Comparative Study of Tribological Properties of Modified and Non-modified Graphene-Oil Nanofluids under Heated and Non-heated Conditions

Abstract

1. Introduction

2. Experimental Works

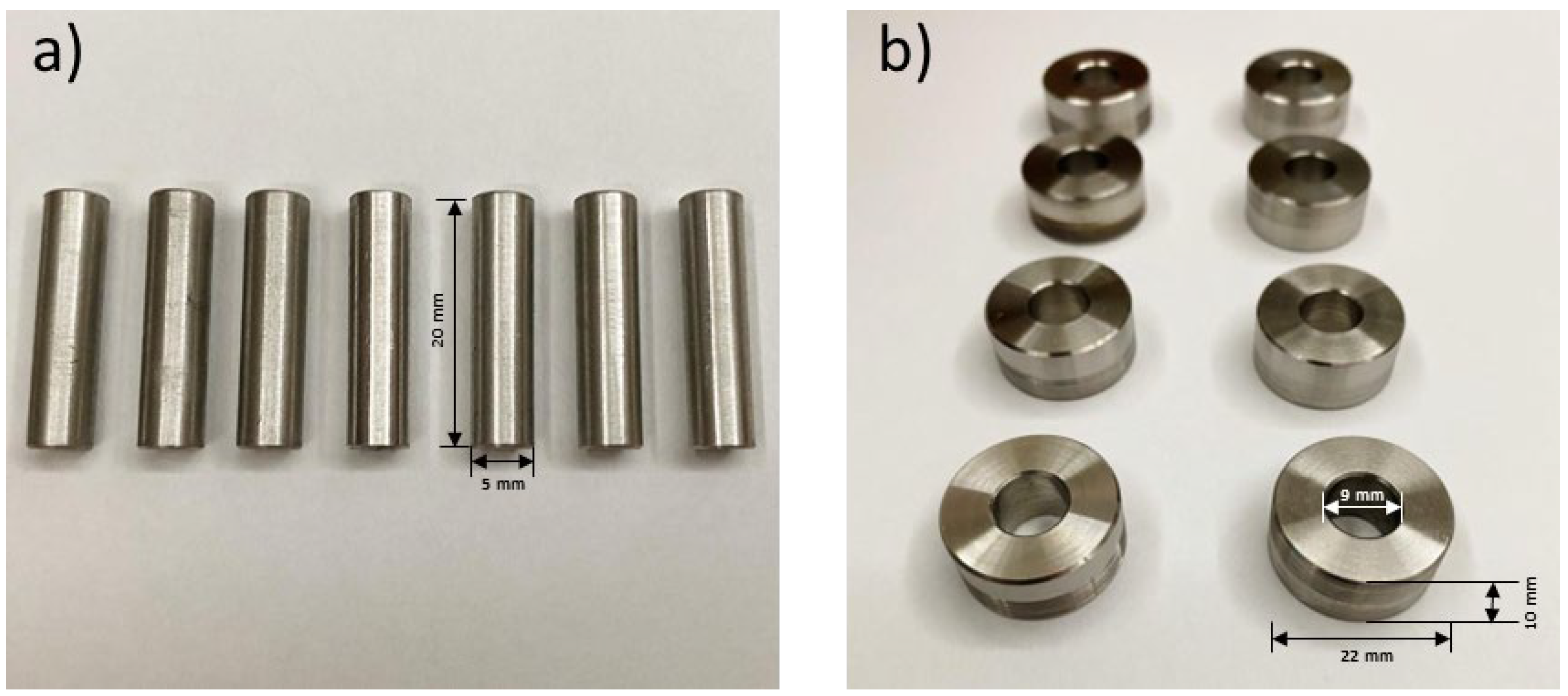

2.1. Tribo Specimens Preparation

2.2. Modified and Non-modified Graphene-Oil Nanofluids Samples Preparation

