Effect of Temperature and Sliding Velocity on the Dry Sliding Wear Mechanisms of Boron Modified Ti-6Al-4V Alloys

Abstract

1. Introduction

2. Materials and Experiments

2.1. Metallographic Analysis of Ti64-xB Samples

2.2. Wear Experiments

2.3. Characterization of Wear Surfaces and Subsurface Deformation

3. Results

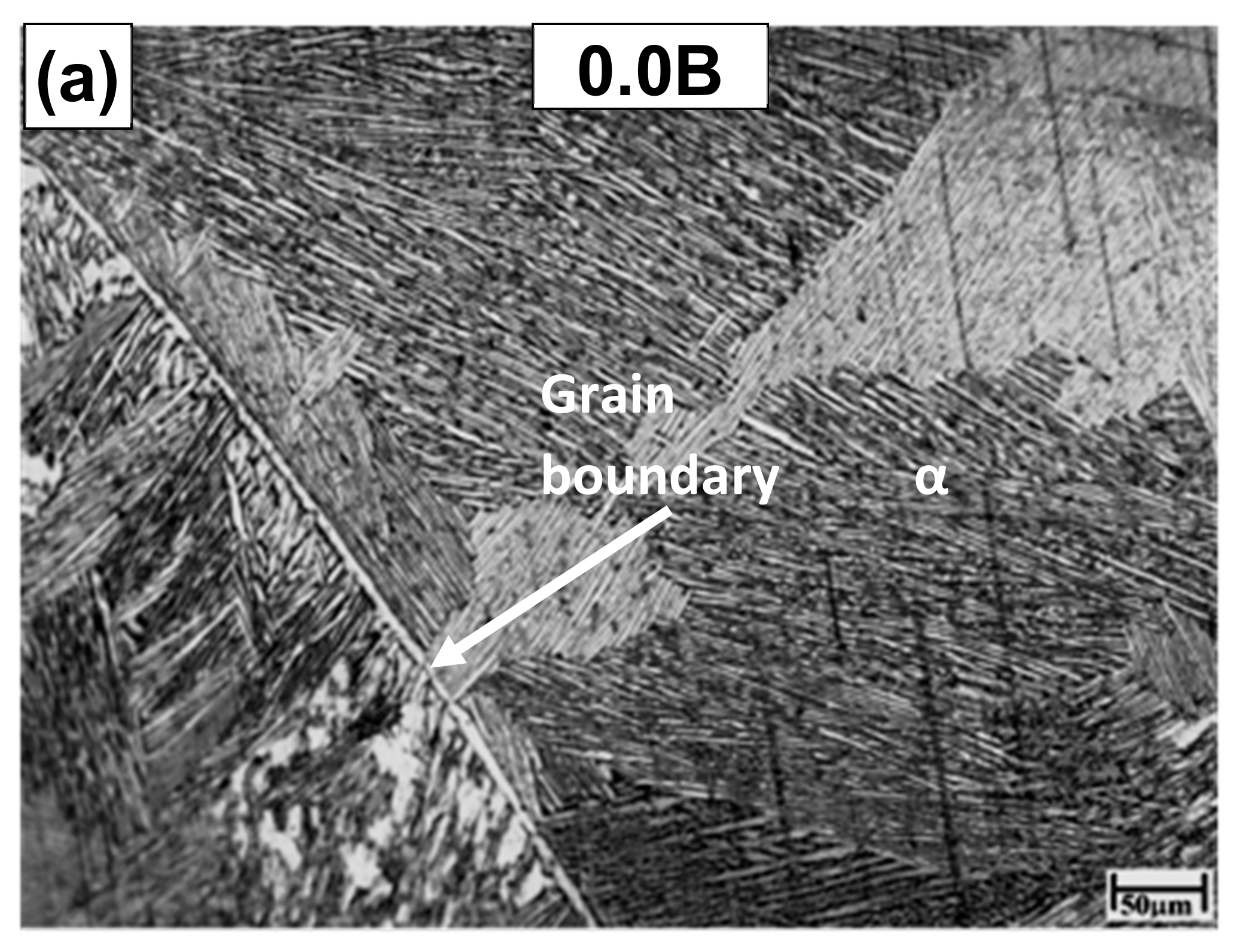

3.1. Microstructural Changes Due to B Addition

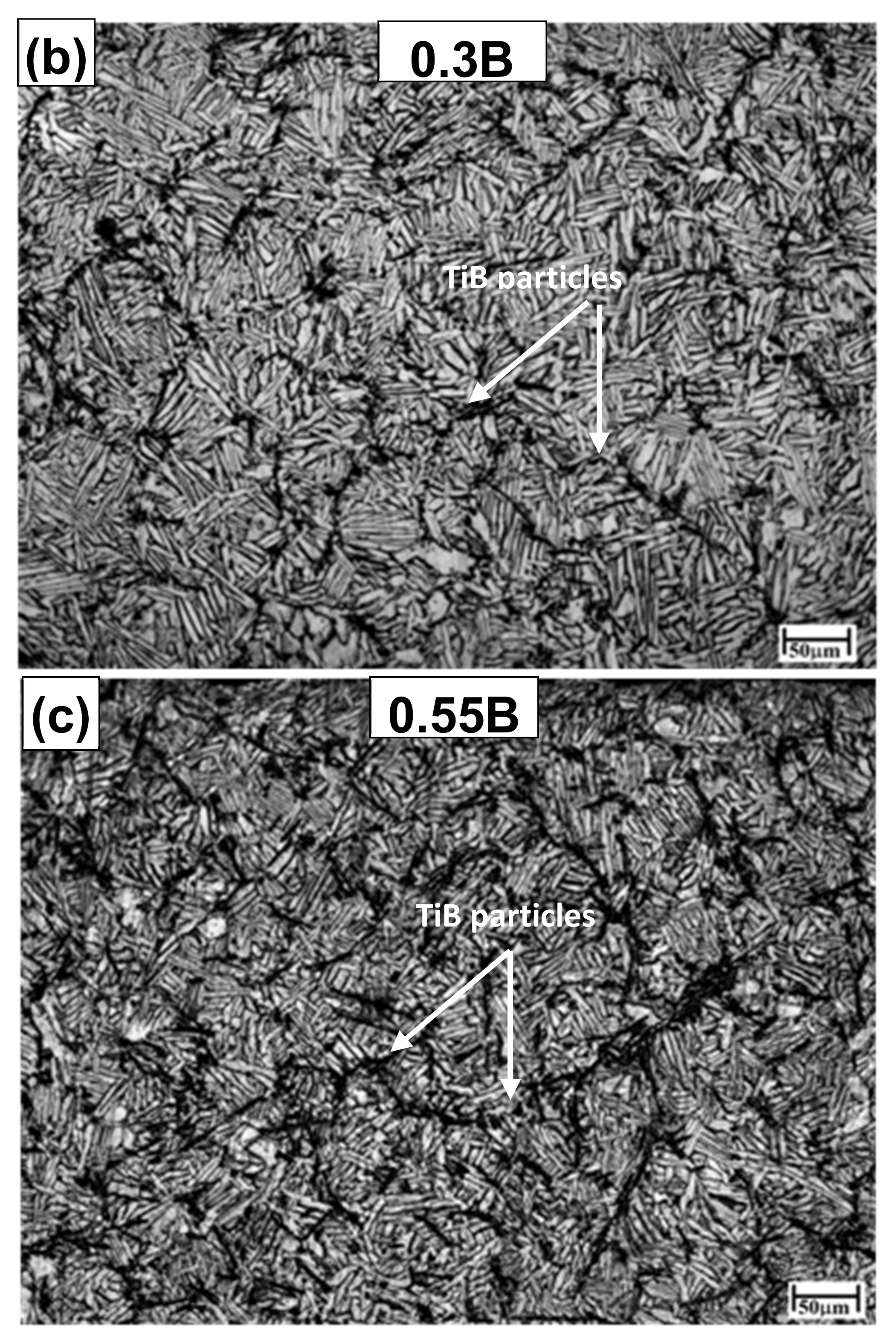

3.2. Variation of Wear Rate with Sliding Speed and Temperature

- (i)

- Exceptionally low η is observed for 0.55B sample at s of 1 m/s and 300 K.

- (ii)

- Overall, the η for all the samples increases with increasing s from 1 to 2 m/s at both the temperatures.

- (iii)

- On transition in s from 2 to 4 m/s, the room temperature η for both 0B and 0.3B continues to increase, while it decreases for 0.55B. On the other hand, at 573 K, η decreases for both 0B and 0.55B samples, while it increases slightly for 0.3B.

