Abstract

Sustainable technologies draw attention in the machining industry thanks to their contributions in many aspects such as ecological, economic, and technological. Minimum quantity lubrication (MQL) is one of these techniques that enable to convey of the high pressurized cutting fluid toward the cutting zone as small oil particulates. This study examines the potency of MQL technology versus dry conditions on the machining quality during the milling of structural Strenx 900 steel within the sustainability index. High strength and toughness properties make this steel a hard-to-cut material providing an important opportunity to test the performances of dry and MQL environments. The outcomes of the experimental data demonstrated that MQL is superior in enhancing the quality of significant machining characteristics namely surface roughness (up to 35%), flank wear (up to 94%), wear mechanisms, cutting energy (up to 28%), and cutting temperatures (up to 14%). Furthermore, after analyzing the main headings of the sustainable indicators, MQL provided the same (+5) desirability value with a dry (+5) medium. This experimental work presents a comparative approach for improved machinability of industrially important materials by questioning the impact of sustainable methods.

1. Introduction

Structural steels, which have remarkable properties such as high ductility, low cost, relatively high strength, recyclability, weldability, and machinability are one of the most studied material systems [1]. Features such as formability and effortless weldability allow structural steels to surpass other materials in load-bearing applications. However, it is thought in the industry that welds are one of the weakest joints. To overcome some of the disadvantages of conventional structural steels, high-strengthened structural steels have been developed [2]. Strenx steel, on the one hand, is a steel that represents the positive sides of structural steels; on the other hand, it is a preferred material in many applications thanks to its superior properties such as high tensile and yield strength, high impact toughness, superior bendability, surface quality, and exceptional welding ability [3]. Due to its high wear resistance and high strength properties, it is frequently preferred in many areas such as heavy vehicles and cranes, building construction, nuclear power reactors, railways, bridge works, excavators, pressure vessels, offshore structures, automotive applications, and lifting/handling equipment [4,5,6]. In addition, it is widely used in applications where cyclic loads are at the forefront thanks to its satisfactory fatigue properties [7]. The Strenx 900 steels can be used in various geometries, but generally, their sheet forms are preferred. Shaping operations and several modifications of the Strenx 900 are performed by milling operations due to its sheet metal geometry.

The literature review demonstrates that there are limited studies published related to the machining of structural steels. Majerík and Barényi [8] carried out a study that investigates the effects of cutting parameters on the tool life of Armox 500 steel during milling. The effects of cutting environments and machining parameters such as feed rates and cutting speeds on the temperature, surface roughness, flank wear, and energy values were reported in another study [9]. In addition, they reported some difficulties in the machining of Armox 500 steel and explained the ways of overcoming these problems. Gitanjali et al. [10] conducted a study that reports the machinability behavior of the Strenx 900 steel by measuring surface roughness. There are two more studies that were reported by researchers about the machining of Strenx steel and ultimately optimum machining conditions were determined [11]. When it comes to the milling of hard-to-cut materials, it is observed that the machining difficulties increase and optimal cutting conditions should be determined properly. It was reported that the depth of cut is the most dominant parameter providing the lower temperature at the cutting zone. Generally, better surface quality can be obtained by the lower cutting parameters in hard milling of AISI D2 steel [12]. In another study, cutting speed was found to be the most significant parameter manipulating the machinability performance of Inconel 718 during milling [13]. Ghani et al. [14] investigated the milling of AISI H13 hardened steel and the optimal cutting conditions were found as high cutting speed, low feed rate, and depth of cut. It is important to monitor the wear behavior of the cutting tool as well as the machining conditions. Krain et al. [15] monitored the tool condition of Inconel 718 during milling and they observed that different kinds of wear mechanisms occurred based on cutting length. It was indicated that crater wear, flank wear, and built-up edge (BUE) wear mechanisms can be observed in the milling of hard-to-cut materials depending on cutting parameters and coating type of tools [16].

All machining operations taking into consideration, the main objective is to cut the workpiece ensuring good surface quality and structural integrity, dimensional accuracy, and geometry. A large amount of plastic deformation is required to obtain the desired geometry and it leads to a high amount of energy demand [17,18,19]. The relative motion of the cutting tool and workpiece, high rotating, and linear motions are needed for this energy. Extremely high temperatures generated at the cutting area stem from the energy transformation. Some undesirable outcomes such as tool life, cutting ability, and mechanical properties of the workpiece can be decreased and power consumption, mechanical vibrations, and cutting forces can be increased based on the excessive temperature [20,21]. Although materials with high mechanical properties are preferred in many applications, substantial mechanical properties also bring some machining difficulties. The Strenx 900 steel, which can be accepted as hard-to-cut material, has challenging issues such as excessive tool wear and poor surface integrity. These problems stem from high cutting forces and temperatures at the contact zone. High cutting forces and temperatures can cause local plastic deformations and microstructural alterations depending on the quick heating and cooling behavior [22,23]. In addition to the condition of the workpiece, such thermal and mechanical imbalances can lead to damage at the cutting edge.

Heat generation, which is the most dominant factor in hard-to-cut materials machining, makes the lubricating and cooling systems inevitable [24]. To keep the cutting temperature under control, several lubrication and cooling systems have been developed. The effects of lubricants can be handled in terms of workpiece, cutting tool, lathe, and environment. The parameters which are positively affected by the lubrications can be lined up as geometrical integrity, prevention of thermal stress damage, improvement of surface roughness, corrosion resistance, tool life extension, chip form control, cutting tool cleaning, and decrease in heat generation [25]. Based on the above discourses, there is a direct or indirect relationship between all these parameters and high temperature. Therefore, the main target of lubrication systems is to decrease heat generation by creating a thin protective layer between the cutting tool and metal chips decreasing the friction at the cutting zone. It is seen that the dry and other conventional or sustainable machining processes possess both advantages and disadvantages. As for dry machining, there are many advantages that can be listed such as low cost (lubrication costs, cleaning costs), reduction in thermal shocks, reducing environmental pollution, and health problems [26]. The formulations of lubrication cause the presence of bacteria and fungi which are susceptible to ecological problems. Furthermore, the release of harmful substances makes the working condition difficult and causes different diseases due to biocides, toxic metal particles, and microorganisms [27]. On the other hand, dry machining is not appropriate for many workpieces and cutting conditions, especially hard-to-cut materials and high cutting speed [28]. Geometrical accuracies, surface properties, and tool life are among the downsides of dry machining according to the literature studies.

Considering the compelling aspects of conventional cooling systems and dry machining, the minimum quantity lubrication (MQL) [29] approach can be preferred due to preventing and/or decreasing environmental contamination, health problems of employees, and high energy consumption [22]. Compared to other machining methods, the MQL method provides a good combination of minimum lubrication usage and maximum efficiency by sending a very small amount of pressurized fluid air mixture toward the cutting area. Even though the MQL system requires additional investment cost, saving from the cutting fluid in MQL method amortizes these requirements in a short time. In recent years, many researchers have excitedly focused on the application of MQL in different machining operations. The studies can be grouped into two categories namely cutting variables and optimization approaches of the MQL parameters. Taguchi [30] and response surface methodology [31] methods were abundantly used to optimize the amount of mist and cutting parameters by evaluating specific cutting energy and surface roughness [32,33]. In another study, the influence of several cutting conditions such as dry, flood, and MQL on the progressive wear of hard-to-cut superalloy was investigated [34]. The authors also tried to optimize and achieve the best machining performance by employing different evolutionary techniques. In all approaches, they found that the MQL strategy not only enhanced the tool life but also gained outstanding cutting time compared with other conditions due to the proper lubrication mechanism resulting in easier material removal from the machined surface. Yildirim et al. [35] investigated the advantages of nano additives added to the MQL system during the turning of Inconel 625. Varying volume fractions of nano additives were added to MQL’s oil during their experiments. Then, the productivity of the produced oils was evaluated in terms of surface integrity, tool life, wear, cutting temperature, and energy. They announced that the choice of an optimum percentage of nano additives is the most dominant factor in the service life and manufacturing cost. Gupta et al. [36] investigated the effectuality of carbide and nitride-coated tool inserts under MQL-assisted cutting, where olive-based oil’s improved tribological properties provide advanced tool life and surface integrity. A significant study investigated the influences of several MQL ingredients and their addition ratio on the machining aspects of Ni-based superalloys [37]. Their outcomes show that sunflower-aided MQL condition exhibits enhanced surface quality and energy saving. Nevertheless, another notable study found that flood machining surpasses the MQL-controlled strategies due to the limited penetrating behavior of lubricants towards the machining zone, specifically for higher cutting parameters [38].

