1. Introduction

Recent market unpredictability with regard to raw material prices is encouraging the development of more efficient and effective solutions in every application. The first sign of these unpredictable market fluctuations was experienced back in 2011 when the price of permanent magnet (PM) materials suddenly and dramatically increased, reaching a 40-fold increment in price in just six months [

1]. In turn, permanent magnet synchronous motors may be a weak point in all those applications where price is the leading market driver. Viable alternatives to the use of permanent magnets are thus very attractive.

Electric pumps are certainly a very sensitive application where these issues can determine the availability of essential goods, such as water, for much of the human population. At present, induction motors are very popular in pump applications due to their mechanical robustness, their capability to work directly from the grid—though at constant speed—and their wide availability on the market [

2]. However, recently established efficiency standards require more efficient electric motors, and the synchronous reluctance motor (SynRM) will likely replace the induction motor, especially in variable speed applications [

3]. These are PM-free and their mechanical characteristics are comparable to those of induction motors. Furthermore, the absence of rotor currents eases the cooling of the motor.

The benefits of applying SynRMs to centrifugal pumps were described in [

4], where the reduction in energy consumption was quantified as

compared to a previous solution based on a fixed-frequency squirrel-cage induction motor. Interest regarding SynRMs is also arising in other technological sectors such as home appliances and building applications. A chiller application was considered in [

5], comparing an induction motor with a SynRM, providing quantitative evidence that SynRM can significantly increase energy efficiency. The slightly higher cost of a SynRM was fully recovered by energy savings.

Interesting proposals mixing photovoltaic panels and thermal generators were considered in [

6]. Solar pumps are also another promising application area for the SynRM [

2,

7,

8,

9].

SynRMs present strong magnetic anisotropy, and are prone to the saturation of magnetic paths, so that the current-flux linkage relationships are nonlinear and there is a cross-saturation between the orthogonal axes. The magnetic non-linearity heavily affects the tuning of the current control loops [

10]. An effective solution requires the complete modelling of the SynRM [

11,

12,

13,

14], but this usually requires lab testing and is specific to the individual motor, so it is impractical and uneconomical for solar pump applications. In a nutshell, all the self-commissioning techniques require sophisticated procedures and their implementation is performed by well-experienced technical personnel.

A different paradigm in comparison to the conventional PI current control of SynRMs is represented by the predictive current control (PCC) [

3,

15,

16]. The advantages of predictive control algorithms are the fast dynamics and the possibility of including nonlinear constraints thanks to the nonlinear characteristics of the control algorithm itself. However, an accurate model of the motor is still required to predict the future currents’ behaviours, which is an important drawback of all predictive control-based techniques.

The need for prior knowledge of an accurate model has recently been overcome by a new control paradigm called model-free [

17,

18]. It is important to stress that the label

model-free still relies on a model for controlling the motor currents, but the current predictions no longer need canonical voltage balance equations. This is particularly attractive for SynRM applications, since it allows skipping the self-commissioning procedure.

The most common model-free predictive current control algorithms are of the

finite-set (FS), which only use the eight basic voltage vectors of a two-level inverter. Their advantages are the simplicity of the prediction and avoiding the need for a modulator [

19,

20,

21].

Actually, the currents’ prediction accuracies are strongly affected by the model-free strategy. Several strategies have been proposed to date, such as totally model-free predictions based on either the system’s previous input and output data [

19,

20,

21,

22], or on adaptive models which adaptation strategies are based on the previous input and output data of the system. For instance, the

ultra-local model was proposed in [

23,

24] or an adaptive model based on a recursive least square (RLS) algorithm for estimating the adaptive parameters was proposed in [

25].

The design of high-performance finite-set predictive control is described in [

26]; however, the most significant problems are those of the computational effort when increasing the horizon prediction length and the pronounced current ripple amplitude in comparison with modulator-based controllers. The problem of the ripple can be fixed by adopting

continuous-set predictive control, which selects the optimal voltage vector among a continuous set of values, i.e., all those that can be produced by a voltage inverter.

An example of continuous-set (CS) predictive control applied to SynRMs is given in [

27], with much less current ripple than a finite-set predictive controller.

In this paper, a new CS predictive control paradigm combined with model-free strategies was proposed with the aim of benefiting from both the advantages of these techniques and reduced computational effort. To the knowledge of the authors, this is a novel approach to the MPC control structure.

When nonlinear constraints are included, finding the optimal voltage vector to apply in the next control step is problematic, since it involves finding the minimum multivariable function, and the computational effort can be very high [

27]. The applicability of the continuous-set predictive control algorithm on low-cost applications, such as electric pumps, is therefore undermined by the need for expensive microprocessors.

