Elastic Contact Analysis of Shot-Peened Rough Surfaces

Abstract

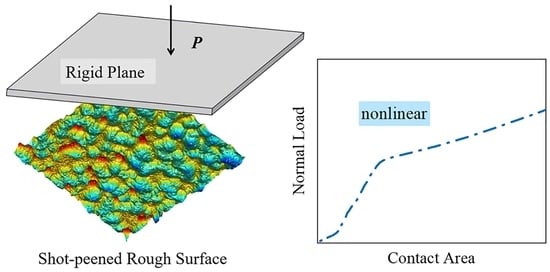

1. Introduction

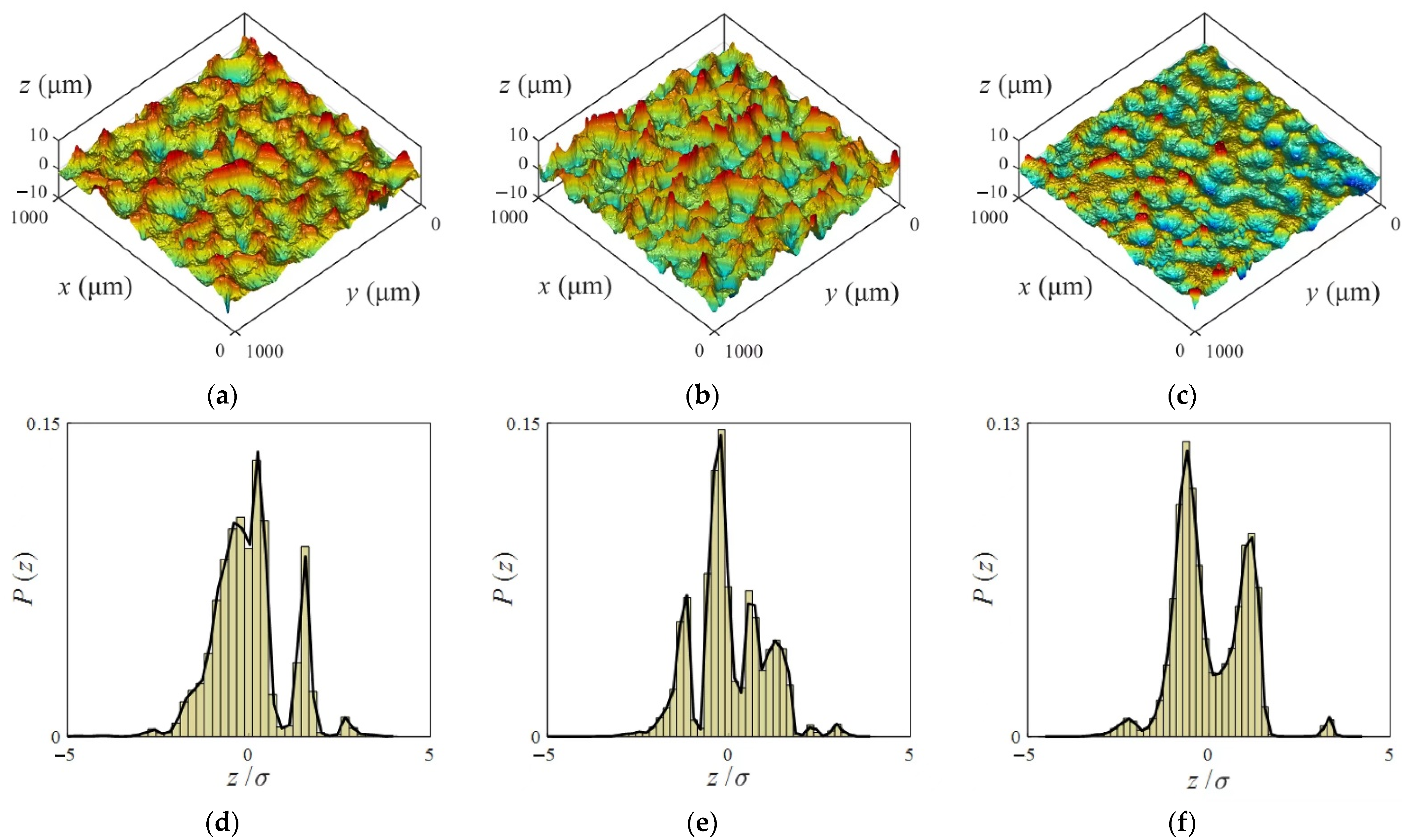

2. Sample Preparation and Experimental Measurement

3. Methods

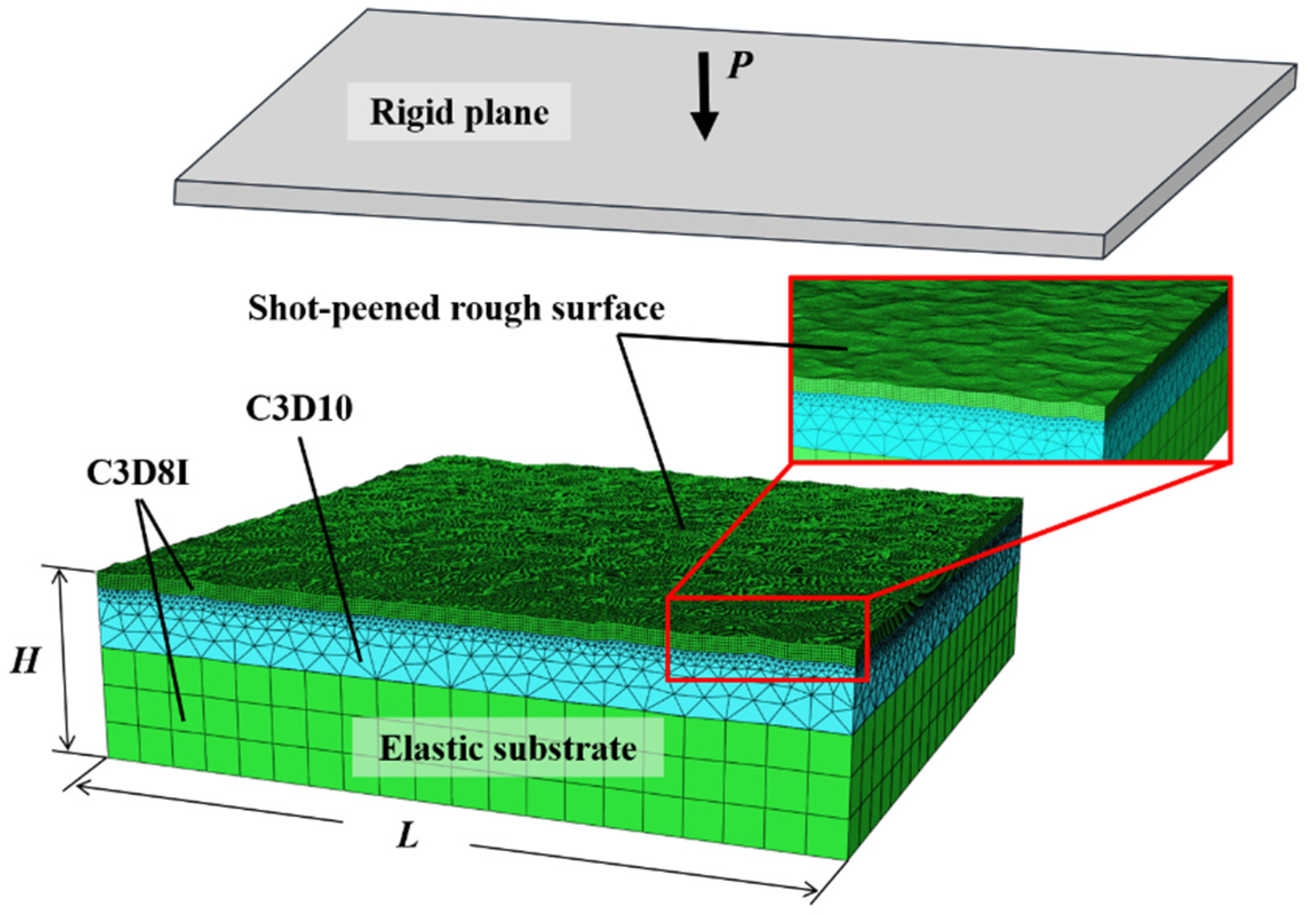

3.1. Finite Element Analysis

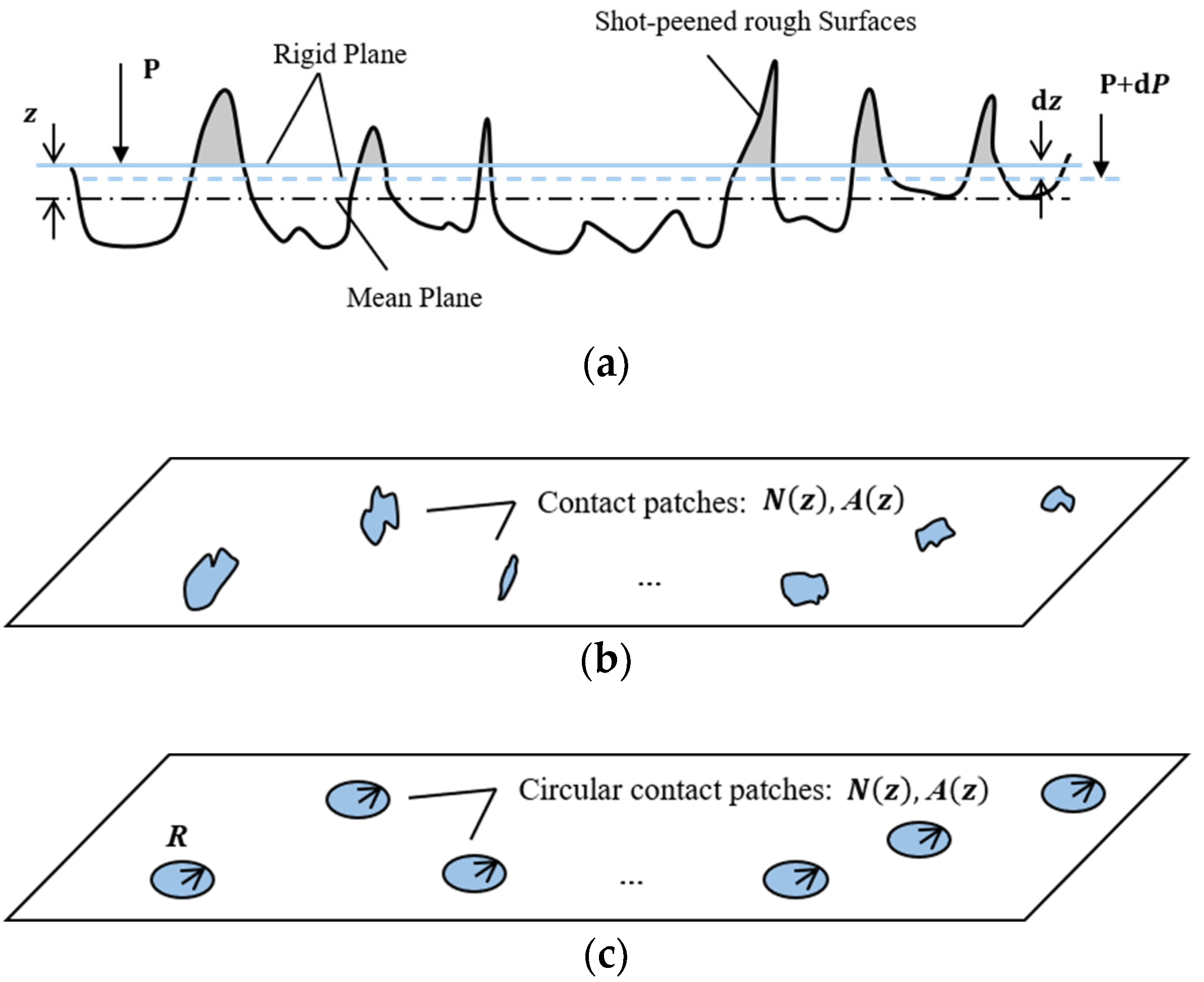

3.2. Incremental Contact Model

