The design of exercise or rehabilitation machines is not a novelty; indeed, there are probably thousands of machines optimized for these tasks. The optimization processes behind these machines led to very efficient mechanisms able to perform the desired exercises correctly. Nevertheless, little, if not at all, care has been paid to possible physical or psychological barriers of their users. A typical user of such pieces of equipment is already motivated to use such machines. Therefore, the psychological aspect is a minor concern of the designer of these machines. However, as introduced before, several studies have reported that obese individuals may avoid using conventional exercise machines due to physical limitations, but mostly due to psychological ones. Similar claims have come from doctors working with bariatric patients at the medical science department of Università degli studi di Torino.

The idea behind this study is to design a rehabilitation machine to enable obese individuals to recover muscle tone and mobility gradually and to softly approach this new healthy exercise routine. However, in trying to achieve this objective, most of the design choices are guided by the concepts of overcoming all the possible psychological barriers of bariatric users and of motivating them to continue their rehabilitation routine. As stated before, the appearance of the machine is key to achieve this aim. However, it is important to state that this work does not want to propose aesthetically appealing machines since this departs from the research team competences. Instead, the actual objective is to design novel mechanisms that enable the user to correctly perform some physical exercises but with the requirement that such mechanisms can be hidden while the machine is in the rest position.

The following subsections address all the requirements and guidelines of the whole machine and its most relevant sub-systems. After that, the synthesis and design of the main mechanisms of the rehabilitation machine are presented. A proposal of the actuation for the leg mechanism control system is discussed at the end of this section.

2.1. System Requirements

The idea is to design a rehabilitation machine that appears like an ordinary object, like a chair. This concept should ease the introduction of obese individuals to physical exercises.

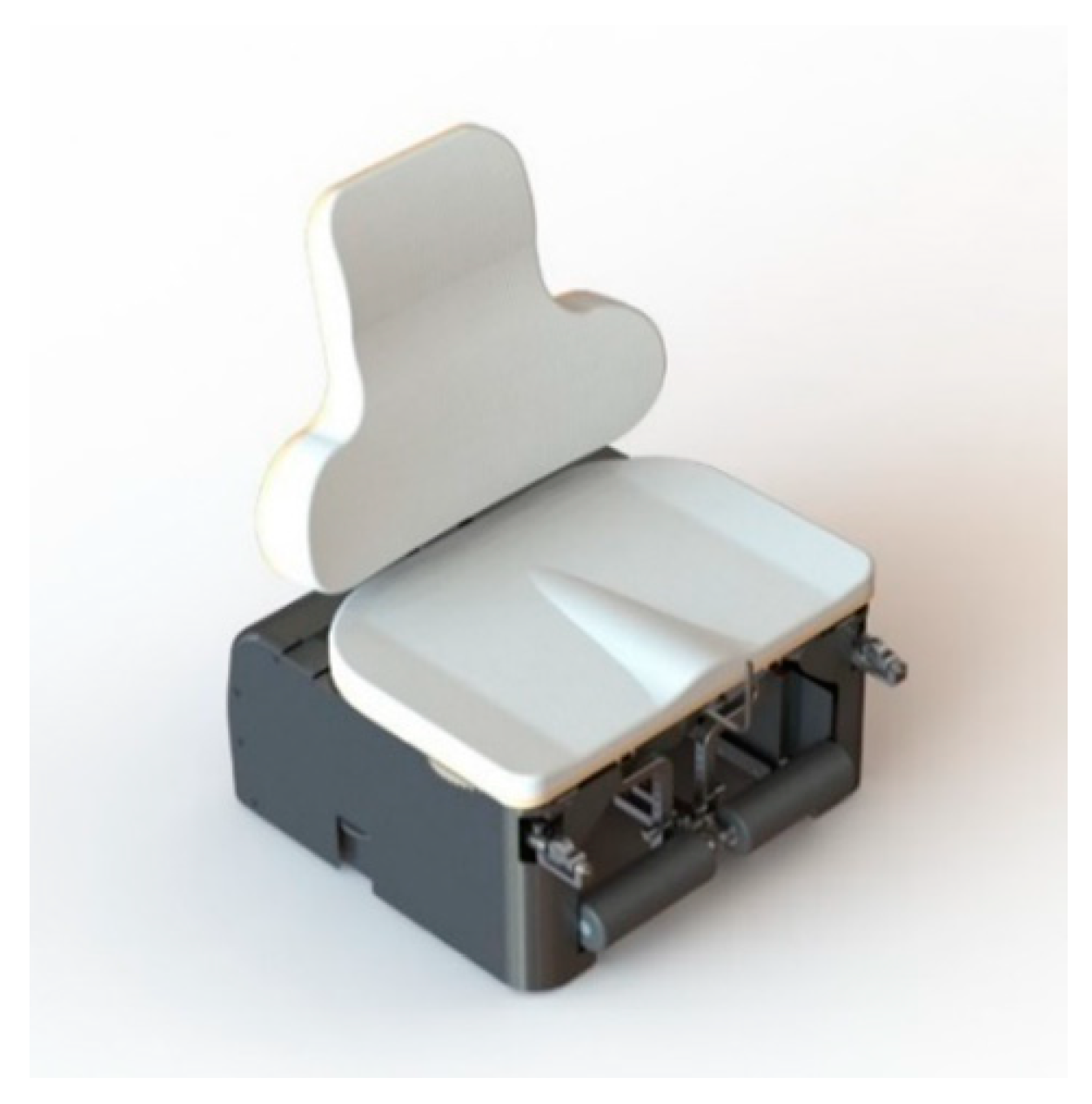

Figure 1 illustrates the concept of the prototype discussed here. At first sight, the machine appears as a chair for bariatric people (i.e., a chair larger than the common chairs in order to accommodate obese individuals). However, under the seat, it is possible to see the mechanisms that enable the physical exercises.

The second requirement coming from the medical department is which exercises an obese individual should do. Following the findings of [

9,

22,

23], the most suitable exercises for rehabilitation of bariatric people have to involve the main and larger muscle groups in order to increase the caloric expenditure. Such exercises should be done in short sessions repeated regularly during the week, almost every day. The load of the exercises should be minimal since aerobic exercises should be preferred and also because the already weakened musculoskeletal structure of obese individuals must not be overloaded and damaged. Obese individuals performing the exercises should avoid loading their articulation with their weight (e.g., doing squats) in order to prevent any damage to their joints. For this reason, seated exercises, or more general exercises where the load applied is only due to an external and known source, should be preferred.

Given these guidelines, the doctors identified the proper exercises involving legs, abdomen, and the upper torso (chest, shoulder, arms), some of the largest muscle groups. More details about the actual exercises will be presented in the following subsections. Whatever the exercises, the machine must permit its user to perform the movement correctly to avoid any damage to muscles or joints. The exercise loads must be controllable by the user, following a protocol defined by the physiotherapists, and it has to be constant during the exercise. The user-exerted force and other useful quantities, such as the movements velocity and energy consumption, must be measured and logged. This feature could give doctors some insight or could motivate its user, for example, through some sort of gamification of the whole exercises.

The last general requirements are linked to the size of the machine. The machine has to stand the weight of bariatric people; therefore, the system must stand a weight of about 400 kg. It is also central that the machine can accommodate users of different sizes. For this reason, the machine should have several auxiliary regulations in order to adapt the machine to a wide range of individuals. The actual references for such dimensions come from [

24], and actual measurements performed on 20 bariatric patients at Molinette hospital in Turin. The final requirement about the overall size of the machine is that the machine must be able to go through hospital doors (approx. 80 cm) and the main doors in the home (approx. 75 cm).