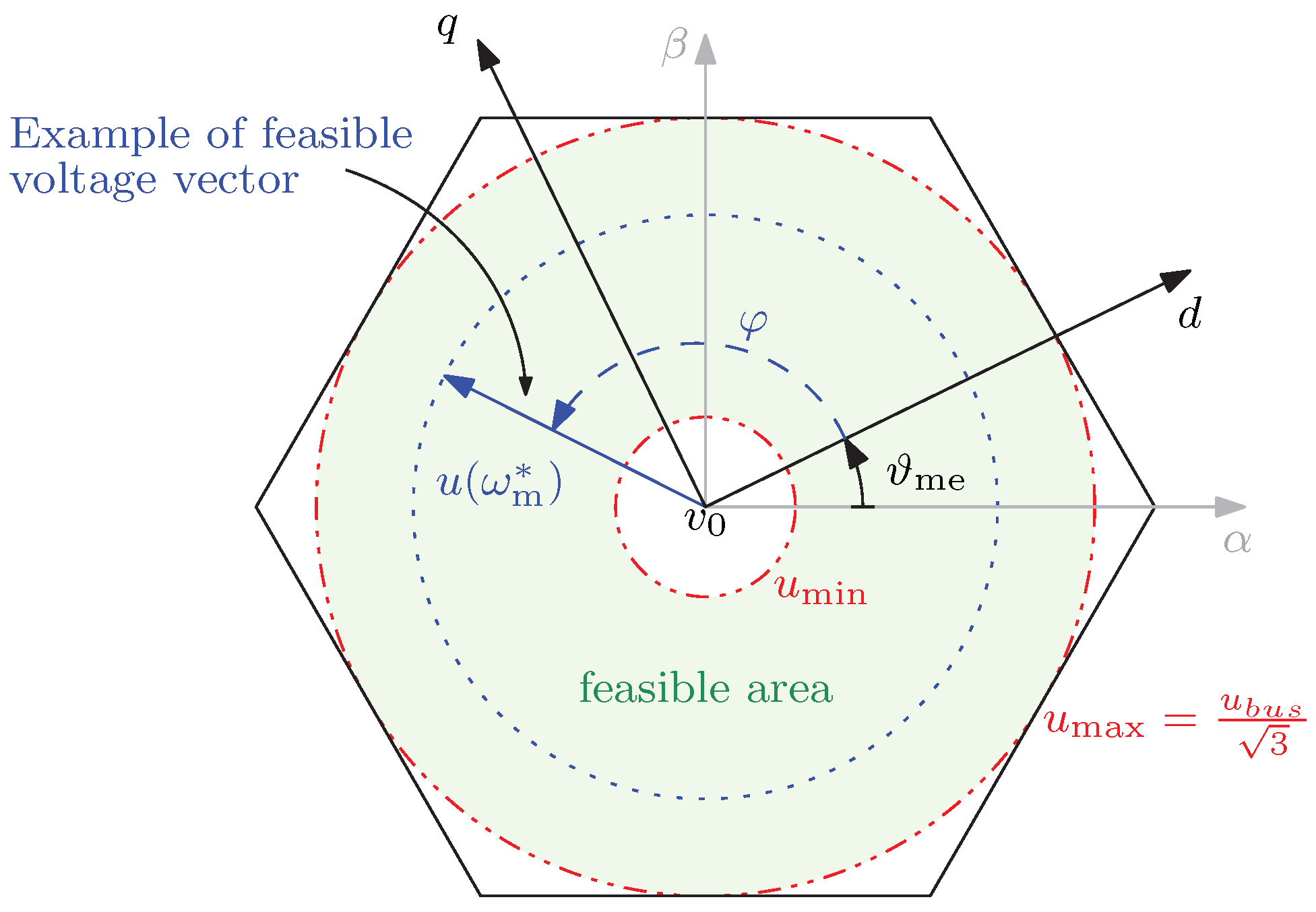

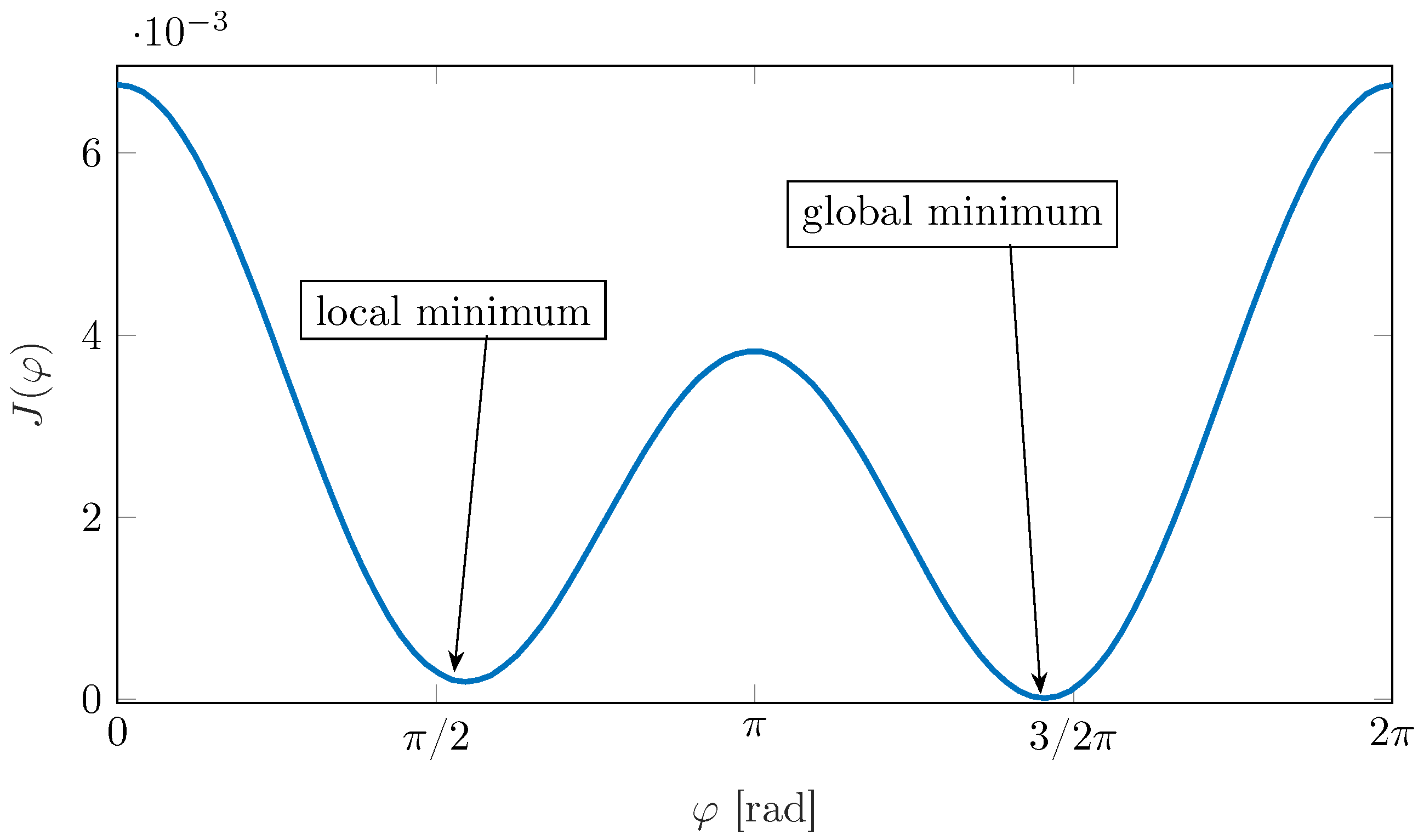

In order to reduce the computational complexity of continuous-set predictive control, the present paper proposes a simplification of the minimisation problem based on setting a maximum voltage vector amplitude, so that the search will be conducted on the phase of the voltage vector only. The low complexity search algorithm was combined with a model-free technique that predicts the currents variations by means of an efficient RLS algorithm [

25]. The result is a very practical current control solution that can be implemented on any industrial drive for pump applications.

In order to demonstrate the feasibility of the proposed technique, a test case was provided and analysed, including two different industrial inverter-driven SynRMs. Both the inverter and motors are supposed to be powered by a conventional 400 three-phase grid supply. However, the test case provided in this paper will simulate the case where only a 230 single-phase grid supply is available, which is realistic for many developing countries where the three-phase grid is not widespread. Each test motor has been connected to the inverter without any initial calibration, to prove the generality of the proposed control algorithm.

