A Review on Sliding Vane and Rolling Piston Compressors

Abstract

1. Introduction

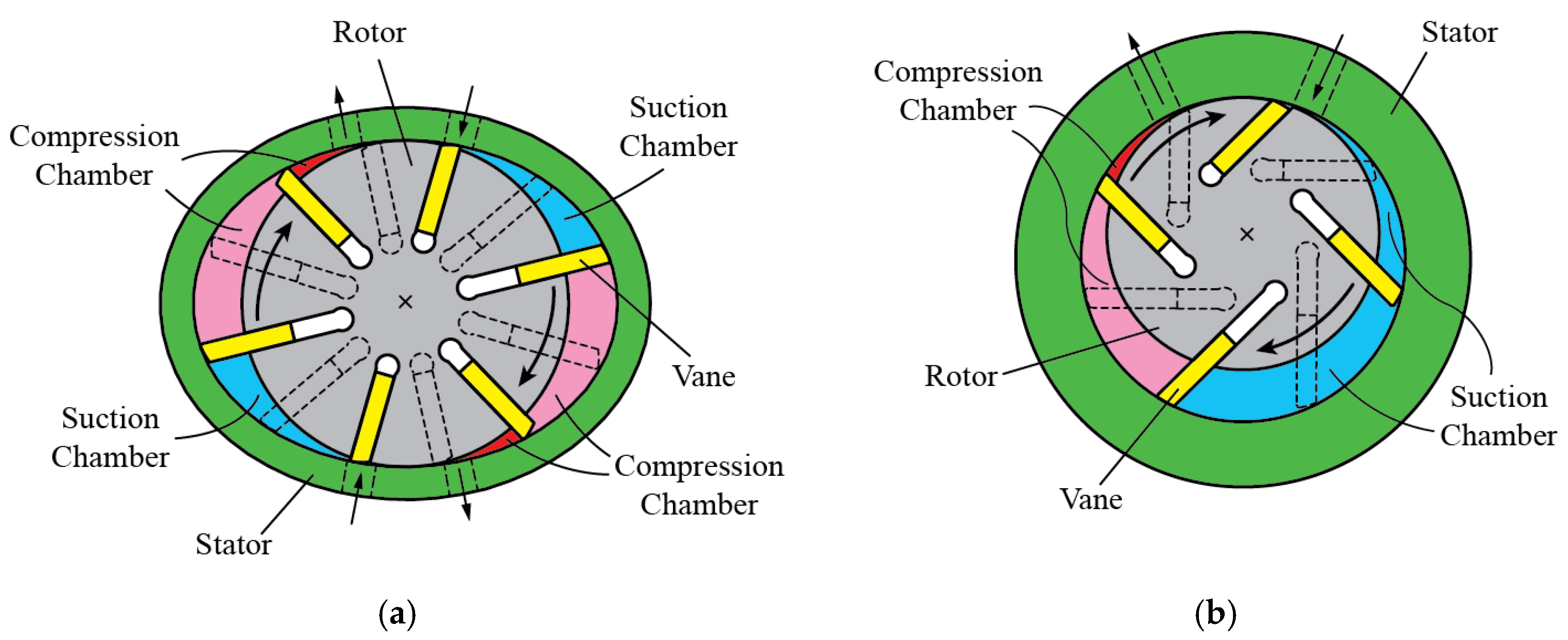

2. The Sliding Vane Compressor

2.1. Performance

2.2. Engineering

2.2.1. Optimization

2.2.2. Vane Dynamics and Lubrication

2.3. Design Variants

2.3.1. Injection Mechanisms

2.3.2. Design Variations

- Fixed Vane Variants

- 2.

- Spool Compressor

- 3.

