The Current Situation and Future Direction of Nanoparticles Lubricant Additives in China

Abstract

1. Introduction

2. Effect of Nanoadditive Composition on Tribological Properties

2.1. Metal

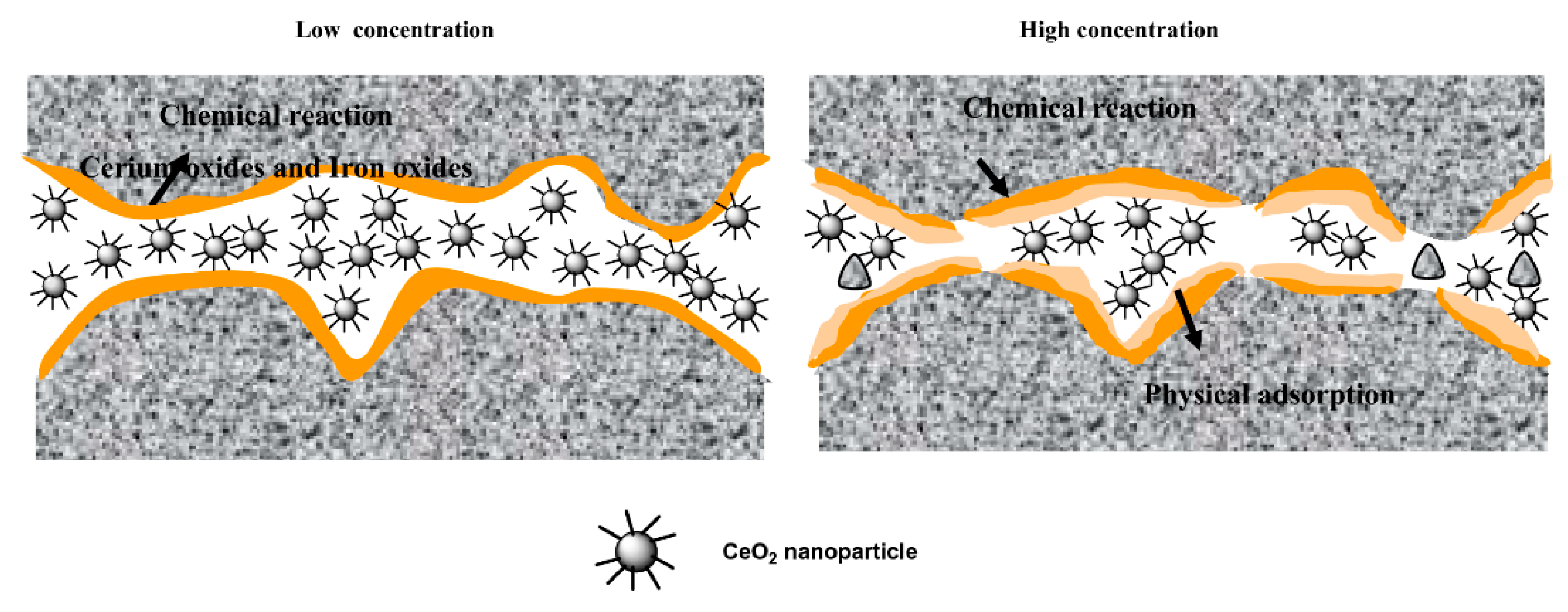

2.2. Oxide

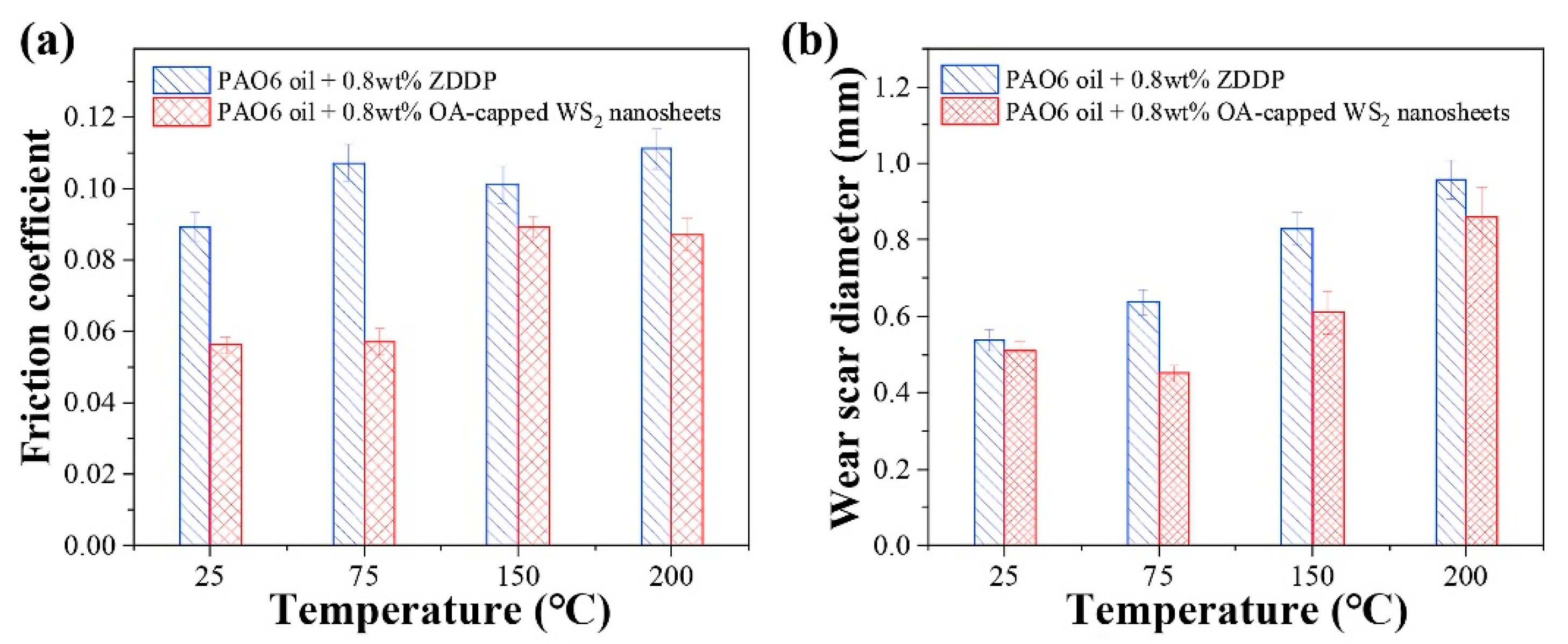

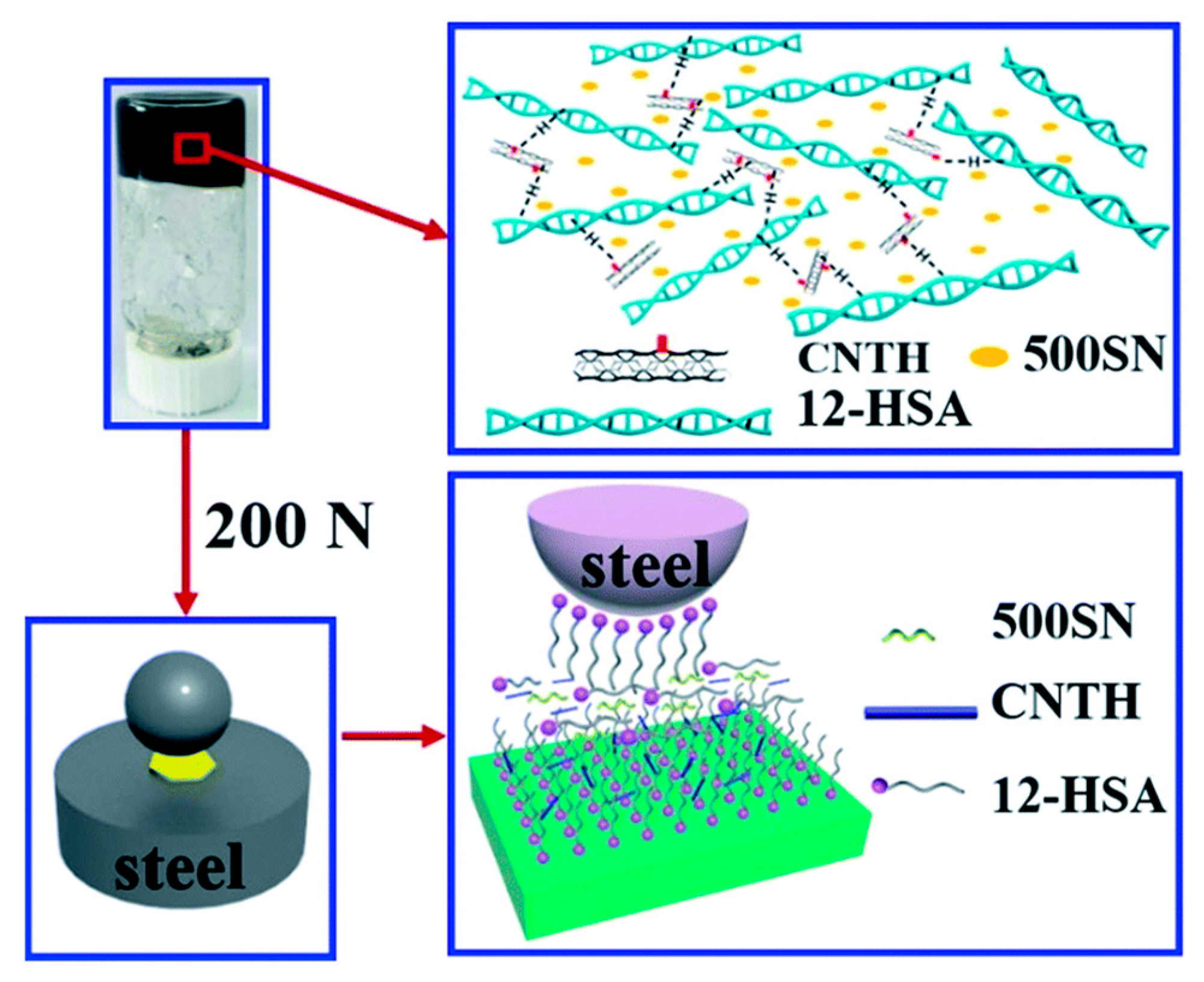

2.3. Sulfide

2.4. Carbon and Its Derivatives

2.5. Rare Earth Compound

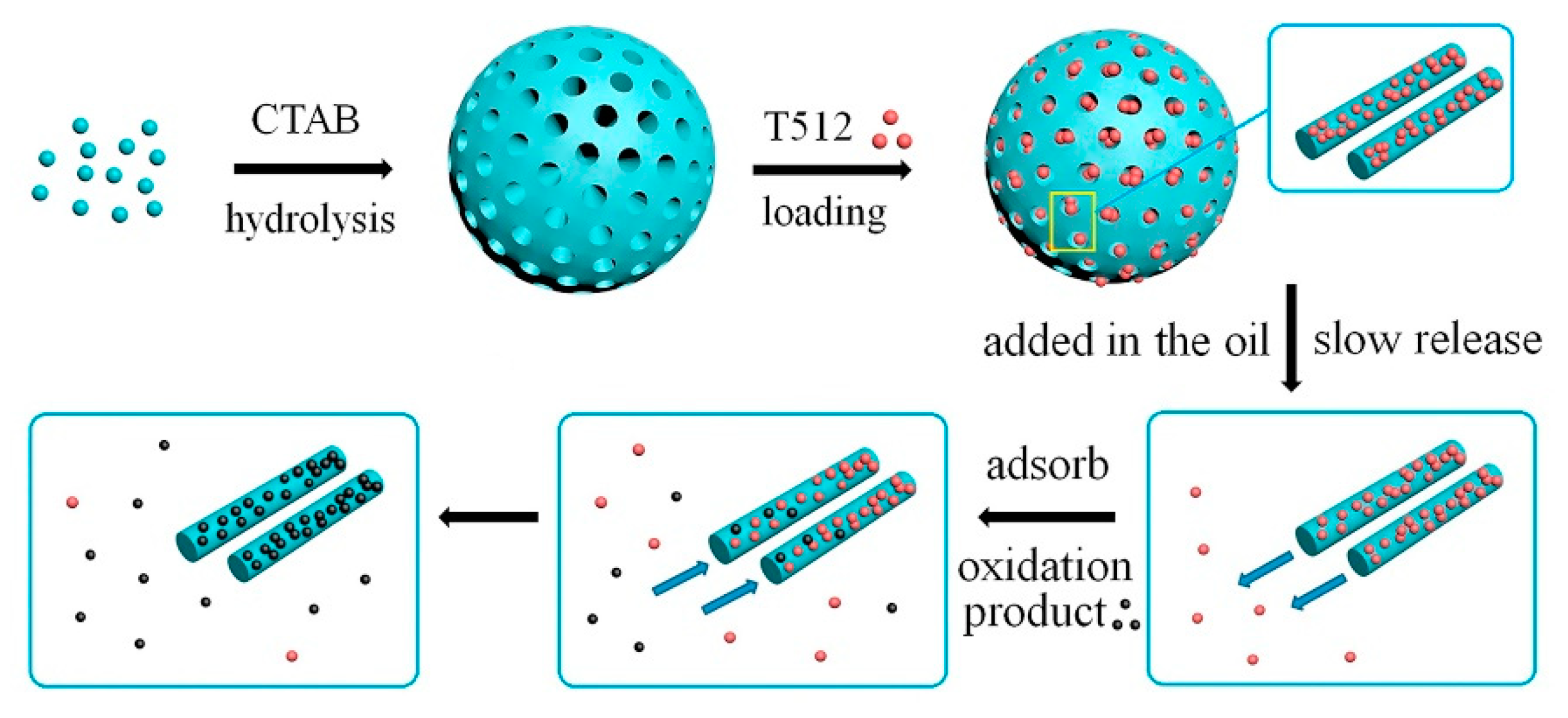

2.6. The Others

3. Effect of Size of Nanoadditive on Tribological Properties

4. Effect of Morphology of Nanoadditive on Tribological Properties

4.1. Sphere

4.2. Sheet

4.3. Onion

4.4. Nanotube

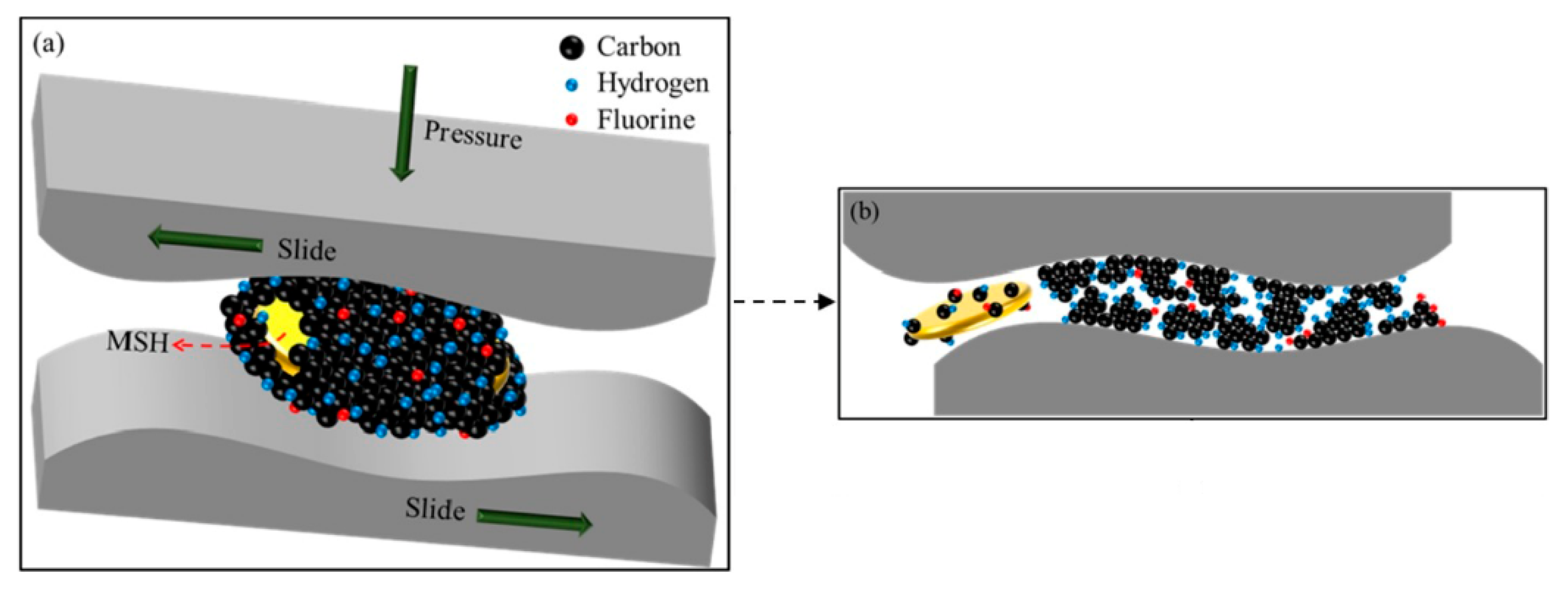