This paper is structured as follows. The model-free current variations prediction and the RLS algorithm implementations are discussed in

Section 2. The core of this paper is the new predictive control algorithm reported in

Section 3, where the new optimisation problem formulation and the computational cost-effective algorithm for finding the optimum voltage vectors are described. The experimental results are reported in

Section 4, and are followed by thorough discussions and considerations. Final conclusive remarks are reported in the Conclusion in

Section 5.

2. Mathematical Background

The motor voltage balance equations are written in the

dq reference frame, synchronously with the rotor. The

d axis position in a SynRM corresponds to the position where the reluctance value is minimum, and its angular displacement is defined as

. The

voltage balance equations are:

where

and

are the voltage and current vectors, respectively,

R is the stator resistance,

and

are the

d and

q axis differential inductances,

is the magnetic flux linkages vector and

is the electrical speed. The current dependence

in the differential inductances and magnetic flux linkages is omitted in the following for the sake of brevity. The symbol ≜ stands for

definition.

To ease the mathematical expression, only the

d axis voltage balance equation is considered at first. Actually, the

q axis voltage balance equation presents the same equation structure; thus, the same analytical results are obtained. The current dynamics can be derived from (

1) as

Observing Equation (

2) and considering the discrete nature of the control system, the current variation at each control period

can be expressed by the following new adaptive model:

where

and

are coefficients that are adapted during online operations. The adaptation strategy is crucial for the correct estimation of the current variations predictions. A recursive least square algorithm was adopted in this work for the adaptation of the coefficients based on previous current measurements and applied voltage vectors as in [

25].

Adaptive Model by Recursive Least Square Algorithm

For the sake of generality, both currents variations can be rearranged as follows:

where

and

are the regressors’ vectors,

and

are the adaptive coefficients vectors of the

d and

q axes, respectively. The standard RLS algorithm, as can be seen in [

28], can be recursively solved by the following set of equations:

where

is the gain matrix,

is the estimated error covariance matrix,

is the regressors’ matrix,

f is the scalar forgetting factor,

is the

coefficients vector and

is the measurements vector.

In order to estimate four parameters, at least four linearly independent and uncorrelated measurements are necessary. However, only two measurements are available during the current control period

k, i.e., one for each of the

axes. The additional two measurements can be retrieved by using the current measurements during the previous control period

. Therefore, the vector of measurements is defined as follows:

The regressors’ vector

can be written in the same fashion of (

6) by adopting the voltage measurements of the actual

and previous

control periods.

The future currents can be predicted based on the assumption that the coefficients

are constant for at least two discrete sampling time periods

. As an example, the

d axis current evolution can be estimated as follows:

More details about the current predictions based on the adaptive model by recursive least squares algorithm, such as the tuning of the forgetting factor parameter

f, are available in [

25]. It is worth highlighting that the voltage

is an unknown value as well as

. These two voltage values are the voltages that shall be applied at time instant

. An optimisation algorithm is thus developed in

Section 3 to determine the optimal voltage reference vector

at every control time

.

4. Experimental Results and Discussion

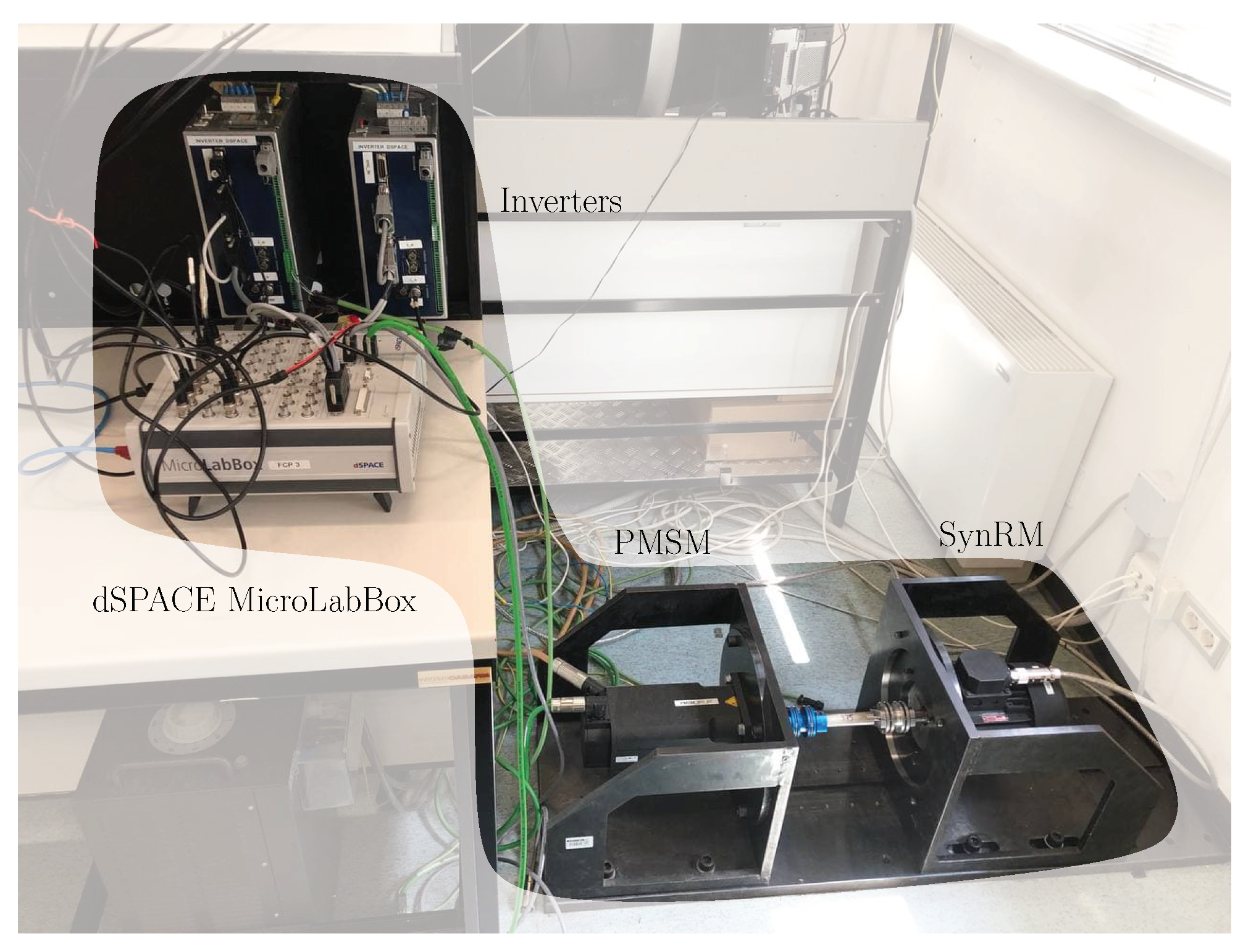

The control algorithm reported in

Section 3 was implemented on a fast control prototyping test rig (

Figure 3) dSpace MicroLabBox featuring a SynRM acting as a motor under test and an isotropic permanent magnet synchronous motor (PMSM) acting as a virtual load. The sampling and switching frequency were both set to 8

