Polyaniline Nanoparticles: A Novel Additive for Augmenting Thermal Conductivity and Tribo-Properties of Mineral Oil and Commercial Engine Oil

Abstract

1. Introduction

2. Materials and Methods

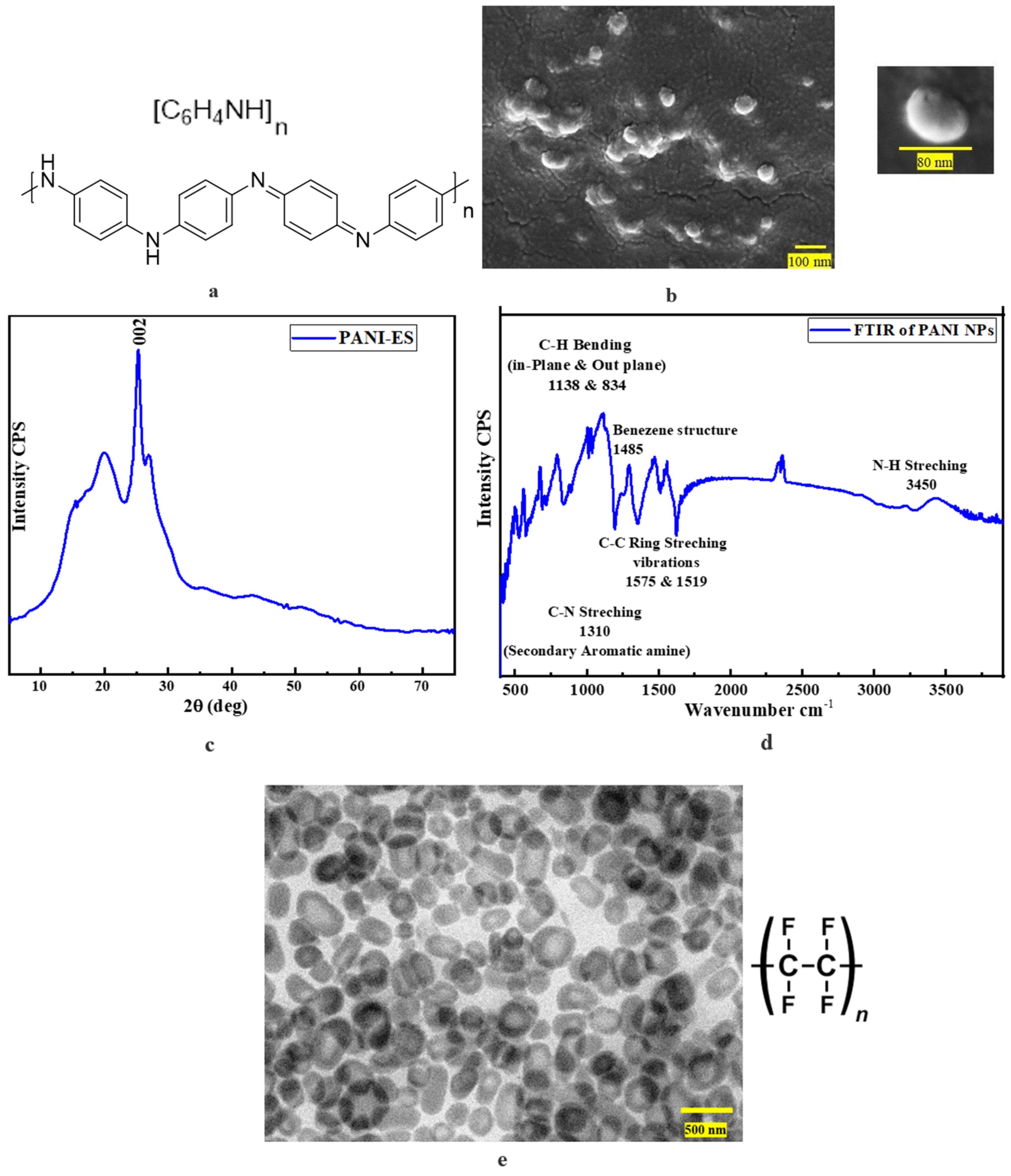

2.1. PANI Nanoparticles (NPs)

2.2. PTFE NPs

2.3. Base Oils Selected for Preparing Nano-Oils