- Coupled Vane Compressor

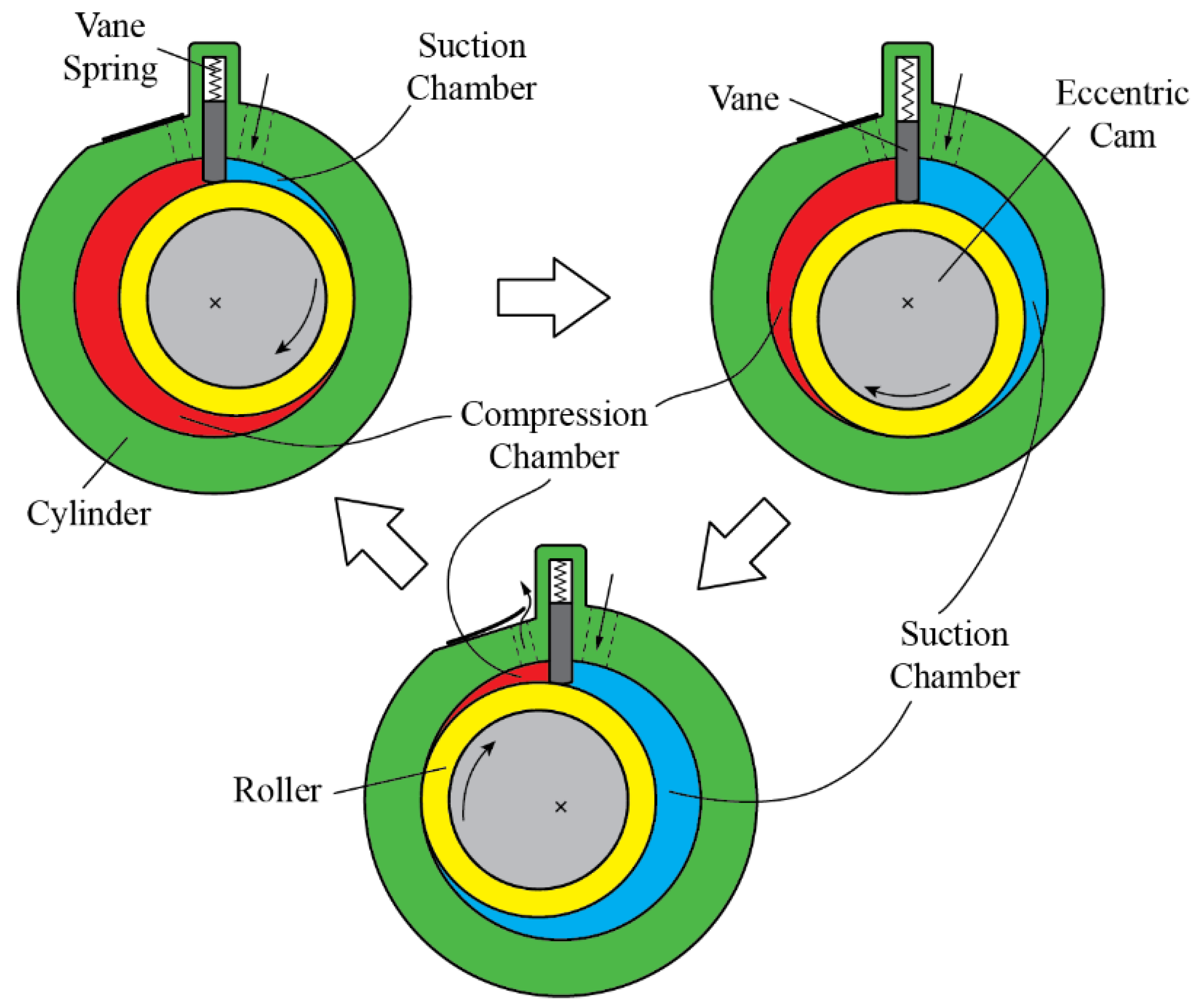

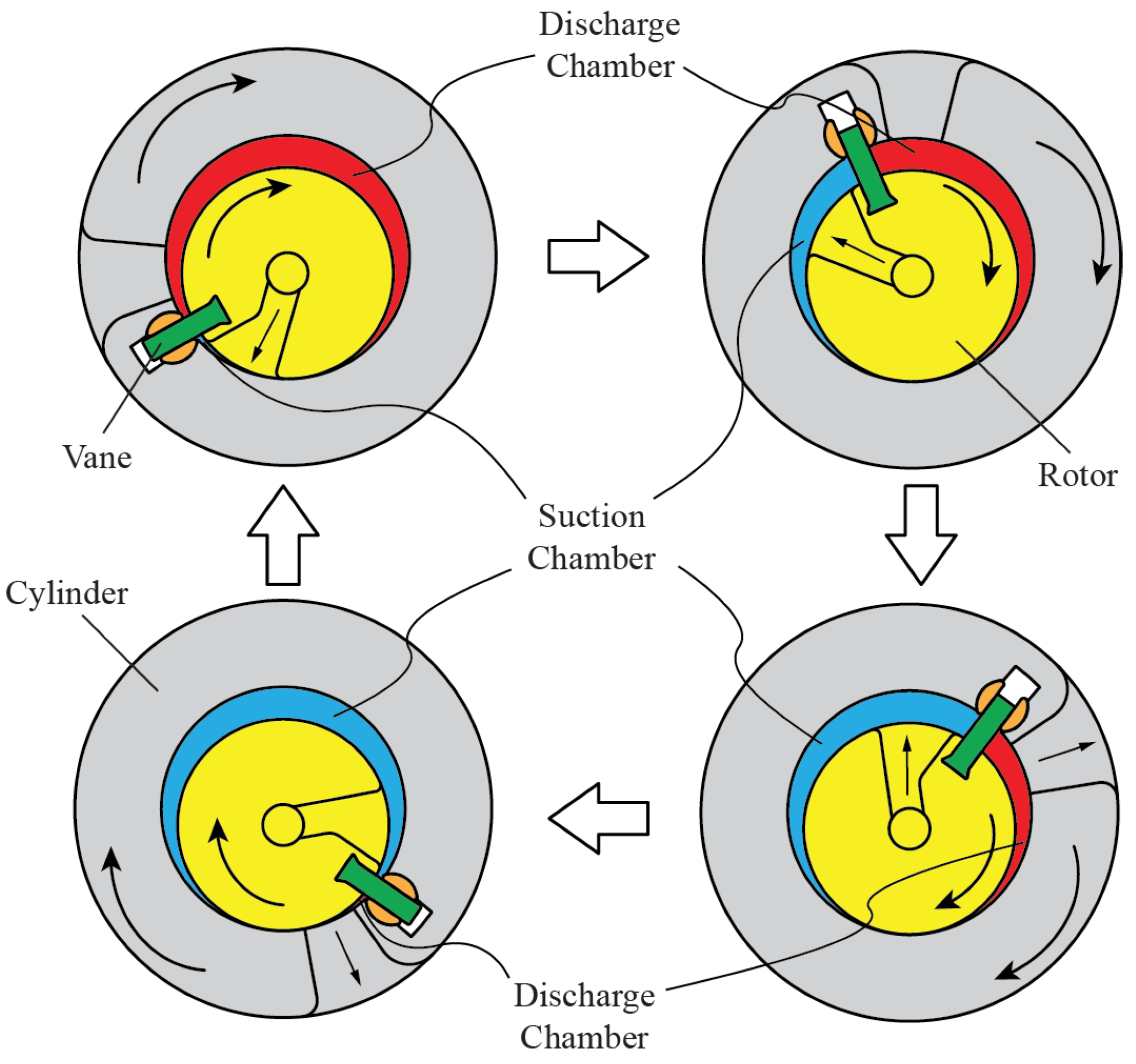

3. The Rolling Piston Compressor

3.1. Performance

3.2. Engineering

3.2.1. Optimization

3.2.2. Transient Analysis

3.2.3. Heat Transfer

3.2.4. Internal Leakage

3.2.5. Compressor Dynamics and Vibration

3.2.6. Valve Mechanics and Port Flow

3.2.7. Vane Dynamics and Vane Tip Tribology

3.2.8. Compressor Lubrication

3.2.9. Refrigerants

3.3. Design Variants

3.3.1. Dual Cylinder and Two-Stage Rolling Piston Compressors

3.3.2. Injection Mechanisms

3.3.3. Compressor Orientation

3.3.4. Swing Mechanism

3.3.5. Synchronal Rotary/Revolving Vane Compressor

4. Concluding Remarks and Future Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Balmer, R.T. Modern Engineering Thermodynamics—Textbook with Tables Booklet; Elsevier Science: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Lorentzen, G. The use of natural refrigerants: A complete solution to the CFC/HCFC predicament. Int. J. Refrig. 1995, 18, 190–197. [Google Scholar] [CrossRef]

- ElBaradei, M. Tackling the Global Energy Crisis. International Atomic Energy Agency. 2008. Available online: https://www.iaea.org/publications/magazines/bulletin/50-1/tackling-global-energy-crisis (accessed on 16 December 2020).

- Ooi, K.T. Twenty Years of Compressor Innovation at NTU, Singapore. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2014. [Google Scholar]

- Barnes, C.C. Rotary Pump. Canada Patent CA3559A, 15 June 1874. [Google Scholar]

- Stokes, D.H. Refrigerating Apparatus. U.S. Patent US1362757A, 7 July 1916. [Google Scholar]

- Costagliola, M. The Theory of Spring-Loaded Valves for Reciprocating Compressors. J. Appl. Mech. 1950, 17, 415–420. [Google Scholar] [CrossRef]

- Ozu, M.; Itami, T. Efficiency analysis of power consumption in small hermetic refrigerant rotary compressors. Int. J. Refrig. 1981, 4, 265–270. [Google Scholar] [CrossRef]

- Edwards, T.C.; McDonald, A.T. Analysis of Mechanical Friction in Rotary Vane Machines. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1972. [Google Scholar]

- Peterson, C.R.; McGahan, W.A. Thermodynamic and Aerodynamic Analyis Methods for Oil Flooded Sliding Vane Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1972. [Google Scholar]

- Pandeya, P.; Soedel, W. Rolling piston type rotary compressors with special attention to friction and leakage. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1978. [Google Scholar]

- United Nations. Handbook for the Montreal Protocol on Substances that Deplete the Ozone Layer (14th ed.). 2020. Available online: https://ozone.unep.org/sites/default/files/Handbooks/MP-Handbook-2020-English.pdf (accessed on 14 June 2021).

- French, D. Kyoto Protocol to the United Nations Framework Convention on Climate Change. J. Environ. Law 1998, 10, 215–224. [Google Scholar] [CrossRef]

- Horowitz, C.A. Paris Agreement. Int. Leg. Mater. 2016, 55, 740–755. [Google Scholar] [CrossRef]

- Kruse, H. Experimental investigations on rotary vane compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1980. [Google Scholar]

- Tramschek, A.B.; Ooi, K.T. Effects of Port Geometry Dimensions and Position on the Performance of a Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1992. [Google Scholar]

- Platts, H.H. Hydrodynamic lubrication of sliding vanes. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1976. [Google Scholar]

- Tojo, K.; Kan, T.; Arai, A. Dynamic behaviour of sliding vane in small rotary compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1978. [Google Scholar]

- Shu, P.; Guo, B.; Li, L.; Hu, J. Influence of Vane Slot Back-Pressure on the Characteristic of Vane Motion in Rotary Vane Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998. [Google Scholar]

- Bianchi, G.; Cipollone, R. Friction power modeling and measurements in sliding vane rotary compressors. Appl. Therm. Eng. 2015, 84, 276–285. [Google Scholar] [CrossRef]

- Lindemann, H.; Kaiser, H.; Kuever, M.; Kruse, H. Optimization of a Special Shaped Rotary Vane Compressor—Comparison of Theoretical and Experimental Results. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1982. [Google Scholar]

- Huang, Y.M.; Yang, S.-A. A measurement method for air pressures in compressor vane segments. Measurement 2008, 41, 835–841. [Google Scholar] [CrossRef]

- Tothero, D.; Keeney, D. A Rotary Vane Compressor for Automotive Air Conditioning Applications. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1978. [Google Scholar]

- Tassou, S.; Qureshi, T. Comparative performance evaluation of positive displacement compressors in variable-speed refrigeration applications. Int. J. Refrig. 1998, 21, 29–41. [Google Scholar] [CrossRef]

- Cipollone, R. Sliding vane rotary compressor technology and energy saving. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2014, 230, 208–234. [Google Scholar] [CrossRef]

- Maruyama, T.; Yamauchi, S.; Kagoroku, N. Capacity control of rotary type compressors for automotive air-conditioners. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1982. [Google Scholar]

- Cipollone, R.; Contaldi, G.; Di Battista, D.; Bianchi, G. Energy optimization in air compression: Theoretical and experimental research activity on sliding vane rotary compressors. In Proceedings of the Motor Driven Systems Conference, Solihull, UK, 9–10 November 2011. [Google Scholar] [CrossRef]

- Tramschek, A.B.; Mkumbwa, M.H. Mathematical Modelling of Radial and Non-Radial Rotary Sliding Vane Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1996. [Google Scholar]

- Al-Hawaj, O. Theoretical modeling of sliding vane compressor with leakage. Int. J. Refrig. 2009, 32, 1555–1562. [Google Scholar] [CrossRef]

- Fukuta, M.; Yanagisawa, T.; Shimizu, T. Analysis of Leakage Flow through Clearance on Rotor Face in Vane Compressors. Trans. Jpn. Soc. Mech. Eng. Ser. B 1992, 58, 174–179. [Google Scholar] [CrossRef][Green Version]

- Aradau, D.; Costiuc, L. Friction power in sliding vane type rotary compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1996. [Google Scholar]

- Li, L.; Zhao, Y.; Guo, B.; Shu, P.; Shen, J.; He, S. Wrap of cylinder and its effect on main features of rotary vane compressor for automobile air conditioning system. Int. J. Refrig. 2003, 26, 566–574. [Google Scholar] [CrossRef]

- Yee, V.; Soedel, W. Comments on blade excited rigid body vibrations of rotary vane compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1980. [Google Scholar]

- Cipollone, R.; Contaldi, G.; Sciarretta, A.; Tufano, R.; Villante, C. A Theoretical Model and Experimental Validation of a Sliding Vane Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2006. [Google Scholar]

- Bianchi, G.; Cipollone, R.; Murgia, S.; Contaldi, G. Development of an internal air cooling sprayed oil injection technique for the energy saving in sliding vane rotary compressors through theoretical and experimental methodologies. Int. J. Refrig. 2015, 52, 11–20. [Google Scholar] [CrossRef]

- Bianchi, G.; Rane, S.; Kovacevic, A.; Cipollone, R. Deforming grid generation for numerical simulations of fluid dynamics in sliding vane rotary machines. Adv. Eng. Softw. 2017, 112, 180–191. [Google Scholar] [CrossRef]

