1. Introduction

With the emergence of global extremes in recent years, the frequency of disasters such as droughts and urban flooding has suddenly increased, which greatly affect security and the economy. Because of its flexibility, the emergency pump truck has obvious advantages in dealing with urban flooding [

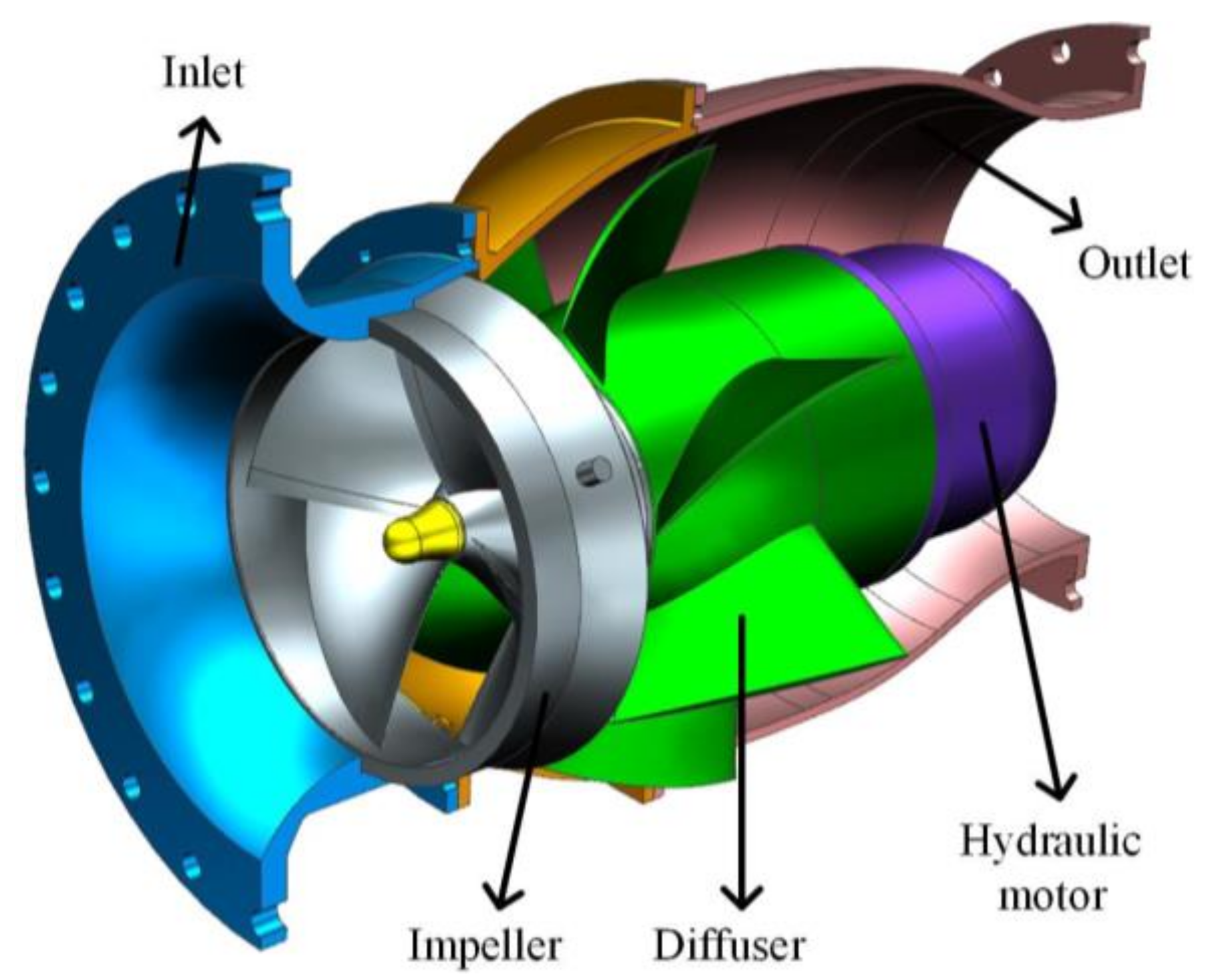

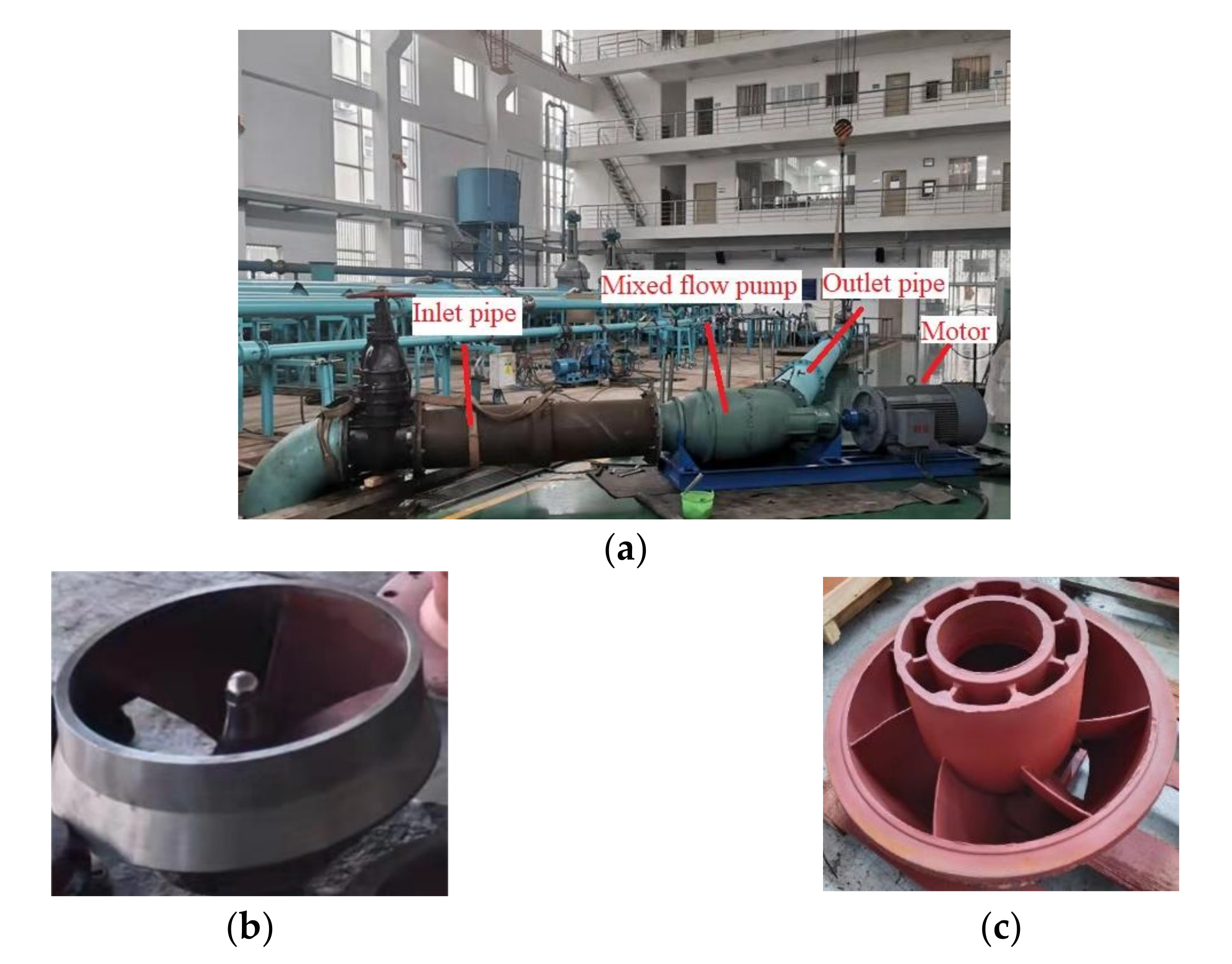

1]. To minimize economic losses, the main requirements of dealing with urban flood are rapid drainage and long-distance transportation. Because of its characteristics of large flow and high head, mixed flow pumps have been widely used in emergency situations. The mobile pump truck is a highly integrated drainage equipment, with all power coming from the engine. Limited by the vehicle output power, improving the pump efficiency and reducing the operating energy consumption can provide protection for emergency work. Therefore, a mixed flow pump with high efficiency is required for the design of the emergency pump truck.

The impeller and diffuser are the key components of energy conversion in pumps. Much of the research mainly focuses on the meridional flow passage shape and blade profile. Based on computational fluid dynamics (CFD) technology, Kim et al. [

2] performed optimization of the meridional shape of a mixed flow pump impeller to improve its suction performance. Hao et al. [

3] further investigated the effect of the hub and shroud radius ratio on the hydraulic efficiency of a mixed flow pump by numerical simulation. Ji et al. [

4] analyzed the effect of the blade thickness on the rotating stall of a mixed flow pump using the entropy generation method. Ikuta et al. [