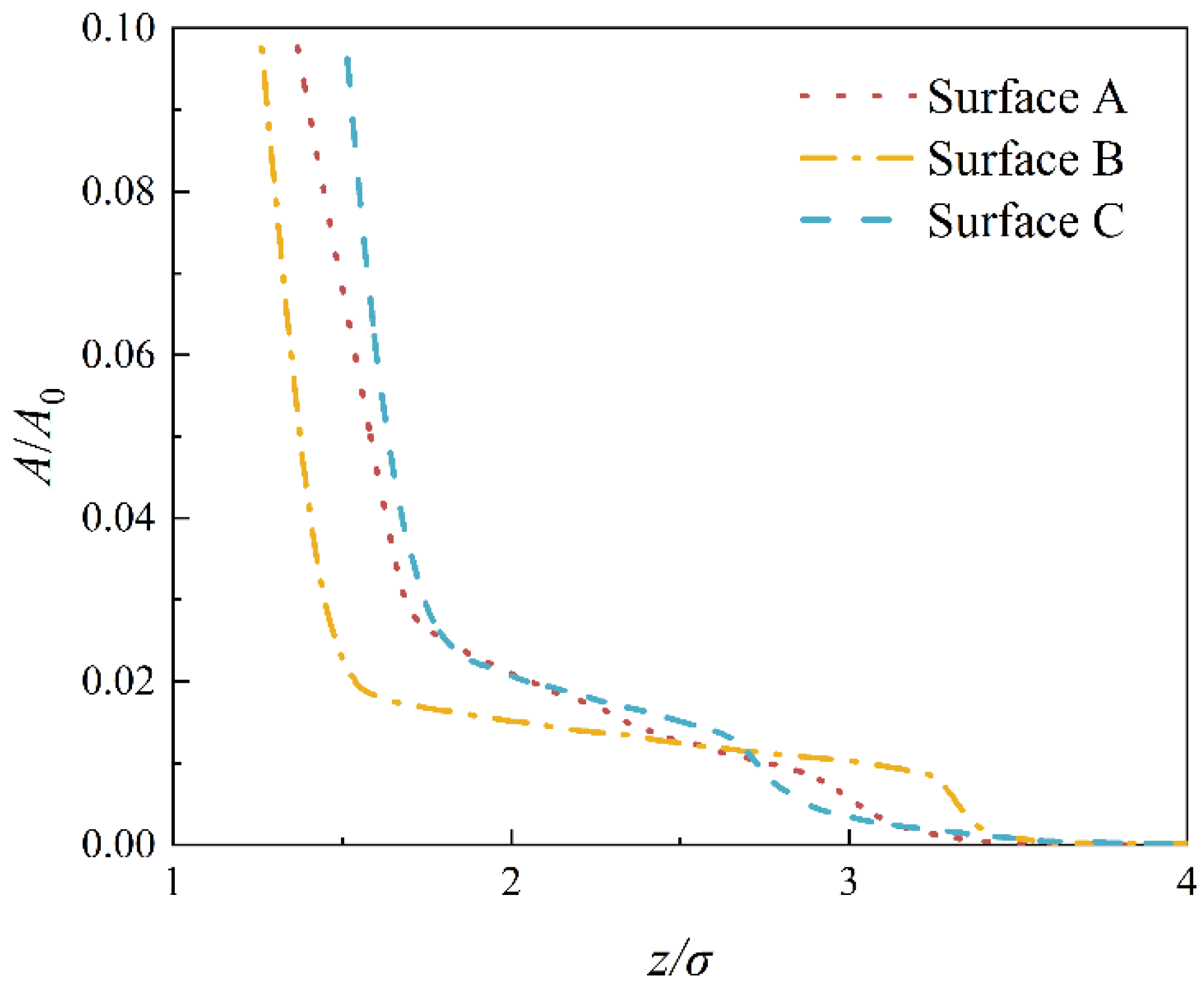

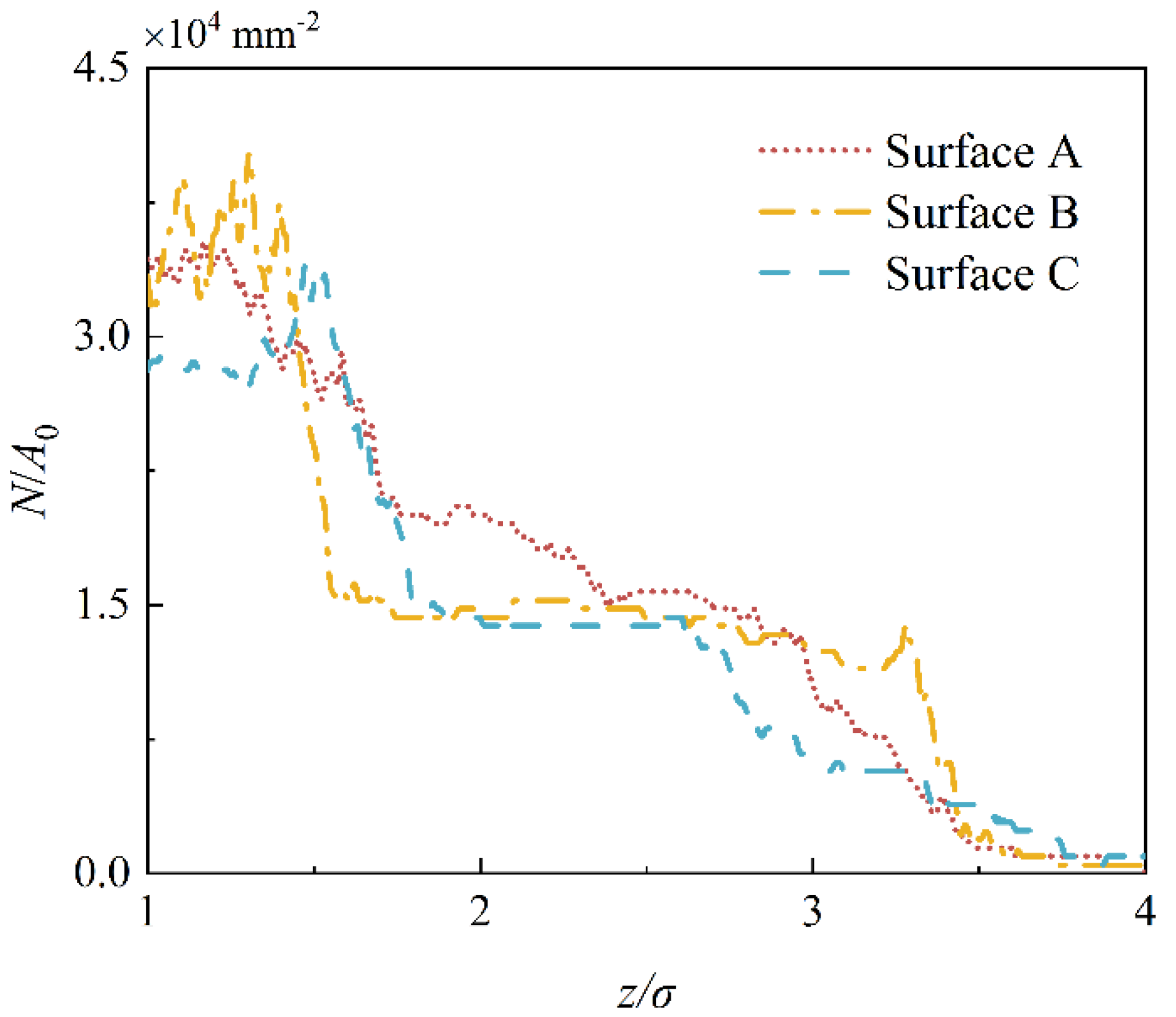

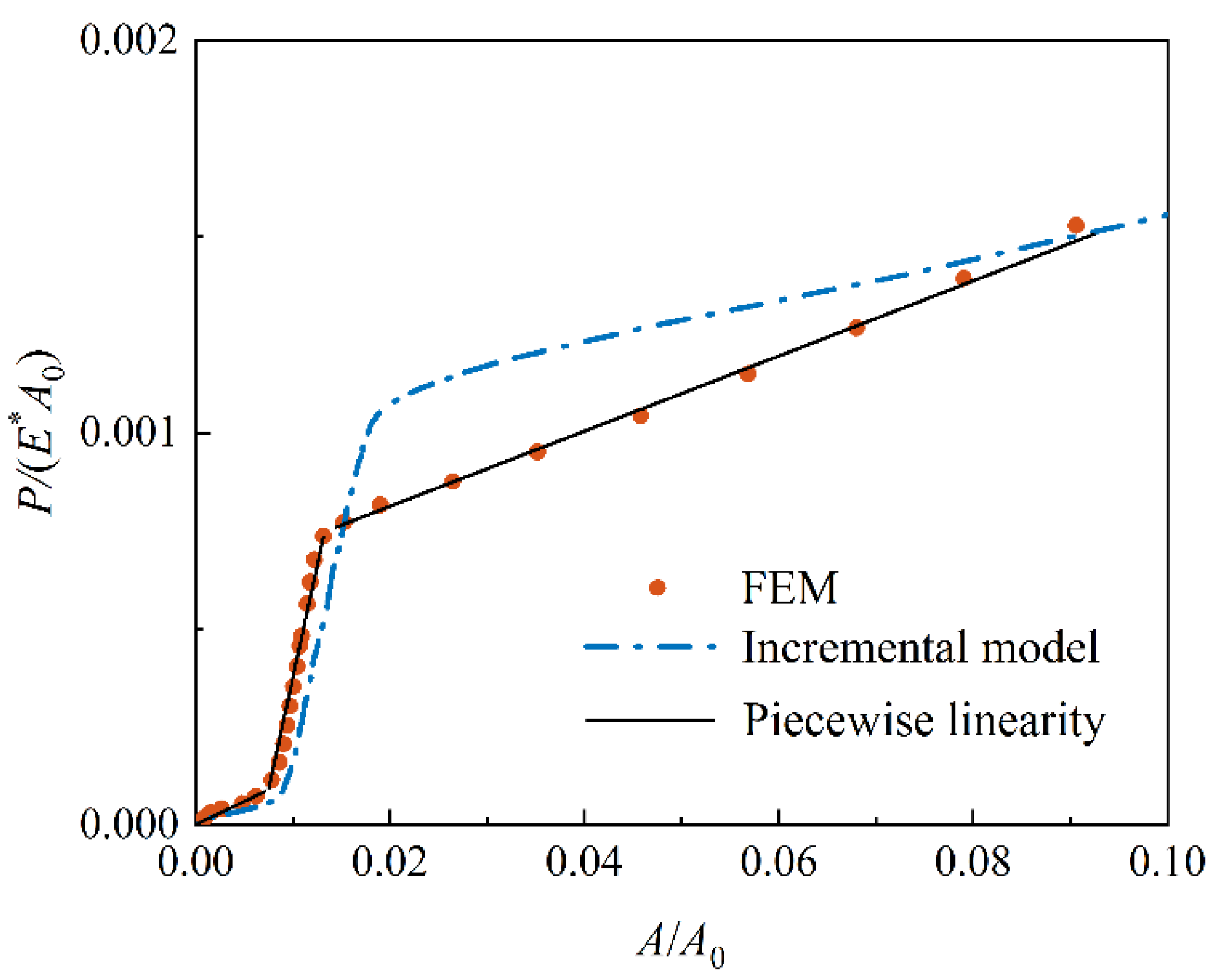

4. Results and Discussion

5. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Hu, Y.; Gong, C.; Yao, Z.; Hu, J. Investigation on the non-homogeneity of residual stress field induced by laser shock peening. Surf. Coat. Technol. 2009, 203, 3503–3508. [Google Scholar] [CrossRef]

