Selection of Optimal Magnets for Traction Motors to Prevent Demagnetization

Abstract

1. Introduction

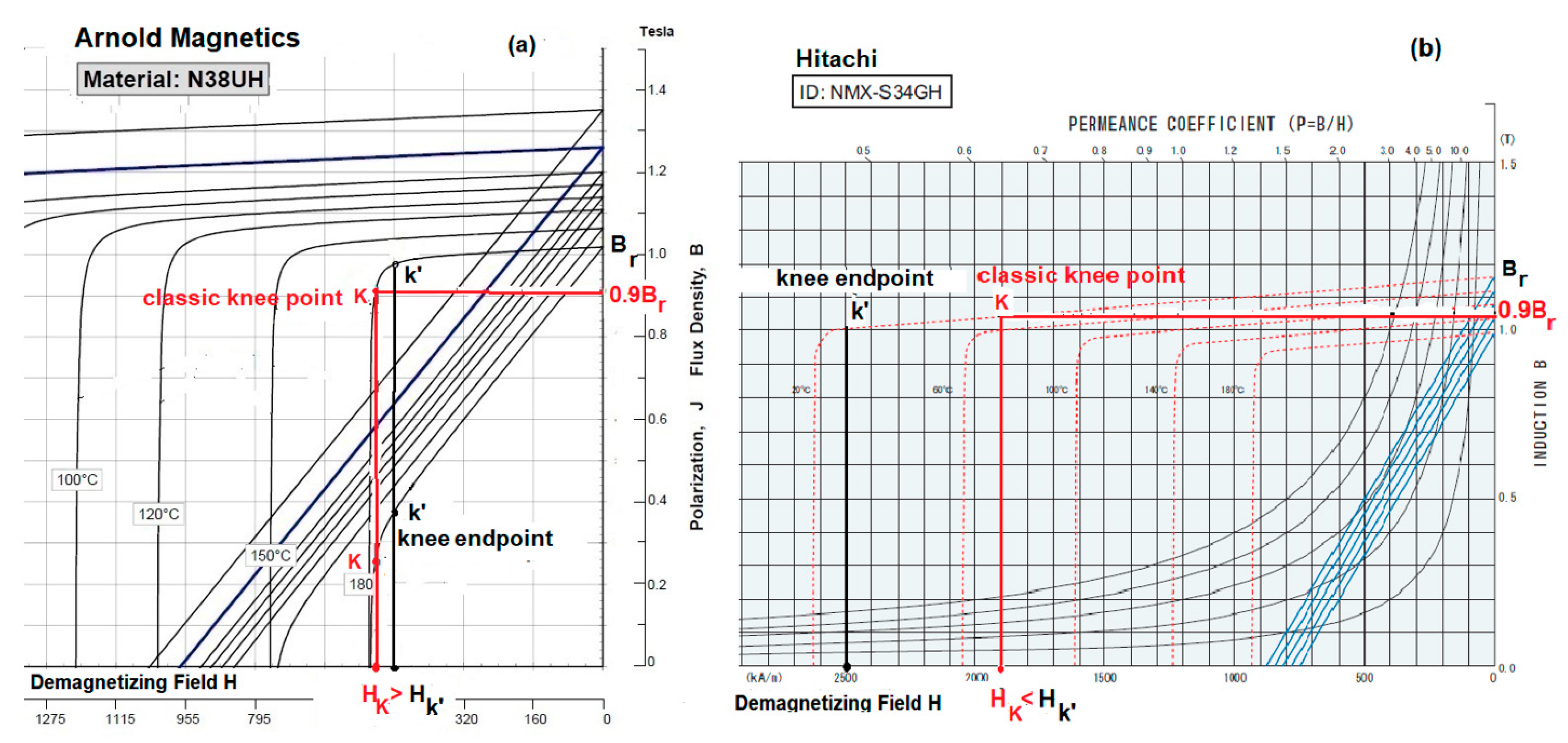

- Classic knee point K;

- Knee endpoint k′.

