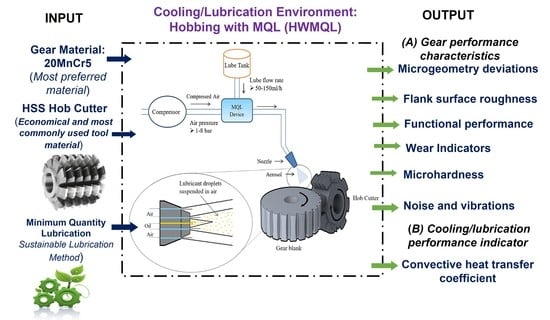

Performance Characteristics of Spur Gears Hobbed under MQL, Flood Lubrication, and Dry Environments

Abstract

:1. Introduction

- To study the influence of three hobbing lubrication environments, i.e., HWAL, HWMQL, and HWFL, on the performance characteristics of the best-quality spur gears (manufactured using their corresponding optimum parametric combinations) in terms of wear, microhardness, functional performance, noise and vibrations, flank surface roughness, and microgeometry deviations.

- To study heat dissipation from the hobbing zone in HWMQL and HWFL during spur gear manufacturing by estimating their convective heat transfer coefficients theoretically and experimentally.

2. Materials and Methods

2.1. Materials and Experimental Apparatus

2.2. Experimentation

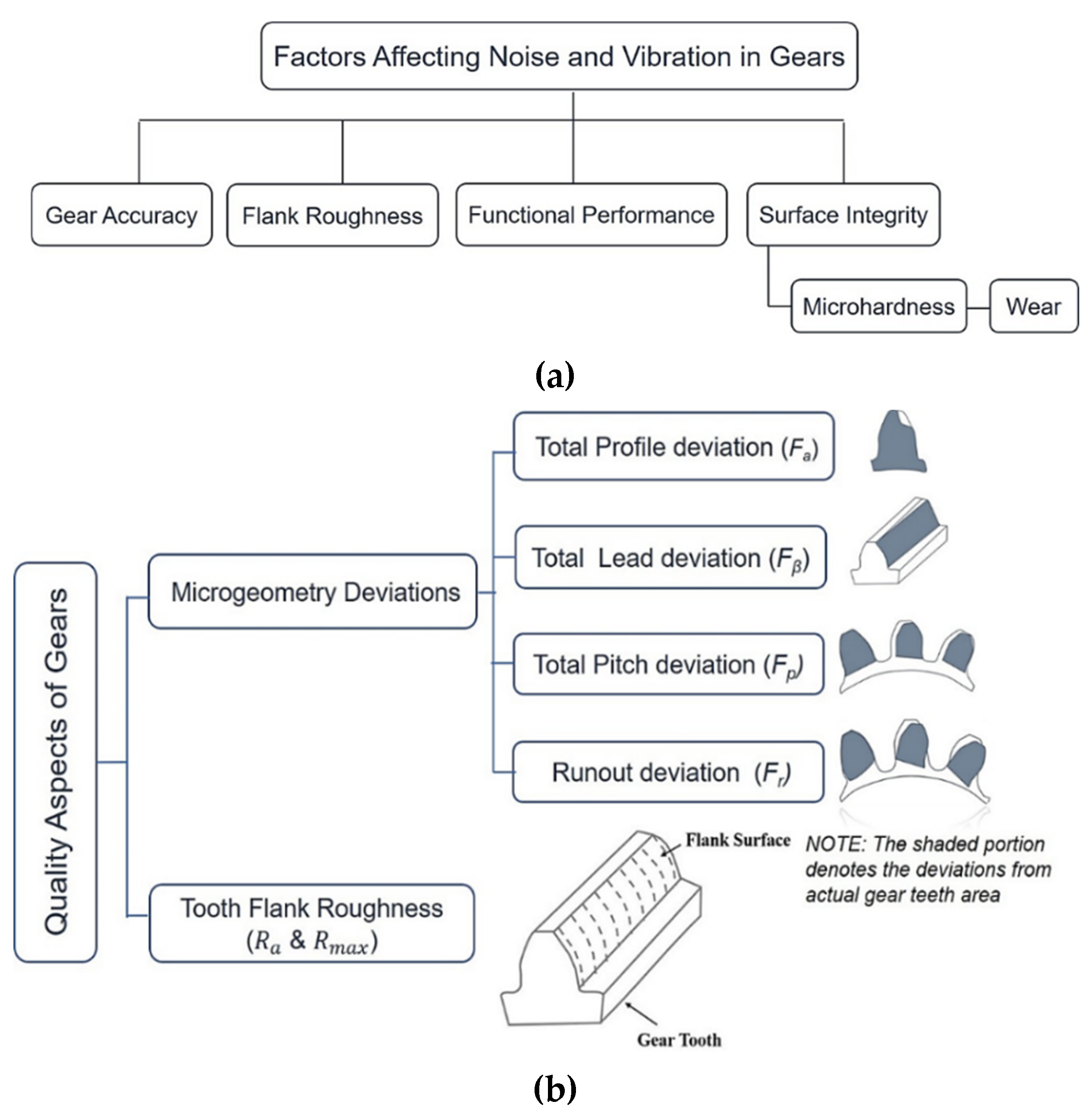

2.3. Measurement of Responses

2.3.1. Wear-Indicating Parameters and Microhardness

2.3.2. Noise and Vibration Levels

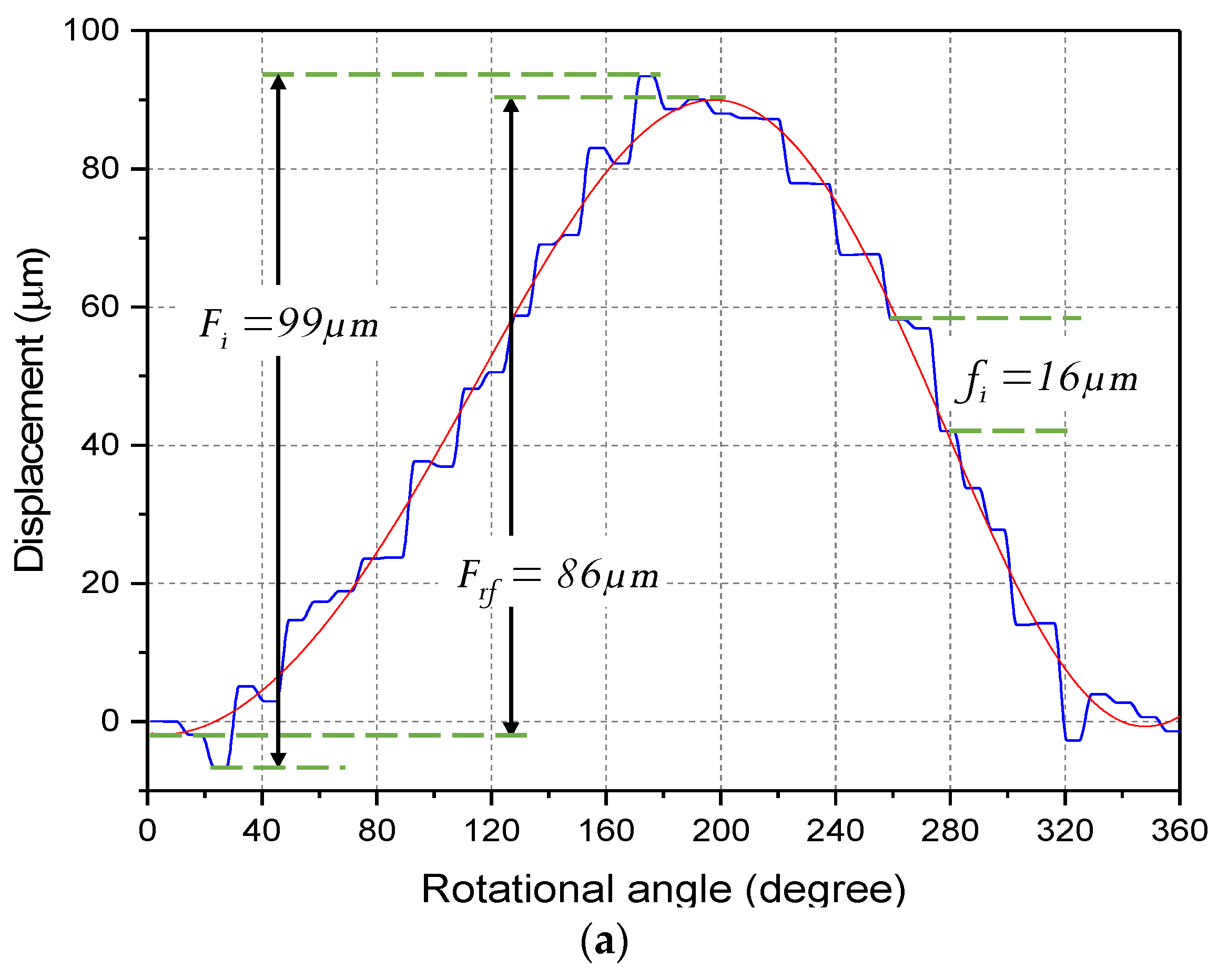

2.3.3. Functional Performance Parameters

2.3.4. Microgeometry Deviations and Flank Surface Roughness

2.3.5. Evaluation of Convective Heat Transfer Coefficient in HWMQL and HWFL

2.3.6. Evaluation of Theoretical Heat Transfer Coefficient in HWMQL

2.3.7. Evaluation of Theoretical Convective Heat Transfer Coefficient in HWFL

2.3.8. Measurement of Experimental Values of Convective Heat Transfer Coefficients

3. Results and Discussion

3.1. Microgeometry Deviations, Flank Surface Roughness, and Functional Performance

3.2. Wear Indicators and Microhardness

- The generation of a large amount of heat in the hobbing zone increases the surface temperature of the manufactured gear, which results in the formation of residual tensile stresses within the gear material after its cooling [25]. The presence of tensile residual stresses significantly decreases the microhardness, thereby adversely affecting the wear and fatigue resistance of gear material. Heat generation is significantly reduced in the case of HWMQL