5] found that the forward skew blade angle has an obvious effect on positive slope characteristics of the mixed flow pumps. The positive slope region can be moved to a smaller flow rate by increasing the skew blade angle. Most vaned mixed flow pumps are equipped with an unshrouded impeller. The tip clearance between the impeller and casing may cause adverse flow phenomena such as leakage, cavitation, and so on. Li et al. [

6] studied the influence of tip clearance on the rotating stall in a mixed flow pump using CFD. By investigating the effect of rotational speed on the tip leakage vortex, Han et al. [

7] found that with the increase of rotational speed, the leakage flow and oscillating frequency of the tip leakage vortex will also increase. To inhibit the leakage and improve the energy performance in the unshrouded centrifugal pumps, Wang et al. [

8] proposed a T-shaped blade. The CFD results show that the leakage and flow loss of the T-shaped blade is decreased. Zhu et al. [

9] studied dynamics performance of the centrifugal pumps with different diffuser vane heights and found that the half vane diffuser could increase the flow uniformity and reduce the pressure pulsation intensity. The effect of the divergence angle of the diffuser on the performance of a centrifugal pump was studied by Khoeini et al. [

10]; the results show that the diffuser parameters have a remarkable influence on the head and efficiency. Wang et al. [

11] performed the optimization of the vaned diffuser in a centrifugal pump to improve the pump efficiency. Kim et al. [

12] presented an optimization process based on a radial basis neural network model to optimize four design variables of a diffuser in a mixed flow pump, and the optimization increased in efficiency by 9.75% at the design point.