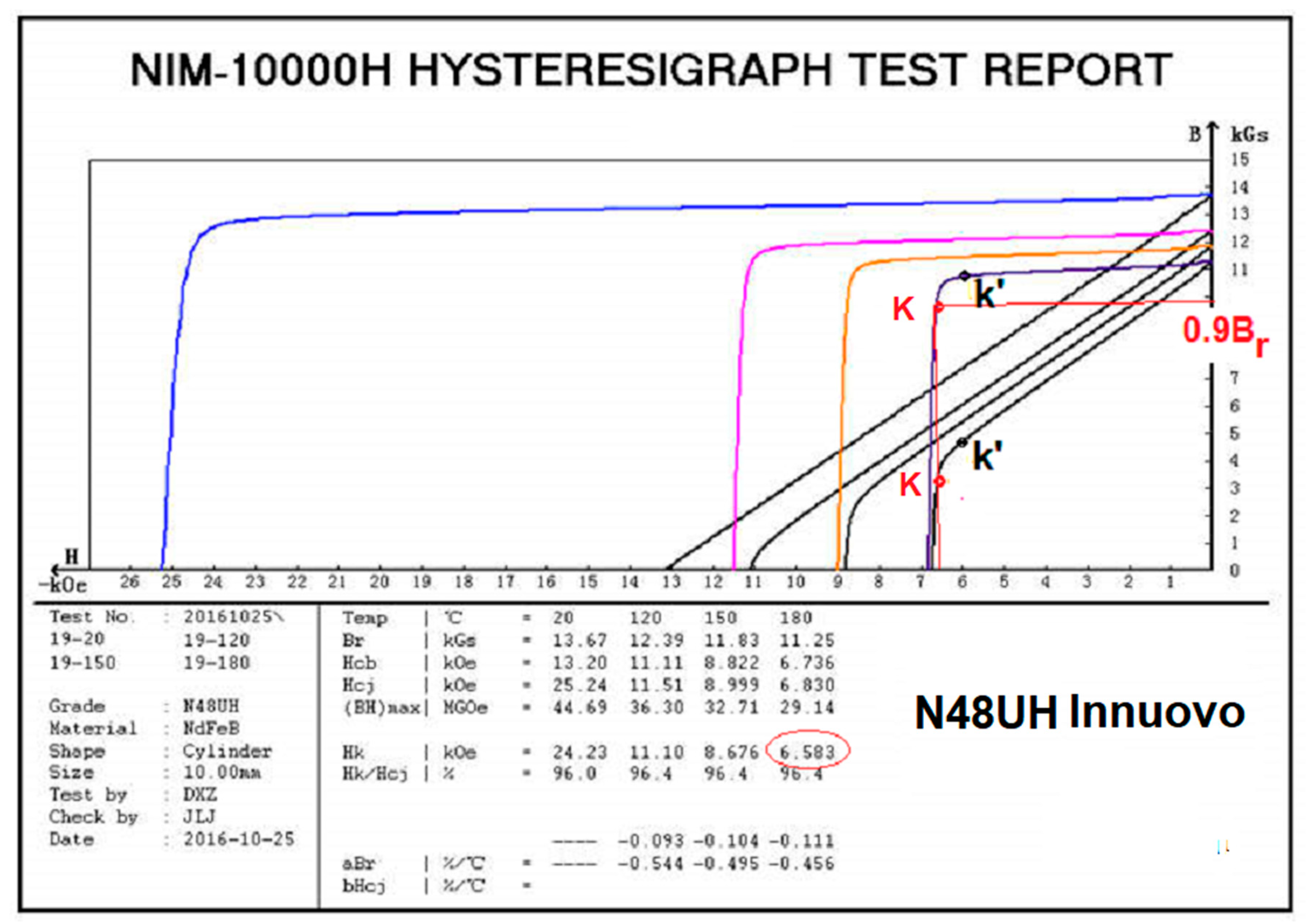

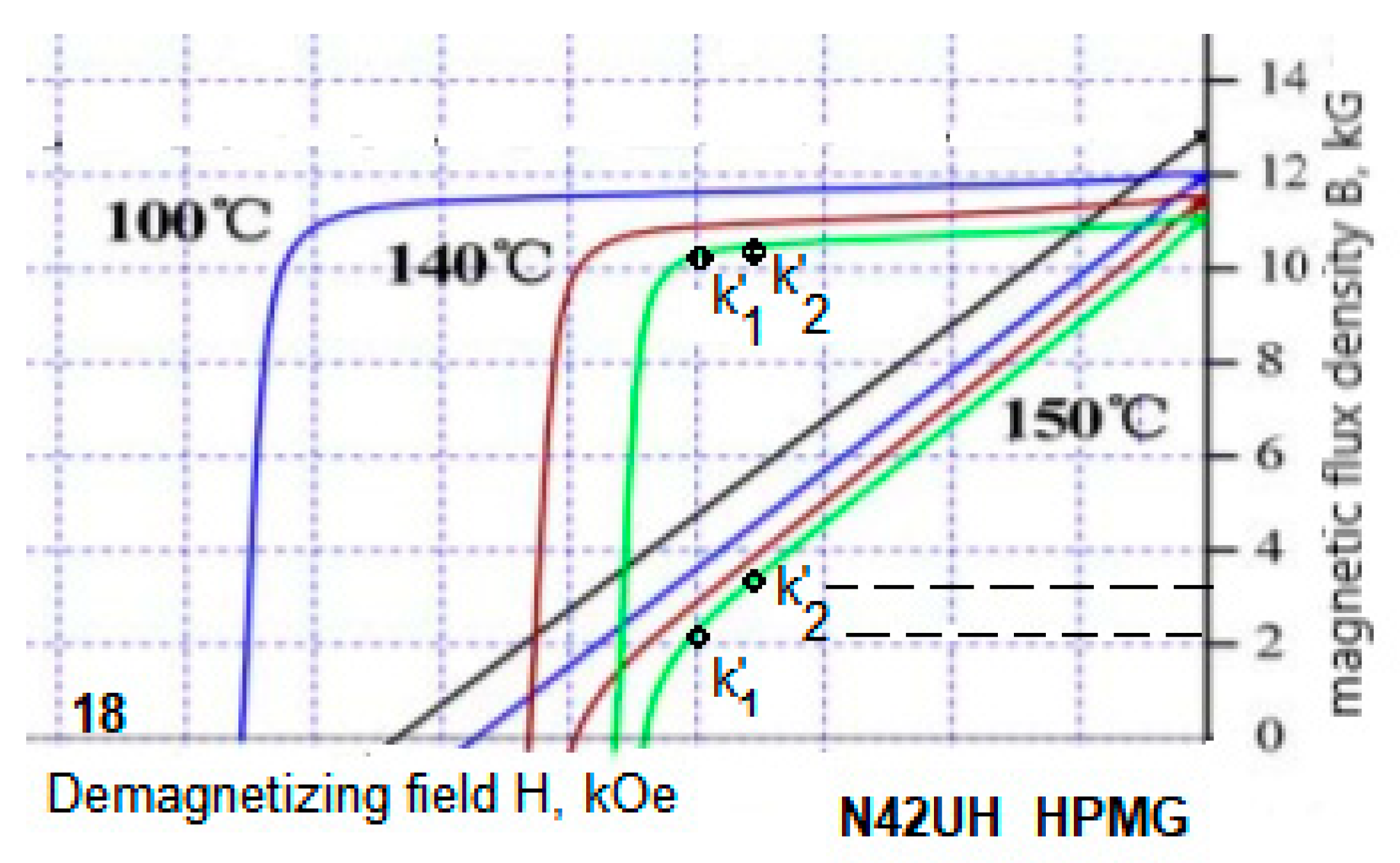

1.1. Difference between K, k′

1.2. Manual Method to Locate k′

1.3. Other Prior Methods to Locate k′

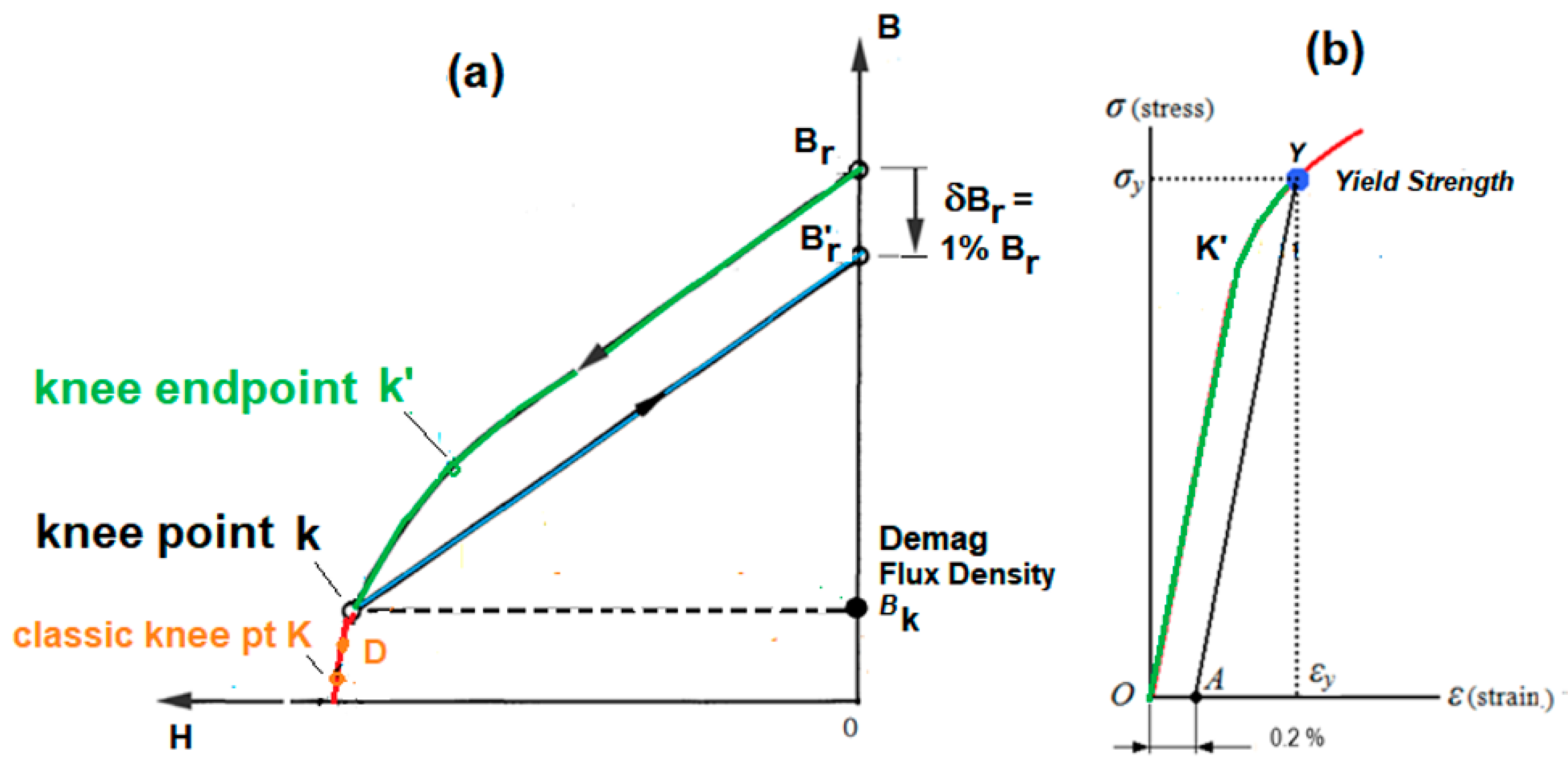

2. Knee Point k

2.1. Offset Method

2.2. Options for Offset x

- 10% offset (K). This classic knee point K was proposed in the 1990s by magnet material engineers [20] as one that tolerates 10% Br loss. However, consider the N40UH grade with Br of 1.29 T. A 10% loss reduces it to Br′ of 1.16 T. Table 1 below shows that this is the Br for N33UH, which is three grades below N40UH. Thus, operating at the classic knee point K degenerates a magnet forever to a lower grade, so is unacceptable.

