Microstructure and Wear Resistance of FeCuNiTiAl High-Entropy Alloy Coating on Ti6Al4V Substrate Fabricated by Laser Metal Deposition

Abstract

1. Introduction

2. Experimental

2.1. Material and LMD Process

2.2. Materials Characterization

2.3. Microhardness and Wear Tests

3. Results and Discussion

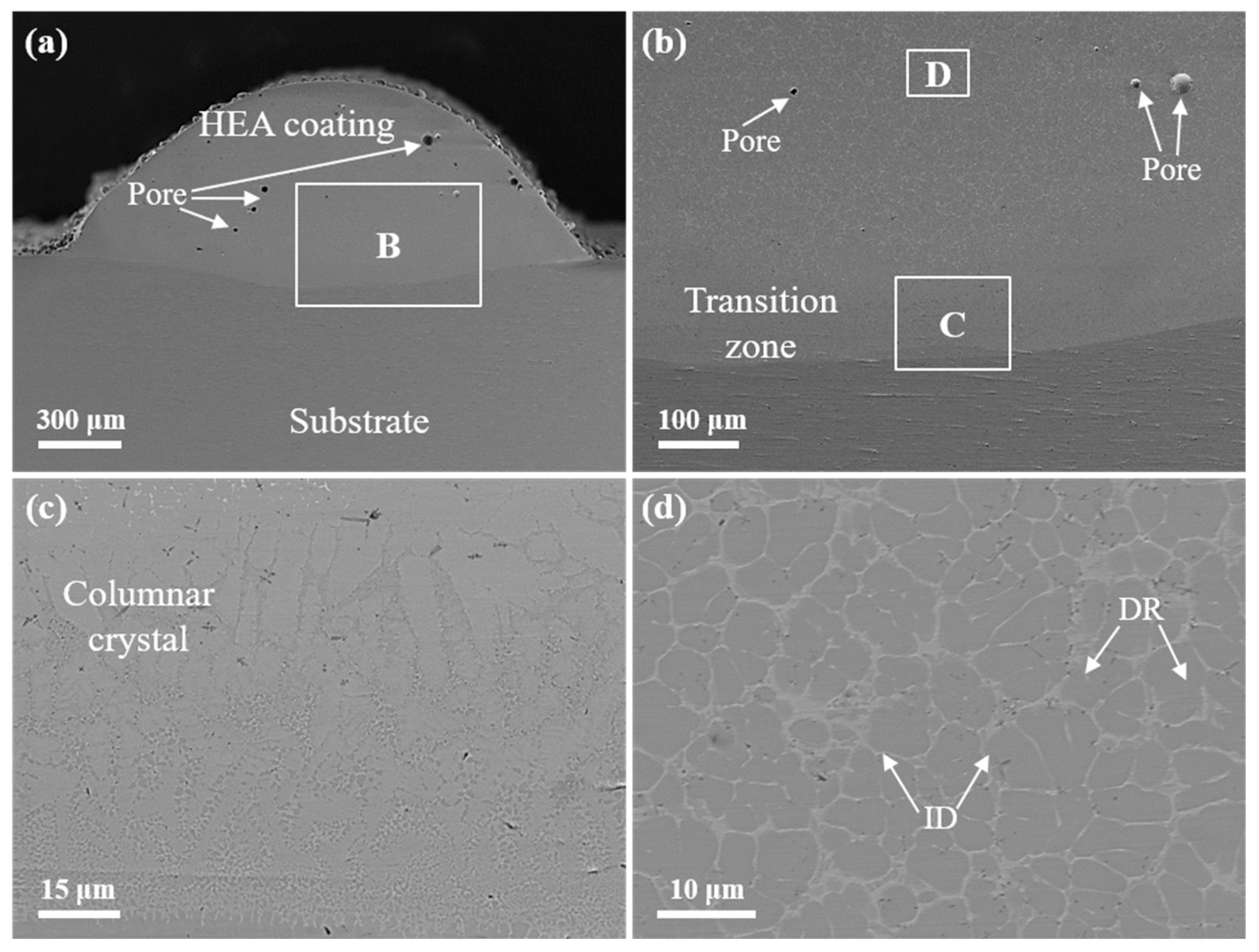

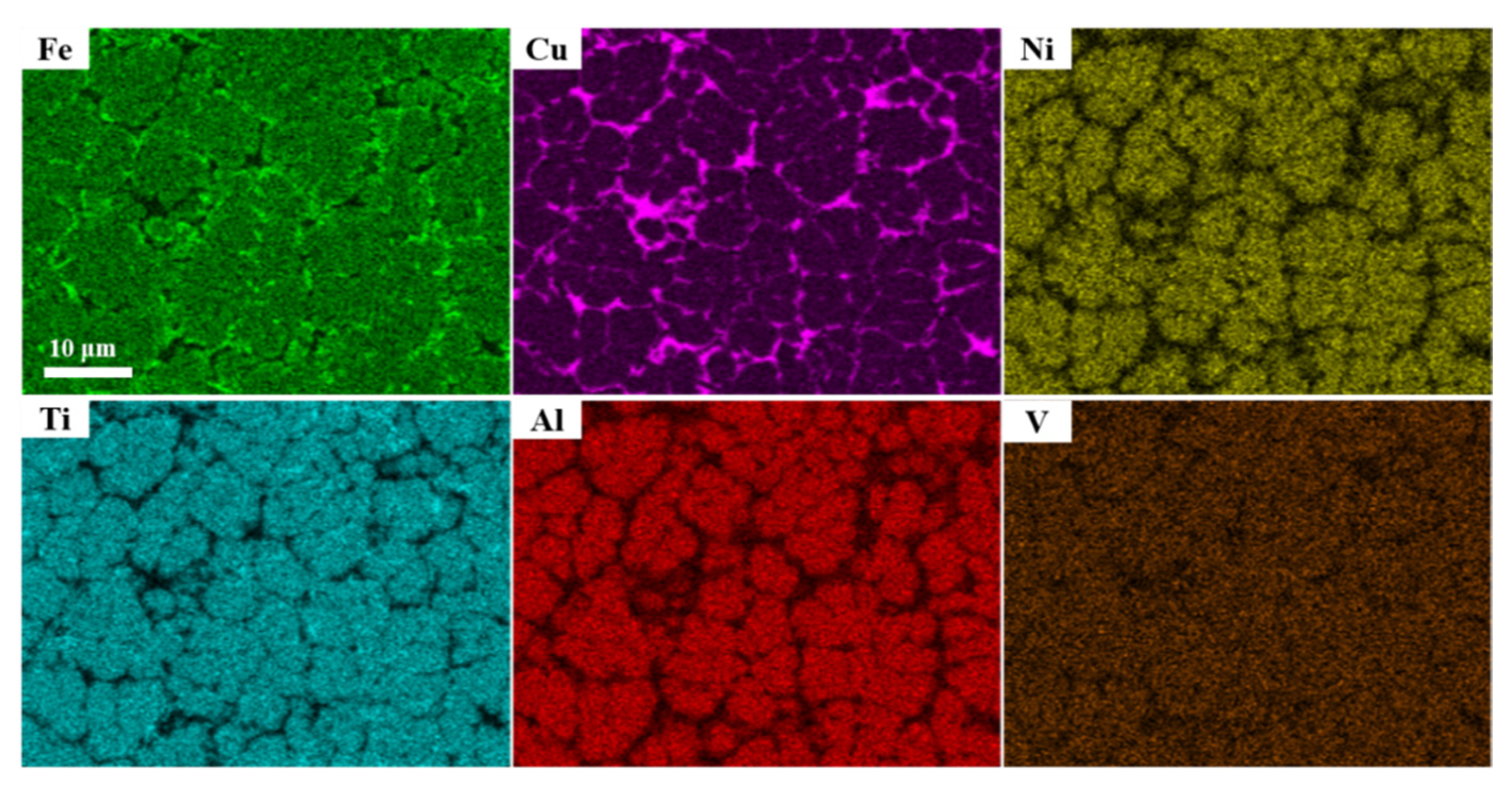

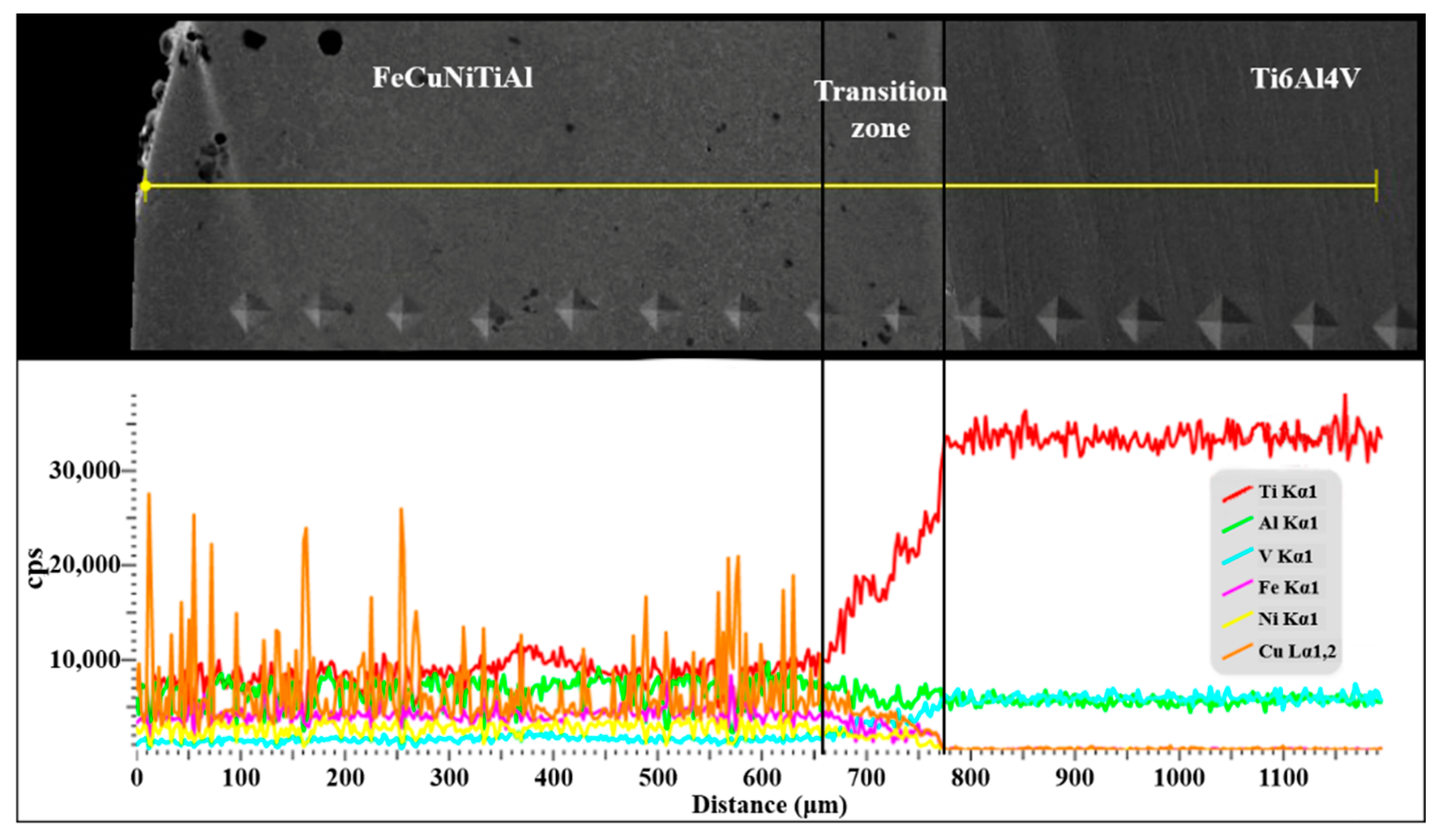

3.1. Microstructure

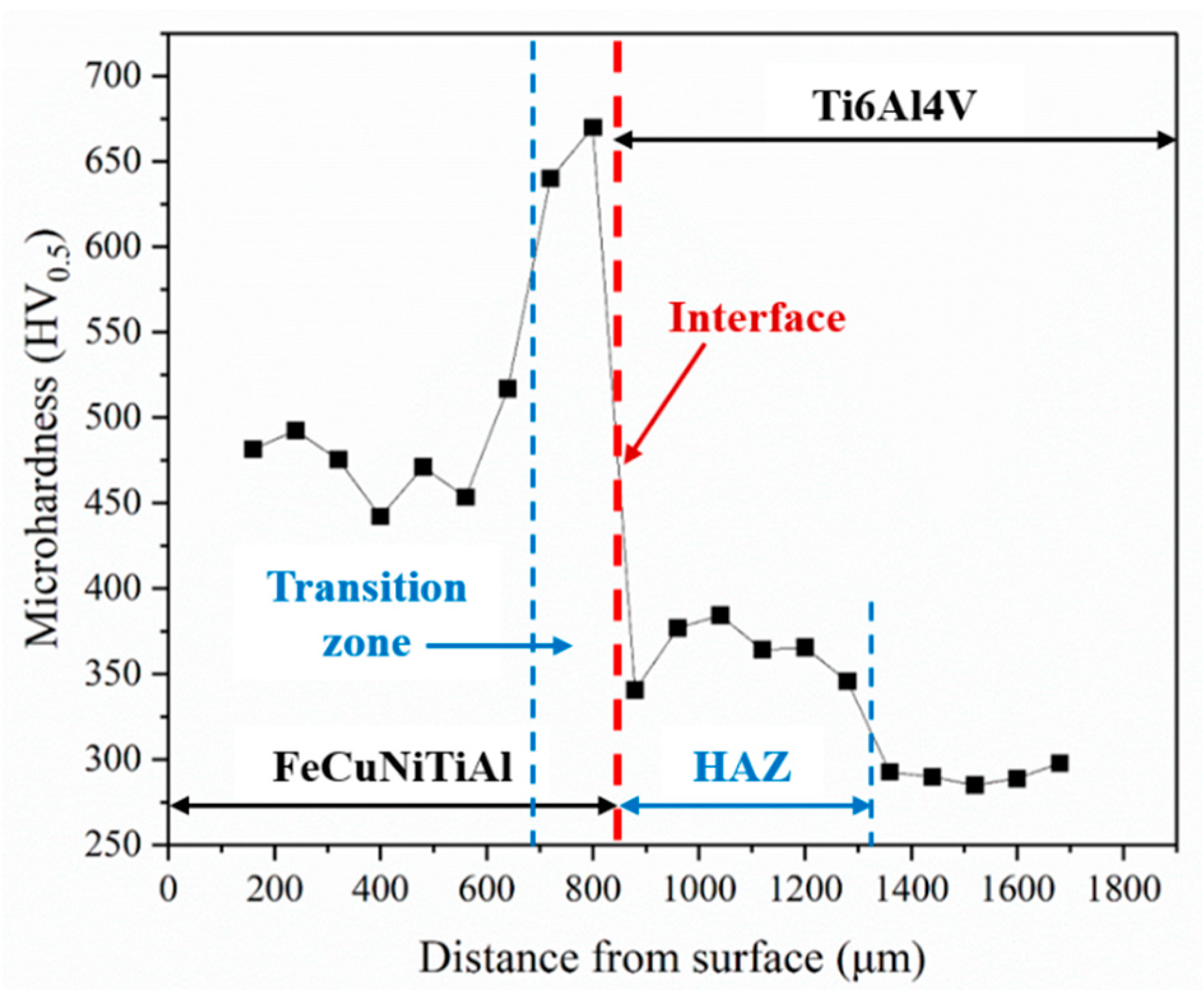

3.2. Microhardness

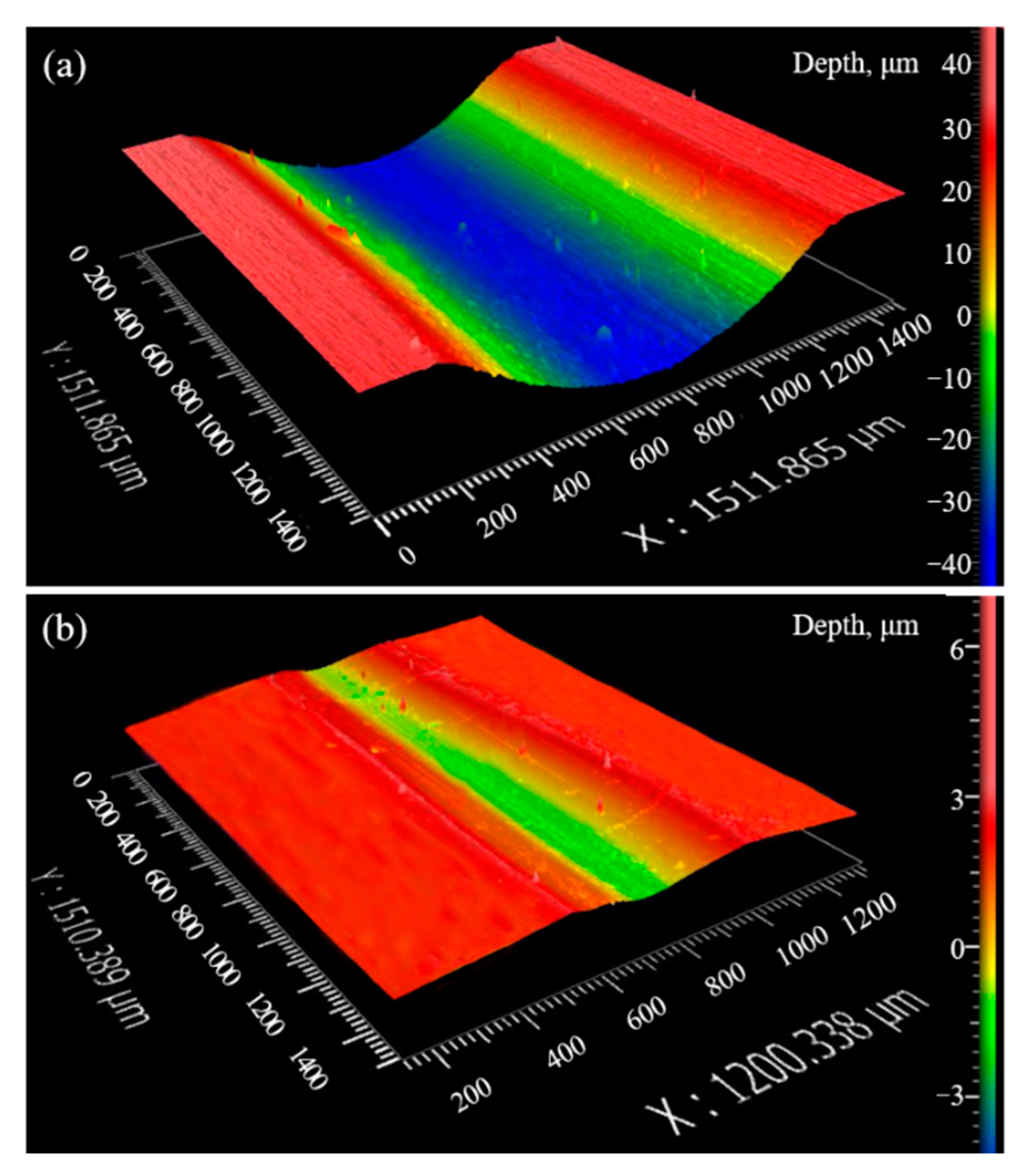

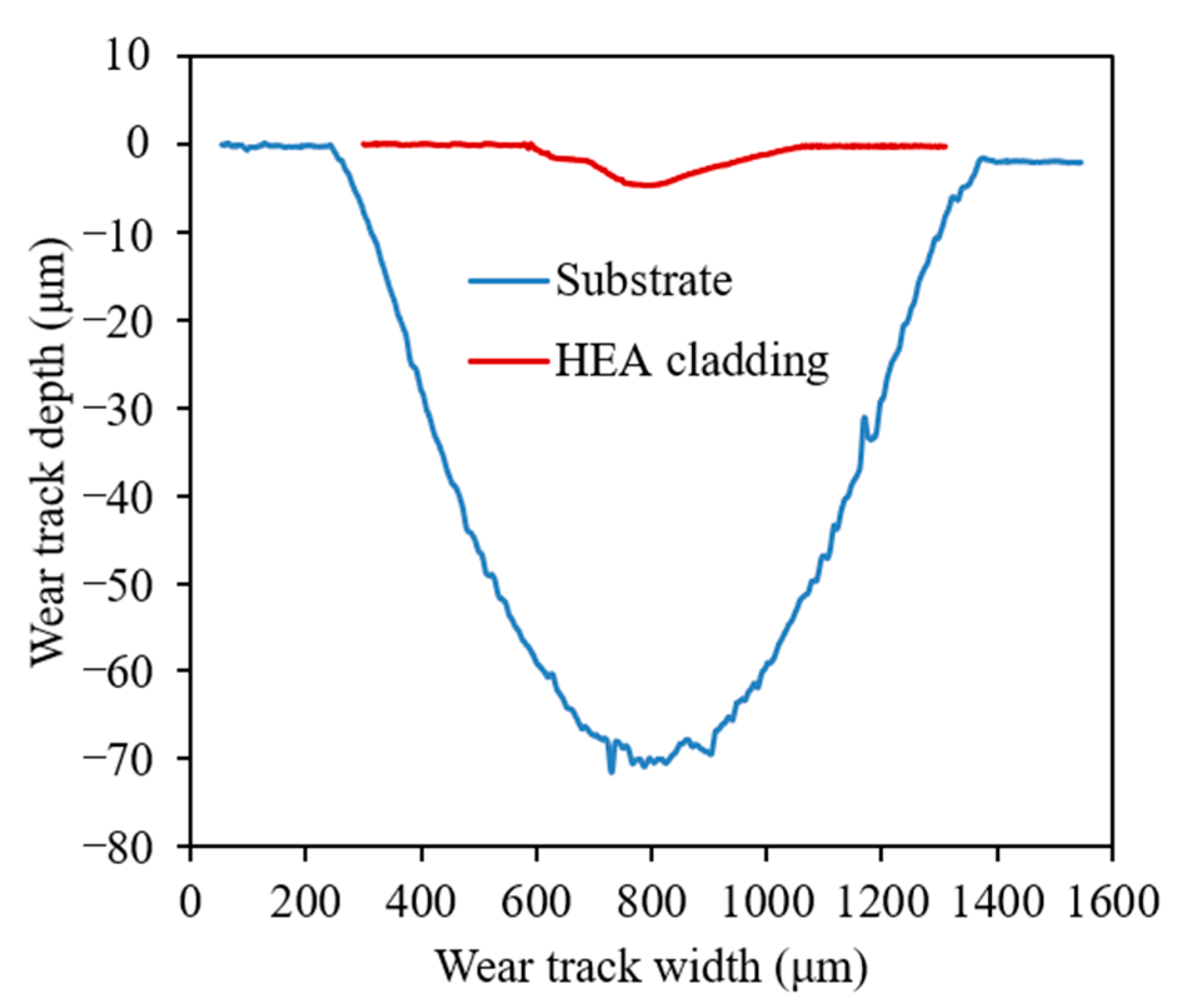

