Reducing Wheel Loading in the Grinding of Titanium Alloys through Ultrasonic-Assisted Plasma Oxidation Modification

Abstract

:1. Introduction

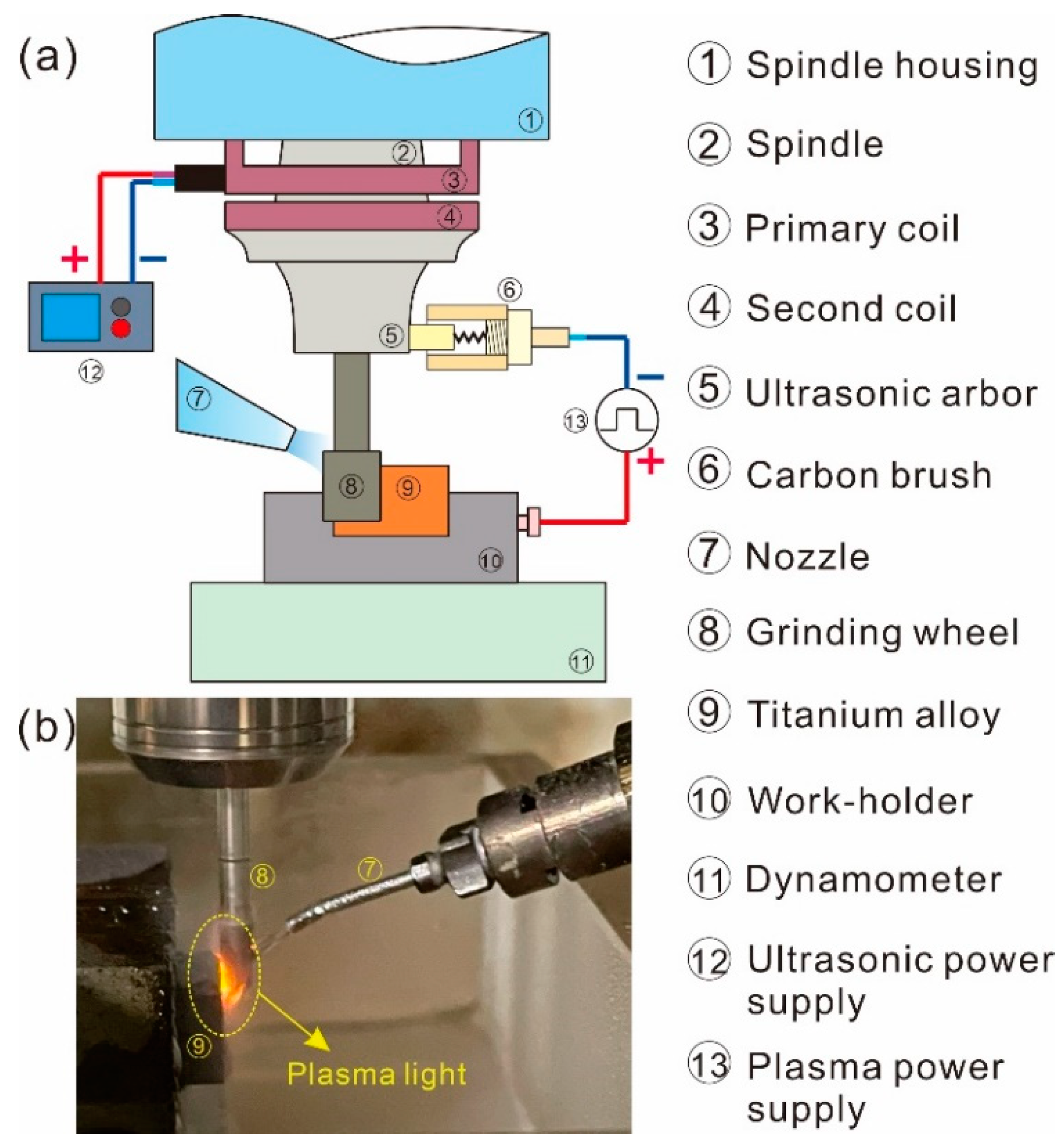

2. Processing Principle and Experimental Details

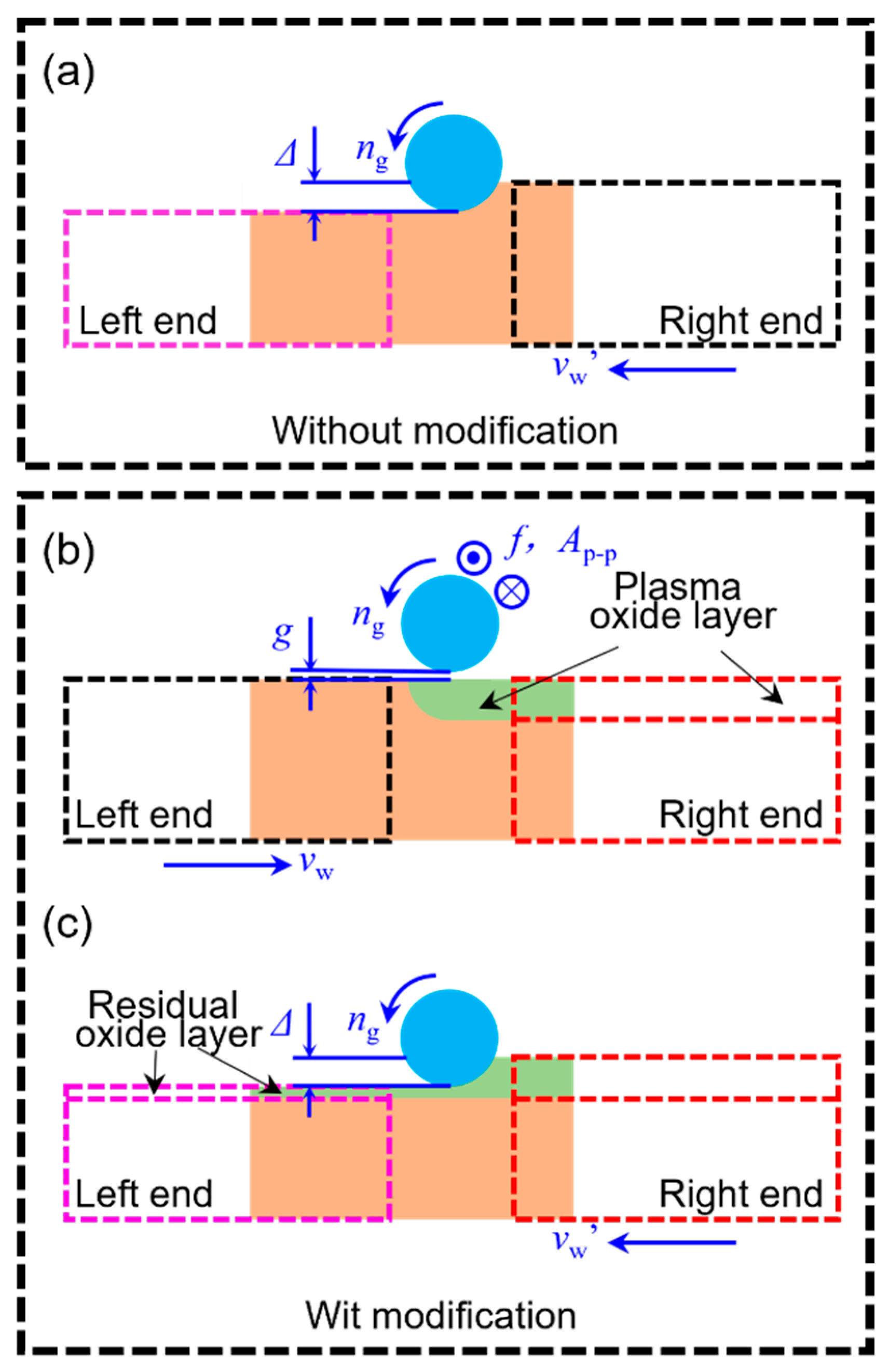

2.1. Processing Principle

2.2. Experimental Details

3. Results and Discussion

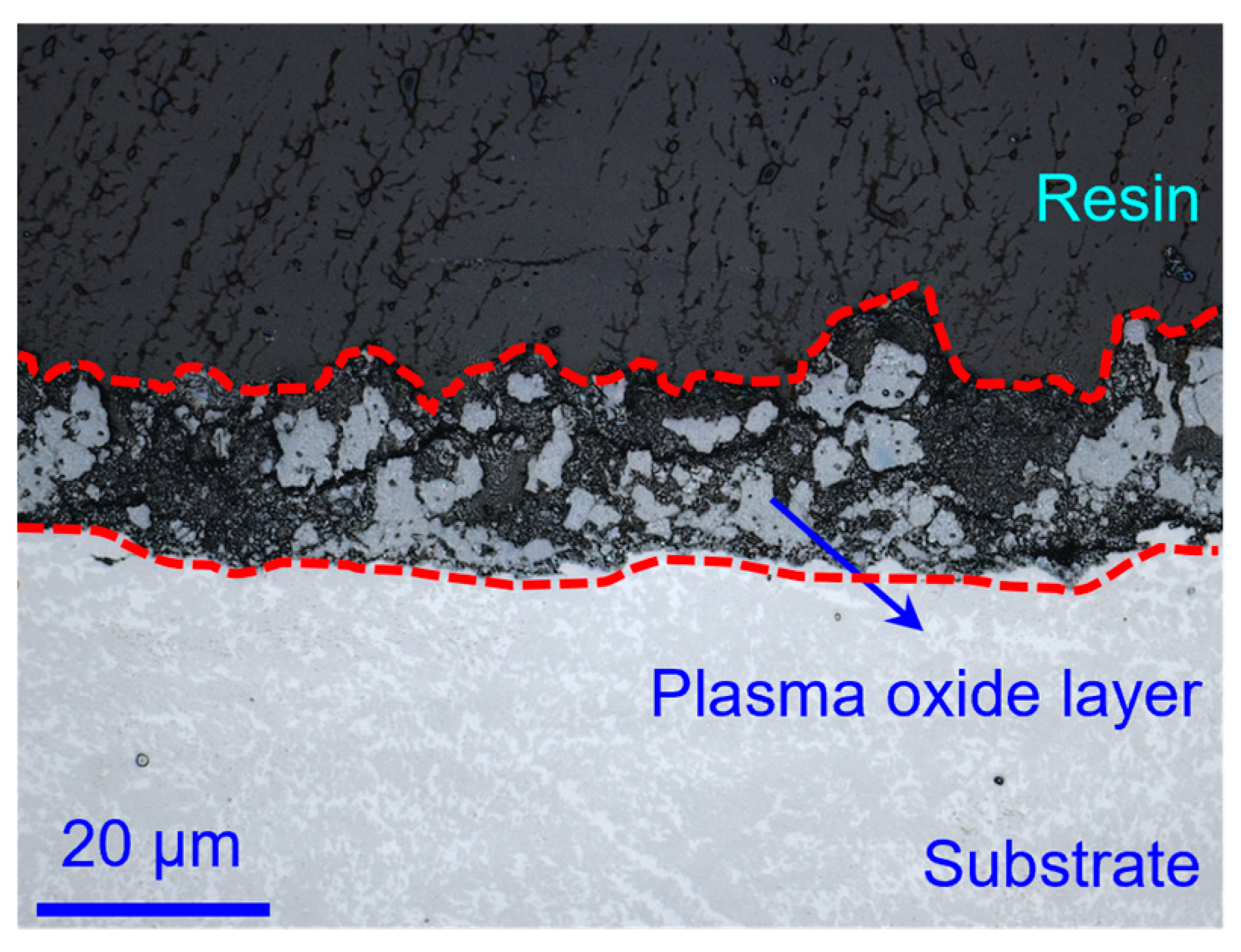

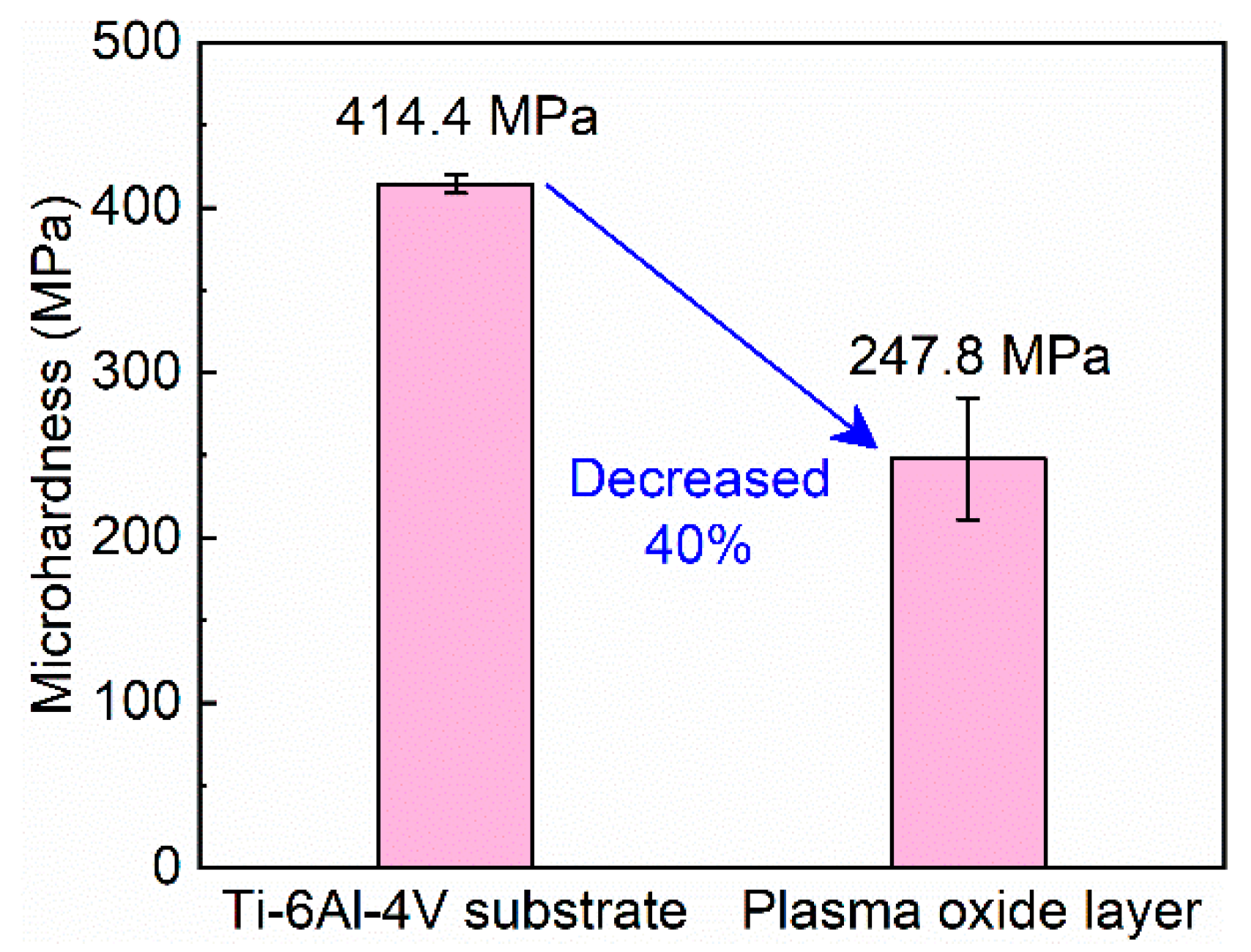

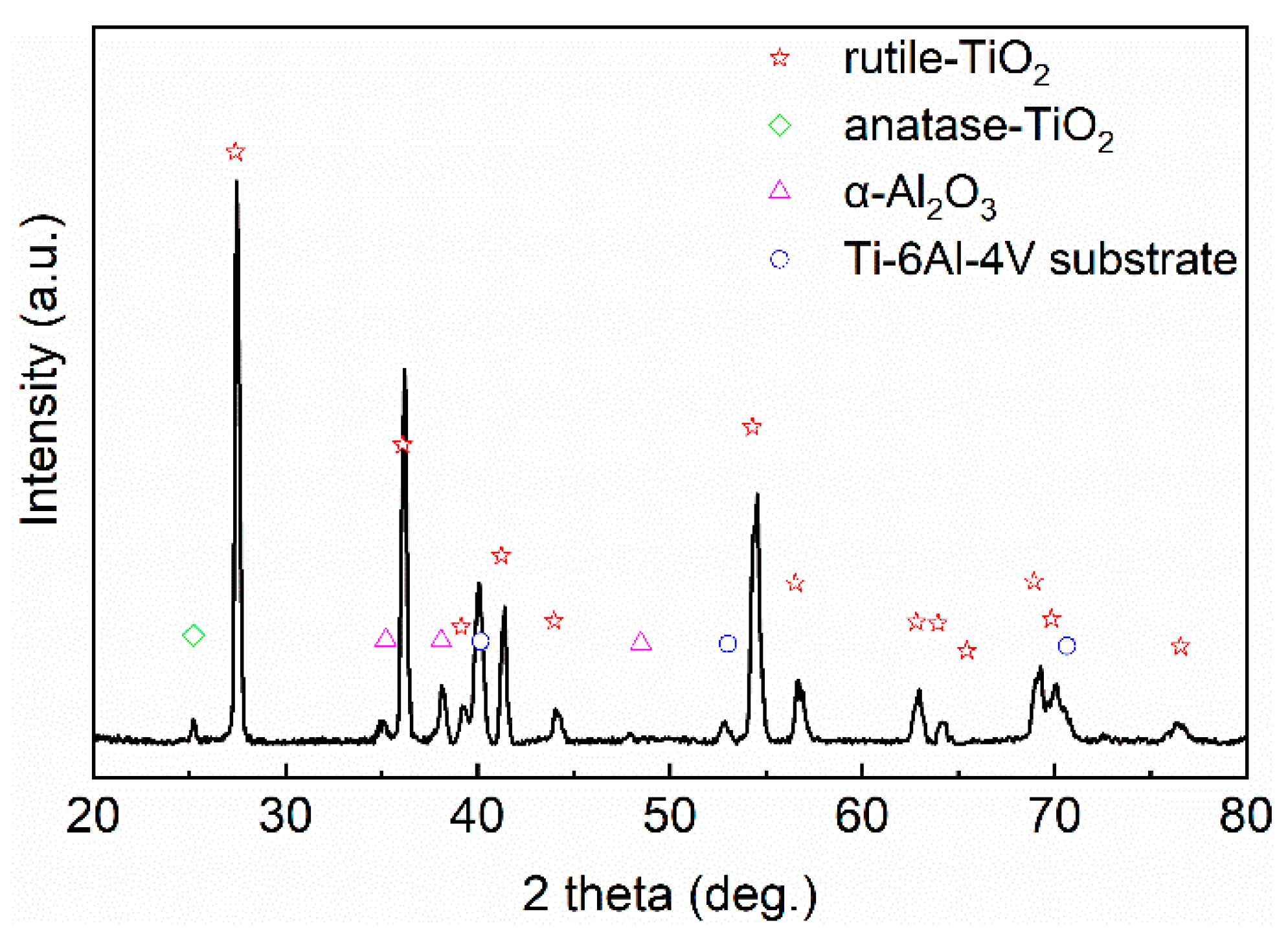

3.1. Properties of the Plasma Oxide Layer

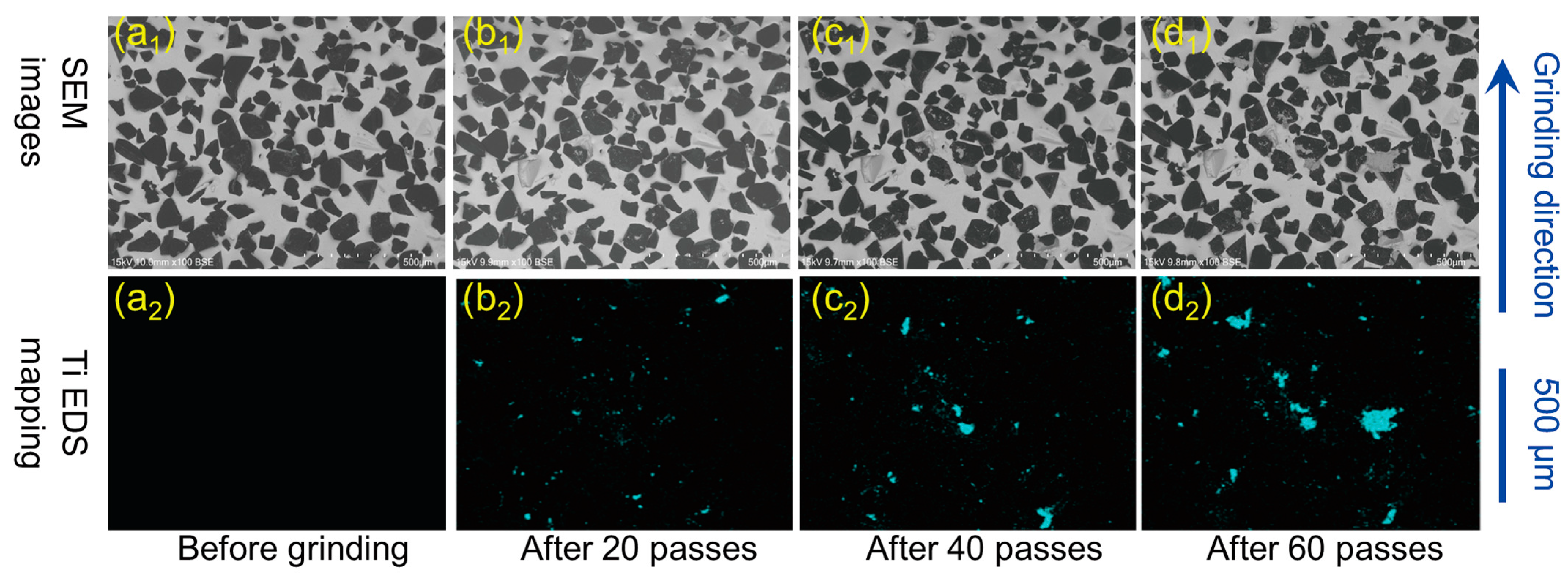

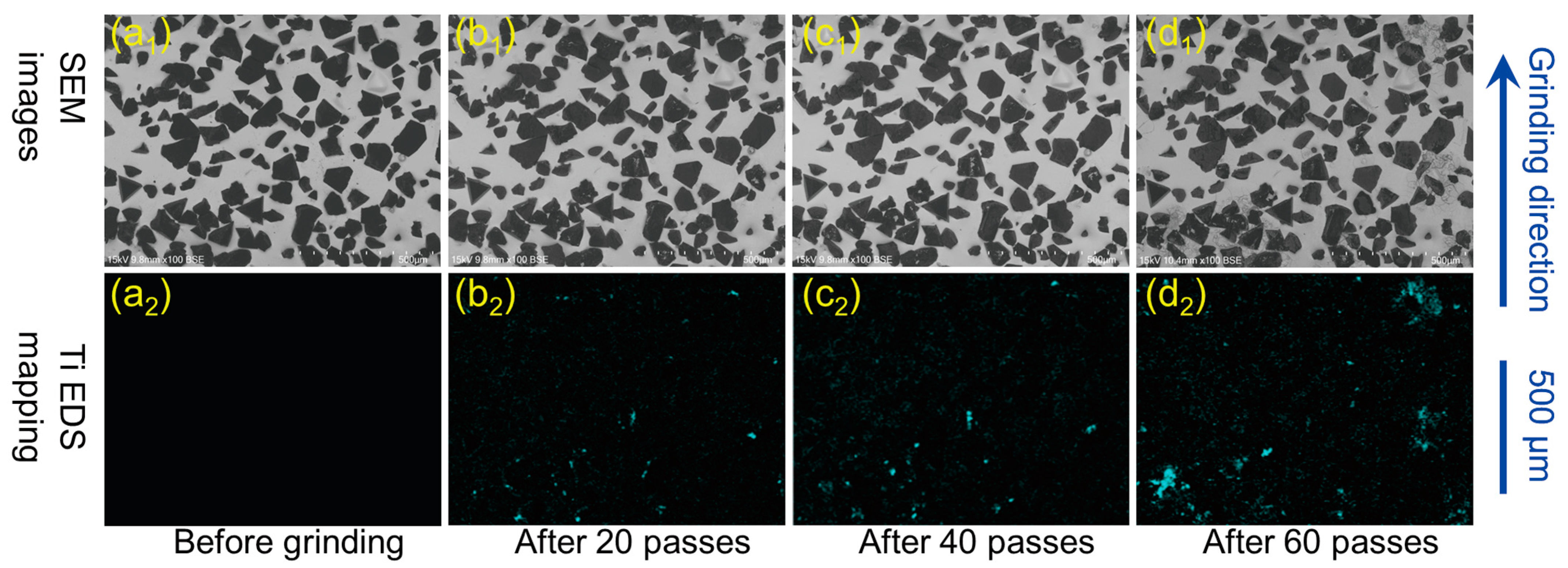

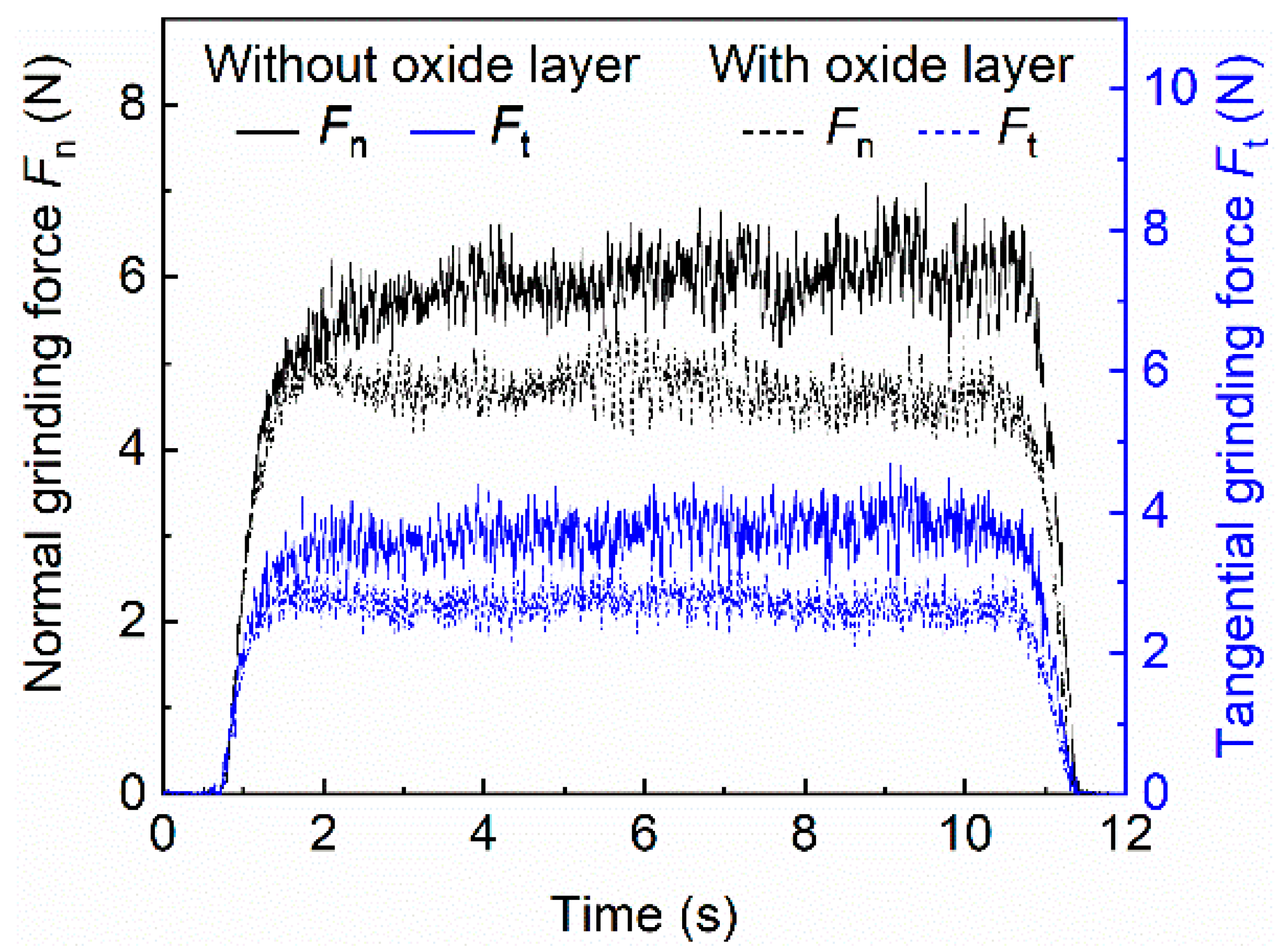