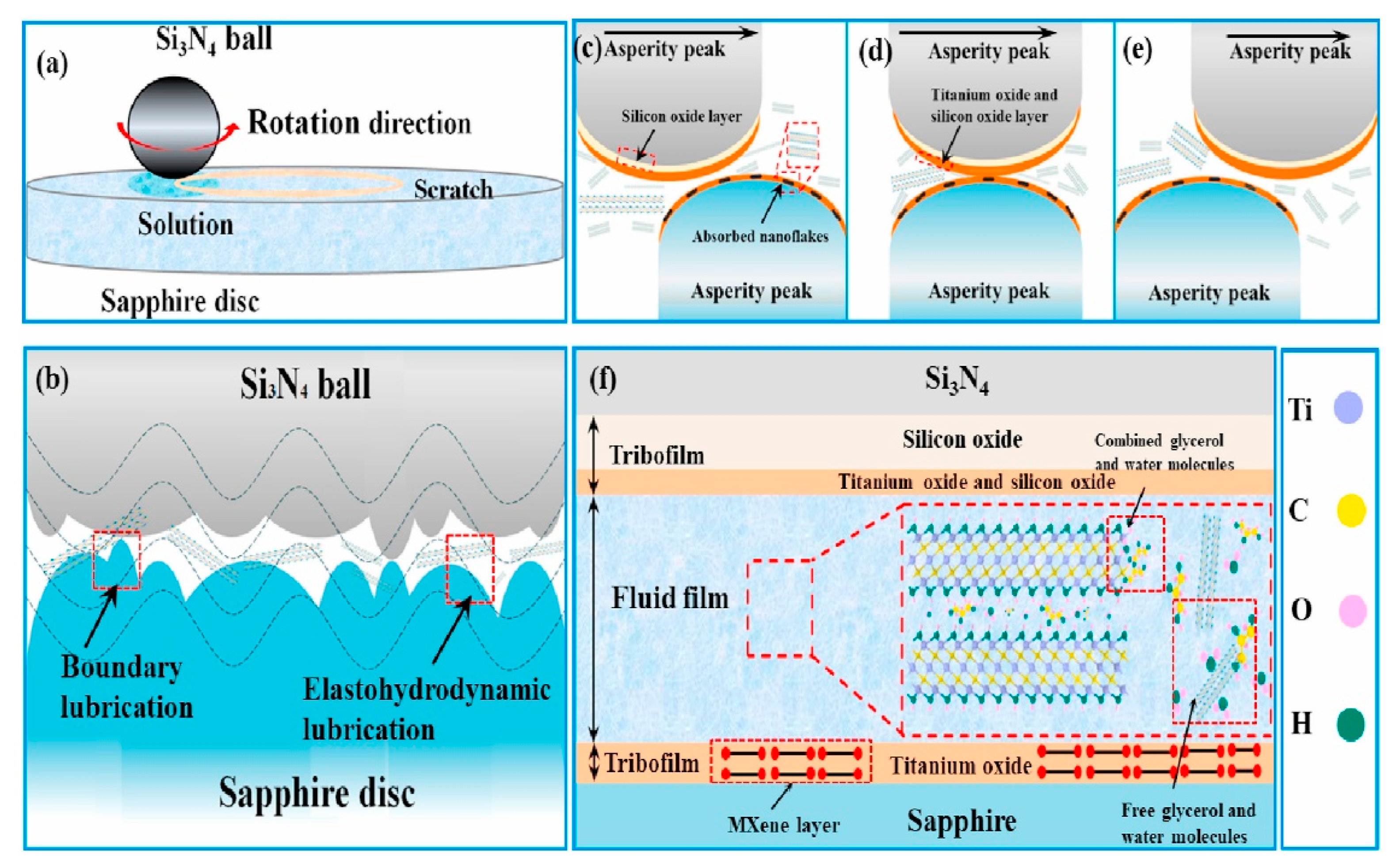

5. Lubrication Mechanisms

5.1. Ball Bearing Effect

5.2. Mending Effect

5.3. Polishing Effect

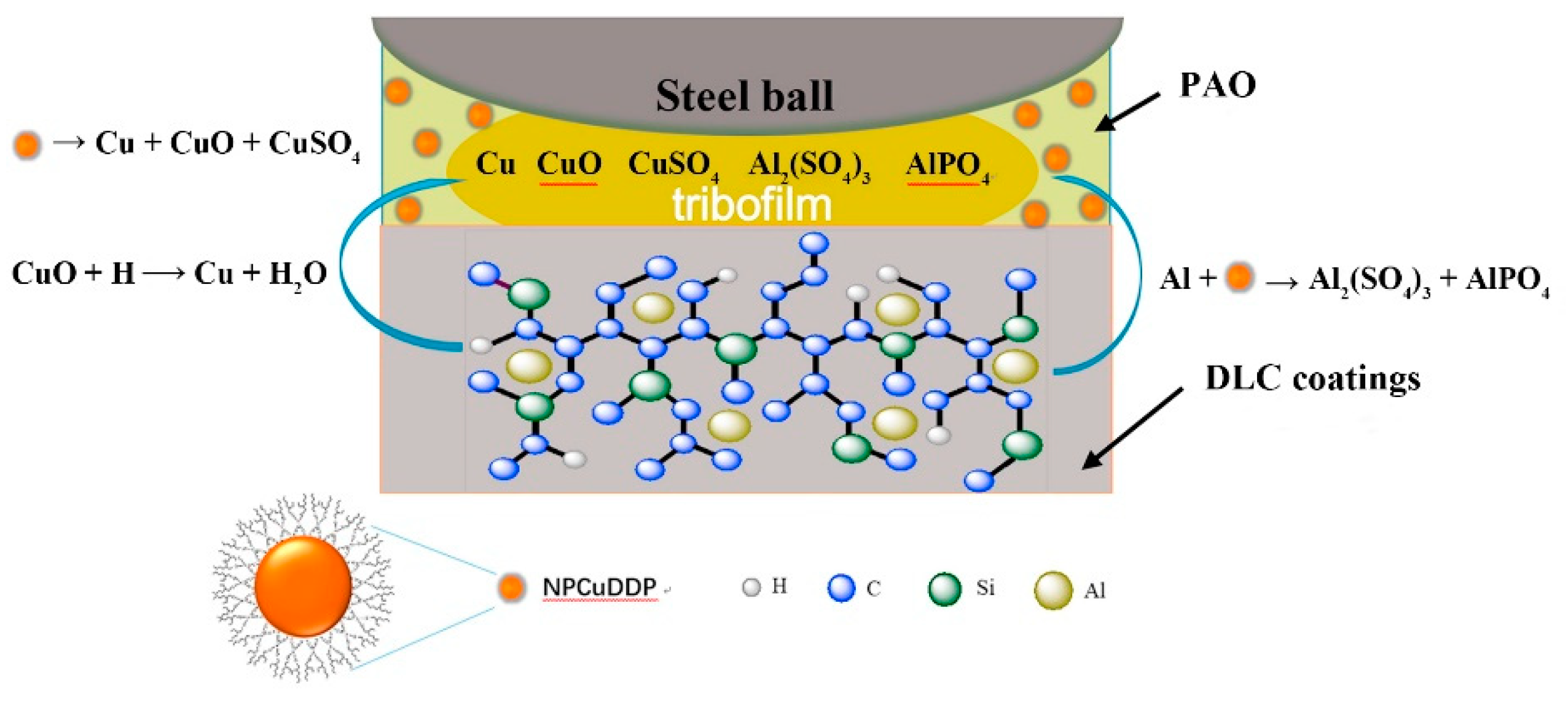

5.4. Formation of Tribofilm

5.5. Extension of Tribomechanism of Nanoadditive

6. Effect of Other Additives on the Tribological Properties of Nanoparticles

7. Effect of Different Base Oils on the Tribological Properties of Nanoparticles

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, B.; Qiu, F.; Barber, G.C.; Zou, Q.; Wang, J.; Guo, S.; Yuan, Y.; Jiang, Q. Role of nano-sized materials as lubricant additives in friction and wear reduction: A review. Wear 2022, 490, 204206. [Google Scholar] [CrossRef]

