1. Introduction

Gear measurements play an important role in the quality assessment of finished products, and they also represent a technical guarantee for quality control during processing. With the development of industrial technology and the increasing requirements for gears, comprehensive gear measurements are being widely used. Mainstream examples of gear measuring equipment include gear meshing testers, CNC gear measuring centers, online measuring and sorting machines for gears, and laser measuring instruments [

1]. Gear meshing testers are used to mesh and rotate the measured gear as a function of an ideal and accurate measuring gear, and the recorded error curve can reflect the multiple errors of the gear. These testers can be divided into single-sided meshing and double-sided meshing comprehensive measuring instruments. Single-sided meshing comprehensive measuring instruments can be further characterized as mechanical type, grating type, magnetic index type, and inertial type, and their movement is close to the state of gear in use [

2]. Gear measuring centers are similar in principle to polar coordinate measuring machines. The probe produces the required measurement motion relative to the workpiece, and the computer collects the indication value of the micrometer and the actual position of each coordinate axis to obtain the measurement result. This method has high precision but a large amount of data calculation and a long measurement time.

In recent years, many applications of laser displacement sensors have been revealed in the detection of gear geometric accuracy and transmission stability. Ma et al. [

3] proposed an experimental device composed of a specially fabricated micro-displacement platform and a pair of laser displacement sensors to measure the vertical and horizontal displacement of the flexspline of harmonic drive gears to determine the radial displacement. Tian et al. [

4] proposed using two opposing adjustable laser sensors to obtain tooth profile information through one scan and to reconstruct the key geometric model of the gear profile after compensation. Raghuwanshi et al. [

5] presented a laser displacement sensor technique to measure the tooth deflection of spur gears to calculate the friction stiffness of cracked teeth, but the mechanism used by the experimental device for the determination of tooth surface friction was not very clear. Jiang et al. [

6] used a laser displacement sensor to measure the bending deformation and stiffness of the output shaft to obtain the friction force. Qiu [

7] proposed a non-contact gear measurement method to measure various geometric errors of gears by building a gear detection platform. However, as described in [

8,

9], if the laser beam passes through the center of the gear during measurement, the angle between the laser beam and the normal vector of the tooth surface is too large to form an irregular elliptical spot, which affects the detection accuracy. Pei et al. [

10] optimized the installation angle and position of the laser displacement sensor to address this problem; however, during the measurement process, the previous tooth blocks the measuring laser beam of the target tooth across a large range, which leads to a decrease in the effectiveness of the measurement.

Therefore, this paper proposes an offset laser measurement method for the deviation analysis of cylindrical gears to address these problems and increase the accuracy of the measurement. Firstly, a mathematical model of the best offset selection was established to clarify the selection range of the offset, and the best measurement position was selected according to the offset value and the range of the laser displacement sensor. Then, an offset measurement control software was developed to control the three-coordinate translation device and the workpiece turntable, as well as record the values of the laser displacement sensor and the encoder on the turntable during the measurement process to obtain the measurement data of the tooth profile. Lastly, the various parameters and deviations of the gear were obtained through coordinate conversion and data analysis of the measurement data.