2.2. Leg Exercises Mechanism

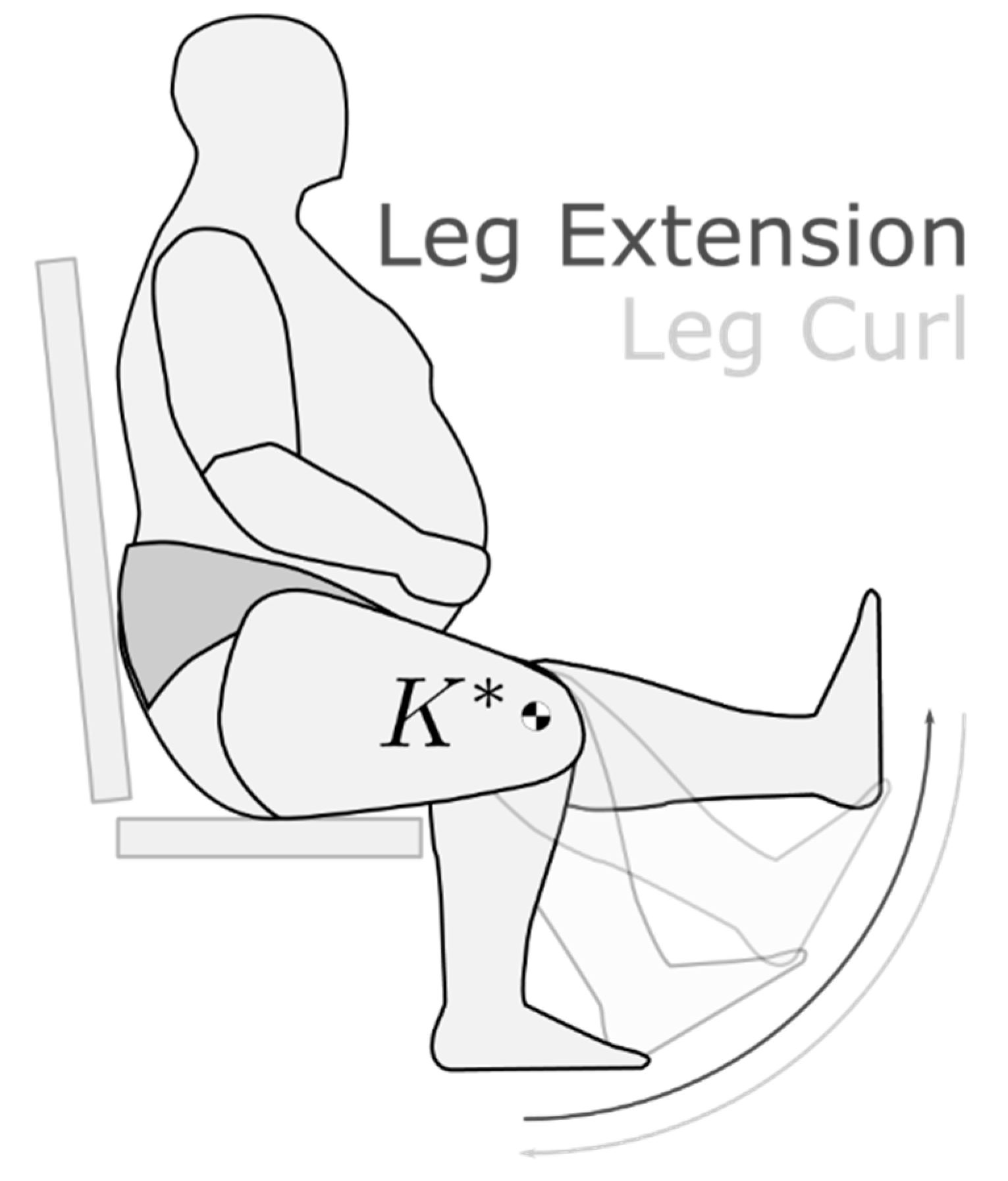

The main exercises that can be done with this machine involve the legs, since some of the largest group muscles are in the lower body. In particular, the exercises are seated leg curls (the flexion movement of the legs) and seated leg extensions, two antagonist exercises involving sartorius, gracilis, gastrocnemius, and femoral quadriceps muscles.

Figure 2 depicts a schematic representation of the two exercises. In the figure, but also in designing the machine, an ideal rotational joint, named

, approximates the knee joint. Such hypothesis is present in all common gym equipment, even if the actual knee joint is more complicated than that, and the instantaneous center of rotation (ICR) of the leg is not a fixed point.

To guide the leg correctly during the exercises, the ICRs of the leg and of the mechanism links moving with it must be the point

. In typical machines, this is done by placing a rotational joint in

. By doing so, however, the mechanism would stick out of the chair, being a possible obstacle to the user. The mechanism proposed here instead has a virtual joint at the ICR

, but the whole mechanism lies under the seat when entirely retracted in the rest position.

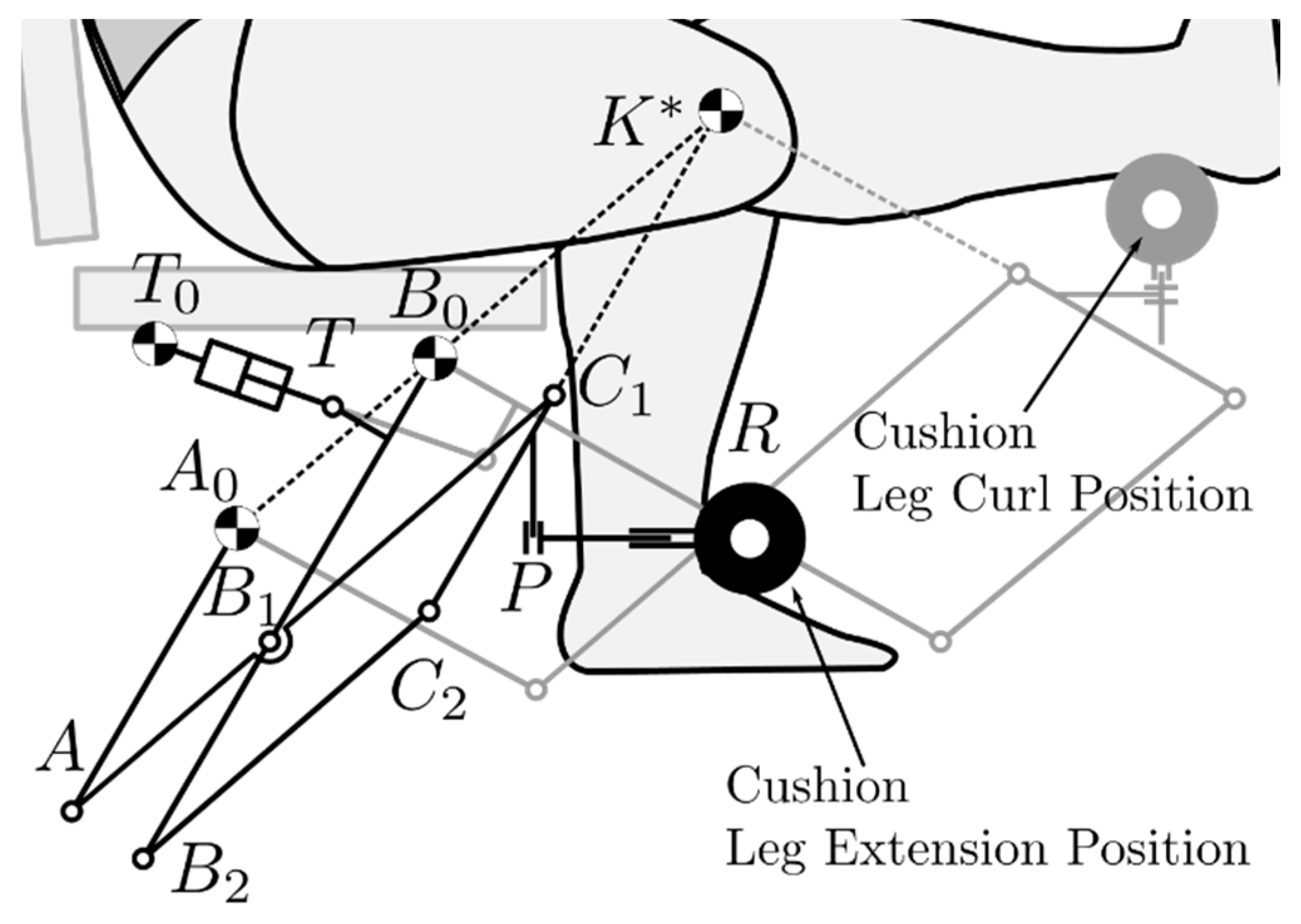

Figure 3 shows the functional scheme of the mechanism composed by a double parallelogram. In order to have the mechanism ICR in

, the revolute joints

and

fixed to the seat and the point

must be along of the same line. The same must be true also for the joint

,

, and the point

. With this configuration, the mechanism can follow the leg along its rotation about

. In order to accommodate a wide range of users, two prismatic joints are present in

and

to adjust the point

of the mechanism where can be fixed the user-machine contact device, i.e., a cylindrical cushion. The figure shows the two alternative positions of the cushion that can be set in order to perform the two different exercises: leg curl (the cushion is behind the ankle) and leg extension (the cushion is in front of the ankle). A linear actuator, connected between the revolute joints

(fixed to the frame) and

, is controlled to exert a constant and desired torque about

that the user has to match applying a force in

with their leg. It is important to highlight that the ICR

is fixed with respect to the structure and not with the user; therefore, some auxiliary regulations are required to align the knee with this point.