2.3. Heating of Non-modified Graphene-Oil Nanofluids and Modified Graphene-Oil Nanofluids

2.4. Friction and Wear Test

2.5. Thermophysical Test—Dynamic Viscosity Measurement

3. Results and Discussions

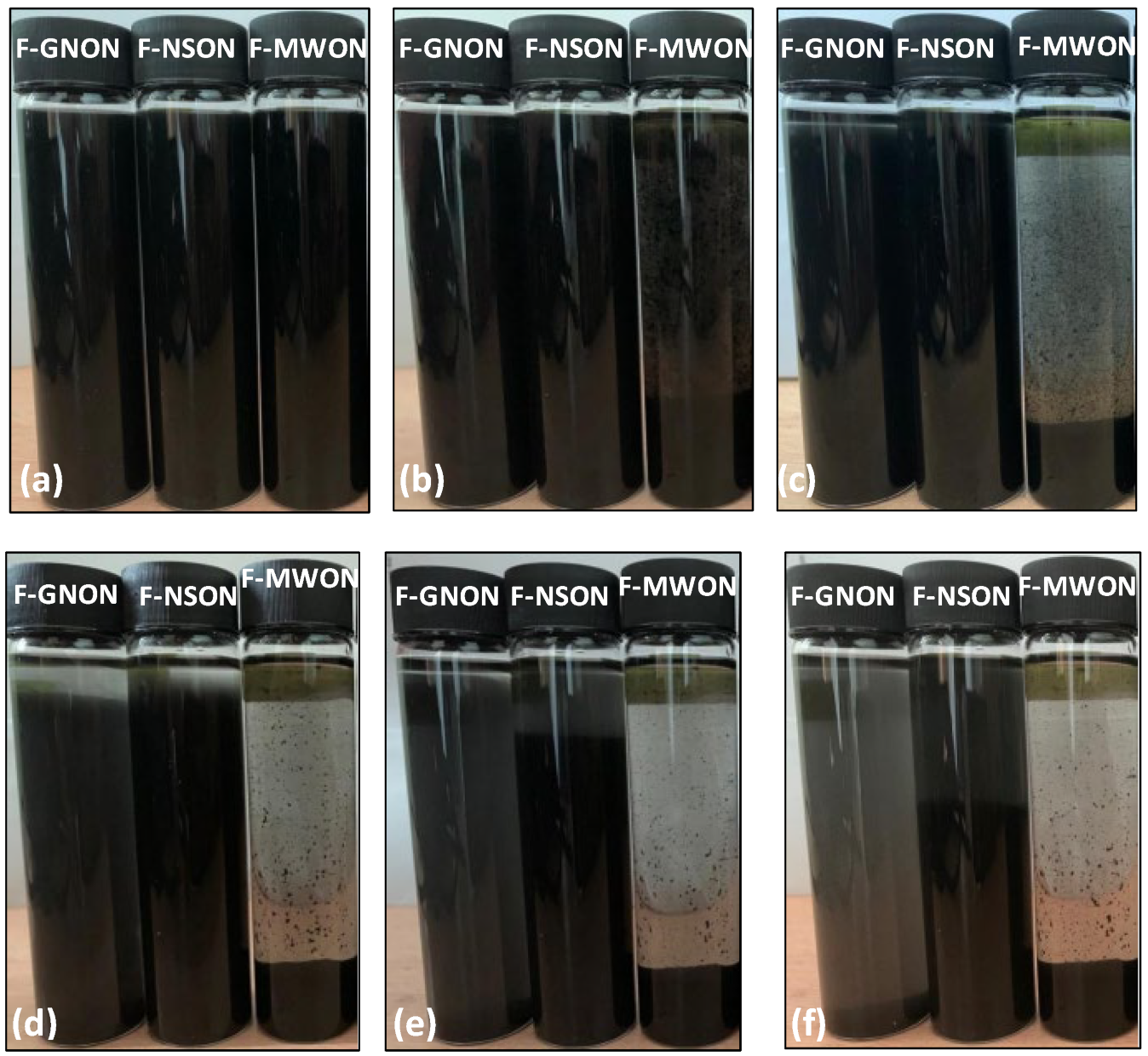

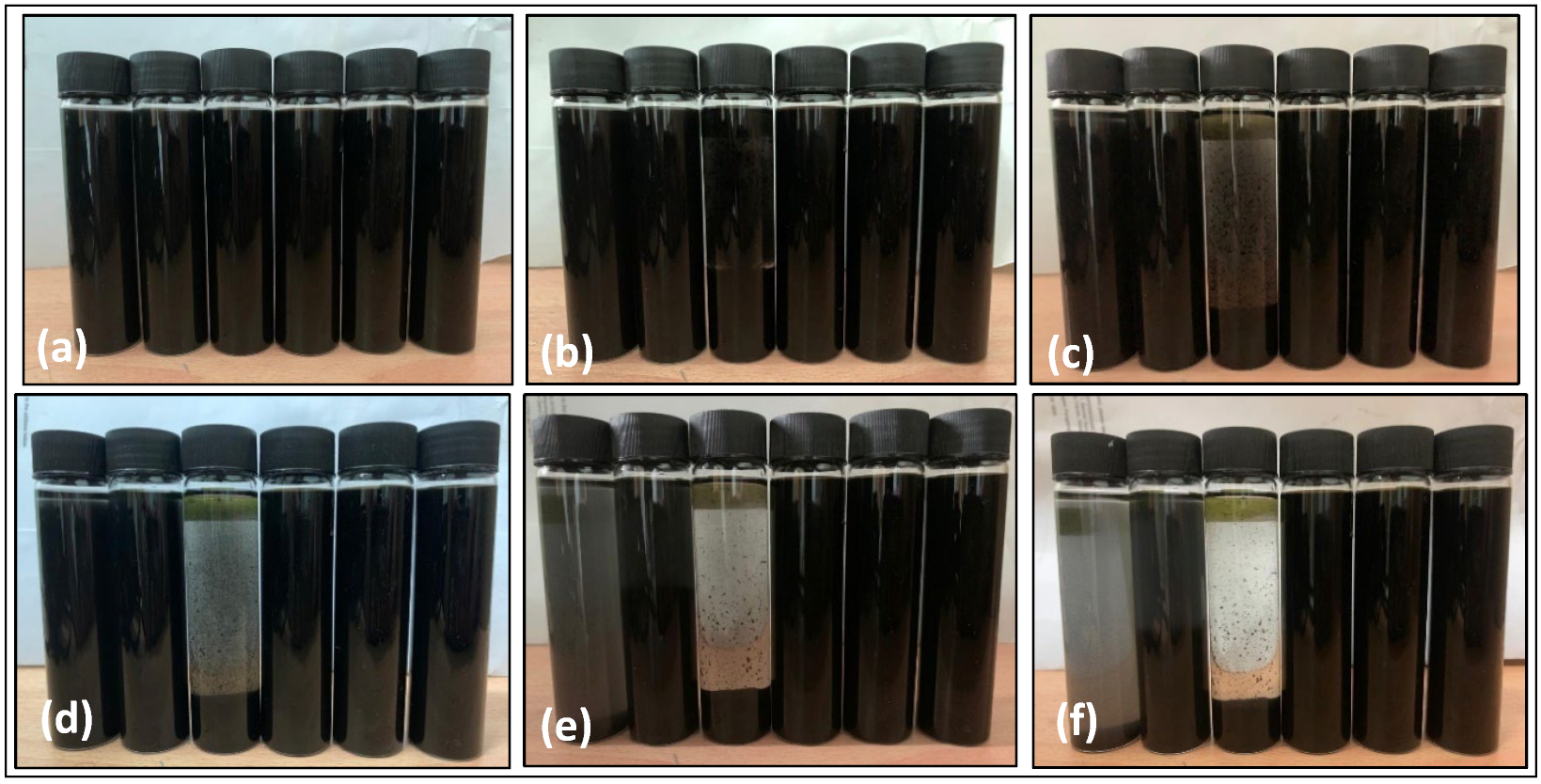

3.1. Dispersion Stability

