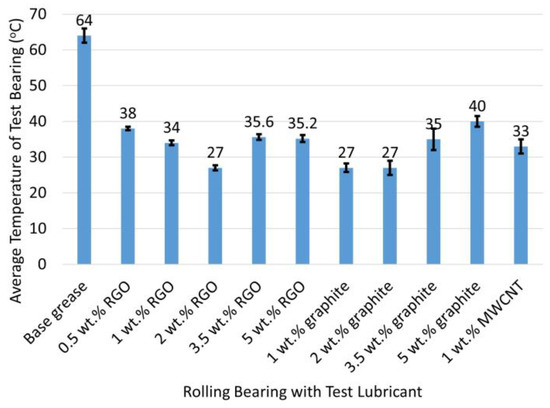

In this section, thermograms were obtained from the IRT measurement for each test bearing. Figure 10 shows the IRT measurement and corresponding thermogram for the test bearing with base grease lubricant. The thermograms were post-processed, and the average temperature at the test bearing hotspot was detected and considered for analysis, as shown in Figure 11. A noticeable variation of average temperature was detected between bearings at steady-state operating conditions, i.e., after running the test rig for 10 min.

Figure 10.

(a) The test bearing mounted on the test rig and (b) Infrared thermal image (thermogram) of the test bearing.

Figure 11.

Average temperatures of bearings under selected test lubricants after running for 10 min.

The thermal images and the bar chart results indicated that the test bearing with base grease lubrication exhibited the highest temperature during operation, peaking at 64 °C. This was confirmed by thermogram (A), which demonstrated the distribution of heat and maximum temperature at the tested bearing. All test bearings lubricated with nano-additives showed temperature below 40 °C. Adding rGO additives gradually reduced the temperature until reaching the lowest temperature, which accounted for 27 °C in the case of the 2 wt.% rGO addition. This means that the heat energy generated on the test bearing decreased by 57% due to adding 2 wt.% rGO compared to the base grease case. Additionally, this value was repeated when adding 1 wt.% graphite and 2 wt.% graphite to the grease. However, the MWCNTs’ addition reached only 33 °C, which surprisingly denoted the superiority of small graphite additions over MWCNTs in reducing the heat inside rolling bearings.

It was also noticed that the effect of the agglomeration in the case of 3.5 and 5 wt.% rGO and graphite nano-additives gave rise to more friction between the rolling elements and lubricant nano-additives themselves; hence, this led to more energy losses in the form of heat. IRT results were consistent with the vibrations’ measurements obtained for the same test bearings.

3.6. Timken Load Test Results

Table 3 shows the Timken OK load values of each test grease. Commercial Mobil fibra x235 grease was tested in a Timken tester, and its results were used for comparison. The results revealed that lithium grease and Mobil fibra x235 grease showed the lowest load-carrying capacities among the test samples. However, samples with 1 wt.% rGO, 1 wt.% MWCNT, and 1 wt.% graphite showed an insignificant difference in Timken OK load values from base grease samples. Increasing rGO nano-additive percentages in grease to 2 wt.%, 3.5 wt.%, and 5 wt.% resulted in a remarkable increase of Timken OK load by 25%, 50%, and 100% compared to samples of base grease (without additives).

Table 3.

Timken OK load and corresponding wear scar dimensions and area for each roller element.

The rolling action between the loaded roller element and the ring component of the Timken test was accompanied by wear, which resulted in uniform elliptical-shaped surface scars. These wear scars on the test rollers were examined using brinelling microscopy and found to be smooth. The wear scar area for the roller elements under each lubricant was calculated using measurements of the minor (x) and major (y) axes [71]. The wear scar dimensions and area are summarized in Table 3.

It can be seen that the wear scar area was the largest in the case of lithium grease and Mobil fibra x235 grease, and it decreased gradually with the increase of wt.% rGO nano-additives in grease samples. Lithium grease with 3.5 wt.% and 5 wt.% rGO nano-additives produced around 50% smaller scar areas than those produced in the case of base grease. This revealed a positive influence of rGO nano-additives to improve anti-wear (AW) and extreme pressure (EP) properties.