- 5% offset (D). This demagnetization point D was suggested in IEC 60404-8-1 [25,67] as one that tolerates 5% Br loss. However, consider the N50H magnet with Br of 1.40 T. A 5% loss reduces it to Br′ of 1.33 T. Table 1 shows that this is the Br for N42H, which is three grades below N50H. Thus, operating at the demag point D degenerates a magnet forever to a lower grade, so is unacceptable.

- 2% offset. This does not degenerate some magnets (for example, it reduces the 1.25 T Br of N35UH to 1.226 T. It is larger than the 1.15 T Br for a lower grade N33UH. Therefore, it will not degenerate this magnet). However, consider N52H with Br of 1.42 T Br. The 2% loss reduces it to Br′ of 1.39 T. This is Br for N50H, which is one grade below N52H. Thus, operating at this 2% loss the knee point can degenerate some magnets forever to a lower grade, so is unacceptable.

- 0.5% offset. This also does not degenerate a magnet, so it may seem to be acceptable. However, for N28EH with Br of 1.05 T, it amounts to 0.005 T, which is close to the measurement noise floor. However, at present, manufacturing a grade to such tight tolerances is nearly impossible. Specifying such tight tolerance will only increase their cost. Furthermore, tests by Allcock [68] revealed that most magnets suffer from a 0.4% Br long-term irreversible loss (LTIL). Therefore, specifying a 0.5% offset is unacceptable.