2. The Influence of Spot Shape on Laser Measurement

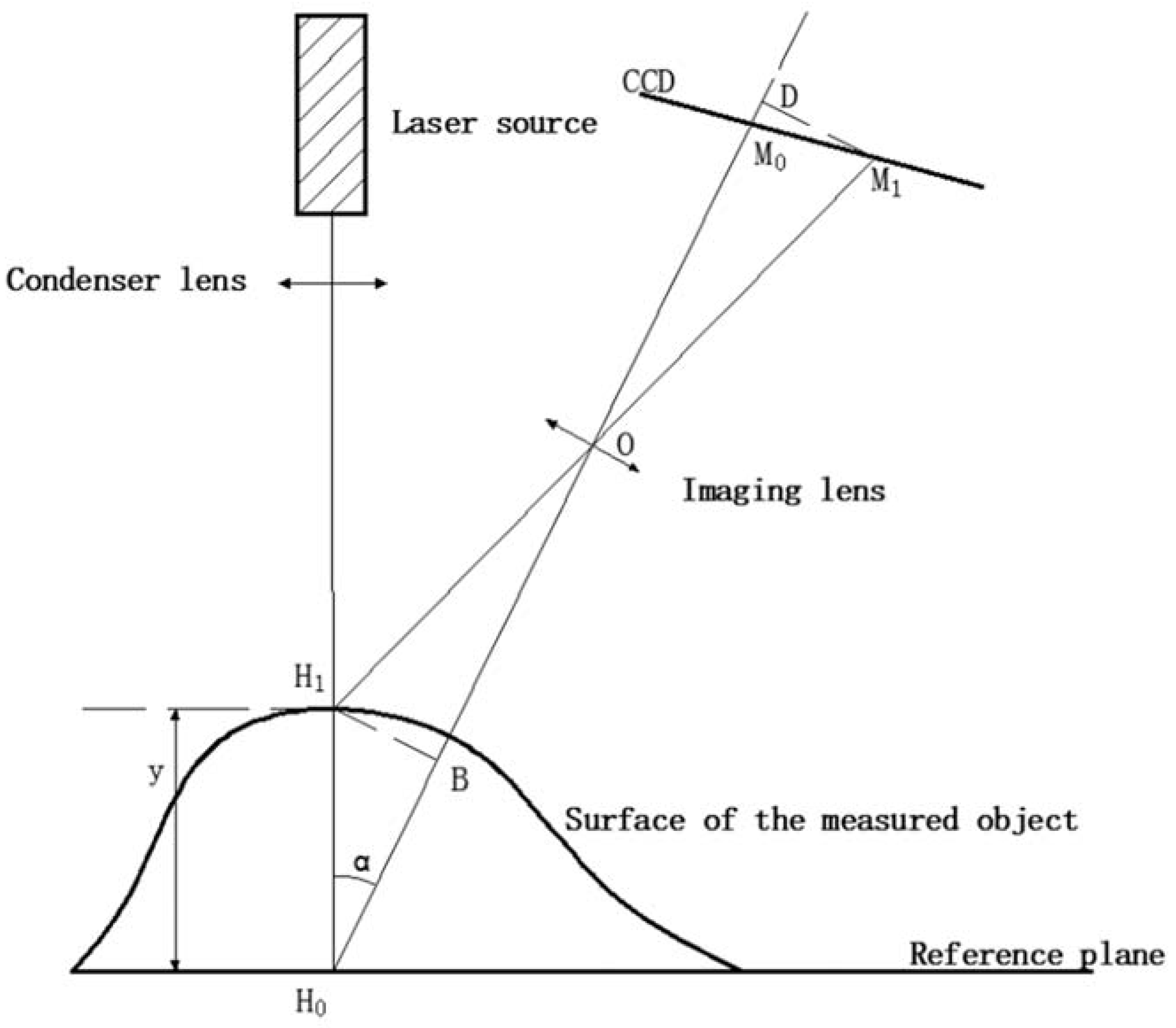

The laser displacement sensor used in gear measurement is based on triangulation. As shown in

Figure 1, the laser beam emitted by the laser source hits

on the surface of the object, while

is a point on the reference plane, and the imaging of the two points on the CCD is denoted by

and

. A perpendicular can be drawn from

and

to

and

to obtain

and

, respectively. The triangle

is, thus, similar to the triangle

. The distance of

can be calculated according to the triangle similarity rule, and then the distance of

can be obtained.

According to the principle of triangulation, the calculation of length

is restricted by the accuracy of the two points

and

, while the accuracy of the two points is affected by the shape and size of the spot. The tooth surface is a complex space curve, and its curvature changes constantly, which easily leads to measurement fluctuations. Huang [

11] proposed an object surface inclination error. It was obtained through experiments that, when the tilt angle is within 5°, the measurement error can be controlled at 0.12 mm, and, when the tilt angle is 30°, the maximum measured displacement error reaches 0.5 mm.

When the measured surface is close to a flat surface, the laser beam hits the surface with a uniform circular spot, which is common in the measurement of gear addenda and dedenda. At this time, the angle between the normal vector of the tooth profile and the laser beam is close to 0°, which is equivalent to the laser beam hitting the surface vertically. At this time, it has no effect on the accuracy of the laser beam. When the curvature of the surface changes continuously and there is a large height difference, the laser beam hits the surface with an uneven and approximate ellipse. At this time, the angle between the normal vector of the tooth profile and the laser beam is close to 90°, which is equivalent to the laser beam being tangent to the surface. The non-linear error in the measurement system increases, which is common in measurements of the tooth profile. Therefore, by improving the angle between the laser beam and tooth profile, placing the maximum angle within a reasonable range, the accuracy of tooth profile measurement can be greatly improved.