The sustainability index generally consists of three elements namely, society, environment, and economy. The key factors of these elements are energy efficiency, low-cost production, and a clean environment based on effective waste production [39]. In machining, which is one of the important areas of sustainability, researchers have focused on the methods of increasing efficiency by minimizing power consumption and reducing carbon dioxide emissions [40]. The main headings of the sustainability indicators are shown in Figure 1. The literature review exhibited that the sustainability studies are directly related to cooling strategies in machining. Therefore, it has been investigated that the type of lubrication (nanofluids [41,42], biodegradable vegetable oils [43]), type of cooling strategies (MQL [44], dry [45,46,47], conventional cooling system [48], cryogenic cooling systems [49], high-pressure cooling [48]), and optimization of cutting parameters prevent the negative impact on the environment [29]. According to the consensus of many researchers, in terms of sustainability, the MQL cooling system remains ahead of the others due to high and fast lubricating capability, very little amount of cutting fluid requirement, ease of application, and, perhaps most importantly, its low cost.

Figure 1.

Main headings of the sustainability indicators.

The most important side and novelty of this study which is distinguished from the present literature is the evaluation of the sustainable machining index of the Strenx 900 steel. There is no available paper encountered about the machinability and sustainability aspects of Strenx 900 in the current literature. Therefore, in this study, the assessment of the machining performance and sustainability indicators of the industrially important Strenx 900 steel under dry and MQL conditions is of the essence. In this context, two cutting speeds and feed rates were selected as cutting parameters and flank wear, surface roughness/topography, cutting energy, and cutting temperature values measured and optimized. In addition, the whole process was evaluated in terms of sustainability via a radar graph.

2. Materials and Methods

2.1. Workpiece and Cutting Tool Material

The mechanical and chemical properties of the structural Strenx 900 steel can be reached by the producer’s website [50]. The unique strength and hardness properties make this structural steel special and hard-to-cut material. To evaluate the machinability performance, TiAlN-coated HM90 APKT 100316 PDR-coded carbide tools were used in the experiments. Cutting inserts were fastened to the 403 BT 40 ER32 × 70 cutting tool holders. In total, 8 experimental tests were carried out and a new cutting tool insert was used for each experiment. In addition to the cutting environments, two levels of cutting speed and feed rate values were added to the experimental design as represented in Table 1.

Table 1.

Machining parameters applied in this study.

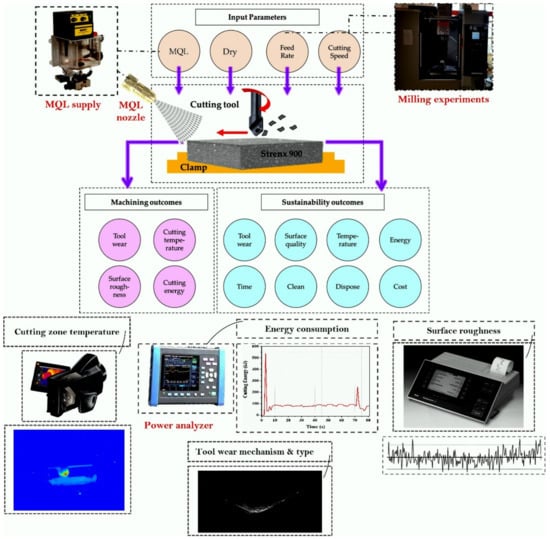

2.2. Experiments and Machine Tool

Experiments were performed with a CNC milling machine. The as-received structural steels were clamped into the milling machine one by one. Then, 8 total physical tests were carried out using new cutting tool inserts. Cutting environments, feed rates, and cutting speeds were considered as the inputs while machining and sustainability outcomes were taken as the outputs. The schematic illustration of the experimental setup is demonstrated in Figure 2. Before making the actual experiments, a broad range of cutting speed and feed rate combinations were tested to reach the desired range. The vibration-induced challenges and problems in chip formation were observed during the time of pretests, and so the experimental line was canceled. Before starting each of the tests, a layer (~0.2 mm) was removed from the surfaces to overcome possible metallurgical problems.

Figure 2.

Schematic illustration of the experimental setup.

2.3. Setup of Cooling and Lubricating Facilities

As defined before, two cooling and lubricating regimes were applied to investigate the cutting performances in the milling of structural steel. The prominent sides of both mediums in the view of advantages and disadvantages are summarized below:

Dry: Dry medium is the oldest and simplest way and used from the first experiences of machining operations [27]. The simplicity of this approach provides to avoid the extra equipment, lubricants, and their economic and storage burden. In this direction, this method also can be accepted as a sustainable strategy. On the other hand, the machinability performance of dry cutting is still controversial due to the absence of lubricating/cooling agents. Considering the wide application in industry and mentioned positivity, the dry medium is worth evaluating in experimental studies.

MQL: MQL is a technique that allows for the accelerated convey of small oil particles into the contact surfaces between tool and workpiece material. Contrary to conventional flood cooling, MQL reduces the abundant consumption of the assets such as water and oil [51]. Such an idea saves resources and provides sustainability. Not only for the green manufacturing facility but also for the technological influence of this type of lubrication brings unique contributions to machining quality. Near-dry machining provides improved tribological performance with oiling agents sending them into the contact areas. Previous researchers addressed many times the contributions of the MQL strategy. For the application procedure of the MQL method, synthetic oil was used in the present study. The nozzle was set 10 mm from the cutting zone with 6 bar pressure. In addition, the oil was sent from Ø2 mm nozzle which was arranged at a 45° angle.

2.4. Machining Indicators

After completing all tests, cutting tool wear was measured by using an SEM device. Flank wear measurements were carried out by Toolmaker’s microscope (Mitutoyo, Japan) systematically. In addition, surface roughness values were immediately measured after the experimental line was completed, on the other hand, cutting temperature and cutting energy were measured during the experiments and evaluated by using the whole data obtained and calculating the average values to achieve the ultimate results. The roughness measurements were carried out with a perthometer (Mahr, Germany). For the determination of the ultimate value of roughness, five measurements were taken as sampling and three of the middle values were averaged. A thermal camera (Testo, Turkey) was used to measure temperature and it was placed at a 500 mm distance from the machining zone. The sensor was able to cover the whole machine tool for sensing the maximum temperature zones. It would be beneficial to say that the sensor is capable of capturing high-resolution images in 640 × 480 pixels and sensing temperatures up to 1200 °C which is highly sufficient in this study. While analyzing the energy consumption, a power calculator device (Hioki, Japan) was utilized. During this period, the measurement of energy consumption was performed by wires connected to the primary phases of the CNC machine allowing tracking of the current. More detailed information about experimental setup and measurement instruments was reported in our previously published different papers [52,53,54].