Although much of the research involves the improvement of the impeller and diffuser, the blade profile of the mixed flow pump is space-distorted and too many geometric parameters make it difficult to be fully optimized. The inverse design method (IDM) is a technique to design the blade profile by distribution of blade loading. Compared with the traditional design method, fewer design parameters are required for IDM [

13]. Wang et al. [

14] performed the optimization of the mixed flow impeller using IDM. The effect of different vortex distributions of the blade exit on the hydraulic performance were investigated using CFD. Lu et al. [

15] proposed a modified inverse design method for the optimization of the runner blade of the mixed flow pump. The IDM is also suitable for the design of the axial impeller and diffuser [

16]. Although the IDM has certain advantages, it only involves the design of the blade profile with no consideration for the meridional passage shape.

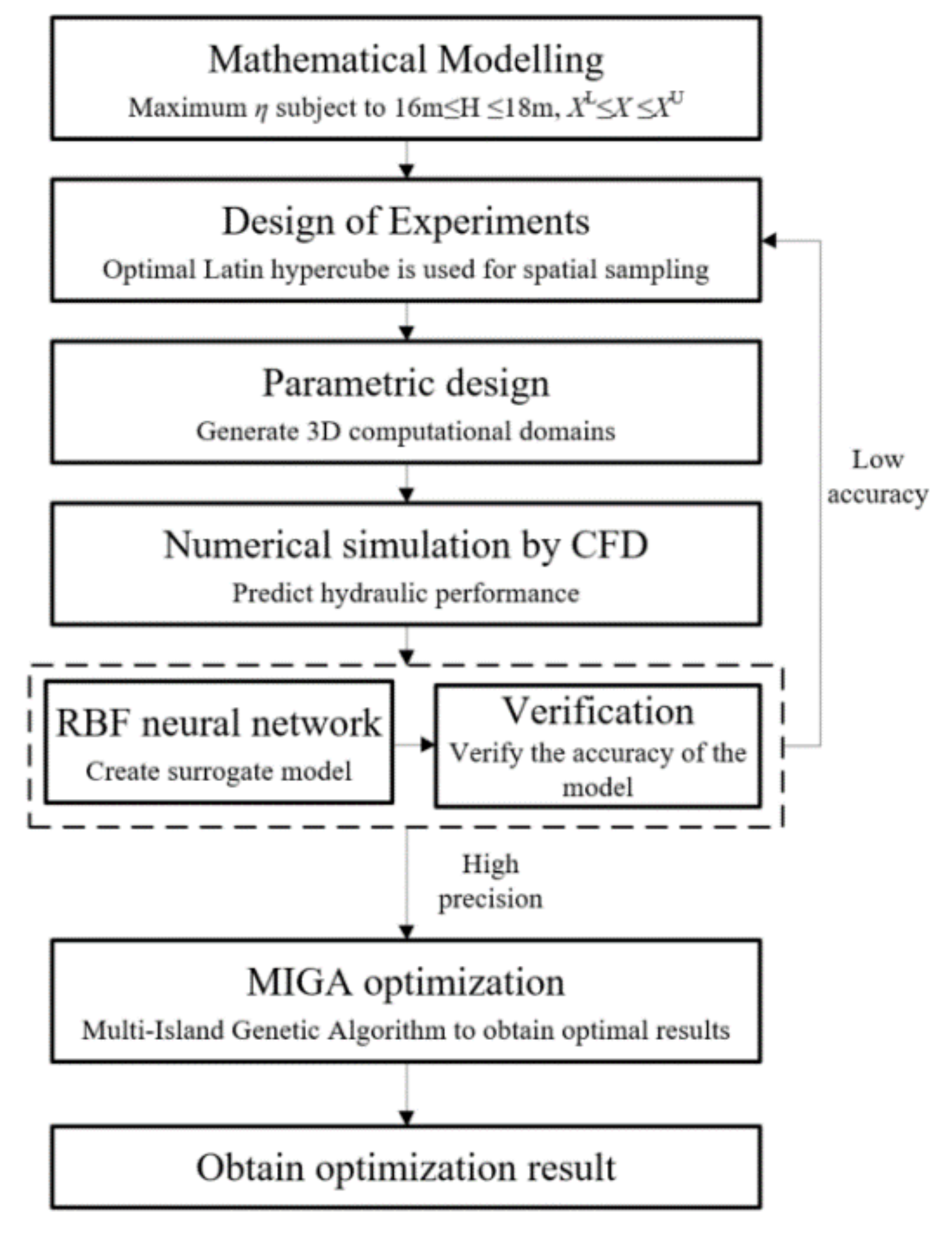

Based on the above literature, the application of CFD is almost indispensable in pump optimization. In recent years, CFD technology combined with computer aided optimization methods have been widely used in the design and optimization of fluid machinery [

