1. Introduction

With the emergence of ultra-precision manufacturing technology, a large number of complex and precision components and objects were fabricated to meet various needs, which pushed the development of many cutting-edge industries (such as aerospace, automobile manufacturing, large scale integrated circuit, etc.). The precision 3D data of the objects is a basic evaluation criterion of their machining accuracy and also an important guarantee for their functions and surface properties [

1]. Therefore, the 3D shape measurement has gradually become an indispensable part of modern industry, and a precise detection will greatly improve the quality of the products [

2,

3]. The three-coordinate measuring machine (CMM) has been utilized to obtain the spatial coordinates of the object points with a probe for many years; its principle is simple but time-consuming and easily causes scratches on the surface, which may damage the surface property [

4]. With the concept of nondestructive inspection and the progress of computer technology and electronics devices, the optical 3D measurement methods with the advantages of non-contact operation and dense-data acquisition have been widely explored [

5,

6,

7]. The fringe projection technique is a typical optical measurement method [

8,

9]. When the coded fringe pattern is projected onto the measured surface, the image is modulated by the topography of the surface. Once the deformed fringe pattern is demodulated, the 3D coordinate of the measured surface can be accurately obtained. After years of development, the fringe projection technology has made great progress in speed, accuracy, size, and other measurement aspects. However, this technique is only suitable for diffused surface measurement. When the coded fringe pattern is projected onto a specular surface, like an astronomical telescope, car windshield, painted body, polished mechanical parts, and so on, light spots appear on the tested surface, so that the shape information is difficult to retrieve from the deformed patterns. A traditional way to solve this problem is to spray coating materials on the specular surface to make it show diffuse reflection characteristics, then the fringe projection technique can be applied to obtain its 3D data, but this behavior may damage the optical properties of the precision specular surface [

10].

In order to flexibly measure the specular surfaces and satisfy various kinds of engineering demands, some optical methods that cleverly use the reflective characteristics of the specular surface have been proposed [

11,

12,

13,

14]. Among these techniques, interferometry and PMD technology demonstrate great advantages [

15,

16]. Interferometry is the most accurate optical measurement technology. Based on the principle of light wave superposition, it obtains the relevant information of the object by analyzing the alternating light and dark interference fringes. The surface form determined by this method often has a sub-nanometer resolution [

17,

18]. However, it is difficult to measure a specular object with complicated surfaces, especially a free-form surface, and usually requires expensive auxiliary equipment. PMD does not have these restrictions. Its simple system structure, large measuring area, and high dynamic range give it more applicability in the measurement of specular surfaces.

As commonly known, when a camera is used to shoot a specular object, the image captured by the camera is not the texture image of the target object, but a virtual image of the surrounding environment reflected by the object. Moreover, the reflected image is distorted by the topography of the object. PMD technology takes the advantage of this fact to reconstruct the 3D shape of the object [

19,

20,

21]. In order to weaken the brightness of the light source and avoid the light spots on the measured specular surface, the coded sinusoidal fringe pattern is displayed on a liquid crystal display (LCD) screen as the input source, and then a camera is utilized to collect the deformed patterns reflected by the object. Then the slope information of the measured object is obtained through the phase difference between the input fringe pattern and the deformed pattern. Finally, an integral algorithm is implemented to recover the 3D shape of the object [

22,

23]. Su et al. proposed a software-configurable optical test system for the measurement of large, highly aspherical shapes; the spatial relationship between the imaging point, the measured point, and the corresponding screen pixel is set up to reconstruct the 3D shape of the object [

24]. However, this system is mostly used for measuring the regular specular surfaces (i.e., spherical or aspherical mirrors). Knauer et al. established a stereo deflectometry system, in which two cameras were used to capture the reflected fringe patterns [

25]. By assuming the spatial position of a measured point along its reflected ray, two normal vectors with respect to different cameras are obtained. Then, the uniqueness of the normal vector of the object point is used to identify the real slope value, and finally the 3D shape is recovered by slope integration. This method seriously relies on the system calibration accuracy, otherwise it will get an inaccurate result. Graves et al. presented a model-free iteration deflectometry approach, which takes no input model. The relationship between phase, slope, and height is correlated by system parameters, and the iteration strategy is applied to get a converged reconstruction surface [

26]. It provides an accurate 3D measurement result, but the multiple integrations lead to a continuously accumulating system error. To eliminate the system error in each cycle, Wang et al. introduced a system error control method with rotation self-shearing into the iteration circle, and then the measured points were iteratively corrected according to the reconstructed surface [

27]. Furthermore, some dynamic specular surfaces measurement methods were proposed, only one fringe pattern is required in these methods. Huang et al. built a monoscopic fringe reflection system with a two-dimensional Fourier algorithm [

28]. In this case, a composite fringe pattern is used for the measurement of dynamic specular surfaces. Later, Wu et al. replaced the cross grating with a color-encoded fringe pattern to solve the spectrum overlapping problem [

29]. Additionally, the color intensity crosstalk problem between the three channels is discussed in their study, and the results show that it seldom affects the phase accuracy. All the methods mentioned above retrieve the topography of the object by slope integration. Even though they guarantee high precision, the integration process makes them unable to measure structured specular surfaces.