- Uflyand, I.E.; Zhinzhilo, V.A.; Burlakova, V.E. Metal-containing nanomaterials as lubricant additives: State-of-the-art and future development. Friction 2019, 7, 93–116. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Xue, Q. Synthesis and characterization of a molybdenum disulfide nanocluster. J. Phys. Chem. 1994, 98, 12973–12977. [Google Scholar] [CrossRef]

- Bakunin, V.N.; Suslov, A.Y.; Kuzmina, G.N.; Parenago, O.P. Synthesis and application of inorganic nanoparticles as lubricant components-a review. J. Nanopart. Res. 2004, 6, 273–284. [Google Scholar] [CrossRef]

- Bai, G.; Wang, J.; Yang, Z.; Wang, H.; Wang, Z.; Yang, S. Preparation of a highly effective lubricating oil additive—Ceria/graphene composite. RSC Adv. 2014, 4, 47096–47105. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Liu, Y.; Gunsel, S.; Luo, J. Ultrathin MoS2 Nanosheets with Superior Extreme Pressure Property as Boundary Lubricants. Sci. Rep. 2015, 5, 12869. [Google Scholar] [CrossRef]

- Yu, H.; Xu, Y.; Shi, P.; Wang, H.; Wei, M.; Zhao, K.; Xu, B. Microstructure, mechanical properties and tribological behavior of tribofilm generated from natural serpentine mineral powders as lubricant additive. Wear 2013, 297, 802–810. [Google Scholar] [CrossRef]

- Rapoport, L.; Feldman, Y.; Homyonfer, M.; Cohen, H.; Sloan, J.; Hutchison, J.L.; Tenne, R. Inorganic fullerene-like material as additives to lubricants: Structure–function relationship. Wear 1999, 225, 975–982. [Google Scholar] [CrossRef]

- Rabaso, P.; Ville, F.; Dassenoy, F.; Diaby, M.; Afanasiev, P.; Cavoret, J.; Vacher, B.; Le Mogne, T. Boundary lubrication: Influence of the size and structure of inorganic fullerene-like MoS2 nanoparticles on friction and wear reduction. Wear 2014, 320, 161–178. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Zhang, B.; Xu, B.; Xu, Y.; Gao, F.; Shi, P.; Wu, Y. CU nanoparticles effect on the tribological properties of hydrosilicate powders as lubricant additive for steel–steel contacts. Tribol. Int. 2011, 44, 878–886. [Google Scholar] [CrossRef]

- Liu, L.; Chen, L.; Wan, H.; Chen, J.; Zhou, H. Study on the Tribological Behaviors of N,N-dioctyldithiocarbamate Monolayer-Stabilized Copper Nanoparticles in Liquid Paraffin. J. Dispers. Sci. Technol. 2009, 30, 144–147. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H. Colloidal stability mechanism of copper nanomaterials modified by bis(2-ethylhexyl) phosphate dispersed in polyalphaolefin oil as green nanolubricants. J. Colloid Interface Sci. 2020, 578, 24–36. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Zhang, Z.; Zhang, S.; Yu, L.; Zhang, P.; Hou, Y. Preparation and characterization of copper nanoparticles surface-capped by alkanethiols. Surf. Interface Anal. 2013, 45, 1695–1701. [Google Scholar] [CrossRef]

- Wang, J.; Guo, X.; He, Y.; Jiang, M.; Sun, R. The synthesis and tribological characteristics of triangular copper nanoplates as a grease additive. RSC Adv. 2017, 7, 40249–40254. [Google Scholar] [CrossRef]

- Ma, J.; Mo, Y.; Bai, M. Effect of Ag nanoparticles additive on the tribological behavior of multialkylated cyclopentanes (MACs). Wear 2009, 266, 627–631. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, L.; Wang, H.; Feng, D. The anti-seizure effect of Ag nanoparticles additive in multialkylated cyclopentanes oil under vacuum condition. Tribol. Int. 2012, 55, 1–6. [Google Scholar] [CrossRef]

- Chang, H.; Chen, C.; Tu, H. The Fabrication and Effect of Bi and Bi/Cu Nanoparticles on the Tribological Properties of SAE-30 Lubricating Oil. J. Comput. Theor. Nanosci. 2015, 12, 852–857. [Google Scholar] [CrossRef]

- Liu, C.; Yin, Y.; Li, C.; Xu, M.; Li, R.; Chen, Q. Nano Bi Chemical Modification and Tribological Properties of Bi/SiO2 Composite as Lubricating Oil Additives. Tribol. Lett. 2022, 70, 69. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Hu, L.; Feng, D.; Wang, H. AntiWear Effect of Mo and W Nanoparticles as Additives for Multialkylated Cyclopentanes Oil in Vacuum. J. Tribol. 2017, 139, 021607. [Google Scholar] [CrossRef]

- Peng, D.; Kang, Y.; Chen, S.; Shu, F.; Chang, Y. Dispersion and tribological properties of liquid paraffin with added aluminum nanoparticles. Ind. Lubr. Tribol. 2010, 62, 341–348. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, H.; Hu, W.; Li, J. Tribological Properties and Lubrication Mechanism of Nickel Nanoparticles as an Additive in Lithium Grease. Nanomaterials 2022, 12, 2287. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.; Zhang, Y.; Wang, S.; Guo, K.; Tang, J.; Wu, Z.; Zhang, G.; Zhu, Y.; Yan, P.; Zhang, W. Tribological properties of oleylamine-modified nickel nanoparticles as lubricating oil additive. Mater. Res. Express 2019, 6, 105037. [Google Scholar] [CrossRef]

- Guo, J.; Cheng, J.; Tan, H.; Sun, Q.; Yang, J.; Liu, W. Constructing a novel and high-performance liquid nanoparticle additive from a Ga-based liquid metal. Nanoscale 2020, 12, 9208–9218. [Google Scholar] [CrossRef]

- He, B.; Liu, S.; Zhao, X.; Liu, J.; Ye, Q.; Liu, S.; Liu, W. Dialkyl Dithiophosphate-Functionalized Gallium-Based Liquid-Metal Nanodroplets as Lubricant Additives for Antiwear and Friction Reduction. ACS Appl. Nano Mater. 2020, 3, 10115–10122. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, L.; Feng, D.; Wang, H. Anti-wear and friction-reduction mechanism of Sn and Fe nanoparticles as additives of multialkylated cyclopentanes under vacuum condition. Vacuum 2013, 87, 75–80. [Google Scholar] [CrossRef]

- Luo, T.; Wei, X.; Huang, X.; Huang, L.; Yang, F. Tribological properties of Al2O3 nanoparticles as lubricating oil additives. Ceram. Int. 2014, 40, 7143–7149. [Google Scholar] [CrossRef]

- Ma, J.; Bai, M. Effect of ZrO2 Nanoparticles Additive on the Tribological Behavior of Multialkylated Cyclopentanes. Tribol. Lett. 2009, 36, 191–198. [Google Scholar] [CrossRef]

- Zhang, F.; Zheng, S.; Yin, Y.; Liu, B. Anti-Wear and Friction-Reducing Behavior of Nano-ZrO2 Additive. Adv. Mater. Res. 2009, 79, 605–608. [Google Scholar] [CrossRef]

- Gao, C.; Wang, Y.; Hu, D.; Pan, Z.; Xiang, L. Tribological properties of magnetite nanoparticles with various morphologies as lubricating additives. J. Nanoparticle Res. 2013, 15, 1502. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Y.; Zhang, S.; Chen, Y.; Zhang, P.; Zhang, Z. Preparation and evaluation of tribological properties of oil-soluble rice-like CuO nanoparticles. Ind. Lubr. Tribol. 2015, 67, 276–283. [Google Scholar] [CrossRef]

- Zheng, B.; Zhou, J.; Jia, X.; He, Q. Friction and wear property of lithium grease contained with copper oxide nanoparticles. Appl. Nanosci. 2019, 10, 1355–1367. [Google Scholar] [CrossRef]

- Wu, Y.; Tsui, W.; Liu, T. Experimental analysis of tribological properties of lubricating oils with nanoparticle additives. Wear 2007, 262, 819–825. [Google Scholar] [CrossRef]

- Peng, D.; Kang, Y.; Hwang, R.; Shyr, S.; Chang, Y. Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribol. Int. 2009, 42, 911–917. [Google Scholar] [CrossRef]

- Ge, X.; Xia, Y.; Cao, Z. Tribological properties and insulation effect of nanometer TiO2 and nanometer SiO2 as additives in grease. Tribol. Int. 2015, 92, 454–461. [Google Scholar] [CrossRef]

- Ma, H.; Wu, W.; Wang, Z. Bisurfactant-functionalized TiO2 nanoparticles as additives of the lubricating oil. Lubr. Sci. 2022, 34, 441–448. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, Y.; Yang, G.; Zhang, S.; Yu, L.; Zhang, P. Tribological properties of oleic acid-modified zinc oxide nanoparticles as the lubricant additive in poly-alpha olefin and diisooctyl sebacate base oils. RSC Adv. 2016, 6, 69836–69844. [Google Scholar] [CrossRef]

- Mousavi, S.B.; Heris, S.Z.; Estelle, P. Experimental comparison between ZnO and MoS2 nanoparticles as additives on performance of diesel oil-based nano lubricant. Sci. Rep. 2020, 10, 5813. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, D. Preparation and tribological properties of unmodified and oleic acid-modified CuS nanorods as lubricating oil additives. Ceram. Int. 2017, 43, 4246–4251. [Google Scholar] [CrossRef]

- Liu, C.; Friedman, O.; Meng, Y.; Tian, Y.; Golan, Y. CuS Nanoparticle Additives for Enhanced Ester Lubricant Performance. ACS Appl. Nano Mater. 2018, 1, 7060–7065. [Google Scholar] [CrossRef]

- Gu, C. Modifying the lubricating and tribological properties via introducing the oleic acid in CuS nanomaterials for vehicle. Opt. Laser Technol. 2018, 108, 1–6. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, Y.; Yang, G.; Gao, C.; Yu, L.; Zhang, S.; Zhang, P. Synthesis of oil-soluble WS2 nanosheets under mild condition and study of their effect on tribological properties of poly-alpha olefin under evaluated temperatures. Tribol. Int. 2019, 138, 68–78. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, Y.; Yang, G.; Yang, K.; Zhang, S.; Yu, L.; Zhang, P. Tribological Properties of Oleylamine-Modified Ultrathin WS2 Nanosheets as the Additive in Polyalpha Olefin Over a Wide Temperature Range. Tribol. Lett. 2016, 61, 24. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, Y.; Yang, G.; Ma, J.; Zhang, S.; Yu, L.; Zhang, P. Tribological Properties of Tungsten Disulfide Nanoparticles Surface-Capped by Oleylamine and Maleic Anhydride Dodecyl Ester as Additive in Diisooctylsebacate. Ind. Eng. Chem. Res. 2017, 56, 1365–1375. [Google Scholar] [CrossRef]