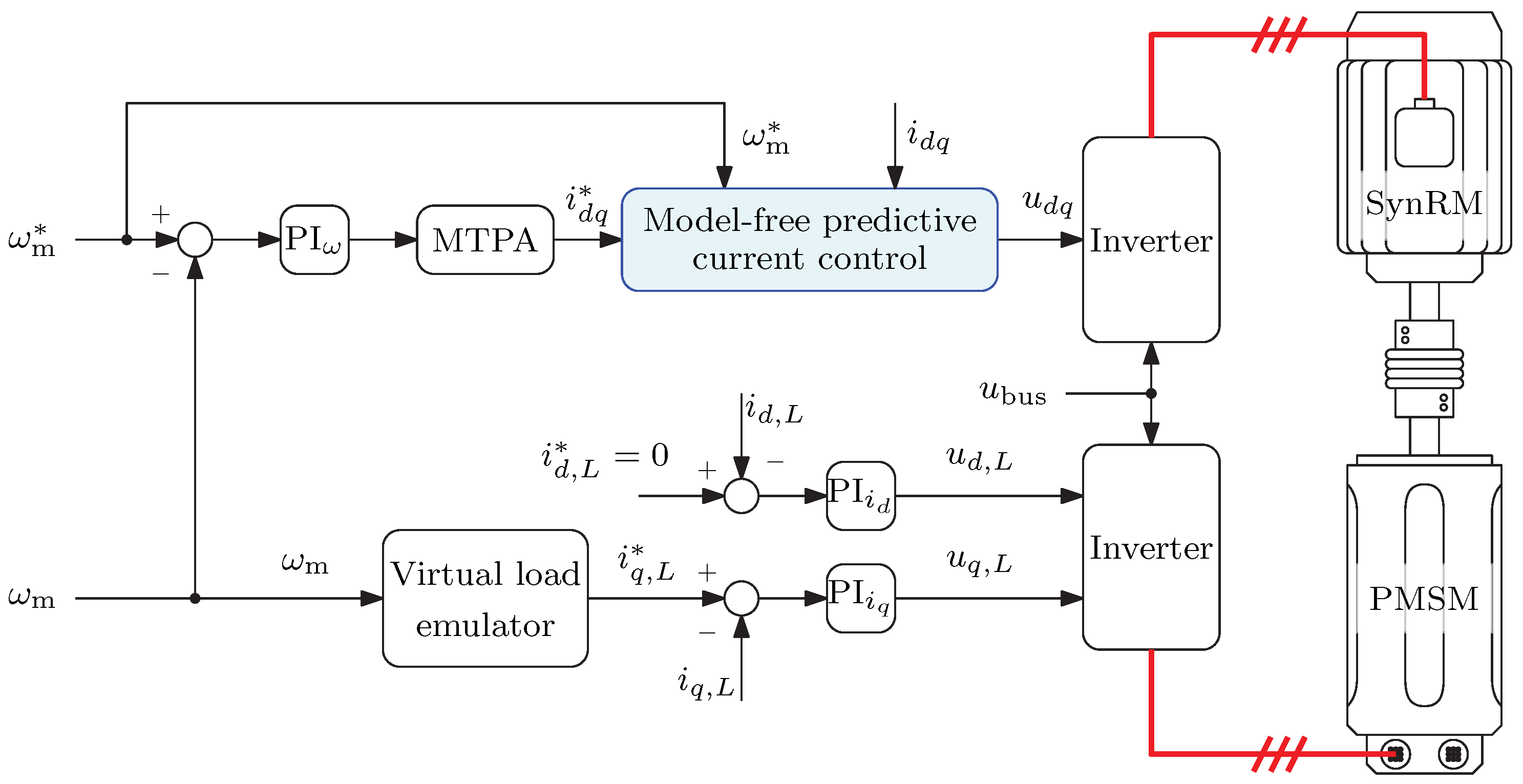

. It is worth highlighting that a higher switching frequency introduces only benefits in terms of current ripple, but at the price of additional switching losses and a reduced equivalent time for the control algorithm to be carried out.

In order to represent a realistic scenario, the bus voltage was set considering a single-phase 230

grid supply. However, the two motors under test of

Table 1 considered in this work were designed for three-phase grid supplied inverters. The situation could take place in those geographical areas where the three-phase grid supply is not available. The solar pumps represent another example where the bus voltage is lower than in the industrial case, but the available motors windings are designed for the full bus voltage value. The schematic of the proposed experimental setup is sketched in

Figure 4. Simple PI speed control was implemented and a traditional 45 MTPA strategy [

31] was adopted since the main focus was the current control and not the current references generation.

The only parameters that must be chosen in the proposed current control algorithm are the forgetting factor

f in (

5) and

in (

9). The former parameter,

f, can be set to a constant value equal to

with little reflections on the current dynamic performance deterioration, as can be seen in [

25]. The minimum voltage

is set to

of

, which is a fair approximation that guarantees the balance of the Joule losses at all working points. It is worth pointing out that the

value could be set to lower (or higher) values provided that the motor resistance is known. However, the

value slightly affects the dynamic of the currents, but the current tracking is guaranteed.

4.1. Design of Experiment: The Pump Load Emulator

The behaviour of an electric pump was emulated by means of a PMSM drive coupled to the motor under test and programmed as a virtual load. This is a very practical and common approach, which can be extended to represent many different loads behaviours, e.g., [

32].

The load torque

characteristic of a pump can be approximated by the sum of two terms. The first contribution is the

friction torque

, which includes a constant term due to dry friction

and a term proportional to the speed due to motor ventilation. The second contribution is the

pump torque

, which depends on the pump type under consideration. A centrifugal pump was considered in this paper, and the total load torque

was calculated as follows:

where

for the sake of brevity. The values of the parameters

,

and

were decided in order to guarantee that the nominal torque was produced by the motor under test when operating at nominal speed. Bearing in mind that the nominal speed values were reduced to meet the voltage constraint requirement set by the limited bus voltage, the values of the parameters adopted during the experimental stage are reported in

Table 2.