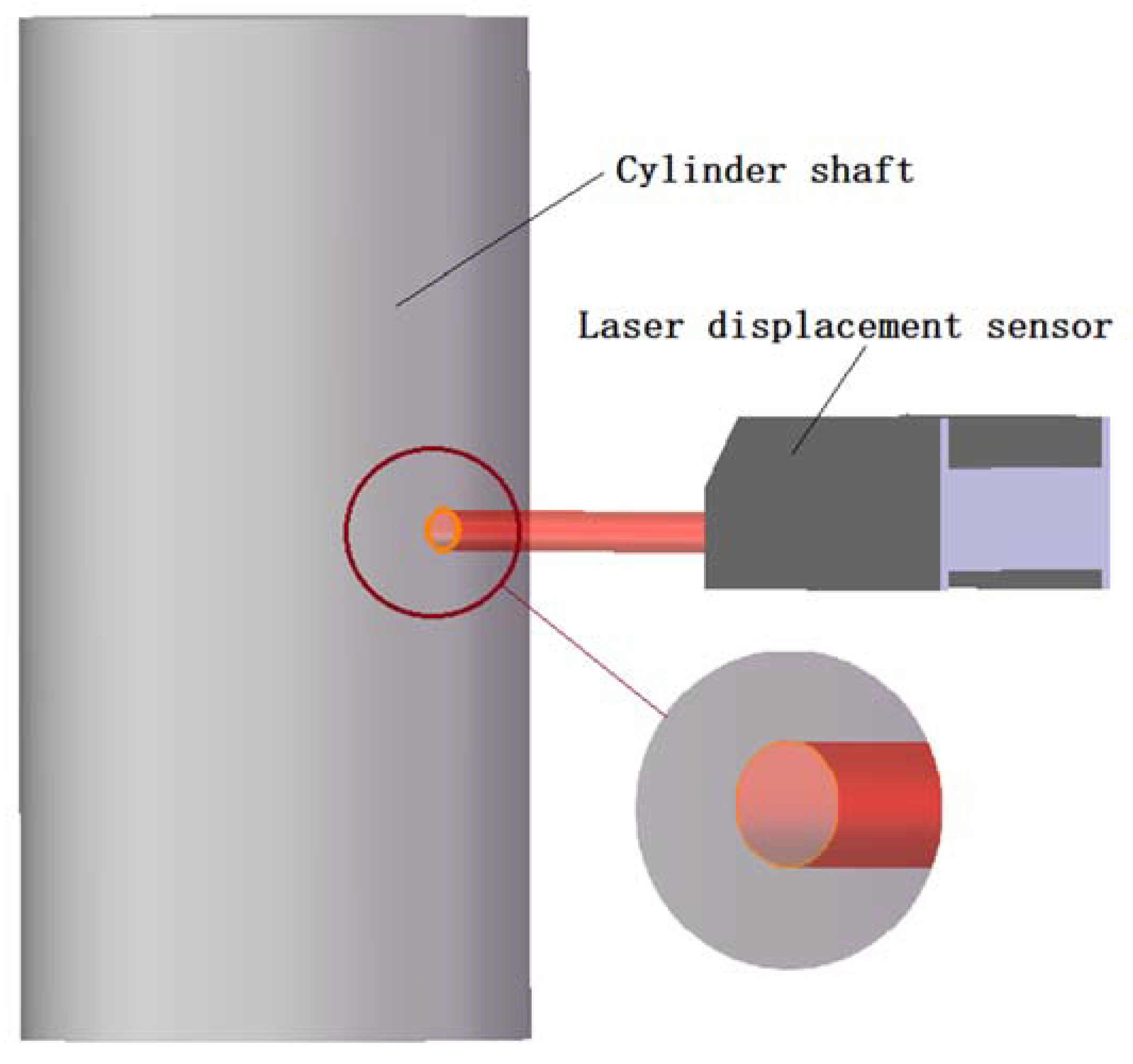

Figure 2 and

Figure 3 are schematic diagrams of the laser beam spots when the laser beam is at different positions on the cylinder shaft.

Figure 2 shows the spot formed by the laser beam directly facing the center of the shaft. In this case, the spot is uniform and convergent.

Figure 3 shows the spot formed by the laser beam on the steep surface of the cylinder shaft, which is uneven and has large scattering during practical application.