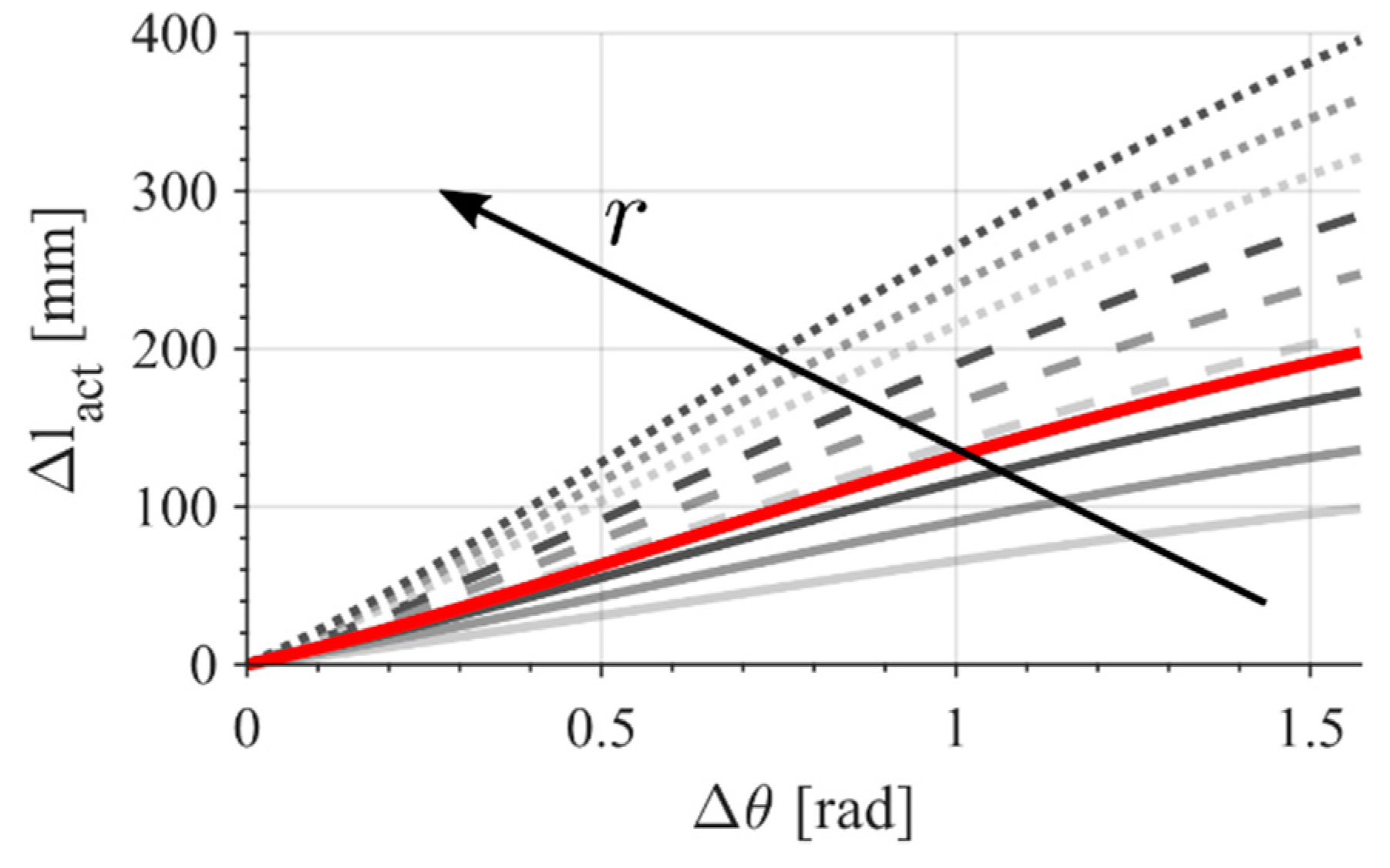

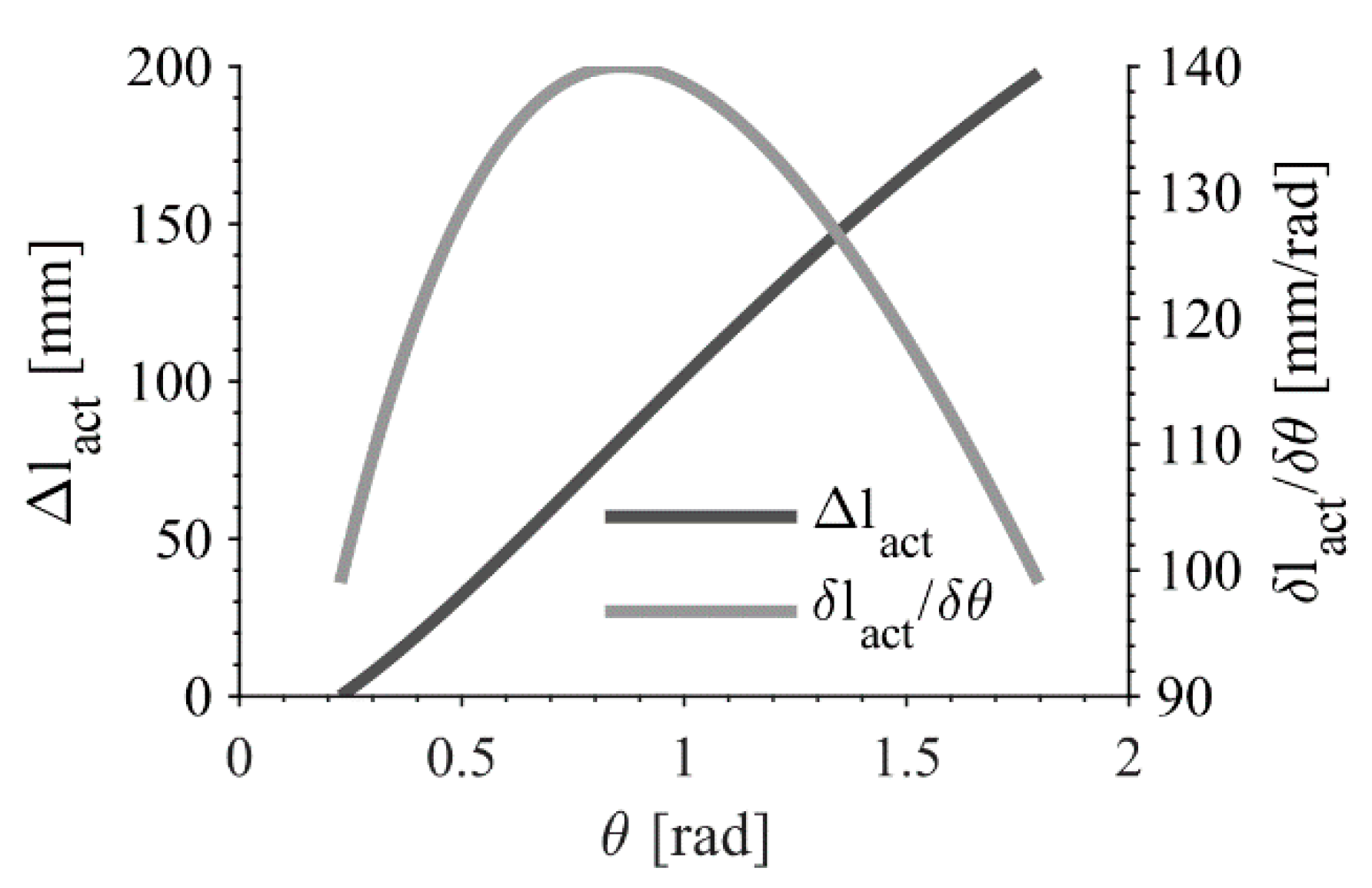

During both exercises, the leg has to span an angle . Therefore, the link rotates around the same angle, since it is rigidly connected to the user leg (when the regulations in and are fixed). Moreover, given the mechanism architecture, the and links must rotate around too because they are always parallel to . It is supposed that the maximum force produced by the mechanism in is about for each leg, with an average angular velocity of the leg of (one repetition per second). The opposing force must be constant during the movement; therefore, the instantaneous transmission ratio of the mechanism has to be as constant as possible. The last requirement is that the mechanism must be contained under the seat when it is completely retracted.

