Prediction of Tribological Properties of Alumina-Coated, Silver-Reinforced Copper Nanocomposites Using Long Short-Term Model Combined with Golden Jackal Optimization

Abstract

1. Introduction

2. Experimental Procedure

3. Machine Learning Model

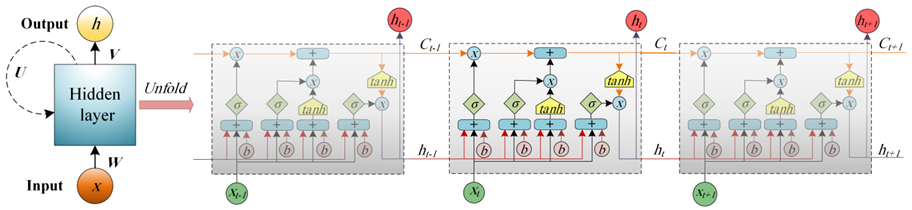

3.1. Long Short-Term Memory Neural Network Model

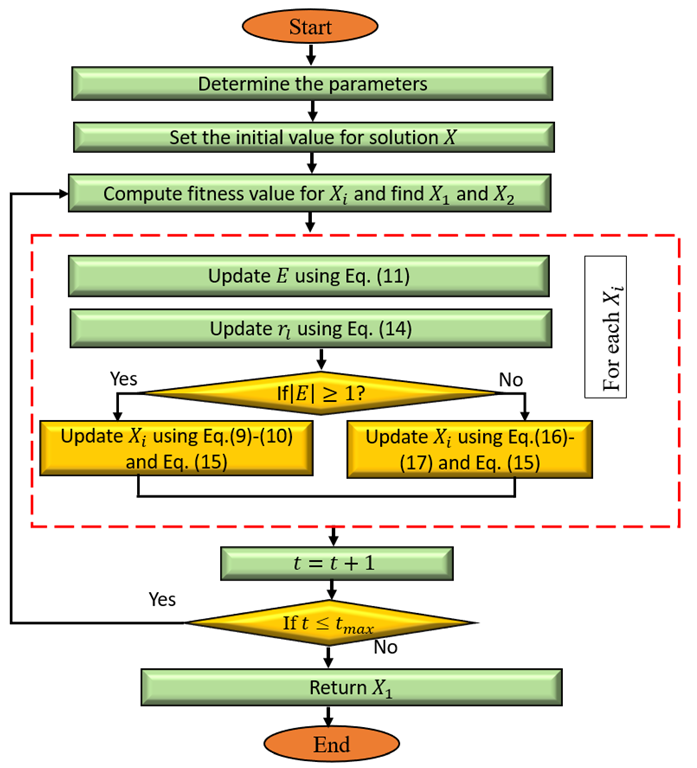

3.2. Golden Jackal Optimization (GJO)

3.2.1. Exploration Stage

3.2.2. Exploitation Stage

3.2.3. Switching from Exploration to Exploitation

3.3. Proposed Model

4. Results and Discussion

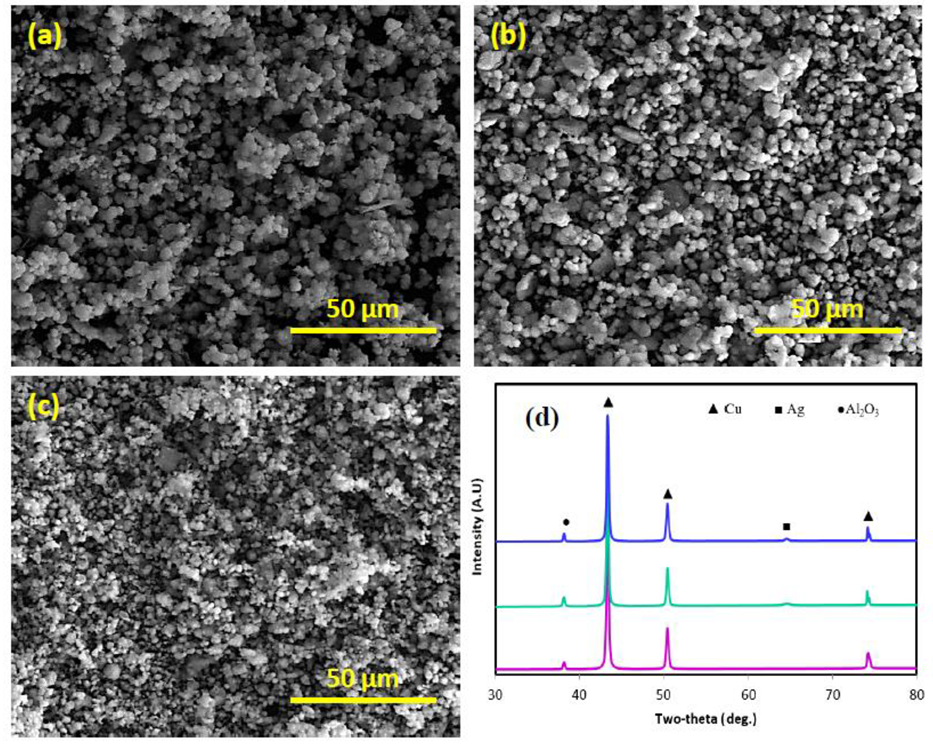

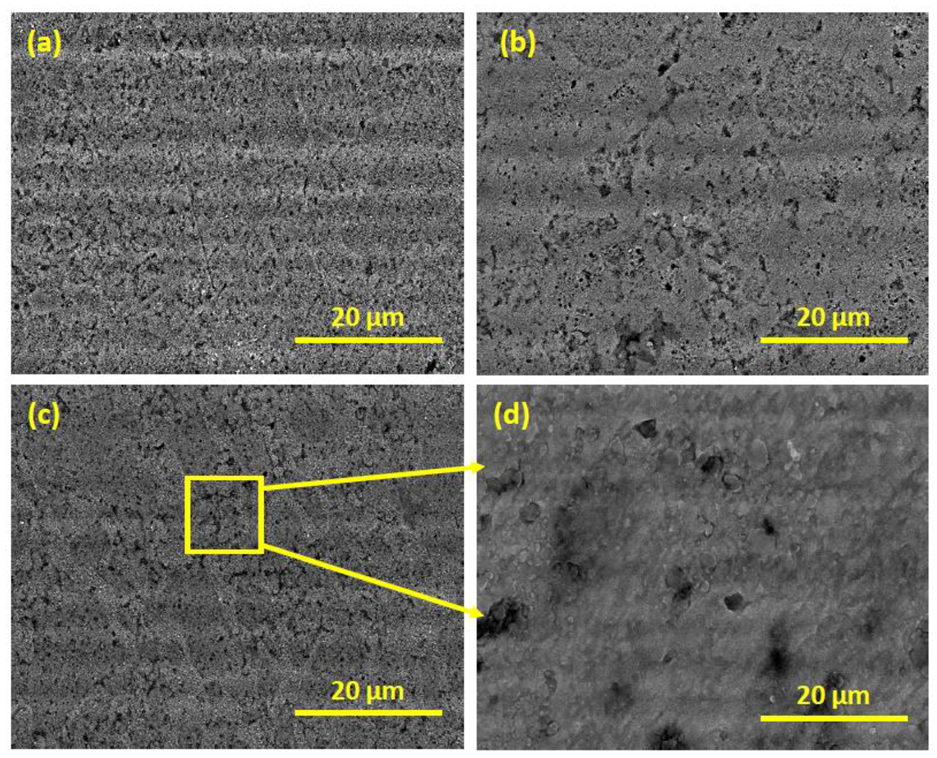

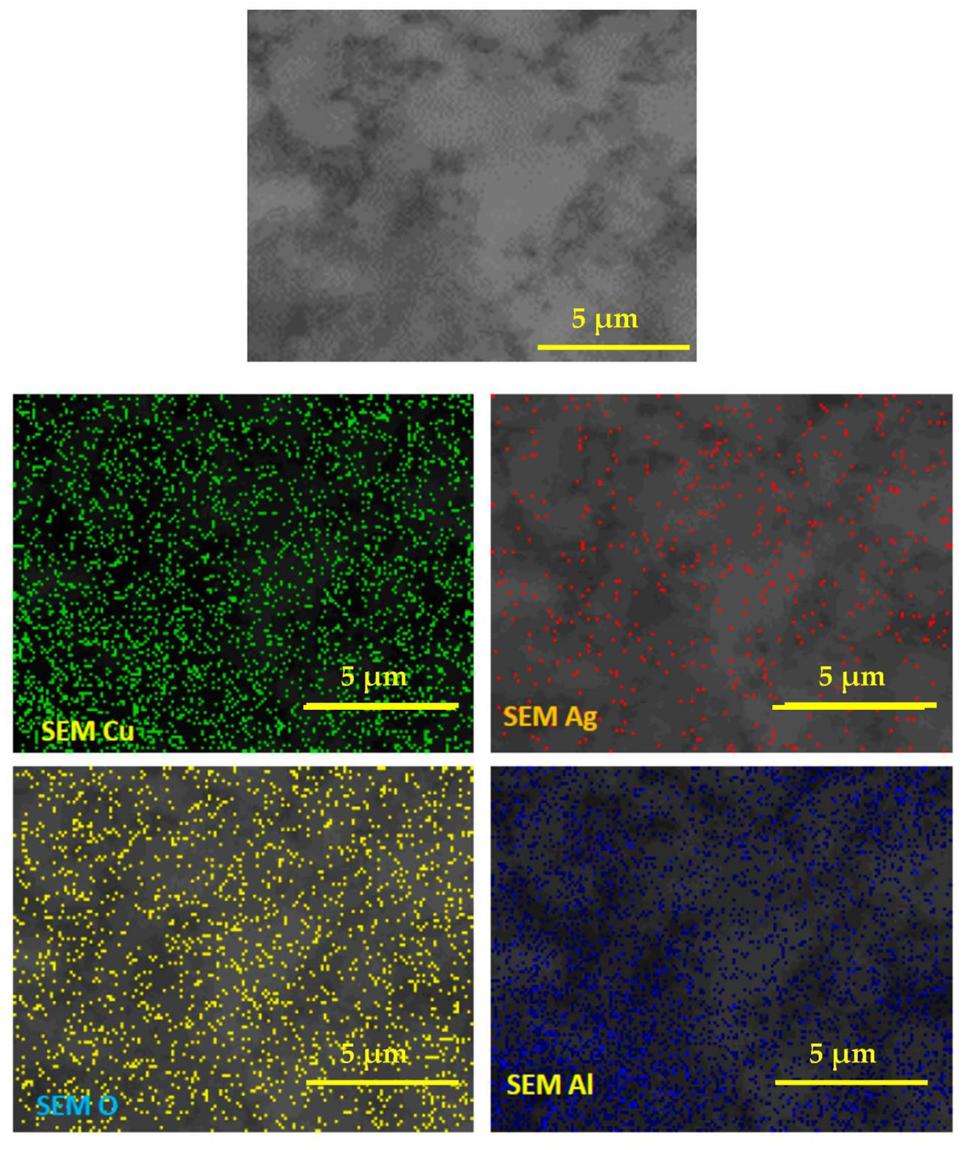

4.1. Microstructural Observations

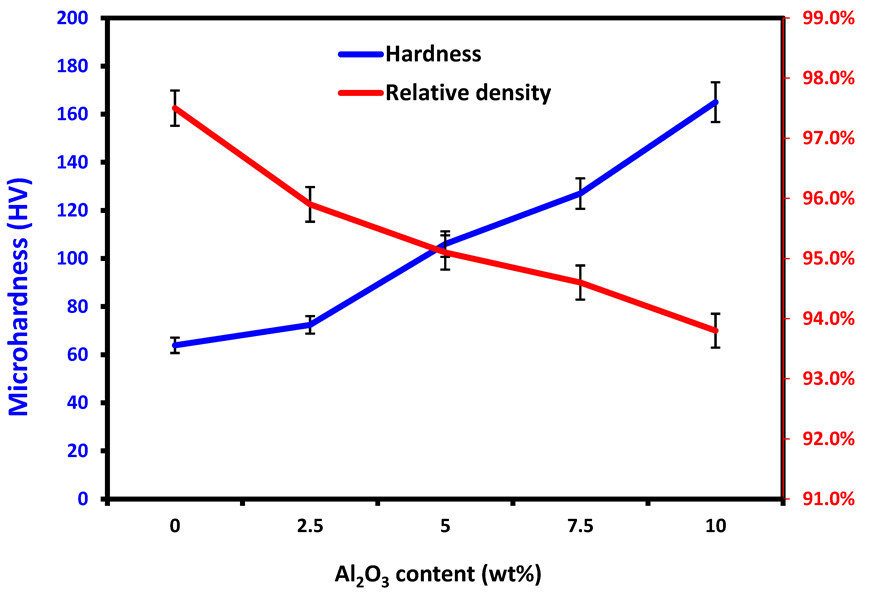

4.2. Microhardness

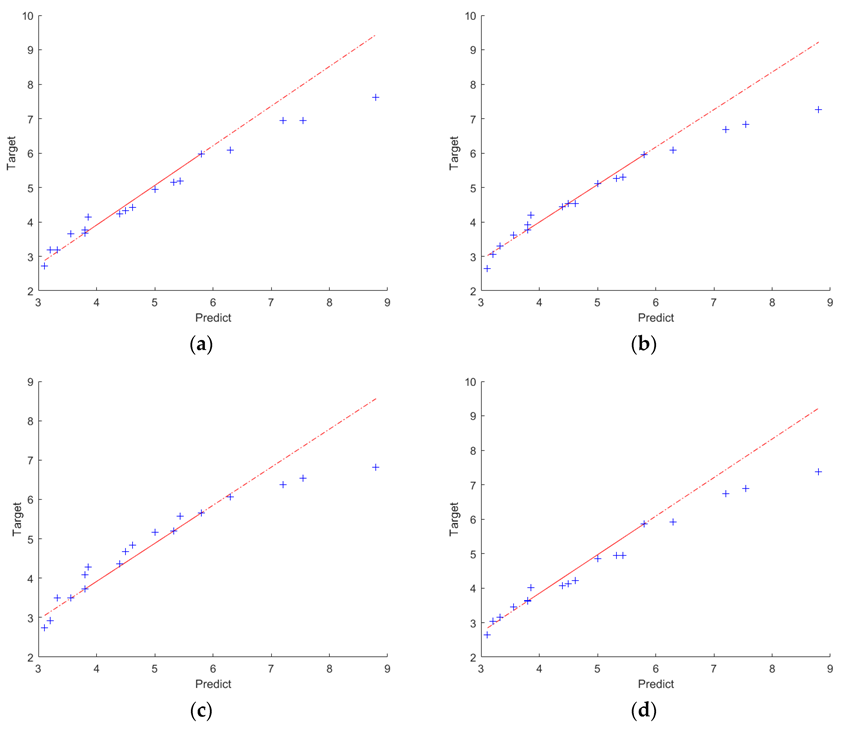

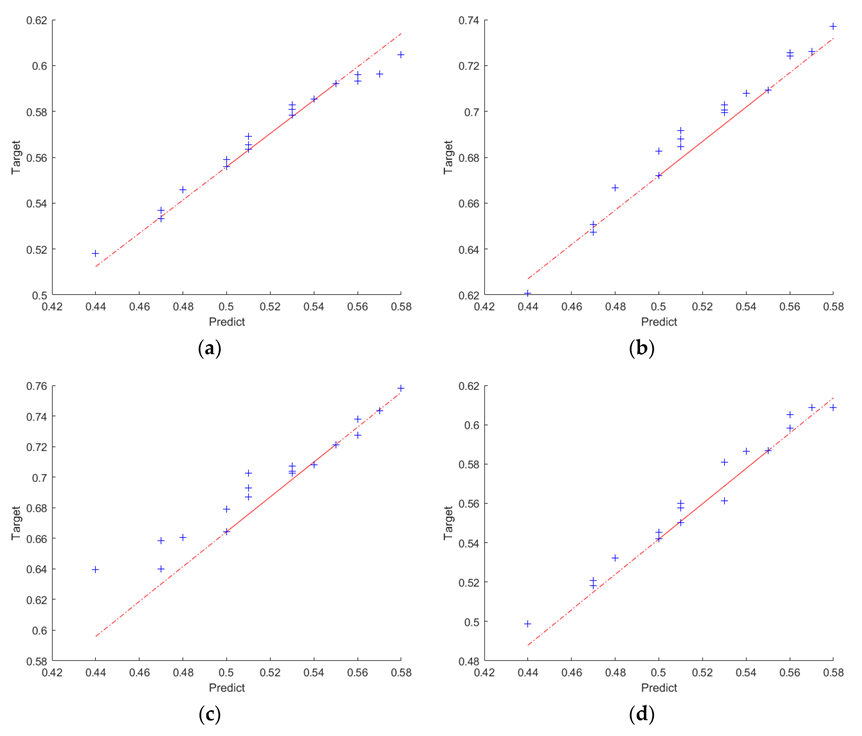

4.3. Tribological Properties

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhan, Y.Z.; Shi, X.B.; Xie, H.F. Microstructural investigation on antifriction characteristics of self-lubricating copper hybrid composite. Mater. Sci. Technol. 2006, 22, 368–374. [Google Scholar] [CrossRef]

- Akbarpour, M.; Alipour, S. Wear and friction properties of spark plasma sintered SiC/Cu nanocomposites. Ceram. Int. 2017, 43, 13364–13370. [Google Scholar] [CrossRef]