- Xiong, S.; Liang, D.; Zhang, B.; Wu, H.; Mao, X. Tribological behavior of mineral and synthetic ester base oil containing MoS2 nanoparticles. J. Dispers. Sci. Technol. 2019, 42, 493–502. [Google Scholar] [CrossRef]

- Wu, P.; Li, W.; Feng, Y.; Ge, T.; Liu, Z.; Cheng, Z. Fabrication and tribological properties of oil- soluble MoS2 nanosheets decorated by oleic diethanolamide borate. J. Alloy. Compd. 2019, 770, 441–450. [Google Scholar] [CrossRef]

- Han, Z.; Gan, C.; Li, X.; Feng, P.; Ma, X.; Fan, X.; Zhu, M. Electrochemical preparation of modified-graphene additive towards lubrication requirement. Tribol. Int. 2021, 161, 107057. [Google Scholar] [CrossRef]

- Zhang, L.; He, Y.; Zhu, L.; Jiao, Z.; Deng, W.; Pu, C.; Han, C.; Tang, S. Alkyl phosphate modified graphene oxide as friction and wear reduction additives in oil. J. Mater. Sci. 2018, 54, 4626–4636. [Google Scholar] [CrossRef]

- Yu, B.; Wang, K.; Hu, Y.; Nan, F.; Pu, J.; Zhao, H.; Ju, P. Tribological properties of synthetic base oil containing polyhedral oligomeric silsesquioxane grafted graphene oxide. RSC Adv. 2018, 8, 23606–23614. [Google Scholar] [CrossRef]

- Mao, J.; Zhao, J.; Wang, W.; He, Y.; Luo, J. Influence of the micromorphology of reduced graphene oxide sheets on lubrication properties as a lubrication additive. Tribol. Int. 2018, 119, 614–621. [Google Scholar] [CrossRef]

- Ge, X.; Chai, Z.; Shi, Q.; Li, J.; Tang, J.; Liu, Y.; Wang, W. Functionalized graphene-oxide nanosheets with amino groups facilitate macroscale superlubricity. Friction 2022, 1–14. [Google Scholar] [CrossRef]

- Jin, B.; Zhao, J.; He, Y.; Chen, G.; Li, Y.; Zhang, C.; Luo, J. High-quality ultra-flat reduced graphene oxide nanosheets with super-robust lubrication performances. Chem. Eng. J. 2022, 438, 135620. [Google Scholar] [CrossRef]

- Qian, S.; Wang, H.; Huang, C.; Zhao, Y. Experimental investigation on the tribological properties of modified carbon nanotubes as the additive in castor oil. Ind. Lubr. Tribol. 2018, 70, 499–505. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Gu, A.; Guo, Z. Lubrication Effect of the Paraffin Oil Filled with Functionalized Multiwalled Carbon Nanotubes for Bismaleimide Resin. Tribol. Lett. 2011, 42, 59–65. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, T.; Shang, W.; Liu, D.; Guo, Q.; Liu, S. Facile synthesis of photoluminescent inorganic-organic hybrid carbon dots codoped with B and N: Towards an efficient lubrication additive. Dalton Trans. 2017, 46, 12306–12312. [Google Scholar] [CrossRef]

- Shen, M.; Luo, J.; Wen, S. The Tribological Properties of Oils Added with Diamond Nano-Particles. Tribol. Trans. 2001, 44, 494–498. [Google Scholar] [CrossRef]

- Han, X.; Barber, G.C.; Zhang, Z.; Thrush, S.; Schall, J.D.; Li, Z.; Wang, B. Tribological performance of oil-based ZnO and diamond nanofluids. Lubr. Sci. 2019, 31, 73–84. [Google Scholar] [CrossRef]

- Du, P.; Chen, G.; Song, S.; Chen, H.; Li, J.; Shao, Y. Tribological Properties of Muscovite, CeO2 and Their Composite Particles as Lubricant Additives. Tribol. Lett. 2016, 62, 29. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, L.; Li, T.; Zhang, K.; Lu, B. Tribological properties of lanthanum perrhenate as lubricating additive over a wide temperature range. RSC Adv. 2017, 7, 37447–37458. [Google Scholar] [CrossRef]

- Liu, R.; Wei, X.; Tao, D.; Zhao, Y. Study of preparation and tribological properties of rare earth nanoparticles in lubricating oil. Tribol. Int. 2010, 43, 1082–1086. [Google Scholar] [CrossRef]

- Xu, Y.; Geng, J.; Peng, Y.; Liu, Z.; Yu, J.; Hu, X. Lubricating mechanism of Fe3O4@MoS2 core-shell nanocomposites as oil additives for steel/steel contact. Tribol. Int. 2018, 121, 241–251. [Google Scholar] [CrossRef]

- Ma, X.; Gan, C.; Li, X.; Li, Y.; Feng, P.; Fan, X.; Ye, X.; Zhu, M. Tribological Properties of SiO2@Cu and SiO2@MoS2 Core–Shell Microspheres as Lubricant Additives. Tribol. Lett. 2021, 69, 108. [Google Scholar] [CrossRef]

- Jia, X.; Huang, J.; Li, Y.; Yang, J.; Song, H. Monodisperse Cu nanoparticles @ MoS2 nanosheets as a lubricant additive for improved tribological properties. Appl. Surf. Sci. 2019, 494, 430–439. [Google Scholar] [CrossRef]

- Gong, K.; Lou, W.; Zhao, G.; Wu, X.; Wang, X. MoS2 nanoparticles grown on carbon nanomaterials for lubricating oil additives. Friction 2020, 9, 747–757. [Google Scholar] [CrossRef]

- Jin, B.; Chen, G.; Zhao, J.; He, Y.; Huang, Y.; Luo, J. Improvement of the lubrication properties of grease with Mn3O4/graphene (Mn3O4#G) nanocomposite additive. Friction 2020, 9, 1361–1377. [Google Scholar] [CrossRef]

- Jin, B.; Zhao, J.; Chen, G.; He, Y.; Huang, Y.; Luo, J. In situ synthesis of Mn3O4/graphene nanocomposite and its application as a lubrication additive at high temperatures. Appl. Surf. Sci. 2021, 546, 149019. [Google Scholar] [CrossRef]

- Zheng, D.; Wu, Y.; Li, Z.; Cai, Z. Tribological properties of WS2/graphene nanocomposites as lubricating oil additives. RSC Adv. 2017, 7, 14060–14068. [Google Scholar] [CrossRef]

- Luo, Z.; Yu, J.; Xu, Y.; Xi, H.; Cheng, G.; Yao, L.; Song, R.; Dearn, K.D. Surface characterization of steel/steel contact lubricated by PAO6 with novel black phosphorus nanocomposites. Friction 2020, 9, 723–733. [Google Scholar] [CrossRef]

- Kumara, C.; Luo, H.; Leonard, D.N.; Meyer, H.M.; Qu, J. Organic-Modified Silver Nanoparticles as Lubricant Additives. ACS Appl. Mater. Interfaces 2017, 9, 37227–37237. [Google Scholar] [CrossRef]

- Yang, G.; Chai, S.; Xiong, X.; Zhang, S.; Yu, L.; Zhang, P. Preparation and tribological properties of surface modified Cu nanoparticles. Trans. Nonferrous Met. Soc. China 2012, 22, 366–372. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Yang, Y.; Zhang, S.; Zhang, P.; Zhang, Z. Synthesis and tribological properties of oil-soluble copper nanoparticles as environmentally friendly lubricating oil additives. Ind. Lubr. Tribol. 2015, 67, 227–232. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, J.; Yu, L.; Zhang, P. Effect of Nano-Cu Lubrication Additive on the Contact Fatigue Behavior of Steel. Tribol. Lett. 2009, 37, 203–207. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Sun, D.; Yang, G.; Gao, C.; Zhou, C.; Zhang, C.; Zhang, P. Wide adaptability of Cu nano-additives to the hardness and composition of DLC coatings in DLC /PAO solid-liquid composite lubricating system. Tribol. Int. 2019, 138, 184–195. [Google Scholar] [CrossRef]

- Hu, J.; Wang, C.; Zhang, P.; Zhang, S.; Zhang, Y. Diisooctyl Sebacate-Containing Nickel Nanoparticles for Lubrication of Steel Sliding Parts under Magnetic Fields. ACS Appl. Nano Mater. 2021, 4, 7007–7016. [Google Scholar] [CrossRef]

- Liu, Y.; Xin, L.; Zhang, Y.; Chen, Y.; Zhang, S.; Zhang, P. The Effect of Ni Nanoparticles on the Lubrication of a DLC-Based Solid–Liquid Synergetic System in All Lubrication Regimes. Tribol. Lett. 2017, 65, 28. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, Y.; Yang, G.; Gao, C.; Song, N.; Zhang, S.; Zhang, P. In-situ formed carbon based composite tribo-film with ultra-high load bearing capacity. Tribol. Int. 2020, 152, 106577. [Google Scholar] [CrossRef]

- Li, D.; Xie, Y.; Yong, H.; Sun, D. Surfactant-assisted preparation of Y2O3-stabilized ZrO2 nanoparticles and their tribological performance in mineral and commercial lubricating oils. RSC Adv. 2017, 7, 3727–3735. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Zhang, S.; Yang, G.; Gao, C.; Zhou, C.; Zhang, C.; Zhang, P. One step synthesis of ZnO nanoparticles from ZDDP and its tribological properties in steel-aluminum contacts. Tribol. Int. 2020, 141, 105890. [Google Scholar] [CrossRef]

- Huang, L.; Ma, J.; Wang, X.; Zhang, P.; Yu, L.; Zhang, S. Mesoporous silica nanoparticles-loaded methyl 3-(3,5-di-tert-butyl-4-hydroxyphenyl) propanoate as a smart antioxidant of synthetic ester oil. Tribol. Int. 2018, 121, 114–120. [Google Scholar] [CrossRef]

- Jiang, Z.; Yang, G.; Zhang, Y.; Gao, C.; Ma, J.; Zhang, S.; Zhang, P. Facile method preparation of oil-soluble tungsten disulfide nanosheets and their tribological properties over a wide temperature range. Tribol. Int. 2019, 135, 287–295. [Google Scholar] [CrossRef]

- Xu, Y.; Hu, E.; Hu, K.; Xu, Y.; Hu, X. Formation of an adsorption film of MoS2 nanoparticles and dioctyl sebacate on a steel surface for alleviating friction and wear. Tribol. Int. 2015, 92, 172–183. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Gunsel, S.; Luo, J. Mechanism of Antiwear Property Under High Pressure of Synthetic Oil-Soluble Ultrathin MoS2 Sheets as Lubricant Additives. Langmuir 2018, 34, 1635–1644. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Zhang, Z.; Li, Y. Applications of carbon quantum dots in lubricant additives: A review. J. Mater. Sci. 2021, 56, 12061–12092. [Google Scholar] [CrossRef]

- Liu, Y.; Ge, X.; Li, J. Graphene lubrication. Appl. Mater. Today 2020, 20, 100662. [Google Scholar] [CrossRef]

- Chu, H.; Hsu, W.; Lin, J. The anti-scuffing performance of diamond nano-particles as an oil additive. Wear 2010, 268, 960–967. [Google Scholar] [CrossRef]

- Lu, H.; Tang, W.; Liu, X.; Wang, B.; Huang, Z. Oleylamine-modified carbon nanoparticles as a kind of efficient lubricating additive of polyalphaolefin. J. Mater. Sci. 2016, 52, 4483–4492. [Google Scholar] [CrossRef]

- Kumar, S.; Nehra, M.; Kedia, D.; Dilbaghi, N.; Tankeshwar, K.; Kim, K.H. Nanodiamonds: Emerging face of future nanotechnology. Carbon 2019, 143, 678–699. [Google Scholar] [CrossRef]

- Ye, Q.; Liu, S.; Zhang, J.; Xu, F.; Zhou, F.; Liu, W. Superior Lubricity and Antiwear Performances Enabled by Porous Carbon Nanospheres with Different Shell Microstructures. ACS Sustain. Chem. Eng. 2019, 7, 12527–12535. [Google Scholar] [CrossRef]