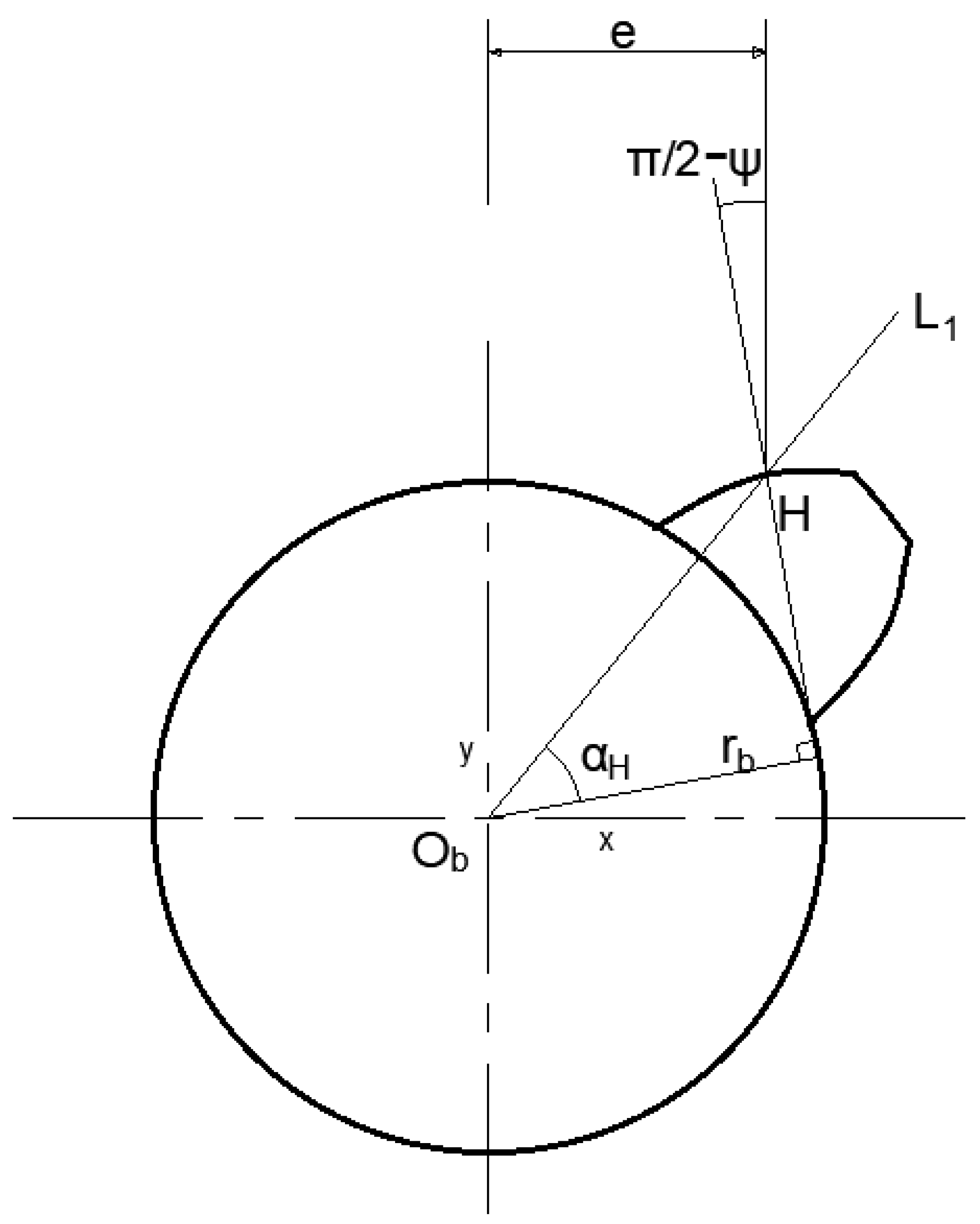

As shown in

Figure 4,

is the center of the base circle,

is the measured point on the gear,

is the line connecting the center of the base circle and point

,

is the normal line of the involute at point

, and the radius of the base circle is

. After the involute has turned at a certain angle, the center of the base circle is described as

,

is the pressure angle at point

, and k is the slope of

. The line

within the normal vector of the tooth profile at point

can be expressed as:

During offset measurement, the laser beam is offset by a distance along the x-axis. If the angle between the normal of the tooth profile and the x-axis is , the angle between the normal of the tooth profile and the laser beam is . It can be seen that a larger k value leads to a larger value and a smaller angle, thereby increasing the stability of the measured value. By contrast, a smaller k value leads to a smaller value and a larger angle, thereby increasing the fluctuation of the measurement data.

3. Principle of Offset Laser Measurement Method

During measurement, the laser displacement sensor measures the distance from the laser emitting point to the tooth surface, and the encoder feeds back angle information. When the laser passes through the center of the gear, the sensor and the encoder reflect the position and angle data of the same point. In the offset laser measurement, the y-axes of the measurement coordinate system and the workpiece coordinate system are not collinear. The position and angle data actually correspond to the position data of the measured point and the gear rotation angle. The corresponding position and angle of the current point can be obtained through coordinate system conversion.

The schematic diagram of offset measurement data conversion is shown in

Figure 5. The offset distance between the laser displacement sensor and the gear center is

,

is the distance from the sensor to the measured point, the distance from the sensor to the

x-axis is

, and the distance from the measured point to the

x-axis is

. When taking any two points

and

on the gear, the measured data of the two points are

and

. When taking

as the initial point, the angle between

and the

x-axis is

, the angle rotated by the gear from

to

is

, and the angle between

and the

y-axis is

; thus, the angle between

and

relative to the gear coordinate system can be expressed as:

The measurement result can be transformed into polar coordinates as follows:

Taking consecutive points for iterative calculation yields:

Then, the conversion formula becomes:

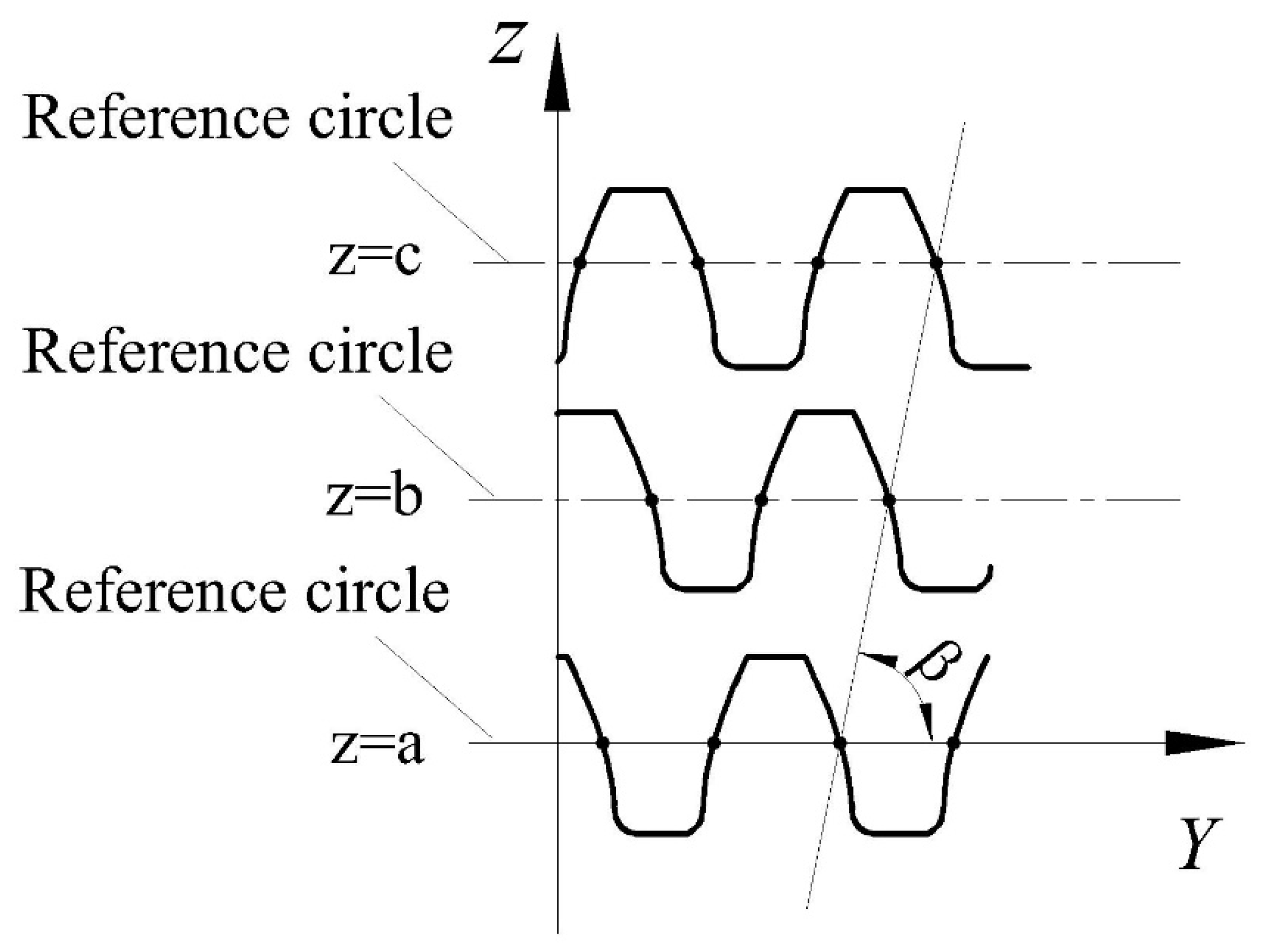

4. Basis for Offset Selection

Offset selection is affected by many factors. When using a small offset value, the problem of laser incident angle is not addressed, whereas a larger offset value leads to greater occlusion of the target tooth by the previous tooth, thereby reducing the effectiveness of the measurement, which cannot accurately reflect the gear error. Accordingly, the front tooth occlusion degree , the slope of the tooth profile normal line k, and the overall data efficiency were introduced to best select the range of the offset.

Here, the tooth number is

z, the modulus is

, the addendum radius is

, the dedendum radius is

, the reference circle radius is

, the tooth thickness at the reference circle is

s, and the pressure angle is

. Furthermore,

is the angle occupied by the effective part of the measured point on the tooth profile,

is the gear center angle occupied by the single-sided tooth line,

is the gear center angle occupied by the addendum, and

is the gear center angle occupied by the dedendum. The front tooth occlusion degree

can be expressed as:

where

.