due to an enhanced lubrication action by the lubricant particles in the hobbing zone and cooling provided by the accompanying compressed air. It decreases residual tensile stresses, thereby increasing the microhardness of HWMQL-manufactured gear. The absence of lubrication in HWAL increases surface temperature but not enough to reach the phase transformation point, resulting in a softening of the gear material, thereby decreasing the microhardness.

- The cutting and ploughing action of the hob cutter over the gear workpiece during hobbing results in severe plastic deformation and work hardening, which leads to the generation of compressive stress within the material [26]. Since HWMQL was carried out with higher MRR at the identified optimum parametric combination of hob cutter speed as 29 m/min and axial feed rate as 0.44 mm/rev as compared to HWFL (having a combination of 22 m/min and 0.44 mm/rev) and HWAL (having a combination of 29 m/min and 0.32 mm/rev), significant plastic deformation occurred in the surface and subsurface region, which resulted in higher compressive residual stress formation, yielding higher values of microhardness [27]. The least amount of plastic deformation occurred in the case of HWAL, resulting in less values of microhardness, whereas HWFL-manufactured gear yielded intermediate values.

- The effect of subsurface microhardness on wear resistance is clearly evident from the fact that the HWAL-manufactured gear, despite showing lower values of friction force (13.7 N) and coefficient of friction (as 0.685) than the HWFL-manufactured gear (15.6 N; 0.784), exhibited less wear resistance, resulting in higher values of specific wear rate, wear rate, and sliding wear volume. This is due to the higher microhardness of HWFL-manufactured gear as compared to HWAL caused by higher plastic deformation. Thus, after the irregularities and peaks present on the flank surface in HWFL gear are worn out via abrasive wear modes, the subsurface resists further adhesive wear due to predominant effect of higher microhardness. Superior wear resistance exhibited by HWMQL-manufactured spur gear is due to a higher subsurface microhardness of its flank surface.