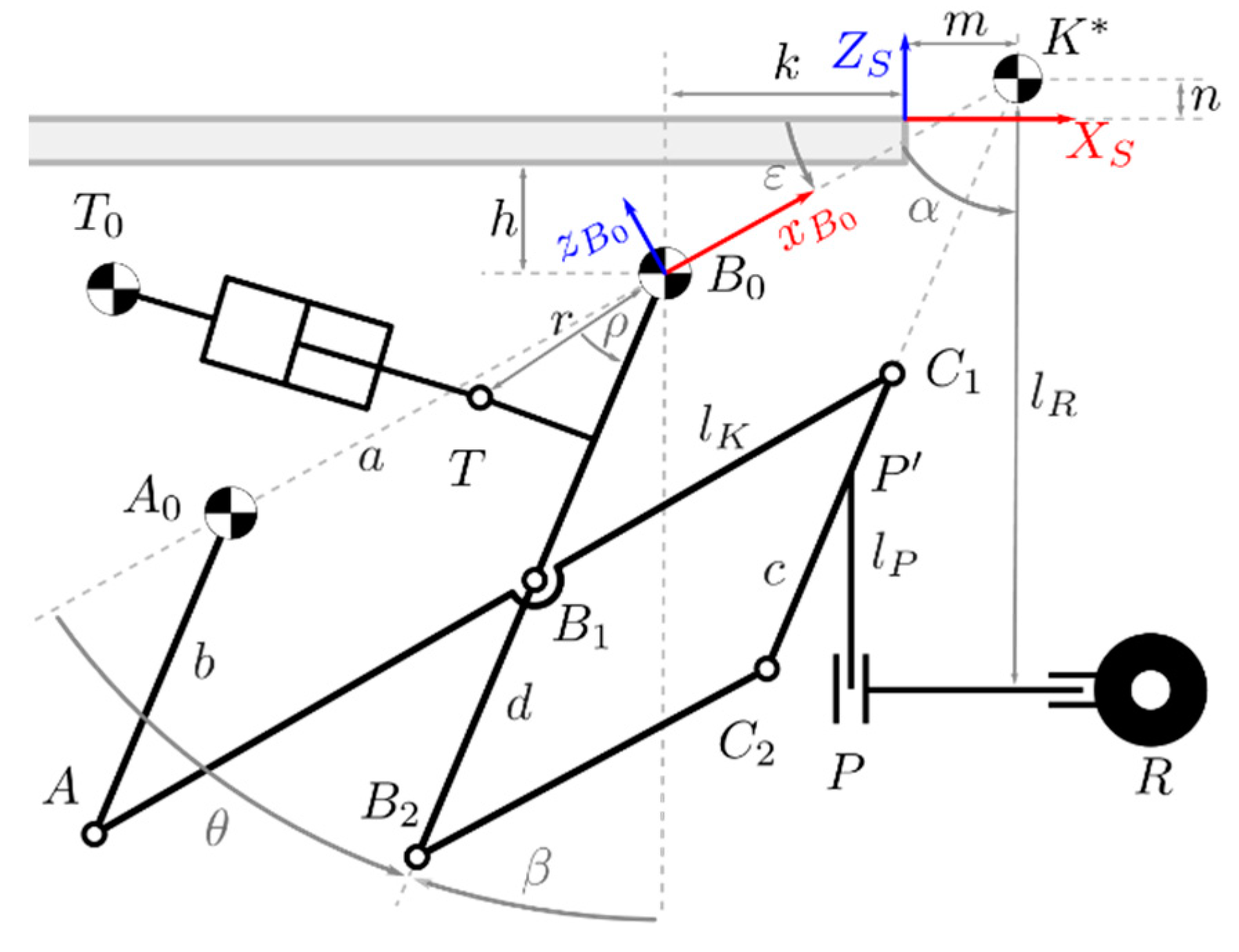

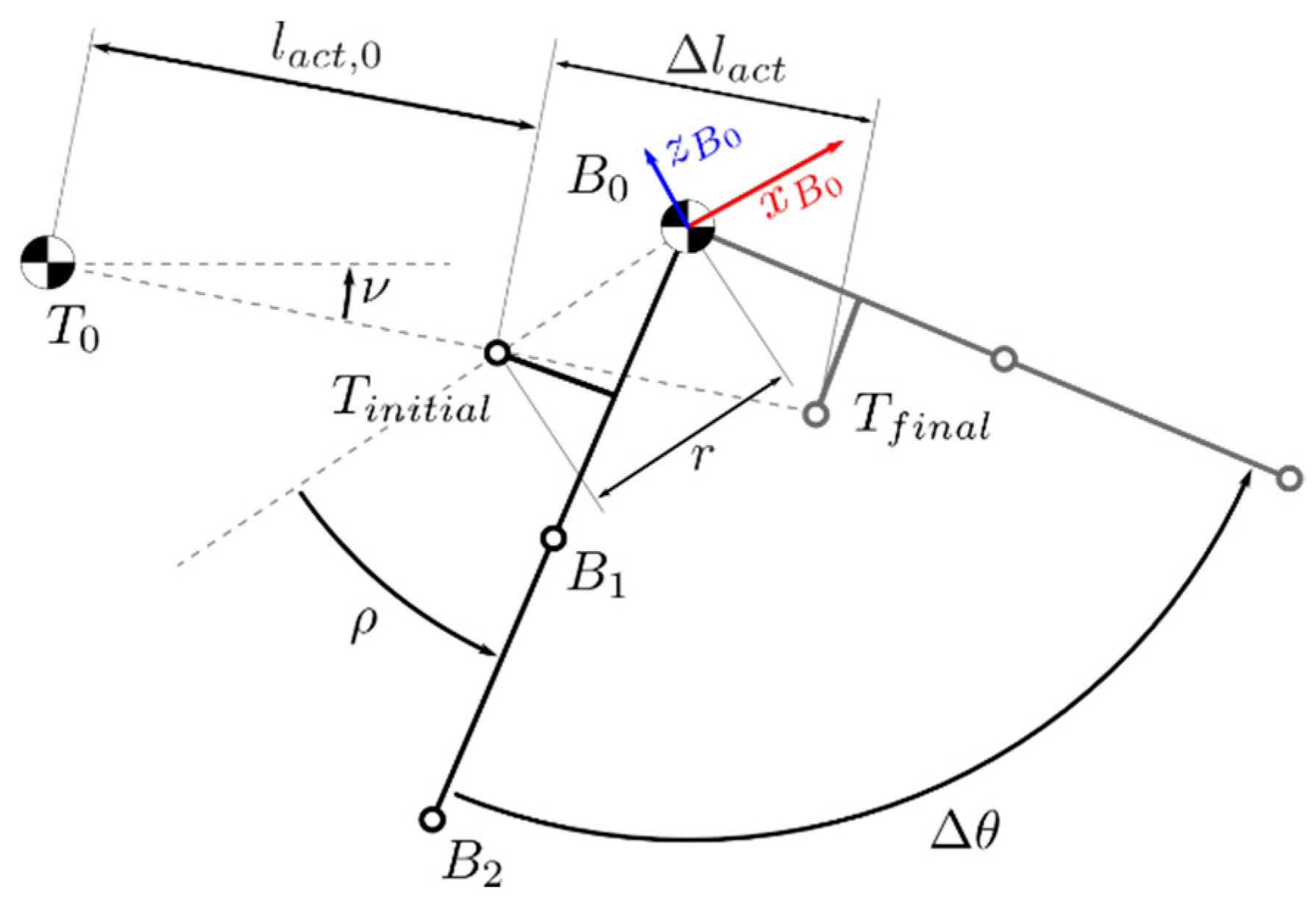

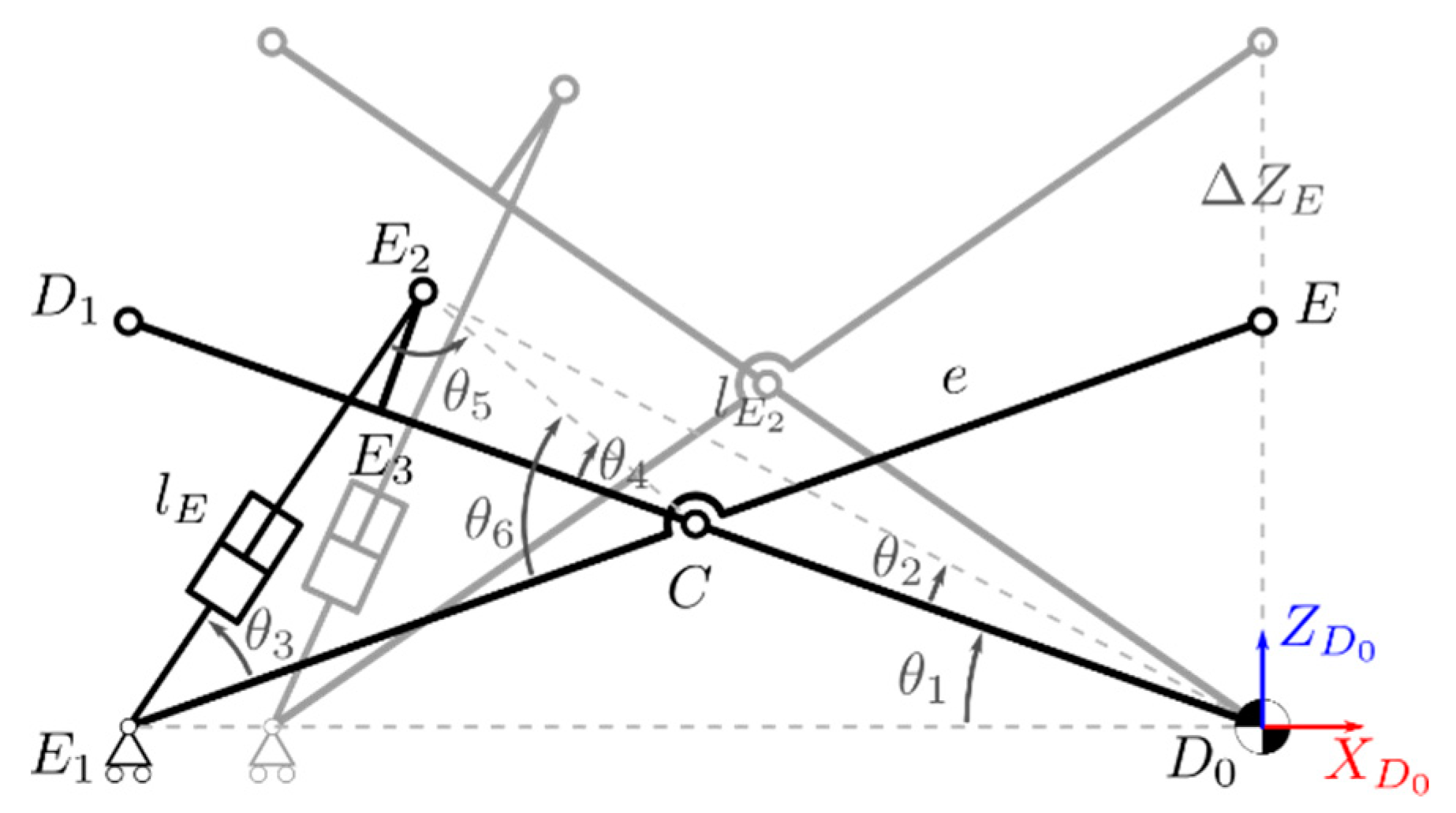

Figure 4 shows the mechanism with its main parameters and its variables.

Table 1 collects symbols and descriptions of such quantities.

Figure 5 represents the optimal configuration of the actuator in the mechanism: in order to obtain an instantaneous transmission ratio as constant as possible, the points

,

and

must be aligned. The other related parameters are then optimized in order to improve the mechanism performance but also to minimize the dimensions of the whole mechanism. Given this architecture and a movement that spans

, the linear actuator stroke

is always

.

From

Figure 4 it is also possible to derive the angle

between

and

, the angle

between

and the link

, the angle

, and the last unknown length of the mechanism

:

Given these new quantities, it is possible to obtain the relative positions of each point of the mechanism. However, since such relations are easily obtained using trigonometry, they are not shown here. The most relevant relation that can be obtained from the cited ones is the length

as a function of

, or, in other words, the relation between the rotation of the system

and the length of the actuator

where

and

.

is a fixed length of the linear actuator that depends on the specific commercial model. The chosen actuator needs to satisfy the initial length

and the maximum length

.

The derivative of Equation (5) about

is the mechanism transmission ratio:

By knowing these relations and the requirements listed before, it has been possible to perform an optimization of the mechanism parameters by an iterative procedure in order to satisfy the requirements while obtaining a feasible solution mostly composed of typical commercial parts.