To tackle this issue, some other PMD models that can directly calculate the height data of the tested surface through phase change were explored. Guo et al. moved the LCD screen parallel to several positions, then the incident light was fitted by the least square method to solve the intrinsic height-slope ambiguity problem in PMD technology, thus the spatial position of each object point was acquired without slope integration [

30]. However, the physical movement of the LCD screen may introduce errors. To avoid moving of the device, a method named direct PMD (DPMD) is put forward [

31], in which two LCD screens are introduced to construct the incident ray and a reference plane mirror is used to evaluate the topography of the measured surface. In a properly configured DPMD system, suppose

R is a point on the reference plane mirror, and it reflects the information of pixel

R1 on the first LCD plane and pixel

R2 on the second LCD plane into point

m in the camera image plane. The reflected ray of

R can be easily obtained by connecting point

m and the optical center

o of the camera. Subsequently, the physical positions of

R1 and

R2 are positioned by the phase values collected by

m, and then the incident light

is determined. When the measured object is placed in front of the reference plane, it is assumed that point

M on the measured surface reflects the screen pixels into

m. Since

m only collects information along

, the reflected rays of

R and

M coincide, and the incident ray of

M is achieved by the new phase value collected by

m. Finally, the height information of

M can be deduced by the geometric relationship between incident rays and reflected ray. Therefore, the DPMD technique is not only displacement-free, but it can also calculate the height value of each object point independently, which means it has the ability to measure specular objects having isolated surfaces. However, compared to the height change of the surface, PMD technology is more sensitive to slope variation, which leads to the fact that the accuracy of DPMD is far lower than the accuracy of the object shape reconstructed by the slope integration method [

32].

Considering the limitations of the existing PMD technologies, we proposed a stereo-DPMD method to realize the high accuracy measurement of structured specular surfaces. In our method, a camera is added into the DPMD measurement system to obtain the slope data of the measured surface. The measured structured specular object is separated into individual continuous regions, hence, the topography of each region can be obtained accurately by slope integration. Meanwhile, the advantage of the original DPMD system that can calculate the height information of discrete object points is maintained, so the 3D shape of the measured object is reconstructed by combining the topography and spatial position of each continuous surface.

The rest of the paper is organized as follows.

Section 2 presents the stereo-DPMD system, the height and slope calculation geometric model is introduced, and the measurement principle of the structured specular surfaces is also demonstrated. The system parameters that need to be calibrated are analyzed in

Section 3. Moreover, a global optimization calibration method is demonstrated. In

Section 4, an experimental setup is calibrated and two structured specular objects are measured to verify the feasibility of the proposed method.

Section 5 summarizes the paper.

2. Materials and Methods

In PMD technology, the deformed fringe pattern reflected by the object contains the shape information of the measured surface, and its absolute phase information is used to calculate the slope field or height dataset of the surface. Nevertheless, limited by the accuracy of the phase calculation algorithm and various noises in the measurement, phase error is inevitable. Thus, the PMD measurement models with higher phase error tolerance can obtain better reconstruction results [

32,

33]. The influence of the phase error on the measurement results is analyzed, as shown in

Figure 1. The phase information

of

A is collected by point

m in the camera image plane after being reflected by point

M on the surface

S. However, the phase error makes the actual calculated phase value of

m be

, which causes the incident point to be wrongly positioned at point

A’. If the height information of the measured point is deduced directly from this reflection, a point

M’ on the surface

S1 will be searched as the real point

M. The slope values of

M and

M’ are equivalent, while the height difference between them is

h. However, if the surface is expected to be recovered with a slope integration algorithm,

A’ will be taken as the incident point and

m as the imaging point to solve the slope data of the point under test; its corresponding incident ray changes from

AM to

A’

M, and the slope error is

γ. It can be seen clearly from

Figure 1 that the anti-noise performance of slope data is better than that of height data, and the relevant formula derivation can be found in [

32]. Therefore, slope integration is the key step to obtain high accuracy measurements of specular surfaces.

However, the nature of the integration algorithm makes it impossible to reconstruct the 3D shape of structured specular surfaces. Incorrect height data appears at the edges of two discontinuous surfaces and is then accumulated into the height calculation process of other surfaces. The reason for this phenomenon is that the height of discontinuous edge points cannot be simply calculated with the slope data and step length of adjacent edge points. Therefore, we proposed a stereo-DPMD method to perform the high precision 3D measurement of structured specular surfaces. The measured object is separated into individual continuous surfaces, and the relative positions between different surfaces are estimated by a DPMD model, then the topography of each isolated surface is accurately achieved by slope integration. Finally, the topography and spatial position of each surface are fused to reconstruct the 3D shape of the structured specular object.