3.3. Noise and Vibration Characteristics

- There were considerable changes in the noise and vibrations levels of spur gears at the rotational speeds of 500 r/min and 750 r/min.

- HWMQL-manufactured spur gears resulted in the minimum noise generation for all the values of applied load and rotational speed as compared to HWAL and HWFL manufactured spur gears. They resulted in a maximum reduction in noise by 1.7 dBA and 1.8 dBA, respectively (refer experiment no. 10 of Table 6), at 750 r/min and an applied load of 0.054 Nm greater than that of HWFL and HWAL manufactured gears. This is due to the least amount of heat generation facilitated by the lubrication of fine particles and forcing the convective effect of the compressed air supplied in HWMQL. It reduces thermal deviations and BUE formation, thus resulting in smoother surfaces, helping to reduce the generation of noise and vibrations.

- The vibration of HWMQL-manufactured spur gears was also found to be lowest for all combinations of speed and applied load. It can be observed that the vibration reductions are more for speeds of 500 r/min and 750 r/min. Although reductions were also achieved for the speeds of 250 r/min and 1000 r/min, the results are insignificant. HWMQL-manufactured spur gears performed significantly better by reducing the vibration level by almost 1.09 m/s2 at a speed of 500 r/min and an applied load of 0.081 Nm, as compared to HWFL-manufactured gear. The vibration of HWMQL-manufactured spur gear was less by 1.03 m/s2 at a speed of 750 r/min and a load of 0.027 Nm than HWAL-manufactured gear. HWAL-manufactured spur gear also resulted in less vibrations as compared to HWFL-manufactured gear. Although values are almost comparable for most of the combinations of speed and applied load, it can be observed that vibration is reduced by a maximum of 0.69 m/s2 at 500 r/min and 0.054 Nm applied load.