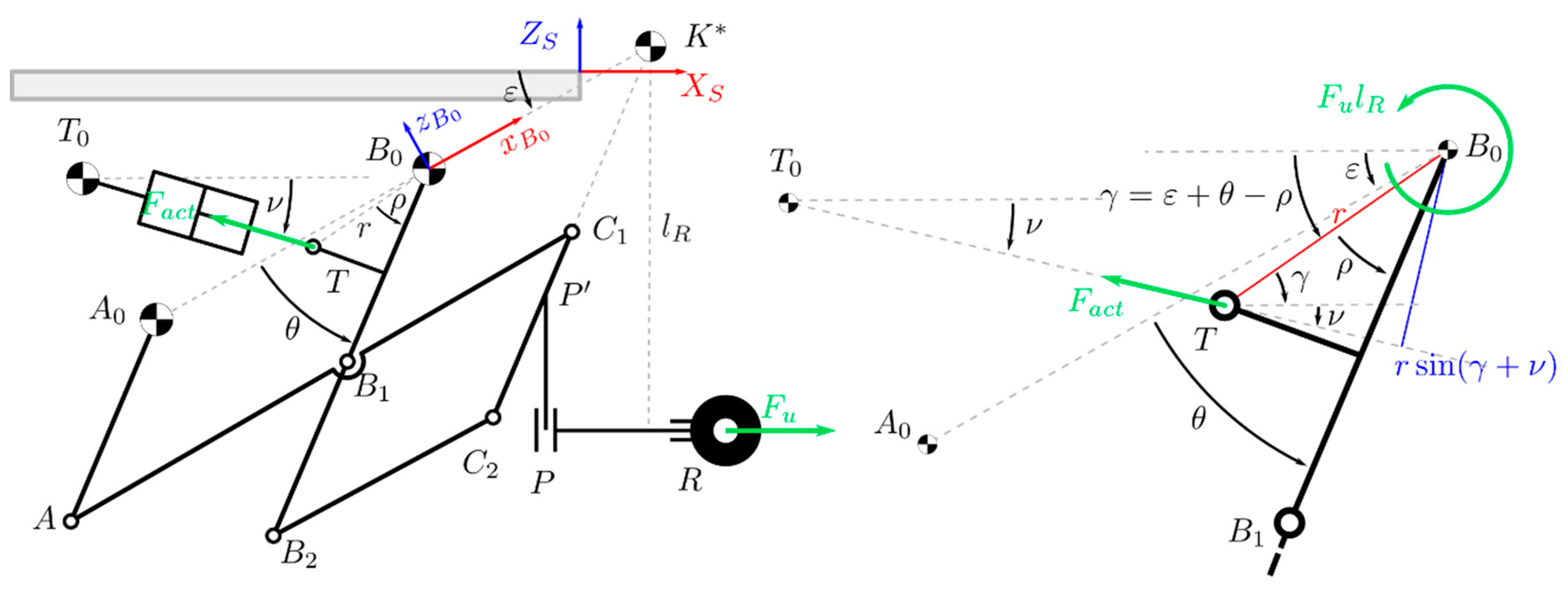

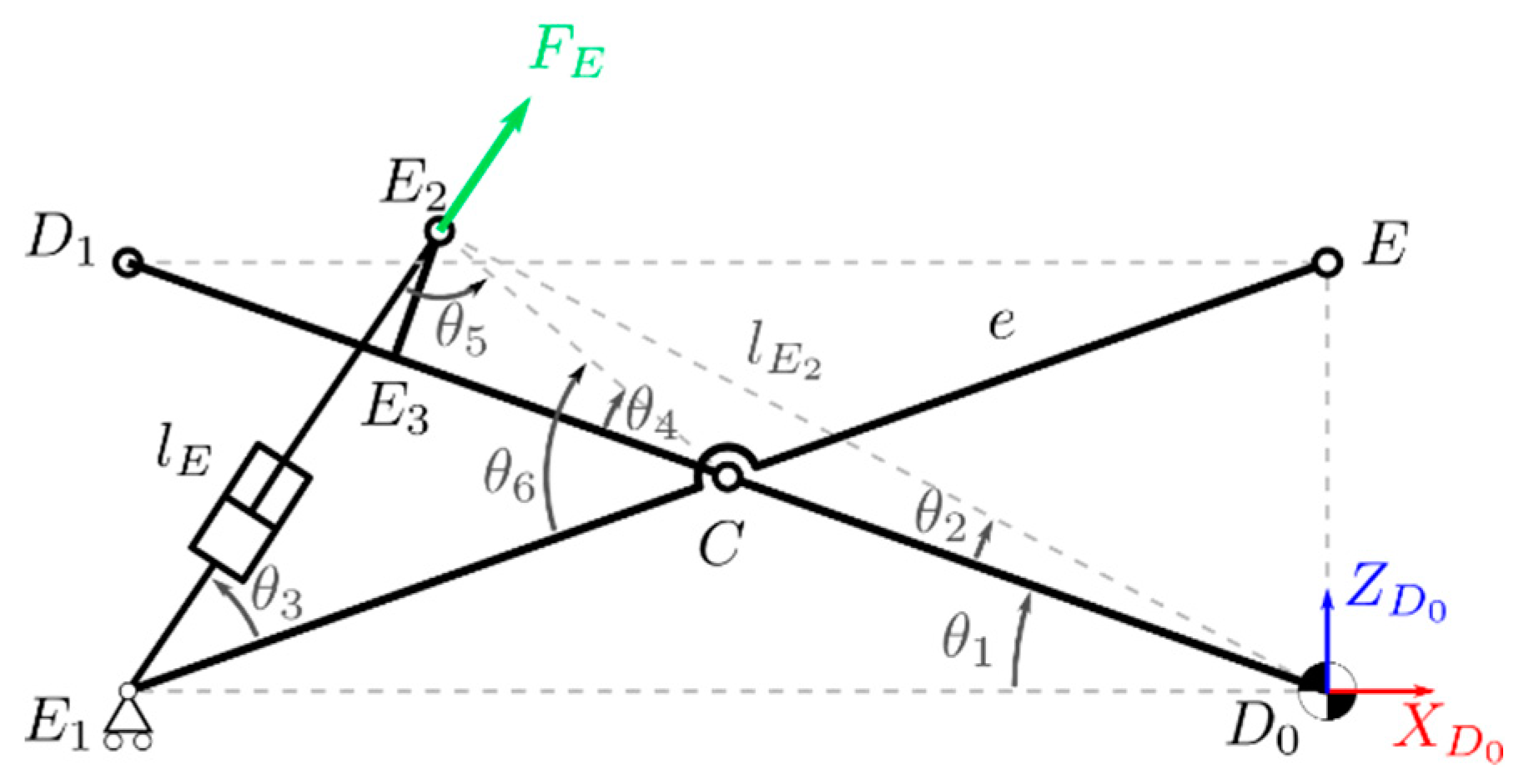

From the diagram in

Figure 6, it is already possible to derive a first approximation of the actuator force

that it is required to balance the user force

. The figure shows the leg extension case, but the leg curl exercise is analogous but with forces with opposite signs. For this initial approximation, just the actuator and user forces are considered. Here it is made the hypothesis that the user applies a constant force

in

that it is perpendicular to the link

. Therefore, it is like a torque equal to

is acting on the mechanism. In order to oppose the user movement, the machine must generate the force

. The force balance is the following:

From this simple case, it is then possible to size the mechanism links, joints, and the actuator. After that, it is possible to refine the initial approximation taking into consideration the links weight and the effect of an elastic element required to compensate the weight of the mechanism at rest. This more precise model can be expressed as:

where

is the equivalent torque applied to the link

generated by the effect of the weight of the whole mechanism,

is the torque applied by an elastic element to the same link in order to balance the weight when the mechanism is closed,

is the actuator force required to balance all the other components.

is easily derived, after the first definition of the links sizes and weights, computing the equivalent torque due to each mass with respect to the pivot point

. By knowing the value of

at

, it is possible to design the elastic element characteristics (stiffness, preload, free-length) in order to balance the weight when no external force is applied. One end of the spring is fixed to the chair structure, while the other is fixed to the link

.

2.3. Leg Exercises Control System

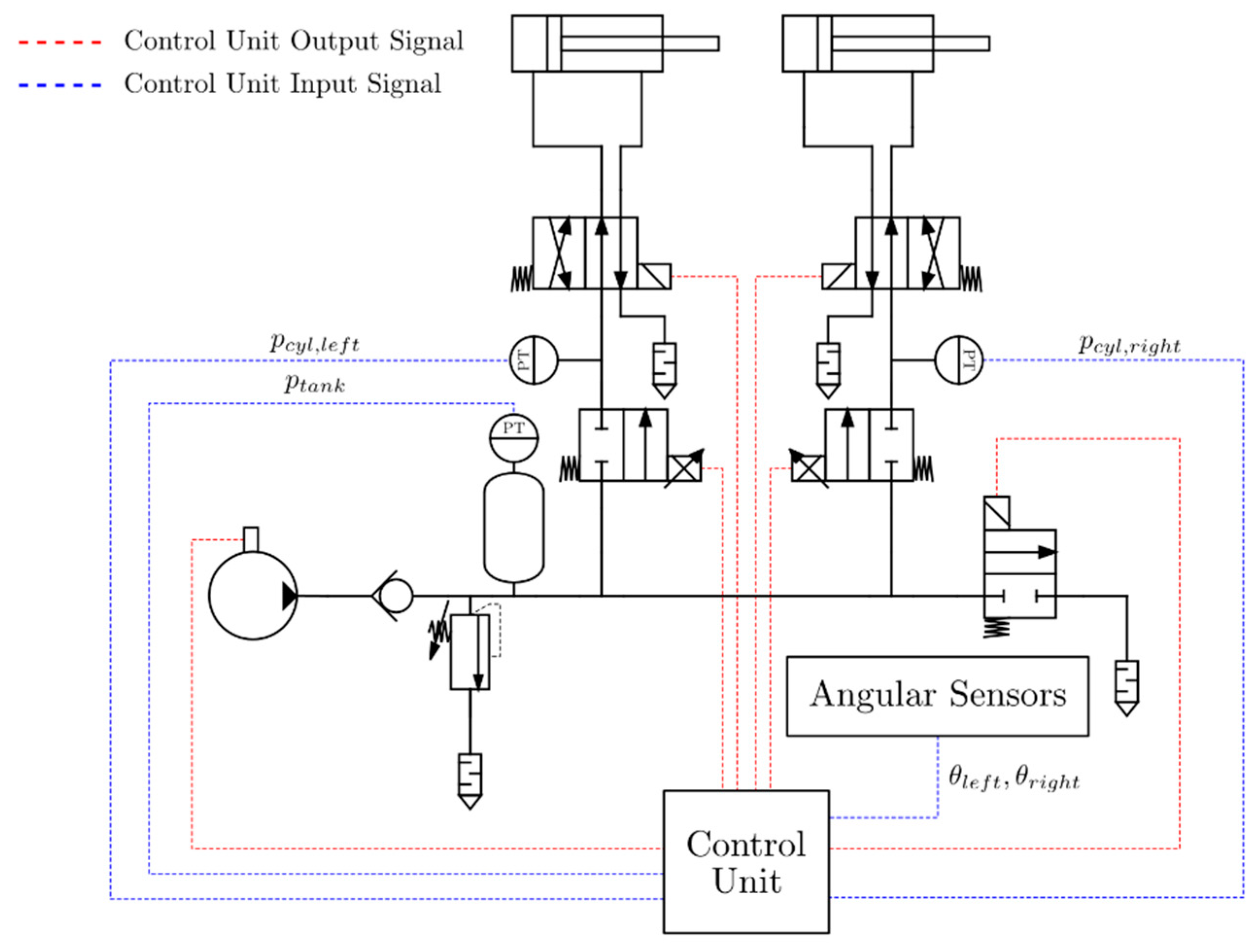

A pneumatic cylinder is used to apply the force required to oppose the user effort. Pneumatic actuation systems are commonly used in several gym equipments because it is possible to achieve the desired force with consistency and precision, regulating the pressure of the system. Moreover, such systems have minimal weight inertial effects during the exercise movement compared to weight-based gym machines for the same exercises.

Figure 7 shows the working principle of the pneumatic system used in this mechanism. During the exercise, only one chamber of the cylinder is under pressure, while the other one can be directly connected to the environment. It is possible to select the desired exercise, leg curl or leg extension, by switching the active chamber. The active chamber is connected to an accumulator through a normally closed proportional flow valve. The cylinder moving during the exercise reduces the volume of the active chamber, increasing the pressure within and, therefore, the generated resisting force. It is possible to control the cylinder pressure