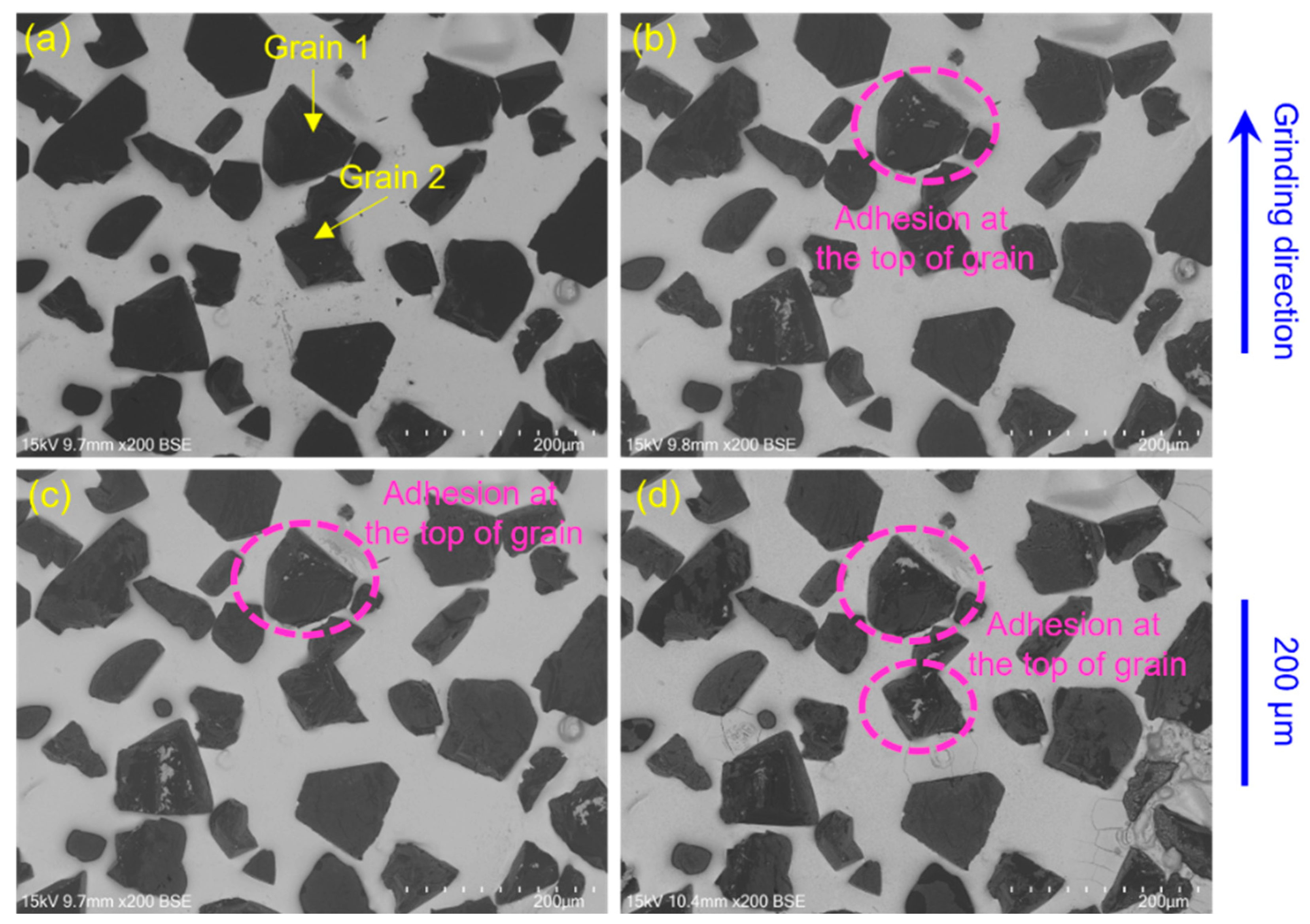

3.2. Evolution of Wheel Loading on the Grinding Wheel Surface

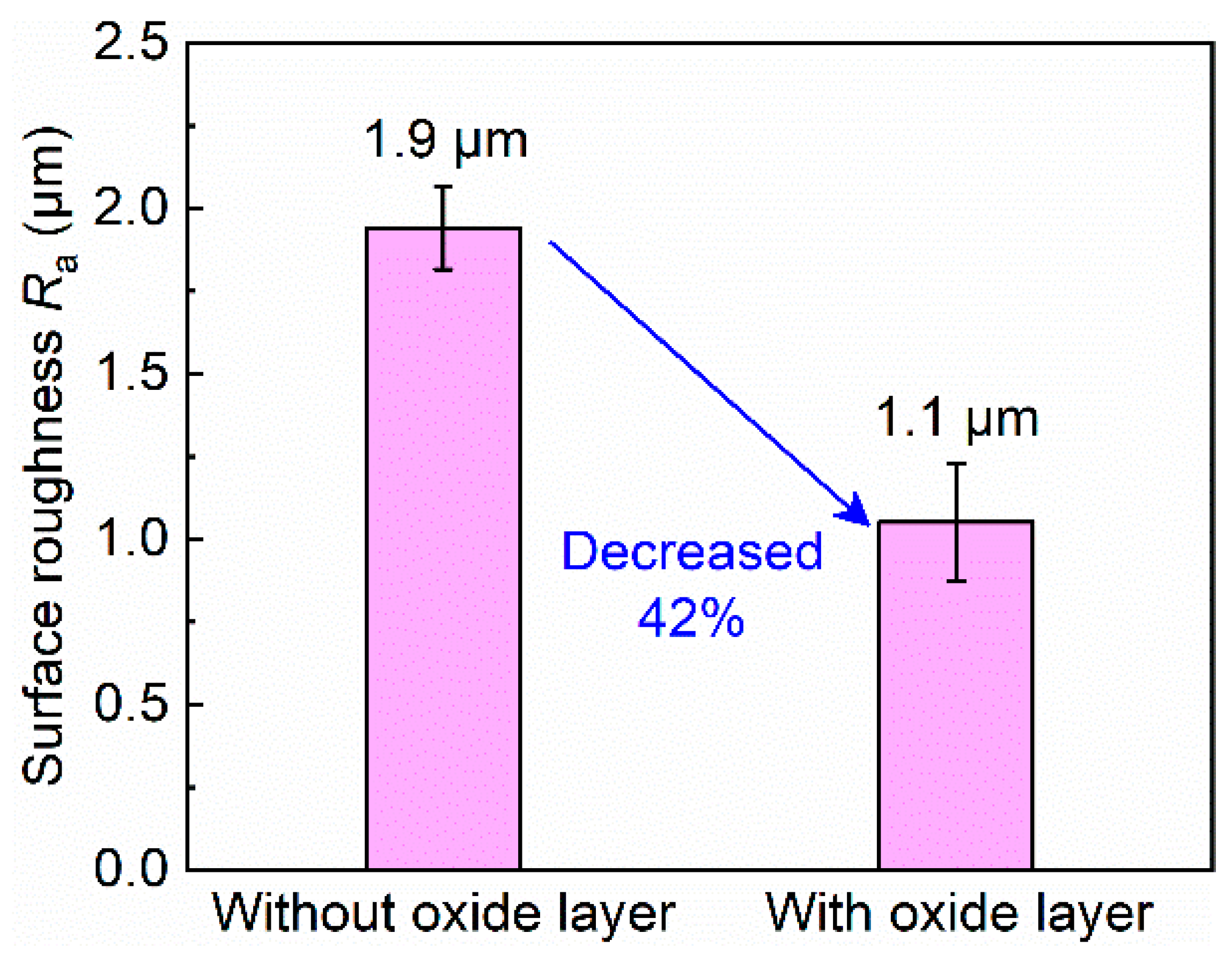

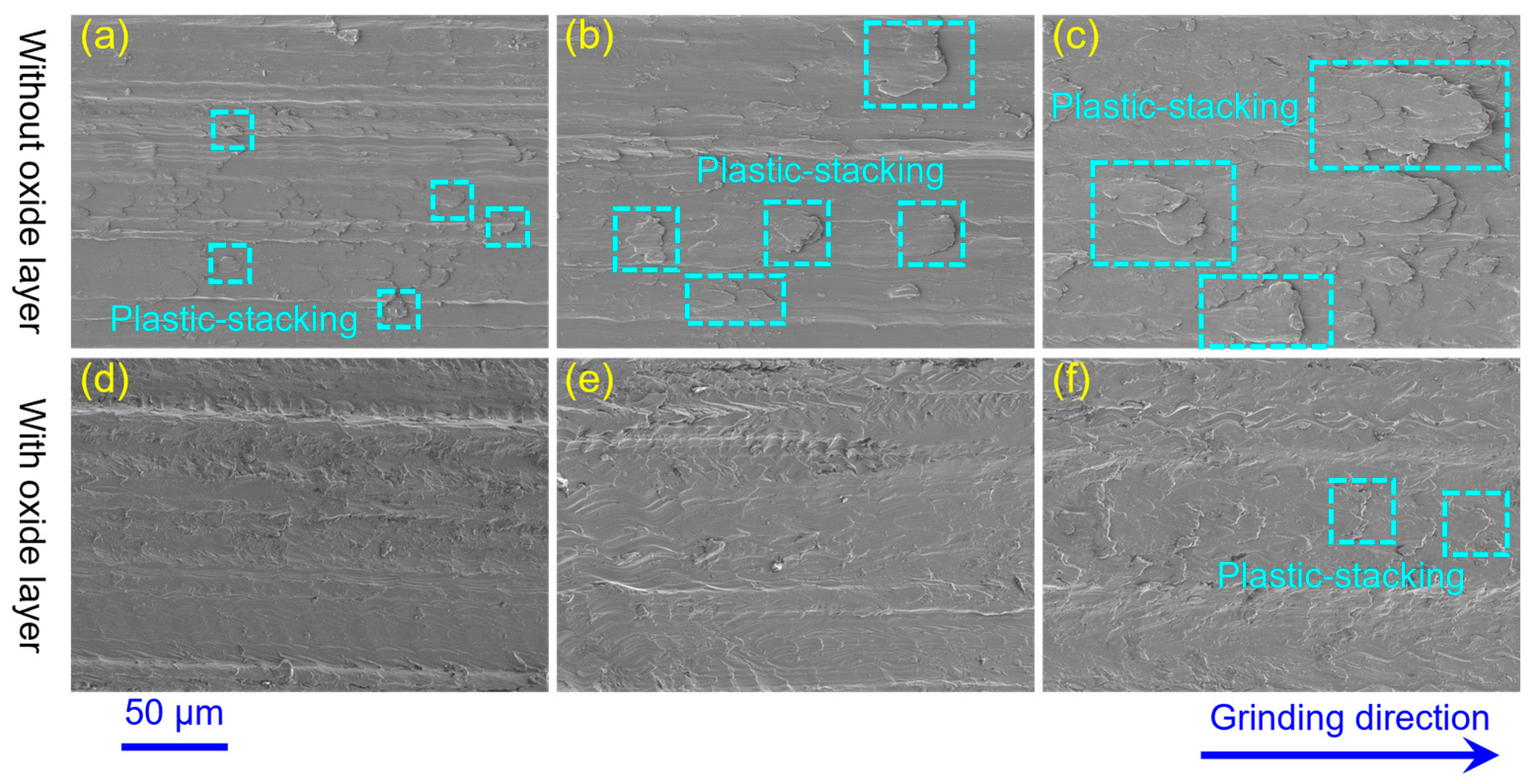

3.3. Ground Workpiece Surface Quality

4. Conclusions

- (1)

- The surface microhardness of the oxide layer decreased by 40.2% compared with that of the titanium alloy substrate. The loose and fragile oxide layer, mainly containing TiO2 and Al2O3 with low fracture toughness, could reduce wheel loading and improve the ground surface quality.

- (2)

- After 60 grinding passes, an oxide layer caused a 35.6% decline in the overall occupied area fraction of chip adhesion compared with the