- HWAL-manufactured spur gears also exhibited less noise generation than HWFL-manufactured spur gears for most of the combinations of speed and applied load. This is due to higher values of flank surface roughness, microgeometry deviations, and functional performance parameters in HWFL, which are caused due to inefficient lubrication conditions at comparatively higher MRR than HWAL, leading to higher heat generation and BUE formation.

3.4. Convective Heat Transfer Coefficients

4. Conclusions

- HWMQL-manufactured gears yielded the minimum values of microgeometry deviations, flank surface roughness, and functional performance parameters and simultaneously higher MRR values, as compared to HWFL and HWAL, due to the superior lubrication facilitated by the better dispersion of the lubricant particles to the hobbing zone.

- Better accessibility of the finer lubricant particles mixed with compressed air used in HWMQL helped to give a heat transfer coefficient almost nine times that of HWFL. A reduction in heat generation reduces the thermal distortion and BUE formation, thereby giving a smoother flank surface and better accuracy gears, enabling a reduction in the generation of noise and vibrations.

- HWMQL-manufactured gear yielded the minimum values of all the indicators of wear, implying their better wear resistance in actual working conditions.

- HWMQL improved the microhardness of the gear flank through the minimization of the heat accumulation at the hobbing zone, leading to a reduction in tensile residual stresses which occurs at high workpiece temperature, thereby improving the fatigue strength of the manufactured gear.

- HWFL gear exhibited better wear resistance than HWAL due to higher flank microhardness at higher MRR, whereas HWAL accounted for better gear accuracy with a comparatively smoother flank surface, although with less MRR.

- This study proves that HWMQL is capable of manufacturing comparatively better gears than HWFL and HWAL by simultaneously improving flank surface finish and microgeometry with smoother and quieter operational performance, superior wear resistance, higher fatigue strength, and longer service life, owing to its better cooling and lubrication actions. The results of this study will be very helpful for the manufacturers and users of spur gears.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Cross-section area of nozzle (m2) |

| Ag | Surface area of gear blank (m2) |

| Cpa | Specific heat of compressed air (J/kg K) |

| Cpf | Specific heat of lubricant (J/kg K) |

| Cpg | Specific heat of gear material (J/kg K) |

| Cpm | Specific heat of mixture of lubricant and its carrier (J/kg K) |

| D | Depth of cut (mm) |

| d | Diameter of nozzle (mm) |

| f | Axial feed rate (mm/rev) |

| F | Applied normal load during the fretting wear test (N) |

| Fmax | Max. value of sliding frictional force (N) |

| Fa | Total profile deviation (μm) |

| Fi | Total composite error (μm) |

| fi | Tooth-to-tooth composite error (μm) |

| Fp | Total or cumulative pitch deviation (μm) |

| Fra | Radial runout by analytical testing (μm) |

| Frf | Radial runout by functional testing (μm) |

| Fβ | Total lead deviation (μm) |

| hHWMQL | Convective heat transfer coefficient in HWMQL (W/m2K) |

| hHWFL | Convective heat transfer coefficient in HWFL (W/m2K) |

| ka | Thermal conductivity of air (W/m K) |

| kf | Thermal conductivity of lubricant (W/m K) |

| kg | Thermal conductivity of gear material (W/m K) |

| ki | Specific wear rate (mm3/Nm); |

| km | Thermal conductivity of mixture of lubricant and its carrier (W/m K) |

| Lc | Characteristic length (m) |

| mi | Mass loss during the wear test (g) |

| Nu | Nusselt number |

| Pa | Pressure of compressed air (N/m2) |

| Patm | Atmospheric pressure (N/m2) |

| Pr | Prandtl number |

| Q | Heat taken away by lubricant (W) |

| 𝑅𝑎 | Average surface roughness (μm) |

| Re | Reynold number |

| 𝑅𝑚𝑎𝑥 | Maximum surface roughness (μm) |

| S | Total sliding distance in the fretting wear test (mm) |

| Tcf | Temperature of lubricant (K) |

| Tg | Temperature of gear blank surface at hobbing zone (K) |

| tmax | Maximum interface temperature (K) |

| ∆T | Temperature reduction in the gear blank after supply of lubricant in HWMQL or HWFL (K) |