regulating the airflow from the chamber to the accumulator (that it is always kept at lower pressure) acting on the proportional flow valve. If the accumulator volume is much larger than the active chamber one, ideally infinitely large, it is possible to minimize the times when a compressor has to be used to keep the pressure to the desired set value, because its pressure stays almost constant.

This layout has been chosen in order to avoid high energy consumption and noise issues due to a full pressure control in the actuator chambers using, for example, controllable proportional valves. In this case, the initial pressure of the tank is set depending on the desired force , then during the exercises the proportional flow valve is modulated to obtain the required .

From Equation (8), it is possible to obtain

, the set pressure of the cylinder chamber required to maintain a constant resistance to the user movement:

where

is a corrective factor used to model the internal actuator losses. Due to the cylinder rod, the effective areas

of the two chambers are slightly different; therefore, the set pressures for leg curl or leg extension exercises with the same reference force are slightly different.

Figure 8 shows a possible pneumatic circuit. Starting from the concept presented before, the required valves, the sensors, a compressor, and a control unit are added to obtain a functional pneumatic circuit to actuate and control the left and right leg exercises mechanisms. A 2/2 proportional valve works as a proportional flow control valve, while 4/2 valves are used to select which exercise perform, leg curl or leg extension. Pressure sensors are used to keep track of the controlled pressure closing the loop of the control system and to monitor the pressure in the circuit to avoid failure. Angular sensors measure the mechanism angular displacement in order to compute all the elements of Equation (10) and, therefore, to define the reference pressure

. Silenced exhausts are implemented to minimize the machine noise. A compressor, a pressure regulator valve, and a exhaust valve guarantee that the pressure within the circuit is kept at a defined value slightly lower than the minimum value of

. This condition is required to maintain the correct flow direction from the cylinder to the air tank, because, in the real pneumatic circuit, the accumulator pressure increases during the exercises.