- Li, J.; Mayer, J.W. Colgan EG: Oxidation protection in copper copper alloy thin films. J. Appl. Phys. 1991, 70, 2820–2827. [Google Scholar]

- Smirnov, V.M.; Shalunov, E.P.; Golyushov, I.S. Physical and mechanical properties and structure of copper-based composite materials for diamond tools binder. J. Phys. Conf. Ser. 2020, 1431, 012054. [Google Scholar] [CrossRef]

- Nicolicescu, C.; Nicoară, V.H.; Bălulescu, C.S. Synthesis of Cu/Cr and Cu/Cr/W Materials by Powder Metallurgy Techniques. Appl. Mech. Mater. 2018, 880, 241–247. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, Y.; Liu, Y.; Wang, Z. Direct diffusion bonding of immiscible tungsten and copper at temperature close to Copper’s melting point. Mater. Des. 2018, 137, 473–480. [Google Scholar] [CrossRef]

- Sun, X.; Ebrahimi, M.; Attarilar, S. The decisive impact of microstructure on the machinability of pure copper. Arch. Civ. Mech. Eng. 2021, 21, 136. [Google Scholar] [CrossRef]

- Han, S.Z.; Kim, K.H.; Kang, J.; Joh, H.; Kim, S.M.; Ahn, J.H.; Lee, J.; Lim, S.H.; Han, B. Design of exceptionally strong and conductive Cu alloys beyond the conventional spec-ulation via the interfacial energy-controlled dispersion of γ-Al2O3nanoparticles. Sci. Rep. 2015, 5, 17364. [Google Scholar]