In order to evaluate the current control algorithm proposed in this paper, a simple test was designed.

The motor under test was set in speed control mode, while the load motor was torque controlled as sketched in

Figure 4. The desired load torque

(

13) was guaranteed by applying the following current references:

where

is the load permanent magnet flux, and

p is the load pole pairs. The subscript

L denotes (also in

Figure 4) load quantities.

4.2. Pump Load Emulator Results

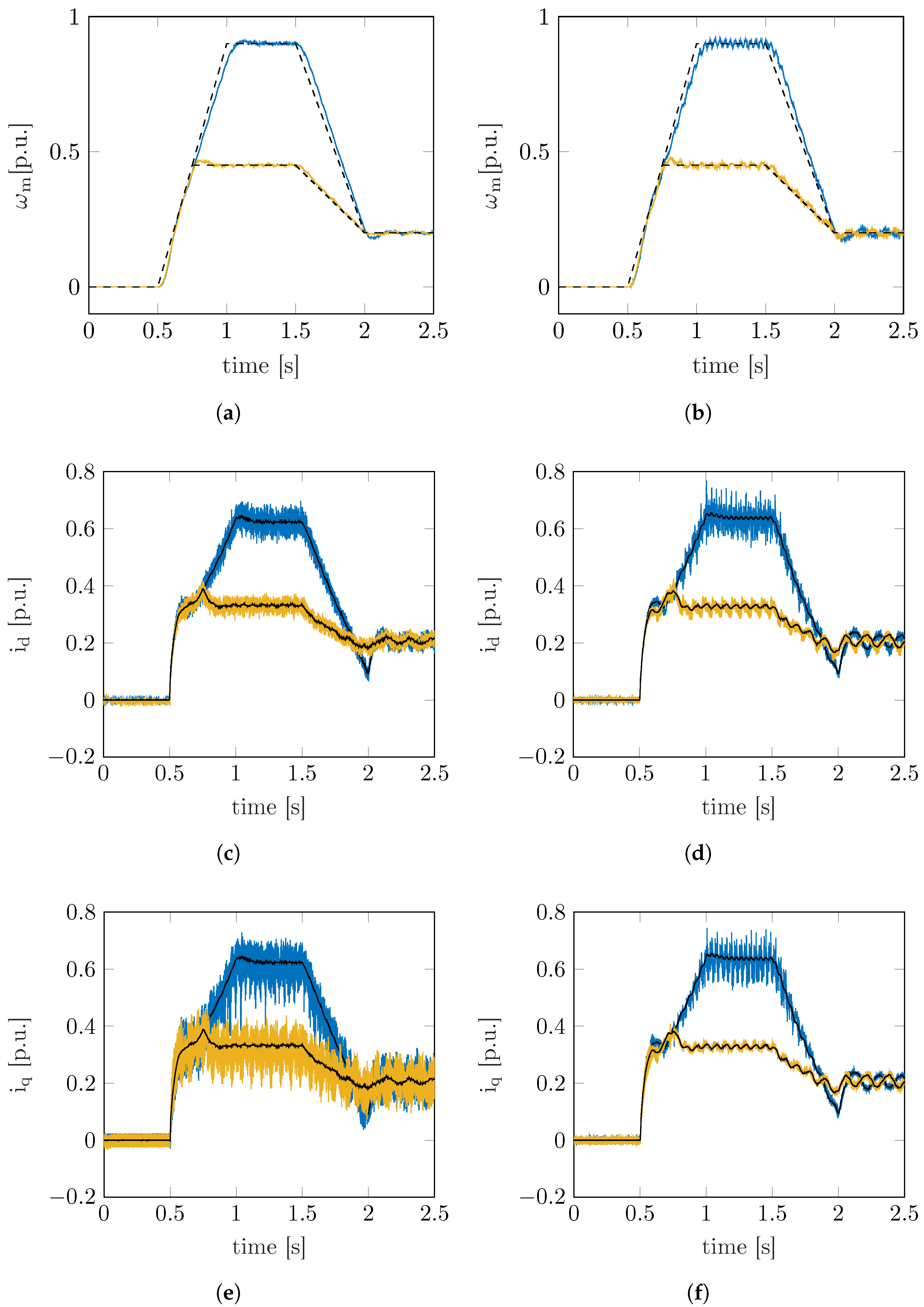

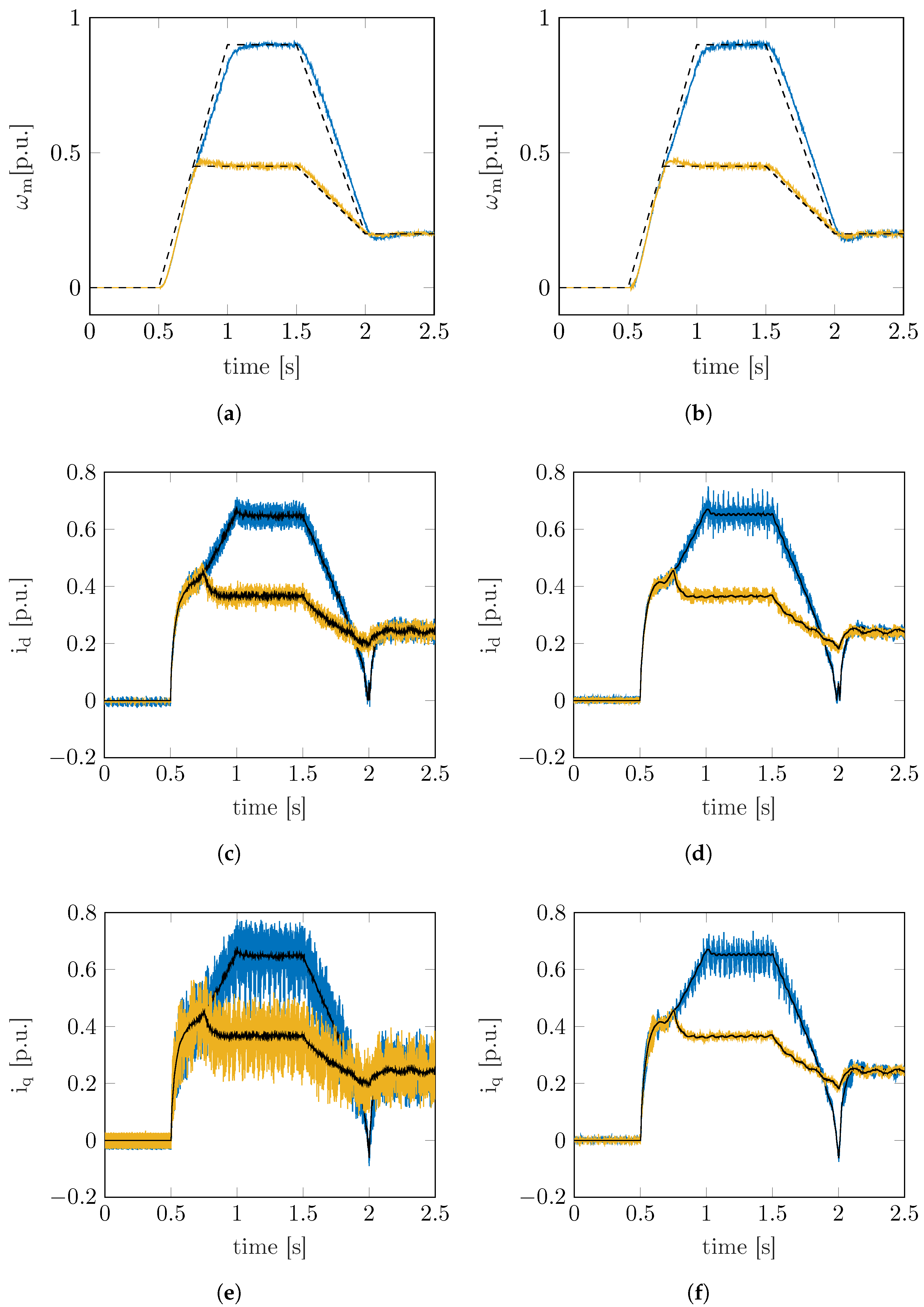

Two different speed set points were evaluated. The speed and current measurements as well as the references of the two motors under test are reported in

Figure 5 and

Figure 6. The comparison with the benchmark model-free finite-set predictive current control proposed in [

25] is also reported. The characteristic pump toque load behaviour is evident during the acceleration phase in both

axes currents, which show a parabolic curve-like characteristic in

Figure 5c–f for the SynRM

motor under test. The same applies for the current measurements of the SynRM

motor under test reported in

Figure 6.

The current ripple is considerably reduced for both motors under test by using the proposed model-free predictive current control. This was obtained since the equivalent voltage vector obtained by the predictive control proposed in

Section 3 was selected in a continuous-set domain rather than a finite-set domain as in [

25]. The equivalent switching frequency of the finite-set predictive current controller is surely lower than that of the proposed control, which is fixed at 8

. Finite-set algorithms are known for their unpredictable switching frequency, which depends on the optimal voltage vector sequence applied during runtime operation. From the current ripple reduction point of view in the finite-set algorithm, the higher the control frequency, the better. However, the control time period is of utmost importance when the computational capacity of the microcontroller is under consideration.

The computational burden required by the proposed method remains limited. The benchmark finite-set algorithm requires an average turnaround time of the microcontroller routine of 34 , i.e., the of the control period . The proposed model-free predictive current control required an average turnaround time of 42 , i.e., the of . In other words, the proposed model-free predictive current control algorithm requires of more than the benchmark finite-set method.

It is worth remarking that no parameter tuning was required in the proposed current control algorithm of

Section 3 for both motors under test. This is a distinctive feature of the proposed model-free predictive control algorithm which can be applied to different SynRMs without the need for any knowledge of motor parameters’ values. Furthermore, the algorithm proposed in

Section 3 can also be applied to permanent magnet motors, provided that the current ripple value remains limited.