- Bianchi, G.; Rane, S.; Kovacevic, A.; Cipollone, R.; Murgia, S. Development of a general numerical methodology for CFD analyses in sliding vane machines and application on a mid-size oil injected air compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2016. [Google Scholar]

- Valente, R.; Villante, C. On the Optimal Design of One-Rotor Two-Stages Rotary-Vane Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2008. [Google Scholar]

- Huang, Y.M.; Shiau, C.-S. Optimal Tolerance Allocation for a Sliding Vane Compressor. J. Mech. Des. 2006, 128, 98–107. [Google Scholar] [CrossRef]

- Fukuta, M.; Tanaka, M.; Shimizu, T.; Yanagisawa, T. Analysis of Oil Film on Vane Sides of Vane Compressors. Trans. Jpn. Soc. Mech. Eng. Ser. B 1991, 57, 2007–2012. [Google Scholar] [CrossRef][Green Version]

- Basaj, L. Lubrication of the Non-Flooded Rotary Sliding Vane Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1974. [Google Scholar]

- Bianchi, G.; Cipollone, R. Theoretical modeling and experimental investigations for the improvement of the mechanical efficiency in sliding vane rotary compressors. Appl. Energy 2015, 142, 95–107. [Google Scholar] [CrossRef]

- Tramschek, A.B.; Mkumbwa, M.H. Experimental Studies of Non-Radial Vane Rotary Sliding Vane Air Compressors During Steady State Operation. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1996. [Google Scholar]

- Cipollone, R.; Valenti, G.; Bianchi, G.; Murgia, S.; Contaldi, G.; Calvi, T. Energy saving in sliding vane rotary compressors using pressure swirl oil atomizers. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2015, 229, 96–103. [Google Scholar] [CrossRef]

- Hickman, C.; Neal, W.E.J. Implications of cooling rotary sliding vane heat-pump compressors. Int. J. Ambient. Energy 1984, 5, 207–212. [Google Scholar] [CrossRef]

- Taguchi, T.; Abe, Y.; Maruyama, T.; Aburaya, K.; Kagoroku, N. New Capacity Control in Vane Rotary Type Compressor for Automotive Air Conditioners. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1988. [Google Scholar]

- Gu, H.; Zhou, X.; Chen, Y.; Wu, J.; Wu, Z.; Jiang, Y.; Sundén, B. Analysis, modeling and simulations of an innovative sliding vane rotary compressor with a rotating cylinder. Energy Convers. Manag. 2021, 230, 113822. [Google Scholar] [CrossRef]

- Gu, H.; Chen, Y.; Wu, J.; Jiang, Y.; Sundén, B. Impact of discharge port configurations on the performance of sliding vane rotary compressors with a rotating cylinder. Appl. Therm. Eng. 2021, 186, 116526. [Google Scholar] [CrossRef]

- Guoyuan, M.; Qisen, Y.; Yongzhang, Y. Dynamic Behavior of Twin-Piece Vane Machine. J. Mech. Des. 2000, 124, 74–78. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Chen, Z.; Tan, Q. Geometric Model and Pressurization Analysis on a Novel Sliding Vane Compressor with an Asymmetrical Cylinder Profile. Int. J. Refrig. 2021. [Google Scholar] [CrossRef]

- Smith, I.; Harrison, H.; Cox, M. A preliminary evaluation of the Groll rotary vane compressor. Int. J. Refrig. 1992, 15, 69–73. [Google Scholar] [CrossRef][Green Version]

- Edwards, T. The Controlled Rotary Vane Gas- Handling Machine. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1988. [Google Scholar]

- Edwards, T.C. Initial development of the orbital vane compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1994. [Google Scholar]

- Kemp, G.; Garrett, N.; Groll, E.A. Novel Rotary Spool Compressor Design and Preliminary Prototype Performance. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2008. [Google Scholar]

- Kemp, G.; Orosz, J.; Bradshaw, C.R.; Groll, E.A. Spool compressor tip seal design considerations and testing. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2012. [Google Scholar]

- Kemp, G.; Orosz, J.; Bradshaw, C.R.; Groll, E.A. Spool seal design and testing for the spool compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2012. [Google Scholar]

- Wood, N.; Bradshaw, C.R.; Orosz, J.; Kemp, G.; Groll, E.A. Dynamic Modeling of a Poppet Valve for use in a Rotating Spool Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2016. [Google Scholar]

- Orosz, J.; Kemp, G.; Bradshaw, C.R.; Groll, E.A. Performance and Operating Characteristics of a Novel Rotating Spool Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2012. [Google Scholar]

- Orosz, J.; Kemp, G.; Bradshaw, C.R.; Groll, E.A. An Update on the Performance and Operating Characteristics of a Novel Rotating Spool Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2014. [Google Scholar]

- Orosz, J.; Bradshaw, C.R.; Kemp, G.; Groll, E.A. Updated Performance and Operating Characteristics of a Novel Rotating Spool Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2016. [Google Scholar]

- Bradshaw, C.R.; Groll, E.A. A comprehensive model of a novel rotating spool compressor. Int. J. Refrig. 2013, 36, 1974–1981. [Google Scholar] [CrossRef][Green Version]

- Bradshaw, C.R.; Kemp, G.; Orosz, J.; Groll, E.A. Development of a loss pareto for a rotating spool compressor using high-speed pressure measurements and friction analysis. Appl. Therm. Eng. 2016, 99, 392–401. [Google Scholar] [CrossRef]

- Bradshaw, C.R.; Kemp, G.; Orosz, J.; Groll, E.A. Loss Analysis of Rotating Spool Compressor Based on High-Speed Pressure Measurements. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2014. [Google Scholar]

- Bradshaw, C.R.; Kemp, G.; Orosz, J.; Groll, E.A. An Indicated Loss Analysis of a Light-Commercial Spool Compressor using High-Speed Pressure Measurements. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2018. [Google Scholar]

- Bradshaw, C.R.; Kemp, G.; Orosz, J.; Groll, E.A. Influence of Volumetric Displacement and Aspect Ratio on the Performance Metrics of the Rotating Spool Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2014. [Google Scholar]

- Bradshaw, C.R.; Kemp, G.; Orosz, J.; Groll, E.A. Design Methodology Improvements of a Rotating Spool Compressor using a Comprehensive Model. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2016. [Google Scholar]

- Bradshaw, C.R.; Kemp, G.; Orosz, J.; Groll, E.A. Improved design method of a rotating spool compressor using a comprehensive model and comparison to experimental results. IOP Conf. Ser. Mater. Sci. Eng. 2017, 232, 012056. [Google Scholar] [CrossRef]

- Mathison, M.M.; Braun, J.E.; Groll, E.A. Modeling of a novel spool compressor with multiple vapor refrigerant injection ports. Int. J. Refrig. 2013, 36, 1982–1997. [Google Scholar] [CrossRef]

- Kemp, G.; Elwood, L.; Groll, E.A. Evaluation of a prototype rotating spool compressor in liquid flooded operation. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2014. [Google Scholar]

- Ooi, K.T.; Shakya, P. A New Compact Rotary Compressor: Coupled Vane Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2018. [Google Scholar]

- Ooi, K.T.; Shakya, P. Simulation studies of a coupled vane compressor. IOP Conf. Series: Mater. Sci. Eng. 2019, 604, 012069. [Google Scholar] [CrossRef]

- Shakya, P.; Ooi, K.T. Introduction to Coupled Vane compressor: Mathematical modelling with validation. Int. J. Refrig. 2020, 117, 23–32. [Google Scholar] [CrossRef]

- JARN Ltd. World Compressor Market—Update 2021; Japan Air Conditioning, Heating & Refrigeration News Special Issue; JARN Ltd.: Tokyo, Japan, 2021. [Google Scholar]

- Chu, I.; Shiga, T.; Ishijima, K.; Sakainc, M. Analysis of the Rolling-Piston Type Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1978. [Google Scholar]

- Matsuzaka, T.; Nagatomo, S. Rolling Piston Type Rotary Compressor Performance Analysis. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1982. [Google Scholar]

- Wakabayashi, H.; Yuuda, J.; Aizawa, T.; Yamamura, M. Analysis of performance in a rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1982. [Google Scholar]

- Sakaino, K.; Muramatsu, S.; Shida, S.; Ohinata, O. Some approaches towards a high efficient rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1984. [Google Scholar]

- Sathe, A.A.; Groll, E.A.; Garimella, S.V. Experimental evaluation of a miniature rotary compressor for application in electronics cooling. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2008; pp. 1115/1–1115/12. [Google Scholar]

- Lee, J.; Min, T.S. Performance analysis of rolling piston type rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1988. [Google Scholar]

- Hsu, L.-C.; Wong, G.-W.; Lu, P.-J.; Hsu, F.-S.; Chen, Y.-C. Numerical Simulation for Flow of Rolling Piston Type of Rotary Compressor. Energies 2020, 13, 2526. [Google Scholar] [CrossRef]

- Gayeski, N.T.; Armstrong, P.R.; Zakula, T.; Norford, L.K. Empirical Modeling of a Rolling-Piston Compressor Heat Pump for Predictive Control in Low-Lift Cooling; ASHRAE Transactions: Peachtree Corners, GA, USA, 2011; pp. 735–745. [Google Scholar]

- Lowrey, S.; Reboux, G. Rotary Compressor Performance at Low Ambient Temperatures. Int. J. Air-Cond. Refrig. 2020, 28, 1–12. [Google Scholar] [CrossRef]