- Hussain, M.Z.; Khan, S.; Sarmah, P. Optimization of powder metallurgy processing parameters of Al2O3/Cu composite through Taguchi method with Grey relational analysis. J. King Saud. Univ.-Eng. Sci. 2020, 32, 274. [Google Scholar]

- Güler, O.; Varol, T.; Alver, Ü; Kaya, G.; Yıldız, F. Microstructure and wear characterization of Al2O3 reinforced silver coated copper matrix composites by electroless plating and hot pressing methods. Mater. Today Commun. 2021, 27, 102205. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R. Application of ARB process for manufacturing high-strength, finely dispersed and highly uniform Cu/Al2O3 composite. Mater. Sci. Eng. A 2010, 527, 7430–7435. [Google Scholar] [CrossRef]

- Shehata, F.; Fathy, A.; Abdelhameed, M.; Moustafa, S. Fabrication of copper–alumina nanocomposites by mechano-chemical routes. J. Alloy. Compd. 2009, 476, 300–305. [Google Scholar] [CrossRef]

- Wagih, A.; Fathy, A. Experimental investigation and FE simulation of spherical indentation on nano-alumina reinforced cop-per-matrix composite produced by three different techniques. Adv. Powder Technol. 2017, 28, 1954. [Google Scholar] [CrossRef]