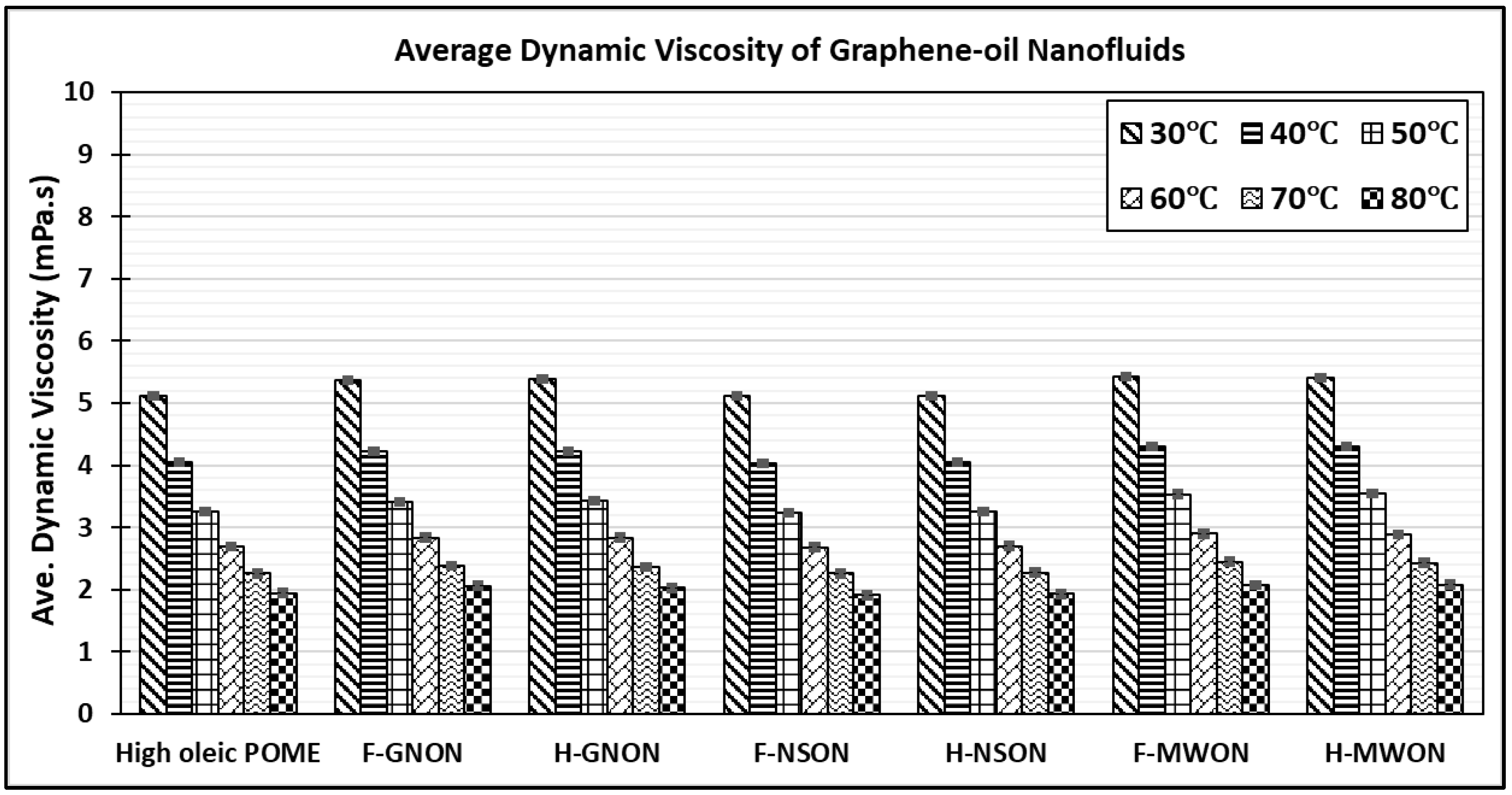

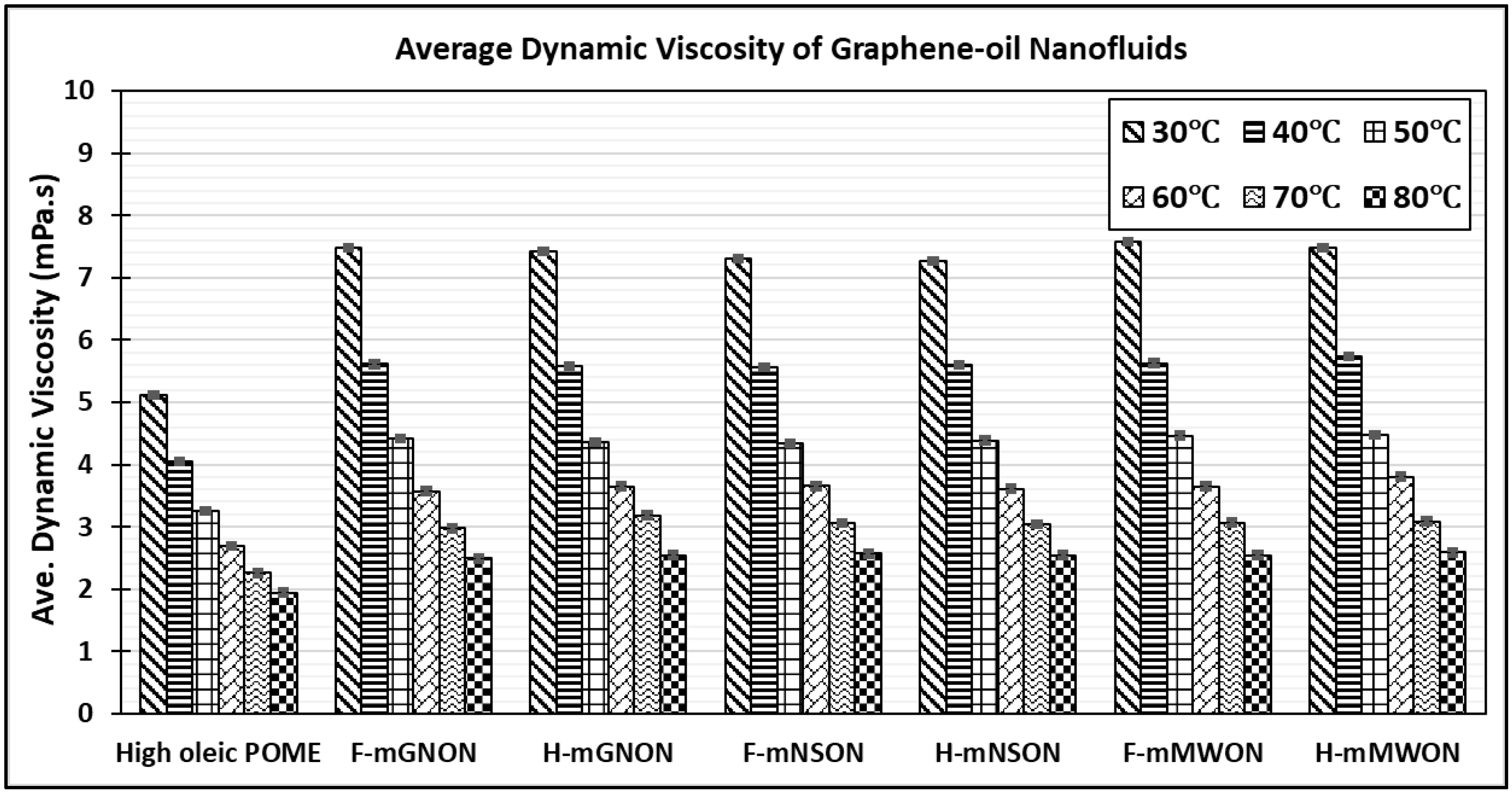

3.2. Dynamic Viscosity

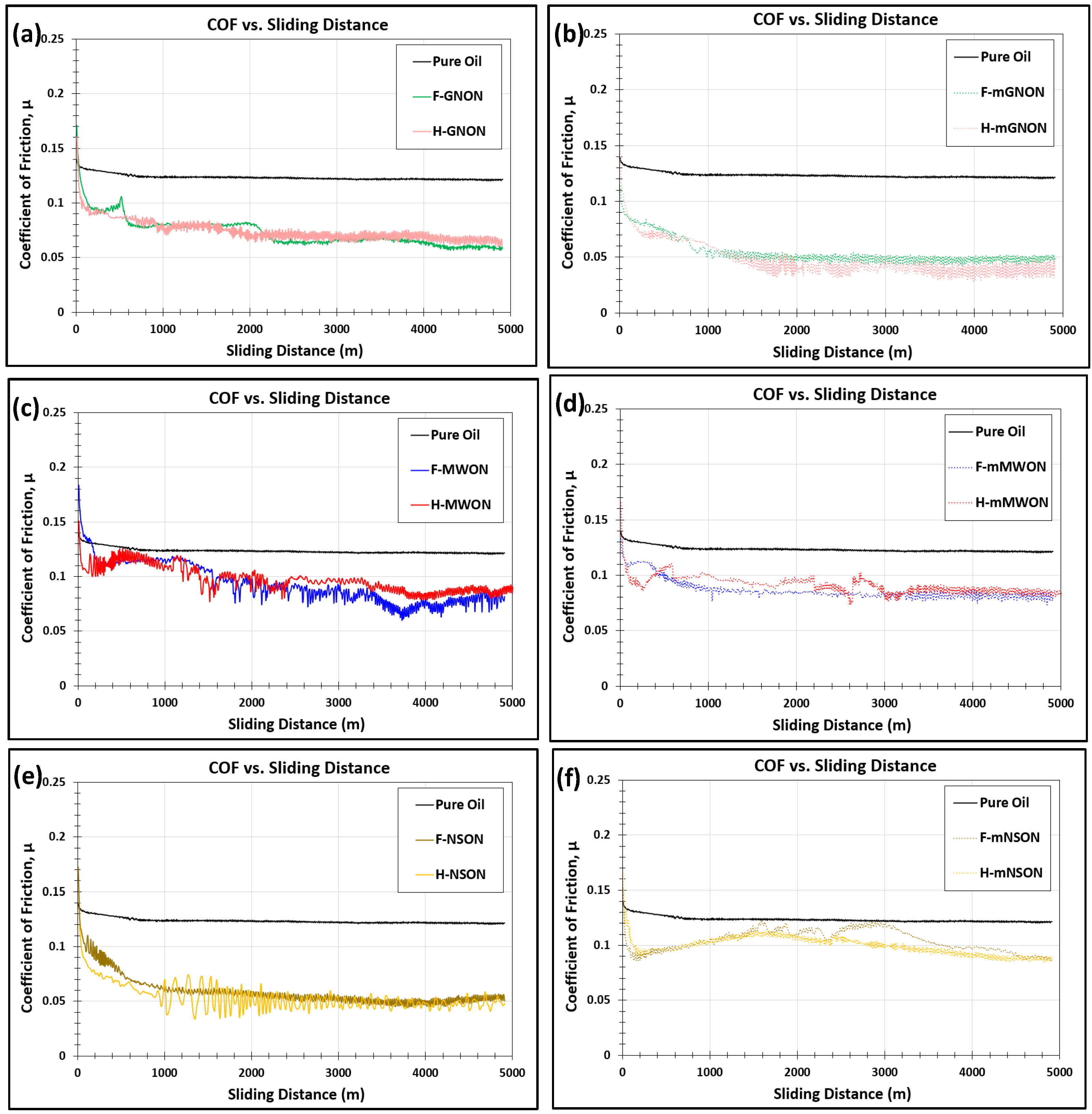

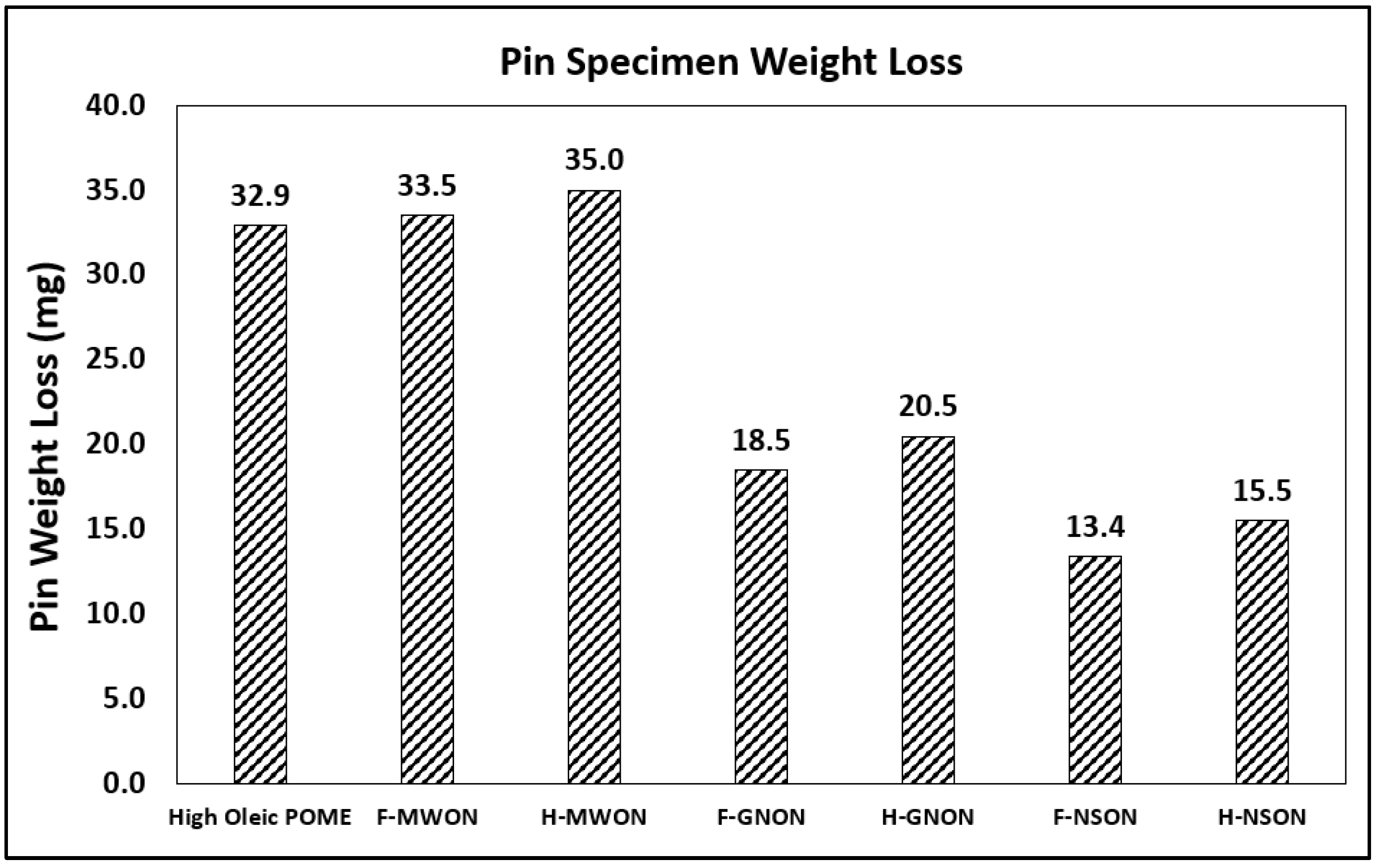

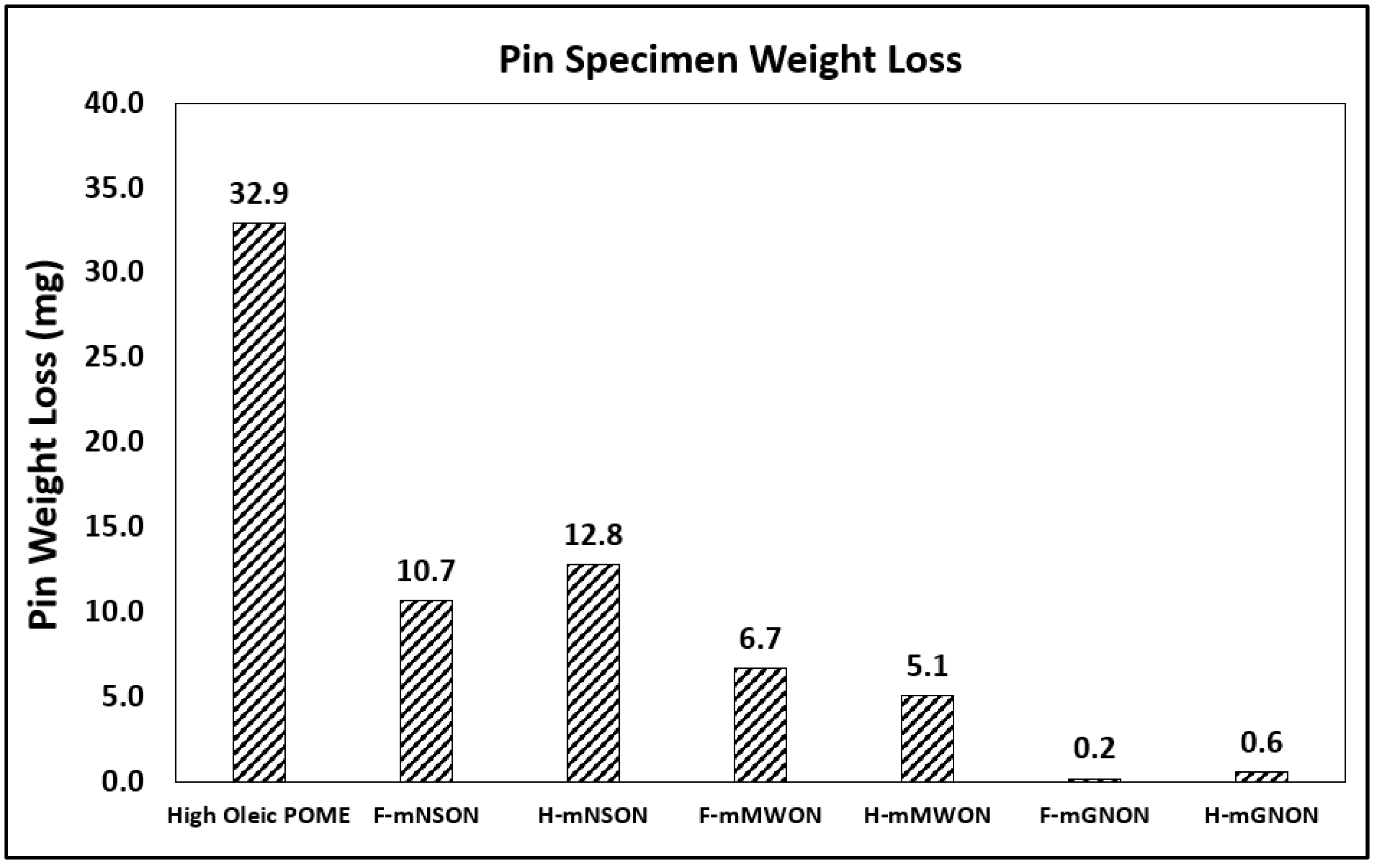

3.3. Friction and Wear Test Results

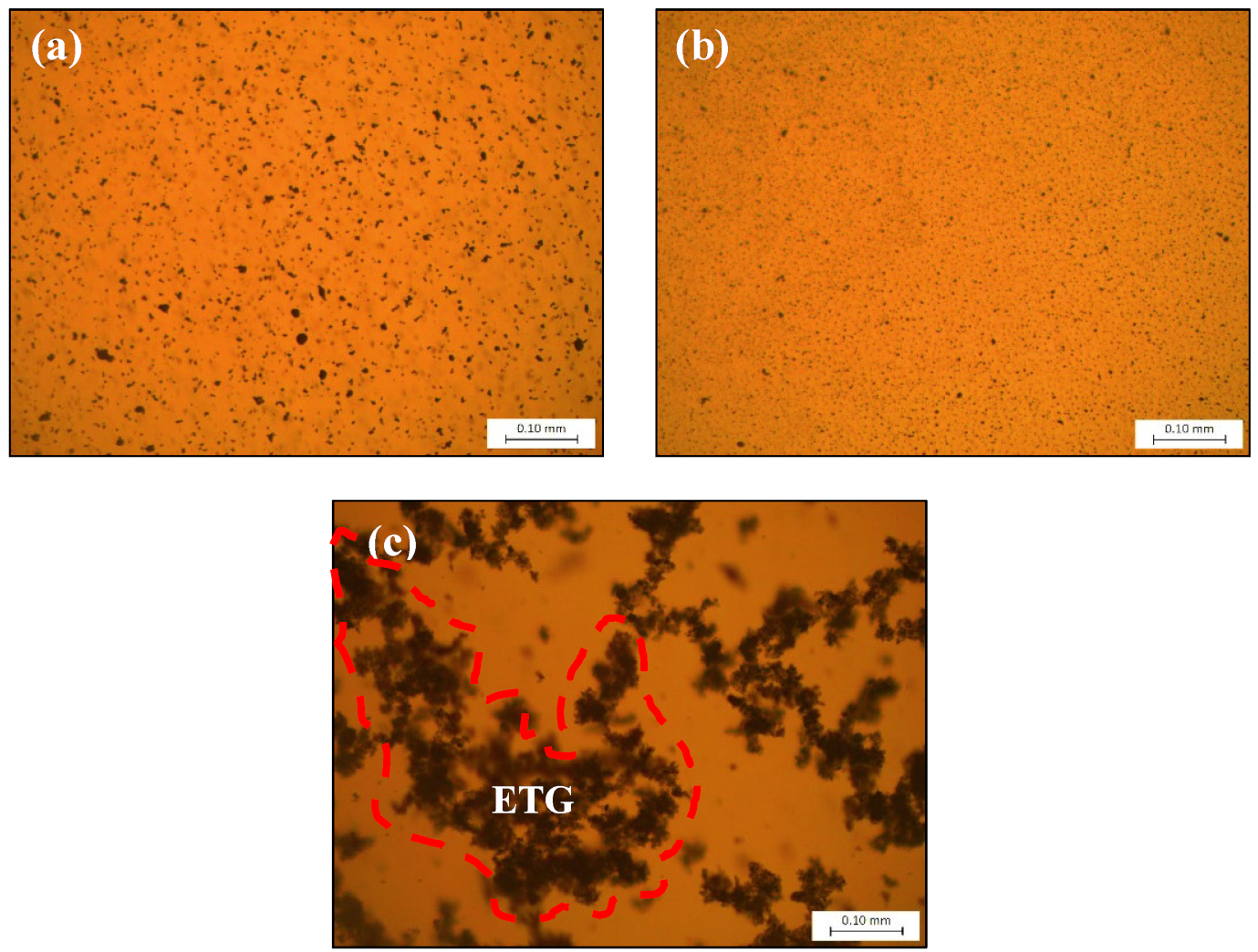