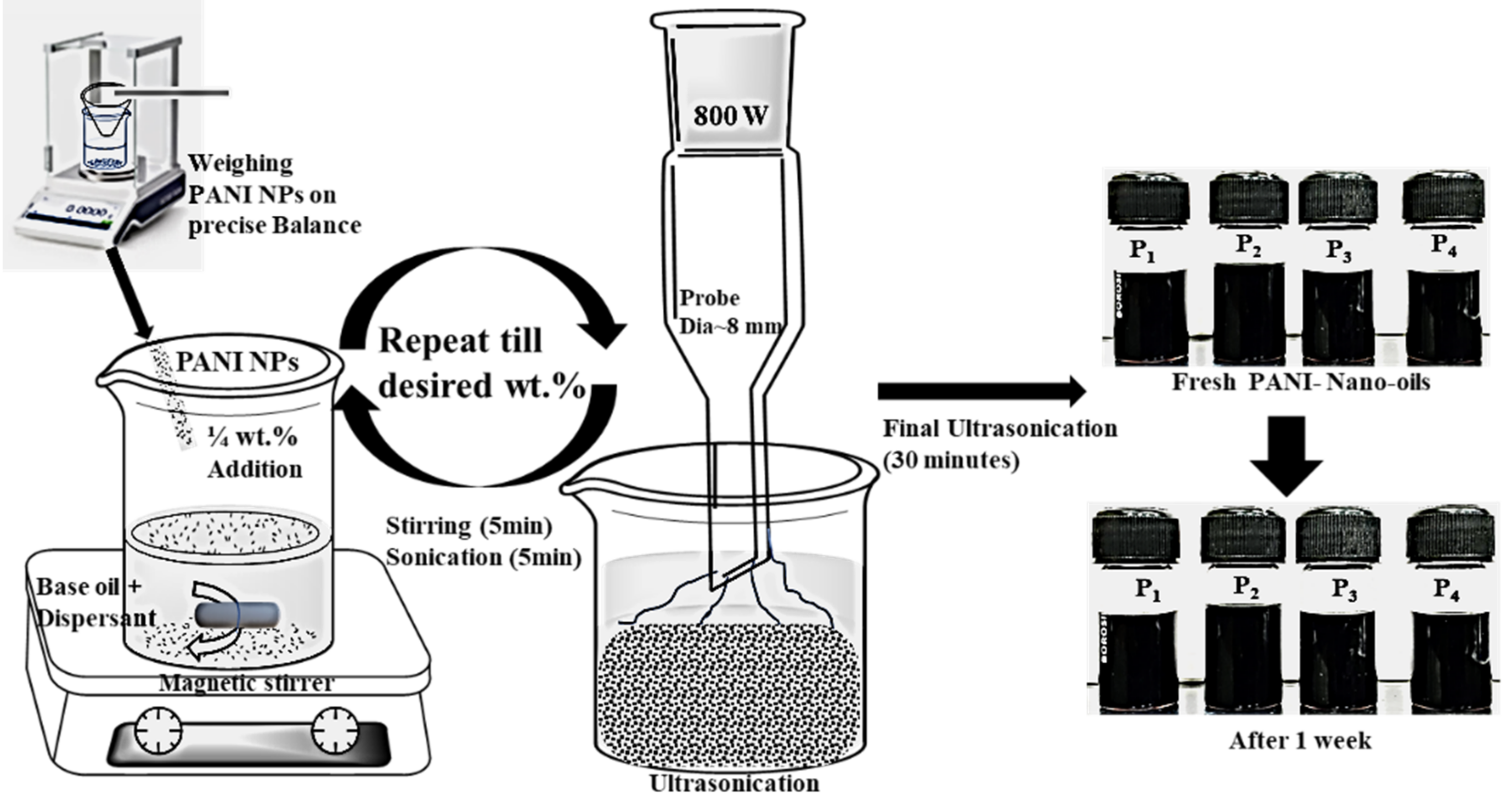

2.4. Nano-Oils Formulation

2.5. Thermal Properties

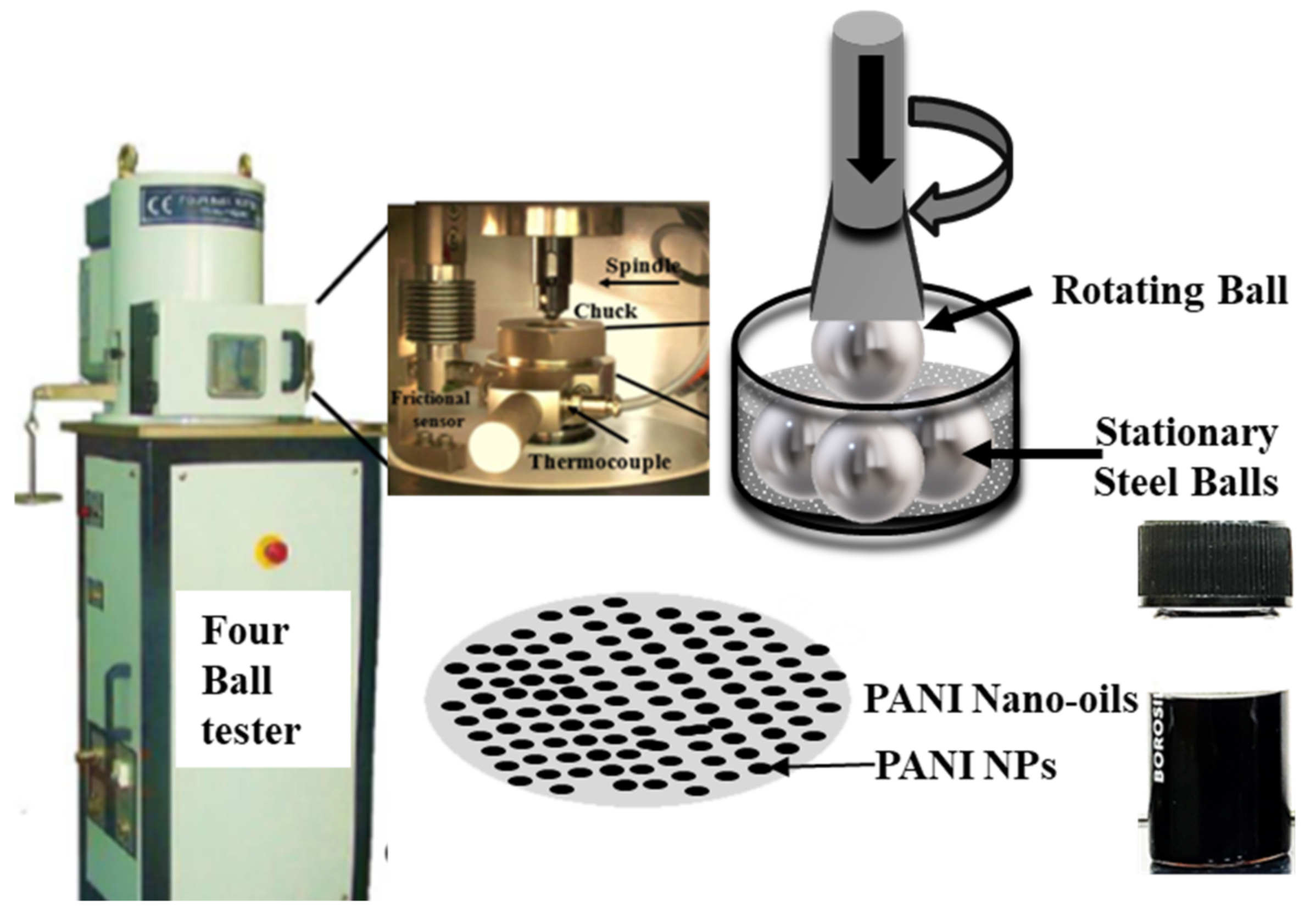

2.6. Tribological Performance Evaluation of Developed Oil Samples

3. Results and Discussion

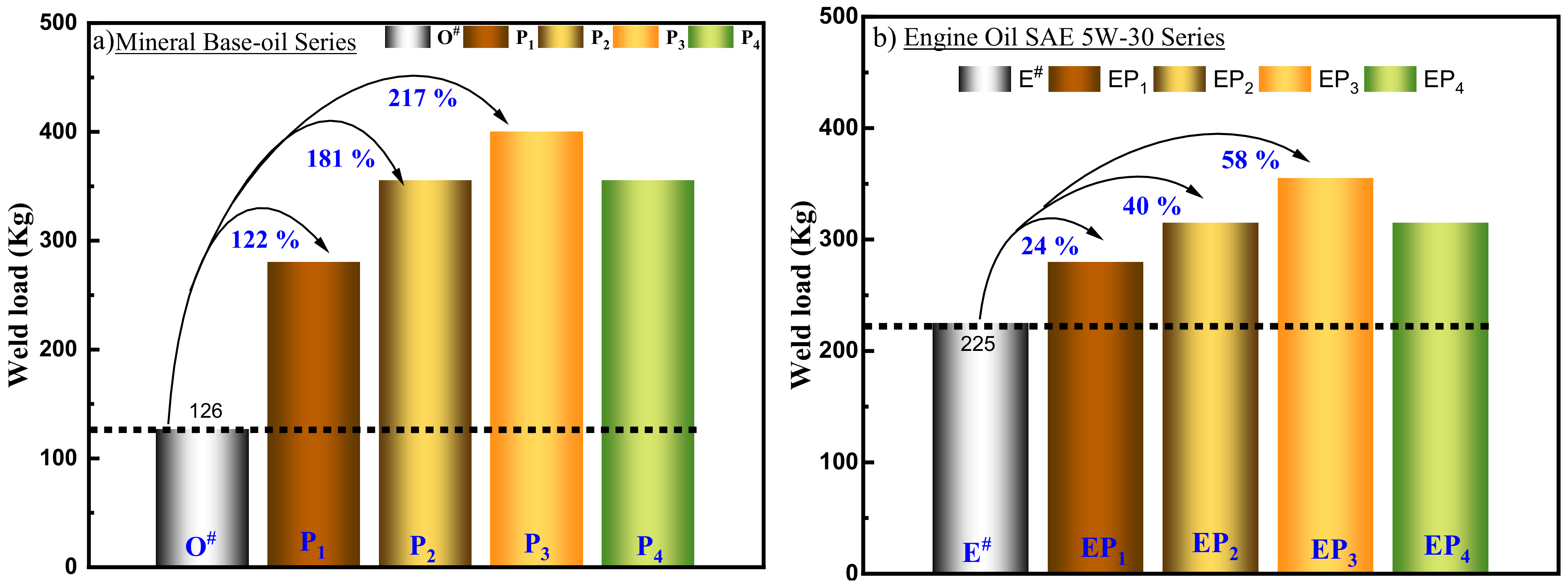

3.1. Influence on EP Property of Oils