- Bagherifard, S.; Slawik, S.; Fernández-Pariente, I.; Pauly, C.; Mücklich, F.; Guagliano, M. Nanoscale surface modification of AISI 316L stainless steel by severe shot peening. Mater. Des. 2016, 102, 68–77. [Google Scholar] [CrossRef]

- Wu, D.; Yao, C.; Zhang, D. Surface characterization and fatigue evaluation in GH4169 superalloy: Comparing results after finish turning; shot peening and surface polishing treatments. Int. J. Fatigue 2018, 113, 222–235. [Google Scholar] [CrossRef]

- Soyama, H. Comparison between the improvements made to the fatigue strength of stainless steel by cavitation peening, water jet peening, shot peening and laser peening. J. Mater. Process. Technol. 2019, 269, 65–78. [Google Scholar] [CrossRef]

- Taylor, R.I. Rough surface contact modelling-A Review. Lubricants 2022, 10, 98. [Google Scholar] [CrossRef]

- Vakis, A.I.; Yastrebov, V.A.; Scheibert, J.; Nicola, L.; Dini, D.; Minfray, C.; Almqvist, A.; Paggi, M.; Lee, S.; Limbert, G.; et al. Modeling and simulation in tribology across scales: An overview. Tribol. Int. 2018, 125, 169–199. [Google Scholar] [CrossRef]

- Archard, J.F. Elastic deformation and the laws of friction. Proc. R. Soc. Lond. 1957, 243, 190–205. [Google Scholar]

- Greenwood, J.A.; Williamson, J.B.P. Contact of nominally flat surfaces. Proc. R. Soc. A 1966, 295, 300–319. [Google Scholar]

- Nayak, P.R. Random process model of rough surfaces. J. Lubr. Technol. 1971, 93, 398–407. [Google Scholar] [CrossRef]

- Nayak, P.R. Random process model of rough surfaces in plastic contact. Wear 1973, 26, 305–333. [Google Scholar] [CrossRef]