When considering the angle between the laser beam and the tooth profile normal, the angle can be judged according to the slope of the tooth profile normal line k. The center of the basic circle is

, and, after the involute has turned at a certain angle, it is recorded as

. Moreover,

is the measured point, the basic circle radius is

, and

is the pressure angle at point

. Thus, the normal line of the tooth profile is:

As the value of k decreases, the angle between the normal of the tooth profile and the laser beam increases, and the fluctuation of the measurement data increases. In order to improve the angle during the measurement process, the angle should be close to parallel; in other words, the maximum k on the involute line should be kept at a large value under the offset. To reduce the angle to less than 30°, the absolute value of k should be larger than .

The rationality of the offset value selection can be judged by the overall data efficiency. Accordingly,

is the number of valid data points in the measurement result data and

constitutes all the data points of the measurement result. The overall data efficiency can be expressed as:

Combining the three factors, the best offset value can be described as

, with the following boundary conditions:

For example, for an involute gear with 20 teeth, a modulus of 3, and a pressure angle of 20°, assuming no fluctuation in the measurement data, . In this scenario, is a point on the reference circle, where . Let or , such that , and the solution is . Furthermore, is a point on the addendum; let the point of the addendum just cover the dedendum, whereby the angle between the addendum and the dedendum is , where and . Let , such that solution is . The value of the offset is, thus, between 15 and 21.54.

6. Measuring Device and Software System

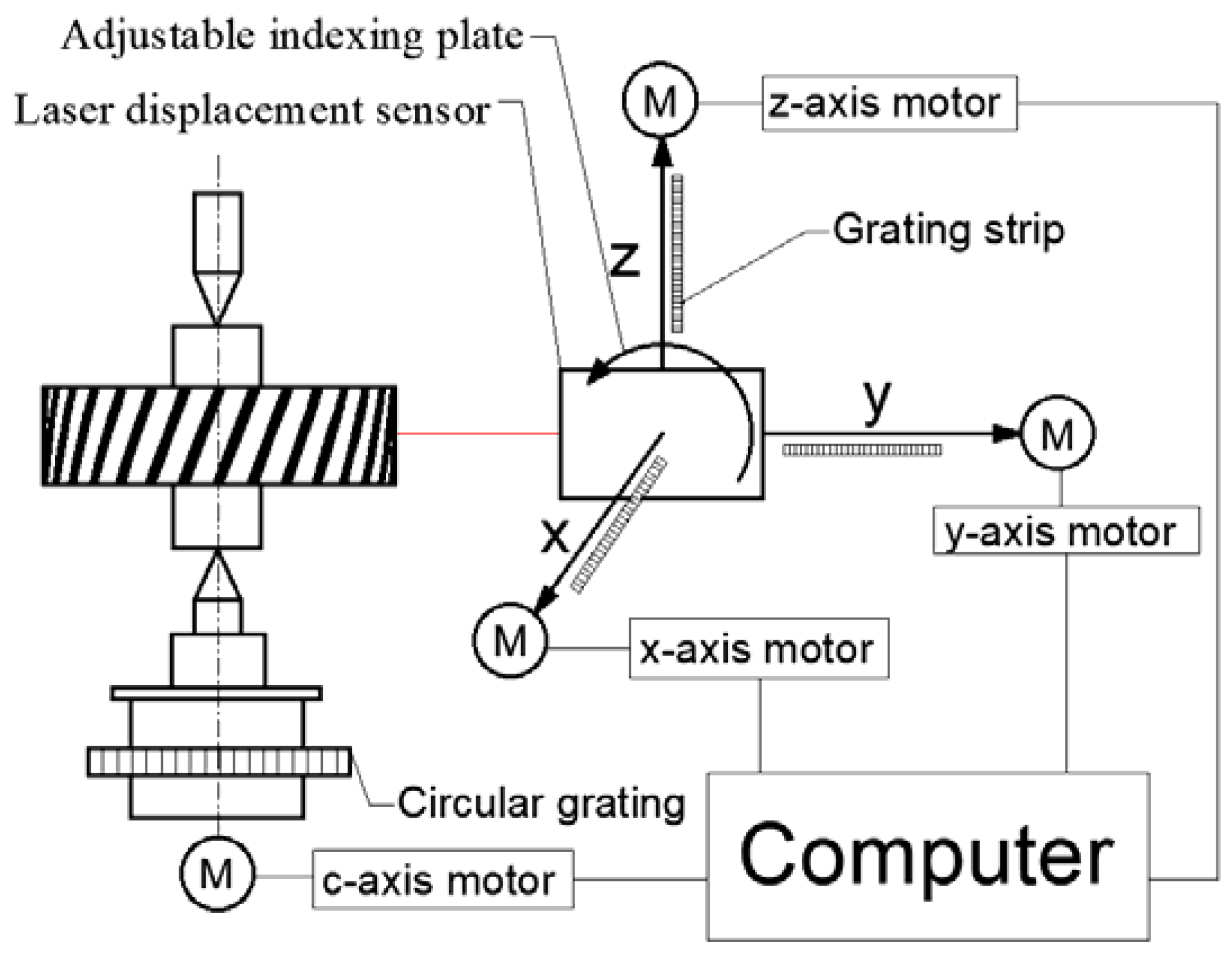

As shown in

Figure 7, the designed measuring device is mainly composed of three parts: the computer control system, the servo system, and the grating feedback system. The position data are measured by the laser displacement sensor. The angle data are read by the encoder on the workpiece turntable. The spatial position and movement of the laser displacement sensor are fed back by the grating of the three coordinates.