- Molinaroli, L.; Joppolo, C.M.; De Antonellis, S. A semi-empirical model for hermetic rolling piston compressors. Int. J. Refrig. 2017, 79, 226–237. [Google Scholar] [CrossRef]

- Farkas, B.; Suda, J.M. Application of morphed non-linear phase oscillators for representing rolling piston compressor performance. Proc. Inst. Mech. Eng. Part A J. Power Energy 2019, 234, 332–341. [Google Scholar] [CrossRef]

- Ito, Y.; Hattori, H.; Miura, K. Numerical Analysis for Rotating Motion of a Rolling Piston in Rotary Compressors—Effective Factors for Characteristics of Rotating Motion of a Rolling Piston. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2010. [Google Scholar]

- Ishii, N.; Fukushima, M.; Yamamura, M.; Fujiwara, S.; Kakita, S. Optimum combination of dimensions for high mechanical efficiency of a rolling-piston rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1990. [Google Scholar]

- Ishii, N.; Bird, K.; Yamamoto, S.; Matsunaga, H.; Sano, K.; Hayashi, M. A Fundamental Optimum Design for High Mechanical and Volumetric Efficiency of Compact Rotary Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998; Volume 1314, pp. 649–654. [Google Scholar]

- Ishii, N.; Morita, N.; Ono, M.; Aiba, O.; Sano, K.; Sawai, K. Net Efficiency Simulations of Compact Rotary Compressors for Its Optimal Performance. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2000. [Google Scholar]

- Ooi, K. Design optimization of a rolling piston compressor for refrigerators. Appl. Therm. Eng. 2005, 25, 813–829. [Google Scholar] [CrossRef]

- Ooi, K.T.; Lee, H.Q. Multi-objective design optimization of a rotary compressor for household air-conditioning. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2008, 222, 241–250. [Google Scholar] [CrossRef]

- Yanagisawa, T.; Shimizu, T.; Horioka, T. A study on starting characteristics of a rolling piston type rotary compressor. 1st report Analyses and measurements of starting load torque. Trans. Jpn. Soc. Mech. Eng. Ser. B 1985, 51, 3962–3969. [Google Scholar] [CrossRef]

- Park, Y.C. Transient analysis of a variable speed rotary compressor. Energy Convers. Manag. 2010, 51, 277–287. [Google Scholar] [CrossRef]

- Lin, J.; Wu, J.; Zhang, Z.; Chen, Z.; Xie, J.; Lu, J. Experimental investigation of startup characteristics of R290 rotary compressor under low ambient temperature heating condition. Int. J. Refrig. 2017, 77, 128–135. [Google Scholar] [CrossRef]

- Wu, J.; Lin, J.; Zhang, Z.; Chen, Z.; Xie, J.; Lu, J. Experimental investigation of dynamic characteristics of a rotary compressor and its air conditioner using R290 during warm startup. Appl. Therm. Eng. 2017, 125, 1469–1477. [Google Scholar] [CrossRef]

- Wu, J.; Lin, J.; Zhang, Z.; Chen, Z.; Xie, J.; Lu, J. Experimental investigation on cold startup characteristics of a rotary compressor in the R290 air-conditioning system under cooling condition. Int. J. Refrig. 2016, 65, 209–217. [Google Scholar] [CrossRef]

- Yanagisawa, T.; Shimizu, T.; Fukuta, M.; Suzuki, H. Mathematical Model of Rotary Compressor to Simulate its Transient Behavior. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1990. [Google Scholar]

- Liu, Z.; Soedel, W. An investigation of compressor slugging problems. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1994. [Google Scholar]

- Padhy, S.K.; Dwivedi, S.N. Heat transfer analysis of a rolling-piston rotary compressor. Int. J. Refrig. 1994, 17, 400–410. [Google Scholar] [CrossRef]

- Ooi, K.T. Heat transfer study of a hermetic refrigeration compressor. Appl. Therm. Eng. 2003, 23, 1931–1945. [Google Scholar] [CrossRef]

- Ishii, N.; Morita, N.; Kurimoto, M.; Yamamoto, S.; Sano, K.; Sawai, K. Calculations for compression efficiency caused by heat transfer in compact rotary compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2000. [Google Scholar]

- Wu, J.; Hu, J.; Chen, A.; Mei, P.; Zhou, X.; Chen, Z. Numerical analysis of temperature distribution of motor-refrigerant in a R32 rotary compressor. Appl. Therm. Eng. 2016, 95, 365–373. [Google Scholar] [CrossRef]

- Shi, H.; Wu, J. Thermal analysis of oil sump and compression unit in a rotary compressor. Appl. Therm. Eng. 2020, 164, 114465. [Google Scholar] [CrossRef]

- Wu, J.; Li, J. Effect of part deformation on performance of a rotary compressor using propane under high temperature. Appl. Therm. Eng. 2021, 194, 117145. [Google Scholar] [CrossRef]

- Costa, C.; Ferreira, R.; Prata, A. Considerations about the leakage through the minimal clearance in a rolling piston compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1990. [Google Scholar]

- Gasche, J.L.; Ferreira, R.T.S.; Prata, A.T. Transient Flow of the Lubricant Oil through the Radial Clearance in Rolling Piston Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998; pp. 25–30. [Google Scholar]

- Kim, G.; Min, B.; Na, S.; Choi, G.; Kim, D. Estimation of leakage through radial clearance during compression process of a rolling piston rotary compressor. J. Mech. Sci. Technol. 2017, 31, 6033–6040. [Google Scholar] [CrossRef]

- Yanagisawa, T.; Shimizu, T. Leakage losses with a rolling piston type rotary compressor. I. Radical clearance on the rolling piston. Int. J. Refrig. 1985, 8, 75–84. [Google Scholar] [CrossRef]

- Fan, Z.; Chen, Z. A calculating method for gas leakage in compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1994; pp. 47–53. [Google Scholar]

- Yuan, X.; Chen, Z.; Fan, Z. Calculating model and experimental investigation of gas leakage. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1992; pp. 1249–1255. [Google Scholar]

- Yanagisawa, T.; Shimizu, T. Friction losses in rolling piston type rotary compressors. Int. J. Refrig. 1985, 8, 159–165. [Google Scholar] [CrossRef]

- Gasche, J.L.; Ferreira, R.T.S.; Prata, A.T. Two-Phase Flow of Oil-Refrigerant Mixture through the Radial Clearance in Rolling Piston Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2000. [Google Scholar]

- Cai, D.; He, G.; Yokoyama, T.; Tian, Q.; Yang, X.; Pan, J. Simulation and comparison of leakage characteristics of R290 in rolling piston type rotary compressor. Int. J. Refrig. 2015, 53, 42–54. [Google Scholar] [CrossRef]

- Gasche, J.L.; Andreotti, T.; Maia, C.R.M. A model to predict R134a refrigerant leakage through the radial clearance of rolling piston compressors. Int. J. Refrig. 2012, 35, 2223–2232. [Google Scholar] [CrossRef]

- Cai, D.; Qiu, C.; Pan, J.; Yang, X.; He, G.; Tetsuhide, Y.; Chen, X.; Li, H. Leakage characteristics and an updated volumetric efficiency prediction model of rolling piston type rotary compressor for small capacity air-conditioner and heat pump applications. Appl. Therm. Eng. 2017, 121, 1080–1094. [Google Scholar] [CrossRef]

- He, G.; Sun, W.; Zhu, Y.; Yang, X.; Cai, D. Experimental performance evaluation on leakage characteristics of R32 in rolling piston type rotary compressor. Int. J. Refrig. 2018, 91, 177–188. [Google Scholar] [CrossRef]

- Dreiman, N.; Herrick, K. Vibration and Noise Control of a Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998; p. 1320. [Google Scholar]

- Yoshimura, T.; Koyama, T.; Morita, I.; Kobayashi, M.; Uetsuji, T. A Study of the Vibration Reduction of Rolling Piston Type Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1992. [Google Scholar]

- Yanagisawa, T.; Shimizu, T.; Chu, I.; Ishijima, K. Motion Analysis of Rolling Piston in Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1982; pp. 185–192. [Google Scholar]

- Zhou, Z.; Gong, Y. The estimation of the frictional losses of the rolling piston type refrigerant compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1988. [Google Scholar]

- Okada, K.; Kuyama, K. Motion of rolling piston in rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1982. [Google Scholar]

- Imaichi, K.; Fukushima, M.; Muramatsu, S.; Ishii, N. Vibration Analysis of Rotary Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1982; p. 407. [Google Scholar]

- Yanagisawa, T.; Mori, M.; Shimizu, T.; Ogi, Y. Vibration of a rolling piston type rotary compressor. Int. J. Refrig. 1984, 7, 237–244. [Google Scholar] [CrossRef]

- Sato, Y.; Shirafuji, Y. The Study of Rotary Compressor Driven Under Low Electric Frequencies. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1990. [Google Scholar]

- Dufour, R.; Charreyron, M.; Gerard, M. Dynamics Prediction of Refrigerant Rotary Compressor Crankshaft. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998. [Google Scholar]

- Xie, F.; Zhang, H.; Wu, J.; Ma, W.; Liu, C.; Gao, X. Dynamic Analysis of a Rotor-Journal Bearing System of Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2006. [Google Scholar]