3. Results

3.1. Wear Mechanisms and Discussion of Cutting Tool Wear

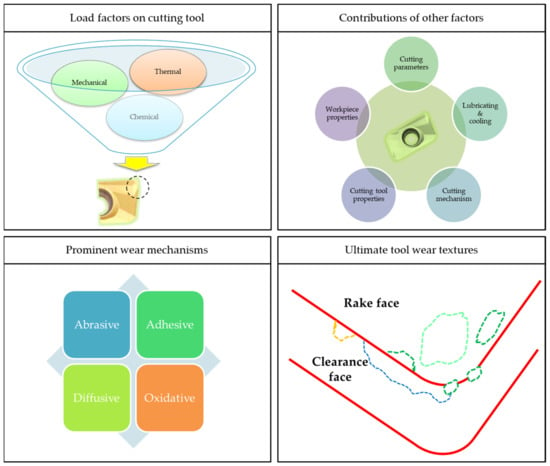

Tool wear on the cutting inserts dynamically develops as an expected outcome of the machining operations [47]. The progression of several wear types associating with a series of wear mechanisms reveals because of some load factors. The primary trigger factor for the development of these loads is the existence of high pressure and temperature along with the multiple contact areas between the triangles of chip–workpiece–tool [55]. Mechanical, thermal, and chemical loads emerge at the different locations on the cutting insert [52]. The place and time of these parameters play a critical role in shaping and speed of deformation. Therefore, some prominent wear mechanisms such as abrasion, adhesion, diffusion, and oxidation show themselves on the rake and clearance of the cutting tool. All these factors affecting the tool wear development on cutting tools are summarized and illustrated in Figure 3.

Figure 3.

Wear mechanisms developed on the cutting tools.

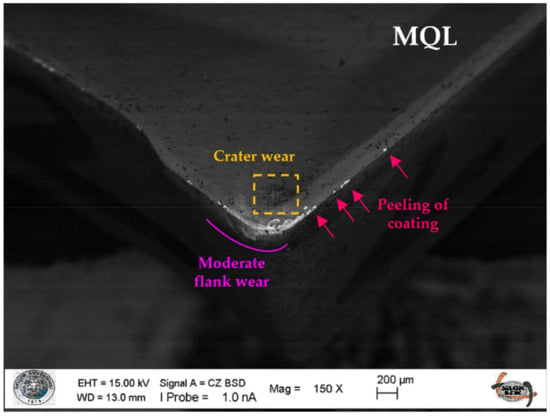

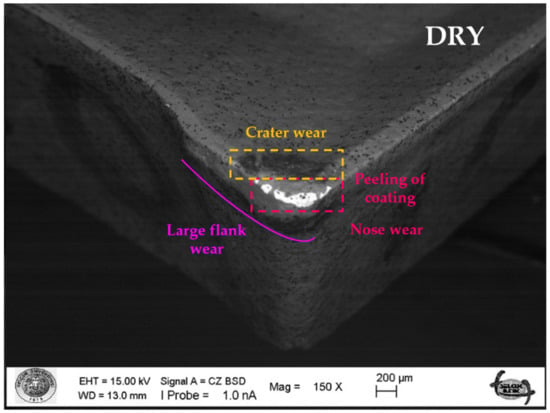

Figure 4 outlines the final view of the TiAlN-coated carbide tool inserts after machining of Strenx 900 hard-to-cut material under dry and MQL regimes. Different studies about the milling of such strengthened steels reported that the most observed wear type is notch wear [56,57]. Nevertheless, limited studies announced that there is no development of notch wear [58]. It is an expected situation since the behind of the wear mechanisms is a very complicated and dynamic issue due to various uncontrollable parameters. This study’s outcomes harmonize with the latter one. To evaluate tool wears more accurately and to observe maximum wear traces, backscattered SEM (BSD) images of carbide inserts were taken under the highest milling parameters, i.e., cutting speed = 150 m/min and feed rate = 0.2 mm/rev. From the images, it can be easily graspable that the MQL method is beneficial for minimizing the total tool wear, but it cannot eliminate wear while cutting such a hard-to-cut metal. As the reasons will be discussed in the later sections, the MQL regime is significantly powerful for reducing the generated temperature during milling related to heat exhaustion stemming from the forced convention mechanism [59,60]. A wide range of published studies reported that transferring the heat from the machining area is a primary parameter to provide thermal equilibrium which has a paramount effect on the deterioration of interacted workpiece and tool material pairs [61,62]. With the application of the MQL method, peeling of coating, crater and flank wear rates exhibit a decreasing trend, as can be seen in Figure 4. Moreover, Demirsöz et al. [63] reported that the used oil’s low density and its increasing viscosity during milling operation provide excellent lubricating phenomenon and concomitant decreased frictional forces and easier material removal procedure. Some traces of rupture and breakage formations were observed under the dry condition and these observations were experienced by different authors [64,65]. Formerly described different wear types can play a dominant role in the dry regime due to the lack of influential lubricating/cooling conditions along with harsh tribological conditions. On the other hand, it can be said that the cutting speed is the governing factor on the progressive flank and crater wear regardless of other parameters. When the feed rate was increased from 0.15 to 0.2 mm/rev, more flank and crater wear were detected. This situation is ascribed to the hammering impact of the milling operation, which aggravated the progression of wear as a function of increasing cutting parameters [20]. Consequently, the MQL method with the smallest cutting parameters was decided as the most influential selection to enhance tool lifesaving compared to dry regime. Different available papers in the literature and the outcomes of thoroughly carried out assessments (to be discussed in later subsections) also agree to a great extent with these observations.

Figure 4.

SEM photos of the cutting tools belonging to MQL and dry environments.

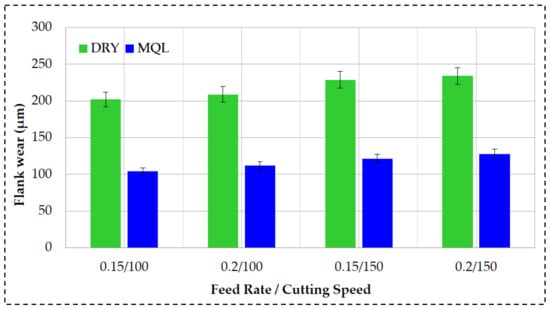

From a technical viewpoint of tribological science, some of the recently published studies in the current literature were discussed. Wakabayashi et al. [66] stated that the frictional forces at contacted parts and accompanying coefficient of friction (COF), cutting forces and resultant tool wear were significantly decreased specifically for oil-based MQL regime thanks to the formation of a thin tribo-film between interacted material interfaces. Such a formation playacts as a cushion at the cutting region and it decreases frictional forces along with rubbing, and plowing formations, finally leading to improved tool wear [67]. Various studies also announced that dry strategies result in higher COF values, cutting forces, and tool wear than all other sustainable machining processes such as MQL, nMQL, cryogenic, and their hybrid versions due to the drought nature of dry conditions [68,69,70]. As shown in Figure 5, when the cutting parameters are increased, the MQL regime remarkably exhibits its impact. This case is ascribed to the special influence of oil-based cutting fluids with minimizing BUE formation, chatter tendency, COF, and cutting forces [18]. Similar observations were reported by different studies since the high pressurized oil transferred to the cutting region decreases thermal impacts, frictional forces, and severe wear formations [71,72].