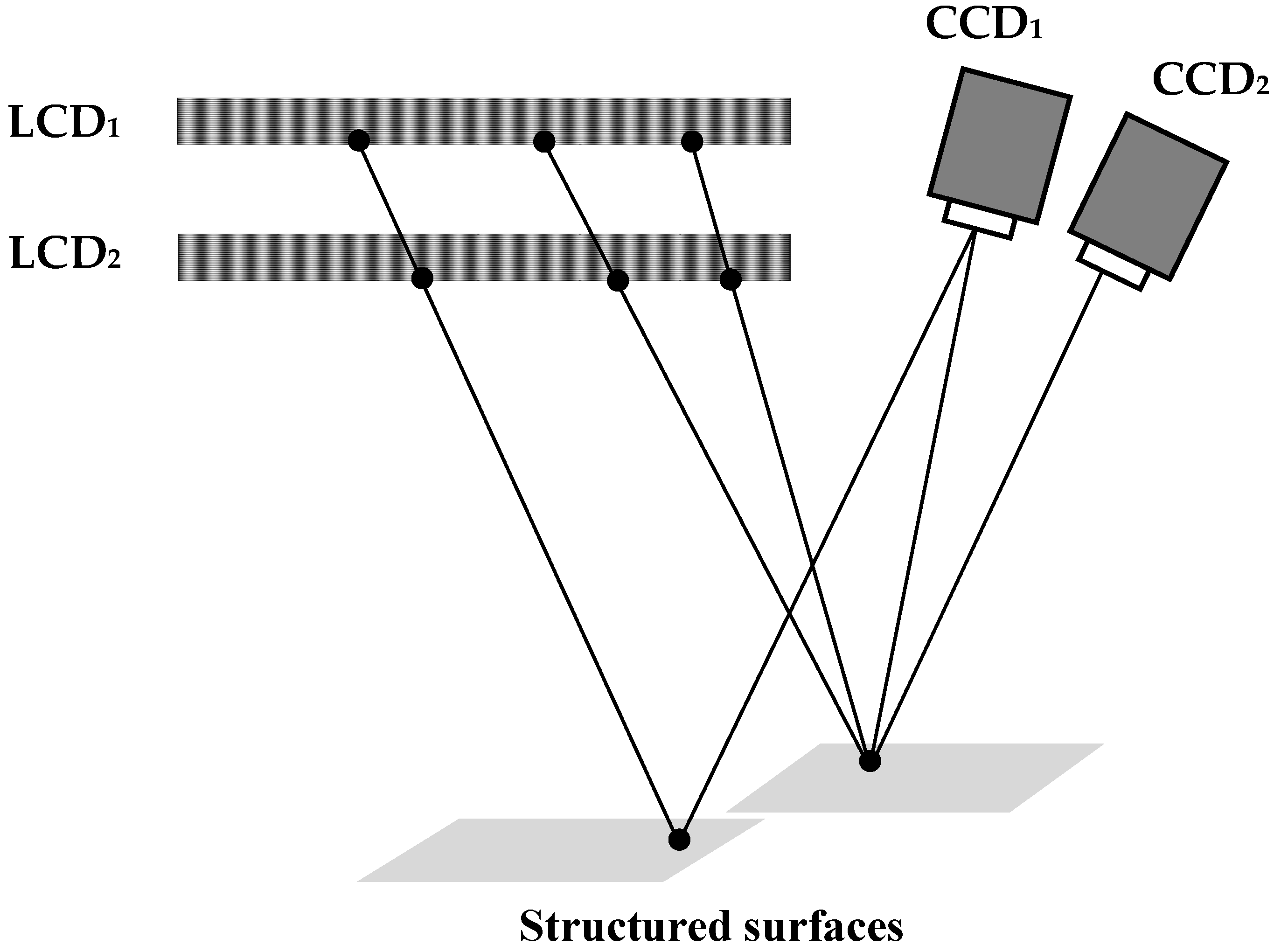

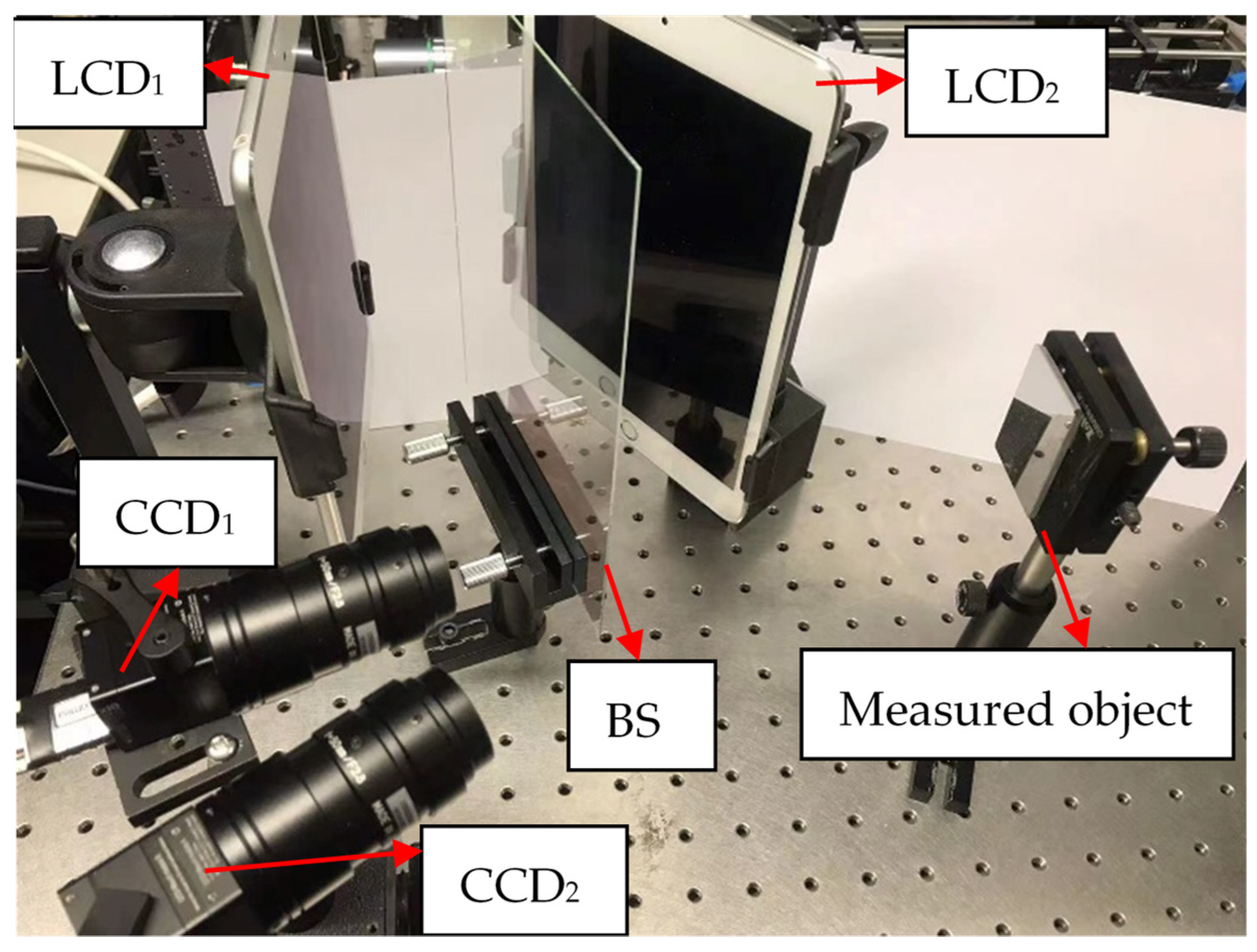

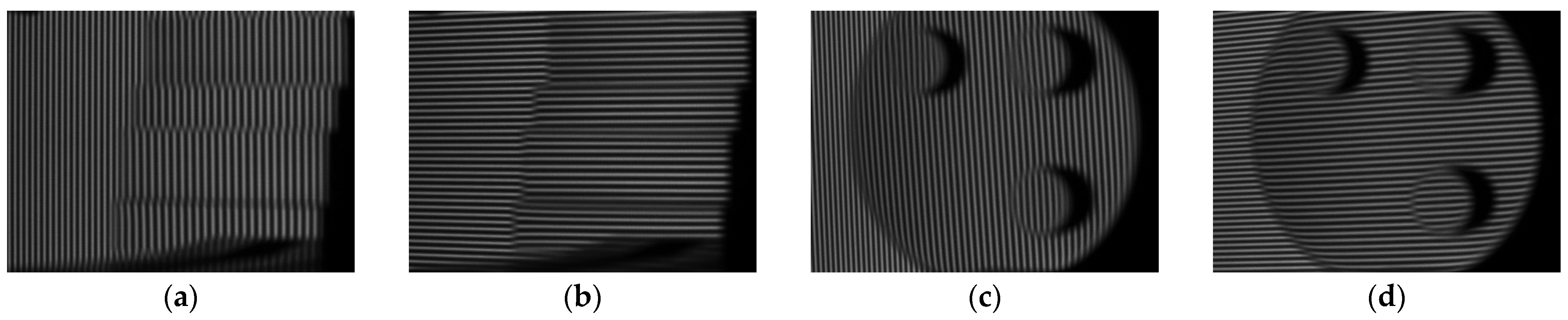

Figure 2 shows the schematic setup of the stereo-DPMD technology. It includes two LCD screens, LCD

1 and LCD

2, which are parallel; two charge coupled device (CCD) cameras; and the measured object. In the system, the two LCD screens and CCD

1 make up the DPMD system to evaluate the relative position between the two different isolated surfaces, the two CCD cameras and LCD

1 form the stereo deflectometry model for the calculation of the slope field. When the sinusoidal fringe patterns are displayed onto the LCD screens, the CCD cameras collect the images reflected by the object. Then, the absolute phase information of the deformed fringe patterns is calculated to retrieve the 3D shape of the object through system parameters.