- Xu, D.; Xie, Y.; Song, Y.; Deng, W. A green and facile method toward synthesis of waste paper-derived 3D functional porous graphene via in situ activation of cobalt(ii). J. Mater. Chem. A 2015, 3, 16072–16078. [Google Scholar] [CrossRef]

- Ye, M.; Cai, T.; Shang, W.; Zhao, L.; Zhang, Y.; Liu, D.; Liu, S. Friction-induced transfer of carbon quantum dots on the interface: Microscopic and spectroscopic studies on the role of inorganic–organic hybrid nanoparticles as multifunctional additive for enhanced lubrication. Tribol. Int. 2018, 127, 557–567. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Gan, C.; Han, Z.; Yan, H.; Chen, D.; Li, W.; Li, H.; Fan, X.; Li, D.; Zhu, M. High dispersivity and excellent tribological performance of titanate coupling agent modified graphene oxide in hydraulic oil. Carbon 2020, 165, 238–250. [Google Scholar] [CrossRef]

- Deng, B.; Wang, X.; Luong, D.X.; Carter, R.A.; Wang, Z.; Tomson, M.B.; Tour, J.M. Rare earth elements from waste. Sci. Adv. 2022, 8, eabm3132. [Google Scholar] [CrossRef] [PubMed]

- Jin, F.; Yang, G.; Song, S.; Zhang, S.; Yu, L.; Zhang, P. Synthesis of nanostructured lanthanum fluoborate modified by oleylamine and evaluation of its tribological properties as a lubricating additive in synthetic ester. Surf. Interface Anal. 2016, 48, 1033–1039. [Google Scholar] [CrossRef]

- Wu, L.; Lei, X.; Zhang, Y.; Zhang, S.; Yang, G.; Zhang, P. The Tribological Mechanism of Cerium Oxide Nanoparticles as Lubricant Additive of Poly-Alpha Olefin. Tribol. Lett. 2020, 68, 101. [Google Scholar] [CrossRef]

- Kang, J.; Kang, A.M. Trend of the research on rare earth elements in environmental science. Environ. Sci. Pollut. Res. Int. 2020, 27, 14318–14321. [Google Scholar] [CrossRef]

- Liu, T.; Chen, J. Extraction and separation of heavy rare earth elements: A review. Sep. Purif. Technol. 2021, 276, 119263. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, L.; Li, M.; Xie, G. Synthesis of Core-Shell Micro/Nanoparticles and Their Tribological Application: A Review. Materials 2020, 13, 4590. [Google Scholar] [CrossRef]

- Zhang, H.; Chang, Q. Friction-induced rehybridization of hydrothermal amorphous carbon in magnesium silicate hydroxide-based nanocomposite. Carbon 2019, 155, 650–659. [Google Scholar] [CrossRef]

- Man, W.; Huang, Y.; Gou, H.; Li, Y.; Zhao, J.; Shi, Y. Synthesis of novel CuO@Graphene nanocomposites for lubrication application via a convenient and economical method. Wear 2022, 498, 204323. [Google Scholar] [CrossRef]

- Gan, C.; Liang, T.; Li, W.; Fan, X.; Zhu, M. Amine-terminated ionic liquid modified graphene oxide/copper nanocomposite toward efficient lubrication. Appl. Surf. Sci. 2019, 491, 105–115. [Google Scholar] [CrossRef]

- Wang, W.; Xie, G.; Luo, J. Black phosphorus as a new lubricant. Friction 2018, 6, 116–142. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, Y.; Zhang, S.; Luo, J. Controllable superlubricity of glycerol solution via environment humidity. Langmuir 2013, 29, 11924–11930. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Xie, G.; Si, L.; Wen, S.; Guo, D. Ultralow Friction Self-Lubricating Nanocomposites with Mesoporous Metal-Organic Frameworks as Smart Nanocontainers for Lubricants. ACS Appl. Mater. Interfaces 2017, 9, 38146–38152. [Google Scholar] [CrossRef] [PubMed]

- Lei, W.; Liu, G.; Zhang, J.; Liu, M. Black phosphorus nanostructures: Recent advances in hybridization, doping and functionalization. Chem. Soc. Rev. 2017, 46, 3492–3509. [Google Scholar] [CrossRef]

- Artel, V.; Guo, Q.; Cohen, H.; Gasper, R.; Ramasubramaniam, A.; Xia, F.; Naveh, D. Protective molecular passivation of black phosphorus. NPJ 2d Mater. Appl. 2017, 1, 6. [Google Scholar] [CrossRef]

- Tang, G.; Wu, Z.; Su, F.; Wang, H.; Xu, X.; Li, Q.; Ma, G.; Chu, P. Macroscale Superlubricity on Engineering Steel in the Presence of Black Phosphorus. Nano Lett. 2021, 21, 5308–5315. [Google Scholar] [CrossRef]

- Choi, S.; Kim, T.; Ji, H.; Lee, H.J.; Oh, M. Isotropic and Anisotropic Growth of Metal-Organic Framework (MOF) on MOF: Logical Inference on MOF Structure Based on Growth Behavior and Morphological Feature. J. Am. Chem. Soc. 2016, 138, 14434–14440. [Google Scholar] [CrossRef]

- Furukawa, H.; Cordova, K.E.; O’Keeffe, M.; Yaghi, O.M. The chemistry and applications of metal-organic frameworks. Science 2013, 341, 1230444. [Google Scholar] [CrossRef]

- Roy, S.; Suresh, V.M.; Maji, T.K. Self-cleaning MOF: Realization of extreme water repellence in coordination driven self-assembled nanostructures. Chem. Sci. 2016, 7, 2251–2256. [Google Scholar] [CrossRef]

- Zhu, N.; Wei, Z.; Chen, C.; Wang, D.; Cao, C.; Qiu, Q.; Jiang, J.; Wang, H.; Su, C. Self-Generation of Surface Roughness by Low-Surface-Energy Alkyl Chains for Highly Stable Superhydrophobic/Superoleophilic MOFs with Multiple Functionalities. Angew. Chem. Int. Ed. 2019, 58, 17033–17040. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Liu, J.; Li, Z.; Zhao, X.; Liu, G.; Liu, S.; Ma, S.; Li, W.; Liu, W. Surface-functionalized nanoMOFs in oil for friction and wear reduction and antioxidation. Chem. Eng. J. 2021, 410, 128306. [Google Scholar] [CrossRef]

- Peng, D.; Chen, C.; Kang, Y.; Chang, Y.; Chang, S. Size effects of SiO2 nanoparticles as oil additives on tribology of lubricant. Ind. Lubr. Tribol. 2010, 62, 111–120. [Google Scholar] [CrossRef]

- Peng, D.; Kang, Y.; Chen, C.; Chen, S.; Shu, F. The tribological behavior of modified diamond nanoparticles in liquid paraffin. Ind. Lubr. Tribol. 2009, 61, 213–219. [Google Scholar] [CrossRef]

- Li, X.; Zhang, D.; Xu, X.; Lee, K.R. Tailoring the Nanostructure of Graphene as an Oil-Based Additive: Toward Synergistic Lubrication with an Amorphous Carbon Film. ACS Appl. Mater. Interfaces 2020, 12, 43320–43330. [Google Scholar] [CrossRef]

- Xu, Z.; Hu, K.; Han, C.; Hu, X.; Xu, Y. Morphological Influence of Molybdenum Disulfide on the Tribological Properties of Rapeseed Oil. Tribol. Lett. 2013, 49, 513–524. [Google Scholar] [CrossRef]

- Huo, L.; Guo, J.; Hu, H.; Zhang, K.; Zhou, H.; Liu, P. Graphene Nanosheets as Lubricant Additives: Effects of Nature and Size on Lubricating Performance. Langmuir 2022, 38, 9678–9685. [Google Scholar] [CrossRef] [PubMed]

- Xu, N.; Zhang, M.; Li, W.; Zhao, G.; Wang, X.; Liu, W. Study on the selectivity of calcium carbonate nanoparticles under the boundary lubrication condition. Wear 2013, 307, 35–43. [Google Scholar] [CrossRef]

- Tang, X.; Li, J. Tribological Characteristics of Nano-Lubricated High-Speed Rolling Bearings Considering Interaction between Nanoparticles and Rough Surface. Lubricants 2022, 10, 117. [Google Scholar] [CrossRef]

- Lee, C.; Li, Q.; Kalb, W.; Liu, X.; Berger, H.; Carpick, R.W.; Hone, J. Frictional characteristics of atomically thin sheets. Science 2010, 328, 76–80. [Google Scholar] [CrossRef]

- Ci, X.; Zhao, W.; Luo, J. A sustainable interlayer slip leads to the excellent tribological behaviour of hexagonal boron nitride microsheets. Colloids Surf. 2020, 598, 124859. [Google Scholar] [CrossRef]

- Ye, X.; Songfeng, E.; Fan, M. The influences of functionalized carbon nanotubes as lubricating additives: Length and diameter. Diam. Relat. Mater. 2019, 100, 107548. [Google Scholar] [CrossRef]

- Yi, M.; Zhang, C. The synthesis of MoS2 particles with different morphologies for tribological applications. Tribol. Int. 2017, 116, 285–294. [Google Scholar] [CrossRef]

- Huitink, D.; Kundu, S.; Park, C.; Mallick, B.; Huang, J.; Liang, H. Nanoparticle shape evolution identified through multivariate statistics. J. Phys. Chem. A 2010, 114, 5596–5600. [Google Scholar] [CrossRef]

- Chen, G.; Jin, B.; Zhao, J.; Li, Y.; He, Y.; Luo, J. Efficient one-pot synthesis of mussel-inspired Cu-doped polydopamine nanoparticles with enhanced lubrication under heavy loads. Chem. Eng. J. 2021, 426, 131287. [Google Scholar] [CrossRef]

- Zhang, Q.; Song, H.; Wu, B.; Feng, W.; Li, X.; Jiao, Y.; Hu, X. Effect of magnetic field on the tribological behaviors of Fe3O4@MoS2 as polyalphaolefin additive in the steel/steel friction interface. Wear 2021, 466, 203586. [Google Scholar] [CrossRef]

- Guan, S.; Liu, X.; Eli, W. The synthesis of nanocarbon-poly(ricinoleic acid) composite as a lubricant additive with improved dispersity and anti-wear properties. RSC Adv. 2021, 11, 18171–18178. [Google Scholar] [CrossRef]

- Song, H.; Wang, Z.; Yang, J. Tribological properties of graphene oxide and carbon spheres as lubricating additives. Appl. Phys. A 2016, 122, 933. [Google Scholar] [CrossRef]

- Wu, C.; Wei, C.; Jin, X.; Akhtar, R.; Zhang, W. Carbon spheres as lubricant additives for improving tribological performance of polyetheretherketone. J. Mater. Sci. 2018, 54, 5127–5135. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, X.; Tian, Q.; Yang, J.; Wang, S.; Li, Y.; Shao, D.; Feng, L.; Song, H. Synthetic Kilogram Carbon Dots for Superior Friction Reduction and Antiwear Additives. Langmuir 2022, 38, 7791–7801. [Google Scholar] [CrossRef]

- Lv, X.; Cao, L.; Yang, T.; Wan, Y.; Gao, J. Lubricating behavior of Submicrometer carbon spheres as lubricant additives. Particul. Sci. Technol. 2019, 38, 568–572. [Google Scholar] [CrossRef]

- Gu, Y.; Fei, J.; Zheng, X.; Li, M.; Huang, J.; Qu, M.; Zhang, L. Graft PEI ultra-antiwear nanolayer onto carbon spheres as lubricant additives for tribological enhancement. Tribol. Int. 2021, 153, 106652. [Google Scholar] [CrossRef]

- Zhou, X.; Shi, H.; Zhang, S.; Fu, X.; Wang, X. Friction and Wear Properties of Cyanex 302-Modified MoS2Micro-Sized Spheres as Additive in Liquid Paraffin. Tribol. Trans. 2008, 51, 454–459. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, Y.; Hu, K.; Xu, Y.; Hu, X. Formation and tribological properties of hollow sphere-like nano-MoS2 precipitated in TiO2 particles. Tribol. Int. 2015, 81, 139–148. [Google Scholar] [CrossRef]