Figure 5.

Flank wear changes according to different environments.

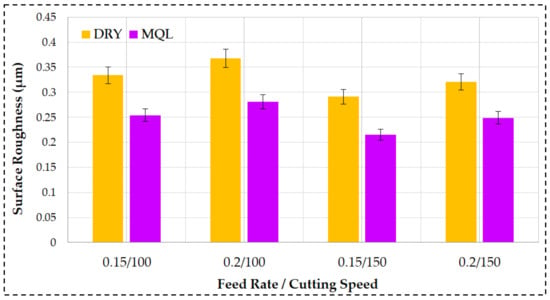

3.2. Discussion of Surface Roughness and Topographies

Figure 6 shows the differences in arithmetic surface roughness under MQL and dry milling environments. As shown in the graph, it can be clearly seen that the milling process with higher levels of cutting speeds and lower levels of feed rates results in enhanced surface quality. In addition, it is easily observed that the dry-cutting strategy yields the poorest surface roughness as compared to the MQL-assisted cutting operation. This tendency is ascribed to the distinct impact of utilized cutting fluid reducing severe frictions between interacting parts, i.e., workpiece and tool. Such interactions also regulate chatter tendency and minimize build-up-edge formation, cutting forces, and friction coefficients [18]. Sivalingam et al. [73] also declared that the high pressurized oil conveyed towards the cutting region decreases thermal imbalances, cutting, and frictional forces due to its protective thin film behavior. The strong penetration of the droplets in MQL-assisted cutting provides an influential bonding between material pairs and this leads to easier plastic flow surrounding the chips. This was also attributed, by Salur [74], to the decreased cutting temperature phenomena triggering easier material removal and smoother surfaces with fewer traces as can be discussed in a later section. The aforementioned concomitant factors provide the cut of the workpiece properly and create a new finer surface. Nevertheless, it is critical to note that the infertile cooling ability and fast evaporation before supplying sufficient lubricating are listed as disadvantages of the MQL technique as compared to other lubricating/cooling strategies. A noticeable decrement in Ra value was achieved by the MQL method compared with the dry regime. On the other hand, the feed rate and tool radius are other predominant factors on the newly generated surface aspects based on the described equation [75]. According to the equation, as the feed rate increase the surface roughness increase which can be proved by Figure 6. Additionally, increased cutting speed is also beneficial to the machined surface quality since it reduces BUE development and adherence tendency between material pairs. Similar observations were also experienced by Kar et al. [76] when studying the milling of hard-to-cut materials at lower speeds.

Figure 6.

Surface roughness changes according to different environments.

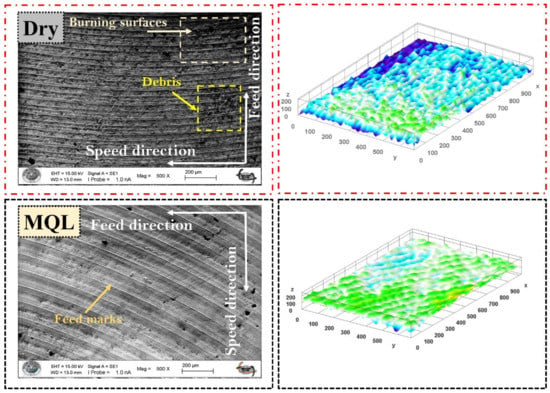

To evaluate more accurately the surface morphologies, SEM images of machined surfaces and corresponding 3D topographies are represented in Figure 7. The machined surfaces under different environments were selected from the same cutting parameters (highest feed rate/cutting speed combination) to supply consistency. As is easily graspable from the images, the MQL-assisted cutting process generates discernibly smoother surfaces as compared to the dry regime. According to the SEM images, feed marks are clearly observable in a dry medium while these traces are significantly decreased under the MQL system. In addition, some burning traces and debris formations were monitored on the machined surface under dry conditions. It can be obviously said that the 3D image of the dry regime shows many irregular peaks throughout the scanned surface. Such irregularities and hilly-like forms indicate the material adhesion between the workpiece-tool parts or peeling of coating proving in priorly discussed tool wear SEM images. The thin protective film formation in the MQL method provides a greasing mechanism at the cutting zone and it protects the tool insert from material adhesion [77]. The frictional forces occurred at the cutting zone are reduced due to the natural affinity of synthetic-based oil throughout the machined surfaces [78]. Such low friction forces and COF values can be related to the presence of the dipolar aspects of the ester function group attracting to oppositely charged workpiece material surface as protection [79]. Observed morphological studies here are supported by average surface roughness and tool wear results.

Figure 7.

SEM images and corresponding 3D images of machined surfaces under different environments.

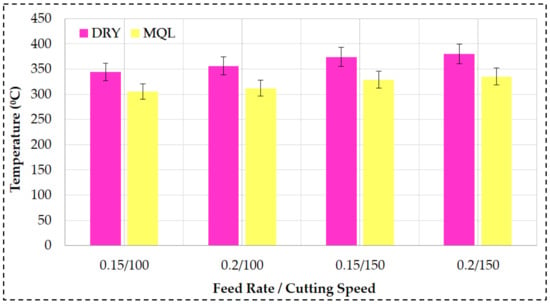

3.3. Discussion of Cutting Temperatures

Figure 8 outlines the influence of different cutting environments and milling parameters on the temperature variations and evidently, the MQL regime with the lowest cutting levels yields near-perfect results. The decreased temperatures and cutting energies have been mainly related to the development of the tool hardness creating effortless material deformation from the workpiece material surface thanks to the superb lubricating impact of oil used in the MQL method. This can be attributed to the fact that ester-based oil acts as a hindrance to the development of thin protective oil film and thus it results in a decrement in frictional forces between workpiece and tool material interfaces [48]. Similar observations were reported by several studies when milling strengthened or structural materials under different cooling/lubricating mediums [80,81]. One of the most encountered explanations for these achievements is the excellent adeptness of cutting fluids towards the absorption of the heat intensity around the interacting bodies by the formation of a liquid cushion [58]. The MQL environment enhances the cutting temperature as compared to the dry regime within the same cutting parameters. On the other hand, increasing cutting speed results in an aggravated plastic deformation rate and so it finally elevates the cutting temperatures at the machining area. Plus, the lubricants cannot achieve adequate time to evacuate heat agglomeration at the cutting region owing to the development of relatively stronger frictions between counterparts resulting from thinning of protective oil film [82]. The primary reason for this situation can be linked to an increment in COF value and frictional forces at workpiece–tool interfaces since the higher cutting parameters result in thinning influence on the protective film causing breakage at the protection thickness [83]. Thus, degradation under these circumstances advances to impairs of effectivity of protective film creating higher COF, cutting temperature, and accompanying wear rates. Seemingly, even such a little decrement in the cutting temperature is assumed to exhibit some fruitful effects on other machining criteria. Based on above discourses, it can be clearly deduced that the achievement of optimal temperature is one of the most effectual parameters for machinability aspects.

Figure 8.

Cutting temperature changes according to different environments.