- Wang, Z.; Yu, X.; Liu, F.; Feng, Q.; Tan, Q. Dynamic analyses for the rotor-journal bearing system of a variable speed rotary compressor. Int. J. Refrig. 2013, 36, 1938–1950. [Google Scholar] [CrossRef]

- Sano, K.; Mitsui, K. Analysis of hermetic rolling piston type compressor noise, and countermeasures. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1984. [Google Scholar]

- Kawaguchi, S.; Yamamoto, T.; Hirahara, T.; Ohinata, O.; Morinushi, K. Noise reduction of rolling piston type rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1986. [Google Scholar]

- Adachi, Y.; Onoda, I.; Takashima, K. Development of a Low Noise Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1996. [Google Scholar]

- Jang, S.; Choung, H.; Park, S.; Lee, S. Investigation on noise of rotary compressors using fluid-structure interaction. J. Mech. Sci. Technol. 2019, 33, 5129–5135. [Google Scholar] [CrossRef]

- Deng, W.-J.; Zhang, Y.-L.; Zhu, Z.-P.; Yue, X.-J.; Ba, D.-C.; Che, S.-G. Fluid–solid coupling numerical simulation for the performance prediction and valve dynamic analysis of a rotary compressor. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 6928–6938. [Google Scholar] [CrossRef]

- Ooi, K.; Wong, T. A computer simulation of a rotary compressor for household refrigerators. Appl. Therm. Eng. 1997, 17, 65–78. [Google Scholar] [CrossRef]

- Hirahara, T.; Ohinata, O. An analysis of cylinder overpressure using the method of characteristics. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1982. [Google Scholar]

- Prater, G.; Hnat, W.P. Optical measurement of discharge valve modal parameters for a rolling piston refrigeration compressor. Measurement 2003, 33, 75–84. [Google Scholar] [CrossRef]

- Wang, J.; Ding, H.; Wang, B.; Ding, Y.; Huang, Y. CFD simulation of a rotary compressor with gas injection. IOP Conf. Series: Mater. Sci. Eng. 2019, 604, 012084. [Google Scholar] [CrossRef]

- Geng, W.; Liu, C.; Wang, Y. The Performance Optimization of Rolling Piston Compressors Based on Cfd Simulation. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2004. [Google Scholar]

- Ooi, K.T.; Chai, G.B.; Kwek, E.C. A Simple Valve Model to Study the Performance of a Small Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1992. [Google Scholar]

- Kakuda, M.; Kitora, Y.; Hirahara, T.; Yamamoto, T. Investigation of Pressure Pulsation in Suction Pipe on Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1988. [Google Scholar]

- Liu, Z.; Soedel, W. Using a Gas Dynamic Model to Predict the Supercharging Phenomenon in a Variable Speed Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1994. [Google Scholar]

- Liu, Z.; Soedel, W. Performance Study of a Variable Speed Compressor with Special Attention to Supercharging Effect. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1994. [Google Scholar]

- Ooi, K.T.; Chai, G.B.; Khoo, C.T. Stress Analysis of a Compressor Vane-Spring. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1994. [Google Scholar]

- Bae, J.-Y.; Kim, J.-D.; Lee, B.-C.; Noh, T.-Y.; Byun, S.-M. Vane jumping in rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998. [Google Scholar]

- Liu, Y.; Kosco, J. Vane Dynamics Analysis of a Tilted Vane Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998; pp. 403–408. [Google Scholar]

- Padhy, S.K.; Scheldorf, G.O. Wear and Tribodynamics of a Rolling Piston Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1994. [Google Scholar]

- Tanaka, S.; Nakahara, T.; Kyogoku, K. Mixed Lubrication Analysis of Vane Tip in Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2000. [Google Scholar]

- Ito, Y.; Hattori, H.; Miura, K.; Hirayama, T. Mixed Lubrication Analysis of Vane Sliding Surface in Rotary Compressor Mechanisms. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2006. [Google Scholar]

- Ito, Y.; Hattori, H.; Miura, K. Lubricating characteristics and motion characteristics of a rolling piston for rotary compressors in air conditioners. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 984–996. [Google Scholar] [CrossRef]

- Cho, I.-S.; Oh, S.-H.; Jung, J.-Y. Lubrication characteristics between the vane and the rolling piston in a rotary compressor used for refrigeration and air-conditioning systems. KSME Int. J. 2001, 15, 562–568. [Google Scholar] [CrossRef]

- Cho, I.-S.; Jung, J.-Y. The Influence of the vane on the lubrication characteristics between the vane and the rolling piston of a rotary compressor. J. Mech. Sci. Technol. 2006, 20, 2242–2249. [Google Scholar] [CrossRef]

- Cho, I.-S.; Jung, J.-Y. Lubrication characteristics of a rotary compressor used for refrigeration and air-conditioning systems (the influence of alternative refrigerants). J. Mech. Sci. Technol. 2010, 24, 851–856. [Google Scholar] [CrossRef]

- Ito, Y.; Hattori, H.; Miura, K. Mixed Lubrication Analysis of Vane Sliding Surface in Rotary Compressor Mechanisms—Influences of Elastic Deformation at Surface End of Vane-slot. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2008. [Google Scholar]

- Sheiretov, T.; Van Glabbeek, W.; Cusano, C. Simulative friction and wear study of retrofitted swash plate and rolling piston compressors. Int. J. Refrig. 1995, 18, 330–335. [Google Scholar] [CrossRef][Green Version]

- Takebayashi, M.; Hata, H.; Iizuka, T.; Ishiyama, A.; Kohsokabe, H. A Study on Wear Characteristics of a Rolling-Piston-Type Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2000. [Google Scholar]

- Jeon, H.-G.; Oh, S.-D.; Lee, Y.-Z. Friction and wear of the lubricated vane and roller materials in a carbon dioxide refrigerant. Wear 2009, 267, 1252–1256. [Google Scholar] [CrossRef]

- Chen, Z.; Wu, J.; Li, G. Experimental study on the tribological characteristic of vane–roller interface of HC290 rotary compressor with mineral oil. Int. J. Refrig. 2018, 94, 205–213. [Google Scholar] [CrossRef]

- Geng, K.; Geng, A.; Wang, X.; Zheng, X.; Wei, W.; Zhao, T.; Lei, Y.; He, Y. Frictional characteristics of the vane–chute pair in a rolling piston compressor based on the second-order motion. Tribol. Int. 2019, 133, 111–125. [Google Scholar] [CrossRef]

- Se-Doo, O.; Jong-Woo, K.; Young-Ze, L. Friction and Wear Characteristics of TiN Coated Vane for the Rotary Compressor in a R410A Refrigerant©. Tribol. Trans. 2004, 47, 29–33. [Google Scholar] [CrossRef]

- Sung, H.C. Tribological characteristics of various surface coatings for rotary compressor vane. Wear 1998, 221, 77–85. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Y.; Liao, Y. Performance of rolling piston type rotary compressor using fullerenes (C70) and NiFe2O4 nanocomposites as lubricants additives. Front. Energy 2017, 14, 1–5. [Google Scholar] [CrossRef]

- Asanuma, H.; Itami, T.; Ishikawa, H. An experimental study of the shaft oil supply mechanism of a rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1984. [Google Scholar]

- Yanagisawa, T.; Shimizu, T. Foaming of refrigerating oil in a rolling piston type rotary compressor. Int. J. Refrig. 1986, 9, 17–20. [Google Scholar] [CrossRef]

- Sakurai, L.; Hamilton, J.F. The prediction of frictional losses in variable-speed rotary compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1984. [Google Scholar]

- Fujimoto, S.; Sakitani, K.; Watada, M. Tribology analysis in rolling piston type compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1984. [Google Scholar]

- Ozu, M.; Itami, T. Some electrical observations of metallic contact between lubricated surfaces under dynamic conditions of rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1980. [Google Scholar]

- Zhu, Y.; He, G.; Sun, W.; Shimoji, M.; Chen, X. Experimental investigation on startup process for oil supply system of a variable speed rotary compressor. Int. J. Refrig. 2020, 113, 58–69. [Google Scholar] [CrossRef]

- Gasche, J.L.; Ferreira, R.T.S.; Prata, A.T. Influence of the Roller Velocity on the Flow of Lubricating Oil in a Rolling Piston Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1994. [Google Scholar]

- Mi, J.; Meng, Y. Numerical Analyses of Hydrodynamic Lubrication and Dynamics of the Rolling Piston and Crankshaft in a Rotary Compressor. Tribol. Trans. 2014, 57, 1136–1147. [Google Scholar] [CrossRef]

- Itoh, T.; Kobayashi, H.; Fujitani, M.; Murata, N. Study on the Oil Supply System for Rotary Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1992. [Google Scholar]

- Kim, H.J.; Lee, E.S.; Kwag, S.H.; Yun, K.W.; Min, K.K. A study on the oil supply system of a rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2000. [Google Scholar]

- Kim, H.J.; Lancey, T.W. Numerical study on the lubrication oil distribution in a refrigeration rotary compressor. Int. J. Refrig. 2003, 26, 800–808. [Google Scholar] [CrossRef]

- Liu, R.; Jing, L.; Meng, X.; Lyu, B. Mixed elastohydrodynamic analysis of a coupled journal-thrust bearing system in a rotary compressor under high ambient pressure. Tribol. Int. 2021, 159, 106943. [Google Scholar] [CrossRef]