absence of an oxide layer. A decrease in wheel loading improved the ground surface roughness by 45.9% and decreased the grinding force by about 25%.

- (3)

- In the absence of an oxide layer, the abrasive grains covered with adhered chips lost their cutting ability, causing the production of plastic-stacking under the mutual extrusion between the adhered chips and the titanium alloy substrate. However, in the presence of an oxide layer, the abrasive grains with sharp cutting edges cut the oxide layer to constrain plastic-stacking production, resulting in an evenly ground surface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, M.; Li, C.; Yang, M.; Gao, T.; Wang, X.; Cui, X.; Zhang, Y.; Said, Z.; Sharma, S. Mechanism and enhanced grindability of cryogenic air combined with biolubricant grinding titanium alloy. Tribol. Int. 2023, 187, 108704. [Google Scholar] [CrossRef]

- Singh, P.K.; Kumar, S.; Jain, P.K. Effect of cryogenic grinding on surface characteristics of additively manufactured Ti-6Al-4V alloy. Surf. Topogr. Metrol. Prop. 2023, 11, 015014. [Google Scholar] [CrossRef]

- Cui, X.; Li, C.; Zhang, Y.; Said, Z.; Debnath, S.; Sharma, S.; Ali, H.M.; Yang, M.; Gao, T.; Li, R. Grindability of titanium alloy using cryogenic nanolubricant minimum quantity lubrication. J. Manuf. Process. 2022, 80, 273–286. [Google Scholar] [CrossRef]