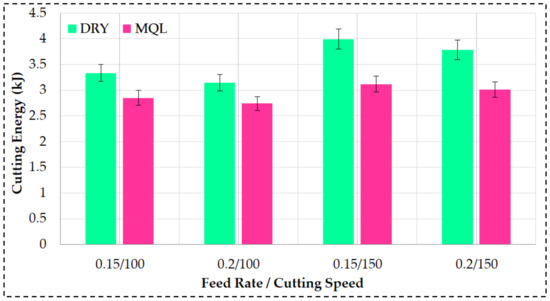

3.4. Discussion of Cutting Energy

As can be easily noticeable in Figure 9, the different cutting environments play a major role in regulating energy consumption. Irrespective of milling parameters, MQL shows better results for minimal cutting energy depletion as compared to the dry strategy. The energy released during cutting significantly depends on the cutting forces due to harsh frictional circumstances between the tool, workpiece, and chip interfaces. Such a hard and difficult-to-cut workpiece material in the present study (Strenx 900) requires extreme cutting forces [84]. Considering Figure 9, it can be said that the dry-cutting environment is inadequate for machining the workpiece material productively because of its drought habitat [52]. Moreover, the monitored discernible adhesions and larger wear traces in the dry media (as earlier examined in Figure 4) can be playacted as an inhomogeneous extra cutting edge and extends the workpiece-tool contact length. Bayraktar [85] declared that such interactions also intentionally accelerate frictional forces at the cutting zone and cutting energy demands. However, desirable outcomes were observed with the application of the MQL method since, as mentioned above, energy is dependent on power consumption and cutting forces. The introduction of the lubricants towards the cutting region minimizes the frictional forces at the interacted surfaces. The consumed energy is the function of frictional and cutting forces at workpiece-tool interfaces. As compared to dry conditions, transferred oil in mist form with high pressurized air in the MQL system supplies noticeable cooling, influential greasing, and effortless intervening in the small emptiness of interfaces at the machining region [77]. Such impacts ultimately result in a decrement in COF, cutting forces, and concomitant energy consumption. On the other hand, a noticeable decrement in the cutting energy is observed with the application of the highest feed rate and smallest cutting speed combinations. It is ascribed that the elevating speeds supply easier material removal and minimize the cutting forces. The concurrent effects of discussed parameters yield a significant improvement in the energy demand when cutting with MQL condition during the milling of Strenx 900. To the best of our knowledge, decreasing COF values thanks to the excellent lubricating properties of MQL systems can vary the material performance in terms of an increment in surface hardness and wear resistance or it minimizes adhesion tendency, cutting temperature, energy, and elimination of coating. The obtained outcomes in here show a good agreement with the literature studies and previously discussed other machining outputs.

Figure 9.

Cutting energy changes according to different environments.

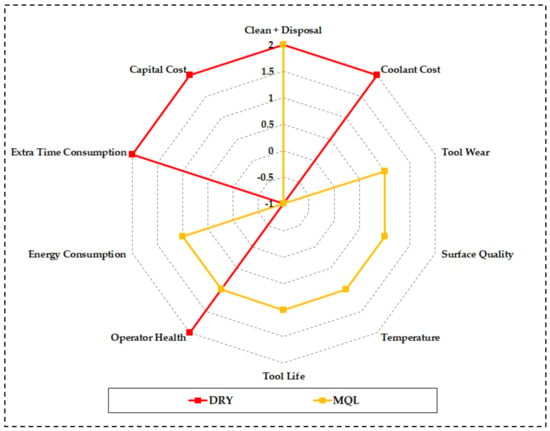

3.5. Sustainability Assessment

Sustainability is a term defining the long-term usability of the sources. With the developing technologies all over the world, sustainable methods have attracted more attention than before. The main motivations for that are the strict laws determined by the governments and the desire to protect the ecological balance. Moreover, saving sources with sustainable technologies increases productivity and avoids excessive costs. In this manner, machining operations have high potential with huge waste material, consumed energy, production time, and costs. Moreover, machining-induced variations affect the quality of the work material and the useful lifetime of the cutting tool. As a consequence, a quite number of factors can be considered as total desirability for sustainability. In the concept of this work, both cutting environments namely dry and MQL are earth-friendly methods as per their functions. Therefore, determining their sustainability is an important perspective to measure holistic performance. The Pugh matrix is one of the effective diagrams to discover the best option among all criteria [86]. To make a decision by this method, there is a need to determine the values ranging from −2 to +2 defining the significance level from the worst to the best. During composing the matrix, a number is given for each variable in the list and the total value is calculated for each performance criterion. In this paper, various parameters were defined as the influential factors for sustainability such as clean + disposal, coolant cost, capital cost, tool wear, surface quality, temperature, tool life, operator health, energy consumption, and extra time consumption. The defined values are given in Figure 10 and the reasons for these scores are summarized below:

Figure 10.

Sustainability assessment of MQL and dry environments.

1. Clean + disposal: MQL uses a minimum amount of lubricants, and it can be easily eliminated. Dry cutting on the other hand is already a clean method by using no cutting fluid. As a result, both regimes enable green machining facilities which make them deserve +2.

2. Coolant cost: The cutting fluids may be highly costly depending on the requirement and machining time. Furthermore, they can dominate a large part of the total costs. In this direction, dry cutting was determined as +2 while the MQL strategy was assigned as −1 since it uses a small amount of lubricants.

3. Tool wear, surface quality, tool life, temperature, and energy consumption: MQL regime provided better results with its high-performance lubricating ability. When comparing the results with a dry medium a clear difference was observed. In this direction, MQL was allotted as +1 and dry was appointed as −1.

4. Operator health: Operator health can be affected by the particles spread through the air and after respiration. Thinking of the fast evaporation of the MQL oil particles this strategy deserves −1 point which may also cause respiratory issues unless a suitable mist removal mechanism is added, and the drought medium of dry-cutting strategies deserves +2.

5. Extra time consumption: Each contributor to increasing the total machining time can be accepted as idle time. In this direction, the dry medium is simple to complete the operation. However, the MQL system requires repairing, refilling, and possible malfunctions in time. Therefore, the scores for extra time consume were attended as +2 and −1 for dry and MQL, respectively.

6. Capital cost: Considering the capital cost of the MQL system, this approach deserves −1; however, dry cutting requires no additional equipment which makes it +2.

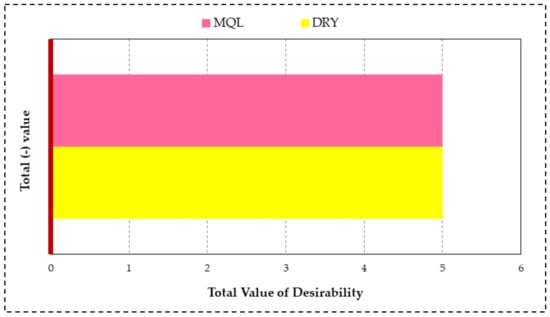

Consequently, total scores are graphically given in Figure 11 according to the above-defined numbers. The total desirability of MQL and dry environments were found as +5 and +5, respectively. Interestingly, both approaches have similar points in terms of sustainability making them equal.

Figure 11.

Total desirability of MQL and dry environments.

4. Conclusions

This paper aims to investigate the machinability and sustainability point of view in the milling of structural Strenx 900 steel under different lubricating mediums. In this direction, dry and MQL regimes were considered as machining conditions, and the obtained outcomes are given below:

- The pressurized oil agents of MQL provided better cutting tool conditions by protecting it from excessive damage. Peeling, crater wear, and flank wear were observed during milling under both cutting mediums. It was seen that MQL assistance was able to reduce the effect of all these wear types when compared to dry media during the milling of Strenx 900 steel.

- Seemingly, the temperature on the cutting tool can be decreased by about 12–14% with the usage of the MQL method after trials of dry cutting. This is an important outcome for further investigation of the reduced thermal effects while machining structural materials.

