1. Introduction

A vehicle active suspension is a mechanical vibration system. The active suspension aims primarily to minimize the transmission of vertical road forces to the sprung mass (passenger comfort) and to maximize tire–road contact (road holding) [

1]. An active suspension system must operate within safe travel ranges to avoid exceeding the suspension travel limits. Consequently, the hydraulic actuator of the active suspension generates vertical forces to enable a compromise between ride comfort, suspension deflection, and road holding. To ensure passenger comfort, the hydraulic actuator can absorb the road energy transmitted to the sprung mass. Further, the actuator can generate vertical forces to improve car stability and safety. Although the active suspension is an important system in the vehicle structure, it must deal with several challenges. For example, the system has several inherent undesirable dynamic characteristics, such as nonlinear dynamics, parametric uncertainties, and external perturbations [

2]. Moreover, it forces a trade-off between passenger comfort, road holding, and limited suspension travels.

Many control strategies have been applied in vehicle systems, which have multiple modeling systems. A high-precision hydraulic pressure control based on linear pressure drop modulation in valve critical equilibrium state was developed in [

3]. The control methodology in that study was a sliding mode control based on high-precision hydraulic pressure for an automobile brake system. The experimental tests and validation system showed improvements in the control performance and robustness. In [

4], a dynamic state estimation for the advance brake system of an electric vehicle was implemented by using deep recurrent neural networks. In that study, an integrated time series model based on multivariate deep recurrent neural networks with long short-term memory units was applied for brake pressure estimation of the electric vehicle system. The test results showed the effectiveness of the proposed integrated method. In [

5], a neuro-fuzzy adaptive control for a full car nonlinear active suspension with onboard antilock braking system was investigated. A comparative study was done between the intelligent control system and passive suspension. The method showed an improvement in control performance.

The vehicle active suspension system is among the systems that have been most studied in recent years. Active suspensions in vehicles serve mainly to isolate the car cabin from road perturbations and provide vehicle handling under different operating conditions. Many researchers have developed control strategies for these systems. Testing and simulation of a motor vehicle suspension were carried out in [

6]. In the study, experiments were done by applying impulse road input perturbation. The results showed reduction of transmitted road energy to the system. Road profiles on a rig for indoor vehicle chassis and suspension durability testing were reproduced in [

7]. An impulse road input was applied in the test rig. The results showed control performance improvements. Other studies have been developed for the active suspension system in a bed to overcome the dynamic nonlinearities and parametric uncertainties present. In [

8], a sliding mode and fuzzy hybrid control system were developed to overcome dynamic nonlinearities and reduce control chattering for a quarter-car active suspension. There, a fuzzy hybrid control system was designed to track a force and a position and reduce the control chattering. The controller provided control performance improvements. On the other hand, the road holding and the suspension travel limits were not addressed.

Many researchers have also developed control strategies for active suspension systems. For example, in [

9], an adaptive tracking control was developed to overcome the dynamic nonlinearities for a non-ideal actuator of a quarter-car active suspension. The actuator’s nonlinearities of both dead-zone and hysteresis were addressed in that study. The experimental results showed a better balance between isolation performance and energy consumption for the active suspension. Even though several road case designs were applied, road holding was not clearly indicated in results. An adaptive neural networks’ control system was designed by [

10]. In that study, the road design could not generate the tire liftoff phenomenon to indicate road holding. In [

11], a backstepping control law was investigated to monitor suspension travel by using a nonlinear control filter. The results showed an improvement in control performance. However, road holding was not addressed. A multi-objective control system for a constrained active suspension, designed based on both barrier and quadratic Lyapunov functions, was developed in [

12], with results showing control performance improvements. However, the system did not address tire liftoff phenomenon. In [

13], an adaptive control was developed for nonlinear active suspension. While the system provided suspension deflection and road holding, its bumpy road design did not address tire liftoff either. In [

14], an adaptive backstepping-based tracking controller was investigated for nonlinear half-active suspension. In that study, zero dynamics system was applied to ensure that all dynamic order errors were bounded. Although the results showed improvements in control performance, tire liftoff was not tested. In [

15], an adaptive backstepping tracking control was developed for an uncertain nonlinear active suspension. The control consisted of a model-reference control combined with coordinated adaptive backstepping control systems. Simulation results showed control performance degradation and, once again, tire liftoff was not examined. In [

16], a linear disturbance observer coupled with a sliding mode scheme was developed for an active suspension with a non-ideal actuator. The results showed compensation improvements despite the presence of a dead-zone and hysteresis, as well as modeling uncertainty. In this case as well, the tire liftoff effect was not considered. In [

17], an adaptive neural networks’ control was developed for a restricted quarter-car active suspension. Both the barrier Lyapunov function and zero dynamics system were applied to prevent any violation of the system’s constraints. There was an improvement in the control performance, but the tire liftoff was not evaluated.