- Liu, C.; Meng, Y.; Tian, Y. Potential-Controlled Boundary Lubrication Using MoS2 Additives in Diethyl Succinate. Tribol. Lett. 2020, 68, 72. [Google Scholar] [CrossRef]

- Feng, P.; Ren, Y.; Li, Y.; He, J.; Zhao, Z.; Ma, X.; Fan, X.; Zhu, M. Synergistic lubrication of few-layer Ti3C2Tx/MoS2 heterojunction as a lubricant additive. Friction 2022, 1–15. [Google Scholar] [CrossRef]

- Tang, G.; Su, F.; Xu, X.; Chu, P.K. 2D black phosphorus dotted with silver nanoparticles: An excellent lubricant additive for tribological applications. Chem. Eng. J. 2020, 392, 123631. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Liu, Y.; Zhao, J.; Li, J.; Wang, Q.; Luo, J. Tribological behavior of layered double hydroxides with various chemical compositions and morphologies as grease additives. Friction 2020, 9, 952–962. [Google Scholar] [CrossRef]

- Ba, Z.; Han, Y.; Qiao, D.; Feng, D.; Huang, G. Composite Nanoparticles Based on Hydrotalcite as High Performance Lubricant Additives. Ind. Eng. Chem. Res. 2018, 57, 15225–15233. [Google Scholar] [CrossRef]

- Wu, H.; Yin, S.; Du, Y.; Wang, L.; Yang, Y.; Wang, H. Alkyl-Functionalized Boron Nitride Nanosheets as Lubricant Additives. ACS Appl. Nano Mater. 2020, 3, 9108–9116. [Google Scholar] [CrossRef]

- Meng, F.; Li, Z.; Ding, H.; Hu, J.; Wang, W.; Guo, J.; Liu, Q. Study on the preparation and tribological properties of BN@C-OA nano-additive lubricants. Wear 2021, 474, 203876. [Google Scholar] [CrossRef]

- Ma, Z.; Ding, H.; Liu, Z.; Cheng, Z. Preparation and tribological properties of hydrothermally exfoliated ultrathin hexagonal boron nitride nanosheets (BNNSs) in mixed NaOH/KOH solution. J. Alloy. Compd. 2019, 784, 807–815. [Google Scholar] [CrossRef]

- Chen, H.; Xiao, G.; Chen, Z.; Yi, M.; Zhang, J.; Li, Z.; Xu, C. Hexagonal boron nitride (h-BN) nanosheets as lubricant additive to 5CB liquid crystal for friction and wear reduction. Mater. Lett. 2022, 307, 131007. [Google Scholar] [CrossRef]

- Xiong, S.; Zhang, B.; Luo, S.; Wu, H.; Zhang, Z. Preparation, characterization, and tribological properties of silica-nanoparticle-reinforced B-N-co-doped reduced graphene oxide as a multifunctional additive for enhanced lubrication. Friction 2020, 9, 239–249. [Google Scholar] [CrossRef]

- Zang, C.; Yang, M.; Liu, E.; Qian, Q.; Zhao, J.; Zhen, J.; Zhang, R.; Jia, Z.; Han, W. Synthesis, characterization and tribological behaviors of hexagonal boron nitride/copper nanocomposites as lubricant additives. Tribol. Int. 2022, 165, 107312. [Google Scholar] [CrossRef]

- Wu, L.; Gu, L.; Jian, R. Lubrication mechanism of graphene nanoplates as oil additives for ceramics/steel sliding components. Ceram. Int. 2021, 47, 16935–16942. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, S.; Zhang, X.; Gao, J.; Yu, H.; Ye, Q.; Liu, S.; Liu, W. Fabrication of Two-Dimensional Functional Covalent Organic Frameworks via the Thiol-Ene “Click” Reaction as Lubricant Additives for Antiwear and Friction Reduction. ACS Appl. Mater. Interfaces 2021, 13, 36213–36220. [Google Scholar] [CrossRef] [PubMed]

- Wen, P.; Lei, Y.; Yan, Q.; Han, Y.; Fan, M. Multilayer Tribofilm: An Unique Structure to Strengthen Interface Tribological Behaviors. ACS Appl. Mater. Interfaces 2021, 13, 11524–11534. [Google Scholar] [CrossRef]

- Zhang, C.; Dong, R.; Wang, X.; Liang, Y.; Zhang, M.; Yu, Q.; Tang, Z.; Lv, H.; Wang, L.; Cai, M.; et al. Stable dispersibility of bentonite-type additive with gemini ionic liquid intercalation structure for oil-based drilling. Friction 2022, 1–15. [Google Scholar] [CrossRef]

- Guo, M.; Yang, G.; Zhang, S.; Zhang, Y.; Gao, C.; Zhang, C.; Zhang, P. Co-modification of Bentonite by CTAB and Silane and its Performance in Oil-Based Drilling Mud. Clays Clay Miner. 2021, 68, 646–655. [Google Scholar] [CrossRef]

- Chen, W.; Thummavichai, K.; Chen, X.; Liu, G.; Lv, X.; Zhang, L.; Chen, D.; Tiwari, S.K.; Wang, N.; Zhu, Y. Design and Evaluation the Anti-Wear Property of Inorganic Fullerene Tungsten Disulfide as Additive in PAO6 Oil. Crystals 2021, 11, 570. [Google Scholar] [CrossRef]

- Huang, G.; Yu, Q.; Ma, Z.; Cai, M.; Zhou, F.; Liu, W. Fluorinated Candle Soot as the Lubricant Additive of Perfluoropolyether. Tribol. Lett. 2017, 65, 28. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Y.; Wu, H. Tribological properties of onion like fullerenes and NiFe2O4 nanocomposites in reciprocating motion. Front. Energy 2017, 15, 208–212. [Google Scholar] [CrossRef]

- Yu, B.; Liu, Z.; Ma, C.; Sun, J.; Liu, W.; Zhou, F. Ionic liquid modified multi-walled carbon nanotubes as lubricant additive. Tribol. Int. 2015, 81, 38–42. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. Effective lubricant additive of nano-Ag/MWCNTs nanocomposite produced by supercritical CO2 synthesis. Tribol. Int. 2018, 118, 180–188. [Google Scholar] [CrossRef]

- Wang, Z.; Ren, R.; Song, H.; Jia, X. Improved tribological properties of the synthesized copper/carbon nanotube nanocomposites for rapeseed oil-based additives. Appl. Surf. Sci. 2018, 428, 630–639. [Google Scholar] [CrossRef]

- Qin, Y.; Wu, M.; Yang, Y.; Yang, Y.; Yang, G. Enhanced ability of halloysite nanotubes to form multilayer nanocrystalline tribofilms by thermal activation. Tribol. Int. 2022, 174, 107718. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, X.; Zhang, F.; Tang, G.; Li, C.; Xu, J. 3D/1D heterostructure of flower-like MoS2 nanospheres anchored on carbon nanotubes for enhanced friction and wear properties as oil additives. Mater. Res. Express 2020, 6, 1050f9. [Google Scholar] [CrossRef]

- Meng, Y.; Su, F.; Chen, Y. Nickel/Multi-walled Carbon Nanotube Nanocomposite Synthesized in Supercritical Fluid as Efficient Lubricant Additive for Mineral Oil. Tribol. Lett. 2018, 66, 134. [Google Scholar] [CrossRef]

- Jeng, Y.; Huang, Y.; Tsai, P.; Hwang, G. Tribological Properties of Carbon Nanocapsule Particles as Lubricant Additive. J. Tribol. 2014, 136, 0418011–0418019. [Google Scholar] [CrossRef]

- Liu, J.; Wickramaratne, N.P.; Qiao, S.; Jaroniec, M. Molecular-based design and emerging applications of nanoporous carbon spheres. Nat. Mater. 2015, 14, 763–774. [Google Scholar] [CrossRef] [PubMed]

- St. Dennis, J.E.; Jin, K.; John, V.T.; Pesika, N.S. Carbon microspheres as ball bearings in aqueous-based lubrication. ACS Appl. Mater. Interfaces 2011, 3, 2215–2218. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Wu, H.; Jiang, Z.; Huang, H. Water-based nanosuspensions: Formulation, tribological property, lubrication mechanism, and applications. J. Manuf. Process. 2021, 71, 625–644. [Google Scholar] [CrossRef]

- Deshmukh, A.A.; Mhlanga, S.D.; Coville, N.J. Carbon spheres. Mater. Sci. Eng. R Rep. 2010, 70, 1–28. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, N.; Tack, F.M.G.; Sato, S.; Alessi, D.S.; Oleszczuk, P.; Wang, H.; Wang, X.; Wang, S. Modification of ordered mesoporous carbon for removal of environmental contaminants from aqueous phase: A review. J. Hazard. Mater. 2021, 418, 126266. [Google Scholar] [CrossRef]

- Feng, Y.; Chen, Y.; Wang, Z.; Wei, J. Synthesis of mesoporous carbon materials from renewable plant polyphenols for environmental and energy applications. New Carbon Mater. 2022, 37, 196–222. [Google Scholar] [CrossRef]

- Li, W.; Zhang, Z.; Kong, B.; Feng, S.; Wang, J.; Wang, L.; Yang, J.; Zhang, F.; Wu, P.; Zhao, D. Simple and green synthesis of nitrogen-doped photoluminescent carbonaceous nanospheres for bioimaging. Angew. Chem. Int. Ed. 2013, 52, 8151–8155. [Google Scholar] [CrossRef]

- Matsagar, B.M.; Yang, R.; Dutta, S.; Ok, Y.S.; Wu, K.C.W. Recent progress in the development of biomass-derived nitrogen-doped porous carbon. J. Mater. Chem. A 2021, 9, 3703–3728. [Google Scholar] [CrossRef]

- Ye, Q.; Liu, S.; Xu, F.; Zhang, J.; Liu, S.; Liu, W. Nitrogen-Phosphorus Codoped Carbon Nanospheres as Lubricant Additives for Antiwear and Friction Reduction. ACS Appl. Nano Mater. 2020, 3, 5362–5371. [Google Scholar] [CrossRef]

- Li, W.; Zheng, S.; Cao, B.; Ma, S. Friction and wear properties of ZrO2/SiO2 composite nanoparticles. J. Nanopart. Res. 2010, 13, 2129–2137. [Google Scholar] [CrossRef]

- Zhou, X.; Qiu, S.; Liu, L.; Xing, W.; He, L.; Hou, Y.; Fang, M.; Gui, Z.; Song, L.; Hu, Y. Hierarchical hollow SiO2@TiO2 sphere structure for enhancing the lubrication and photo-catalytic degradation of liquid paraffin. Compos. B Eng. 2019, 167, 599–607. [Google Scholar] [CrossRef]

- Li, Z.; Xu, C.; Xiao, G.; Zhang, J.; Chen, Z.; Yi, M. Lubrication Performance of Graphene as Lubricant Additive in 4-n-pentyl-4′-cyanobiphyl Liquid Crystal (5CB) for Steel/Steel Contacts. Materials 2018, 11, 2110. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Yan, H.; Wang, X.; Bai, M. Graphene quantum dots prepared by gaseous detonation toward excellent friction-reducing and antiwear additives. Diam. Relat. Mater. 2018, 89, 293–300. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, M.; Li, X.; Jin, L.; Su, G.; Mo, Y.; Li, L.; Zhu, H.; Tian, Y. Research Progress in Application of 2D Materials in Liquid-Phase Lubrication System. Materials 2018, 11, 1314. [Google Scholar] [CrossRef]

- Arenal, R.; Lopez-Bezanilla, A. Boron nitride materials: An overview from 0D to 3D (nano)structures. Wiers. Comput. Mol. Sci. 2015, 5, 299–309. [Google Scholar] [CrossRef]

- Wang, L.; Han, W.; Ge, C.; Zhang, R.; Bai, Y.; Zhang, X. Covalent Functionalized Boron Nitride Nanosheets as Efficient Lubricant Oil Additives. Adv. Mater. Interfaces 2019, 6, 1901172. [Google Scholar] [CrossRef]