- Wu, J.; Wang, G. Numerical study on oil supply system of a rotary compressor. Appl. Therm. Eng. 2013, 61, 425–432. [Google Scholar] [CrossRef]

- Bushnell, P. Oil Droplet Generation and Control in Rolling Piston Type Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1996. [Google Scholar]

- Kim, Y.J.; Lee, S.K.; Youn, Y.; Ko, H.S. Experimental Study of Refrigerant-Oil Behavior Inside Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2004. [Google Scholar]

- Min, K.; Hwang, I. Oil Circulation Rate in Rotary Compressor: Its Measurement and Factors Affecting the Rate. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2000. [Google Scholar]

- Huang, B.; Ma, M.; Geng, W. Experimental Study on Reduction of Oil Circulation Rate in Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2010. [Google Scholar]

- Ogata, T.; Hasegawa, H.; Okaichi, A.; Nishiwaki, F. Reduction of Oil Discharge for Rolling Piston Compressor Using CO2 Refrigerant. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2006. [Google Scholar]

- Ooi, K.T.; Wong, T.N.; Kwek, E.C. A Real Gas Simulation of a Refrigeration Compressor and its Performance Comparison for CFCs and Non-CFCs. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1992. [Google Scholar]

- Hwang, S.W.; Kim, K.H.; Lee, S.Y.; Kim, J.S.; Park, S.K. Development of the High Efficiency Rolling Piston Type Rotary Compressor for Alternative Refrigerant R410a. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998. [Google Scholar]

- Ooi, K. Assessment of a rotary compressor performance operating at transcritical carbon dioxide cycles. Appl. Therm. Eng. 2008, 28, 1160–1167. [Google Scholar] [CrossRef]

- Fukuda, T.; Hayano, M. HFC/POE Lubricity evaluation on the rotary compressor in system operation. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1996. [Google Scholar]

- Fang, X.; Lin, J.; Ma, X. Simulation study on compression characteristics of low GWP refrigerants in the cylinder of rotary compressors. Appl. Therm. Eng. 2021, 193, 117056. [Google Scholar] [CrossRef]

- Lin, J.; Lian, Y.; Wu, J. Numerical investigation on vapor-liquid two-phase compression in the cylinder of rotary compressors. Appl. Therm. Eng. 2020, 170, 115022. [Google Scholar] [CrossRef]

- Wang, C.; Wu, J.; Du, Y.; Lei, B. Lubricating condition evaluation of the rotary compressor under high ambient temperature. Int. J. Refrig. 2020, 118, 220–229. [Google Scholar] [CrossRef]

- Wu, J.; Shi, H.; Li, J. Analysis on the reliability of R290 rotary compressor in the high ambient temperature. Int. J. Refrig. 2020, 110, 132–141. [Google Scholar] [CrossRef]

- Wu, J.; Chen, Z.; Lin, J.; Li, J. Experimental analysis on R290 solubility and R290/oil mixture viscosity in oil sump of the rotary compressor. Int. J. Refrig. 2018, 94, 24–32. [Google Scholar] [CrossRef]

- Zhu, Y.; He, G.; Sun, W.; Shimoji, M.; Chen, X. Effect of oil stirrer on the performance of oil supply system for a variable speed rotary compressor. Int. J. Refrig. 2019, 101, 1–10. [Google Scholar] [CrossRef]

- Zhu, Y.; He, G.; Sun, W.; Shimoji, M.; Chen, X. Investigation on the characteristics of oil supply system for a hermetic variable speed rotary compressor. Int. J. Refrig. 2020, 118, 150–160. [Google Scholar] [CrossRef]

- Zhu, Y.; He, G.; Sun, W.; Shimoji, M.; Chen, X. Effect of Inlet Structures on the Performance of Oil Supply System of a Variable Speed Rotary Compressor. J. Fluids Eng. 2019, 141, 081114. [Google Scholar] [CrossRef]

- Ooi, K.T.; Wong, T.N.; Kwek, E.C. Effects of Vane Spring Stiffness on Compressor Performance. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1994; pp. 549–553. [Google Scholar]

- Wu, J.; Chen, A. A new structure and theoretical analysis on leakage and performance of an oil-free R290 rolling piston compressor. Int. J. Refrig. 2015, 49, 110–118. [Google Scholar] [CrossRef]

- Farkas, B.; Suda, J. Performance analysis of a novel oil-free rotary compressor. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 870–887. [Google Scholar] [CrossRef]

- Shin, M.S.; Na, S.K.; Choi, G.M. A Novel Structure of Rolling Piston Type Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2018. [Google Scholar]

- Na, S.K.; Lee, T.M.; Choi, G.M. Efficiency analysis of the novel twin chamber rotary compressor. IOP Conf. Ser. Mater. Sci. Eng. 2019, 604, 012066. [Google Scholar] [CrossRef]

- Shin, M.; Na, S.; Lee, J.; Min, B.; Choi, G. Model analysis of a novel compressor with a dual chamber for high-efficiency systems. Appl. Therm. Eng. 2019, 158, 113717. [Google Scholar] [CrossRef]

- Sakaino, K.; Kawasaki, K.; Shirafuji, Y.; Ohinata, O. The Study of Dual Cylinder Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1986; Volume 532, pp. 292–305. [Google Scholar]

- Hattori, H.; Kawashima, N. Dynamic Analysis of a Rotor-Journal Bearing System for Twin Rotary Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1990. [Google Scholar]

- Yang, J.-S.; Mei, L.; Noh, K.-Y.; Moon, S.-H.; Sa, B.-D.; Choi, G.-M.; Kim, D.-J. A sensitivity study of size parameters in a twin-type rolling piston compressor. Int. J. Refrig. 2013, 36, 786–794. [Google Scholar] [CrossRef]

- Min, B.; Na, S.; Yang, J.; Choi, G. Geometric correlation of discharge coefficients for discharge valve system in rolling piston rotary compressor. J. Mech. Sci. Technol. 2018, 32, 3943–3954. [Google Scholar] [CrossRef]

- Na, S.; Shin, M.; Choi, G.; Min, B. Effect of pressure ratio and oil viscosity on rotary compressor efficiency. J. Mech. Sci. Technol. 2018, 32, 4971–4981. [Google Scholar] [CrossRef]

- Kim, H.J.; Ahn, J.M.; Hwang, S.W.; Kiem, M.K. Performance analysis of a twin rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2004. [Google Scholar]

- Sasahara, Y.; Komine, K.; Ootori, M.; Kawabe, I.; Kumazawa, T.; Fujita, S. Development of 2-Cylinder Rotary Compressor with R-410A. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998. [Google Scholar]

- Minami, K.; Hattori, H.; Hayano, M. Lubrication Analysis of Rotary Compressors for HFC Refrigerants. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998. [Google Scholar]

- Jin, X.; Wang, S.; Zhang, T.T.; Zu, F. Intermediate pressure of two-stage compression system under different conditions based on compressor coupling model. Int. J. Refrig. 2012, 35, 827–840. [Google Scholar] [CrossRef]

- Yan, G.; Jia, Q.; Bai, T. Experimental investigation on vapor injection heat pump with a newly designed twin rotary variable speed compressor for cold regions. Int. J. Refrig. 2016, 62, 232–241. [Google Scholar] [CrossRef]

- Jin, X.; Zhang, K.; Liu, Z.; Li, X.; Jiang, S. Numerical research on coupling performance of inter-stage parameters for two-stage compression system with injection. Appl. Therm. Eng. 2018, 128, 1430–1445. [Google Scholar] [CrossRef]

- Dreiman, N.; Bunch, R.; Hwang, Y.H.; Radermacher, R. Two-Stage Rolling Piston Carbon Dioxide Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2004; p. 8. [Google Scholar]

- Yang, J.; Qi, Z.; Chen, J.; Chen, Z. Experimental study on a two-stage rolling piston CO2 compressor based on p–V indicator diagrams. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2011, 226, 995–1003. [Google Scholar] [CrossRef]

- Shuxue, X.; Guoyuan, M. Experimental study on two-stage compression refrigeration/heat pump system with dual-cylinder rolling piston compressor. Appl. Therm. Eng. 2014, 62, 803–808. [Google Scholar] [CrossRef]

- Lee, S.-J.; Shim, J.; Kim, K.C. Development of capacity modulation compressor based on a two stage rotary compressor—part I: Modeling and simulation of compressor performance. Int. J. Refrig. 2015, 54, 22–37. [Google Scholar] [CrossRef]

- Lee, S.-J.; Shim, J.; Kim, K.C. Development of capacity modulation compressor based on a two-stage rotary compressor—Part ΙΙ: Performance experiments and P–V analysis. Int. J. Refrig. 2016, 61, 82–99. [Google Scholar] [CrossRef]

- Hu, Y.S.; Wei, H.J.; Yu, B.; Yang, O.X.; Wang, J.; Wu, J. Research on the Vapor Injection of Two-stage Rotary Compressor. IOP Conf. Ser. Mater. Sci. Eng. 2019, 604, 012072. [Google Scholar] [CrossRef]

- Liu, X.; Wang, B.; Shi, W.; Zhang, P. A novel vapor injection structure on the blade of a rotary compressor. Appl. Therm. Eng. 2016, 100, 1219–1228. [Google Scholar] [CrossRef]

- Wang, B.; Liu, X.; Shi, W.; Ding, Y. An enhanced rotary compressor with gas injection through a novel end-plate injection structure. Appl. Therm. Eng. 2018, 131, 180–191. [Google Scholar] [CrossRef]