- For Mineral Oils; P3 (217%) > P2 (25%) > P3 (11%) ~ P1 (11%) > O#

- For Engine Oils; EP3 (58%) > EP2 (40%) > P4 (40%) ~ P1 (24%) > E#

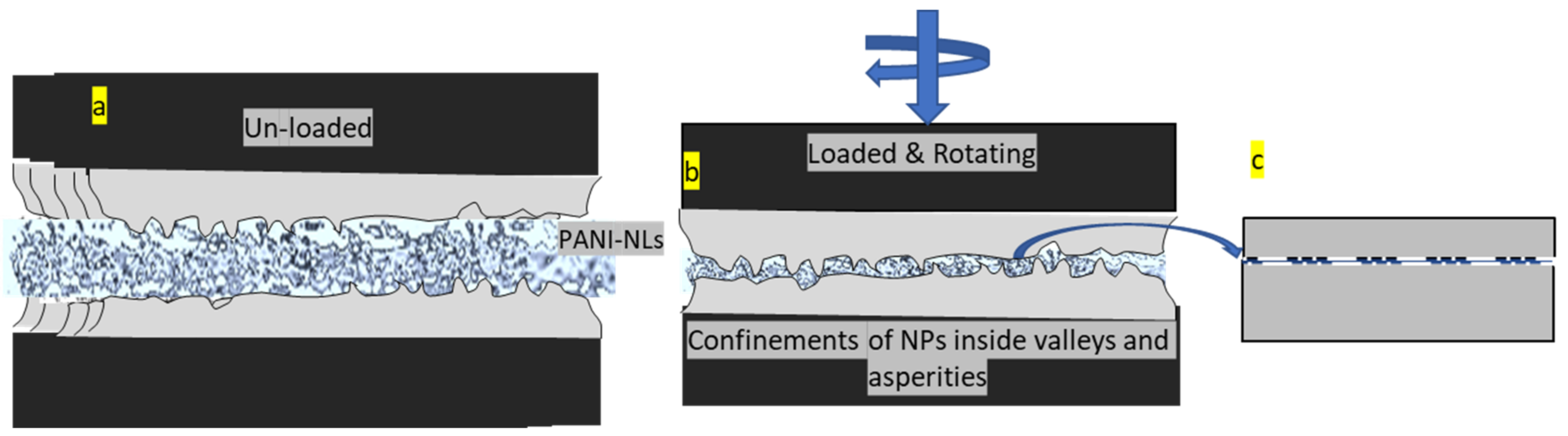

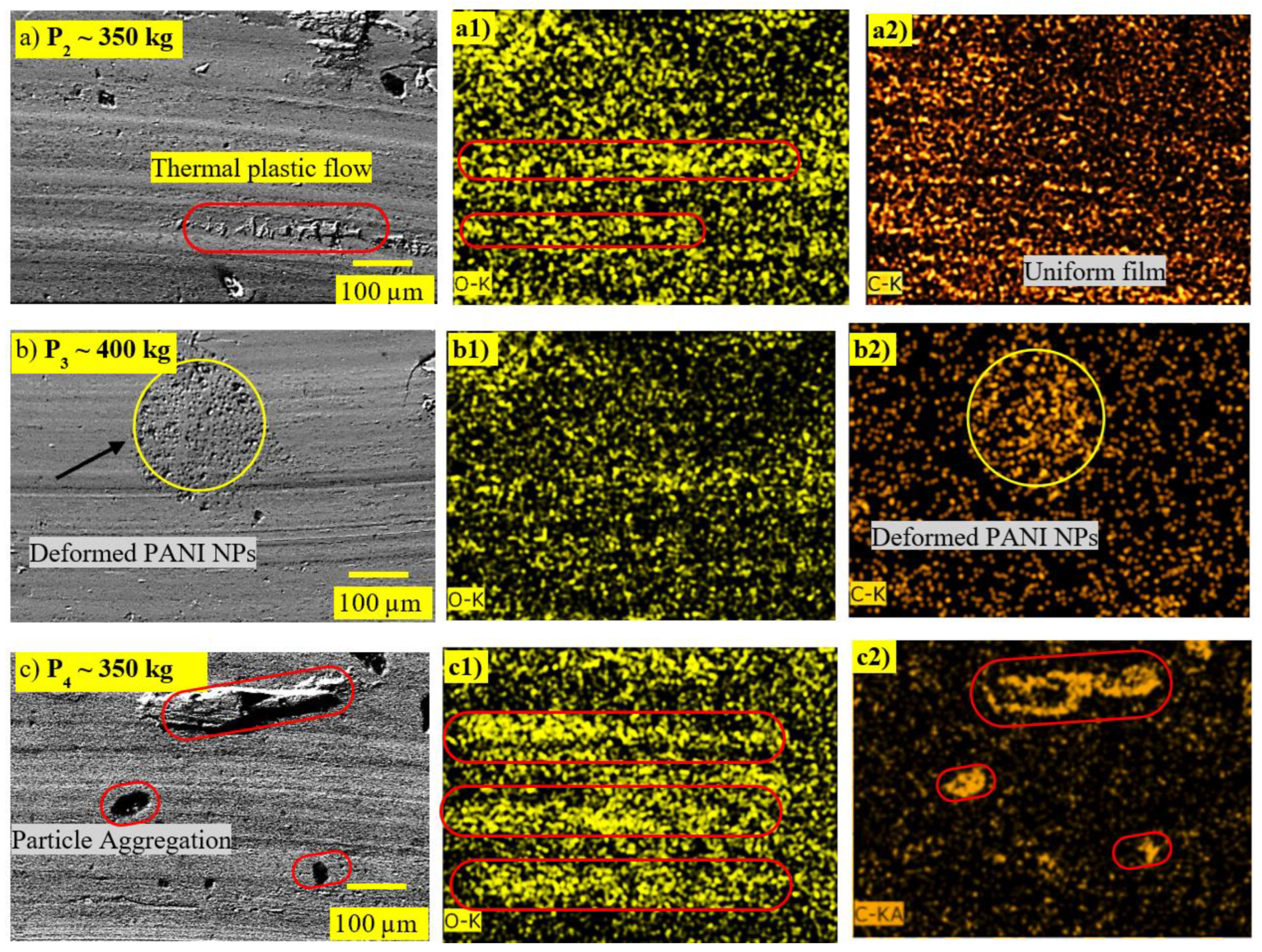

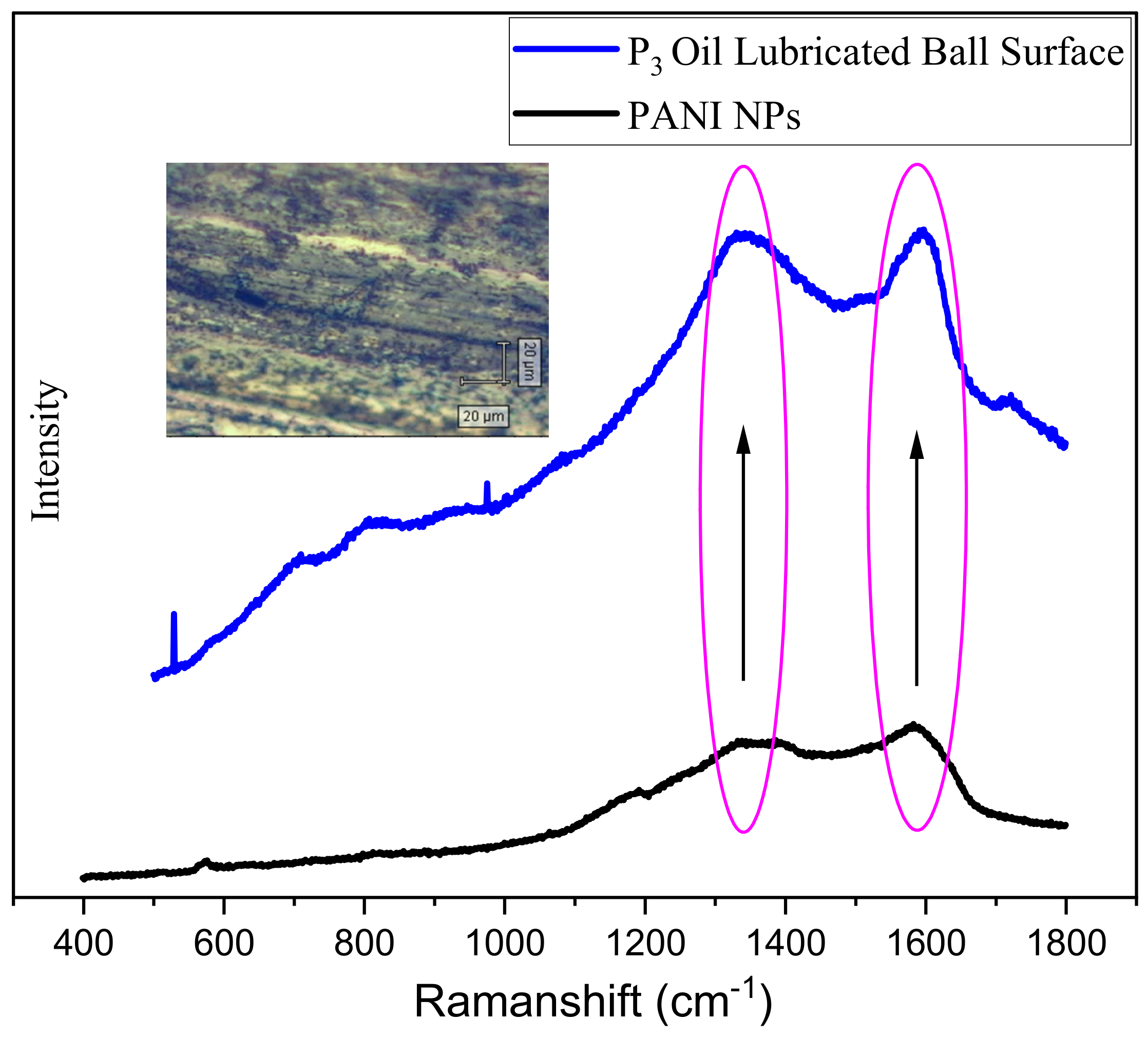

Tribo-Films Characterization on Worn Surface Pre-Weld Balls of PANI-Nano-Oils

3.2. Antiwear (AW.) Performance of Nano-Oils

Antiwear Tribo-Film Analysis on Balls Lubricated with Combo Oils

3.3. Hybrid Oil EP Performance

4. Conclusions

5. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jha, S.; Nanda, S.; Acharya, B.; Dalai, A.K. A Review of Thermochemical Conversion of Waste Biomass to Biofuels. Energies 2022, 15, 6352. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, X.; Fu, X.; Xia, Y. Performance and Anti-Wear Mechanism of CaCO3 Nanoparticles as a Green Additive in Poly-Alpha-Olefin. Tribol. Int. 2009, 42, 1029–1039. [Google Scholar] [CrossRef]