- Bush, A.W.; Gibson, R.D.; Thomas, T.R. The elastic contact of a rough surface. Wear 1975, 35, 87–111. [Google Scholar] [CrossRef]

- Bush, A.W.; Gibson, R.D.; Keogh, G.P. Strongly anisotropic rough surfaces. J. Tribol. 1979, 101, 15–20. [Google Scholar] [CrossRef]

- Majumdar, A.; Bhushan, B. Fractal model of elastic-plastic contact between rough surfaces. J. Tribol. 1991, 113, 1–11. [Google Scholar] [CrossRef]

- Persson, B.N.J. Theory of rubber friction and contact mechanics. J. Chem. Phys. 2001, 115, 3840–3861. [Google Scholar] [CrossRef]

- Carbone, G.; Bottiglione, F. Asperity contact theories: Do they predict linearity between contact area and load? J. Mech. Phys. Solids 2008, 56, 2555–2572. [Google Scholar] [CrossRef]

- Bagherifard, S.; Ghelichi, R.; Guagliano, M. Numerical and experimental analysis of surface roughness generated by shot peened. Appl. Surf. Sci. 2012, 258, 6831–6840. [Google Scholar] [CrossRef]

- Hyun, S.; Pei, L.; Molinari, J.F.; Robbins, M.O. Finite-element analysis of contact between elastic self-affine surfaces. Phys. Rev. E 2004, 70, 026117. [Google Scholar] [CrossRef]

- Pei, L.; Hyun, S.; Molinari, J.F.; Robbins, M.O. Finite element modeling of elasto-plastic contact between rough surfaces. J. Mech. Phys. Solids 2005, 53, 2385–2409. [Google Scholar] [CrossRef]

- Song, H.; Van der Giessen, E.; Liu, X. Strain gradient plasticity analysis of elasto-plastic contact between rough surfaces. J. Mech. Phys. Solids 2016, 96, 18–28. [Google Scholar] [CrossRef]

- Wang, G.F.; Liang, X.M.; Yan, D. An incremental equivalent circular contact model for rough surfaces. J. Tribol. 2021, 143, 081503. [Google Scholar] [CrossRef]

- Wang, S.H.; Yuan, W.K.; Liang, X.M.; Wang, G.F. A new analytical model for the flattening of Gaussian rough surfaces. Eur. J. Mech.-A/Solids 2022, 94, 104578. [Google Scholar] [CrossRef]

- Tiwari, A.; Almqvist, A.; Persson, B.N.J. Plastic deformation of rough metallic surfaces. Tribol. Lett. 2020, 68, 129. [Google Scholar] [CrossRef]

- Pérez-Ràfols, F.; Almqvist, A. On the stiffness of surfaces with non-Gaussian height distribution. Sci. Rep. 2021, 11, 1863. [Google Scholar] [CrossRef] [PubMed]

| Shot Material | Shot Diameter (mm) | Pressure (MPa) | Rate of Flow (kg/min) |

|---|---|---|---|

| ASH 230 steel | 0.58–0.71 | 0.12 | 12 |

| Ceramic | 0.61–0.84 | 0.20 | 10 |

| Global Size | RMS Roughness, σ (μm) | Mechanical Parameter | ||||

|---|---|---|---|---|---|---|

| L (mm) | H (mm) | Surface A | Surface B | Surface C | E (GPa) | ν |

| 1.04 | 0.26 | 1.3803 | 1.9868 | 0.8808 | 91 | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, W.; Yuan, W.; Wang, G. Elastic Contact Analysis of Shot-Peened Rough Surfaces. Lubricants 2022, 10, 331. https://doi.org/10.3390/lubricants10120331

Dai W, Yuan W, Wang G. Elastic Contact Analysis of Shot-Peened Rough Surfaces. Lubricants. 2022; 10(12):331. https://doi.org/10.3390/lubricants10120331

Chicago/Turabian StyleDai, Wanlin, Weike Yuan, and Gangfeng Wang. 2022. "Elastic Contact Analysis of Shot-Peened Rough Surfaces" Lubricants 10, no. 12: 331. https://doi.org/10.3390/lubricants10120331

APA StyleDai, W., Yuan, W., & Wang, G. (2022). Elastic Contact Analysis of Shot-Peened Rough Surfaces. Lubricants, 10(12), 331. https://doi.org/10.3390/lubricants10120331