As we can see, while previous works showed improvements in control performance, they universally did not examine tire liftoff. Therefore, the results in previous studies cannot indicate road-holding robustness.

In general, high-frequency bumpy road input can generate tire liftoff phenomenon. Thus, road holding can clearly be addressed. In [

18], an approximation-free control was developed for quarter-car active suspension. In that study, both a random road and a high-frequency bumpy road designs were examined. The results showed an improvement in road holding when the random road design was applied. Even though previous studies were developed, improving in control performance, the researchers did not explicitly address both a trade-off between ride comfort and road holding, and a trade-off between ride comfort and suspension travel limits.

In this study, a novel control system was developed to handle the inherent trade-off between passenger comfort/road holding, passenger comfort/suspension contraction limitation, and passenger comfort/suspension expansion limitation, as well as to overcome the dynamic nonlinearities and parametric uncertainties of quarter-car active suspension systems. The novelty of this study lies in its aim, which is two-fold. On the one hand, it aimed to overcome and prevent the dynamic tire liftoff phenomenon by implementing a new model of a dynamic landing tire system. On the other hand, it aimed to avoid exceeding suspension travel limits. We broke down the suspension deflection into two different suspension travel limits, namely, suspension contraction limitation and suspension expansion limitation. We then redesigned a nonlinear control filter that was introduced in [

11]. The redesigned filter became three regions, which are a dead zone, a dynamic landing tire nonlinear function, and a suspension deflection nonlinear function. This design of the nonlinear control filter can accommodate and improve the trade-off between passenger comfort, road holding, and suspension travel. Therefore, the novel adaptive control system ‘NAC’ system is an adaptive neural networks’ backstepping control system coupled with the nonlinear control filter. The adaptive neural networks’ control system can deal with unknown smooth functions of the modeling system. The summarized contributions of this article are:

The NAC was established to achieve passenger comfort while keeping road holding and prevention of exceeding suspension travel limits.

The NAC was also designed to reduce suspension travel oscillations.

A dynamic landing tire modeling system was developed to evaluate a required tire vertical displacement, which maintains road holding for the car.

The suspension travel limits were separately chosen to be suspension contraction limitation and suspension expansion limitation in order to realize operation conditions.

In NAC structure, the adaptive radial basis function neural networks were designed to approximate nonlinear and unknown bounding functions in the modeling system.

Finally, simulation examples demonstrated the performance of the NAC in enhancing passenger comfort, maintaining road holding, avoiding reaching suspension travel limits, and reducing suspension travel oscillation.

The rest of the paper is broken down as follows.

Section 2 presents the notations used and the problem statement.

Section 3 describes the control law design, which includes the nonlinear control filter, the adaptive neural networks’ backstepping control design, and zero dynamics system.

Section 4 discusses the illustrated example of a comparative study of a filtered active suspension, an unfiltered active suspension, and a passive suspension.

Section 5 presents the conclusion and future works.

2. Notation and Problem Statement

The primary purpose of the active suspension is to provide a compromise between ride comfort, car–road stability, and safety [

19]. This suspension is mainly composed of a sprung mass, an unsprung mass, a spring suspension, a suspension damper, a tire, an electrohydraulic servovalve system, and other accessories [