2.3. Rationale for 1% Offset

2.4. Grade Spacing

2.5. Example

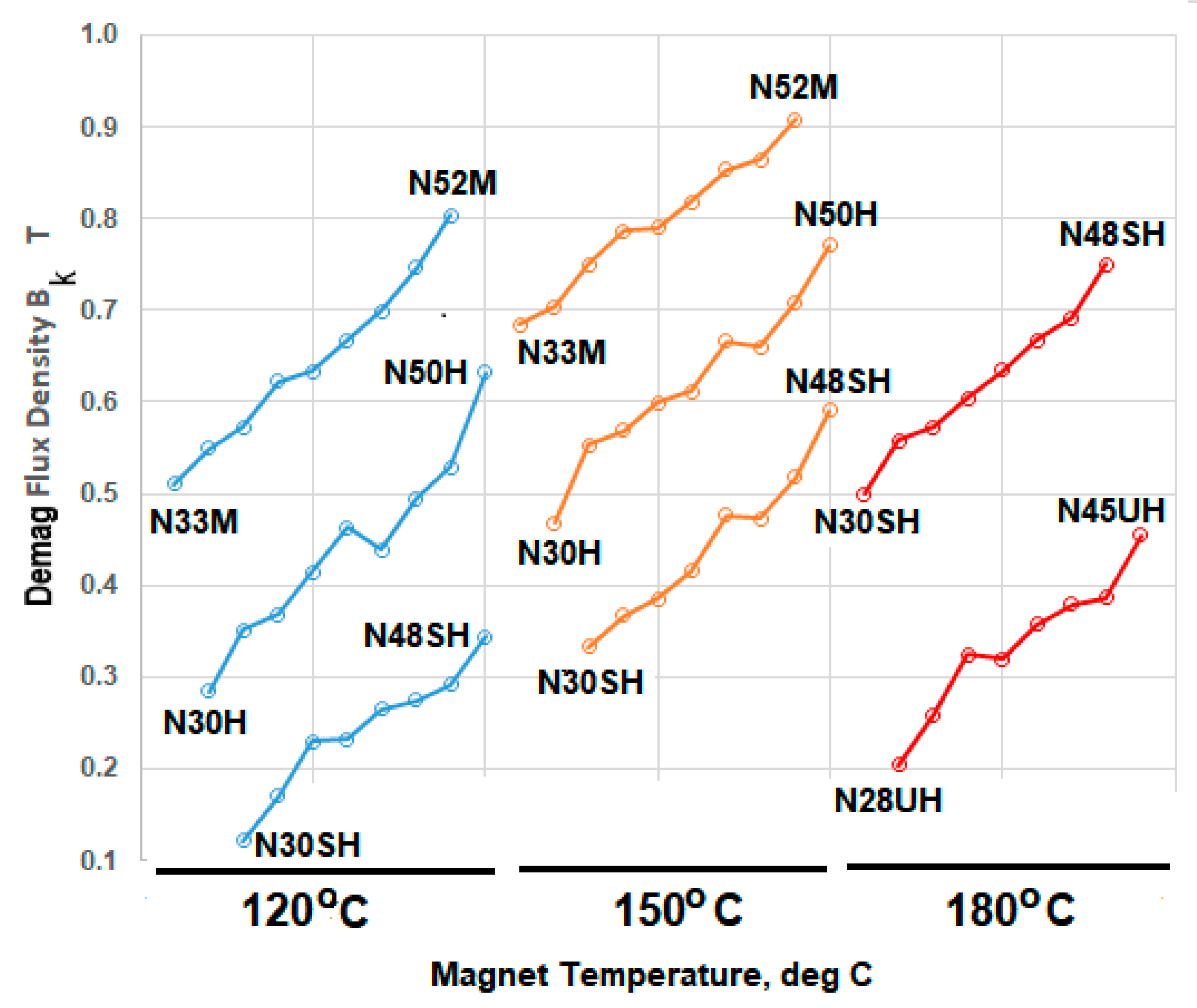

3. Demag Flux Density

4. Demag Flux Density Map

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Castilloux, R. Spotlight on Dysprosium. p. 25. Available online: https://www.adamasintel.com/spotlight-on-dysprosium/ (accessed on 20 February 2020).

- Lombardo, T. How to ensure EV traction motor magnets aren’t pushed beyond their operating limits. Charged 2020, 49, 3. [Google Scholar]

- Ullah, Z.; Hur, J. A comprehensive review of winding short circuit fault and irreversible demagnetization fault detection in PM type machines. Energies 2018, 11, 3309. [Google Scholar] [CrossRef]

- Islam, M.Z.; Arafat, A.; Bonthu, S.S.R.; Choi, S. Design of a Robust Five-Phase Ferrite-Assisted Synchronous Reluctance Motor With Low Demagnetization and Mechanical Deformation. IEEE Trans. Energy Convers. 2018, 34, 722–730. [Google Scholar] [CrossRef]

- Adly, A.; Huzayyin, A. The impact of demagnetization on the feasibility of permanent magnet synchronous motors in industry applications. J. Adv. Res. 2019, 17, 103–108. [Google Scholar] [CrossRef] [PubMed]

- Hamidizadeh, S.; Alatawneh, N.; Chromik, R.R.; Lowther, D.A. Comparison of different demagnetization models of permanent magnet in machines for electric vehicle application. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Hamidizadeh, S. Study of Magnetic Properties and Demagnetization Models of Permanent Magnets for Electric Vehicles Application; McGill University Libraries: Montreal, QC, Canada, 2016. [Google Scholar]

- Campbell, P. Permanent Magnet Materials and Their Application; Cambridge University Press: Cambridge, UK, 1996. [Google Scholar]

- Xiong, H.; Zhang, J.; Degner, M.W.; Rong, C.; Liang, F.; Li, W. Permanent magnet demagnetization test fixture design and validation. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition, Montreal, QC, Canada, 20–24 September 2015; pp. 3914–3921. [Google Scholar]

- Peng, P.; Zhang, J.; Li, W.; Leonardi, F.; Rong, C.; Degner, M.W.; Liang, F.; Zhu, L. Temperature-Dependent Demagnetization of Nd-Fe-B Magnets for Electrified Vehicles. In Proceedings of the 2019 IEEE International Electric Machines & Drives Conference (IEMDC), San Diego, CA, USA, 12–15 May 2019; pp. 2056–2062. [Google Scholar]

- Ireland, J. New figure of merit for ceramic permanent magnet material intended for dc motor applications. J. Appl. Phys. 1967, 38, 1011–1012. [Google Scholar] [CrossRef]

- Ireland, J.R. Ceramic Permanent-Magnet Motors: Electrical and Magnetic Design and Application; McGraw-Hill: New York, NY, USA, 1968. [Google Scholar]

- Mildrum, H.F.; Graves, G.A. High Speed Permanent Magnet Generator Material Investigations—Rare Earth Magnets; Report No. AFWAL-TR-81-2096; AFWAL: Dayton, OH, USA, 1981; p. 124. [Google Scholar]

- Martin, D.; Mildrum, H.F.; Trout, S. Squareness Ratio for Various Rare Earth Permanent Magnets. (Retroactive Coverage). In Proceedings of the Eighth International Workshop on Rare-Earth Magnets and Their Applications and the Fourth International Symposium on Magnetic Anisotropy and Coercivity in Rare Earth–Transition Metal Alloys, University of Dayton, Dayton, OH, USA; 1985; pp. 269–278. [Google Scholar]