- Shehata, F.; Fathy, A.; Abdelhameed, M.; Moustafa, S. Preparation and properties of Al2O3 nanoparticle reinforced copper matrix composites by in situ processing. Mater. Des. 2009, 30, 2756–2762. [Google Scholar] [CrossRef]

- Fathy, A.; Megahed, A.A. Prediction of abrasive wear rate of in situ Cu–Al2O3 nanocomposite using artificial neural networks. Int. J. Adv. Manuf. Technol. 2012, 62, 953–963. [Google Scholar] [CrossRef]

- Shao, G.; Liu, P.; Zhang, K.; Li, W.; Chen, X.; Ma, F. Mechanical properties of graphene nanoplates reinforced copper matrix composites prepared by electrostatic self-assembly and spark plasma sintering. Mater. Sci. Eng. A 2019, 739, 329–334. [Google Scholar] [CrossRef]

- Sadoun, A.; Fathy, A. Experimental study on tribological properties of Cu–Al2O3 nanocomposite hybridized by graphene nanoplatelets. Ceram. Int. 2019, 45, 24784–24792. [Google Scholar] [CrossRef]

- Wagih, A.; Fathy, A. Improving compressibility and thermal properties of Al–Al2O3 nanocomposites using Mg particles. J. Mater. Sci. 2018, 53, 11393–11402. [Google Scholar] [CrossRef]

- Fathy, A.; Abu-Oqail, A.; Wagih, A. Improved mechanical and wear properties of hybrid Al-Al2O3/GNPs electro-less coated Ni nanocomposite. Ceram. Int. 2018, 44, 22135–22145. [Google Scholar] [CrossRef]