- Laipan, M.; Yu, J.; Zhu, R.; Zhu, J.; Smith, A.T.; He, H.; O’Hare, D.; Sun, L. Functionalized layered double hydroxides for innovative applications. Mater. Horiz. 2020, 7, 715–745. [Google Scholar] [CrossRef]

- Ma, W.; Ma, R.; Wang, C.; Liang, J.; Liu, X.; Zhou, K.; Sasaki, T. A superlattice of alternately stacked Ni-Fe hydroxide nanosheets and graphene for efficient splitting of water. ACS Nano 2015, 9, 1977–1984. [Google Scholar] [CrossRef]

- Li, X.; Du, D.; Zhang, Y.; Xing, W.; Xue, Q.; Yan, Z. Layered double hydroxides toward high-performance supercapacitors. J. Mater. Chem. A 2017, 5, 15460–15485. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Liu, W.; Liu, Y.; Wang, K.; Li, J.; Ma, T.; Eryilmaz, O.L.; Shi, Y.; Erdemir, A.; et al. Superlubricity of Polyalkylene Glycol Aqueous Solutions Enabled by Ultrathin Layered Double Hydroxide Nanosheets. ACS Appl. Mater. Interfaces 2019, 11, 20249–20256. [Google Scholar] [CrossRef]

- Li, S.; Qin, H.; Zuo, R.; Bai, Z. Tribological performance of Mg/Al/Ce layered double hydroxides nanoparticles and intercalated products as lubricant additives. Appl. Surf. Sci. 2015, 353, 643–650. [Google Scholar] [CrossRef]

- Li, S.; Bhushan, B. Lubrication performance and mechanisms of Mg/Al-, Zn/Al-, and Zn/Mg/Al-layered double hydroxide nanoparticles as lubricant additives. Appl. Surf. Sci. 2016, 378, 308–319. [Google Scholar] [CrossRef]

- Wang, K.; Liu, L.; Song, A.; Ma, T.; Wang, H.; Luo, J.; Liu, Y. Macroscale superlubricity under ultrahigh contact pressure in the presence of layered double hydroxide nanosheets. Nano Res. 2022, 15, 4700–4709. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Guo, F.; Sheng, H.; Xia, K.; Liu, W.; Wen, J.; Shi, Y.; Erdemir, A.; Luo, J. Catalytically Active Oil-Based Lubricant Additives Enabled by Calcining Ni-Al Layered Double Hydroxides. J. Phys. Chem. Lett. 2020, 11, 113–120. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C. Interfacial assembly of two-dimensional MXenes. J. Energy Chem. 2021, 60, 417–434. [Google Scholar] [CrossRef]

- Jiang, J.; Bai, S.; Zou, J.; Liu, S.; Hsu, J.P.; Li, N.; Zhu, G.; Zhuang, Z.; Kang, Q.; Zhang, Y. Improving stability of MXenes. Nano Res. 2022, 15, 6551–6567. [Google Scholar] [CrossRef]

- Serles, P.; Hamidinejad, M.; Demingos, P.G.; Ma, L.; Barri, N.; Taylor, H.; Singh, C.V.; Park, C.B.; Filleter, T. Friction of Ti3C2Tx MXenes. Nano Lett. 2022, 22, 3356–3363. [Google Scholar] [CrossRef]

- Yi, S.; Li, J.; Liu, Y.; Ge, X.; Zhang, J.; Luo, J. In-situ formation of tribofilm with Ti3C2Tx MXene nanoflakes triggers macroscale superlubricity. Tribol. Int. 2021, 154, 106695. [Google Scholar] [CrossRef]

- Yi, S.; Guo, Y.; Li, J.; Zhang, Y.; Zhou, A.; Luo, J. Two-dimensional molybdenum carbide (MXene) as an efficient nanoadditive for achieving superlubricity under ultrahigh pressure. Friction 2022, 1–14. [Google Scholar] [CrossRef]

- Tenne, R. Inorganic nanotubes and fullerene-like nanoparticles. Nat. Nanotechnol. 2006, 1, 103–111. [Google Scholar] [CrossRef]

- Joly-Pottuz, L.; Martin, J.M.; Dassenoy, F.; Belin, M.; Montagnac, G.; Reynard, B.; Fleischer, N. Pressure-induced exfoliation of inorganic fullerene-like WS2 particles in a Hertzian contact. J. Appl. Phys. 2006, 99, 023524. [Google Scholar] [CrossRef]

- Matsumoto, N.; Joly-Pottuz, L.; Kinoshita, H.; Ohmae, N. Application of onion-like carbon to micro and nanotribology. Diam. Relat. Mater. 2007, 16, 1227–1230. [Google Scholar] [CrossRef]

- Tevet, O.; Von-Huth, P.; Popovitz-Biro, R.; Rosentsveig, R.; Wagner, H.D.; Tenne, R. Friction mechanism of individual multilayered nanoparticles. Proc. Natl. Acad. Sci. USA 2011, 108, 19901–19906. [Google Scholar] [CrossRef]

- He, C.; Yan, H.; Li, X.; Wang, X. One-step rapid fabrication of high-purity onion-like carbons as efficient lubrication additives. J. Mater. Sci. 2020, 56, 1286–1297. [Google Scholar] [CrossRef]

- Luo, T.; Chen, X.; Wang, L.; Wang, P.; Li, C.; Zeng, H.; Cao, B. Green laser irradiation-stimulated fullerene-like MoS2 nanospheres for tribological applications. Tribol. Int. 2018, 122, 119–124. [Google Scholar] [CrossRef]

- Ouyang, T.; Lei, W.; Tang, W.; Cheng, L.; Shen, Y. Synergistic low friction effect and mechanism of inorganic fullerene-like tungsten disulfide and talcum at the interface of steel tribo-pairs under severe conditions. Appl. Surf. Sci. 2022, 585, 152570. [Google Scholar] [CrossRef]

- Younes, H.; Haiping, H.; Hongmin, J.; Hongtao, L. Tribological properties of carbon nanotube grease. Ind. Lubr. Tribol. 2014, 66, 579–583. [Google Scholar] [CrossRef]

- Kalin, M.; Kogovšek, J.; Remškar, M. Mechanisms and improvements in the friction and wear behavior using MoS2 nanotubes as potential oil additives. Wear 2012, 280, 36–45. [Google Scholar] [CrossRef]

- Stefanov, M.; Enyashin, A.N.; Heine, T.; Seifert, G. Nanolubrication: How Do MoS2-Based Nanostructures Lubricate? J. Phys. Chem. C 2008, 112, 17764–17767. [Google Scholar] [CrossRef]

- Wang, J.; Zhuang, W.; Liang, W.; Yan, T.; Li, T.; Zhang, L.; Li, S. Inorganic nanomaterial lubricant additives for base fluids, to improve tribological performance: Recent developments. Friction 2021, 10, 645–676. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, J.; Wu, T.; Xie, Y. Effect of carbon nanotubes on friction and wear of a piston ring and cylinder liner system under dry and lubricated conditions. Friction 2016, 5, 147–154. [Google Scholar] [CrossRef]

- Bai, Y.; Yu, Q.; Zhang, J.; Cai, M.; Liang, Y.; Zhou, F.; Liu, W. Soft-nanocomposite lubricants of supramolecular gel with carbon nanotubes. J. Mater. Chem. A 2019, 7, 7654–7663. [Google Scholar] [CrossRef]

- Gong, K.; Wu, X.; Zhao, G.; Wang, X. Tribological properties of polymeric aryl phosphates grafted onto multi-walled carbon nanotubes as high-performances lubricant additive. Tribol. Int. 2017, 116, 172–179. [Google Scholar] [CrossRef]

- Kato, H.; Komai, K. Tribofilm formation and mild wear by tribo-sintering of nanometer-sized oxide particles on rubbing steel surfaces. Wear 2007, 262, 36–41. [Google Scholar] [CrossRef]

- Tang, W.; Wang, B.; Li, J.; Li, Y.; Zhang, Y.; Quan, H.; Huang, Z. Facile pyrolysis synthesis of ionic liquid capped carbon dots and subsequent application as the water-based lubricant additives. J. Mater. Sci. 2018, 54, 1171–1183. [Google Scholar] [CrossRef]

- Duan, G.; Hu, X.; Song, X.; Qiu, Z.; Gong, H.; Cao, B. Morphology Evolution of ZnO Submicroparticles Induced by Laser Irradiation and Their Enhanced Tribology Properties by Compositing with Al2O3 Nanoparticles. Adv. Eng. Mater. 2015, 17, 341–348. [Google Scholar] [CrossRef]

- Fei, J.; Qi, Y.; Luo, L.; Gu, Y.; Huang, J. Synergistic effect of talc/carbon spheres composite as oil-based additive enhancing the lubricating properties for steel-steel contact. Lubr. Sci. 2020, 32, 80–89. [Google Scholar] [CrossRef]

- Li, K.; Zhang, X.; Du, C.; Yang, J.; Wu, B.; Guo, Z.; Dong, C.; Lin, N.; Yuan, C. Friction reduction and viscosity modification of cellulose nanocrystals as biolubricant additives in polyalphaolefin oil. Carbohydr. Polym. 2019, 220, 228–235. [Google Scholar] [CrossRef]

- Wang, B.; Tang, W.; Lu, H.; Huang, Z. Ionic liquid capped carbon dots as a high-performance friction-reducing and antiwear additive for poly(ethylene glycol). J. Mater. Chem. A 2016, 4, 7257–7265. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Zhang, Y.; Li, B.; Yang, M.; Zhang, X.; Guo, S.; Liu, G. Experimental evaluation of the lubrication properties of the wheel/workpiece interface in MQL grinding with different nanofluids. Tribol. Int. 2016, 99, 198–210. [Google Scholar] [CrossRef]

- Li, B.; Wang, X.; Liu, W.; Xue, Q. Tribochemistry and antiwear mechanism of organic–inorganic nanoparticles as lubricant additives. Tribol. Lett. 2006, 22, 79–84. [Google Scholar] [CrossRef]

- Vigdorowitsch, M.; Ostrikov, V.V.; Sazonov, S.N.; Safonov, V.V.; Orobinsky, V.I. How Carbon-Based Nanosheets Protect: Mechanistic Models. Tribol. Lett. 2021, 69, 102. [Google Scholar] [CrossRef]

- Meng, Y.; Xu, J.; Ma, L.; Jin, Z.; Prakash, B.; Ma, T.; Wang, W. A review of advances in tribology in 2020–2021. Friction 2022, 10, 1443–1595. [Google Scholar] [CrossRef]

- Wu, J.; Yin, X.; Mu, L.; Feng, X.; Lu, X.; Shi, Y. Hollow IF-MoS2/r-GO Nanocomposite Filled Polyimide Coating with Improved Mechanical, Thermal and Tribological Properties. Coatings 2020, 11, 25. [Google Scholar] [CrossRef]

- Zhao, B.; Yu, X.; Liu, Y.; Yang, L.; Zhang, Z.; Zhang, B. Frictional characteristics of heterostructure film composed of graphene and H-BN with the consideration of defects. Tribol. Int. 2021, 153, 106607. [Google Scholar] [CrossRef]

- Chen, H.; Ba, Z.; Qiao, D.; Feng, D.; Song, Z.; Zhang, J. Study on the tribological properties of graphene oxide composite films by self-assembly. Tribol. Int. 2020, 151, 106533. [Google Scholar] [CrossRef]

- Rejhon, M.; Lavini, F.; Khosravi, A.; Shestopalov, M.; Kunc, J.; Tosatti, E.; Riedo, E. Relation between interfacial shear and friction force in 2D materials. Nat. Nanotechnol. 2022, 1–8. [Google Scholar] [CrossRef]

- Tang, G.; Sun, J.; Chen, W.; Tang, H.; Wang, Y.; Li, C. Surfactant-assisted hydrothermal synthesis and tribological properties of flower-like MoS2 nanostructures. Micro Nano Lett. 2013, 8, 164–168. [Google Scholar] [CrossRef]