- Haavisto, M.; Tuominen, S.; Santa-Nokki, T.; Kankaanpää, H.; Paju, M.; Ruuskanen, P. Magnetic behavior of sintered NdFeB magnets on a long-term timescale. Adv. Mater. Sci. Eng. 2014, 2014, 760584. [Google Scholar] [CrossRef]

- Constantinides, S.; Gulick, D. NdFeB for high temperature motor applications. In Proceedings of the Motor and Motion Association Fall Technical Conference 2004, Indianapolis, IN, USA, 3 November 2004; pp. 3–5. [Google Scholar]

- Branagan, D.; Kramer, M.; Tang, Y.; McCallum, R. Maximizing loop squareness by minimizing gradients in the microstructure. J. Appl. Phys. 1999, 85, 5923–5925. [Google Scholar] [CrossRef]

- Perigo, E.; Takiishi, H.; Motta, C.; Faria, R. On the Squareness Factor Behavior of RE-FeB (RE $= $ Nd or Pr) Magnets Above Room Temperature. IEEE Trans. Magn. 2009, 45, 4431–4434. [Google Scholar] [CrossRef]

- Strnat, K.J. Study and Review of Permanent Magnets for Electric Vehicle Propulsion Motors; Technical Report NASA CR-168178; NASA Lewis Research Center: Cleveland, OH, USA, 1983.

- Niedra, J.M.; Overton, E. 23 to 300 C Demagnetization Resistance of Samarium-Cobalt Permanent Magnets; Technical Paper 3119; NASA Lewis Research Center: Cleveland, OH, USA, 1991; p. 14.

- Niedra, J.M. MH Characteristics and Demagnetization Resistance of Samarium-Cobalt Permanent Magnets to 300 C; Contractor Report 189194; NASA Lewis Research Center: Cleveland, OH, USA, 1992; p. 10.

- Niedra, J.M. Comparative MH Characteristics of 1–5 and 2–17 Type Samarium-Cobalt Permanent Magnets to 300 C; Contractor Report 194440; NASA Lewis Research Center: Cleveland, OH, USA, 1994.

- Niedra, J.M.; Schwarze, G.E. Makeup and Uses of a Basic Magnet Laboratory for Characterizing High-Temperature Permanent Magnets; Technical Memorandum 104508; National Aeronautics and Space Administration: Cleveland, OH, USA, 1994.

- Parker, R.J. Advances in Permanent Magnetism; Wiley: New York, NY, USA, 1990. [Google Scholar]

- Constantinides, S. Hk: A Key Magnetic Figure of Merit; Arnold Magnetic Technologies: Rochester, NY, USA, 2018. [Google Scholar]

- Lacheisserie, E.d.T.d.; Gignoux, D.; Schlenker, M. Magnetism—Materials and Applications; Springer: New York, NY, USA, 2005; p. 518. [Google Scholar]

- Gaster, G. BrHx—Permanent Magnet Intrinsic Parameter. In Coil Wind’86; CWIEME: Chicago, IL, USA, 1986; p. 5. [Google Scholar]

- Gaster, G. The BrHx Parameter and magnet manufacturing process provide a new approach to motor design. In Coil Wind’87; CWIEME: Chicao, IL, USA, 1987; p. 5. [Google Scholar]

- Trout, S. Permanent Magnet Figures of Merit: We Need a Better Story. In SMMA 2008 Fall Technical Conf., 2008, St Louis, USA. Available online: http://spontaneousmaterials.com/Papers/Trout_SMMA_2008.pdf (accessed on 7 May 2018).

- Anonymous. Hybrid and Electric Vehicle Propulsion. Available online: https://www1.eere.energy.gov/vehiclesandfuels/pdfs/mypp/3-2_hybr_elec_prop.pdf (accessed on 1 June 2020).

- Anonymous. AMH 500—Hysteresisgraph Hard Magnetic Materials; Laboratorio Electrofisico: Nerviano, Italy, 2018. [Google Scholar]

- Anonymous. DX-012H DC Hysteresis Graph Test System; Dexing Magnet Tech: Xiamen, China, 2018. [Google Scholar]

- Anonymous. Permagraph C for the Computer Controlled Measurement of Magnetization Curves of Hard Magnetic Materials; Magnet-Physik Dr. Steingrover GmbH: Koln, Germany, 2018. [Google Scholar]

- Kang, G.-H.; Hur, J.; Sung, H.-G.; Hong, J.-P. Optimal design of spoke type BLDC motor considering irreversible demagnetization of permanent magnet. In Proceedings of the Sixth International Conference on Electrical Machines and Systems (ICEMS 2003), Beijing, China, 9–11 November 2003; pp. 234–237. [Google Scholar]

- Ahmad, M.; Sulaiman, E.; Rahimi, S.; Romalan, G.; Jenal, M. Analysis of Permanent Magnet Demagnetization Effect Outer-Rotor Hybrid Excitation Flux Switching Motor. Int. J. Power Electron. Drive Syst. 2017, 8, 255. [Google Scholar] [CrossRef]