- Zhou, K.; Xiao, G.; Xu, J.; Huang, Y. Wear evolution of electroplated diamond abrasive belt and corresponding surface integrity of Inconel 718 during grinding. Tribol. Int. 2023, 177, 107972. [Google Scholar] [CrossRef]

- Guo, G.; Liu, Z.; An, Q.; Chen, M. Experimental investigation on conventional grinding of Ti-6Al-4V using SiC abrasive. Int. J. Adv. Manuf. Technol. 2011, 57, 135–142. [Google Scholar] [CrossRef]

- Pashmforoush, F.; Delir Bagherinia, R. Influence of water-based copper nanofluid on wheel loading and surface roughness during grinding of Inconel 738 superalloy. J. Clean. Prod. 2018, 178, 363–372. [Google Scholar] [CrossRef]

- Gupta, M.K.; Song, Q.; Liu, Z.; Sarikaya, M.; Mia, M.; Jamil, M.; Singla, A.K.; Bansal, A.; Pimenov, D.Y.; Kuntoğlu, M. Tribological performance based machinability investigations in cryogenic cooling assisted turning of α-β titanium Alloy. Tribol. Int. 2021, 160, 107032. [Google Scholar] [CrossRef]

- Elanchezhian, J.; Pradeep Kumar, M.; Manimaran, G. Grinding titanium Ti-6Al-4V alloy with electroplated cubic boron nitride wheel under cryogenic cooling. J. Mech. Sci. Technol. 2015, 29, 4885–4890. [Google Scholar] [CrossRef]

- Aurich, J.C.; Kirsch, B.; Herzenstiel, P.; Kugel, P. Hydraulic design of a grinding wheel with an internal cooling lubricant supply. Prod. Eng. 2010, 5, 119–126. [Google Scholar] [CrossRef]

- Li, X. Application of self-inhaling internal cooling wheel in vertical surface grinding. Chin. J. Mech. Eng. 2014, 27, 86–91. [Google Scholar] [CrossRef]

- Zhou, K.; Xie, F.; Wu, X.; Wang, S. Fretting wear behavior of nano ZrO2 doped plasma electrolytic oxidation composite coatings on TC21 titanium alloy. Surf. Coat. Technol. 2021, 421, 127429. [Google Scholar] [CrossRef]

- Pesode, P.; Barve, S. Surface modification of titanium and titanium alloy by plasma electrolytic oxidation process for biomedical applications: A review. Mater. Today Proc. 2021, 46, 594–602. [Google Scholar] [CrossRef]