| Ua | Velocity of compressed air (m/s) |

| Uf | Velocity of lubricant (m/s) |

| V | Hob cutter speed (m/min) |

| Va | Volumetric flow rate of compressed air (m3/s) |

| Vf | Volumetric flow rate of lubricant (m3/s) |

| Vi | Total sliding wear volume during the fretting wear test (mm3) |

| Vg | Volume of gear blanks (m3) |

| W | Weight of gear material lost during hobbing (g) |

| Wblank | Weight of gear blank (g) |

| Wgear | Weight of the manufactured gear (g) |

| Mass fraction of the lubricant mist particles in aerosol mixture in HWMQL | |

| ΔN | Change in noise level (dBA) |

| ΔT | Reduction in temperature at workpiece (K) |

| ΔV | Change in vibration level (mm/s2) |

| α | Nozzle inclination angle (degrees) |

| µa | Dynamic viscosity of compressed air (kg/m s) |

| µf | Dynamic viscosity of lubricant (kg/m s) |

| µm | Dynamic viscosity of mixture of lubricant and its carrier (kg/m s) |

| ρa | Density of compressed air (kg/m3) |

| ρf | Density of lubricant (kg/m3) |

| ρg | Density of gear material (kg/m3) |

| ρm | Density of lubricant and its carrier (kg/mm3) |

References

- Davis, J.R. Gear Materials, Properties and Manufacture, 1st ed.; ASM International: Materials Park, OH, USA, 2005. [Google Scholar] [CrossRef]

- Sekar, R.; Sathishkumar, R. Enhancement of wear resistance on normal contact ratio spur gear pairs through non-standard gears. Wear 2017, 380–381, 228–239. [Google Scholar] [CrossRef]

- Sikorski, M.E. Correlation of the Coefficient of Adhesion with Various Physical and Mechanical Properties of Metals. Trans. ASME Ser. D—J. Basic Eng. 1963, 85, 279–285. [Google Scholar] [CrossRef]

- Petare, A.C.; Jain, N.K. On simultaneous improvement of wear characteristics, surface finish and microgeometry of straight bevel gears by abrasive flow finishing process. Wear 2018, 404–405, 38–49. [Google Scholar] [CrossRef]

- Kohara Gear Industry, Gear Noise. 2020. Available online: https://khkgears.net/gear-knowledge/introduction-to-gears/gear-noise/ (accessed on 6 January 2020).

- Kharka, V.; Jain, N.K. Achieving sustainability in machining of cylindrical gears. In Sustainable Manufacturing: Handbooks in Advanced Manufacturing; Gupta, K., Salonitis, K., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 391–426. [Google Scholar] [CrossRef]

- Fratila, D. Evaluation of near-dry machining effects on gear milling process efficiency. J. Clean. Prod. 2009, 17, 839–845. [Google Scholar] [CrossRef]

- Fratila, D. Research of environment-friendly techniques influence on gear accuracy in context of sustainable manufacturing. Acta Mech. Slovaca 2012, 16, 58–65. [Google Scholar] [CrossRef]

- Zhang, G.; Wei, H. Selection of optimal process parameters for gear hobbing under cold air minimum quantity lubrication cutting environment. In Proceedings of the 36th International MATADOR Conference, Manchester, UK, July 2010; Hinduja, S., Li, L., Eds.; Springer: London, UK, 2010; pp. 231–234. [Google Scholar]

- Rotella, G.; Dillon, O.W.; Umbrello, D.; Settineri, L.; Jawahir, I.S. The effects of cooling conditions on surface integrity in machining of Ti6Al4V alloy. Int. J. Adv. Manuf. Technol. 2014, 71, 47–55. [Google Scholar] [CrossRef]

- Bordin, A.; Bruschi, S.; Ghiotti, A. The effect of cutting speed and feed rate on the surface integrity in dry turning of CoCrMo alloy. Procedia CIRP 2014, 13, 219–224. [Google Scholar] [CrossRef]

- Qu, D.; Zhang, P.; Xue, J.; Fan, Y.; Chen, Z.; Wang, B. Experimental study on the effects of coolants on surface quality and mechanical properties of micromilled thin-walled elgiloy. Materials 2018, 11, 1497. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Klocke, F.; Döbbeler, B.; Lung, S.; Seelbach, T.; Jawahir, I.S. Analysis of surface integrity in machining of AISI 304 stainless steel under various cooling and cutting conditions. AIP Conf. Proc. 2018, 1960, 070015. [Google Scholar] [CrossRef]

- Kharka, V.; Jain, N.K.; Gupta, K. Influence of MQL and hobbing parameters on microgeometry deviations and flank roughness of spur gears manufactured by MQL assisted hobbing. J. Mater. Res. Technol. 2020, 9, 9646–9656. [Google Scholar] [CrossRef]