- Wagih, A.; Abu-Oqail, A.; Fath, A.Y. Effect of GNPs content on thermal and mechanical properties of a novel hybrid Cu-Al2O3/GNPs coated Ag nanocomposite. Ceram. Int. 2019, 45, 1115. [Google Scholar] [CrossRef]

- Abu-Oqail, A.; Samir, A.; Essa, A.; Wagih, A.; Fathy, A. Effect of GNPs coated Ag on microstructure and mechanical properties of Cu-Fe dual-matrix nanocomposite. J. Alloy. Compd. 2019, 781, 64–74. [Google Scholar] [CrossRef]

- Fathy, A.; Ibrahim, D.; Elkady, O.; Hassan, M. Evaluation of mechanical properties of 1050-Al reinforced with SiC particles via accumulative roll bonding process. J. Compos. Mater. 2018, 53, 209–218. [Google Scholar] [CrossRef]

- Tjong, S.C.; Lau, K.C. Tribological behavior of SiC particle-reinforced copper matrix composites. Mater. Lett. 2000, 43, 274–280. [Google Scholar] [CrossRef]

- Fathy, A.; Elkady, O.; Abuoqail, A. Synthesis and characterization of Cu–ZrO2 nanocomposite produced by thermochemical process. J. Alloy. Compd. 2017, 719, 411–419. [Google Scholar] [CrossRef]

- Fathy, A.; Wagih, A.; El-Hamid, M.A.; Hassan, A. Effect of mechanical milling on the morphology and structural evaluation of Al-Al2O3 nanocomposite powders. Int. J. Eng.-Trans. A Basics 2013, 27, 625. [Google Scholar]

- Fathy, A.; Elkady, O.; Abu-Oqail, A. Microstructure, mechanical and wear properties of Cu–ZrO2 nanocomposites. Mater. Sci. Technol. 2017, 3, 2138. [Google Scholar] [CrossRef]

- Fathy, A. Investigation on microstructure and properties of Cu-ZrO2 nanocomposites synthesized by in situ processing. Mater. Lett. 2018, 213, 95. [Google Scholar] [CrossRef]

- El-Wazery, M.S.; El-Desouky, A.R.; Hamed, O.A.; Fathy, A.; Mansour, N.A. Electrical and mechanical performance of zirco-nia-nickel functionally graded materials. Int. J. Eng. Trans. A Basics 2013, 26, 375–382. [Google Scholar]

- Chen, X.; Bao, R.; Yi, J.; Fang, D.; Tao, J.; Liu, Y. Enhancing Interfacial Bonding and Tensile Strength in CNT-Cu Composites by a Synergetic Method of Spraying Pyrolysis and Flake Powder Metallurgy. Materials 2019, 12, 670. [Google Scholar] [CrossRef]

- Ghorbani, A.; Sheibani, S.; Ataie, A. Microstructure and mechanical properties of consolidated Cu-Cr-CNT nanocomposite prepared via powder metallurgy. J. Alloy. Compd. 2018, 732, 818–827. [Google Scholar] [CrossRef]

- Güler, O.; Alver, Ü.; Varol, T. Fabrication and characterization of novel layered materials produced by electroless plating and hot pressing. J. Alloy. Compd. 2020, 835, 155278. [Google Scholar] [CrossRef]

- Feng, J.; Liang, S.; Guo, X.; Zhang, Y.; Song, K. Electrical conductivity anisotropy of copper matrix composites reinforced with SiC whiskers. Nanotechnol. Rev. 2019, 8, 285–292. [Google Scholar] [CrossRef]

- Jamwal, A.; Mittal, P.; Agrawal, R.; Gupta, S.; Kumar, D.; Sadasivuni, K.K.; Gupta, P. Towards sustainable copper matrix com-posites: Manufacturing routes with structural, mechanical, electrical and corrosion behaviour. J. Compos. Mater. 2020, 54, 2635–2649. [Google Scholar] [CrossRef]

- Güler, O.; Varol, T.; Alver, Ü.; Biyik, S. The wear and arc erosion behavior of novel copper based functionally graded electrical contact materials fabricated by hot pressing assisted electroless plating. Adv. Powder Technol. 2021, 32, 2873–2890. [Google Scholar] [CrossRef]

- Zhao, Q.; Shao, Z.; Liu, C.; Jiang, M.; Li, X.; Zevenhoven, R.; Saxén, H. Preparation of Cu–Cr alloy powder by mechanical alloying. J. Alloy. Compd. 2014, 607, 118–124. [Google Scholar] [CrossRef]

- Shkodich, N.; Rogachev, A.; Vadchenko, S.; Moskovskikh, D.; Sachkova, N.; Rouvimov, S.; Mukasyan, A. Bulk Cu–Cr nanocomposites by high-energy ball milling and spark plasma sintering. J. Alloy. Compd. 2014, 617, 39–46. [Google Scholar] [CrossRef]

- Patra, S.; Gouthama; Mondal, K. Densification behavior of mechanically milled Cu–8at% Cr alloy and its mechanical and electrical properties. Prog. Nat. Sci. 2014, 24, 608–622. [Google Scholar] [CrossRef]

- Gao, N.; Huttunen-Saarivirta, E.; Tiainen, T.; Hemmilä, M. Influence of prior deformation on the age hardening of a phospho-rus-containing Cu–0.61wt.%Cr alloy, Mater. Sci. Eng. A 2003, 342, 270. [Google Scholar] [CrossRef]