- Arora, A.; Jha, S.; Saini, V. Aspects of Green-Sustainable Tribology and Its Impacts on Future Product Development: A Review. Ecol. Environ. Conserv. 2019, 25, S146–S157. [Google Scholar]

- Morshed, A.; Wu, H.; Jiang, Z. A Comprehensive Review of Water-Based Nanolubricants. Lubricants 2021, 9, 89. [Google Scholar] [CrossRef]

- Akl, S.; Elsoudy, S.; Abdel-Rehim, A.A.; Salem, S.; Ellis, M. Recent Advances in Preparation and Testing Methods of Engine-Based Nanolubricants: A State-of-the-Art Review. Lubricants 2021, 9, 85. [Google Scholar] [CrossRef]

- Okokpujie, I.P.; Tartibu, L.K.; Sinebe, J.E.; Adeoye, A.O.M.; Akinlabi, E.T. Comparative Study of Rheological Effects of Vegetable Oil-Lubricant, TiO2, MWCNTs Nano-Lubricants, and Machining Parameters’ Influence on Cutting Force for Sustainable Metal Cutting Process. Lubricants 2022, 10, 54. [Google Scholar] [CrossRef]

- Martin, J.M.; Ohmae, N. Nanolubricants; John Wiley & Sons: London, UK, 2008. [Google Scholar]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R. Tribological Performance of Nanoparticles as Lubricating Oil Additives. J. Nanoparticle Res. 2016, 18, 1–25. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of Nanoparticles in Oil Lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Fan, X.; Li, W.; Fu, H.; Zhu, M.; Wang, L.; Cai, Z.; Liu, J.; Li, H. Probing the Function of Solid Nanoparticle Structure under Boundary Lubrication. ACS Sustain. Chem. Eng. 2017, 5, 4223–4233. [Google Scholar] [CrossRef]

- Rasheed, A.K.K.; Khalid, M.; Rashmi, W.; Gupta, T.C.S.M.; Chan, A. Graphene Based Nanofluids and Nanolubricants–Review of Recent Developments. Renew. Sustain. Energy Rev. 2016, 63, 346–362. [Google Scholar] [CrossRef]

- Saini, V.; Bijwe, J.; Seth, S.; Ramakumar, S.S.V. Role of Base Oils in Developing Extreme Pressure Lubricants by Exploring Nano-PTFE Particles. Tribol. Int. 2020, 143, 106071. [Google Scholar] [CrossRef]

- Gupta, R.N.; Harsha, A.P.; Singh, S. Tribological Study on Rapeseed Oil with Nano-Additives in Close Contact Sliding Situation. Appl. Nanosci. 2018, 8, 567–580. [Google Scholar] [CrossRef]

- Solanki, R.; Saini, V.; Bijwe, J. Exploration of PTFE Sub-Micron Particles for Enhancing the Performance of Commercial Oils. Surf. Topogr. Metrol. Prop. 2021, 9, 025005. [Google Scholar] [CrossRef]

- Maurya, U.; Vasu, V.; Kashinath, D. Ionic Liquid-Nanoparticle-Based Hybrid-Nanolubricant Additives for Potential Enhancement of Tribological Properties of Lubricants and Their Comparative Study with ZDDP. Tribol. Lett. 2022, 70, 11. [Google Scholar] [CrossRef]

- Gupta, T.; Kumar, A.; Prasad, B. Sustainable Lubrication: Low Molecular Weight PTFE Micro-Particles as Extreme Pressure Additives for Heavy Duty Grease Applications. Ind. Lubr. Tribol. 2021, 73, 1209–1218. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Tribological Investigations of Nano and Micro-Sized Graphite Particles as an Additive in Lithium-Based Grease. Tribol. Lett. 2020, 68, 124. [Google Scholar] [CrossRef]

- Rawat, S.S.; Harsha, A.P.; Deepak, A.P. Tribological Performance of Paraffin Grease with Silica Nanoparticles as an Additive. Appl. Nanosci. 2019, 9, 305–315. [Google Scholar] [CrossRef]

- Lee, K.; Hwang, Y.; Cheong, S.; Choi, Y.; Kwon, L.; Lee, J.; Kim, S.H. Understanding the Role of Nanoparticles in Nano-Oil Lubrication. Tribol. Lett. 2009, 35, 127–131. [Google Scholar] [CrossRef]

- Saini, V.; Bijwe, J.; Seth, S.; Ramakumar, S.S.V. Interfacial Interaction of PTFE Sub-Micron Particles in Oil with Steel Surfaces as Excellent Extreme-Pressure Additive. J. Mol. Liq. 2021, 325, 115238. [Google Scholar] [CrossRef]

- Ye, Q.; Liu, S.; Zhang, J.; Xu, F.; Zhou, F.; Liu, W. Superior Lubricity and Antiwear Performances Enabled by Porous Carbon Nanospheres with Different Shell Microstructures. ACS Sustain. Chem. Eng. 2019, 7, 12527. [Google Scholar] [CrossRef]