- Sawant, M.S.; Jain, N.K. Investigations on wear characteristics of stellite coating by micro-plasma transferred arc powder deposition process. Wear 2017, 378–379, 155–164. [Google Scholar] [CrossRef]

- Zhou, J.; Sun, W.; Cao, L. Vibration and noise characteristics of a gear reducer under different operation conditions. J. Low Freq. Noise Vib. Active Control 2019, 38, 574–591. [Google Scholar] [CrossRef]

- Rana, V.; Petare, A.; Jain, N.K.; Parey, A. Using abrasive flow finishing process to reduce noise and vibrations of cylindrical and conical gears. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 236, 1341–1354. [Google Scholar] [CrossRef]

- Shokrani, A.; Betts, J.; Carnevale, M. Thermal analysis in MQL end milling operations. Procedia CIRP 2021, 101, 358–361. [Google Scholar] [CrossRef]

- Hadad, M.; Sadeghi, B. Thermal analysis of minimum quantity lubrication-MQL grinding process. Int. J. Mach. Tools Manuf. 2012, 63, 1–15. [Google Scholar] [CrossRef]

- Graham, D. Dry Out; Cutting Tool Engineering. 2000, pp. 56–65. Available online: https://www.ctemag.com/news/articles/dry-out (accessed on 20 October 2021).

- Levy, S. Two-Phase Flow in Complex Systems; John Wiley & Sons: New York, NY, USA, 1999. [Google Scholar]

- Dogu, Y.; Aslan, E.; Camuscu, N. A numerical model to determine temperature distribution in orthogonal metal cutting. J. Mater. Processing Technol. 2006, 171, 1–9. [Google Scholar] [CrossRef]

- Ganguli, S.; Kapoor, S.G. Improving the performance of milling of titanium alloys using the atomization-based cutting fluid application system. J. Manuf. Proc. 2016, 23, 29–36. [Google Scholar] [CrossRef]

- Gupta, K.; Laubscher, R.F.; Davim, J.P.; Jain, N.K. Recent developments in sustainable manufacturing of gears: A review. J. Clean. Prod. 2016, 112, 3320–3330. [Google Scholar] [CrossRef]

- Marques, A.; Guimarães, C.; Da Silva, R.; Cindra, F.M.; Falco, S.W.; Machado, A. Surface integrity analysis of Inconel 718 after turning with different solid lubricants dispersed in neat oil delivered by MQL. Proc. Manuf. 2016, 5, 609–620. [Google Scholar] [CrossRef]

- Yan, P.; Rong, Y.; Wang, X.; Zhu, J.; Jiao, L.; Liang, Z. Effect of cutting fluid on precision machined surface integrity of heat-resistant stainless steel. Proc. Inst. Mech. Eng. J. Eng. Manuf. 2016, 232, 1535–1548. [Google Scholar] [CrossRef]

- Sakhvadze, G.; Shokhin, A.; Kikvidze, O. Residual stress and microhardness increasing induced by two-sided laser shock processing. Vibroengineering Procedia 2016, 8, 434–439. Available online: https://www.extrica.com/article/17665 (accessed on 18 September 2021).

| Range of Reynold Number | Values of Constants | |

|---|---|---|

| C | b | |

| 0.4–4 | 0.989 | 0.330 |

| 4–40 | 0.911 | 0.385 |

| 40–4000 | 0.683 | 0.466 |

| 4000–40,000 | 0.193 | 0.618 |

| 40,000–400,000 | 0.0266 | 0.805 |

| Property | HWMQL | HWFL | ||||

|---|---|---|---|---|---|---|

| Air | Lubricant | Mixture | Water | Lubricant | Mixture | |

| Density (kg/m3) | 1.225 | 838 | 1.36 | 1000 | 880 | 994 |

| Thermal conductivity (W/m.k) | 0.026 | 0.256 | 0.029 | 0.561 | 0.378 | 0.55 |

| Specific heat (J/kg K) | 1012 | 2494.03 | 1075 | 4217 | 2862 | 4138.62 |

| Dynamic viscosity (kg/m s) | 1.81 × 10−5 | 2.35 × 10−2 | 2.01 × 10−5 | 1.7 × 10−3 | 4.6 × 10−2 | 1.9 × 10−3 |