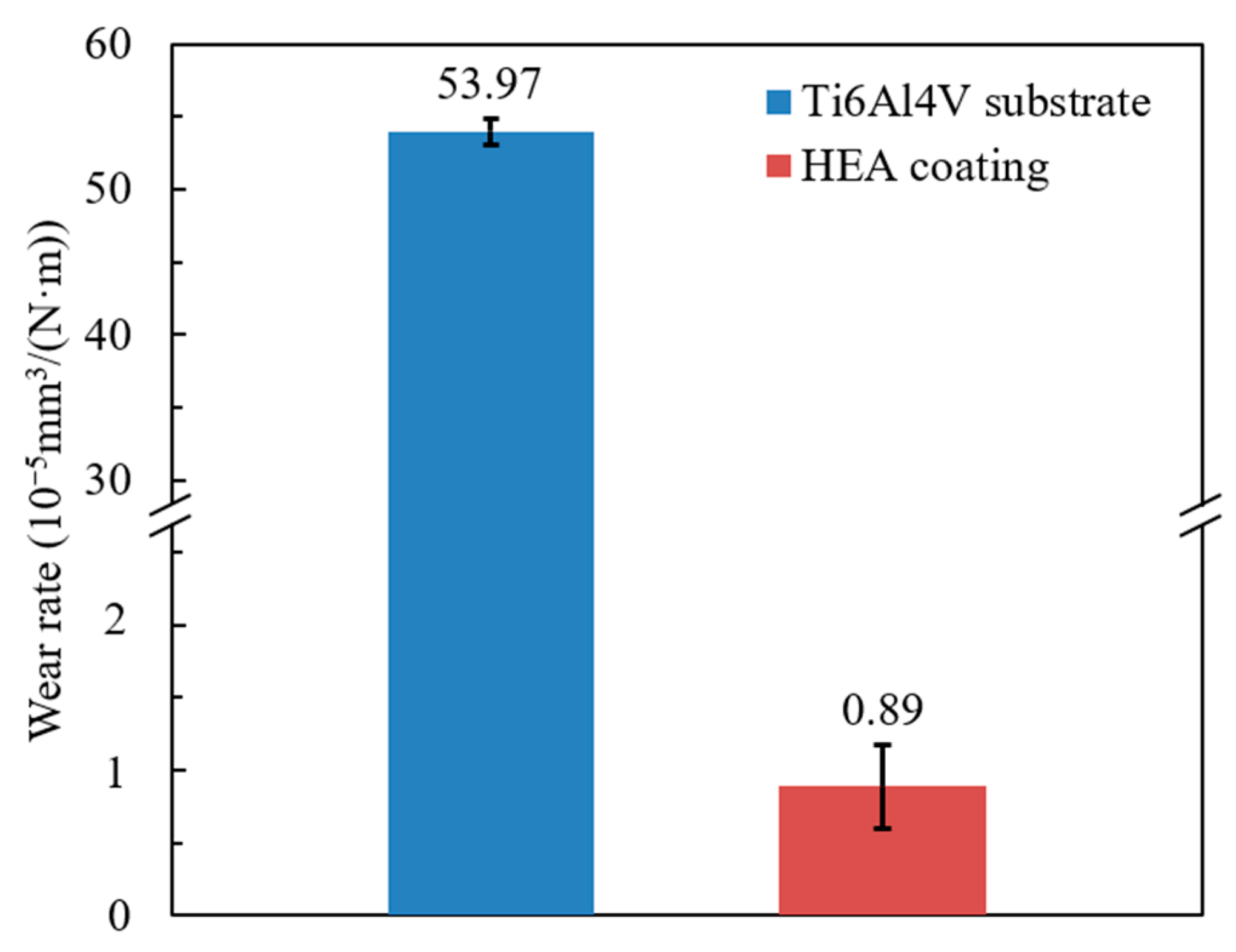

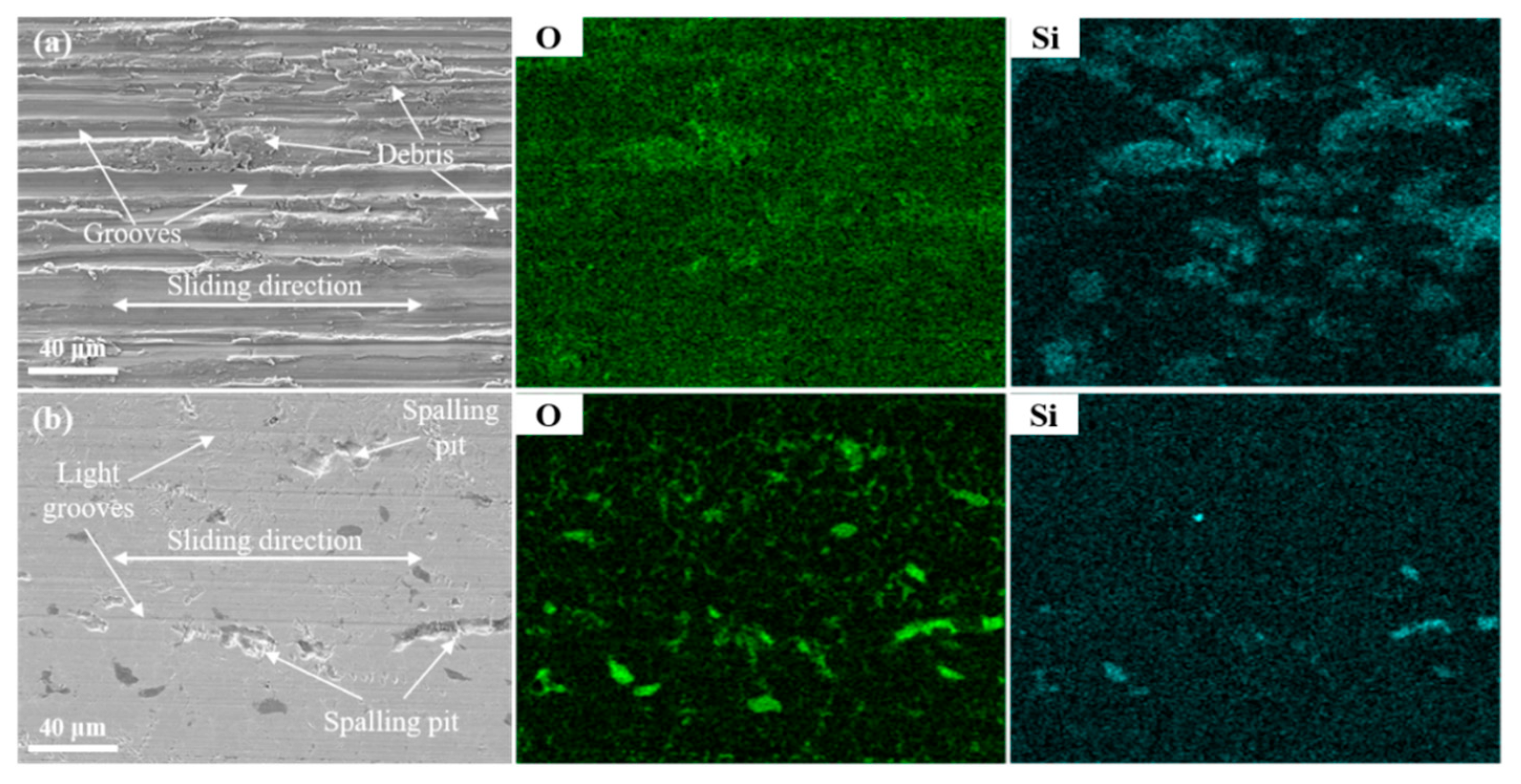

3.3. Wear Resistance

4. Conclusions

- FeCuNiTiAl HEA coating and Ti6Al4V substrate have suitable metallurgical bonding. No cracks, pores, or other defects are found at the interface;

- FeCuNiTiAl HEA can be used as the wear-resistant coating material of Ti6Al4V, greatly improving the wear resistance of Ti6Al4V. The hardness of HEA coating is 1.5 times that of Ti6Al4V substrate, and its wear resistance is 60 times that of Ti6Al4V;