- Thrush, S.J.; Comfort, A.S.; Dusenbury, J.S.; Han, X.; Wang, X.; Qu, H.; Barber, G.C. Study of pressure dependence on sinterable zirconia nanoparticle tribofilm growth. Tribol. Int. 2021, 154, 106683. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Y.; Zhou, C.; Pan, Z. Mechanical properties and tribological behavior of alumina/zirconia composites modified with SiC and plasma treatment. Wear 2015, 332, 885–890. [Google Scholar] [CrossRef]

- Khare, H.S.; Lahouij, I.; Jackson, A.; Feng, G.; Chen, Z.; Cooper, G.D.; Carpick, R.W. Nanoscale Generation of Robust Solid Films from Liquid-Dispersed Nanoparticles via in Situ Atomic Force Microscopy: Growth Kinetics and Nanomechanical Properties. ACS Appl. Mater. Interfaces 2018, 10, 40335–40347. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Bandyopadhyay, A.; Bose, S. Processing of alumina and zirconia nano-powders and compacts. Mater. Sci. Eng. A 2004, 380, 349–355. [Google Scholar] [CrossRef]

- Rabaso, P.; Dassenoy, F.; Ville, F.; Diaby, M.; Vacher, B.; Le Mogne, T.; Belin, M.; Cavoret, J. An Investigation on the Reduced Ability of IF-MoS2 Nanoparticles to Reduce Friction and Wear in the Presence of Dispersants. Tribol. Lett. 2014, 55, 503–516. [Google Scholar] [CrossRef]

- Wu, H.; Qin, L.; Zeng, Q.; Dong, G. Understanding the Physical Adsorption Action Mechanism of MoS2 Nanoparticles in Boundary Lubrication with Different Polyisobutyleneamine Succinimide (PIBS) Concentrations. Tribol. Lett. 2015, 60, 26. [Google Scholar] [CrossRef]

- Tomala, A.; Ripoll, M.R.; Gabler, C.; Remškar, M.; Kalin, M. Interactions between MoS2 nanotubes and conventional additives in model oils. Tribol. Int. 2017, 110, 140–150. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, Y.; Wang, J.; Gao, C.; Zhang, S.; Zhang, P.; Zhang, Z. Interactions of Cu nanoparticles with conventional lubricant additives on tribological performance and some physicochemical properties of an ester base oil. Tribol. Int. 2020, 141, 105941. [Google Scholar] [CrossRef]

- Lei, X.; Zhang, Y.; Zhang, S.; Yang, G.; Zhang, C.; Zhang, P. Study on the mechanism of rapid formation of ultra-thick tribofilm by CeO2 nano additive and ZDDP. Friction 2022, 1–16. [Google Scholar] [CrossRef]

- Zhou, Y.; Qu, J. Ionic Liquids as Lubricant Additives: A Review. ACS Appl. Mater. Interfaces 2017, 9, 3209–3222. [Google Scholar] [CrossRef]

- Jia, J.; Yang, G.; Zhang, C.; Zhang, S.; Zhang, Y.; Zhang, P. Effects of magnetic ionic liquid as a lubricant on the friction and wear behavior of a steel-steel sliding contact under elevated temperatures. Friction 2019, 9, 61–74. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, M.; Mo, Y.; Bai, P.; Wei, Q.; Jin, L.; You, S.; Wang, M.; Li, L.; Chen, X.; et al. Synergistic lubricating effect of graphene/ionic liquid composite material used as an additive. Friction 2020, 9, 1568–1579. [Google Scholar] [CrossRef]

- Ta, T.N.; Chern, S.Y.; Horng, J.H. Tribological Behavior of Ionic Liquid with Nanoparticles. Materials 2021, 14, 6318. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Zhang, S.; Ding, Q.; Li, H.; Qin, B.; Hu, L. Understanding the synergistic lubrication effect of 2-mercaptobenzothiazolate based ionic liquids and Mo nanoparticles as hybrid additives. Tribol. Int. 2018, 125, 39–45. [Google Scholar] [CrossRef]

- Qu, M.; Yao, Y.; He, J.; Ma, X.; Liu, S.; Feng, J.; Hou, L. Tribological performance of functionalized ionic liquid and Cu microparticles as lubricating additives in sunflower seed oil. Tribol. Int. 2016, 104, 166–174. [Google Scholar] [CrossRef]

- Alves, S.M.; Barros, B.S.; Trajano, M.F.; Ribeiro, K.S.B.; Moura, E. Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribol. Int. 2013, 65, 28–36. [Google Scholar] [CrossRef]

- Guzman Borda, F.L.; Ribeiro de Oliveira, S.J.; Seabra Monteiro Lazaro, L.M.; Kalab Leiróz, A.J. Experimental investigation of the tribological behavior of lubricants with additive containing copper nanoparticles. Tribol. Int. 2018, 117, 52–58. [Google Scholar] [CrossRef]

| Component | Nanoparticles | Diameter (nm) | Content (wt%) | Decreasing Degree of COF (%) | Decreasing Degree of WSD (%) | Decreasing Degree of WR (%) | Ref. |

|---|---|---|---|---|---|---|---|

| Metal | Cu | 5 | 0.5 | 37 | / | 90 | [11,12,13,14,15] |

| Ag | 6–7 | 2.0 | 10 | / | 10 | [16,17] | |

| Bi | 40 | 0.1 | 69 | 37 | / | [18,19] | |

| W | 30–60 | 0.5 | 30 | 19 | / | [20] | |

| Al | 65 | 0.5 | 20 | 30 | / | [21] | |

| Ni | 80–120 | 0.1 | 29 | 39 | / | [22,23] | |

| Ga | 286 ± 21 | 0.17 | 39 | / | 93 | [24,25] | |

| Sn | 30–60 | 1.0 | 50 | 62 | / | [26] | |

| Oxide | Al2O3 | 78 | 0.1 | 18 | 42 | / | [27] |

| ZrO2 | 6–7 | 2.0 | 8 | / | 20 | [28,29] | |

| Fe3O4 | 45–50 | 1.5 | 58 | 13 | / | [30] | |

| CuO | 7–15 | 0.5 | −5 | 22 | / | [31,32,33] | |

| SiO2 | 35 | 0.1 | 15 | −3 | / | [19,34,35] | |

| TiO2 | 30 | 0.1 | 15 | 3 | / | [35,36] | |

| SnO2 | 20 | 0.1 | 4 | −9 | / | [35] | |

| ZnO | 4 | 1.2 | 10 | 31 | / | [37,38] | |

| Sulfide | CuS | / | 1.0 | 31 | / | 81 | [39,40,41] |

| WS2 | 20–60 | 1.0 | 27 | / | 85 | [42,43,44] | |

| MoS2 | 50–100 | 0.5 | 37 | 35 | / | [45,46] | |

| Carbon and its derivative | GP | 195–422 | 0.08 | 16 | / | 26 | [47,48,49,50,51,52] |

| CNTs | 10–20 | 0.02 | 24 | 6.6 | / | [53,54] | |

| CQDs | 2.66 | 1.0 | 62 | 89 | / | [55] | |

| Diamond | 110 | 0.2 | 17 | 25 | / | [34,56,57] | |

| Rare earth compound | CeO2 | 300–600 | 2.0 | 18 | 16 | / | [58] |

| La(ReO4)3 | / | 0.5 | 28 | 30 | / | [59] | |

| Mixed rare earth naphthenate | 20–30 | 3.0 | 12 | 55 | / | [60] | |

| Other | Fe3O4@MoS2 | 600–800 | 1.0 | 44 | / | 20 | [61] |

| SiO2@Cu | 694 | 1.0 | 32 | / | 67 | [62] | |

| SiO2@MoS2 | 683 | 1.0 | 32 | / | 58 | [62] | |

| Cu@MoS2 | 8–13 | 0.5 | 38 | 29 | / | [63] | |

| MoS2@CNT | 80 | 1.0 | 33 | / | 98 | [64] | |

| MoS2@GP | 80 | 1.0 | 20 | / | 98 | [64] | |

| MoS2@C60 | 100 | 1.0 | 25 | / | 96 | [64] | |

| Mn3O4/GP | 25 | 0.03 | 35 | / | 76 | [65,66] | |

| WS2/GP | 100 | 0.02−0.04 | 70 | / | 66 | [67] | |

| TiO2/BP | 300–500 | 0.01 | 26 | 13 | / | [68] |

| Morphology | Nanoparticles | Diameter (nm) | Content (wt%) | Decreasing Degree of COF (%) | Decreasing Degree of WSD (%) | Decreasing Degree of WR (%) | Ref. |

|---|---|---|---|---|---|---|---|

| Sphere | PDA@Cu | 200 | 0.4 | 45 | / | 97 | [125] |

| Fe3O4@MoS2 | 500 | 0.5 | 17 | / | 34 | [126] | |

| CNSs | 40–60 | 0.025 | 48 | 14 | / | [127,128,129,130,131] | |

| CNSs-PEI | 200–600 | 0.3 | 28 | / | 42 | [132] | |

| MoS2 | 20 | 0.5 | 37 | 35 | / | [133] | |

| MoS2/TiO2 | 67 | 1.0 | 20 | 33 | / | [134] | |

| Sheet | MoS2 | 400 | 0.06 | 28 | 23 | / | [135] |

| Ti3C2Tx/MoS2 | / | 0.3 | 39 | / | 85 | [136] | |

| Ag/BP | 200–400 | 0.075 | 73 | / | 92 | [137] | |

| LDH | 50–140 | 1.0 | 17 | 30 | / | [138] | |

| LDH/GO | / | 0.2 | 67 | / | 97 | [139] | |

| LDH/MoS2 | / | 0.2 | 67 | / | 98 | [139] | |

| BN | 200–500 | 0.06 | 35 | 35 | / | [140,141,142,143] | |

| SiO2–B–N–GO | 50–100 | 0.15 | 24 | 47 | / | [144] | |

| OAMBN/Cus | / | 0.2 | 27 | 25 | / | [145] | |

| GP | 600 | 0.075 | 27 | 43 | / | [146] | |

| COFs | / | 0.05 | 49 | / | 95 | [147,148] | |

| Onion | Bentonite | / | 1.0 | 48 | / | 50 | [149,150] |

| IF-WS2 | 100–200 | 0.25 | 27 | 43 | 87 | [151] | |

| Candle soot particles | 30–50 | 0.3 | 14 | / | 39 | [152] | |

| NiFe2O4/OLFs | 30 | / | 73 | / | / | [153] | |

| Tube | MWCNTs | / | 0.01 | 8 | / | 91 | [154] |

| Ag/MWCNTs | / | 0.18 | 36 | 32 | / | [155] | |

| Cu/PDA/CNTs | / | 0.2 | 34 | 24 | / | [156] | |

| Halloysite | / | 0.6 | 24 | / | 28 | [157] | |

| CNTs/MoS2 | / | 3.0 | 44 | 34 | / | [158] | |

| Ni/MWCNT | / | 0.2 | 44 | / | 56 | [159] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, K.; Zhang, Y.; Song, N.; Yu, L.; Zhang, P.; Zhang, Z.; Qian, L.; Zhang, S. The Current Situation and Future Direction of Nanoparticles Lubricant Additives in China. Lubricants 2022, 10, 312. https://doi.org/10.3390/lubricants10110312

Han K, Zhang Y, Song N, Yu L, Zhang P, Zhang Z, Qian L, Zhang S. The Current Situation and Future Direction of Nanoparticles Lubricant Additives in China. Lubricants. 2022; 10(11):312. https://doi.org/10.3390/lubricants10110312

Chicago/Turabian StyleHan, Kun, Yujuan Zhang, Ningning Song, Laigui Yu, Pingyu Zhang, Zhijun Zhang, Lei Qian, and Shengmao Zhang. 2022. "The Current Situation and Future Direction of Nanoparticles Lubricant Additives in China" Lubricants 10, no. 11: 312. https://doi.org/10.3390/lubricants10110312

APA StyleHan, K., Zhang, Y., Song, N., Yu, L., Zhang, P., Zhang, Z., Qian, L., & Zhang, S. (2022). The Current Situation and Future Direction of Nanoparticles Lubricant Additives in China. Lubricants, 10(11), 312. https://doi.org/10.3390/lubricants10110312