- Yin, Z.; Tao, S.; Zhou, X.; Ding, C. Microstructure and mechanical properties of Al2O3–Al composite coatings deposited by plasma spraying. Appl. Surf. Sci. 2008, 254, 1636–1643. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, Q.; Zhang, M.-X.; Niu, W.-J.; Tang, C.-B.; Wang, K.-S.; Rui, X.; Zhai, L.; Wang, L. The influence of cold and detonation thermal spraying processes on the microstructure and properties of Al-based composite coatings on Mg alloy. Surf. Coat. Technol. 2018, 352, 627–633. [Google Scholar] [CrossRef]

- Wang, Q.; Birbilis, N.; Huang, H.; Zhang, M.-X. Microstructure characterization and nanomechanics of cold-sprayed pure Al and Al-Al2O3 composite coatings. Surf. Coat. Technol. 2013, 232, 216–223. [Google Scholar] [CrossRef]

- Da Silva, F.S.; Bedoya, J.; Dosta, S.; Cinca, N.; Cano, I.G.; Guilemany, J.M.; Benedetti, A.V. Corrosion characteristics of cold gas spray coatings of reinforced aluminum deposited onto carbon steel. Corros. Sci. 2017, 114, 57–71. [Google Scholar] [CrossRef]

- Yu, M.; Suo, X.K.; Li, W.Y.; Wang, Y.Y.; Liao, H.L. Microstructure, mechanical property and wear performance of cold sprayed Al5056/SiCp composite coatings: Effect of reinforcement content. Appl. Surf. Sci. 2014, 289, 188–196. [Google Scholar] [CrossRef]

- Yandouzi, M.; Böttger, A.J.; Hendrikx RW, A.; Brochu, M.; Richer, P.; Charest, A.; Jodoin, B. Microstructure and me-chanical properties of B4C reinforced Al-based matrix composite coatings deposited by CGDS and PGDS processes. Surf. Coat. Technol. 2010, 205, 2234–2246. [Google Scholar] [CrossRef]

- Fathy, A.; Shehata, F.; Abdelhameed, M.; Elmahdy, M. Compressive and wear resistance of nanometric alumina reinforced copper matrix composites. Mater. Des. 2012, 36, 100–107. [Google Scholar] [CrossRef]

- Daoush, W.M.; Lim, B.K.; Mo, C.B.; Nam, D.H.; Hong, S.H. Electrical and mechanical properties of carbon nanotube reinforced copper nanocomposites fabricated by electroless deposition process. Mater. Sci. Eng. A 2009, 513–514, 247–253. [Google Scholar] [CrossRef]

- Sadoun, A.M.; Fathy, A.; Abu-Oqail, A.; Elmetwaly, H.T.; Wagih, A. Structural. mechanical and tribological properties of Cu–ZrO2/GNPs hybrid nanocomposites. Ceram. Int. 2020, 46, 7586–7594. [Google Scholar] [CrossRef]

- Shukla, S.; Seal, S.; Rahaman, Z.; Scammon, K. Electroless copper coating of cenospheres using silver nitrate activator. Mater. Lett. 2002, 57, 151–156. [Google Scholar] [CrossRef]

- Barakat, W.; Wagih, A.; Elkady, O.A.; Abuoqail, A.; Fathy, A.; El-Nikhaily, A. Effect of Al2O3 nanoparticles content and compaction temperature on properties of Al–Al2O3 coated Cu nanocomposites. Compos. Part B Eng. 2019, 175, 107140. [Google Scholar] [CrossRef]

- Khatir, S.; Boutchicha, D.; Le Thanh, C.; Tran-Ngoc, H.; Nguyen, T.; Abdel-Wahab, M. Improved ANN technique combined with Jaya algorithm for crack identification in plates using XIGA and experimental analysis. Theor. Appl. Fract. Mech. 2020, 107, 102554. [Google Scholar] [CrossRef]

- Zenzen, R.; Khatir, S.; Belaidi, I.; Le Thanh, C.; Wahab, M.A. A modified transmissibility indicator and Artificial Neural Network for damage identification and quantification in laminated composite structures. Compos. Struct. 2020, 248, 112497. [Google Scholar] [CrossRef]

- Wang, S.; Wang, H.; Zhou, Y.; Liu, J.; Dai, P.; Du, X.; Wahab, M.A. Automatic laser profile recognition and fast tracking for structured light measurement using deep learning and template matching. Measurement 2021, 169, 108362. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, L.; Mirjalili, S. Artificial hummingbird algorithm: A new bio-inspired optimizer with its engineering applications. Comput. Methods Appl. Mech. Eng. 2021, 388, 114194. [Google Scholar] [CrossRef]

- Hasheminejad, N.; Pipintakos, G.; Vuye, C.; De Kerf, T.; Ghalandari, T.; Blom, J.; Bergh, W.V.D. Utilizing deep learning and advanced image processing techniques to investigate the microstructure of a waxy bitumen. Constr. Build. Mater. 2021, 313, 125481. [Google Scholar] [CrossRef]

- Sadoun, A.; Najjar, I.; Fathy, A.; Elaziz, M.A.; Al-Qaness, M.A.; Abdallah, A.; Elmahdy, M. An enhanced Dendritic Neural Algorithm to predict the wear behavior of alumina coated silver reinforced copper nanocomposites. Alex. Eng. J. 2022. [Google Scholar] [CrossRef]

- Dobbelaere, M.R.; Plehiers, P.P.; Van de Vijver, R.; Stevens, C.V.; Van Geem, K.M. Machine learning in chemical engi-neering: Strengths, weaknesses, opportunities, and threats. Engineering 2021, 7, 1201–1211. [Google Scholar] [CrossRef]