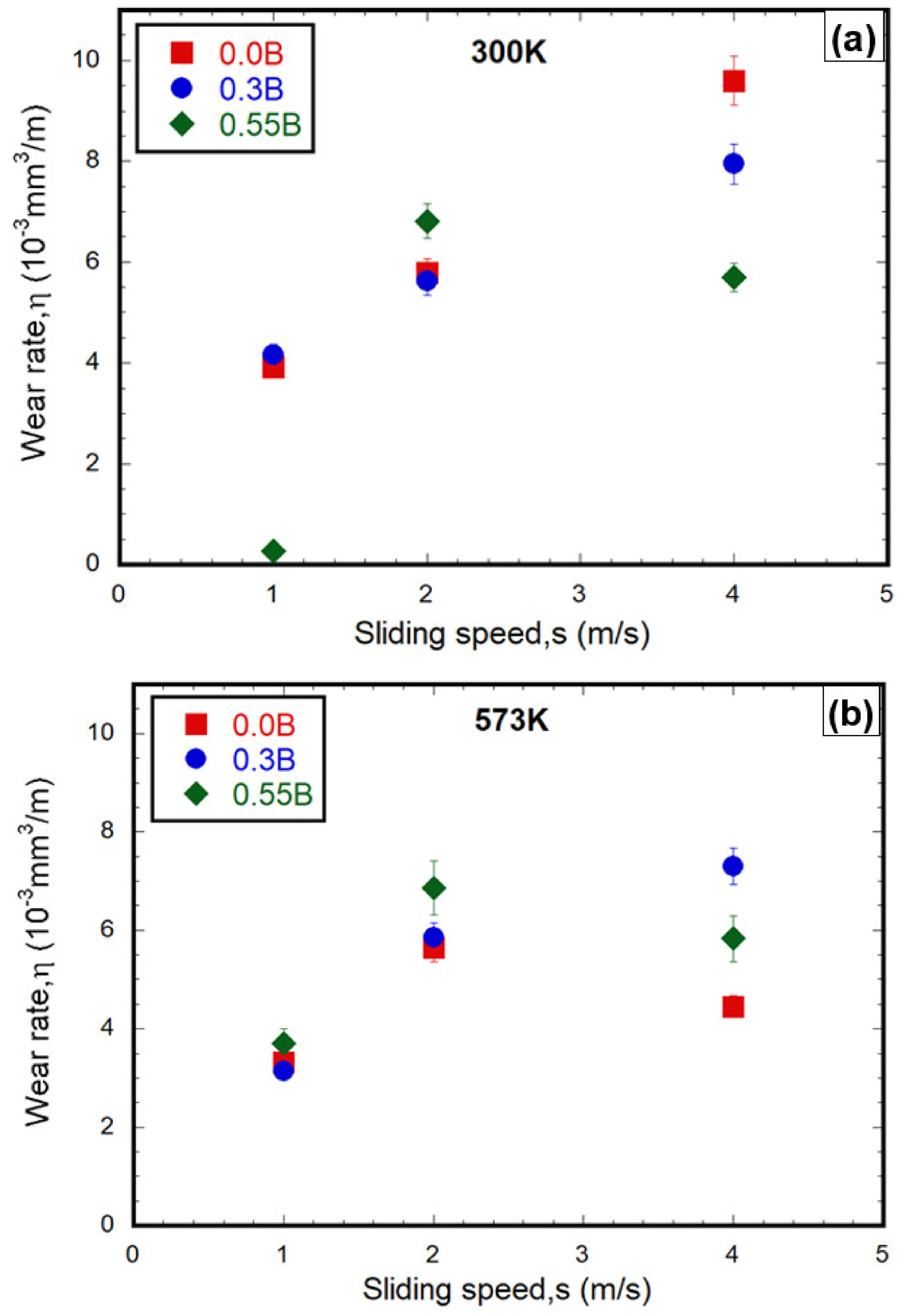

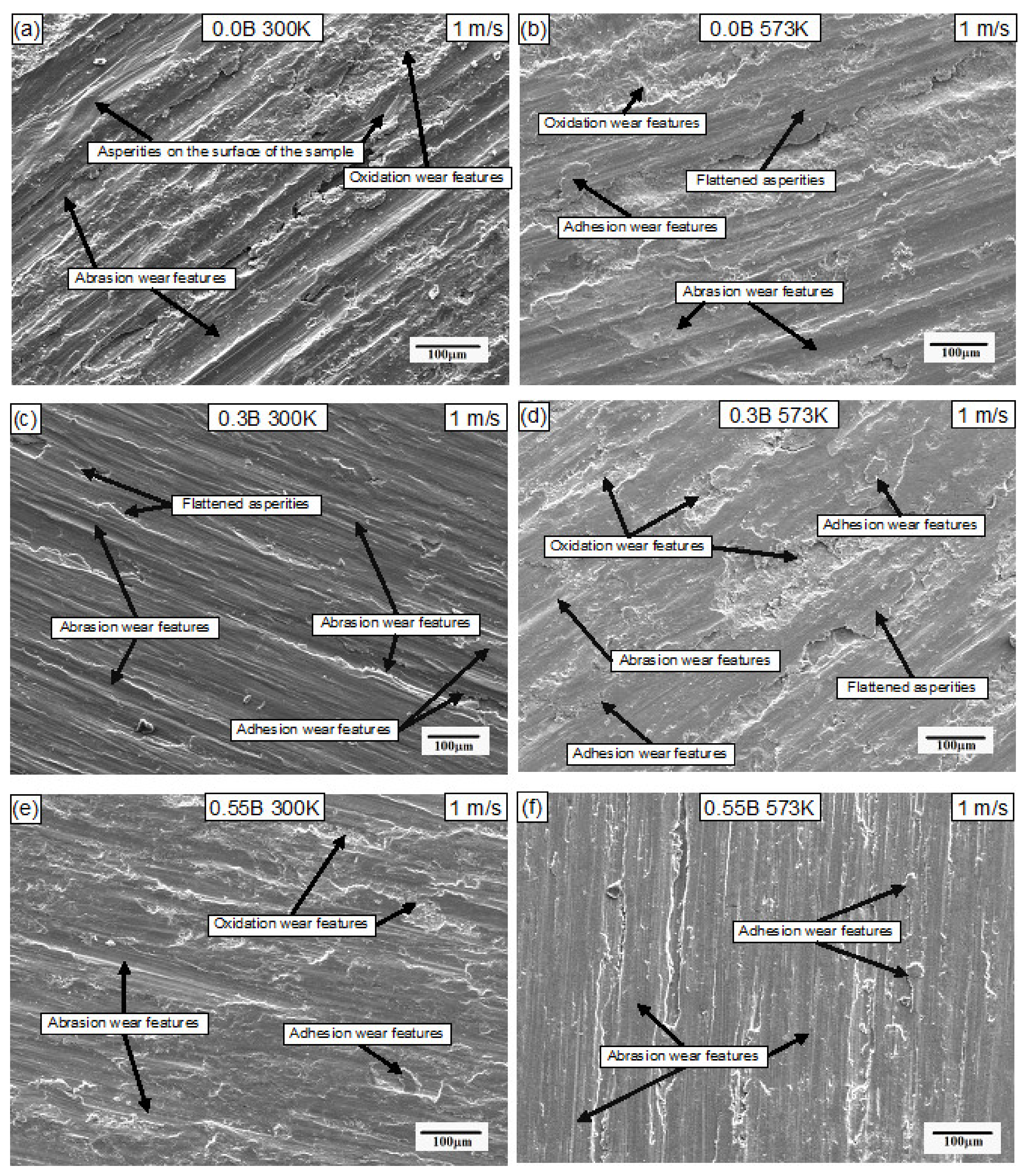

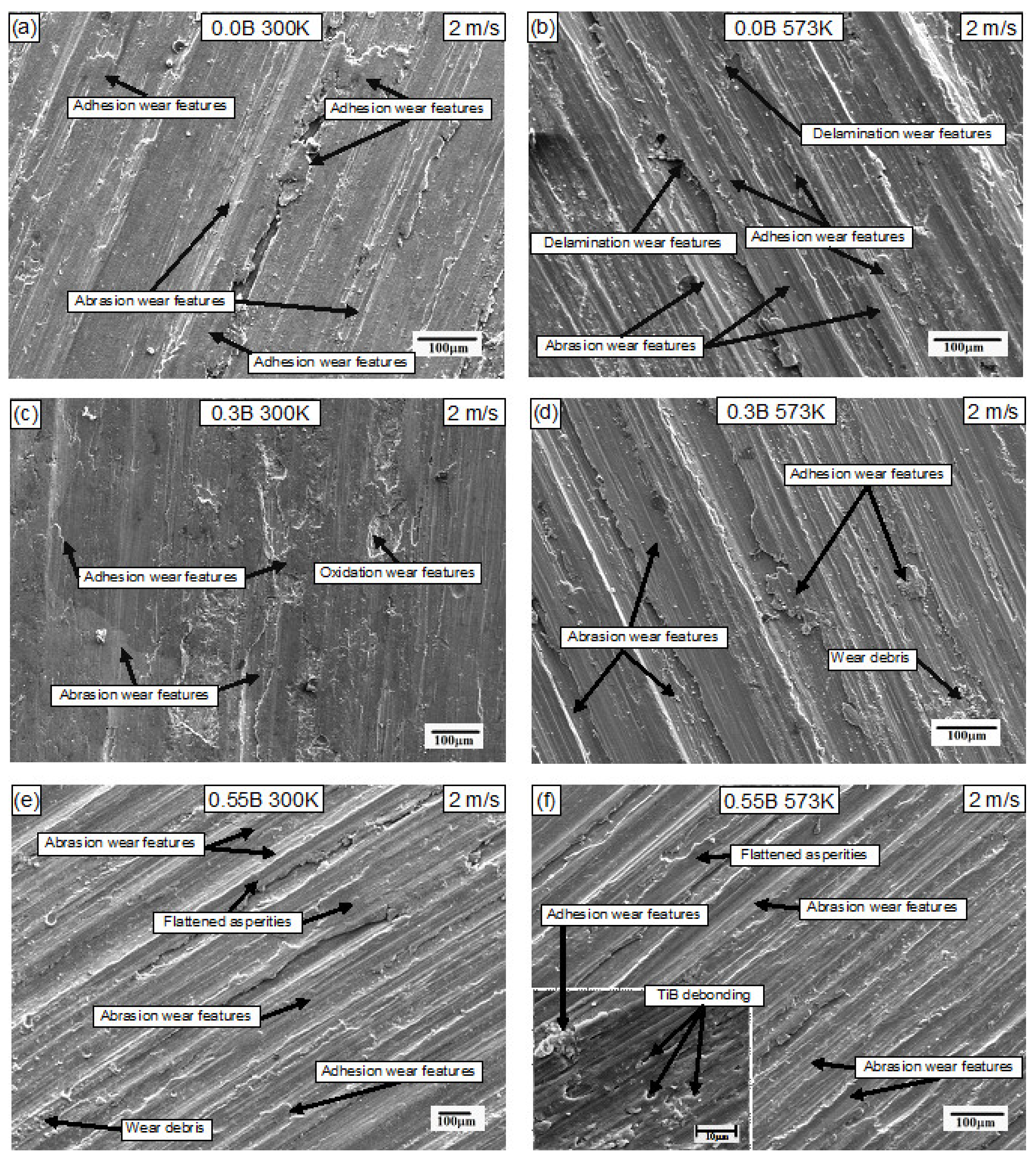

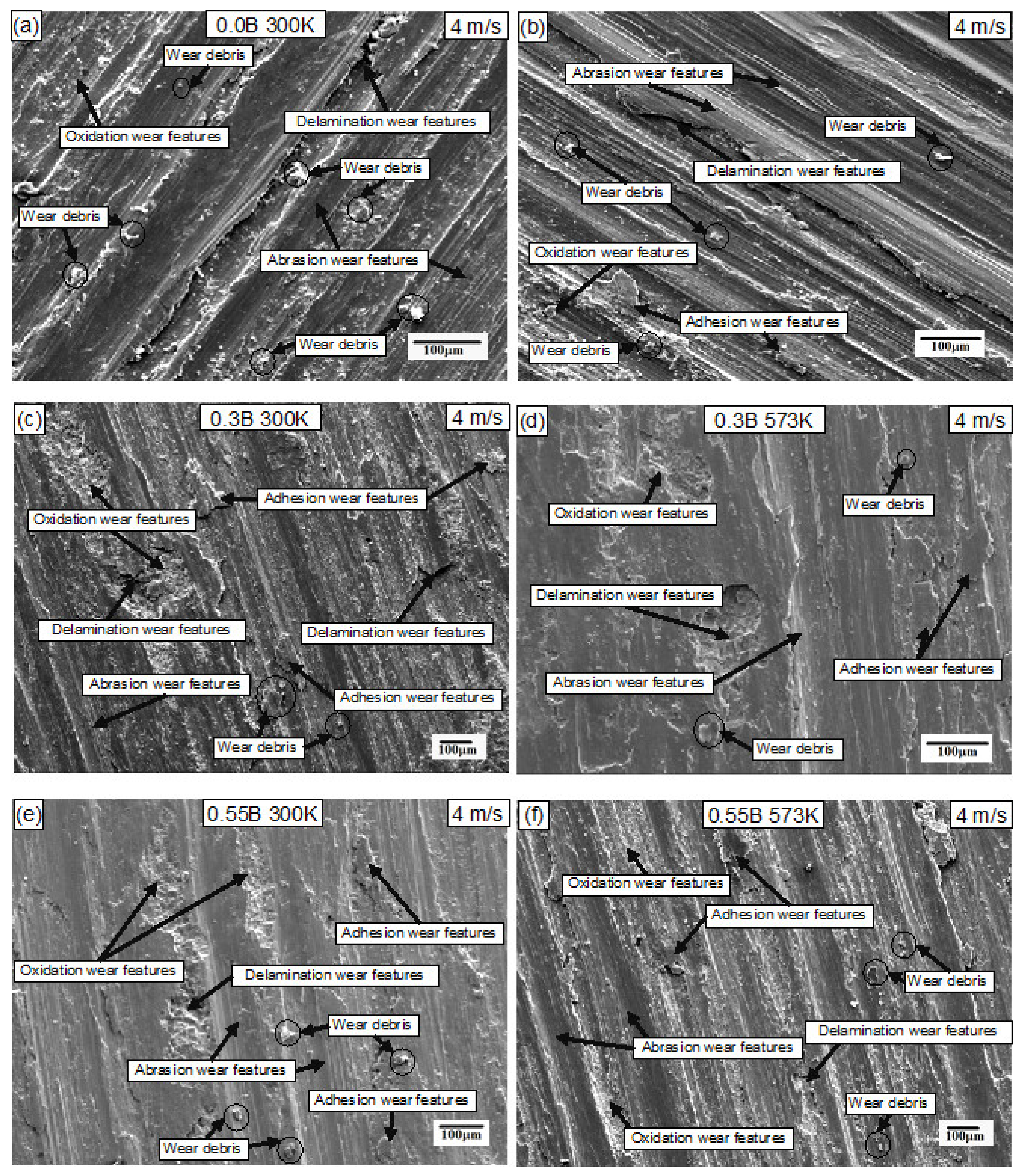

3.3. Morphology of the Wear Surfaces

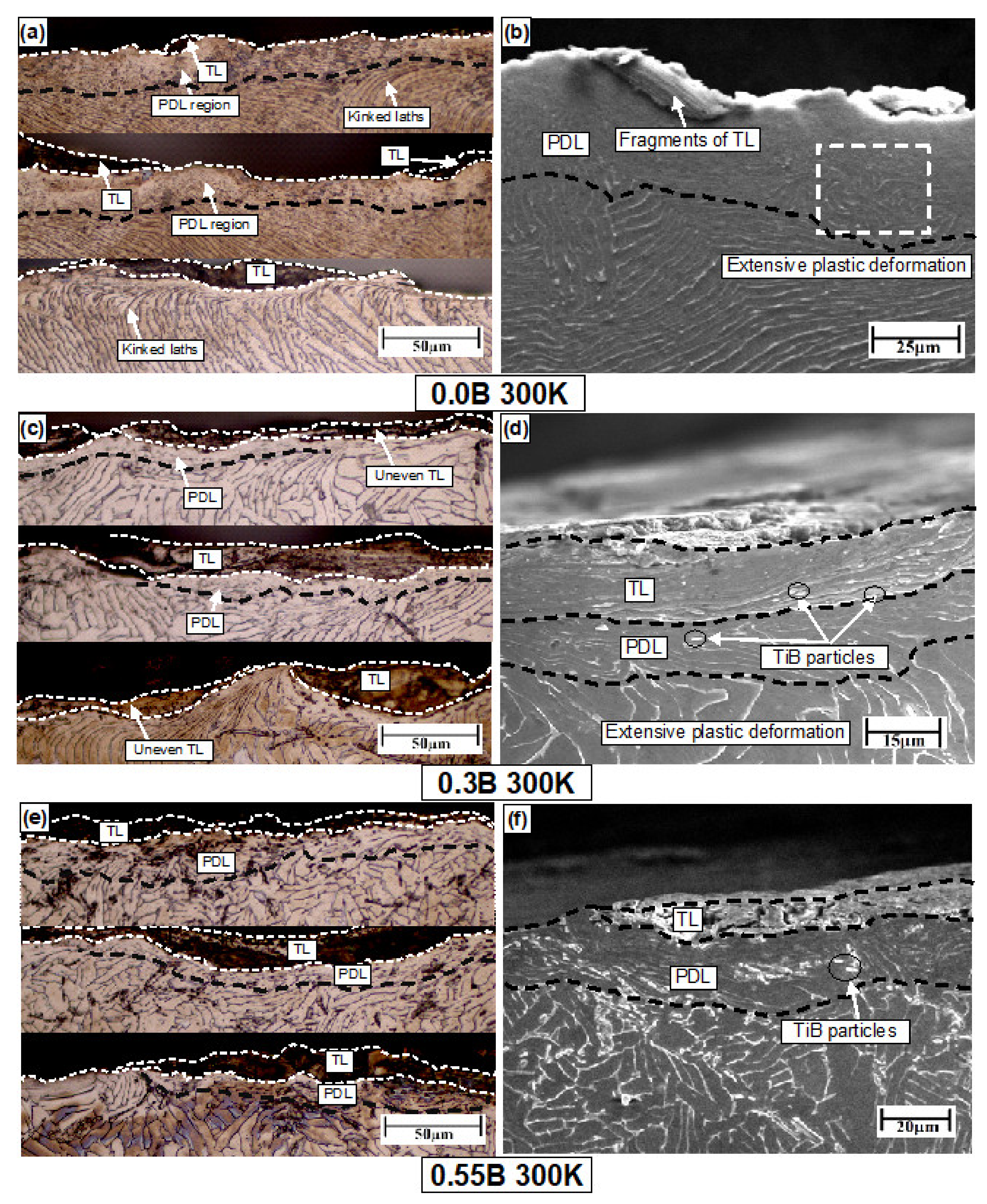

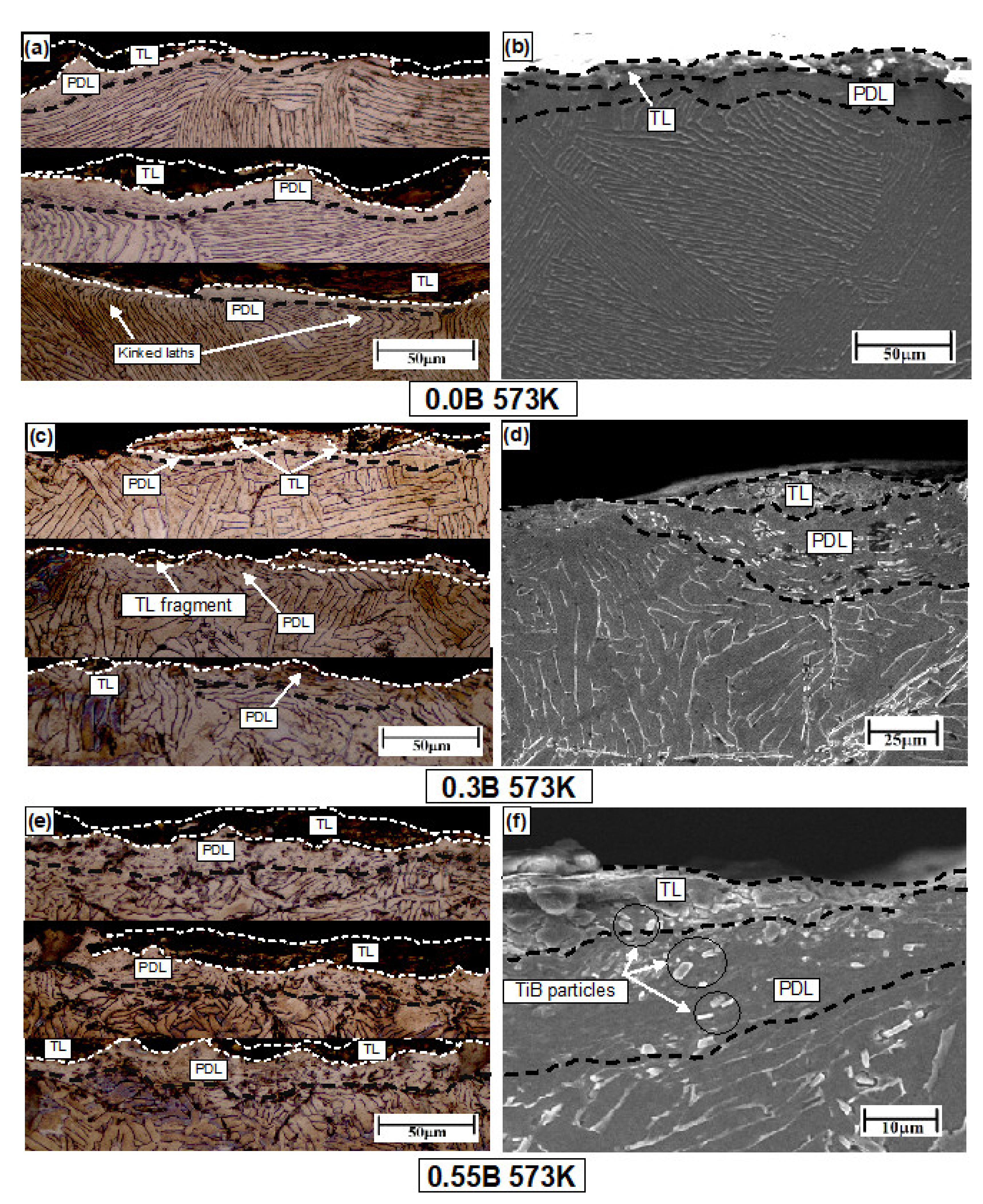

3.4. Microstructures of Subsurface Deformation Regions

4. Discussion

4.1. Effect of Sliding Speed and Temperature on Wear Mechanisms and η

4.1.1. Wear Behavior and Mechanisms at Lowest s = 1 m/s