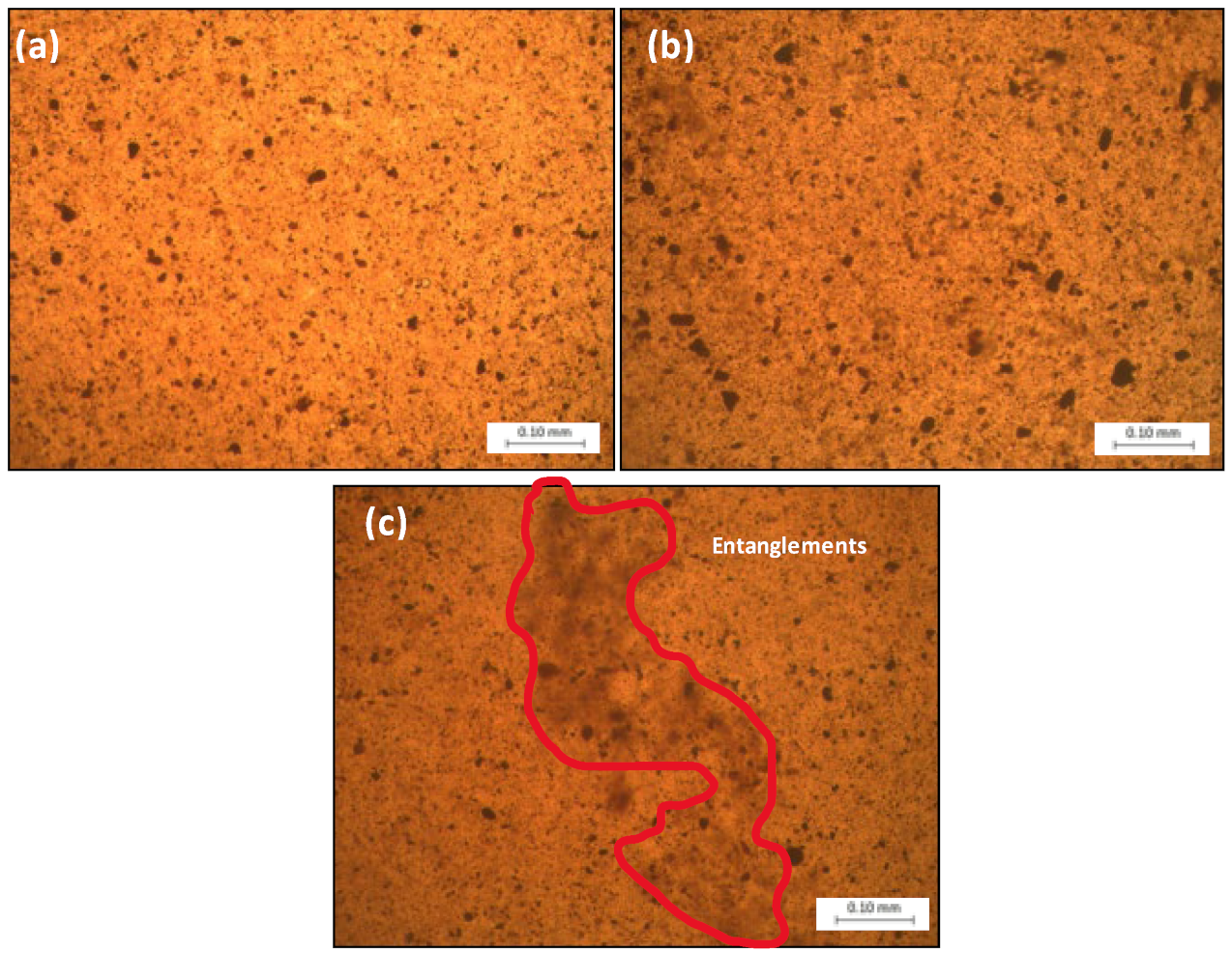

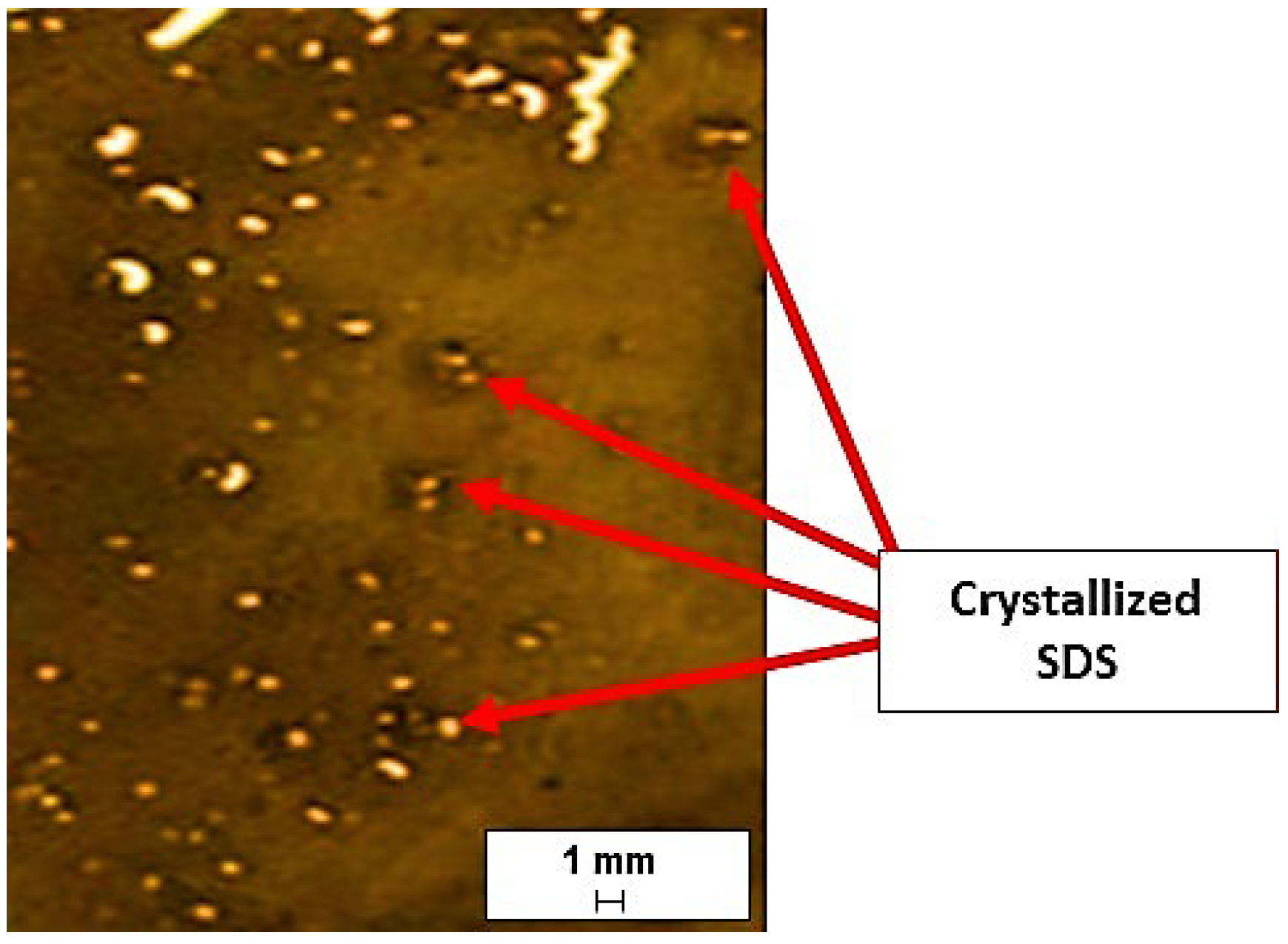

3.4. Pin Worn Surface Micrographs

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cameron, A.; Wood, W.L. The full journal bearing. Proc. Inst. Mech. Eng. 1949, 161, 59–72. [Google Scholar] [CrossRef]

- Ünlü, B.S.; Atik, E. Determination of friction coefficient in journal bearings. Mater. Des. 2007, 28, 973–977. [Google Scholar] [CrossRef]

- Litwin, W. Marine propeller shaft bearings under low-speed conditions: Water vs. oil lubrication. Tribol. Trans. 2019, 62, 839–849. [Google Scholar] [CrossRef]

- de Azevedo, H.D.; Araújo, A.M.; Bouchonneau, N. A review of wind turbine bearing condition monitoring: State of the art and Challenges. Renew. Sustain. Energy Rev. 2016, 56, 368–379. [Google Scholar] [CrossRef]

- Dutta, S. Positive Outlook for Wind-Turbine Lubricants. 2019. Available online: https://www.windpowerengineering.com/positive-outlook-for-wind-turbine-lubricants/ (accessed on 21 August 2022).