- Zhong, S.; Zhang, K.; Bagheri, M.; Burken, J.G.; Gu, A.; Li, B.; Ma, X.; Marrone, B.L.; Ren, Z.J.; Schrier, J.; et al. Machine learning: New ideas and tools in en-vironmental science and engineering. Environ. Sci. Technol. 2021, 55, 12741–12754. [Google Scholar] [CrossRef]

- Sadoun, A.M.; Najjar, I.R.; Alsoruji, G.S.; Wagih, A.; Elaziz, M.A. Utilizing a Long Short-Term Memory Algorithm Modified by Dwarf Mongoose Optimization to Predict Thermal Expansion of Cu-Al2O3 Nanocomposites. Mathematics 2022, 10, 1050. [Google Scholar] [CrossRef]

- Najjar, I.; Sadoun, A.; Alsoruji, G.S.; Elaziz, M.A.; Wagih, A. Predicting the mechanical properties of Cu–Al2O3 nanocomposites using machine learning and finite element simulation of indentation experiments. Ceram. Int. 2022, 48, 7748–7758. [Google Scholar] [CrossRef]

- Haimed, A.M.A.; Saba, T.; Albasha, A.; Rehman, A.; Kolivand, M. Viral reverse engineering using Artificial Intel-ligence and big data COVID-19 infection with Long Short-term Memory (LSTM). Environ. Technol. Innov. 2021, 22, 101531. [Google Scholar] [CrossRef]

- Xiaoyun, Q.; Xiaoning, K.; Chao, Z.; Shuai, J.; Xiuda, M. Short-term prediction of wind power based on deep long short-term memory. In Proceedings of the 2016 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Xi’an, China, 25–28 October 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1148–1152. [Google Scholar]

- Bilgili, M.; Arslan, N.; Şekertekin, A.; Yaşar, A. Application of long short-term memory (LSTM) neural network based on deeplearning for electricity energy consumption forecasting. Turk. J. Electr. Eng. Comput. Sci. 2022, 30, 140–157. [Google Scholar]

- Liu, W.; Pan, J.; Ren, Y.; Wu, Z.; Wang, J. Coupling prediction model for long-term displacements of arch dams based on long short-term memory network. Struct. Control Health Monit. 2020, 27, e2548. [Google Scholar] [CrossRef]

- Chopra, N.; Ansari, M.M. Golden jackal optimization: A novel nature-inspired optimizer for engineering applications. Expert Syst. Appl. 2022, 198, 116924. [Google Scholar] [CrossRef]

- Dong, L.L.; Ahangarkani, M.; Chen, W.G.; Zhang, Y.S. Recent progress in development of tungsten-copper composites: Fabrication, modification and applications. Int. J. Refract. Met. Hard Mater. 2018, 75, 30–42. [Google Scholar] [CrossRef]

- Santos, T.D.E.D.S.; Regiani, I.; Rocha, R.J.; Rocco, J. Copper/Iron Brake Friction for Military Aircraft Application. J. Aerosp. Technol. Manag. 2018, 10. [Google Scholar] [CrossRef]

- Le, X.H.; Ho, H.V.; Lee, G.; Jung, S. Application of Long Short-Term Memory (LSTM) Neural Network for Flood Forecasting. Water 2019, 11, 1387. [Google Scholar] [CrossRef]

- Wagih, A. Mechanical properties of Al–Mg/Al2O3 nanocomposite powder produced by mechanical alloying. Adv. Powder Technol. 2015, 26, 253–258. [Google Scholar] [CrossRef]

- Khamaj, A.; Farouk, W.M.; Shewakh, W.M.; Abu-Oqail AM, I.; Wagih, A.; Abu-Okail, M. Effect of lattice structure evolution on the thermal and mechanical properties of Cu–Al2O3/GNPs nanocomposites. Ceram. Int. 2021, 47, 16511–16520. [Google Scholar] [CrossRef]

- Sadoun, A.M.; Najjar IM, R.; Wagih, A. Electroless-plating of Ag nanoparticles on Al2O3 and graphene Nano sheets (GNs) for improved wettability and properties of Al–Al2O3/GNs nanocomposites. Ceram. Int. 2021, 47, 10855–10865. [Google Scholar] [CrossRef]

- Sadoun, A.M.; Meselhy, A.F.; Abdallah, A.W. Microstructural, mechanical and wear behavior of electroless assisted silver coated Al2O3–Cu nanocomposites. Mater. Chem. Phys. 2021, 266, 124562. [Google Scholar] [CrossRef]

- Shaat, M.; Fathy, A.; Wagih, A. Correlation between grain boundary evolution and mechanical properties of ul-trafine-grained metals. Mech. Mater. 2020, 143, 103321. [Google Scholar] [CrossRef]

- Abd-Elwahed, M.; Wagih, A.; Najjar, I. Correlation between micro/nano-structure, mechanical and tribological properties of copper-zirconia nanocomposites. Ceram. Int. 2019, 46, 56–65. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Prayogo, D. Symbiotic Organisms Search: A new metaheuristic optimization algorithm. Comput. Struct. 2014, 139, 98–112. [Google Scholar] [CrossRef]