- The wear mechanism of the Ti6Al4V substrate is mainly abrasive wear, and the wear mechanism of FeCuNiTiAl HEA coating is mainly adhesive wear, accompanied by slight oxidation wear and abrasive wear.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, Q.; Sun, Q.; Xin, S.; Chen, Y.; Wu, C.; Wang, H.; Xu, J.; Wan, M.; Zeng, W.; Zhao, Y. High-strength titanium alloys for aerospace engineering applications: A review on melting-forging process. Mater. Sci. Eng. A 2022, 845, 143260. [Google Scholar] [CrossRef]

- Kumar, R.R.; Gupta, R.K.; Sarkar, A.; Prasad, M.J.N.V. Vacuum diffusion bonding of α-titanium alloy to stainless steel for aerospace applications: Interfacial microstructure and mechanical characteristics. Mater. Charact. 2022, 183, 111607. [Google Scholar] [CrossRef]

- Cecchel, S.; Montesano, L.; Cornacchia, G. Wear and corrosion characterization of a Ti-6Al-4V component for automotive applications: Forging versus selective laser melting technologies. Adv. Eng. Mater. 2022, 2200082, 1–10. [Google Scholar] [CrossRef]

- You, S.H.; Lee, J.H.; Oh, S.H. A study on cutting characteristics in turning operations of titanium alloy used in automobile. Int. J. Precis. Eng. Manuf. 2019, 20, 209–216. [Google Scholar] [CrossRef]