- As a considerable unit of sustainability, energy consumption of manufacturing energy is covered by the machining industry. The impact of superior oil spraying ability makes the MQL strategy an important tool for reducing cutting forces and indirectly the cutting power and energy (up to 28%) compared to dry medium in milling of Strenx 900 steel.

- The high pressurized impact of the MQL method helps to easy penetration of oil particles into the chip-tool interface improving the tribological mechanism. Therefore, a significant reduction in flank wear (94%) was reached by near-dry machining compared with dry cutting.

- Average surface roughness is a critical outcome of machining operations reflecting the end product quality. When compared to a dry medium, a lubricating environment of the MQL method successfully reduces the surface roughness values which makes an improvement on the surface quality of about 28–35%.

- From a sustainability perspective, clean + disposal, capital cost, coolant cost, tool wear, surface quality, temperature, tool life, operator health, energy consumption, and extra time consumption were considered for the performance evaluation of different cutting mediums. Therefore, the total desirability of MQL and dry environments was found as +5 and +5, respectively.

Author Contributions

Conceptualization, M.K.; Methodology, A.A., E.S. and M.K.; Validation, A.A., E.S. and M.K.; Formal analysis, M.K. and E.S.; Investigation, A.A. and E.S.; Resources, A.A., E.S. and M.K.; Data curation, A.A., E.S. and M.K.; Writing—review and editing, A.A., E.S. and M.K.; Visualization, E.S. and M.K.; Supervision, A.A., E.S. and M.K.; Project administration, A.A. and E.S.; Funding acquisition, A.A. and E.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Srikanth, M.; Asmatulu, R. Nanotechnology safety in the construction and infrastructure industries. In Nanotechnology Safety; Elsevier: Amsterdam, The Netherlands, 2013; pp. 99–113. [Google Scholar]

- Binali, R.; Yaldiz, S.; Neşeli, S. S960QL yapi çeliğinin işlenebilirliğinin sonlu elemanlar yöntemi ile incelenmesi. Avrupa Bilim Teknol. Derg. 2021, 31, 85–91. [Google Scholar]

- Jonsson, T.; Narström, T.; Barsoum, Z. Fatigue and ultimate strength assessment of post weld treated strenx® 1100 plus butt welds. Procedia Struct. Integr. 2022, 38, 411–417. [Google Scholar] [CrossRef]

- Marichamy, S.; Maniraj, S.; Thanigaivelan, R.; Kumaravel, S.; Babu, K.V.; Mallesham, P. Enhancement of material removal rate in EDM process using silicon carbide based strenx 900 steel. Mater. Today Proc. 2021, 45, 780–782. [Google Scholar] [CrossRef]

- Schneider, C.; Ernst, W.; Schnitzer, R.; Staufer, H.; Vallant, R.; Enzinger, N. Welding of S960MC with undermatching filler material. Weld. World 2018, 62, 801–809. [Google Scholar] [CrossRef]

- Khanafer, K.; Eltaggaz, A.; Deiab, I.; Agarwal, H.; Abdul-Latif, A. Toward sustainable micro-drilling of Inconel 718 superalloy using MQL-Nanofluid. Int. J. Adv. Manuf. Technol. 2020, 107, 3459–3469. [Google Scholar] [CrossRef]

- Tümer, M.; Schneider-Bröskamp, C.; Enzinger, N. Fusion welding of ultra-high strength structural steels—A review. J. Manuf. Process. 2022, 82, 203–229. [Google Scholar] [CrossRef]

- Majerík, J.; Barényi, I. Wear and tool life investigation of carbide inserts while hard machining of armox 500 steel. Manuf. Technol. 2018, 18, 273–278. [Google Scholar] [CrossRef]

- Kuntoğlu, M. Measurement and analysis of sustainable indicators in machining of ARMOX 500T armor steel. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2022, 236, 09544062221079775. [Google Scholar] [CrossRef]

- Gitanjali, V.; Nithya, P.; Pandiarajan, P.; Dhruthi, N.; Raj, T.V.; Subbiah, R. Performance machinability through electrochemical grinding of strenx steel. Mater. Today Proc. 2021, 45, 2479–2481. [Google Scholar] [CrossRef]

- Raguraman, D.; Sakthivel, P.; Paramasivam, V.; Girisha, L.; Krishnamoorthy, S.; Alex, S.R.; Subbiah, R. Analyze the effect of abrasives in water jet Machining on strenx steel. Mater. Today Proc. 2022, 66, 1088–1092. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R.; Maciel, C.H.A.; Rubio, J.C.C.; Abrão, A.M. Machinability evaluation in hard milling of AISI D2 steel. Mater. Res. 2016, 19, 360–369. [Google Scholar] [CrossRef]

- Maiyar, L.M.; Ramanujam, R.; Venkatesan, K.; Jerald, J. Optimization of machining parameters for end milling of Inconel 718 super alloy using Taguchi based grey relational analysis. Procedia Eng. 2013, 64, 1276–1282. [Google Scholar] [CrossRef]

- Ghani, J.A.; Choudhury, I.; Hassan, H. Application of Taguchi method in the optimization of end milling parameters. J. Mater. Process. Technol. 2004, 145, 84–92. [Google Scholar] [CrossRef]

- Krain, H.; Sharman, A.; Ridgway, K. Optimisation of tool life and productivity when end milling Inconel 718TM. J. Mater. Process. Technol. 2007, 189, 153–161. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, G.; Zhang, X.; Cheng, X.; Yang, X.; Xu, R. Cutting force, tool wear and surface roughness in high-speed milling of high-strength steel with coated tools. J. Mech. Sci. Technol. 2019, 33, 5393–5398. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V. Experimental comparison of the performance of nanofluids, cryogenic and hybrid cooling in turning of Inconel 625. Tribol. Int. 2019, 137, 366–378. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Pimenov, D.Y.; Singla, A.K.; Machado, A.R.; da Silva, L.R.R.; Gupta, M.K.; Sarikaya, M.; Krolczyk, G.M. Review on design and development of cryogenic machining setups for heat resistant alloys and composites. J. Manuf. Process. 2021, 68, 398–422. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoglu, M.; Gunes, A.; Sahin, O.S. Experimental study and analysis of machinability characteristics of metal matrix composites during drilling. Compos. B Eng. 2019, 166, 401–413. [Google Scholar] [CrossRef]

- Salur, E.; Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y. The effects of MQL and dry environments on tool wear, cutting temperature, and power consumption during end milling of AISI 1040 steel. Metals 2021, 11, 1674. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y.; Usca, Ü.A.; Salur, E.; Gupta, M.K.; Mikolajczyk, T.; Giasin, K.; Kapłonek, W.; Sharma, S. A review of indirect tool condition monitoring systems and decision-making methods in turning: Critical analysis and trends. Sensors 2020, 21, 108. [Google Scholar] [CrossRef]

- Umbrello, D.; Micari, F.; Jawahir, I. The effects of cryogenic cooling on surface integrity in hard machining: A comparison with dry machining. CIRP Ann. 2012, 61, 103–106. [Google Scholar] [CrossRef]

- Tönshoff, H.; Arendt, C.; Amor, R.B. Cutting of hardened steel. CIRP Ann. 2000, 49, 547–566. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Walter, A.; Janssen, R.; Diersen, P. Aspects of cooling lubrication reduction in machining advanced materials. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 1999, 213, 769–778. [Google Scholar] [CrossRef]

- Aslan, A.; Salur, E. Applications of nanofluids in minimum quantity lubrication machining: A review. In Nanomaterials in Manufacturing Processes; CRC Press: Boca Raton, FL, USA, 2022; pp. 53–84. [Google Scholar]