- Sgroi, M.F.; Asti, M.; Gili, F.; Deorsola, F.A.; Bensaid, S.; Fino, D.; Kraft, G.; Garcia, I.; Dassenoy, F. Engine Bench and Road Testing of an Engine Oil Containing MoS2 Particles as Nano-Additive for Friction Reduction. Tribol. Int. 2017, 105, 317–325. [Google Scholar] [CrossRef]

- Saini, V.; Bijwe, J.; Seth, S.; Ramakumar, S.S.V. Potential Exploration of Nano-Talc Particles for Enhancing the Anti-Wear and Extreme Pressure Performance of Oil. Tribol. Int. 2020, 151, 106452. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Exploration of Talc Nanoparticles to Enhance the Performance of Lithium Grease. Tribol. Int. 2021, 162, 107107. [Google Scholar] [CrossRef]

- Rudenko, P.; Bandyopadhyay, A. Talc as Friction Reducing Additive to Lubricating Oil. Appl. Surf. Sci. 2013, 276, 383–389. [Google Scholar] [CrossRef]

- Eswaraiah, V.; Sankaranarayanan, V.; Ramaprabhu, S. Graphene-Based Engine Oil Nanofluids for Tribological Applications. ACS Appl. Mater. Interfaces 2011, 3, 4221–4227. [Google Scholar] [CrossRef]

- Saini, V.; Seth, S.; Ramakumar, S.S.V.; Bijwe, J. Carbon Nanoparticles of Varying Shapes as Additives in Mineral Oil Assessment of Comparative Performance Potential. ACS Appl. Mater. Interfaces 2021, 13, 38844–38856. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A New Emerging Lubricant. Mater. Today 2014, 17, 31. [Google Scholar] [CrossRef]

- Asadauskas, S.J.; Kreivaitis, R.; Bikulčius, G.; Grigucevičienė, A.; Padgurskas, J. Tribological Effects of Cu, Fe and Zn Nano-Particles, Suspended in Mineral and Bio-Based Oils. Lubr. Sci. 2016, 28, 157–176. [Google Scholar] [CrossRef]

- Gupta, M.K.; Bijwe, J.; Padhan, M. Role of Size of Hexagonal Boron Nitride Particles on Tribo-Performance of Nano and Micro Oils. Lubr. Sci. 2018, 30, 441–456. [Google Scholar] [CrossRef]

- Osama, M.; Singh, A.; Walvekar, R.; Khalid, M.; Gupta, T.C.S.M.; Yin, W.W. Recent Developments and Performance Review of Metal Working Fluids. Tribol. Int. 2017, 114, 389–401. [Google Scholar] [CrossRef]

- Ilyas, S.U.; Ridha, S.; Sardar, S.; Estellé, P.; Kumar, A.; Pendyala, R. Rheological Behavior of Stabilized Diamond-Graphene Nanoplatelets Hybrid Nanosuspensions in Mineral Oil. J. Mol. Liq. 2021, 328, 115509. [Google Scholar] [CrossRef]

- Khare, V.; Pham, M.Q.; Kumari, N.; Yoon, H.S.; Kim, C.S.; Park, J., II; Ahn, S.H. Graphene-Ionic Liquid Based Hybrid Nanomaterials as Novel Lubricant for Low Friction and Wear. ACS Appl. Mater. Interfaces 2013, 5, 4063–4075. [Google Scholar] [CrossRef]

- Nasser, K.I.; Liñeira del Río, J.M.; Mariño, F.; López, E.R.; Fernández, J. Double Hybrid Lubricant Additives Consisting of a Phosphonium Ionic Liquid and Graphene Nanoplatelets/Hexagonal Boron Nitride Nanoparticles. Tribol. Int. 2021, 163, 107189. [Google Scholar] [CrossRef]

- Maurya, U.; Vasu, V. Synergistic Effect Between Phosphonium-Based Ionic Liquid and Three Oxide Nanoparticles as Hybrid Lubricant Additives. J. Tribol. 2020, 142, 052101. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Synergism or Antagonism in Tribo-Performance of Nano-Greases Using Combinations of Nanoparticles of Graphite and PTFE. Appl. Nanosci. 2021, 11, 2525–2536. [Google Scholar] [CrossRef]

- Bijwe, J.; Chauhan, V.; Darpe, A. Copper-Free Eco-Friendly Friction Materials/Brake-Pads/Shoes. Indian Patent FT-IDF-12-2020-169, 2021. Submitted Indian Patent. [Google Scholar]

- Bragg, W.H.; Bragg, W.L. X-rays and Crystal Structure; G. Bell and Sons, Limited: London, UK, 1915. [Google Scholar]

- Lin-Vien, D.; Colthup, N.B.; Fateley, W.G.; Grasselli, J.G. The Handbook of Infrared and Raman Characteristic Frequencies of Organic Molecules; Elsevier: Amsterdam, The Netherlands, 1991; ISBN 0080571166. [Google Scholar]

- Ahmadi, Z.; Chauhan, N.P.S.; Zarrintaj, P.; Khiabani, A.B.; Saeb, M.R.; Mozafari, M. Experimental Procedures for Assessing Electrical and Thermal Conductivity of Polyaniline. In Fundamentals and Emerging Applications of Polyaniline; Elsevier: Amsterdam, The Netherlands, 2019; pp. 227–258. [Google Scholar] [CrossRef]

- ASTM D4172-21; Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method). ASTM International: West Conshohocken, PA, USA, 2021.