- Kaur, S.; Ghadirinejad, K.; H. Oskouei, R. An overview on the tribological performance of titanium alloys with surface modifications for biomedical applications. Lubricants 2019, 7, 65. [Google Scholar] [CrossRef]

- Guo, A.X.Y.; Cheng, L.; Zhan, S.; Zhang, S.; Xiong, W.; Wang, Z.; Wang, G.; Cao, S.C. Biomedical applications of the powder-based 3D printed titanium alloys: A review. J. Mater. Sci. Technol. 2022, 125, 252–264. [Google Scholar] [CrossRef]

- Gaikwad, A.; Vázquez-Martínez, J.M.; Salguero, J.; Iglesias, P. Tribological properties of Ti6Al4V titanium textured surfaces created by laser: Effect of dimple density. Lubricants 2022, 10, 138. [Google Scholar] [CrossRef]

- Feng, J.; Wang, J.; Yang, K.; Rong, J. Microstructure and performance of YTaO4 coating deposited by atmospheric plasma spraying on TC4 titanium alloy surface. Surf. Coat. Tech. 2022, 431, 128004. [Google Scholar] [CrossRef]

- Kumari, R.; Majumdar, J.D. Microstructure and surface mechanical properties of plasma spray deposited and post spray heat treated hydroxyapatite (HA) based composite coating on titanium alloy (Ti-6Al-4V) substrate. Mater. Charact. 2017, 131, 12–20. [Google Scholar] [CrossRef]