4. Conclusions

The influence of adding reduced graphene oxide to commercial lithium grease on the dynamic and tribological behavior of a deep-groove ball bearing was investigated. Timken load test results revealed a considerable increase in test grease load-carrying capacities containing rGO nano-additives. Grease samples having 2, 3.5, and 5 weight percent rGO showed the highest load-carrying capacity (among other tested samples) with an increase of 25%, 50%, and 100% compared to base grease values. The wear scar dimensions measured on the rolling element after the rupture of the lubricant film between the rolling element and raceway indicated a remarkably high resistance of the formed graphene layer to wear. The results also proved the superiority of graphene as a lubricant nano-additive in enhancing the tribological properties in terms of load-carrying capacity and wear scar size.

After 10 min running under a radial test load of 2250 N and 1400 rpm, the steady-state temperature of the bearing lubricated by 2 wt.% rGO grease leveled up at 27 °C, whereas, for that lubricated by base grease, the temperature approached 65 °C. These findings implied a reduction in friction forces between contacting surfaces of bearing elements during operation, which also complied with the vibrations and ultrasound measurements. The vibration and ultrasound levels for 2 wt.% rGO grease were found to be 50% and 20% lower than those for bearings lubricated with base grease. Modal analysis results indicated considerable improvement of the damping ratio values of the bearings lubricated with rGO additives up to 50% as compared to base grease. Increasing the aggregate of rGO in grease to 2 wt.% and 5 wt.% resulted in higher damping ratios by 15% and 28% when compared to 2 wt.% and 5 wt.% graphite. The outcomes of this work represent a significant contribution towards improving the reliability and quiet running of rolling element bearings during their service time.

Author Contributions

Conceptualization, G.A.N. and M.G.A.N.; Methodology, M.S., B.G.N. and M.A.D.; Samples’ Preparation, B.G.N. and M.G.A.N.; Validation, M.S., B.G.N. and M.G.A.N.; Formal Analysis, G.A.N., B.G.N. and M.A.D.; Investigation, M.S. and B.G.N.; Resources, M.S. and M.G.A.N.; Data Curation, M.G.A.N. and G.A.N.; Writing—Original Draft Preparation, B.G.N. and M.G.A.N.; Writing—Review and Editing, G.A.N. and M.A.D.; Visualization, M.G.A.N.; Project Administration, G.A.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- S. Group. Bearing Damage and Failure Analysis; Technical Report; SKF Group: Gothenburg, Sweden, 2017. [Google Scholar]

- Market Analysis Report. Bearings Market Size, Share & Trends Analysis. Available online: https://www.grandviewresearch.com/industry-analysis/bearings-market (accessed on 8 November 2021).

- Randall, R.B.; Antoni, J. Rolling element bearing diagnostics—A tutorial. Mech. Syst. Signal Process. 2011, 25, 485–520. [Google Scholar] [CrossRef]

- Vencl, A.; Gašić1, V.; Stojanović, B. Fault tree analysis of most common rolling bearing tribological failures. IOP Conf. Ser. Mater. Sci. Eng. 2017, 174, 012048. [Google Scholar] [CrossRef]

- Harris, T.A. Rolling Bearing Analysis, 4th ed.; Wiley: New York, NY, USA, 2001. [Google Scholar]

- Howard, I.A. Review of Rolling Element Bearing Vibration Detection, Diagnosis and Prognosis; Technical Report; Defense Science and Technology Organization Canberra: Canberra, Australia, 1994. [Google Scholar]

- Cann, P. Starved Grease Lubrication of Rolling Contacts. Tribol. Trans. 1999, 42, 867–873. [Google Scholar] [CrossRef]

- Wandel, S.; Bader, N.; Schwack, F.; Glodowski, J.; Lehnhardt, B.; Poll, G. Starvation and relubrication mechanisms in grease lubricated oscillating bearings. Tribol. Int. 2021, 165, 107276. [Google Scholar] [CrossRef]