| Fixed parameters | Diameter of nozzle: 3 (mm) Air pressure: 3 × 105 (N/m2) Flow rate of air: 4.03 × 10−2 (m3/s) Flow rate of lubricant: 2.7 × 10−8 (m3/s) Velocity of air and lubricant: 571.4 (m/s) | Diameter of pipe: 15 (mm) Flow rate of lubricant: 6.94 × 10−7 (m3/s) Velocity of air and lubricant: 3.92 × 10−3 (m/s) | ||||

| Properties of gear material | Density: 7800 (kg/m3); specific heat: 460 (J/kg.K); area of gear blank ‘Ag’: 4.8 × 10−3 (m2); vol. of gear blank ‘Vg’: 153,631.2 × 10−9 (m3) | |||||

| Responses | Best-Quality Spur Gear Manufactured by | ||

|---|---|---|---|

| HWMQL | HWAL | HWFL | |

| Microgeometry deviation parameters determined by analytical testing | |||

| Total profile deviation ‘Fa’ (µm) | 45.1 | 59.3 | 61.2 |

| Total lead deviation ‘Fβ’ (µm) | 13.1 | 14.7 | 17.7 |

| Total pitch deviation ‘Fp’ (µm) | 100.6 | 109.7 | 118.2 |

| Radial runout ‘Fra’ (µm) | 112.5 | 120.7 | 134.4 |

| Functional performance parameters determined by dual flank roll testing | |||

| Total composite error ‘Fi’ (µm) | 99 | 126 | 170 |

| Tooth-to-tooth composite error ‘fi’ (µm) | 16 | 33 | 38 |

| Radial runout ‘Frf’ (µm) | 86 | 119 | 158 |

| Flank surface roughness parameters | |||

| Max. surface roughness ‘Rmax’ (µm) | 5.14 | 5.87 | 7.37 |

| Avg. surface roughness ‘Ra’(µm) | 0.61 | 0.63 | 0.64 |

| Parameters | HWFL | HWMQL | HWAL |

|---|---|---|---|

| Max. value of frictional force | 15.6 | 12.2 | 13.7 |

| Max. value of coefficient of friction | 0.784 | 0.613 | 0.685 |

| Specific wear rate ‘ki’ (/N-m) | 1.63 × 10−5 | 0.52 × 10−5 | 2.21 × 10−5 |

| Wear rate (/m) | 3.25 × 10−4 | 1.04 × 10−4 | 4.42 × 10−4 |

| Wear volume ‘Vi’ () | 0.078 | 0.025 | 0.106 |

| Parameters | HWFL | HWMQL | HWAL | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Indentation force (g) | 100 | 200 | 300 | 100 | 200 | 300 | 100 | 200 | 300 |

| Average diagonal length (µm) | 37.1 | 42.3 | 50.4 | 20.3 | 27.6 | 34.9 | 38.5 | 45.2 | 52.7 |

| Average depth of indentation (µm) | 3.8 | 4.3 | 6.4 | 2.4 | 3.6 | 4.1 | 5.8 | 6.2 | 6.5 |

| Average microhardness (HV) | 423 | 365 | 309 | 515 | 477 | 396 | 398 | 352 | 284 |

| Standard deviation (HV) | 19 | 27 | 22 | 22 | 14 | 18 | 41 | 26 | 19 |

| Exp. No. | Rotational Speed (r/min) | Applied Load (Nm) | For the Best-Quality Spur Gear | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Noise Level (dBA) | Vibration (m/s2) | |||||||||||||

| HWFL | HWAL | HWMQL | ΔNFD | ΔNFM | ΔNDM | HWFL | HWAL | HWMQL | ΔVFD | ΔVFM | ΔVDM | |||

| 1 | 250 | 0.027 | 65.3 | 65.9 | 65.1 | −0.6 | 0.2 | 0.8 | 2.32 | 2.27 | 2.16 | 0.05 | 0.16 | 0.11 |

| 2 | 0.054 | 65.8 | 65.1 | 64.9 | 0.7 | 0.9 | 0.2 | 2.34 | 2.32 | 2.16 | 0.02 | 0.18 | 0.16 | |

| 3 | 0.081 | 65.4 | 64.8 | 64.8 | 0.6 | 0.6 | 0 | 2.37 | 2.34 | 2.20 | 0.03 | 0.17 | 0.14 | |

| 4 | 0.108 | 65 | 65.2 | 64.9 | 0.1 | 0.1 | 0.3 | 2.34 | 2.33 | 2.15 | 0.01 | 0.18 | 0.18 | |

| 5 | 500 | 0.027 | 76 | 75.6 | 75 | 0.4 | 1 | 0.6 | 3.47 | 2.83 | 2.68 | 0.64 | 0.79 | 0.15 |