- Ibrahim, R.A.; Abd Elaziz, M.; Lu, S. Chaotic opposition-based grey-wolf optimization algorithm based on differ-ential evolution and disruption operator for global optimization. Expert Syst. Appl. 2018, 108, 1–27. [Google Scholar] [CrossRef]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

| Wear Rates ×10−5 g/m | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load (N) | Sliding Speed 0.4 m/s | 0.8 m/s | 1.2 m/s | ||||||||||||

| 0% | 2.5% | 5% | 7.5% | 10% | 0% | 2.5% | 5% | 7.5% | 10% | 0% | 2.5% | 5% | 7.5% | 10% | |

| 10 | 3.7±0.2 | 3.0±0.1 | 2.6±0.2 | 1.7±0.1 | 1.1±0.2 | 4.3±0.1 | 4.1±0.2 | 3.5±0.1 | 3.0±0.1 | 2.7±0.1 | 4.6±0.2 | 4.4±0.2 | 3.8±0.1 | 3.2±0.2 | 3.1±0.1 |

| 20 | 4.2±0.1 | 3.4±0.2 | 2.8±0.1 | 1.9±0.2 | 1.4±0.1 | 5.8±0.2 | 4.8±0.1 | 4.2±0.2 | 3.6±0.2 | 3.1±0.1 | 5.9±0.2 | 5.0±0.1 | 4.5±0.2 | 3.9±0.1 | 3.3±0.1 |

| 30 | 4.4±0.1 | 3.8±0.1 | 3.0±0.2 | 2.4±0.1 | 1.6±0.2 | 6.5±0.1 | 5.5±0.2 | 5.0±0.1 | 4.2±0.2 | 3.6±0.1 | 7.2±0.2 | 5.8±0.2 | 5.4±0.1 | 4.6±0.1 | 3.5±0.1 |

| 40 | 5.1±0.3 | 4.2±0.2 | 3.2±0.1 | 2.2±0.2 | 1.8±0.1 | 8.0±0.2 | 6.9±0.1 | 6.2±0.2 | 5.4±0.1 | 4.1±0.1 | 8.58±0.3 | 7.5±0.3 | 6.3±0.2 | 5.3±0.1 | 3.8±0.1 |

| Coefficient of Friction | |||||||||||||||

| 10 | 0.81±0.02 | 0.78±0.01 | 0.77±0.02 | 0.74±0.02 | 0.70±0.01 | 0.72±0.01 | 0.70±0.02 | 0.68±0.02 | 0.65±0.02 | 0.63±0.01 | 0.60±0.01 | 0.58±0.01 | 0.56±0.01 | 0.54±0.02 | 0.53±0.02 |

| 20 | 0.78±0.02 | 0.75±0.03 | 0.73±0.02 | 0.71±0.03 | 0.68±0.02 | 0.71±0.01 | 0.69±0.02 | 0.66±0.02 | 0.62±0.01 | 0.61±0.01 | 0.58±0.01 | 0.56±0.02 | 0.53±0.01 | 0.51±0.02 | 0.50±0.01 |

| 30 | 0.76±0.02 | 0.73±0.02 | 0.71±0.02 | 0.66±0.03 | 0.65±0.01 | 0.68±0.02 | 0.67±0.01 | 0.64±0.02 | 0.60±0.01 | 0.58±0.02 | 0.57±0.01 | 0.53±0.02 | 0.51±0.01 | 0.48±0.02 | 0.47±0.01 |

| 40 | 0.74±0.02 | 0.71±0.03 | 0.68±0.02 | 0.63±0.03 | 0.60±0.01 | 0.66±0.02 | 0.64±0.01 | 0.62±0.02 | 0.58±0.01 | 0.56±0.02 | 0.55±0.01 | 0.51±0.01 | 0.50±0.01 | 0.47±0.01 | 0.44±0.01 |

| Wear Rates | Coefficient of Friction | |||||||

|---|---|---|---|---|---|---|---|---|

| GJO | SOS | GWO | SSA | GJO | SOS | GWO | SSA | |

| R2 | 0.9896 | 0.9493 | 0.8827 | 0.8999 | 0.9950 | 0.9915 | 0.9828 | 0.9911 |

| RMSE | 0.0531 | 0.1171 | 0.1782 | 0.1646 | 0.3677 | 0.4814 | 0.6845 | 0.4929 |

| MAE | 0.0509 | 0.1110 | 0.1774 | 0.1603 | 0.2604 | 0.3311 | 0.5248 | 0.3904 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Najjar, I.R.; Sadoun, A.M.; Fathy, A.; Abdallah, A.W.; Elaziz, M.A.; Elmahdy, M. Prediction of Tribological Properties of Alumina-Coated, Silver-Reinforced Copper Nanocomposites Using Long Short-Term Model Combined with Golden Jackal Optimization. Lubricants 2022, 10, 277. https://doi.org/10.3390/lubricants10110277

Najjar IR, Sadoun AM, Fathy A, Abdallah AW, Elaziz MA, Elmahdy M. Prediction of Tribological Properties of Alumina-Coated, Silver-Reinforced Copper Nanocomposites Using Long Short-Term Model Combined with Golden Jackal Optimization. Lubricants. 2022; 10(11):277. https://doi.org/10.3390/lubricants10110277

Chicago/Turabian StyleNajjar, Ismail R., Ayman M. Sadoun, Adel Fathy, Ahmed W. Abdallah, Mohamed Abd Elaziz, and Marwa Elmahdy. 2022. "Prediction of Tribological Properties of Alumina-Coated, Silver-Reinforced Copper Nanocomposites Using Long Short-Term Model Combined with Golden Jackal Optimization" Lubricants 10, no. 11: 277. https://doi.org/10.3390/lubricants10110277

APA StyleNajjar, I. R., Sadoun, A. M., Fathy, A., Abdallah, A. W., Elaziz, M. A., & Elmahdy, M. (2022). Prediction of Tribological Properties of Alumina-Coated, Silver-Reinforced Copper Nanocomposites Using Long Short-Term Model Combined with Golden Jackal Optimization. Lubricants, 10(11), 277. https://doi.org/10.3390/lubricants10110277