- Yumusak, G.; Leyland, A.; Matthews, A. A microabrasion wear study of nitrided α-Ti and β-TiNb PVD metallic thin films, pre-deposited onto titanium alloy substrates. Surf. Coat. Tech. 2022, 442, 128423. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, W.; Jia, X.; Akasaka, T.; Liao, S.; Watari, F. Deposition of TiC film on titanium for abrasion resistant implant material by ion-enhanced triode plasma CVD. Appl. Surf. Sci. 2012, 262, 156–158. [Google Scholar] [CrossRef]

- Xia, C.; Ma, X.; Zhang, X.; Li, K.; Tan, J.; Qiao, Y.; Liu, X. Enhanced physicochemical and biological properties of C/Cu dual ions implanted medical titanium. Bioact. Mater. 2020, 5, 377–386. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Shao, M.; Wang, Z.; Zhang, Z.; He, Y.; Yan, J.; Lu, J.; Qiu, J.; Li, Y. Comparison of tribological properties of nitrided Ti-N modified layer and deposited TiN coatings on TA2 pure titanium. Tribol. Int. 2022, 174, 107712. [Google Scholar] [CrossRef]

- Jiang, C.; Zhang, J.; Chen, Y.; Hou, Z.; Zhao, Q.; Li, Y.; Zhu, L.; Zhang, F.; Zhao, Y. On enhancing wear resistance of titanium alloys by laser cladded WC-Co composite coatings. Int. J. Refract. Met. Hard Mater. 2022, 107, 105902. [Google Scholar] [CrossRef]

- Gao, Z.; Wang, L.; Wang, Y.; Lyu, F.; Zhan, X. Crack defects and formation mechanism of FeCoCrNi high entropy alloy coating on TC4 titanium alloy prepared by laser cladding. J. Alloy. Compd. 2022, 903, 163905. [Google Scholar] [CrossRef]

- Li, H.; Wang, D.; Hu, C.; Dou, J.; Yu, H.; Chen, C.; Gu, G. Microstructure, mechanical and biological properties of laser cladding derived CaO-SiO2-MgO system ceramic coatings on titanium alloys. Appl. Surf. Sci. 2021, 548, 149296. [Google Scholar] [CrossRef]

- Chi, Y.; Gong, G.; Zhao, L.; Yu, H.; Tian, H.; Du, X.; Chen, C. In-situ TiB2-TiC reinforced Fe-Al composite coating on 6061 aluminum alloy by laser surface modification. J. Mater. Process. Tech. 2021, 294, 117107. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Gan, J.Y.; Lin, S.J.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A 2004, 35, 2533–2536. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta. Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yeh, J.W. Recent progress in high entropy alloys. Ann. Chim. Sci. Mat. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, Y.; Vilar, R.; Shen, J. Dry sliding wear behavior of laser clad TiVCrAlSi high entropy alloy coatings on Ti-6Al-4V substrate. Mater. Des. 2012, 41, 338–343. [Google Scholar] [CrossRef]

- Chuang, M.H.; Tsai, M.H.; Wang, W.R.; Lin, S.J.; Yeh, J.W. Microstructure and wear behavior of AlxCo1. 5CrFeNi1. 5Tiy high-entropy alloys. Acta. Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, C.L.; Yi, J.Z.; Zhang, C.H. Synthesis and characterization of FeCoCrAlCu high-entropy alloy coating by laser surface alloying. Surf. Coat. Tech. 2015, 262, 64–69. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, Y.; Shen, J.; Vilar, R. Thermal stability and oxidation resistance of laser clad TiVCrAlSi high entropy alloy coatings on Ti-6Al-4V alloy. Surf. Coat. Tech. 2011, 206, 1389–1395. [Google Scholar] [CrossRef]

- Han, C.; Fang, Q.; Shi, Y.; Tor, S.; Chua, C.; Zhou, K. Recent advances on high-entropy alloys for 3D printing. Adv. Mater. 2020, 32, 1903855. [Google Scholar] [CrossRef]

- Zhang, H.X.; Dai, J.J.; Sun, C.X.; Li, S.Y. Microstructure and wear resistance of TiAlNiSiV high-entropy laser cladding coating on Ti-6Al-4V. J. Mater. Process. Tech 2020, 282, 116671. [Google Scholar] [CrossRef]

- Xiang, K.; Chen, L.Y.; Chai, L.; Guo, N.; Wang, H. Microstructural characteristics and properties of CoCrFeNiNbx high-entropy alloy coatings on pure titanium substrate by pulsed laser cladding. Appl. Surf. Sci. 2020, 517, 146214. [Google Scholar] [CrossRef]

- Zhao, P.; Li, J.; Zhang, Y.; Li, X.; Xia, M.M.; Yuan, B.G. Wear and high-temperature oxidation resistances of AlNbTaZrx high-entropy alloys coatings fabricated on Ti6Al4V by laser cladding. J. Alloy. Compd. 2021, 862, 158405. [Google Scholar] [CrossRef]

- Liu, G.; Du, D.; Wang, K.; Pu, Z.; Zhang, D.; Chang, B. Microstructure and wear behavior of IC10 directionally solidified superalloy repaired by directed energy deposition. J. Mater. Sci. Technol. 2021, 93, 71–78. [Google Scholar] [CrossRef]

- Prabu, G.; Duraiselvam, M.; Jeyaprakash, N.; Yang, C.H. Microstructural evolution and wear behavior of AlCoCrCuFeNi high entropy alloy on Ti-6Al-4V through laser surface alloying. Met. Mater. Int. 2021, 27, 2328–2340. [Google Scholar] [CrossRef]

- Erdemir, F. Study on particle size and X-ray peak area ratios in high energy ball milling and optimization of the milling parameters using response surface method. Measurement 2017, 112, 53–60. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.; Hao, X.; Zhang, X.; Liu, H. Lightweight refractory high entropy alloy coating by laser cladding on Ti-6Al-4V surface. Vacuum 2021, 183, 109823. [Google Scholar] [CrossRef]