4.1.2. Wear Behavior and Mechanisms at Intermediate s = 2 m/s

4.1.3. Wear Mechanisms at s = 4 m/s

4.1.4. Common Wear Features between the Intermediate and High s

4.2. Effect of Tribo-Layer Formation on Wear Behavior of Ti Alloys

4.3. Effect of the Counter Disc on the Wear Behavior

5. Conclusions

- At 1 m/s and 300 K, the wear rate η is governed by the hardness of materials, and hence, the Ti64-0.55B alloy exhibits the lowest wear rate and 0B alloy the highest η. In contrast, at 1 m/s and 573 K, the η of the 0.55B alloy increased abruptly due to the participation of TiB particles in the wear process, promoting the three-body wear.

- At 2 m/s and 300 and 573 K, the η of 0.55B exhibits the highest rate as the three-body wear continue to be dominant and controls η.

- At the highest s (=4 m/s), the increase in s from 2 to 4 m/s caused an increase in η in a few cases and a decrease in other cases depending on the temperature and composition, suggesting that multiple factors govern the wear behavior of these alloys.

- At 300 K and low s, η follows the trend η0.55B < η0.3B < η0B. Mild abrasive wear is the dominant wear mechanism, which primarily depends on the hardness; hence, the hardest 0.55B samples exhibit the lowest η.

- At 300 K and intermediate s, η follows the trend η0.55B < η0.3B < η0B. The increased wear resistance in the 0.55 and 0.3 B samples despite having the TiB particles is attributed to the small grain size observed in both samples compared with the 0B samples.