- Grützmacher, P.; Jalikop, S.; Gachot, C.; Rosenkranz, A. Thermocapillary lubricant migration on textured surfaces—A review of theoretical and experimental insights. Surf. Topogr. Metrol. Prop. 2021, 9, 013001. [Google Scholar] [CrossRef]

- Grützmacher, P.; Rosenkranz, A.; Szurdak, A.; Grüber, M.; Gachot, C.; Hirt, G.; Mücklich, F. Multi-scale surface patterning–an approach to control friction and lubricant migration in lubricated systems. Ind. Lubr. Tribol. 2019, 71, 1007–1016. [Google Scholar] [CrossRef]

- Grützmacher, P.; Rosenkranz, A.; Szurdak, A.; Gachot, C.; Hirt, G.; Mücklich, F. Lubricant migration on stainless steel induced by bio-inspired multi-scale surface patterns. Mater. Des. 2018, 150, 55–63. [Google Scholar] [CrossRef]

- S. Group. FAG Lubrication of Rolling Bearings; Technical Report; SKF: Bresler, Germany, 2013; p. 8. [Google Scholar]

- Dresel, W.; Heckler, R.P. Lubricating Greases. In Lubricants and Lubrication, 2nd ed.; Mang, H., Dresel, W., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2006; pp. 648–693. [Google Scholar]

- Lansdown, A.R. Lubrication and Lubricant Selection: A Practical Guide, 3rd ed.; ASME Press: New York, NY, USA, 2004. [Google Scholar]

- Gow, G. Lubricating Grease in Chemistry and Technology of Lubricants, 3rd ed.; Mortier, R.M., FoxStefan, M.F., Orszulik, T., Eds.; Springer: Dordrecht, The Netherlands, 2010; pp. 411–432. [Google Scholar]

- Lugt, P.M.; Pallister, D.M. Grease Composition and Properties. In Grease Lubrication in Rolling Bearings, 1st ed.; Lugt, P.M., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; pp. 23–69. [Google Scholar]

- Rosenkranz, A.; Liu, Y.; Yang, L.; Chen, L. 2D nano-materials beyond graphene: From synthesis to tribological studies. Appl. Nanosci. 2020, 10, 3353–3388. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A. Approaches for Achieving Superlubricity in Two-Dimensional Materials. ACS Nano 2018, 12, 2122–2137. [Google Scholar] [CrossRef]

- Zhang, S.; Ma, T.; Erdemir, A.; Li, Q. Tribology of two-dimensional materials: From mechanisms to modulating strategies. Mater. Today 2018, 26, 67–86. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Wang, A.; Edwards, B.J.; Yin, H.; Li, Z.; Ding, Y. Improvement of the Tribological Properties of a Lithium-Based Grease by Addition of Graphene. J. Nanosci. Nanotechnol. 2018, 18, 7163–7169. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, A.; Osman, T.A.; Khattab, A.; Zaki, M. Tribological Behavior of Carbon Nanotubes as an Additive on Lithium Grease. J. Tribol. 2014, 137, 011801. [Google Scholar] [CrossRef]

- Rawat, S.S.; Harsha, A.P.; Khatri, O.P.; Wäsche, R. Pristine, Reduced, and Alkylated Graphene Oxide as Additives to Paraffin Grease for Enhancement of Tribological Properties. J. Tribol. 2020, 143, 11. [Google Scholar] [CrossRef]

- Akbulut, M.; Belman, N.; Golan, Y.; Israelachvili, J. Frictional Properties of Confined Nanorods. Adv. Mater. 2006, 18, 2589–2592. [Google Scholar] [CrossRef]

- Rapoport, L.; Leshchinsky, V.; Lapsker, I.; Volovik, Y.; Nepomnyashchy, O.; Lvovsky, M.; Popovitz-Biro, R.; Feldman, Y.; Tenne, R. Tribological properties of WS2 nanoparticles under mixed lubrication. Wear 2003, 255, 785–793. [Google Scholar] [CrossRef]