In

Section 4, some simulation results related to kinematic and dynamic performances of the system are reported.

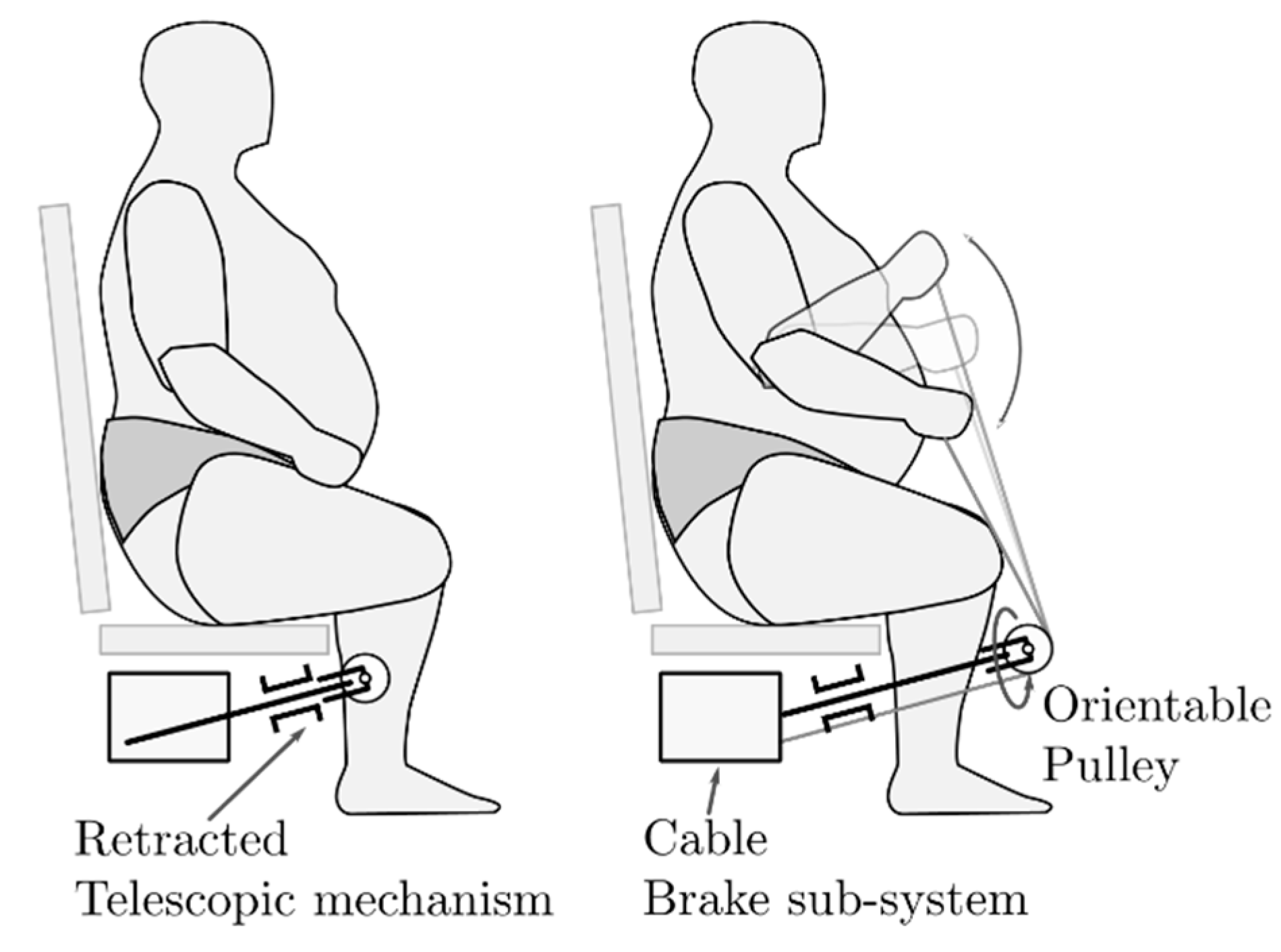

2.4. Upper Body Exercises Mechanism

Figure 9 depicts the second system designed in order to exercise the upper body of bariatric individuals. A cable system enables the user to several exercises for the arms, shoulders, and chest. This architecture is highly inspired by the innovative wheelchair propulsion system proposed in [

25,

26] because it allows its user greater mobility while pulling the cables.

Like for the leg exercises mechanism, the user sets a desired opposing force to their exercises. An electronically controlled brake keeps this force constant as desired. In parallel to the brake, a torsional spring acts as a cable rewinder.

Figure 9 shows a single orientable pulley in the cable system that is required to perform many exercises without difficulty. Depending on the space under the seat, other pulleys can be added to guide the cable to the braking system correctly.

The upper body exercises mechanism follows the same principle of the whole machine: the machine should not appear as gym equipment, but it should look like an ordinary chair. For this reason, a telescopic bar enables to hide the mechanism under the seat when not in use. When required, the telescopic bar can be extracted and locked to position to perform the workout.

The development of this sub-system is still at an early stage, and it is not fully defined. However, the concept is to develop a sub-system that can oppose a controlled and constant resistance to the cable pulling. Several actuator systems could be suitable to perform this task, but the one that could be more interesting is a magnetic particle brake system. Magnetic particle brakes are commonly used in cable tension control because they can apply a torque very accurately with a fast response.

2.5. Structure and Regulation Mechanisms

The final step of the rehabilitation machine is the design of its structure and of some regulation mechanisms to enable individuals to correctly carry out the exercises and to accommodate a wide range of different individuals.