4.3. Load Step Variations

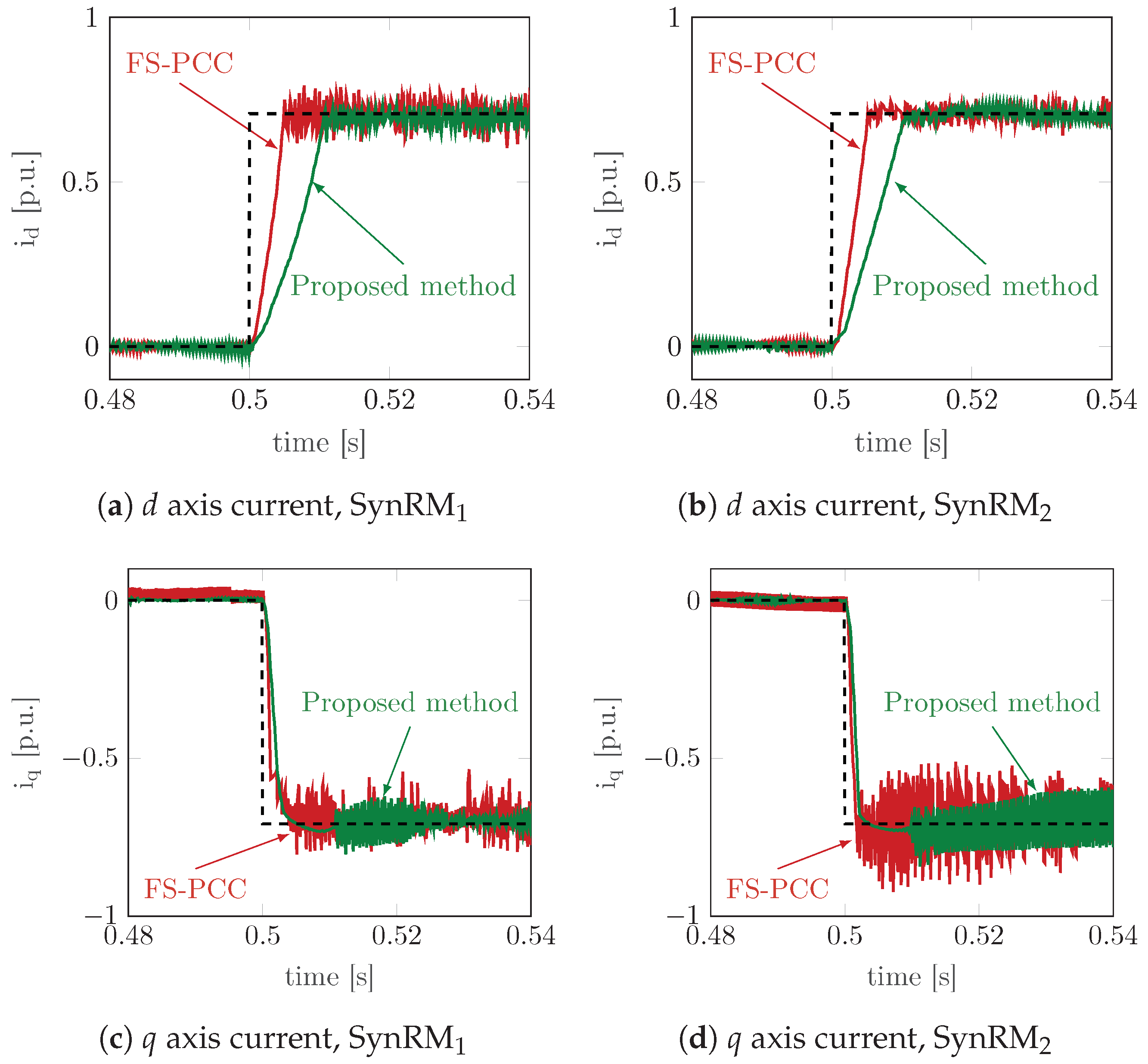

In order to test the current reference tracking capability of the proposed model-free predictive current control, a further test was carried out. A current step reference variation situation is likely to occur in a pump application when a denser fluid suddenly hits the pump. Nonetheless, the test is a canonical procedure to verify the capability of the control algorithm under consideration and thus, general considerations can be drawn.

The motor under test was dragged by the virtual load motor at constant speed, namely

of the motor under test nominal speed, while only the current control was active. A current magnitude reference equal to half the nominal value was imposed, and the results were reported in

Figure 7 for both motors under test.

On the one hand, the

q axis current dynamics obtained by the proposed model-free predictive control was almost the same as for the benchmark finite-set predictive control, as can be seen in

Figure 7c,d. The steady state behaviour shows that the proposed model-free control algorithm yields a smaller current ripple than the benchmark finite-set predictive controller. The results confirm the steady state behaviour of the

q axis current measurements obtained in the pump tests of

Section 4.2, in particular

Figure 5e compared to

Figure 5f and

Figure 6e compared to

Figure 6f.

On the other hand, the

d axis current dynamics reported in

Figure 7a,b shows that the benchmark finite-set controller is faster than the proposed one. The reason is the smaller available voltage of the proposed model-free controller compared to the finite-set one of [