- Cameron, A. The Principles of Lubrication, 1st ed.; Longmans: London, UK, 1966. [Google Scholar]

- Marian, M.; Berman, D.; Rota, A.; Jackson, R.; Rosenkranz, A. Layered 2D Nanomaterials to Tailor Friction and Wear in Machine Elements—A Review. Adv. Mater. 2022, 9, 2101622. [Google Scholar] [CrossRef]

- Kamel, B.M.; Mohamed, A.; El Sherbiny, M.; Abed, K.A.; Abd-Rabou, M. Tribological properties of graphene nanosheets as an additive in calcium grease. J. Dispers. Sci. Technol. 2017, 38, 1495–1500. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Tribological performance of self-lubricating aluminum matrix nanocomposites: Role of graphene nanoplatelets. Int. J. Eng. Sci. Technol. 2016, 19, 463–469. [Google Scholar] [CrossRef] [Green Version]

- Nassef, B.G.; Nassef, G.A.; Daha, M.A. Graphene and Its Industrial Applications—A Review. Int. J. Mater. Eng. 2020, 10, 1–12. [Google Scholar] [CrossRef]

- Singh, J.; Anand, G.; Kumar, D.; Tandon, N. Graphene based composite grease for elastohydrodynamic lubricated point contact. IOP Conf. Ser. Mater. Sci. Eng. 2016, 149, 012195. [Google Scholar] [CrossRef] [Green Version]

- Curà, F.; Mura, A.; Adamo, F. Experimental investigation about tribological performance of grapheme-nanoplatelets as additive for lubricants. Procedia Struct. Integr. 2018, 12, 44–51. [Google Scholar] [CrossRef]

- Fu, H.; Yan, G.; Li, M.; Wang, H.; Chen, Y.; Yan, C.; Lin, C.-T.; Jiang, N.; Yu, J. Graphene as a nanofiller for enhancing the tribological properties and thermal conductivity of base grease. RSC Adv. 2019, 9, 42481–42488. [Google Scholar] [CrossRef] [Green Version]

- Cheng, Z.L.; Qin, X.-X. Study on friction performance of graphene-based semi-solid grease. Chin. Chem. Lett. 2014, 25, 1305–1307. [Google Scholar] [CrossRef]

- Nan, F.; Yin, Y. Improving of the tribological properties of attapulgite base grease with graphene. Lubr. Sci. 2021, 33, 380–393. [Google Scholar] [CrossRef]

- Schwarz, U.D. Tracking antiwear film formation. Science 2015, 348, 40–41. [Google Scholar] [CrossRef] [Green Version]

- Pape, F.; Poll, G. Investigations on Graphene platelets as dry lubricant and as grease additive for rolling and sliding contacts. Lubricants 2019, 8, 3. [Google Scholar] [CrossRef] [Green Version]

- Nassef, B.G. Performance of Rolling Element Bearings Lubricated with Grease-Graphene Mixtures. Master’s Thesis, Alexandria University, Alexandria, Egypt, 2021. [Google Scholar]

- Brisebois, P.P.; Siaj, M. Harvesting graphene oxide—years 1859 to 2019: A review of its structure, synthesis, properties and exfoliation. J. Mater. Chem. C. 2020, 8, 1517–1547. [Google Scholar] [CrossRef]

- Shahriary, L.; Athawale, A. Graphene oxide synthesized by using modified Hummers approach. Renew. Energy Environ. Eng. 2014, 2, 58–63. [Google Scholar]

- Kaur, M.; Kaur, H.; Kukkar, D. Synthesis and characterization of graphene oxide using modified Hummer’s method. AIP Conf. Proc. 2018, 1953, 030180. [Google Scholar] [CrossRef]

- ISO 7626-5:2019; Mechanical Vibration and Shock-Experimental Determination of Mechanical Mobility-5: Measurements Using Impact Excitation with an Exciter Which Is Not Attached to the Structure. International Organization for Standardization ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/68735.html (accessed on 17 February 2022).