- Yu, T.; Wang, H.; Han, K.; Zhang, B. Microstructure and wear behavior of AlCrTiNbMo high-entropy alloy coating prepared by electron beam cladding on Ti600 substrate. Vacuum 2022, 199, 110928. [Google Scholar] [CrossRef]

- Gao, X.L.; Zhang, L.J.; Liu, J.; Zhang, J.X. Porosity and microstructure in pulsed Nd: YAG laser welded Ti6Al4V sheet. J. Mater. Process. Tech. 2014, 214, 1316–1325. [Google Scholar] [CrossRef]

- Casalino, G.; Mortello, M.; Campanelli, S.L. Ytterbium fiber laser welding of Ti6Al4V alloy. J. Manuf. Process. 2015, 20, 250–256. [Google Scholar] [CrossRef]

- Hong, K.M.; Shin, Y.C. Analysis of microstructure and mechanical properties change in laser welding of Ti6Al4V with a multiphysics prediction model. J. Mater. Process. Tech. 2016, 237, 420–429. [Google Scholar] [CrossRef]

- Zhang, G.J.; Tian, Q.W.; Yin, K.X.; Niu, S.Q.; Wu, M.H.; Wang, W.W.; Wang, Y.N.; Huang, J.C. Effect of Fe on microstructure and properties of AlCoCrFexNi (x = 1.5, 2.5) high entropy alloy coatings prepared by laser cladding. Intermetallics 2020, 119, 106722. [Google Scholar] [CrossRef]

- Liu, H.; Sun, S.; Zhang, T.; Zhang, G.; Yang, H.; Hao, J. Effect of Si addition on microstructure and wear behavior of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding. Surf. Coat. Tech. 2021, 405, 126522. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Y. Microhardness, wear resistance, and corrosion resistance of AlxCrFeCoNiCu high-entropy alloy coatings on aluminum by laser cladding. Opt. Laser. Technol. 2021, 134, 106632. [Google Scholar] [CrossRef]

- Cheng, J.; Sun, B.; Ge, Y.; Hu, X.; Zhang, L.; Liang, X.; Zhang, X. Nb doping in laser-cladded Fe25Co25Ni25 (B0.7Si0.3)25 high entropy alloy coatings: Microstructure evolution and wear behavior. Surf. Coat. Tech. 2020, 402, 126321. [Google Scholar] [CrossRef]

- Sun, Z.; Zhang, X.; Li, X.; Xu, Z.; Li, C.; Wang, Z. Study on the wear behavior of CoCrFeNiAl1.0 high entropy alloy at high temperature. Mater. Lett. 2022, 324, 132726. [Google Scholar] [CrossRef]

- Zhou, Y.K.; Kang, J.J.; Zhang, J.; Fu, Z.Q.; Zhu, L.N.; She, D.S.; Yue, W. Microstructure and sliding wear behavior of HVOF sprayed Al(1-x) CoCrFeNiTix high-entropy alloy coatings. Mater. Lett. 2022, 314, 131929. [Google Scholar] [CrossRef]

| Elements | Fe | Cu | Ni | Ti | Al | Else |

|---|---|---|---|---|---|---|

| wt.% | 22.08 | 25.12 | 23.21 | 18.93 | 10.435 | 0.225 |

| Laser power (W) | 400 |

| Laser spot diameter (mm) | 3 |

| Scanning speed (mm/s) | 12.5 |

| Powder feed rate (g/min) | 6.5 |

| Carrier gas flow rate (L/min) | 10 |

| Materials | Friction Pair | Wear Rate/mm3/(N·m) | References |

|---|---|---|---|

| AlCoCrFe2.5Ni | Si3N4 | 1.09 × 10−3 | [41] |

| AlCoCrFeNi | ZrO2 | 5.18 × 10−4 | [42] |

| CrFeCoNiCu | GCr15 | 2.26 × 10−4 | [43] |

| AlNbTaZr0.8 | Si3N4 | 1.16 × 10−4 | [32] |

| TiVCrAlSi | GCr15 | 2.52 × 10−5 | [25] |

| FeCuNiTiAl | Si3N4 | 8.90 × 10−6 | Our work |

| Fe25Co25Ni25(B0.7Si0.3)25 | GCr15 | 3.64 × 10−6 | [44] |

| Al1.5CrFeCoNiCu | GCr15 | 6.64 × 10−7 | [43] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Du, D.; Liu, G.; Pu, Z.; Xue, S.; Chang, B. Microstructure and Wear Resistance of FeCuNiTiAl High-Entropy Alloy Coating on Ti6Al4V Substrate Fabricated by Laser Metal Deposition. Lubricants 2022, 10, 263. https://doi.org/10.3390/lubricants10100263

Zhang D, Du D, Liu G, Pu Z, Xue S, Chang B. Microstructure and Wear Resistance of FeCuNiTiAl High-Entropy Alloy Coating on Ti6Al4V Substrate Fabricated by Laser Metal Deposition. Lubricants. 2022; 10(10):263. https://doi.org/10.3390/lubricants10100263

Chicago/Turabian StyleZhang, Dongqi, Dong Du, Guan Liu, Ze Pu, Shuai Xue, and Baohua Chang. 2022. "Microstructure and Wear Resistance of FeCuNiTiAl High-Entropy Alloy Coating on Ti6Al4V Substrate Fabricated by Laser Metal Deposition" Lubricants 10, no. 10: 263. https://doi.org/10.3390/lubricants10100263

APA StyleZhang, D., Du, D., Liu, G., Pu, Z., Xue, S., & Chang, B. (2022). Microstructure and Wear Resistance of FeCuNiTiAl High-Entropy Alloy Coating on Ti6Al4V Substrate Fabricated by Laser Metal Deposition. Lubricants, 10(10), 263. https://doi.org/10.3390/lubricants10100263