25], since the voltage is limited by the

law in (

9). The effect is preponderant on the

d axis tracking performances due to the larger value of

compared to

in SynRMs. This is the major drawback of the proposed model-free predictive control which is counterbalanced by a better steady state behaviour compared to the finite-set predictive control. It is worth highlighting that the proposed model-free predictive control is designed for pump applications, who are unlikely to require very high dynamic performances from the current controller.

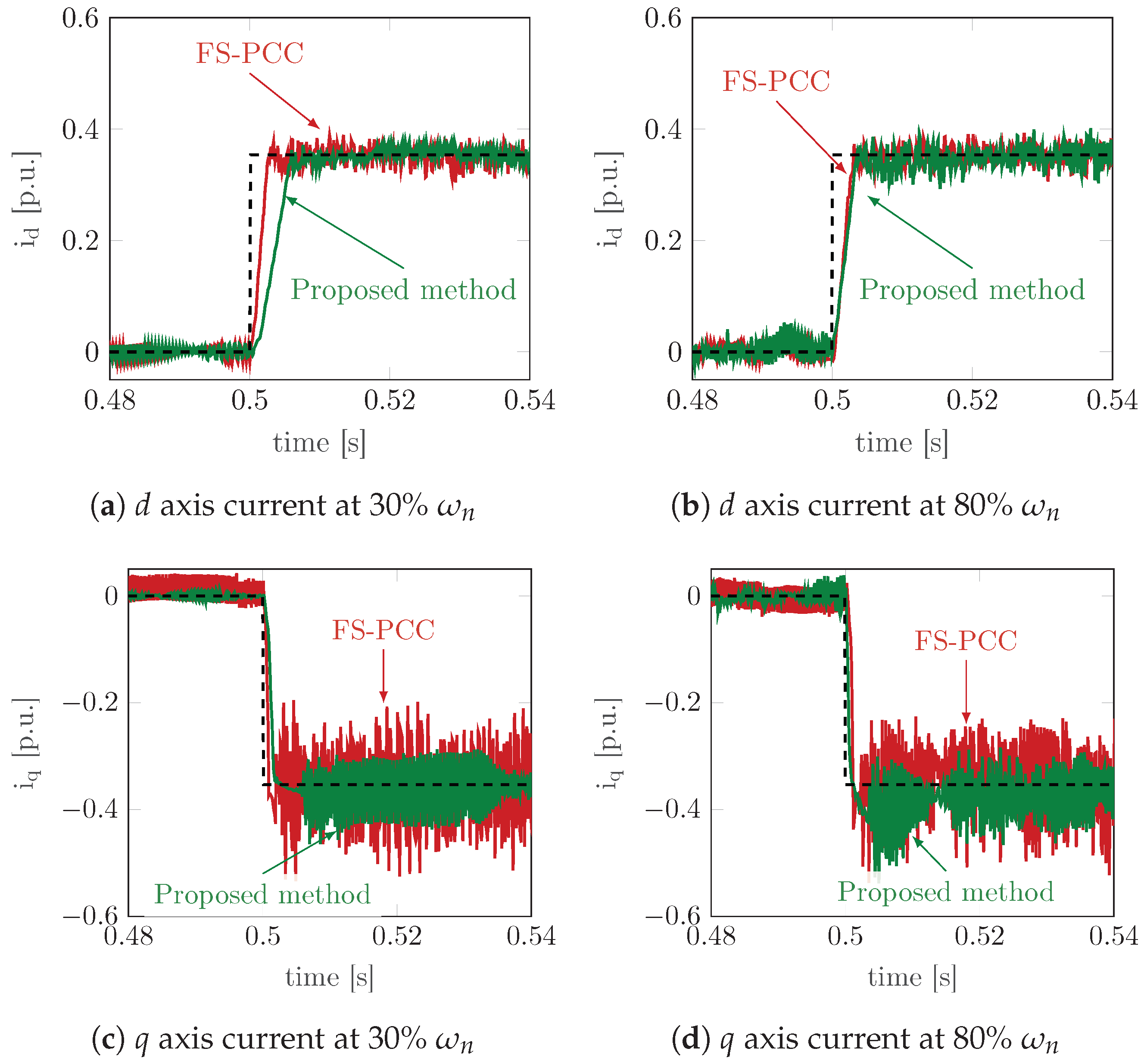

A second batch of measurements with step-like variation of the current reference was collected with the SynRM

as the motor under test, aiming to testing the proposed current control performances at different load and speed values. The results of the second batch are reported in

Figure 8. The current dynamics of both

axes currents in

Figure 8a,c are very similar to the ones at the rated current in

Figure 7b,d, respectively, which is at low speed. However, the current tracking dynamics at higher speed is sensibly improved by the proposed

d axis current predictive controller, as reported in

Figure 8b. The reason is that a higher voltage value

is available for the minimisation of the cost function (

10), since the reference speed is higher in (

9). It is worth recalling that the load torque value in pump applications increases with the speed. Therefore, improvement of current tracking performances with the increase in the speed of the proposed model-free predictive control is attractive for pump applications.