| 6 | 0.054 | 76.2 | 76 | 74.8 | 0.2 | 1.4 | 1.2 | 3.52 | 2.85 | 2.55 | 0.67 | 0.97 | 0.3 | |

| 7 | 0.081 | 76.1 | 76.5 | 75.3 | −0.4 | 0.8 | 1.2 | 3.62 | 3.06 | 2.53 | 0.56 | 1.09 | 0.53 | |

| 8 | 0.108 | 76.5 | 75.5 | 75.1 | 1 | 1.4 | 0.4 | 3.54 | 3.00 | 2.50 | 0.54 | 1.04 | 0.5 | |

| 9 | 750 | 0.027 | 79.1 | 79 | 77.6 | 0.1 | 1.5 | 1.4 | 3.92 | 4.02 | 2.99 | −0.1 | 0.93 | 1.03 |

| 10 | 0.054 | 79.2 | 79.3 | 77.5 | −0.1 | 1.7 | 1.8 | 3.97 | 4.05 | 3.18 | −0.08 | 0.79 | 0.87 | |

| 11 | 0.081 | 79.3 | 79 | 77.9 | 0.3 | 1.4 | 1.1 | 4.16 | 4.02 | 3.43 | 0.14 | 0.73 | 0.59 | |

| 12 | 0.108 | 80.1 | 79.7 | 78.1 | 0.2 | 2 | 1.6 | 4.42 | 4.11 | 3.36 | 0.31 | 1.06 | 0.75 | |

| 13 | 1000 | 0.027 | 80.7 | 80.3 | 80.1 | 0.6 | 0.4 | 0.2 | 4.91 | 4.60 | 4.34 | 0.31 | 0.57 | 0.26 |

| 14 | 0.054 | 81.1 | 80.4 | 80.1 | 0.7 | 1 | 0.3 | 4.66 | 4.52 | 4.19 | 0.14 | 0.47 | 0.33 | |

| 15 | 0.081 | 80.9 | 80.8 | 80.5 | 0.4 | 0.1 | 0.3 | 4.99 | 4.83 | 4.32 | 0.16 | 0.67 | 0.51 | |

| 16 | 0.108 | 81 | 80.7 | 79.9 | 0.3 | 1.1 | 0.8 | 4.76 | 4.90 | 4.08 | −0.14 | 0.68 | 0.82 | |

| Process | Identified Optimum Parameters | Reading Number | Temperature Change | Net Heat Loss Q (W) | |

|---|---|---|---|---|---|

| Measured Values | Average | ||||

| HWMQL | Hob cutter speed: 29 m/min Axial feed rate: 0.44 mm/rev | R-1 | 63.5 | 67.0 | 2638.4 |

| R-2 | 67.2 | ||||

| R-3 | 64.8 | ||||

| R-4 | 72.3 | ||||

| R-5 | 69.5 | ||||

| HWFL | Hob cutter speed: 22 m/min Axial feed rate: 0.44 mm/rev | R-1 | 34.7 | 32.5 | 271.3 |

| R-2 | 33.6 | ||||

| R-3 | 32.9 | ||||

| R-4 | 30.3 | ||||

| R-5 | 31.5 | ||||

| Process | Convective Heat Transfer Coefficient | ||

|---|---|---|---|

| Theoretically Computed | Experimentally Measured | Error % | |

| HWMQL | 2782.81 | 3214.4 | 13.4 |

| HWFL | 303.23 | 353.3 | 14.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kharka, V.; Rana, V.; Jain, N.K.; Gupta, K. Performance Characteristics of Spur Gears Hobbed under MQL, Flood Lubrication, and Dry Environments. Lubricants 2022, 10, 230. https://doi.org/10.3390/lubricants10100230

Kharka V, Rana V, Jain NK, Gupta K. Performance Characteristics of Spur Gears Hobbed under MQL, Flood Lubrication, and Dry Environments. Lubricants. 2022; 10(10):230. https://doi.org/10.3390/lubricants10100230

Chicago/Turabian StyleKharka, Vishal, Vivek Rana, Neelesh Kumar Jain, and Kapil Gupta. 2022. "Performance Characteristics of Spur Gears Hobbed under MQL, Flood Lubrication, and Dry Environments" Lubricants 10, no. 10: 230. https://doi.org/10.3390/lubricants10100230

APA StyleKharka, V., Rana, V., Jain, N. K., & Gupta, K. (2022). Performance Characteristics of Spur Gears Hobbed under MQL, Flood Lubrication, and Dry Environments. Lubricants, 10(10), 230. https://doi.org/10.3390/lubricants10100230