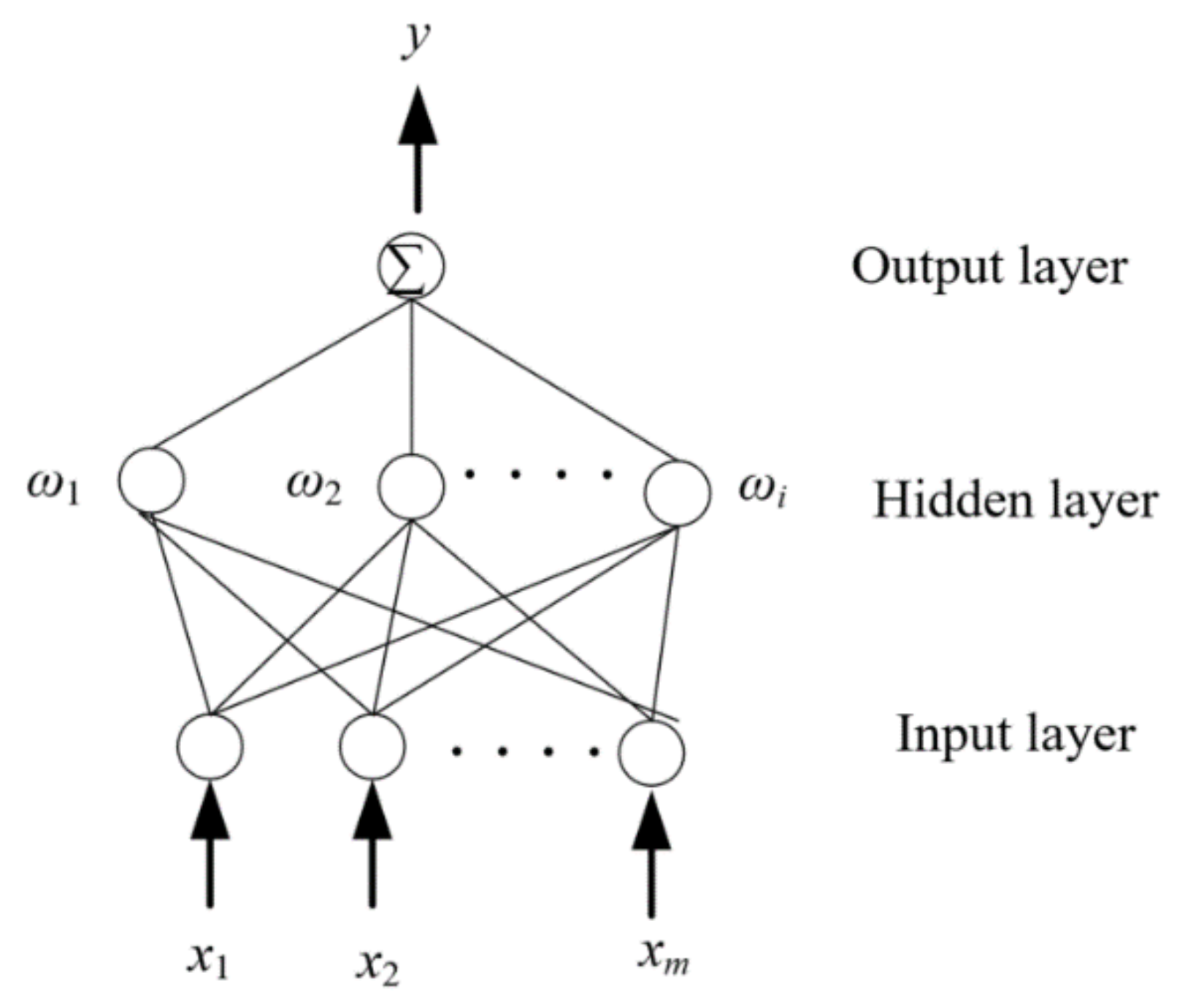

17]. Design of experiment (DOE) and surrogate models are the most popular auxiliary methods. The precision of the surrogate model is one of the key factors for the success of optimization. Wang et al. [