- Wang, B.; Liu, X.; Ding, Y.; Shi, W. Optimal design of rotary compressor oriented to end-plate gas injection with check valve. Int. J. Refrig. 2018, 88, 516–522. [Google Scholar] [CrossRef]

- Sun, W.; He, G.; Ning, Q.; Song, H.; Pang, Q. Performance investigation and optimization analysis for vapor injection rotary compressor oriented to circular end-plate injection port without check valve. Appl. Therm. Eng. 2021, 183, 116196. [Google Scholar] [CrossRef]

- Kawai, H. Efficiency improvement in rolling piston type rotary compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1984. [Google Scholar]

- Okoma, K.; Onoda, I. Study of lubrication mechanism for horizontal type rolling piston rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1988. [Google Scholar]

- Kim, H.J. Lubrication oil pumping by utilizing vane motion in a horizontal rotary compressor. Int. J. Refrig. 2005, 28, 498–505. [Google Scholar] [CrossRef]

- Takebayashi, M.; Iwata, H.; Sakazume, A.; Hata, H. Discharge characteristics of an oil feeder pump using nozzle type fluidic diodes for a horizontal compressor depend on the driving speed. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1988. [Google Scholar]

- Kim, K.-M.; Cho, K.Y. A study on lubricating system of hermetic rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1988. [Google Scholar]

- Masuda, M.; Sakitani, K.; Yamamoto, Y.; Uematsu, T.; Mutoh, A. Development of Swing Compressor for Alternative Refrigerants. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1996. [Google Scholar]

- He, Z.; Yang, X.; Li, D.; Wu, W. Dynamic characteristics of a swing compressor for an air conditioning system at different discharge pressures. Int. J. Refrig. 2020, 112, 125–135. [Google Scholar] [CrossRef]

- Furusho, K.; Okawa, T.; Saitoh, K.; Sakitani, K. Numerical and Experimental Investigation of Swing Compressor Characteristics. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 1998. [Google Scholar]

- Tanaka, S.; Nakahara, T.; Kyogoku, K.; Toyama, T. Lubrication Characteristics between Bush and Blade of Swing Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2002. [Google Scholar]

- Morimoto, K.; Kataoka, Y.; Uekawa, T.; Kamiishida, H. Noise Reduction of Swing Compressors with Concentrated Winding Motors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2004. [Google Scholar]

- Higuchi, M.; Mori, H.; Taniwa, H.; Ida, K.; Nabetani, Y. Development of the high efficiency and low noise swing compressor for CO2 heat pump water heater. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2006. [Google Scholar]

- Ohkawa, T.; Kumakura, E.; Higashi, H.; Sakitani, K.; Higuchi, M.; Taniwa, H.; Ozawa, H. Development Of Hermetic Swing Compressors For CO2 Refrigerants. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2002. [Google Scholar]

- Yamamoto, Y.; Kanayama, T.; Yuasa, K.; Matsuura, H. Development of High Efficiency Swing Compressor for R32 Refrigerant. J. Energy Power Eng. 2015, 9. [Google Scholar] [CrossRef]

- Hugenroth, J. Oil-less Swing Compressor Development. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2014. [Google Scholar]

- De Lim, Y.; Poh, W.C.; Ooi, K.T. Leakage Simulation of a Lubricant-free Rotary Swing Compressor Rotor Endface Clearance. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2018. [Google Scholar]

- Lim, Y.D.; Lin, M.; Ooi, K.T. Simulation study of multi-chamber rotary compressor. IOP Conf. Ser. Mater. Sci. Eng. 2017, 232, 12064. [Google Scholar] [CrossRef]

- Pan, X.; Wang, M.; Li, W.; Xing, Z.; Pan, S. Structural study on a swing compressor with no valves for air conditioning systems. Int. J. Refrig. 2018, 88, 300–306. [Google Scholar] [CrossRef]

- Pan, X.; Tian, C.; Wu, S.; Xing, Z.; Pan, S. Experimental study of the swing compressor with no valves. Appl. Therm. Eng. 2019, 163, 114274. [Google Scholar] [CrossRef]

- Pan, X.; Sun, S.; Xing, Z.; Pan, S. Theoretical study and experimental verification of the leakage losses of R410A in the swing compressor with no valves. Int. J. Refrig. 2019, 99, 327–336. [Google Scholar] [CrossRef]

- Shintaku, H.; Ikoma, M.; Hasegawa, H.; Nishiwaki, F.; Harada, T.; Nakata, H.; Kurimoto, M. Experimental and theoretical study of an advanced rotary compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2000. [Google Scholar]

- Okur, M.; Akmandor, I.S. Experimental investigation of hinged and spring loaded rolling piston compressors pertaining to a turbo rotary engine. Appl. Therm. Eng. 2011, 31, 1031–1038. [Google Scholar] [CrossRef]

- Hu, X.; Qu, Z.; Yang, X.; Sun, J. Theoretical study on frictional losses of a novel automotive swing vane compressor. Int. J. Refrig. 2013, 36, 758–767. [Google Scholar] [CrossRef]

- Ma, J.; Chen, X.; Qu, Z. Structural optimal design of a swing vane compressor. Front. Energy 2019, 13, 764–769. [Google Scholar] [CrossRef]

- Yang, X.; Dong, C.; Qu, Z. Design and dynamic analysis of a novel double-swing vane compressor for electric vehicle air conditioning systems. Int. J. Refrig. 2017, 76, 52–62. [Google Scholar] [CrossRef]

- De Lim, Y.; Ooi, K.T. Performance analysis of a U-Vane compressor. Appl. Therm. Eng. 2020, 178, 115570. [Google Scholar] [CrossRef]

- Qu, Z.C.; Lin, X.W.; Feng, J.M.; Zhou, H. Theory of Synchronal Rotary Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2004. [Google Scholar]

- Dreiman, N.; Bunch, R. Motion Analysis of Compact Rotating Cylinder Compressor. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2006. [Google Scholar]

- Yang, X.; Qu, Z.; Hu, X.; Wu, Y. Theoretical and experimental performance analysis of a synchronal rotary multiphase pump with the inlet gas volume fractions of 0–0.9. Proc. Inst. Mech. Eng. Part A J. Power Energy 2012, 226, 727–737. [Google Scholar] [CrossRef]

- Yang, X.; Hu, C.; Hu, Y.; Qu, Z. Theoretical and experimental study of a synchronal rotary multiphase pump at very high inlet gas volume fractions. Appl. Therm. Eng. 2017, 110, 710–719. [Google Scholar] [CrossRef]

- Yang, X.; Qu, Z. Suction port design for a synchronal rotary multiphase pump. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2018, 232, 127–132. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, J.; Hu, X.; Qu, Z. Design optimization of a synchronal rotary multiphase pump. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2014, 230, 134–145. [Google Scholar] [CrossRef]

- Teh, Y.; Ooi, K. Experimental study of the Revolving Vane (RV) compressor. Appl. Therm. Eng. 2009, 29, 3235–3245. [Google Scholar] [CrossRef]

- Teh, Y.; Ooi, K. Theoretical study of a novel refrigeration compressor—Part I: Design of the revolving vane (RV) compressor and its frictional losses. Int. J. Refrig. 2009, 32, 1092–1102. [Google Scholar] [CrossRef]

- Teh, Y.; Ooi, K.; Djamari, D.W. Theoretical study of a novel refrigeration compressor—Part II: Performance of a rotating discharge valve in the revolving vane (RV) compressor. Int. J. Refrig. 2009, 32, 1103–1111. [Google Scholar] [CrossRef]

- Teh, Y.; Ooi, K. Theoretical study of a novel refrigeration compressor- Part III: Leakage loss of the revolving vane (RV) compressor and a comparison with that of the rolling piston type. Int. J. Refrig. 2009, 32, 945–952. [Google Scholar] [CrossRef]

- Yang, H.; Qu, Z.; Zhou, H.; Yu, B. Study on leakage via the radial clearance in a novel synchronal rotary refrigeration compressor. Int. J. Refrig. 2011, 34, 84–93. [Google Scholar] [CrossRef]

- Aw, K.T.; Ooi, K.T. Leakage study of a lubricant-free revolving vane compressor. Int. J. Refrig. 2021, 124, 122–133. [Google Scholar] [CrossRef]

- Tan, K.; Ooi, K. Heat transfer in compression chamber of a revolving vane (RV) compressor. Appl. Therm. Eng. 2011, 31, 1519–1526. [Google Scholar] [CrossRef]

- Subiantoro, A.; Ooi, K. Analytical study of the endface friction of the revolving vane mechanism. Int. J. Refrig. 2011, 34, 1276–1285. [Google Scholar] [CrossRef]

- Yang, X.; Chen, X.; Ma, J.; Qu, Z. Analytical study of the end-face friction loss in a synchronal rotary multiphase pump. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 231, 3614–3623. [Google Scholar] [CrossRef]

- Aw, K.T.; Ooi, K.T. Theoretical Analysis of Revolving Vane Compressor Vibrations. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2014. [Google Scholar]

- Tan, K.; Ooi, K. A novel revolving vane compressor with a fixed-vane. Int. J. Refrig. 2011, 34, 1980–1988. [Google Scholar] [CrossRef]