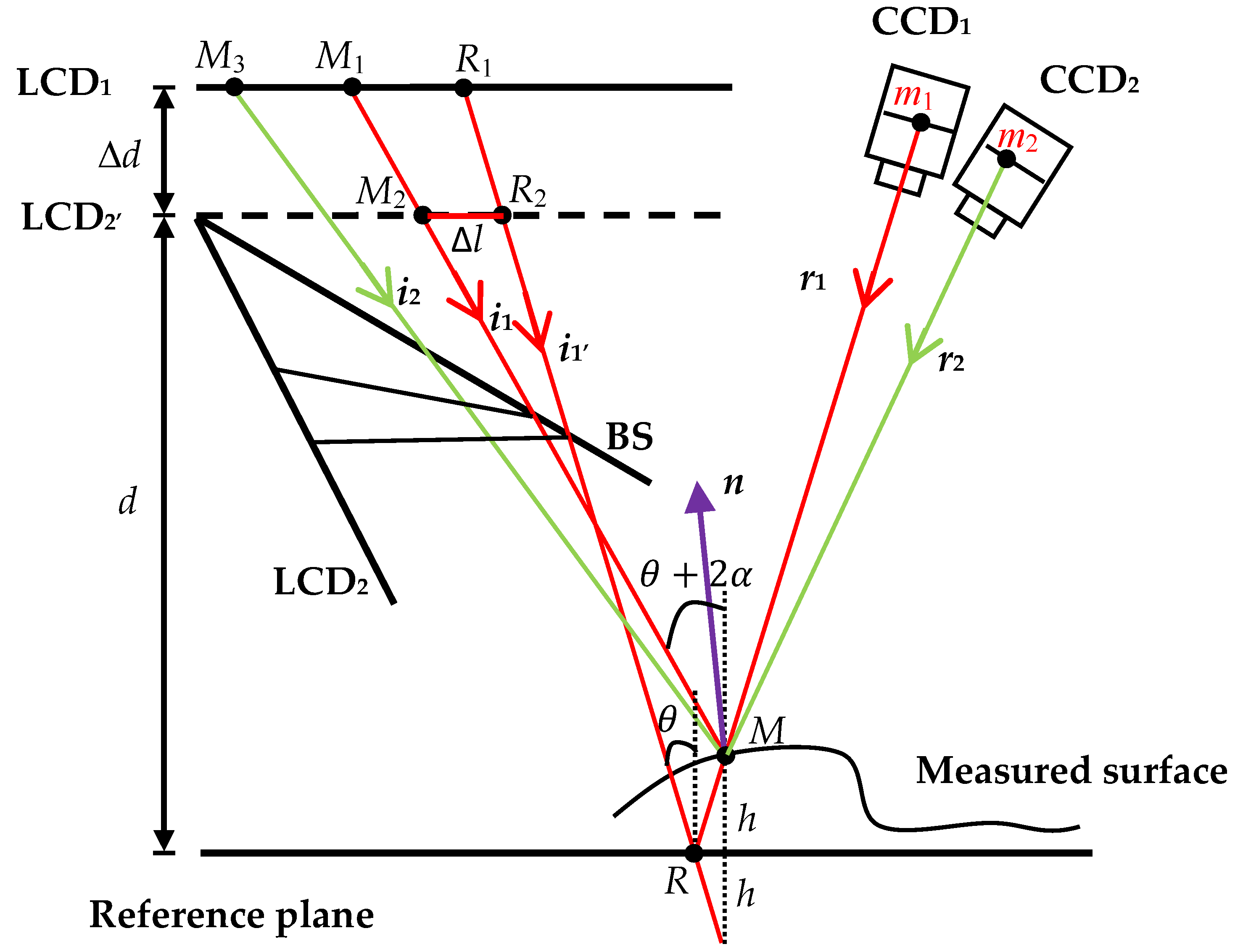

The mathematical model is demonstrated in

Figure 3. A beam splitter (BS) is utilized to avoid the occlusion of LCD

1 by LCD

2. The BS is placed at a position where the virtual image of the LCD

2 screen LCD

2′ is parallel to LCD

1. Additionally, a reference plane mirror is added to assist the measurement, and this plane mirror is located parallel to the two LCD screens. In

Figure 3, the distance between LCD

2′ and LCD

1 is Δ

d, and the distance between LCD

2′ and the reference mirror is

d.

For a point

R on the reference plane, its reflected ray

r1 passes through the optical center of CCD

1 and imaged at point

m1. Based on the phase information recorded by

m1, the corresponding screen points

R1 on LCD

1 and

R2 on LCD

2′ are acquired, then the incident light

i1′ is determined accordingly. When a measured object is placed in front of the plane mirror, the reflected ray collected by pixel

m1 still passes through the optical center, so its direction remains unchanged. However, the height and slope change of the measured point (from

R to

M) varies the incident ray from

i1′ to

i1. The corresponding screen pixels locate at

M1 and

M2. According to the geometrical relationship in

Figure 2, the following equations are obtained, in which

denotes the vertical phase data of point

X,

q is the physical period of fringe pattern,

and

are the incident angles of

i1′ and

i1,

is the angle difference between the normal vectors of

R and

M, and

represents the horizontal distance between

R2 and

M2.

Then, the height information of the point

M can be deduced by [

28]:

Equation (2) shows that a well-deployed DPMD system is capable of acquiring the height dataset of the structured specular object and can reconstruct its 3D topography. However, to improve the measurement accuracy of each isolated surface, the slope field of the object is calculated. The horizontal and vertical sinusoidal fringe patterns are displayed on LCD

1 screen, then the patterns reflected by the object are captured by CCD

1 and CCD

2 simultaneously. An imaging point

m is selected to make an inverse ray tracing. Its reflected ray

r1 is still determined by the pinhole model, and its screen pixel

M1 is acquired based on the phase value captured by

m. Assuming that the point

M on

r1 is the measured point, the second reflected ray

r2 of point

M with respect to CCD

2 is achieved by linking

M with the optical center of CCD

2, which intersects the image plane of CCD

2 at point

m2. Then, by looking up the phase value of

m2 on the LCD

1 plane, the screen point

M3 can be found, and a new reflection relation is formed. At this time, two normal vectors

(

k = 1 or 2) of the point

M can be calculated through two groups of incident rays and reflected rays

.

Subsequently, the fact that the target point M has only one normal vector is used to distinguish the real slope data. If n1 and n2 are equal, the correct slope information is obtained, otherwise a new point on r1 will be reassumed to seek the slope value. Moreover, to tolerate the inevitable systematical error, a threshold is set to stop the point assuming process. When the difference between two normal vectors is less than the threshold, the slope value is acquired.