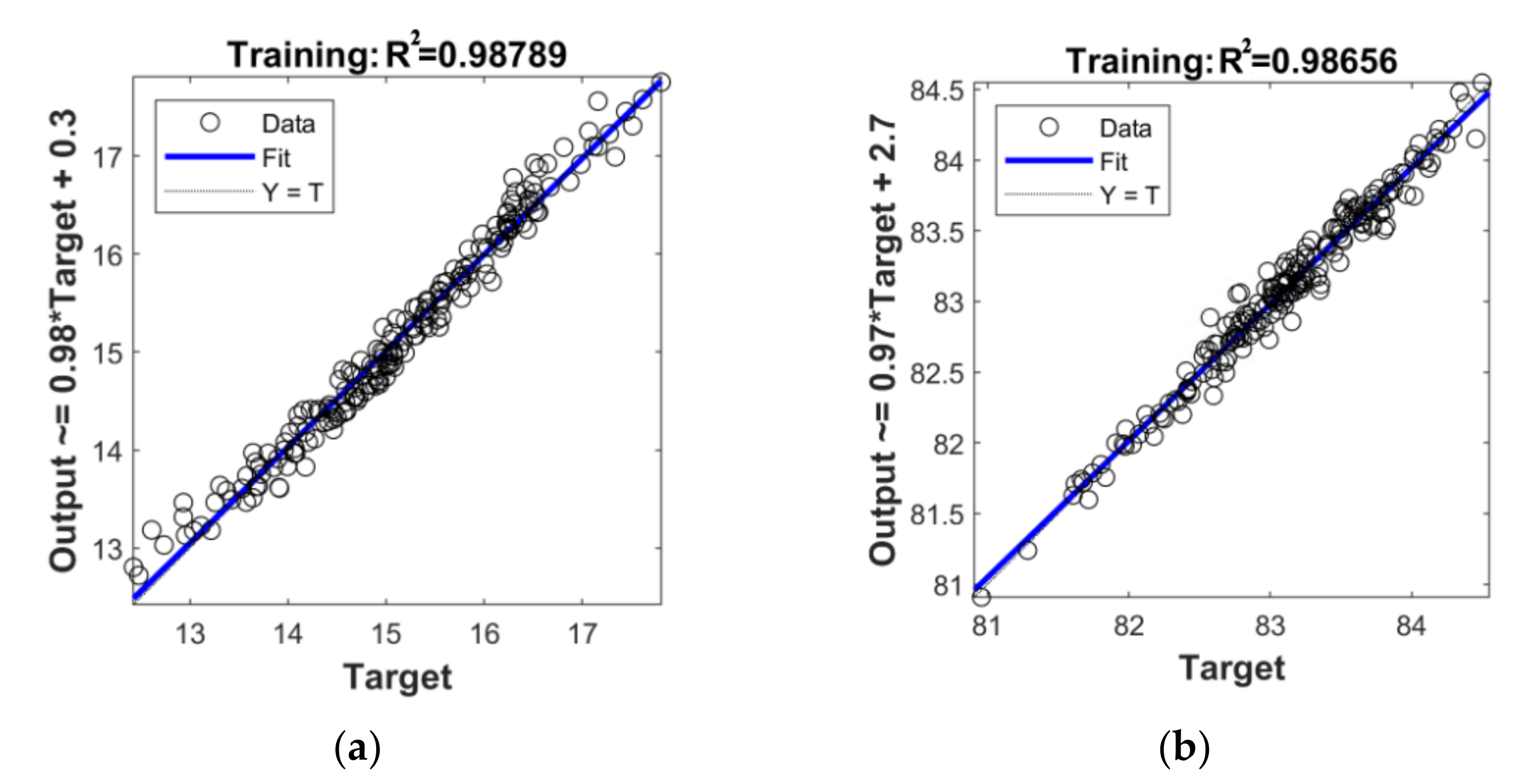

18] tested the accuracy of different surrogate models in centrifugal pump optimization and the results showed that the prediction accuracy of the radial basis neural network is better than other models. Si et al. [

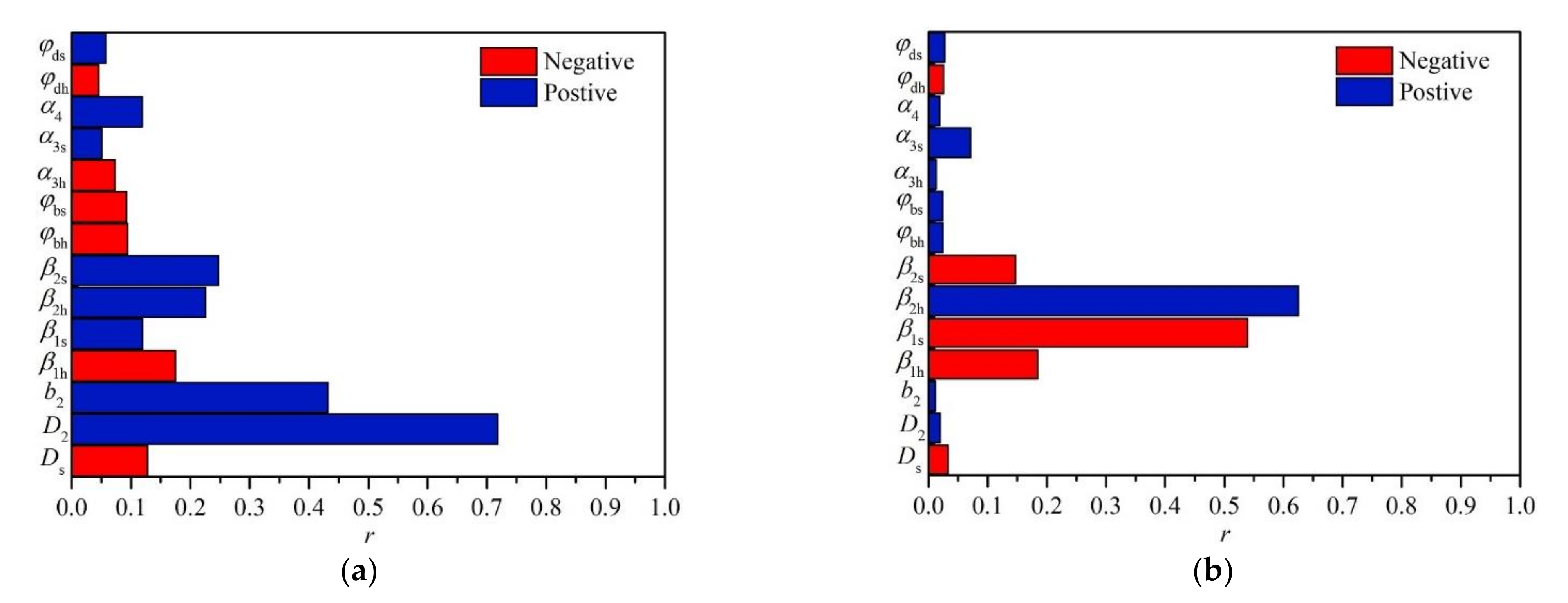

19] implemented the multi-condition optimization of an electronic pump using DOE. The influence of each parameter on the head and efficiency was estimated, and the number of design parameters were diminished by analysis of variance (AOV). Xu et al. [