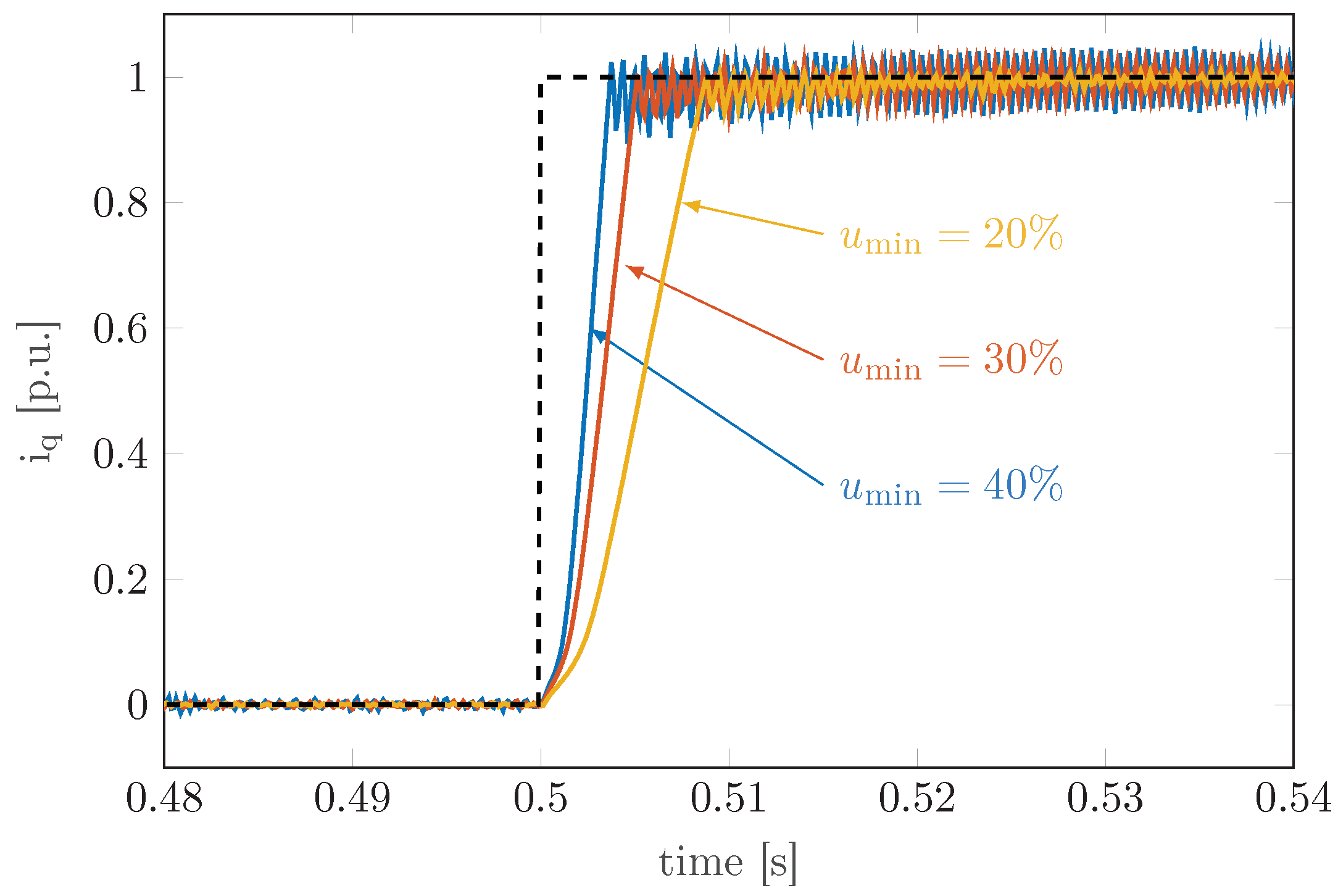

4.4. Effects of Different Values

The

value is the only parameter of the proposed current control that apparently requires tuning. Three different

d axis current measurements using different

values and imposing a rated current step variation at null speed are reported in

Figure 9. The current dynamics during the transient is penalised as the

value decays; however, the current ripple amplitude also decreases, which improves the steady state behaviour of the current controller.

A conservative choice for the

value was made following the model-free control paradigm. The 25 % of

is a reasonable choice because it provides good current dynamics and simultaneously improves the current ripple compared to the finite-set algorithm, as can be seen in

Figure 5 and

Figure 6. It is worth pointing out that the purpose of this paper was to propose a proof of concept about a new continuous-set model-free predictive control and highlight the implementation aspects that determine the functioning of the algorithm. The

value can be set by different simple strategies that do not involve specialised human interaction, such as the choice between two predetermined values.

5. Conclusions

A new continuous-set model-free predictive current control was studied in this paper, addressing simple, low-cost electric pump applications.

As a distinguishing feature, the proposed predictive control was based on an adaptive RLS-based model, which is linked to but not constrained by knowledge of any specific motor parameter. This fact, combined with a simplified search strategy within a continuous set of voltage vectors, resulted in efficient, low-cost, and low-ripple current control. The proposed current control skips any initial motor calibration, allowing an immediate operational startup with a generic electric pump based on the SynRM. In addition to this, there are many other applications where this control can be applied with higher benefits if compared with the traditional linear controller.

The validity of the proposed control was proven by several tests on an experimental test rig featuring two different SynRMs and the results were thoroughly discussed.

Simple and automatic initial self-tuning has the invaluable advantage of not requiring the presence of expert personnel either at the first start-up or in case of the replacement of a faulty motor.

In conclusion, the proposed strategy makes use of complex technology to achieve similar or better results than PI control and finite set model-free predictive control with the specific goal of making the complexity transparent to the end user, as an established trend in any smart home device.