- Feng, Y.; Qiu, Y.; Crabtree, C.J.; Long, H.; Tavner, P.J. Monitoring wind turbine gearboxes. Wind Energy 2012, 16, 728–740. [Google Scholar] [CrossRef]

- Hennigan, G.; Page, C. Maximizing Maintenance Dollars In a Post-PTC World. 2018. Available online: https://www.mobil.com/en/industrial/~/media/7EDB938B727C4B59B7BE32EE8DB82053.ashx (accessed on 21 August 2022).

- Moghadam, A.D.; Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene—A review. Compos. Part B Eng. 2015, 77, 402–420. [Google Scholar] [CrossRef]

- Tevrüz, T. Tribological behaviours of carbon filled polytetrafluoroethylene (PTFE) dry journal bearings. Wear 1998, 221, 61–68. [Google Scholar] [CrossRef]

- Kim, S.S.; Park, D.C.; Lee, D.G. Characteristics of carbon fiber phenolic composite for journal bearing materials. Compos. Struct. 2004, 66, 359–366. [Google Scholar] [CrossRef]

- Srivyas, P.D.; Charoo, M.S. Friction and wear reduction by graphene nano platelets for hybrid nano aluminium matrix composite under dry sliding conditions. Metall. Mater. Eng. 2020, 27, 27–47. [Google Scholar] [CrossRef]

- Zhang, G.; Xu, Y.; Xiang, X.; Zheng, G.; Zeng, X.; Li, Z.; Ren, T.; Zhang, Y. Tribological performances of highly dispersed graphene oxide derivatives in vegetable oil. Tribol. Int. 2018, 126, 39–48. [Google Scholar] [CrossRef]

- Song, H.; Wang, Z.; Yang, J. Tribological properties of graphene oxide and carbon spheres as lubricating additives. Appl. Phys. A 2016, 122, 933. [Google Scholar] [CrossRef]

- Senatore, A.; D’Agostino, V.; Petrone, V.; Ciambelli, P.; Sarno, M. Graphene oxide nanosheets as effective friction modifier for oil lubricant: Materials, methods, and tribological results. ISRN Tribol. 2013, 2013, 425809. [Google Scholar] [CrossRef]

- Chengara, A.; Nikolov, A.D.; Wasan, D.T.; Trokhymchuk, A.; Henderson, D. Spreading of nanofluids driven by the structural disjoining pressure gradient. J. Colloid Interface Sci. 2004, 280, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.K.; Dixit, A.R.; Sharma, A.K.; Tiwari, A.K.; Mandal, V.; Pramanik, A. Influence of graphene and multi-walled carbon nanotube additives on tribological behaviour of lubricants. Int. J. Surf. Sci. Eng. 2018, 12, 207–227. [Google Scholar] [CrossRef]

- Fillon, M.; Bouyer, J. Thermohydrodynamic analysis of a worn plain journal bearing. Tribol. Int. 2004, 37, 129–136. [Google Scholar] [CrossRef]

- Yunus, M.; Munshi, S.M. Performance Evaluation of Hydrodynamic Journal Bearing using Gearbox and Engine Oil (SAE90 and SAE20w50) by Experimental and Theoretical Methods. Int. J. Mech. Eng. Inf. Technol. 2015, 3, 1573–1583. [Google Scholar]

- Bao, T.; Wang, Z.; Zhao, Y.; Wang, Y.; Yi, X. Long-term stably dispersed functionalized graphene oxide as an oil additive. RSC Adv. 2019, 9, 39230–39241. [Google Scholar] [CrossRef]

- Lin, J.; Wang, L.; Chen, G. Modification of graphene platelets and their tribological properties as a lubricant additive. Tribol. Lett. 2010, 41, 209–215. [Google Scholar] [CrossRef]

- Soudagar, M.E.; Nik-Ghazali, N.-N.; Kalam, M.A.; Badruddin, I.A.; Banapurmath, N.R.; Khan, T.M.Y.; Bashir, M.N.; Akram, N.; Farade, R.; Afzal, A. The effects of graphene oxide nanoparticle additive stably dispersed in dairy scum oil biodiesel-diesel fuel blend on CI engine: Performance, emission and combustion characteristics. Fuel 2019, 257, 116015–116031. [Google Scholar] [CrossRef]

- Tummala, N.R.; Grady, B.P.; Striolo, A. Lateral confinement effects on the structural properties of surfactant aggregates: SDS on graphene. Phys. Chem. Chem. Phys. 2010, 12, 13137–13143. [Google Scholar] [CrossRef]

- La, D.D.; Truong, T.N.; Pham, T.Q.; Vo, H.T.; Tran, N.T.; Nguyen, T.A.; Nadda, A.K.; Nguyen, T.T.; Chang, S.W.; Chung, W.J.; et al. Scalable fabrication of modified graphene nanoplatelets as an effective additive for engine lubricant oil. Nanomaterials 2020, 10, 877. [Google Scholar] [CrossRef]

- Aleklett, K.; Höök, M.; Jakobsson, K.; Lardelli, M.; Snowden, S.; Söderbergh, B. The peak of the oil age—Analyzing the world oil production reference scenario in World Energy Outlook 2008. Energy Policy 2010, 38, 1398–1414. [Google Scholar] [CrossRef]

- Mobarak, H.M.; Mohamad, E.N.; Masjuki, H.H.; Kalam, M.A.; al Mahmud, K.A.H.; Habibullah, M.; Ashraful, A.M. The prospects of biolubricants as alternatives in automotive applications. Renew. Sustain. Energy Rev. 2014, 33, 34–43. [Google Scholar] [CrossRef]

- Udonne, J.D. A comparative study of recycling of used lubrication oils using distillation, acid and activated charcoal with clay methods. J. Pet. Gas Eng. 2011, 2, 12–19. [Google Scholar]

- Naddaf, A.; Heris, S.Z.; Pouladi, B. An experimental study on heat transfer performance and pressure drop of nanofluids using graphene and multi-walled carbon nanotubes based on diesel oil. Powder Technol. 2019, 352, 369–380. [Google Scholar] [CrossRef]

- McCash, L.B.; Akhtar, S.; Nadeem, S.; Saleem, S. Entropy analysis of the peristaltic flow of hybrid nanofluid inside an elliptic duct with sinusoidally advancing boundaries. Entropy 2021, 23, 732. [Google Scholar] [CrossRef]

- Ali, A.; Saleem, S.; Mumraiz, S.; Saleem, A.; Awais, M.; Marwat, D.N.K. Investigation on tio2–cu/H2O hybrid nanofluid with slip conditions in MHD peristaltic flow of Jeffrey Material. J. Therm. Anal. Calorim. 2020, 143, 1985–1996. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Li, Q.; Lee, C.; Carpick, R.W.; Hone, J. Substrate effect on thickness-dependent friction on graphene. Phys. Status Solidi (B) 2010, 247, 2909–2914. [Google Scholar] [CrossRef]

- Davis, J.R. Alloying: Understanding the Basics; ASM International: Materials Park, OH, USA, 2011. [Google Scholar]

- Meyer, T. Validation of Journal Bearings for Use in Wind Turbine Gearboxes. 2015. Available online: https://www.windsystemsmag.com/educational-opportunities-abound-at-windpower-2015/ (accessed on 21 August 2022).