- ISO 10816-8:2014; Mechanical Vibration-Evaluation of Machine Vibration by Measurements on Non-Rotating Parts-Part 1: General Guidelines. International Organization for Standardization ISO: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/56782.html (accessed on 17 February 2022).

- ISO 29821:2018; Condition Monitoring and Diagnostics of Machines-Ultrasound-General Guidelines, Procedures and Validation. International Organization for Standardization ISO: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/71196.html (accessed on 17 February 2022).

- ISO 18434-1:2008; Condition Monitoring and Diagnostics of Machines-Thermography-Part 1: General Procedures. International Organization for Standardization ISO: Geneva, Switzerland, 2008. Available online: https://www.iso.org/standard/41648.html (accessed on 17 February 2022).

- Luong, M.P. Fatigue limit evaluation of metals using an infrared thermographic technique. Mech. Mater. 1998, 28, 155–163. [Google Scholar] [CrossRef]

- Maldague, X. Theory and Practice of Infrared Technology for Nondestructive Testing, 1st ed.; Wiley: New York, NY, USA, 2001. [Google Scholar]

- La Rosa, G.; Risitano, A. Thermographic methodology for rapid determination of the fatigue limit of materials and mechanical components. Int. J. Fatigue 2000, 22, 65–73. [Google Scholar] [CrossRef]

- ISO 18434-2:2019; Condition Monitoring and Diagnostics of Machine systems-Thermography-Part 2: Image Interpretation and Diagnostics. International Organization for Standardization ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/67617.html (accessed on 17 February 2022).

- ASTM D2509-20ae1; Standard Test Method for Measurement of Load-Carrying Capacity of Lubricating Grease (Timken Method). American Society for Testing and Materials (ASTM International): West Conshohocken, PA, USA. Available online: https://www.astm.org/d2509-20ae01.html (accessed on 17 February 2022).

- Krishnamoorthy, K.; Veerapandian, M.; Mohan, R.; Kim, S.-J. Investigation of Raman and photoluminescence studies of reduced graphene oxide sheets. Appl. Phys. A 2012, 106, 501–506. [Google Scholar] [CrossRef]

- Thakur, S.; Karak, N. Green reduction of graphene oxide by aqueous phytoextracts. Carbon 2012, 50, 5331–5339. [Google Scholar] [CrossRef]

- Tai, M.; Liu, W.; Khe3, C.; Hidayah, N.; Teoh, Y.; Voon, C.; Lee, H.; Adelyn, P. Green synthesis of reduced graphene oxide using green tea extract. AIP Conf. Proc. 2018, 2045, 020032. [Google Scholar] [CrossRef]

- Song, P.; Cao, Z.; Cai, Y.; Zhao, L.; Fang, Z.; Fu, S. Fabrication of exfoliated graphene-based polypropylene nanocomposites with enhanced mechanical and thermal properties. Polymer 2011, 52, 4001–4010. [Google Scholar] [CrossRef]

- Hidayah, N.; Liu, W.; Lai, C.; Noriman, N.; Khe, C.; Hashim, U.; Lee, H. Comparison on graphite, graphene oxide and reduced graphene oxide: Synthesis and characterization. AIP Conf. Proc. 2017, 1892, 150002. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.; Piner, R.; Kohlhaas, K.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.; Ruoff, R. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Tuinstra, F.; Koenig, J. Raman spectrum of graphite. J. Chem. Phys. 1970, 53, 1126–1130. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, A.; Meyer, J.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.; Roth, S.; et al. Raman Spectrum of Graphene and Graphene Layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Kumar, A.; Lee, D.; Park, S. Estimation of Number of Graphene Layers Using Different Methods: A Focused Review. Materials 2021, 14, 4590. [Google Scholar] [CrossRef]