- At 573 K and high s, η follows the trend η0B < η0.55B < η0.3B. The increased wear resistance of the 0B samples is attributed to the formation of a stable oxide layer which in the 0.55B and 0.3B samples is removed by the hard TiB precipitates.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 3-540-42990-5. [Google Scholar]

- Han, J.; Zhang, G.; Chen, X.; Liu, B.; Cai, Y.; Zhang, X.; Tian, Y. Fabrication and study of innovative Ni-added Ti–6Al–4V through directed energy deposition. Mater. Sci. Eng. A 2022, 856, 143946. [Google Scholar] [CrossRef]

- Yang, Z.; Wen, F.; Sun, Q.; Chai, L.; Ma, X.; Zhu, M. Strength-ductility improvement achieved by introducing heterostructured martensite in a Ti-6Al-4 V alloy. Mater. Charact. 2022, 192, 112230. [Google Scholar] [CrossRef]

- Çam, G.; Ipekoğlu, G.; Bohm, K.-H.; Koçak, M. Investigation into the microstructure and mechanical properties of diffusion bonded TiAl alloys. J. Mater. Sci. 2006, 41, 5273–5282. [Google Scholar] [CrossRef]

- Cam, G.; Clemens, H.; Gerling, R.; Kocak, M. Diffusion bonding of fine grained gamma-TiAl sheets. Z. Metallkd. 1999, 90, 284–288. [Google Scholar]

- Polishetty, A.; Nomani, J.; Littlefair, G. Effect of transus based heat treatment on material characterisation of wrought and additive titanium alloy Ti-6Al-4 V. Mater. Today Proc. 2022, 59, 1749–1753. [Google Scholar] [CrossRef]

- Philip, J.T.; Mathew, J.; Kuriachen, B. Tribology of Ti6Al4V: A review. Friction 2019, 7, 497–536. [Google Scholar] [CrossRef]

- Zhu, J.; Kamiya, A.; Yamada, T.; Shi, W.; Naganuma, K. Influence of boron addition on microstructure and mechanical properties of dental cast titanium alloys. Mater. Sci. Eng. A 2003, 339, 53–62. [Google Scholar] [CrossRef]

- Tamirisakandala, S.; Miracle, D.B. Microstructure engineering of titanium alloys via small boron additions. Int. J. Adv. Eng. Sci. Appl. Math. 2010, 2, 168–180. [Google Scholar] [CrossRef]

- Sen, I.; Tamirisakandala, S.; Miracle, D.B.; Ramamurty, U. Microstructural effects on the mechanical behavior of B-modified Ti–6Al–4V alloys. Acta Mater. 2007, 55, 4983–4993. [Google Scholar] [CrossRef]

- Sen, I.; Ramamurty, U. Elastic modulus of Ti–6Al–4V–xB alloys with B up to 0.55wt%. Scr. Mater. 2010, 62, 37–40. [Google Scholar] [CrossRef]

- Sen, I.; Ramamurty, U. High-Temperature (1023 K to 1273 K [750 °C to 1000 °C]) Plastic Deformation Behavior of B-Modified Ti-6Al-4V Alloys: Temperature and Strain Rate Effects. Met. Mater. Trans. A 2010, 41, 2959–2969. [Google Scholar] [CrossRef]

- Singh, G.; Satyanarayana, D.V.V.; Pederson, R.; Datta, R.; Ramamurty, U. Enhancement in Creep Resistance of Ti–6Al–4V Alloy Due to Boron Addition. Mater. Sci. Eng. A 2014, 597, 194–203. [Google Scholar] [CrossRef]

- Sen, I.; Gopinath, K.; Datta, R.; Ramamurty, U. Fatigue in Ti–6Al–4V–B Alloys. Acta Mater. 2010, 58, 6799–6809. [Google Scholar] [CrossRef]

- Singh, G.; Ramamurty, U. Reprint: Boron Modified Titanium Alloys. Prog. Mater. Sci. 2021, 120, 100815. [Google Scholar] [CrossRef]

- Blau, P.J.; Jolly, B.C.; Qu, J.; Peter, W.H.; Blue, C.A. Tribological Investigation of Titanium-Based Materials for Brakes. Wear 2007, 263, 1202–1211. [Google Scholar] [CrossRef]

- Feng, C.; Khan, T.I. The Effect of Quenching Medium on the Wear Behaviour of a Ti–6Al–4V Alloy. J. Mater. Sci. 2008, 43, 788–792. [Google Scholar] [CrossRef]

- Sahoo, R.; Jha, B.B.; Sahoo, T.K.; Sahoo, D. Effect of Microstructural Variation on Dry Sliding Wear Behavior of Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2014, 23, 2092–2102. [Google Scholar] [CrossRef]

- Hadke, S.; Khatirkar, R.K.; Shekhawat, S.K.; Jain, S.; Sapate, S.G. Microstructure Evolution and Abrasive Wear Behavior of Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2015, 24, 3969–3981. [Google Scholar] [CrossRef]

- Dixit, T.; Singh, I.; Prasad, K.E. Room and High Temperature Dry Sliding Wear Behavior of Boron Modified As-Cast Ti-6Al-4V Alloys against Hardened Steel. Wear 2019, 420–421, 207–214. [Google Scholar] [CrossRef]

- Burgers, W.G. On the Process of Transition of the Cubic-Body-Centered Modification into the Hexagonal-Close-Packed Modification of Zirconium. Physica 1934, 1, 561–586. [Google Scholar] [CrossRef]

- Palty, A.E.; Margolin, H.; Nielsen, J. Titanium-Nitrogen and Titanium-Boron Systems. Ph.D. Thesis, New York University, New York, NY, USA, 1954. [Google Scholar]

- Hsu, S.M.; Shen, M.C.; Ruff, A.W. Wear Prediction for Metals. Tribol. Int. 1997, 30, 377–383. [Google Scholar] [CrossRef]