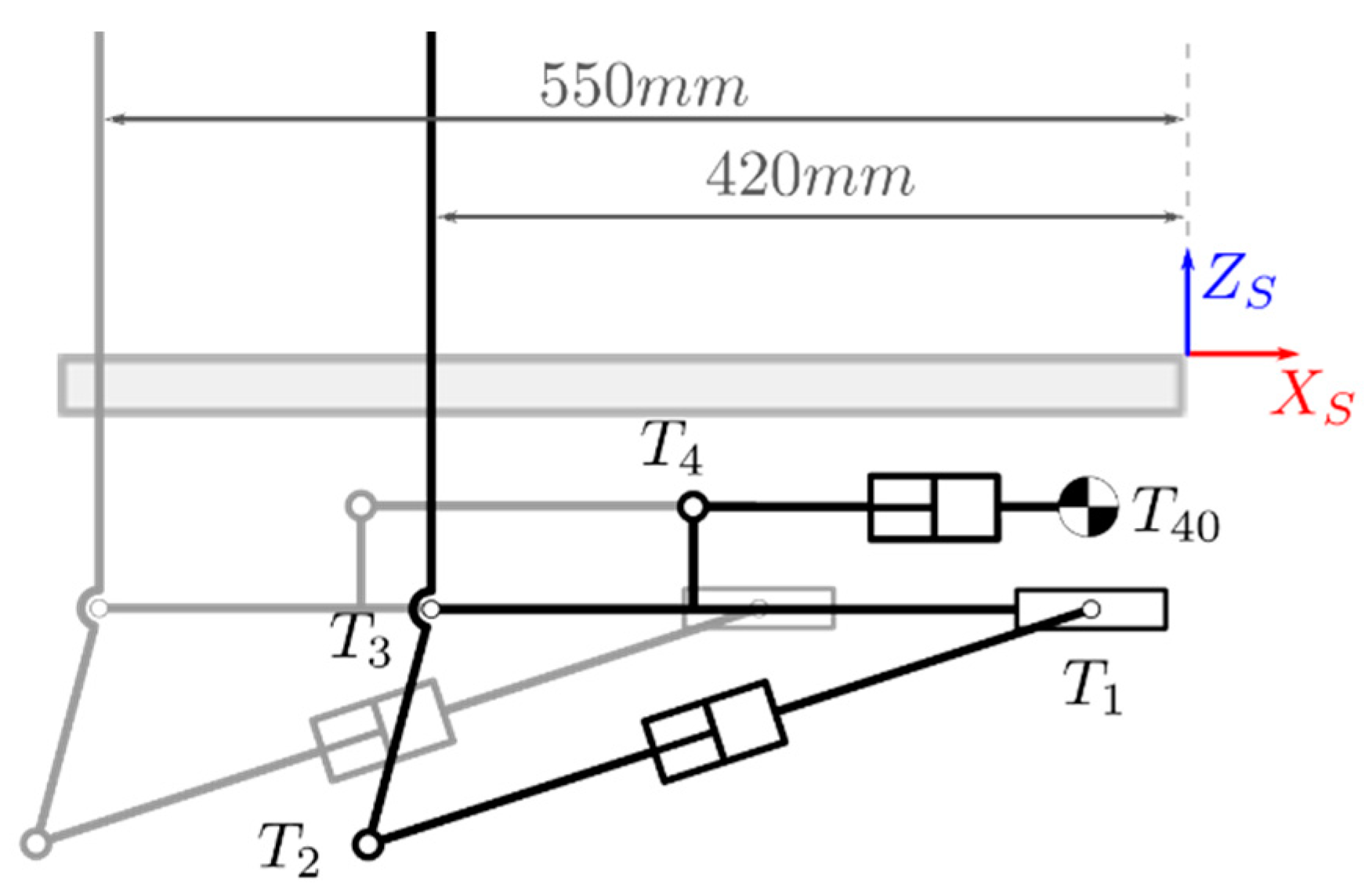

The first requirement of the structure is obviously to support the weight of the user and the whole machine. However, the structural elements of the machine are mainly made of bars, rods, and profiles; therefore, most of the weight is due to the user and, given the pathology of the potential users of the machine, this weight can be considerably high. The maximum weight of 400 kg has been considered to size the structure with a proper safety factor. The weights distribution of the user and the machine leads to another requirement of the structure. The base of the structure must be wide enough to guarantee the stability and avoid rollovers also during the exercises when relevant masses are in motion. Nevertheless, at the same time, it is desirable to minimize the size of the base and at least guarantee that the machine can go through hospital and main household doors. The last requirement related to the size of the machine is about the free space under the seat. The free space under the seat should be large enough to integrate all the required sub-systems. This volume can be approximated by a rectangular box with a base of and a height of when completely retracted. Hence, the components that not require direct interaction with the mechanism or the structure are integrated into a separated volume that is connected with the machine through pneumatic lines and electrical connections. Parts of these components can be the air tank, the compressor, the control unit, and the human-machine interface.

Individuals of different body sizes could use the machine; hence, it is mandatory to adapt the machine to the user by lifting and rotating the seat and by adjusting the back of the chair. These regulations are needed to allow the user to perform his exercise correctly and comfortably. Moreover, it is useful to underline again that the machine should look and work, as close as possible to a chair, in particular when it is not used to do physical activities.

A scissor-lift mechanism lifts the seat in order to accommodate the shortest and tallest individuals. From the anthropometric data, the increment in height should be at least . The same mechanism also acts as a structure; hence it is the same on the left and right side of the machine. The two sides are linked together to improve stiffness and stability and to avoid any asynchronous motion of one side relative to the other.

Figure 10 display the schematic representation of the scissor-lift mechanism in its two extreme configurations. The revolute joint

and the sliding revolute joint

are fixed to the bottom structure, while the sliding revolute joint

and the revolute joint

are placed into the upper one, where the seat is fixed. Acting on a linear actuator fixed with two revolute joints in

and

it is possible to change the height of the seat. Several variations of the actuator placement had been considered, but, for the sake of simplicity, more empty volume under the seat, and slightly better performance, only this one is presented here.

Table 2 collects the parameter useful to define this mechanism. In the figure, there are other angles useful to write the input-output relation compactly.

From

Figure 10, it is possible to obtain:

knowing

as a function of the geometric parameters of the mechanism and of the variable actuator length, it is possible to derive the relation between the seat height and the actuator length:

From this equation, it is possible to optimize the parameters with an iterative process with the purpose of design a mechanism that can lift the seat of at least with a feasible actuator stroke. The instantaneous transmission ratio that, in this case, is evaluated only numerically, and should be as constant as possible to obtain a smooth motion.

Given all the previous angles, it is also possible to evaluate the force required to stand a user with a weight of

using the free body diagram of the mechanism derived from

Figure 11.

It is clear from the equation that it is irrelevant where the load is applied from the actuator perspective.

The back of the seat implements two degrees of freedom as regulations. A translational motion sets the depth of the seat to align the knee of the user correctly to point

(

Figure 12). One end of a linear actuator,

, is fixed to the upper structure while the other one,

, is fixed to a structure where the back of the seat is mounted. The actuator moves a structure where the revolute joints

and

are fixed. The back of the chair rotates about

employing another linear actuator fixed between

and

(

Figure 13). This second degree of freedom allows the user to improve the chair comfort, but it also enables the possibility of doing some abdominal exercises if the back is reclined completely. The seat depth spans from 420 to 550 mm from the reference

S, while the back can rotate up to 45° from the vertical direction.

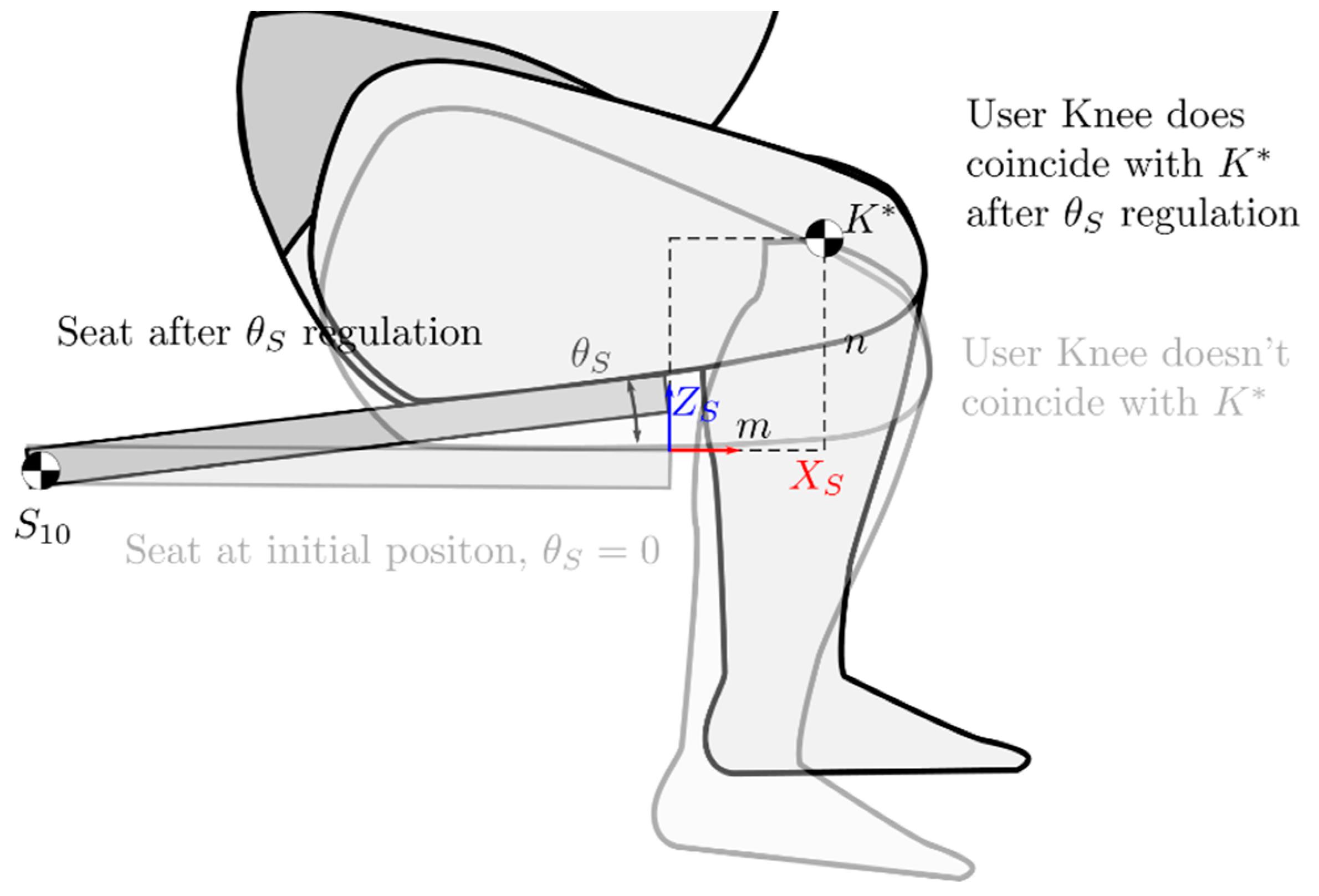

The final regulation allows tuning the alignment between the knee of the user and the point

finely. Point

is defined with respect to the upper structure so it does not move. As shown in

Figure 14, the seat is fixed to the upper structure through the revolute joint

, the user can manually adjust the seat inclination, defining an angle

(that goes up to 2.5°) about the revolute joint

. To aid the user during this process, a removable element represents the position of the point

. At this stage of the study, the mechanism is not completely designed.