- Moon, I.K.; Lee, J.; Ruoff, R.; Lee, H. Reduced graphene oxide by chemical graphitization. Nat. Commun. 2010, 1, 73. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yasin, G.; Arif, M.; Shakeel, M.; Dun, Y.; Zuo, Y.; Khan, W.; Tang, Y.; Khan, A.; Nadeem, M. Exploring the Nickel–Graphene Nanocomposite Coatings for Superior Corrosion Resistance: Manipulating the Effect of Deposition Current Density on its Morphology, Mechanical Properties, and Erosion-Corrosion Performance. Adv. Eng. Mater. 2018, 20, 1701166. [Google Scholar] [CrossRef]

- Gupta, B.; Kumar, N.; Panda, K.; Kanan, V.; Joshi, S.; Visoly-Fisher, I. Role of oxygen functional groups in reduced graphene oxide for lubrication. Sci. Rep. 2017, 7, 45030. [Google Scholar] [CrossRef]

- Zeillinger, R.; Kottritsch, H. Damping in a rolling arrangement, Technical Report ed. SKF Business and Technology Magazine (Evolution). 15 February 1996, pp. 27–30. Available online: https://evolution.skf.com/damping-in-a-rolling-bearing-arrangement/ (accessed on 14 January 2022).

- Ali, N.J.; García, J.M. Experimental studies on the dynamic characteristics of rolling element bearings. Proc. Inst. Mech. Eng. Part J. Eng. Tribol. 2010, 224, 659–666. [Google Scholar] [CrossRef]

- Singh, R.; Dixit, A.; Sharma, A.; Tiwari, A.; Mandal, V.; Pramanik, A. Influence of graphene and multi-walled carbon nanotube additives on tribological behaviour of lubricants. Int. J. Surf. Sci. Eng. 2018, 12, 207–227. [Google Scholar] [CrossRef] [Green Version]

- Kamel, B.M.; Mohamed, A.; El-Sherbiny, M.; Abed, K.; Abd-Rabou, M. Rheological characteristics of modified calcium grease with graphene nanosheets Fuller Nanotube Carbon Nanostructures. Fuller. Nanotub. Carbon Nanostructures 2017, 25, 429–434. [Google Scholar] [CrossRef]

- ISO 13373-2:2016; Condition Monitoring and Diagnostics of Machines—Vibration Condition Monitoring—Part 2: Processing, analysis and Presentation of Vibration Data. International Organization for Standardization ISO: Geneva, Switzerland, 2016. Available online: https://www.iso.org/standard/68128.html (accessed on 17 February 2022).

- ISO 10816-7:2009; Mechanical Vibration—Evaluation of Machine Vibration by Measurements on Non-Rotating Parts—Part 7: Rotodynamic Pumps for Industrial Applications, Including Measurements on Rotating Shafts. International Organization for Standardization ISO: Geneva, Switzerland, 2009. Available online: https://www.iso.org/standard/41726.html (accessed on 17 February 2022).

- Wu, C.; Yang, K.; Chen, Y.; Ni, J.; Yao, L.; Li, X. Investigation of friction and vibration performance of lithium complex grease containing nano-particles on rolling bearing. Tribol. Int. 2021, 155, 106761. [Google Scholar] [CrossRef]

- Rawat, S.S.; Harsha, A.P.; Chouhan, A.; Khatri, O.P. Effect of Graphene-Based Nanoadditives on the Tribological and Rheological Performance of Paraffin Grease. J. Mater. Eng. Perform. 2020, 29, 2235–2247. [Google Scholar] [CrossRef]

- Adhvaryu, A.; Sung, C.; Erhan, S.Z. Fatty acids and antioxidant effects on grease microstructures. Ind. Crops Prod. 2005, 21, 285–291. [Google Scholar] [CrossRef]

- Tippayawong, N.; Sooksarn, P. Assessment of lubricating oil degradation in small motorcycle engine fueled with gasohol. Maejo Int. J. Sci. Technol. 2010, 4, 201–209. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).