- Menezes, P.L.; Nosonovsky, M.; Ingole, S.; Kailas, S.V.; Lovell, M.R. Tribology for Scientists and Engineers: From Basics to Advanced Concepts; Springer: New York, NY, USA, 2013. [Google Scholar]

- Budinski, K.G. Tribological Properties of Titanium Alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Cui, X.H.; Mao, Y.S.; Wei, M.X.; Wang, S.Q. Wear Characteristics of Ti-6Al-4V Alloy at 20–400 °C. Tribol. Trans. 2012, 55, 185–190. [Google Scholar] [CrossRef]

- Suh, N.P. The delamination theory of wear. Wear 1973, 25, 111–124. [Google Scholar] [CrossRef]

- Straffelini, G.; Molinari, A. Dry Sliding Wear of Ti–6Al–4V Alloy as Influenced by the Counterface and Sliding Conditions. Wear 1999, 236, 328–338. [Google Scholar] [CrossRef]

- Alam, M.O.; Haseeb, A. Response of Ti–6Al–4V and Ti–24Al–11Nb alloys to dry sliding wear against hardened steel. Tribol. Int. 2002, 35, 357–362. [Google Scholar] [CrossRef]

- Qin, M.; Zhang, Y.-Z.; Yang, J.-H.; Zhu, J. Microstructure and Tribological Characteristics of Ti–6Al–4V Alloy against GCr15 under High Speed and Dry Sliding. Mater. Sci. Eng. A 2006, 434, 71–75. [Google Scholar] [CrossRef]

- Pauschitz, A.; Roy, M.; Franek, F. Mechanisms of Sliding Wear of Metals and Alloys at Elevated Temperatures. Tribol. Int. 2008, 41, 584–602. [Google Scholar] [CrossRef]

- Raj, A.J.; Pottirayil, A.; Kailas, S.V. Dry Sliding Wear Behavior of Ti-6Al-4V Pin Against SS316L Disk at Constant Contact Pressure. J. Tribol. 2016, 139, 021603. [Google Scholar] [CrossRef]

- Mao, Y.S.; Wang, L.; Chen, K.M.; Wang, S.Q.; Cui, X.H. Tribo-Layer and Its Role in Dry Sliding Wear of Ti–6Al–4V Alloy. Wear 2013, 297, 1032–1039. [Google Scholar] [CrossRef]

- Alvi, S.; Neikter, M.; Antti, M.-L.; Akhtar, F. Tribological Performance of Ti6Al4V at Elevated Temperatures Fabricated by Electron Beam Powder Bed Fusion. Tribol. Int. 2021, 153, 106658. [Google Scholar] [CrossRef]

- Coddet, C.; Craze, A.M.; Beranger, G. Measurements of the Adhesion of Thermal Oxide Films: Application to the Oxidation of Titanium. J. Mater. Sci. 1987, 22, 2969–2974. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Q.Y.; Li, X.X.; Cui, X.H.; Wang, S.Q. Severe-to-Mild Wear Transition of Titanium Alloys as a Function of Temperature. Tribol. Lett. 2014, 53, 511–520. [Google Scholar] [CrossRef]

- Lee, C.; Sanders, A.; Tikekar, N.; Chandran, K.S.R. Tribology of Titanium Boride-Coated Titanium Balls against Alumina Ceramic: Wear, Friction, and Micromechanisms. Wear 2008, 265, 375–386. [Google Scholar] [CrossRef]

- Collings, E.W. The Physical Metallurgy of Titanium Alloys; ASM Series in Metal Processing; American Society for Metals: Almere, The Netherlands, 1984; ISBN 978-0-87170-181-7. [Google Scholar]

- Pearson, S.R.; Shipway, P.H.; Abere, J.O.; Hewitt, R.A.A. The Effect of Temperature on Wear and Friction of a High Strength Steel in Fretting. Wear 2013, 303, 622–631. [Google Scholar] [CrossRef]

- Li, X.X.; Zhou, Y.; Ji, X.L.; Li, Y.X.; Wang, S.Q. Effects of Sliding Velocity on Tribo-Oxides and Wear Behavior of Ti–6Al–4V Alloy. Tribol. Int. 2015, 91, 228–234. [Google Scholar] [CrossRef]

| Ti64-xB | d (μm) | λα (μm) | VTiB (%) |

|---|---|---|---|

| 0 | 2345 ± 452 | 2.4 | 0 |

| 0.3 | 121 ± 15 | 4.7 | 1.8 |

| 0.55 | 103 ± 13 | 5.3 | 2.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dixit, T.; Prasad, K.E. Effect of Temperature and Sliding Velocity on the Dry Sliding Wear Mechanisms of Boron Modified Ti-6Al-4V Alloys. Lubricants 2022, 10, 296. https://doi.org/10.3390/lubricants10110296

Dixit T, Prasad KE. Effect of Temperature and Sliding Velocity on the Dry Sliding Wear Mechanisms of Boron Modified Ti-6Al-4V Alloys. Lubricants. 2022; 10(11):296. https://doi.org/10.3390/lubricants10110296

Chicago/Turabian StyleDixit, Tulika, and K. Eswar Prasad. 2022. "Effect of Temperature and Sliding Velocity on the Dry Sliding Wear Mechanisms of Boron Modified Ti-6Al-4V Alloys" Lubricants 10, no. 11: 296. https://doi.org/10.3390/lubricants10110296

APA StyleDixit, T., & Prasad, K. E. (2022). Effect of Temperature and Sliding Velocity on the Dry Sliding Wear Mechanisms of Boron Modified Ti-6Al-4V Alloys. Lubricants, 10(11), 296. https://doi.org/10.3390/lubricants10110296