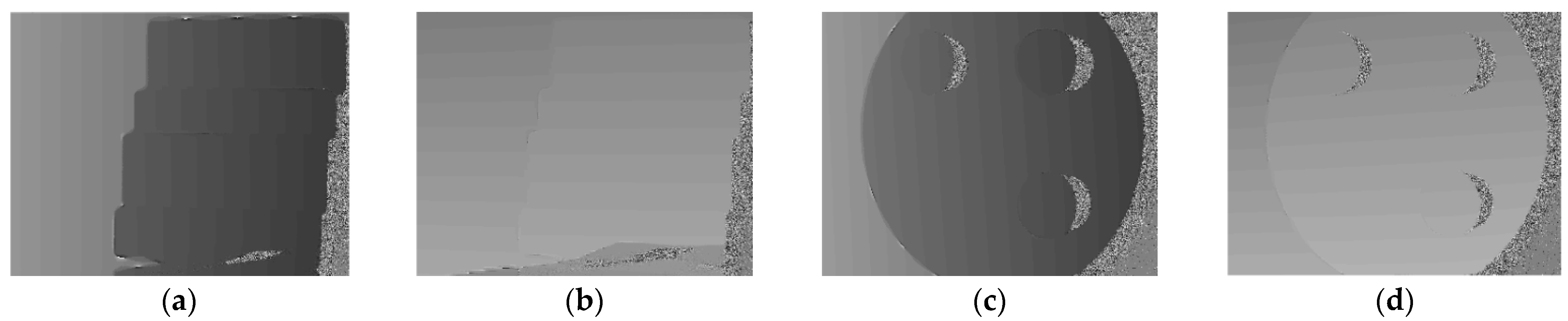

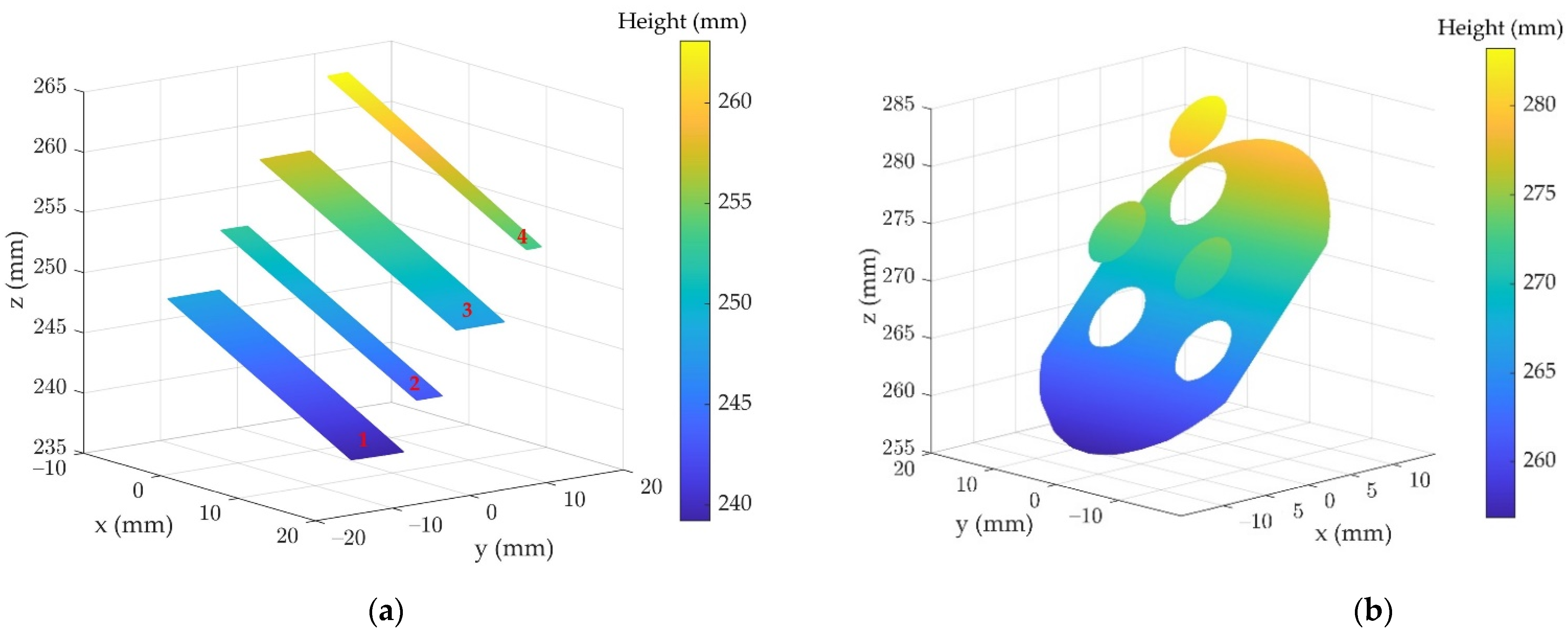

Then, the slope data of the structured specular object is separated into several continuous fields to eliminate the integration error between the discontinuous edges, and then the 3D shape of each isolated surface is reconstructed precisely by slope integration. Note that the integration algorithm has difficulty in determining the absolute position of the surface; the form of each continuous surface obtained by slope integration and the discontinuous depth information calculated by DPMD technology are combined to reconstruct the final 3D shape of the structured specular surfaces.