- Yu, D.; Huang, X.; Fang, Y.; Zhang, J. Design and comparison of interior permanent magnet synchronous traction motors for high speed railway applications. In Proceedings of the 2017 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Nottingham, UK, 20–21 April 2017; pp. 58–62. [Google Scholar]

- Hussain, S.; Chang, K. Effects of Incorporating Permanent Magnet Demagnetization in Simulations of Modern Electric Machines for Electric Vehicles; Siemens: Munich, Germany, 2018; p. 13. [Google Scholar]

- Mahmouditabar, F.; Vahedi, A.; Ojaghlu, P. Investigation of demagnetization effect in an interior V-Shaped magnet synchronous motor at dynamic and static conditions. Iran. J. Electr. Electron. Eng. 2018, 14, 22–27. [Google Scholar]

- Choi, G.; Jahns, T. Demagnetization characteristics of permanent magnet synchronous machines. In Proceedings of the IECON 2014-40th Annual Conference of the IEEE Industrial Electronics Society, Dallas, TX, USA, 29 October 2014; pp. 469–475. [Google Scholar]

- McFarland, J.D.; Jahns, T.M. Investigation of the rotor demagnetization characteristics of interior PM synchronous machines during fault conditions. IEEE Trans. Ind. Appl. 2013, 50, 2768–2775. [Google Scholar] [CrossRef]

- Kim, K.-C.; Kim, K.; Kim, H.J.; Lee, J. Demagnetization analysis of permanent magnets according to rotor types of interior permanent magnet synchronous motor. IEEE Trans. Magn. 2009, 45, 2799–2802. [Google Scholar]

- Fu, W.N.; Ho, S.L. Dynamic Demagnetization Computation of Permanent Magnet Motors Using Finite Element Method with Normal Magnetization Curves; ANSYS: Canonsburg, PA, USA, 2011. [Google Scholar]

- Anonymous. Neodymium Iron Boron Magnet Catalog. Available online: https://www.arnoldmagnetics.com/wp-content/uploads/2019/06/Arnold-Neo-Catalog.pdf (accessed on 7 May 2021).

- Anonymous. Neodymium-Iron-Boron Magnets Neomax Series Demagnetization Curves. Available online: http://www.hitachi-metals.co.jp/e/products/auto/el/pdf/nmx_a.pdf (accessed on 3 February 2020).

- Anonymous. Demagnetization Curves. Available online: http://www.magnet-innuovo.com/product/16839.htm (accessed on 5 February 2020).

- Kral, C.; Sprangers, R.; Waarma, J.; Haumer, A.; Winter, O.; Lomonova, E. Modeling demagnetization effects in permanent magnet synchronous machines. In Proceedings of the XIX International Conference on Electrical Machines-ICEM, Rome, Italy, 6–8 September 2010; pp. 1–6. [Google Scholar]

- Nair, S.S.; Patel, V.I.; Wang, J. Post-demagnetization performance assessment for interior permanent magnet AC machines. IEEE Trans. Magn. 2015, 52, 1–10. [Google Scholar] [CrossRef]

- Sjökvist, S.; Eriksson, S. Investigation of permanent magnet demagnetization in synchronous machines during multiple short-circuit fault conditions. Energies 2017, 10, 1638. [Google Scholar] [CrossRef]

- Zhu, S.; Cheng, M.; Hua, W.; Cai, X.; Tong, M. Finite element analysis of flux-switching PM machine considering oversaturation and irreversible demagnetization. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Hendershot, J.R.; Miller, T.J.E. Design of Brushless Permanent-Magnet Machines; Oxford University Press: Oxford, UK, 1994. [Google Scholar]

- Anonymous. Datasheets NdFeB. Available online: http://www.chinahpmg.com/col.jsp?id=148 (accessed on 3 February 2020).

- Gieras, J.F.; Wing, M. Permanent Magnet Motor Technology: Design and Applications; Marcel Dekker: NewYork, NY, USA, 1997. [Google Scholar]

- Zhou, P.; Lin, D.; Xiao, Y.; Lambert, N.; Rahman, M. Temperature-dependent demagnetization model of permanent magnets for finite element analysis. IEEE Trans. Magn. 2012, 48, 1031–1034. [Google Scholar] [CrossRef]

- Bavendiek, G.; Müller, F.; Sabirov, J.; Hameyer, K. Magnetization dependent demagnetization characteristic of rare-earth permanent magnets. Arch. Electr. Eng. 2019, 68, 33–45. [Google Scholar]

- Kim, Y.H.; Lee, S.S.; Cheon, B.C.; Lee, J.H. Study on optimal design of 210 kW traction IPMSM considering thermal demagnetization characteristics. AIP Adv. 2018, 8, 047504. [Google Scholar] [CrossRef]

- Sjökvist, S.; Eriksson, S. Study of demagnetization risk for a 12 kW direct driven permanent magnet synchronous generator for wind power. Energy Sci. Eng. 2013, 1, 128–134. [Google Scholar] [CrossRef]

- Fratila, R.; Benabou, A.; Tounzi, A.; Mipo, J.C. Nonlinear modeling of magnetization loss in permanent magnets. IEEE Trans. Magn. 2012, 48, 2957–2960. [Google Scholar] [CrossRef]