- Sreejith, P.; Ngoi, B. Dry machining: Machining of the future. J. Mater. Process. Technol. 2000, 101, 287–291. [Google Scholar] [CrossRef]

- Goindi, G.S.; Sarkar, P. Dry machining: A step towards sustainable machining–Challenges and future directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Klocke, F.; Gierlings, S.; Brockmann, M.; Veselovac, D. Influence of temperature on surface integrity for typical machining processes in aero engine manufacture. Procedia Eng. 2011, 19, 203–208. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Mia, M.; Gupta, M.K.; Machado, Á.R.; Pintaude, G.; Unune, D.R.; Khanna, N.; Khan, A.M.; Tomaz, Í.; Wojciechowski, S. Resource saving by optimization and machining environments for sustainable manufacturing: A review and future prospects. Renew. Sustain. Energy Rev. 2022, 166, 112660. [Google Scholar] [CrossRef]

- Awale, A.S.; Vashista, M.; Yusufzai, M.Z.K. Multi-objective optimization of MQL mist parameters for eco-friendly grinding. J. Manuf. Process. 2020, 56, 75–86. [Google Scholar] [CrossRef]

- Mia, M. Mathematical modeling and optimization of MQL assisted end milling characteristics based on RSM and Taguchi method. Measurement 2018, 121, 249–260. [Google Scholar] [CrossRef]

- Viswanathan, R.; Ramesh, S.; Subburam, V. Measurement and optimization of performance characteristics in turning of Mg alloy under dry and MQL conditions. Measurement 2018, 120, 107–113. [Google Scholar] [CrossRef]

- Mia, M.; Bashir, M.A.; Khan, M.A.; Dhar, N.R. Optimization of MQL flow rate for minimum cutting force and surface roughness in end milling of hardened steel (HRC 40). Int. J. Adv. Manuf. Technol. 2017, 89, 675–690. [Google Scholar] [CrossRef]

- Singh, G.; Gupta, M.K.; Mia, M.; Sharma, V.S. Modeling and optimization of tool wear in MQL-assisted milling of Inconel 718 superalloy using evolutionary techniques. Int. J. Adv. Manuf. Technol. 2018, 97, 481–494. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Sarıkaya, M.; Kıvak, T.; Şirin, Ş. The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol. Int. 2019, 134, 443–456. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mia, M.; Jamil, M.; Singh, R.; Singla, A.K.; Song, Q.; Liu, Z.; Khan, A.M.; Rahman, M.A.; Sarikaya, M. Machinability investigations of hardened steel with biodegradable oil-based MQL spray system. Int. J. Adv. Manuf. Technol. 2020, 108, 735–748. [Google Scholar] [CrossRef]

- Virdi, R.L.; Chatha, S.S.; Singh, H. Machining performance of Inconel-718 alloy under the influence of nanoparticles based minimum quantity lubrication grinding. J. Manuf. Process. 2020, 59, 355–365. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, G.; Sood, P. Modelling and optimization of tool wear in machining of EN24 steel using taguchi approach. J. Inst. Eng. (India): Ser. C 2015, 96, 269–277. [Google Scholar] [CrossRef]

- Gupta, K.; Laubscher, R.F. Sustainable machining of titanium alloys: A critical review. Proc. Inst. Mech. Eng. B J. Eng. Manuf. 2017, 231, 2543–2560. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Li, Z.; Krolczyk, G.M.; Kuntoğlu, M.; Binali, R.; Yaşar, N.; Pimenov, D.Y. Indirect monitoring of machining characteristics via advanced sensor systems: A critical review. Int. J. Adv. Manuf. Technol. 2022, 120, 7043–7078. [Google Scholar] [CrossRef]

- Li, G.; Yi, S.; Li, N.; Pan, W.; Wen, C.; Ding, S. Quantitative analysis of cooling and lubricating effects of graphene oxide nanofluids in machining titanium alloy Ti6Al4V. J. Mater. Process. Technol. 2019, 271, 584–598. [Google Scholar] [CrossRef]

- Guan, J.; Gao, C.; Xu, Z.; Yang, L.; Huang, S. Lubrication Mechanisms of a Nanocutting Fluid with Carbon Nanotubes and Sulfurized Isobutylene (CNTs@ T321) Composites as Additives. Lubricants 2022, 10, 189. [Google Scholar] [CrossRef]

- Emmanuel, O.A.; Kessington, O.O.; Mudiakeoghene, O.-j. Biodegradation of vegetable oils: A review. Sci. Res. Essays 2009, 4, 543–548. [Google Scholar]

- Baldin, V.; da Silva, L.R.R.; Gelamo, R.V.; Iglesias, A.B.; da Silva, R.B.; Khanna, N.; Rocha Machado, A. Influence of graphene nanosheets on Thermo-physical and tribological properties of sustainable cutting fluids for MQL application in machining processes. Lubricants 2022, 10, 193. [Google Scholar] [CrossRef]

- Aslan, A. Optimization and analysis of process parameters for flank wear, cutting forces and vibration in turning of AISI 5140: A comprehensive study. Measurement 2020, 163, 107959. [Google Scholar] [CrossRef]

- Şap, E.; Usca, U.A.; Gupta, M.K.; Kuntoğlu, M. Tool wear and machinability investigations in dry turning of Cu/Mo-SiCp hybrid composites. Int. J. Adv. Manuf. Technol. 2021, 114, 379–396. [Google Scholar] [CrossRef]

- Şap, S.; Uzun, M.; Usca, Ü.A.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Investigation of machinability of Ti–B-SiCp reinforced Cu hybrid composites in dry turning. J. Mater. Res. Technol. 2022, 18, 1474–1487. [Google Scholar] [CrossRef]

- Yildiz, Y.; Nalbant, M. A review of cryogenic cooling in machining processes. Int. J. Mach. Tools Manuf. 2008, 48, 947–964. [Google Scholar] [CrossRef]

- Liu, F.; Su, B.; Zhang, G.; Ren, J.; Zhang, W. Development of a cryogenic tester with air bearing to test sliding-rolling contact friction. Lubricants 2022, 10, 119. [Google Scholar] [CrossRef]

- Available online: https://www.ssab.com/api/sitecore/Datasheet/GetDocument?productId=8D731736F9C84BEF86C6486D4BA75905&language=enSsab (accessed on 1 October 2022).

- Şap, E.; Usca, Ü.A.; Uzun, M. Machining and optimization of reinforced copper composites using different cooling-lubrication conditions. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 399. [Google Scholar] [CrossRef]

- Şap, S.; Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Salur, E.; Pimenov, D.Y. Investigation of the effects of cooling and lubricating strategies on tribological characteristics in machining of hybrid composites. Lubricants 2022, 10, 63. [Google Scholar] [CrossRef]

- Kuntoglu, M. Machining induced tribological investigations in sustainable milling of Hardox 500 steel: A new approach of measurement science. Measurement 2022, 201, 111715. [Google Scholar] [CrossRef]

- Şap, S.; Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Salur, E. Performance evaluation of AlTiN coated carbide tools during machining of ceramic reinforced Cu-based hybrid composites under cryogenic, pure-minimum quantity lubrication and dry regimes. J. Compos. Mater. 2022, 56, 3401–3421. [Google Scholar] [CrossRef]

- Binali, R.; Kuntoğlu, M.; Pimenov, D.Y.; Usca, Ü.A.; Gupta, M.K.; Korkmaz, M.E. Advance monitoring of hole machining operations via intelligent measurement systems: A critical review and future trends. Measurement 2022, 201, 111757. [Google Scholar] [CrossRef]