3. System Calibration

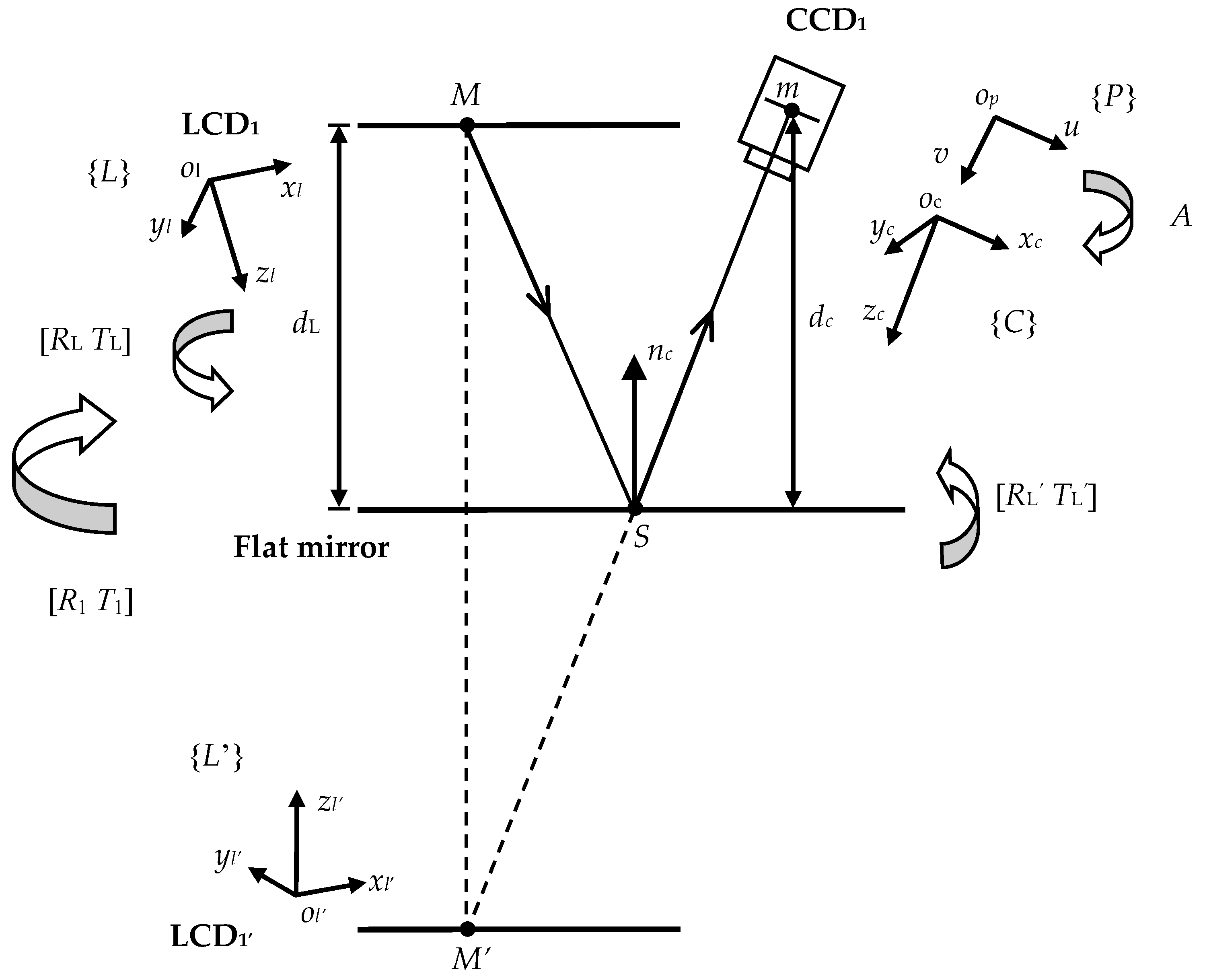

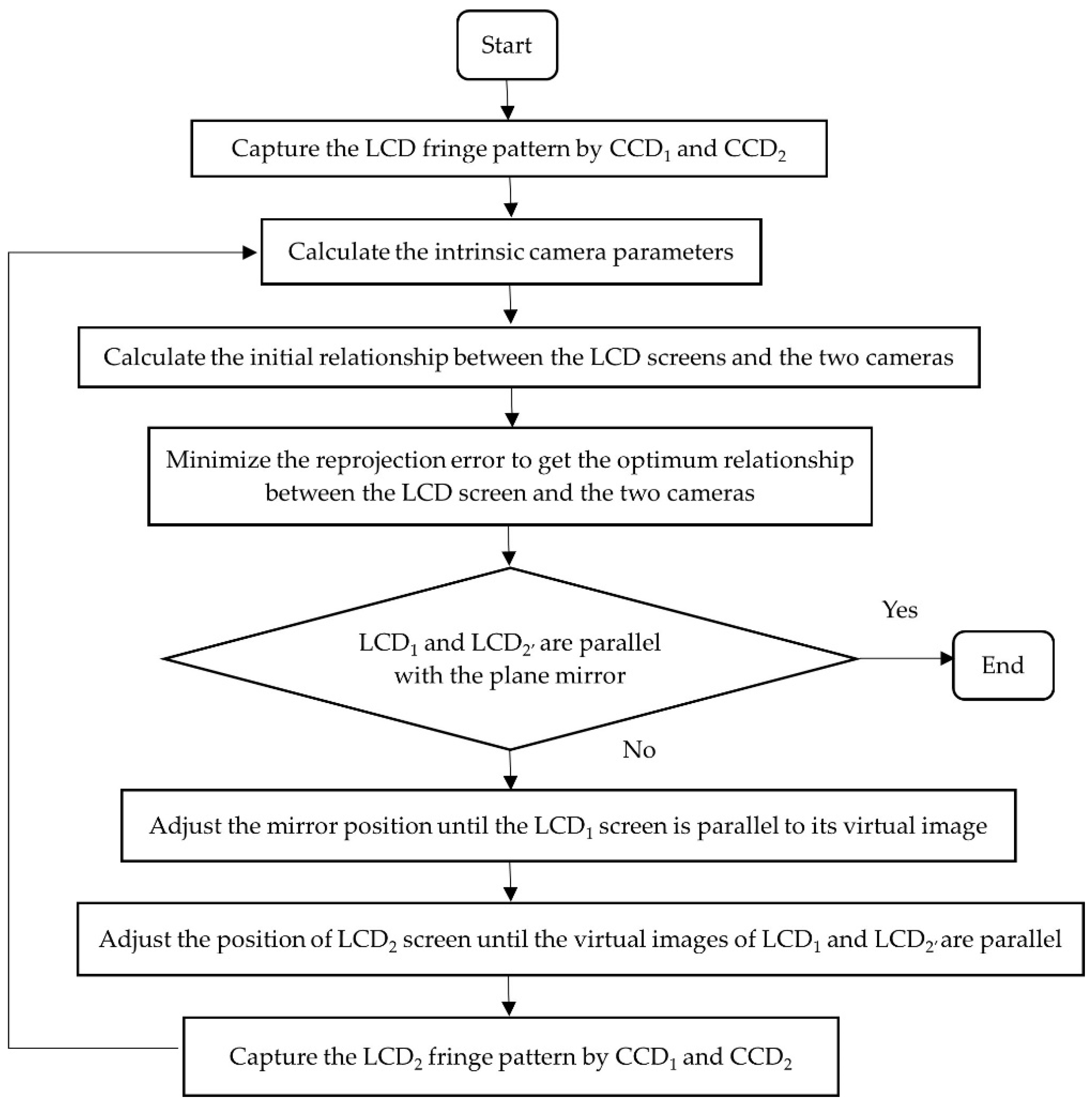

The phase map of the deformed fringe patterns collected by the CCD cameras carries the shape information of the measured object, and the system parameters connect them. It can be seen from Equation (2) that the parameters Δd and d need to be calibrated when the height information of the target point is calculated. Meanwhile, the calculation of surface slope relies on the relative positions between CCD cameras and LCD1 screen. Since the screen is not in the field of view of the cameras, a markless reference plane mirror is used to assist the calibration process.

In order to obtain system parameters accurately, a global optimization calibration algorithm is applied [

34]. Take the calibration process between LCD

1 and CCD

1 as an example, as shown in

Figure 4. The horizontal and vertical sinusoidal fringe patterns are sequentially displayed on the LCD

1 screen, then the camera captures the virtual images reflected by the plane mirror. A phase unwrapping algorithm is performed to establish the corresponding pairs between the camera and the screen pixels. The LCD screen is assumed to be an ideally flat plane to acquire the physical coordinates of the screen pixels. Thus, for a camera pixel

m, its virtual screen pixel

M’ in the mirrored LCD

1′ coordinate system can be located uniquely by the phase information recorded by point

m:

where

is the horizontal and vertical phase data collected by point

m,

is the physical coordinate of

M’ in LCD

1′ frame.

Based on the pinhole imaging model, the relative position [

RL’ tL’] between LCD

1′ and CCD

1 can be obtained with the patterns reflected by three arbitrary mirror positions.