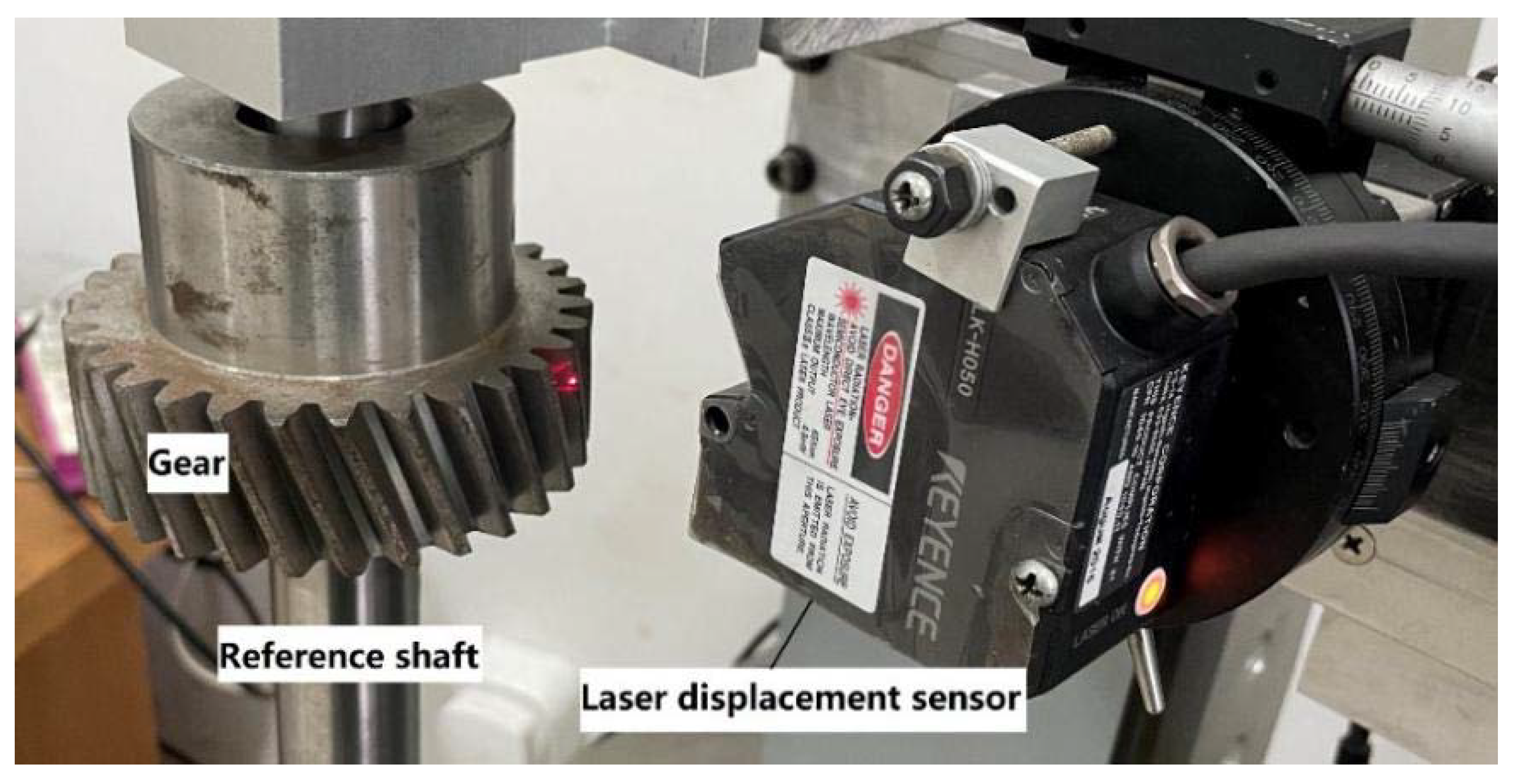

As shown in

Figure 8, the device has a vertical structure. The three-coordinate displacement device is equipped with a laser displacement sensor, which can move linearly in the

x-,

y-, and

z-directions. The laser displacement sensor and the guide rail are connected by an adjustable indexing plate, which can be adjusted on the

YOZ plane. The workpiece turntable is driven by a motor with a built-in encoder. The spatial positions of the laser beam and gear are checked by the reference shaft. Parts with holes can be installed on the shaft for measurement. The laser displacement sensor used was an LK-H050 from KEYENCE, and the reference shaft used was a GCr15-SUS440C with five-level accuracy.