- Widger, G. Representation of magnetisation curves over extensive range by rational-fraction approximations. Proc. Inst. Electr. Eng. 1969, 116, 156–160. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, Z.; Anderson, P.I.; Jarman, P.; Moses, A.J. Approximation and prediction of AC magnetization curves for power transformer core analysis. IEEE Trans. Magn. 2014, 51, 1–8. [Google Scholar] [CrossRef]

- Rao, D.K.; Kuptsov, V. Effective use of magnetization data in the design of electric machines with over fluxed regions. IEEE Trans. Magn. 2015, 51, 1–9. [Google Scholar] [CrossRef]

- JMAG. Demagnetization Analysis of an SPM Motor; JSOL Corp: Tokyo, Japan, 2007. [Google Scholar]

- Ruoho, S.; Dlala, E.; Arkkio, A. Comparison of demagnetization models for finite-element analysis of permanent-magnet synchronous machines. IEEE Trans. Magn. 2007, 43, 3964–3968. [Google Scholar] [CrossRef]

- Egorov, D.; Petrov, I.; Link, J.; Kankaanpää, H.; Stern, R.; Pyrhönen, J.J. Linear Recoil Curve Demagnetization Models for Rare-Earth Magnets in Electrical Machines. In Proceedings of the IECON 2019-45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 1157–1164. [Google Scholar]

- Borg, E.; Brischetto, M.; Thorendal, V.; Sandin, P.; Johansson Byberg, J.; Karlsson, A.; Koivisto, D. Demagnetization Characterization of Ferrites: Independent Project in Materials Engineering; Uppsala Universitet: Uppsala, Sweden, 2016. [Google Scholar]

- Shi, Y.; Wang, J. Continuous demagnetisation assessment for triple redundant nine-phase fault-tolerant permanent magnet machine. J. Eng. 2019, 2019, 4359–4363. [Google Scholar] [CrossRef]

- ASTM E8/E8M-13a: Standard test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2013.

- IEC. IEC 60404-8-1 Magnetic Materials—Part 8-1: Specifications for Individual Materials—Magnetically Hard Materials; International Electrotechnical Commission: Geneva, Switzerland, 2015; p. 78. [Google Scholar]

- Allcock, R.; Constantinides, S. Magnetic Measuring Techniques for Both Magnets and Assemblies; Arnold Magnetic Technologies: Rochester, NY, USA, 2012. [Google Scholar]

- Anonymous. Toyota Develops Neodymium-Reduced Magnets for Electric Motors. Available online: https://magneticsmag.com/toyota-develops-neodymium-reduced-magnet-for-electric-motors/ (accessed on 5 August 2020).

- Rao, D.K. PMAG Database Handbook—Properties of Hard Magnetic Materials. Available online: https://magweb.us/wp-content/uploads/2020/09/PMAG-Handbook-Version2.pdf (accessed on 9 March 2020).

| Br tesla | 1.05 | 1.10 | 1.15 | 1.20 | 1.25 | 1.29 | 1.32 | 1.35 | 1.38 | 1.40 | 1.42 | 1.45 | 1.49 | Max Temp |

| Label | GRADES | deg C | ||||||||||||

| AH | 28AH | 30AH | 33AH | 35AH | 38AH | 40AH | 230 | |||||||

| EH | 28EH | 30EH | 33EH | 35EH | 38EH | 40EH | 42EH | 45EH | 200 | |||||

| UH | 30UH | 33UH | 35UH | 38UH | 40UH | 42UH | 45UH | 48UH | 50UH | 52UH | 54UH | 180 | ||

| SH | 30SH | 33SH | 35SH | 38SH | 40SH | 42SH | 45SH | 48SH | 50SH | 52SH | 150 | |||

| H | 30H | 33H | 35H | 38H | 40H | 42H | 45H | 48H | 50H | 52H | 120 | |||

| M | 30M | 33M | 35M | 38M | 40M | 42M | 45M | 48M | 50M | 52M | 100 | |||

| N30 | N33 | N35 | N38 | N40 | N42 | N45 | N48 | N50 | N52 | N54 | N55 | 80 | ||

| BHmax | 28 | 30 | 33 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 52 | 54 | 55 | MGOe |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rao, D.; Bagianathan, M. Selection of Optimal Magnets for Traction Motors to Prevent Demagnetization. Machines 2021, 9, 124. https://doi.org/10.3390/machines9060124

Rao D, Bagianathan M. Selection of Optimal Magnets for Traction Motors to Prevent Demagnetization. Machines. 2021; 9(6):124. https://doi.org/10.3390/machines9060124

Chicago/Turabian StyleRao, Dantam, and Madhan Bagianathan. 2021. "Selection of Optimal Magnets for Traction Motors to Prevent Demagnetization" Machines 9, no. 6: 124. https://doi.org/10.3390/machines9060124

APA StyleRao, D., & Bagianathan, M. (2021). Selection of Optimal Magnets for Traction Motors to Prevent Demagnetization. Machines, 9(6), 124. https://doi.org/10.3390/machines9060124