- Zeng, H.; Yan, R.; Du, P.; Zhang, M.; Peng, F. Notch wear prediction model in high speed milling of AerMet100 steel with bull-nose tool considering the influence of stress concentration. Wear 2018, 408, 228–237. [Google Scholar] [CrossRef]

- Özbek, N.A.; Çiçek, A.; Gülesin, M.; Özbek, O. Investigation of the effects of cryogenic treatment applied at different holding times to cemented carbide inserts on tool wear. Int. J. Mach. Tools Manuf. 2014, 86, 34–43. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Rubaiee, S.; Ahmed, A.; Korkmaz, M.E. Influence of hybrid Cryo-MQL lubri-cooling strategy on the machining and tribological characteristics of Inconel 718. Tribol. Int. 2021, 163, 107178. [Google Scholar] [CrossRef]

- Sharma, V.S.; Dogra, M.; Suri, N. Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. 2009, 49, 435–453. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Uzun, M.; Şap, S.; Giasin, K.; Pimenov, D.Y.; Prakash, C. Determination of machinability metrics of AISI 5140 steel for gear manufacturing using different cooling/lubrication conditions. J. Mater. Res. Technol. 2022, 21, 893–904. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Lozano, J.A.; Carou, D.; Pimenov, D.Y.; Królczyk, G.; Khan, A.M.; Dhar, N.R. Multi-objective optimization and life cycle assessment of eco-friendly cryogenic N2 assisted turning of Ti-6Al-4V. J. Clean. Prod. 2019, 210, 121–133. [Google Scholar] [CrossRef]

- Mamedov, A.; Lazoglu, I. Thermal analysis of micro milling titanium alloy Ti–6Al–4V. J. Mater. Process. Technol. 2016, 229, 659–667. [Google Scholar] [CrossRef]

- Demirsöz, R.; Korkmaz, M.E.; Gupta, M.K. A novel use of hybrid Cryo-MQL system in improving the tribological characteristics of additively manufactured 316 stainless steel against 100 Cr6 alloy. Tribol. Int. 2022, 173, 107613. [Google Scholar] [CrossRef]

- Jang, D.-y.; Jung, J.; Seok, J. Modeling and parameter optimization for cutting energy reduction in MQL milling process. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 5–12. [Google Scholar] [CrossRef]

- Yin, Q.; Li, C.; Dong, L.; Bai, X.; Zhang, Y.; Yang, M.; Jia, D.; Li, R.; Liu, Z. Effects of physicochemical properties of different base oils on friction coefficient and surface roughness in MQL milling AISI 1045. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 1629–1647. [Google Scholar] [CrossRef]

- Wakabayashi, T.; Inasaki, I.; Suda, S.; Yokota, H. Tribological characteristics and cutting performance of lubricant esters for semi-dry machining. CIRP Ann. 2003, 52, 61–64. [Google Scholar] [CrossRef]

- Virdi, R.L.; Chatha, S.S.; Singh, H. Experimental investigations on the tribological and lubrication behaviour of minimum quantity lubrication technique in grinding of Inconel 718 alloy. Tribol. Int. 2021, 153, 106581. [Google Scholar] [CrossRef]

- Mohsan, A.U.; Liu, Z.; Padhy, G. A review on the progress towards improvement in surface integrity of Inconel 718 under high pressure and flood cooling conditions. Int. J. Adv. Manuf. Technol. 2017, 91, 107–125. [Google Scholar] [CrossRef]

- Gajrani, K.K. Assessment of cryo-MQL environment for machining of Ti-6Al-4V. J. Manuf. Process. 2020, 60, 494–502. [Google Scholar] [CrossRef]

- Binali, R.; Patange, A.D.; Kuntoğlu, M.; Mikolajczyk, T.; Salur, E. Energy Saving by Parametric Optimization and Advanced Lubri-Cooling Techniques in the Machining of Composites and Superalloys: A Systematic Review. Energies 2022, 15, 8313. [Google Scholar] [CrossRef]

- Muaz, M.; Choudhury, S.K. Experimental investigations and multi-objective optimization of MQL-assisted milling process for finishing of AISI 4340 steel. Measurement 2019, 138, 557–569. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V. Investigation of hard turning performance of eco-friendly cooling strategies: Cryogenic cooling and nanofluid based MQL. Tribol. Int. 2020, 144, 106127. [Google Scholar] [CrossRef]

- Sivalingam, V.; Zan, Z.; Sun, J.; Selvam, B.; Gupta, M.K.; Jamil, M.; Mia, M. Wear behaviour of whisker-reinforced ceramic tools in the turning of Inconel 718 assisted by an atomized spray of solid lubricants. Tribol. Int. 2020, 148, 106235. [Google Scholar] [CrossRef]

- Salur, E. Understandings the tribological mechanism of Inconel 718 alloy machined under different cooling/lubrication conditions. Tribol. Int. 2022, 174, 107677. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Güllü, A. Taguchi design and response surface methodology based analysis of machining parameters in CNC turning under MQL. J. Clean. Prod. 2014, 65, 604–616. [Google Scholar] [CrossRef]

- Kar, B.C.; Panda, A.; Kumar, R.; Sahoo, A.K.; Mishra, R.R. Research trends in high speed milling of metal alloys: A short review. Mater. Today Proc. 2020, 26, 2657–2662. [Google Scholar] [CrossRef]

- Shokrani, A.; Al-Samarrai, I.; Newman, S.T. Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy. J. Manuf. Process. 2019, 43, 229–243. [Google Scholar] [CrossRef]

- Rahim, E.; Sasahara, H. A study of the effect of palm oil as MQL lubricant on high speed drilling of titanium alloys. Tribol. Int. 2011, 44, 309–317. [Google Scholar] [CrossRef]

- Jamil, M.; He, N.; Zhao, W.; Khan, A.M.; Gupta, M.K.; Meng, L. Tribological behavior of WC-6Co against Ti–6Al–4V alloy under novel cryogenic ethanol-ester oil dry-ice hybrid lubri-cooling. Tribol. Int. 2021, 156, 106812. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Tuan, N.M. Performance investigation of MQL parameters using nano cutting fluids in hard milling. Fluids 2021, 6, 248. [Google Scholar] [CrossRef]

- Qin, S.; Li, Z.; Guo, G.; An, Q.; Chen, M.; Ming, W. Analysis of minimum quantity lubrication (MQL) for different coating tools during turning of TC11 titanium alloy. Materials 2016, 9, 804. [Google Scholar] [CrossRef]

- Manimaran, G.; Venkatasamy, R. Influence of cryogenic cooling on surface grinding of stainless steel 316. Cryogenics 2014, 59, 76–83. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Nieslony, P.; Wojciechowski, S.; Michalski, M.; Legutko, S. The influence of the cooling conditions on the cutting tool wear and the chip formation mechanism. J. Manuf. Process. 2016, 24, 107–115. [Google Scholar] [CrossRef]

- Binali, R.; Coşkun, M.; Neşeli, S. An investigation of power consumption in milling AISI P20 plastic mold steel by finite elements method. Avrupa Bilim Teknol. Derg. 2022, 34, 513–518. [Google Scholar] [CrossRef]

- Bayraktar, S. Dry cutting: A sustainable machining technology. In Sustainable Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 231–257. [Google Scholar]

- Ross, N.S.; Mia, M.; Anwar, S.; Manimaran, G.; Saleh, M.; Ahmad, S. A hybrid approach of cooling lubrication for sustainable and optimized machining of Ni-based industrial alloy. J. Clean. Prod. 2021, 321, 128987. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).