- Li, Y.; Wu, C.; Chen, M. Numerical analysis of the heat-pressure characteristics in ultrasonic vibration assisted plasma arc. J. Appl. Phys. 2020, 128, 114903. [Google Scholar] [CrossRef]

- González, H.; Calleja, A.; Pereira, O.; Ortega, N.; López de Lacalle, L.; Barton, M. Super Abrasive Machining of Integral Rotary Components Using Grinding Flank Tools. Metals 2018, 8, 24. [Google Scholar] [CrossRef]

- Suárez, A.; Veiga, F.; de Lacalle, L.N.L.; Polvorosa, R.; Lutze, S.; Wretland, A. Effects of Ultrasonics-Assisted Face Milling on Surface Integrity and Fatigue Life of Ni-Alloy 718. J. Mater. Eng. Perform. 2016, 25, 5076–5086. [Google Scholar] [CrossRef]

- Celaya, A.; Lopez de Lacalle, L.N.; Campa, F.J.; Lamikiz, A. Ultrasonic Assisted Turning of mild steels. Int. J. Mater. Product. Technol. 2009, 37, 60–70. [Google Scholar] [CrossRef]

- Cheng, Y.-L.; Wu, X.-Q.; Xue, Z.-G.; Matykina, E.; Skeldon, P.; Thompson, G.E. Microstructure, corrosion and wear performance of plasma electrolytic oxidation coatings formed on Ti–6Al–4V alloy in silicate-hexametaphosphate electrolyte. Surf. Coat. Technol. 2013, 217, 129–139. [Google Scholar] [CrossRef]

- Li, Q.; Yang, W.; Liu, C.; Wang, D.; Liang, J. Correlations between the growth mechanism and properties of micro-arc oxidation coatings on titanium alloy: Effects of electrolytes. Surf. Coat. Technol. 2017, 316, 162–170. [Google Scholar] [CrossRef]

- Yao, Z.; Jiang, Y.; Jia, F.; Jiang, Z.; Wang, F. Growth characteristics of plasma electrolytic oxidation ceramic coatings on Ti–6Al–4V alloy. Appl. Surf. Sci. 2008, 254, 4084–4091. [Google Scholar] [CrossRef]

- Wu, H.; Duan, W.; Sun, L.; Zeng, J.; Li, S.; Wang, Q.; Wu, Y.; Chen, Y. Effect of ultrasonic vibration on the machining performance and mechanism of hybrid ultrasonic vibration/plasma oxidation assisted grinding. J. Manuf. Process. 2023, 94, 466–478. [Google Scholar] [CrossRef]

- Xu, X.; Yu, Y.; Huang, H. Mechanisms of abrasive wear in the grinding of titanium (TC4) and nickel (K417) alloys. Wear 2003, 255, 1421–1426. [Google Scholar] [CrossRef]

- Gift, F.C., Jr.; Misiolek, W.Z.; Force, E., II. Mechanics of Loading for Electroplated Cubic Boron Nitride (CBN) Wheels During Grinding of a Nickel-Based Superalloy in Water-Based Lubricating Fluids. J. Tribol. 2004, 126, 795–801. [Google Scholar] [CrossRef]

- Davis, J.R. Metals Handbook: Desk Edition; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Malkin, S. Grinding Technology: Theory and Applications of Machining with Abrasives; Industrial Press: New York, NY, USA, 1989. [Google Scholar]

- Zhang, Y.; Li, C.; Ji, H.; Yang, X.; Yang, M.; Jia, D.; Zhang, X.; Li, R.; Wang, J. Analysis of grinding mechanics and improved predictive force model based on material-removal and plastic-stacking mechanisms. Int. J. Mach. Tools Manuf. 2017, 122, 81–97. [Google Scholar] [CrossRef]

| Parameters | Processes | ||

|---|---|---|---|

| Ultrasonic-Assisted Plasma Oxidation | Grinding | ||

| Pulsed DC Power supply | Frequency f1 (kHz) | 40 | |

| Voltage U (V) | 230 | ||

| Duty ratio D (%) | 35 | ||

| Ultrasonic | Frequency f2 (Hz) | 25 | |

| Amplitude Ap-p (μm) | 4.8 | ||

| Electrolyte | Type | Na2SO4 | |

| Concentration C (mol/L) | 1.0 | ||

| Processes parameters | Width (mm) | 5 | 5 |

| Length (mm) | 10 | 10 | |

| Gap g (μm) | 100 | ||

| Depth of cut Δ (μm) | 10 | ||

| Rotation speed ng (rpm) | 5500 | 5500 | |

| Feed rate vw (mm/min) | 5 | 60 | |

| Grinding wheel | Type | cBN electroplated wheel 240# | |

| Diameter d (mm) | 3 | ||

| Workpiece | Ti-6Al-4V (L10 mm × W10 mm × H8 mm) | ||

| O (wt.%) | Ti (wt.%) | Al (wt.%) | V (wt.%) | Na (wt.%) | S (wt.%) | |

|---|---|---|---|---|---|---|

| Ti-6Al-4V substrate | 1.78 | 87.65 | 5.88 | 4.68 | ||

| Plasma oxidation layer | 26.12 | 66.23 | 3.97 | 2.95 | 0.29 | 0.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Ye, X.; Chen, Z.; Zhang, S.; Zeng, J.; Wang, Q.; Wu, Y. Reducing Wheel Loading in the Grinding of Titanium Alloys through Ultrasonic-Assisted Plasma Oxidation Modification. Lubricants 2023, 11, 397. https://doi.org/10.3390/lubricants11090397

Wu H, Ye X, Chen Z, Zhang S, Zeng J, Wang Q, Wu Y. Reducing Wheel Loading in the Grinding of Titanium Alloys through Ultrasonic-Assisted Plasma Oxidation Modification. Lubricants. 2023; 11(9):397. https://doi.org/10.3390/lubricants11090397

Chicago/Turabian StyleWu, Hanqiang, Ximin Ye, Zhuo Chen, Shibo Zhang, Jiang Zeng, Qiang Wang, and Yongbo Wu. 2023. "Reducing Wheel Loading in the Grinding of Titanium Alloys through Ultrasonic-Assisted Plasma Oxidation Modification" Lubricants 11, no. 9: 397. https://doi.org/10.3390/lubricants11090397

APA StyleWu, H., Ye, X., Chen, Z., Zhang, S., Zeng, J., Wang, Q., & Wu, Y. (2023). Reducing Wheel Loading in the Grinding of Titanium Alloys through Ultrasonic-Assisted Plasma Oxidation Modification. Lubricants, 11(9), 397. https://doi.org/10.3390/lubricants11090397