- Pantazopoulos, G.; Papaefthymiou, S. Failure and fracture analysis of austenitic stainless steel marine propeller shaft. J. Fail. Anal. Prev. 2015, 15, 762–767. [Google Scholar] [CrossRef]

- Lorenzi, S.; Pastore, T.; Bellezze, T.; Fratesi, R. Cathodic protection modelling of a propeller shaft. Corros. Sci. 2016, 108, 36–46. [Google Scholar] [CrossRef]

- Hantoro, R.H.; Utama, I.K.; Sulisetyono, A.S.; Erwandi, E. Validation of lumped mass lateral cantilever shaft vibration simulation on fixed-pitch vertical-axis ocean current turbine. IPTEK J. Technol. Sci. 2010, 21, 1–8. [Google Scholar] [CrossRef][Green Version]

- Kanwal, S.; Ali, N.Z.; Hussain, R.; Shah, F.U.; Akhter, Z. Poly-thiourea formaldehyde based anticorrosion marine coatings on type 304 stainless steel. J. Mater. Res. Technol. 2020, 9, 2146–2153. [Google Scholar] [CrossRef]

- Jayadas, N.H.; Nair, K.P. Coconut oil as base oil for industrial lubricants—evaluation and modification of thermal, oxidative and low temperature properties. Tribol. Int. 2006, 39, 873–878. [Google Scholar] [CrossRef]

- Bhushan, B. Introduction to Tribology; Wiley: New York, OH, USA, 2013. [Google Scholar]

- Ng, K.P.; Liew, K.W.; Lim, E. Role of eco-friendly bio-based graphene-oil nanofluids on friction reduction for wind turbine application. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Sapporo, Japan, 26–28 August 2021; p. 012012. [Google Scholar]

- Krisnangkura, K.; Yimsuwan, T.; Pairintra, R. An empirical approach in predicting biodiesel viscosity at various temperatures. Fuel 2006, 85, 107–113. [Google Scholar] [CrossRef]

- Konijn, B.J.; Sanderink, O.B.J.; Kruyt, N.P. Experimental study of the viscosity of suspensions: Effect of solid fraction, particle size and suspending liquid. Powder Technol. 2014, 266, 61–69. [Google Scholar] [CrossRef]

- Zhang, L.; Pu, J.; Wang, L.; Xue, Q. Frictional dependence of graphene and carbon nanotube in diamond-like carbon/ionic liquids hybrid films in vacuum. Carbon 2014, 80, 734–745. [Google Scholar] [CrossRef]

- Fang, Y.; Ma, L.; Luo, J. Modelling for water-based liquid lubrication with ultra-low friction coefficient in rough surface point contact. Tribol. Int. 2020, 141, 105901–105908. [Google Scholar] [CrossRef]

- Ferrer, P.R.; Mace, A.; Thomas, S.N.; Jeon, J.-W. Nanostructured porous graphene and its composites for energy storage applications. Nano Converg. 2017, 4, 29. [Google Scholar] [CrossRef]

- Carrales-Alvarado, D.H.; Rodríguez-Ramos, I.; Leyva-Ramos, R.; Mendoza-Mendoza, E.; Villela-Martínez, D.E. Effect of surface area and physical–chemical properties of graphite and graphene-based materials on their adsorption capacity towards metronidazole and trimethoprim antibiotics in aqueous solution. Chem. Eng. J. 2020, 402, 126155. [Google Scholar] [CrossRef]

- Abdelbary, A. Sliding mechanics of polymers. In Wear of Polymers and Composites; Woodhead Publishing: Thorston, UK, 2014; pp. 37–66. [Google Scholar]

- Halim, T.; Burgett, M.; Donaldson, T.K.; Savisaar, C.; Bowsher, J.; Clarke, I.C. Profiling the third-body wear damage produced in cocr surfaces by bone cement, COCR, and ti6al4v debris: A 10-cycle metal-on-metal simulator test. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2014, 228, 703–713. [Google Scholar] [CrossRef] [PubMed]

- Rasheed, A.K.; Khalid, M.; Rashmi, W.; Gupta, T.C.S.M.; Chan, A. Graphene based nanofluids and nanolubricants—Review of recent developments. Renew. Sustain. Energy Rev. 2016, 63, 346–362. [Google Scholar] [CrossRef]

- Tjong, S.C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets. Mater. Sci. Eng. R Rep. 2013, 74, 281–350. [Google Scholar] [CrossRef]

| Element | Compositions (wt%) |

|---|---|

| Si | 0.10 |

| Fe | 0.16 |

| Cu | 0.02 |

| Mn | 0.57 |

| Mg | 4.15 |

| Cr | 0.11 |

| Zn | 0.02 |

| Al | 94.87 |

| Mechanical Properties | |

| Tensile Strength | 277 MPa |

| Yield Strength | 130 MPa |

| Elongation Rate | 13% |

| Element | Compositions (wt%) |

|---|---|

| C | 0.018 |

| Mn | 1.58 |

| Si | 0.28 |

| S | 0.025 |

| P | 0.035 |

| Cr | 18.14 |

| Ni | 8.07 |

| Cu | 0.61 |

| Mo | 0.31 |

| Co | 0.18 |

| N | 0.085 |

| Fe | 70.067 |

| Mechanical Properties | |

| Tensile Strength | 622 MPa |

| Yield Strength | 584 MPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ng, K.P.; Liew, K.W.; Lim, E. Comparative Study of Tribological Properties of Modified and Non-modified Graphene-Oil Nanofluids under Heated and Non-heated Conditions. Lubricants 2022, 10, 288. https://doi.org/10.3390/lubricants10110288

Ng KP, Liew KW, Lim E. Comparative Study of Tribological Properties of Modified and Non-modified Graphene-Oil Nanofluids under Heated and Non-heated Conditions. Lubricants. 2022; 10(11):288. https://doi.org/10.3390/lubricants10110288

Chicago/Turabian StyleNg, Kean Pin, Kia Wai Liew, and Elaine Lim. 2022. "Comparative Study of Tribological Properties of Modified and Non-modified Graphene-Oil Nanofluids under Heated and Non-heated Conditions" Lubricants 10, no. 11: 288. https://doi.org/10.3390/lubricants10110288

APA StyleNg, K. P., Liew, K. W., & Lim, E. (2022). Comparative Study of Tribological Properties of Modified and Non-modified Graphene-Oil Nanofluids under Heated and Non-heated Conditions. Lubricants, 10(11), 288. https://doi.org/10.3390/lubricants10110288