20] conducted the multi-parameter optimization of a mixed flow pump based on the orthogonal experimental method and RBF neural network, while the meridional parameters of impeller were not included. Pei et al. [

21] proposed a modified particle swarm algorithm to accelerate the speed of optimization, and an artificial neural network was further applied to build the mathematical model. Zhu et al. [

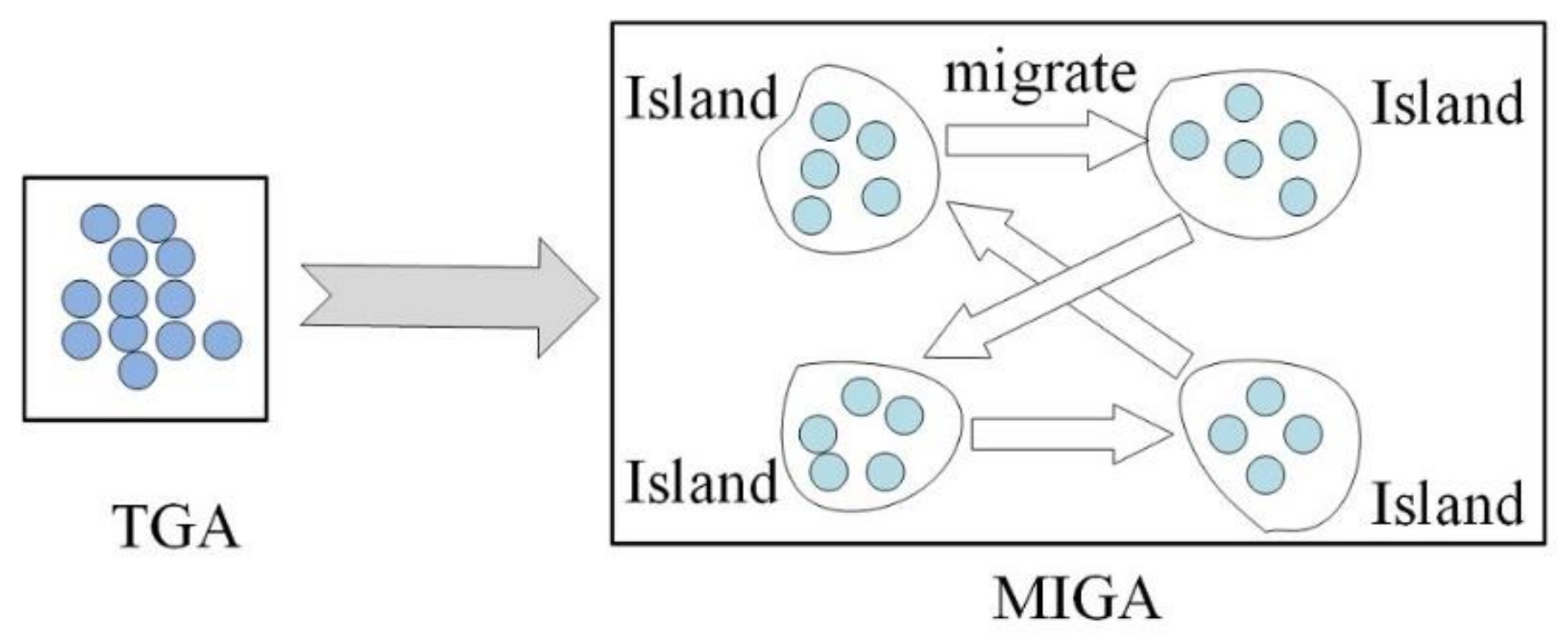

22] applied the global dynamic criterion algorithm to the optimization of a vaned mixed flow pump, and the parallel running was realized to shorten the time consumption. Huang et al. [

23] developed a modified non-dominated sorting genetic algorithm II (NSGA-II) coupled with a dynamic crowding distance (DCD) method, which contributed to the search for the pareto-front.