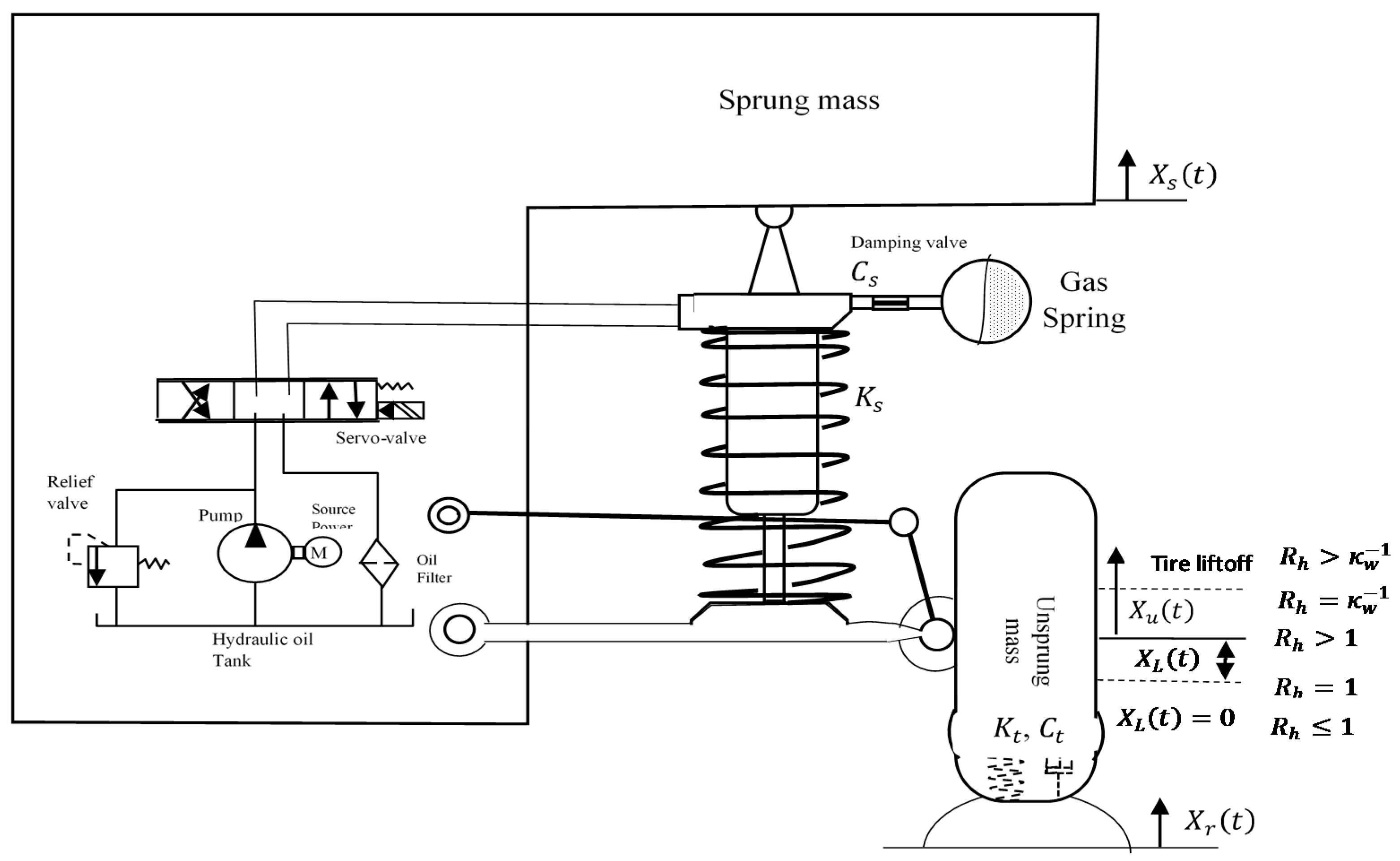

20], as shown in

Figure 1. Passenger comfort definition is to isolate the sprung mass from road perturbations. Moreover, road holding definition is to handle vehicle–road stability. The electrohydraulic servovalve system (EHSS) of the active suspension generates hydraulic forces to provide a compromise between ride comfort and road holding. In

Table 1, the nomenclature for the active suspension system parameters is listed with accompanying descriptions as follows.

The mathematical modeling of the quarter-car active suspension can be described as shown in

Figure 1, while the sprung mass of the same is described as in [

21]:

The unsprung mass dynamic system with tire liftoff can be modeled as [

22].