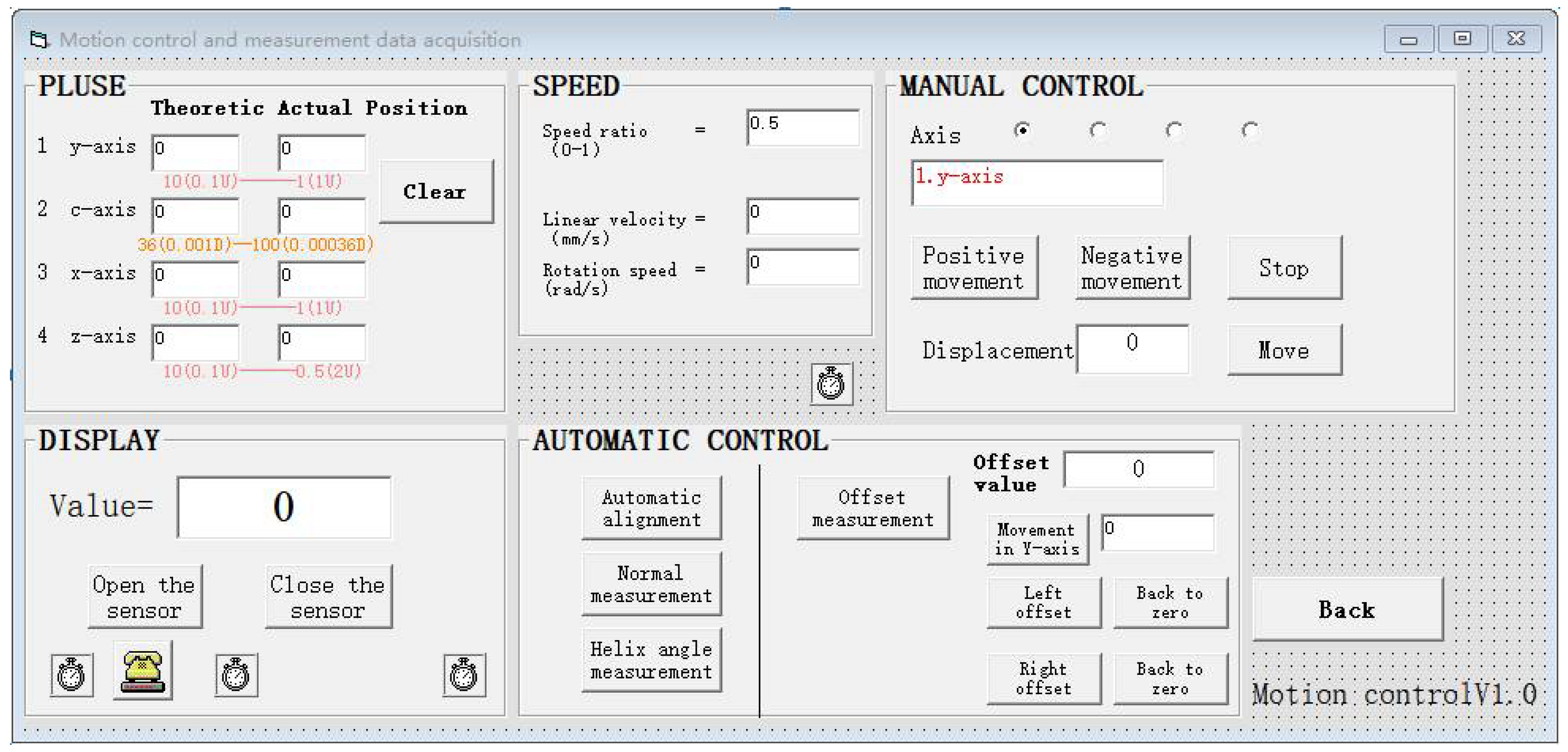

The software system is shown in

Figure 9. The coordinate translation module is used to control the movement of the probe in the

x-,

y-, and

z-directions and the rotation of the workpiece turntable along the

C-axis. The speed control module is used to control the movement speed of the four axes, the grating feedback module feedback is used to control the theoretical displacement and actual displacement of each axis, the measured value display module displays the current laser displacement sensor readings, the automatic control module can realize automatic alignment of the shaft center, and the offset measurement module can realize automatic offset measurement. The spatial position of the laser probe or worktable can be adjusted manually or automatically, whereas the tooth profile measurement and offset measurement can be performed automatically.