A is a matrix that contains the internal parameters of the camera, which can be calibrated by Zhang’s method [

35], and

s is the scale factor:

Subsequently, the relation between the real LCD

1 screen and the camera can be acquired by the mirror relationship between LCD

1 and LCD

1′:

where [

RL tL] is the extrinsic matrix of LCD

1,

nc is the normal vector of the plane mirror and

dc is the distance from the mirror to the center of CCD

1, with all of these parameters expressed in the CCD

1 coordinate system. Since LCD

1 screen is fixed, [

RL tL] does not change with the posture of the mirror. For two different mirror positions

i,

j, there are:

nc can be calculated with three different poses of the plane mirror:

where

mij is the eigenvector to the eigenvalue 1 of

Rij’, and

k is the

kth position of the mirror,

. And

dc can be deduced by:

In the same way, the relative position between LCD

1 and CCD

2 in

Figure 3 can be achieved. Finally, the system parameters are optimized by minimizing the reprojection error of screen pixels in a cost function [

34]. Due to the different values of

nc and

dc in the two CCD frames, they are converted to the LCD

1 coordinate system to simplify the optimization process.

where

is the normal vector of the mirror in LCD

1 frame and

dL is the distance between LCD

1 and the reference mirror. In addition,

dL is also the parameter

d in Equation (2) that needs to be calibrated in the DPMD system. Using the same method demonstrated above to get the relative position between LCD

2′ and CCD

1, the distance Δ

d can be obtained by the differences between the two LCD screens and the reference mirror. The workflow is shown in

Figure 5.