- IP 239. Determination of Extreme Pressure and Antiwear Properties of Lubricating Fluids and Greases-Four Ball Method (European Conditions); Energy Institute: London, UK, 2014. [Google Scholar]

- Mungse, H.P.; Gupta, K.; Singh, R.; Sharma, O.P.; Sugimura, H.; Khatri, O.P. Alkylated Graphene Oxide and Reduced Graphene Oxide: Grafting Density, Dispersion Stability to Enhancement of Lubrication Properties. J. Colloid Interface Sci. 2019, 541, 150–162. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Y.; Li, C.; Zhou, Z.; Nie, X.; Chen, Y.; Sharma, S. Extreme pressure and antiwear additives for lubricant: Academic insights and perspectives. Int. J. Adv. Manuf. Technol. 2022, 120, 1–27. [Google Scholar] [CrossRef]

- Mello, V.S.; Trajano, M.F.; Guedes, A.E.; Alves, S.M. Comparison Between the Action of Nano-Oxides and Conventional EP Additives in Boundary Lubrication. Lubricants 2020, 8, 54. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Cho, Y.-H.; Chiu, C.-T. Tribological Performance of EP Additives in Different Base Oils. Tribol. Trans. 2012, 55, 175–184. [Google Scholar] [CrossRef]

- Quinn, T.F.J.; Sullivan, J.L.; Rowson, D.M. Origins and Development of Oxidational Wear at Low Ambient Temperatures. Wear 1984, 94, 175–191. [Google Scholar] [CrossRef]

- Saini, V.; Bijwe, J.; Seth, S.; Ramakumar, S.S.V. Unexplored Solid Lubricity of Titanium Nanoparticles in Oil to Modify the Metallic Interfaces. Appl. Surf. Sci. 2022, 580, 152127. [Google Scholar] [CrossRef]

- Gupta, M.K.; Bijwe, J.; Kadiyala, A.K. Tribo-Investigations on Oils with Dispersants and Hexagonal Boron Nitride Particles. J. Tribol. 2018, 140, 031801–031810. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman Spectra of Disordered and Amorphous Carbon A. Phys. Rev. B 1969, 31, 632–645. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Few Layer Graphene to Reduce Wear and Friction on Sliding Steel Surfaces. Carbon 2013, 54, 454–459. [Google Scholar] [CrossRef]

- Liñeira del Río, J.M.; López, E.R.; García, F.; Fernández, J. Tribological Synergies among Chemical-Modified Graphene Oxide Nanomaterials and a Phosphonium Ionic Liquid as Additives of a Biolubricant. J. Mol. Liq. 2021, 336, 116885. [Google Scholar] [CrossRef]

- Kumar, N.; Saini, V.; Bijwe, J. Performance Properties of Lithium Greases with PTFE Particles as Additive: Controlling Parameter- Size or Shape? Tribol. Int. 2020, 148, 106302. [Google Scholar] [CrossRef]

- Maurya, U.; Vasu, V. Boehmite Nanoparticles for Potential Enhancement of Tribological Performance of Lubricants. Wear 2022, 498–499, 204311. [Google Scholar] [CrossRef]

- Srinivas, V.; Thakur, R.N.; Jain, A.K. Antiwear, Antifriction, and Extreme Pressure Properties of Motor Bike Engine Oil Dispersed with Molybdenum Disulfide Nanoparticles. Tribol. Trans. 2017, 60, 12–19. [Google Scholar] [CrossRef]

| Series | Oil Codes | Codes-Nano-Oils | ||||

|---|---|---|---|---|---|---|

| 1 | Mineral oil (Grp III) Series + 1% (PIBSI + PIBSA) | O# | P1 | P2 | P3 | P4 |

| 2 | Engine oil (SAE 5W30) Series | E# | EP1 | EP2 | EP3 | EP4 |

| 3 | Hybrid oil (H) Series- + 1% (PIBSI + PIBSA) | H | - | - | T2P1 | T3P1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saini, V.; Bijwe, J. Polyaniline Nanoparticles: A Novel Additive for Augmenting Thermal Conductivity and Tribo-Properties of Mineral Oil and Commercial Engine Oil. Lubricants 2022, 10, 300. https://doi.org/10.3390/lubricants10110300

Saini V, Bijwe J. Polyaniline Nanoparticles: A Novel Additive for Augmenting Thermal Conductivity and Tribo-Properties of Mineral Oil and Commercial Engine Oil. Lubricants. 2022; 10(11):300. https://doi.org/10.3390/lubricants10110300

Chicago/Turabian StyleSaini, Vinay, and Jayashree Bijwe. 2022. "Polyaniline Nanoparticles: A Novel Additive for Augmenting Thermal Conductivity and Tribo-Properties of Mineral Oil and Commercial Engine Oil" Lubricants 10, no. 11: 300. https://doi.org/10.3390/lubricants10110300

APA StyleSaini, V., & Bijwe, J. (2022). Polyaniline Nanoparticles: A Novel Additive for Augmenting Thermal Conductivity and Tribo-Properties of Mineral Oil and Commercial Engine Oil. Lubricants, 10(11), 300. https://doi.org/10.3390/lubricants10110300