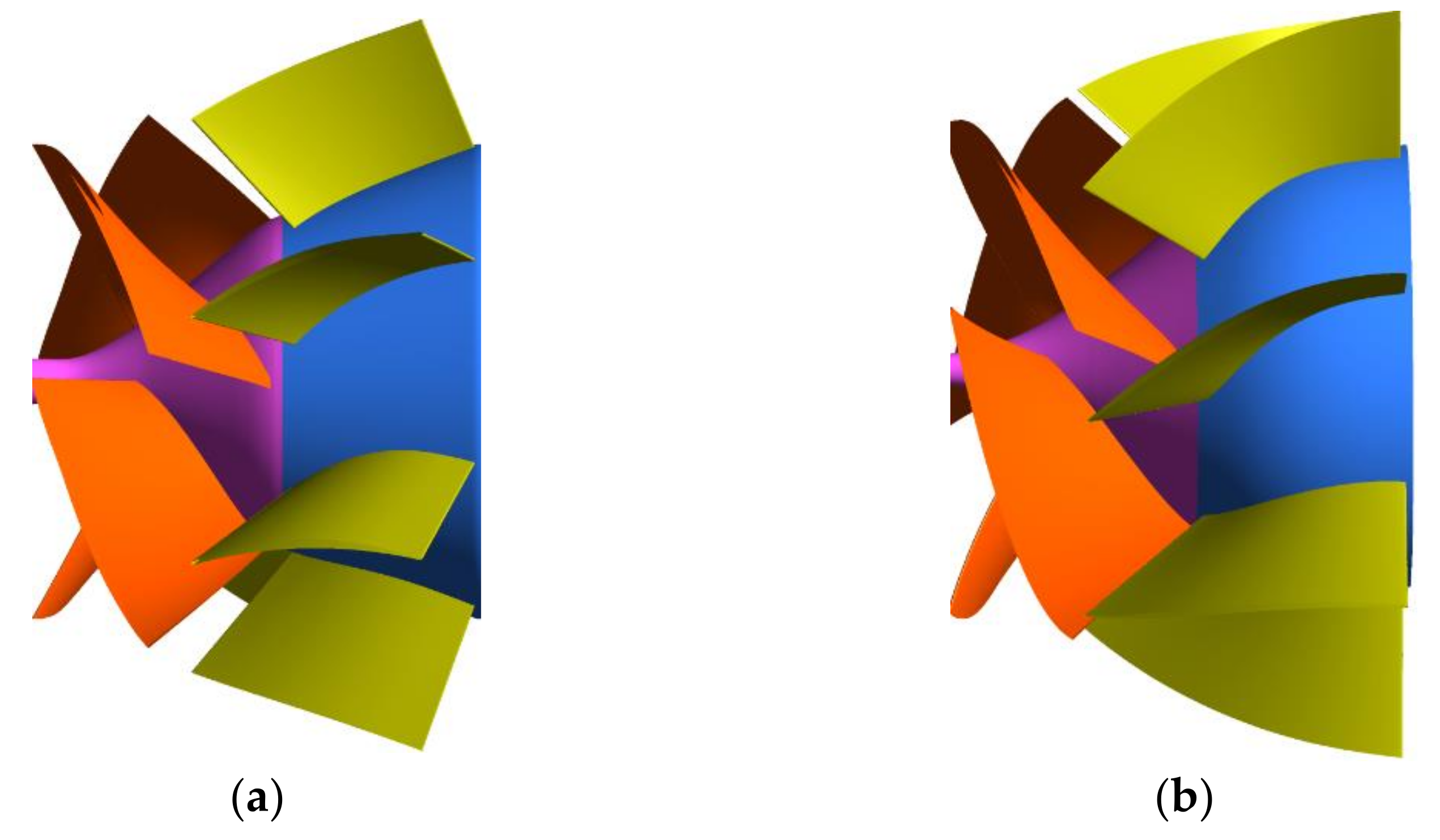

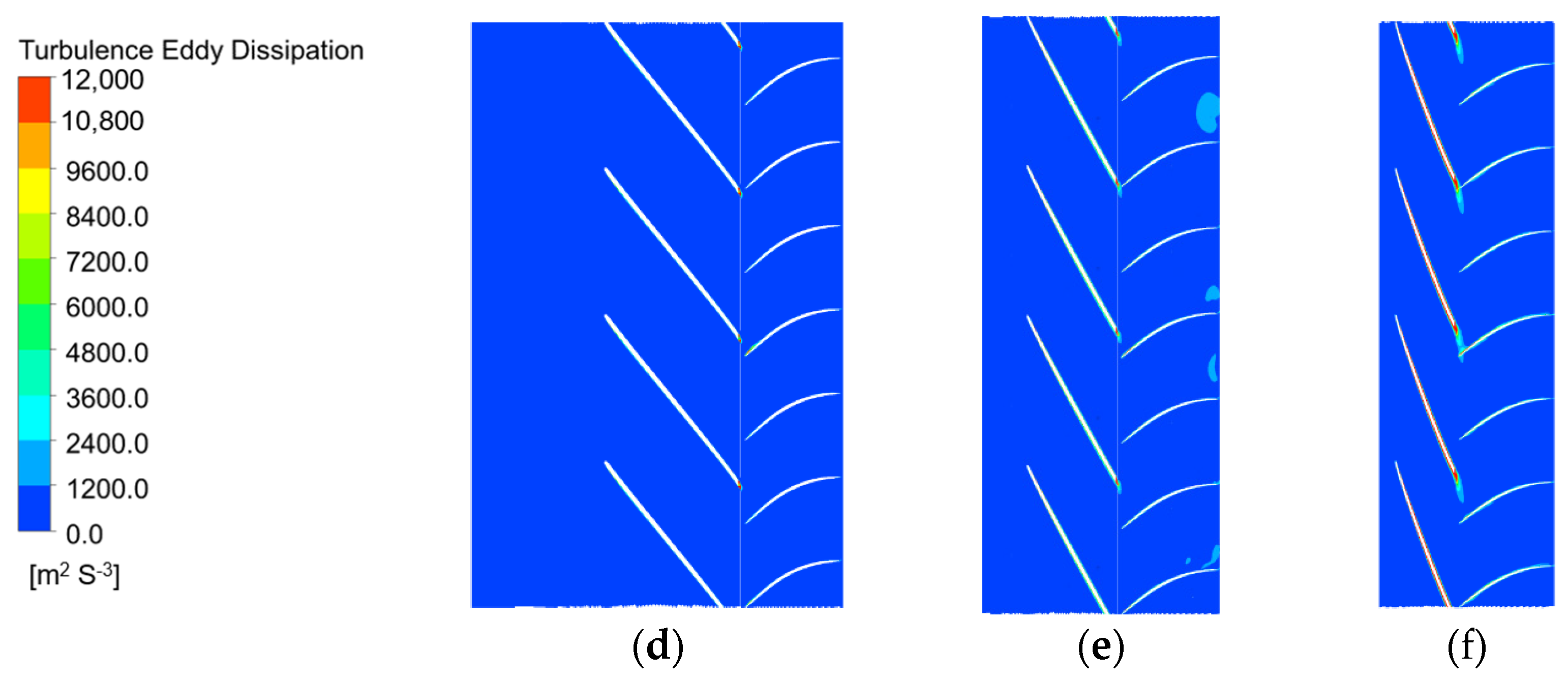

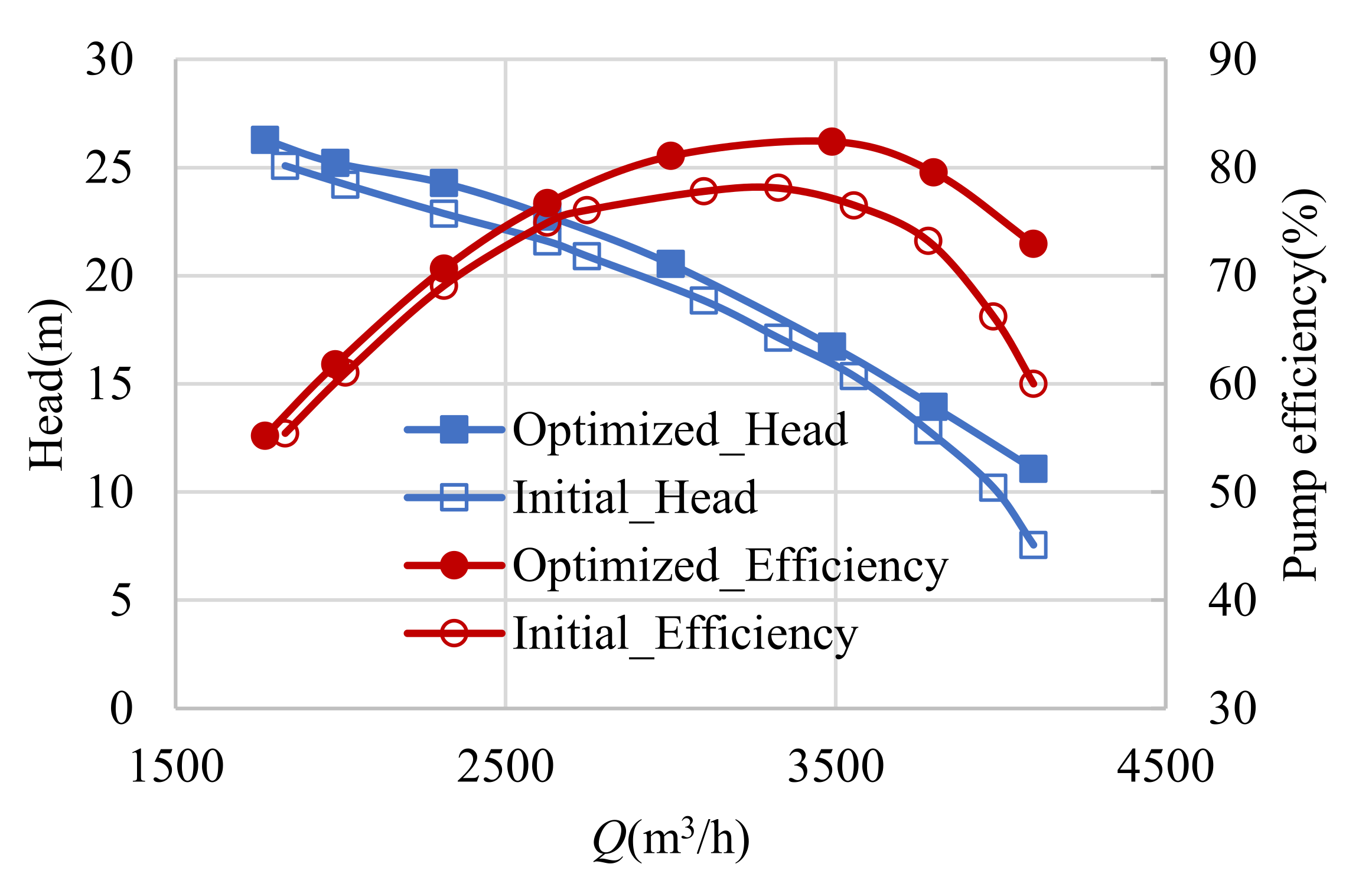

The similarity of the studies above is that most research only focuses on the optimization of a single hydraulic component, ignoring the interaction between the rotor and stator. Further research is needed to optimize the matching of the impeller and diffuser. In this study, a shrouded impeller was proposed to suppress the complex tip leakage flow. The MIGA-RBF algorithm combined with CFD technology was introduced to improve the hydraulic efficiency of the mixed flow pump. An automatic optimization platform integrating 3D design, meshing, and numerical simulation was built. Variables involving the meridional shape and blade profile of both the impeller and diffuser were optimized to fully consider the rotor–stator interaction. The flow regime and local energy loss were analyzed in detail. The paper is organized as follows: the relevant research status is described in

Section 1; the pump information and numerical theories are briefly introduced in

Section 2; the concrete optimization methods are illustrated in

Section 3; the detailed results are present in

Section 4; and finally, the conclusions are provided in

Section 5.