- Tan, K.; Ooi, K. Journal bearings design for a novel revolving vane compressor. Int. J. Refrig. 2011, 34, 94–104. [Google Scholar] [CrossRef]

- Tan, K.; Ooi, K. Experimental study of fixed-vane revolving vane compressor. Appl. Therm. Eng. 2014, 62, 207–214. [Google Scholar] [CrossRef]

- Yap, K.S.; Ooi, K.T.; Chakraborty, A. Introduction of the Novel Cross Vane Expander-Compressor Unit for Vapour Compression Cycle. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2014. [Google Scholar]

- Yap, K.S.; Ooi, K.T.; Chakraborty, A. Modelling and Simulation of the Dynamics of Cross Vane Expander-Compressor Unit for Vapour Compression Cycle. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2014. [Google Scholar]

- Yap, K.S.; Ooi, K.T.; Chakraborty, A. Analysis of the novel cross vane expander-compressor: Mathematical modelling and experimental study. Energy 2018, 145, 626–637. [Google Scholar] [CrossRef]

- Shaffer, B.R.; Groll, E.A. Performance of the Use of Plastics in Oil-Free Scroll Compressors. In International Compressor Engineering Conference; Purdue e-Pubs: West Lafayette, IN, USA, 2012; pp. 1–9. [Google Scholar]

| Year | Description |

|---|---|

| 1834 | First vapor-compression refrigeration system was patented by Jacob Perkins that utilizes a piston compressor [1]. |

| 1856 | James Harrison achieved commercial success for his vapor-compression refrigeration system [1]. |

| 1874 | Charles Barnes patented the first rotary vane pump [5] that evolved into the sliding vane compressor. |

| 1916 | Douglas Henry Stokes invented the first hermetic compressor that utilizes the reciprocating mechanism [6]. |

| 1950 | First computational modeling pertaining to compressor research by Costagliola [7]. |

| 1960s | Commercial production of rolling piston compressors in Japan [8]. |

| 1972 | First publicly available literature on sliding vane compressor modeling [9,10]. |

| 1978 | First publicly available literature on rolling piston compressor modeling [11]. |

| 1987 | Montreal Protocol was signed to phase out chlorofluorocarbons (CFCs) to repair ozone depletion [12]; CFCs were commonly used as refrigerants then, so replacement refrigerants had to be found. |

| 1997 | The Kyoto Protocol was signed to reduce greenhouse gas emissions [13]. |

| 1998 | The Montreal Protocol now included the phase out of hydrochlorofluorocarbons (HCFCs) [12]. HCFC refrigerants were initially used to replace CFC refrigerants but later found to have extremely potent greenhouse effects. |

| 2015 | Paris Agreement was signed to reduce greenhouse gas emissions [14]. |

| 2016 | The Kigali Amendment to the Montreal Protocol was added to include the phase out of hydrofluorocarbons (HFCs) [12]. HFC refrigerants were also found to have extremely potent greenhouse effects. |

| Reference (Year) | Working Fluid | Displacement per Revolution | Max. Efficiency (Type) | Remarks/Features |

|---|---|---|---|---|

| Tothero and Keeney [23] (1978) | R12 | 151 cm3 | 81% (Volumetric efficiency) | Automotive compressor |

| Maruyama et al. [26] (1982) | Air | 85.5 cm3, 94 cm3 | 85% (Volumetric efficiency) | Automotive compressor |

| Tassou and Qureshi [24] (1998) | R22 | 142 cm3 1 | 80% (Volumetric efficiency) 66% 1 (Isentropic efficiency) | Open type (non-hermetic) compressor |

| Cipollone et al. [27] (2011) | Air | 380 cm3 1 | 91.6% 1 (Mechanical efficiency) | 22 kW compressor |

| Reference (Year) | Working Fluid | Displacement per Revolution | Max. Efficiency (Type) | Injection Type |

|---|---|---|---|---|

| Kruse [15] (1980) | Air | – 2 | 44% 1 (Isentropic efficiency) | Oil |

| Hickman and Neal [45] (1984) | R22 | – 2 | 80% (Volumetric efficiency) | Liquid refrigerant |

| Bianchi et al. [35] (2015) | Air | 400 cm3 1 | 90.6% 1 (Mechanical efficiency) | Oil |

| Bianchi and Cipollone [42] (2015) | Air | 378 cm3 | 96.7% (Volumetric efficiency) 88.5% 1 (Mechanical efficiency) | Oil |

| Cipollone et al. [44] (2015) | Air | 400 cm3 1 | 90.7% 1 (Mechanical efficiency) | Oil atomizer spray cooling |

| Reference (Year) | Working Fluid | Displacement per Revolution | Max. Efficiency (Type) | COP | Type |

|---|---|---|---|---|---|

| Edwards [52] (1988) | R114 | 490 cm3 | 80% (Isentropic efficiency) 92% (Volumetric efficiency) | 4.85 | Controlled rotary vane mechanism |

| Smith and Harrison [51] (1992) | – 2 | 227 cm3 | 67% 1 (Isentropic efficiency) 88% 1 (Volumetric efficiency) | 4.4 1 | Groll rotary vane mechanism |

| Reference (Year) | Working Fluid | Displacement per Revolution | Max. Efficiency (Type) | Remarks/Features |

|---|---|---|---|---|

| Chu et al. [74] (1978) | R22 | – 2 | 93% (Volumetric efficiency) | – 2 |

| Ozu and Itami [8] (1981) | – 2 | – 2 | 95% (Volumetric efficiency) 90% (Mechanical efficiency) | 7000 BTU h−1 |

| Matsuzaka and Nagatomo [75] (1982) | R22 | 9 cm3 1 | 94% (Volumetric efficiency) 94% (Mechanical efficiency) 74% (Overall efficiency) | – 2 |

| Wakabayashi et al. [76] (1982) | R22 | 10.5 cm3 1 | 93% (Mechanical efficiency) | – 2 |

| Sakaino et al. [77] (1984) | – 2 | 56.9 cm3 | 98% (Volumetric efficiency) 92% (Mechanical efficiency) | – 2 |

| Sathe et al. [78] (2008) | R134a | 1.4 cm3 | 91% (Volumetric efficiency) 70% (Isentropic efficiency) | Miniature rolling piston |

| Reference (Year) | Working Fluid | Displacement per Revolution | Max. Efficiency (Type) | Type |

|---|---|---|---|---|

| Sakaino et al. (1986) [173] | – 2 | 80.6 cm3 | 98% (Volumetric efficiency) 92% (Mechanical efficiency) | Dual cylinder rolling piston |

| Dreiman et al. (2004) [183] | CO2 | – 2 | 80% (Volumetric efficiency) 60% (Isentropic efficiency) | Two-stage rolling piston |

| Yang et al. (2012) [184] | CO2 | 3.3 cm3 1 | 88% (Volumetric efficiency) 90% (Mechanical efficiency) | Two-stage rolling piston |

| Lee et al. (2016) [186] | R410A | 15 cm3 | 92% (Volumetric efficiency) 94% (Mechanical efficiency) | Two-stage rolling piston |

| Reference (Year) | Working Fluid | Displacement per Revolution | Max. Efficiency (Type) | Remarks/Features |

|---|---|---|---|---|

| Masuda et al. [222] (1996) | R134a, R407C, R410A | 12.8 cm3 | 97% 1 (Volumetric efficiency) | Swing compressor |

| Shintaku et al. [236] (2000) | R22 | 25.2 cm3 | 89% (Mechanical efficiency) 96% (Volumetric efficiency) | Variant–swivel vane fixed on roller |

| Okur et al. [237] (2011) | Air | – 2 | 90% (Isentropic efficiency) | Variant–hinged vane on roller |

| Pan et al. [234] (2019) | R410A | 10.5 cm3 | 91% (Volumetric efficiency) 79% (Isentropic efficiency) | Valve-less swing compressor |

| Lim and Ooi [241] (2020) | Air | 24 cm3 1 | 92% (Volumetric efficiency) | Variant–U-vane swing compressor |

| Reference (Year) | Working Fluid | Displacement per Revolution | Max. Efficiency (Type) | Remarks/Features |

|---|---|---|---|---|

| Teh and Ooi [248] (2009) | Air | 32.5 cm3, 34.6 cm3 | 81% 1 (Volumetric efficiency) | Swivel vane design |

| Tan and Ooi [260] (2014) | Air | 1.7 cm3 1 | 26% (Mechanical efficiency) | Fixed vane design |

| Aw and Ooi [253] (2021) | Air | 50 cm3 | 45% (Volumetric efficiency) 1% (Isentropic efficiency) | Oil-free, fixed vane design |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aw, K.T.; Ooi, K.T. A Review on Sliding Vane and Rolling Piston Compressors. Machines 2021, 9, 125. https://doi.org/10.3390/machines9060125

Aw KT, Ooi KT. A Review on Sliding Vane and Rolling Piston Compressors. Machines. 2021; 9(6):125. https://doi.org/10.3390/machines9060125

Chicago/Turabian StyleAw, Kuan Thai, and Kim Tiow Ooi. 2021. "A Review on Sliding Vane and Rolling Piston Compressors" Machines 9, no. 6: 125. https://doi.org/10.3390/machines9060125

APA StyleAw, K. T., & Ooi, K. T. (2021). A Review on Sliding Vane and Rolling Piston Compressors. Machines, 9(6), 125. https://doi.org/10.3390/machines9060125