The spring-damper forces

can be modeled as:

The dynamic tire force

is modeled as:

In this study, we considered friction forces, which consisted of a viscous friction, Coulomb friction, and a stiction friction phenomenon [

23]. The friction forces are undesirable effects on the control performance. The friction forces

of the hydraulic servosystem can be presented as in [

24].

In Equation (2), the tire must contact the road surface; otherwise, it loses the road contact (tire liftoff phenomenon). The following formula is used to express road holding:

Suspension travel limitations are other suspension restrictions. The maximum allowable suspension deflection can be represented as [

17]:

In real operating conditions, both suspension travel limitations do not always equal the same. In this study, the suspension travel limitations became as following the form:

where the

is a suspension travel contraction limit and the

is a suspension travel expansion limit.

The electrohydraulic servovalve system for the hydraulic actuator and the servovalve can be presented as [

25]:

In this study, a new modeling for a dynamic landing tire system was developed to avoid the dynamic tire liftoff phenomenon, as shown in

Figure 2.

Dynamic tire liftoff only occurs if the unsprung mass position

is higher than the road position

. However, Equation (6) does not consider this condition. Hence, we can rearrange Equation (6):

where

is a road holding ratio.

Therefore, the vertical tire displacement

can use

as a required tire landing position.

In order to avoid tire liftoff, the tire landing position must be evaluated before the critical road holding ratio ‘

’. Thus, the dynamic landing position

is created in the following form:

where the

is an adjustable factor for the road holding ratio

.

Moreover, the differential road holding is differentially determined, as follows:

Equations (12) and (13) can represent the dynamic landing tire system into the state-space modeling system.

3. Control Design

This section consists of three subsections: Nonlinear control filter system, adaptive neural networks’ backstepping control system, and zero dynamic systems.

3.1. Nonlinear Control Filter

In [

11], a nonlinear control filter was developed to adjust the trade-off between passenger comfort and suspension travel for a quarter-car active suspension system. In this study, we redesigned the nonlinear control filter by modifying a nonlinear tire land function

. The input filter was the unsprung mass position

. Therefore, the nonlinear control filter was able to compromise between passenger comfort and road holding and also suspension travel, as follows:

where the symbols

,

, and

are positive constants, and the suspension travel

.

The nonlinear function of suspension travel

is a positive nonlinear function.

where

is a chosen constant

,

is a chosen constant

, and the

are positive constants.

The landing tire nonlinear function

is a positive nonlinear function and evaluates as follows.

where

and

are positive constants.

It can be concluded that the flow chart of the nonlinear control filter dynamic system is sketched in

Figure 3. When the filter dead-zone

was activated, the nonlinear bandwidth filter became a chosen small constant

to obtain passenger comfort. Otherwise, at least one of the suspension constraints

was expected; the nonlinear function

rapidly increased the filter bandwidth. Thus, the suspension travel became stiff:

The state-space modeling system was built from Equations (1), (2), (9), (10), and (13)–(15). Therefore, the state-space modeling of the filtered active suspension system had nine variables, as follows.

State-space modeling system:

3.2. Adaptive Neural Networks’ Backstepping Control Design

In this section, an adaptive neural networks’ backstepping was developed for the recursive closed-loop system in Equation (18). Lyapunov’s stability theory was employed to guarantee control stability. One advantages of this technique is that it allows circumventing the unmodeled model uncertainties of multiple dynamic systems. Several research studies have applied the backstepping control technique to overcome the inherent nonlinearities and uncertainties of the system. The backstepping design complicity is to determine regression matrices of uncertain nonlinear functions. In order to linearize the state-space modeling and simplify the backstepping control system, a linear radial basis function neural networks (RBFNN) was implemented, and could deal with unknown functions. Hence, the state space modeling of the adaptive neural networks’ control (ANNC) design was reduced to fourth orders.

Thus, the functions

and the parameter

are chosen as follows.

In order to approximate the unknown functions

, we needed to know the aspect of the radial basis function neural network. The radial basis function neural networks (RBFNN) can approximate nonlinear and unknown bounding functions. In this study, we used a linear RBFNN to approximate the unknown functions of the modeling system. The linear RBFNN had one hidden layer, a fixed size, and fixed moving basis functions [

26,

27]. Therefore, the unknown smooth functions

could be presented as [

28,

29]:

where the input vector

, the

is the approximation error, the

is an unknown weight vector,

, the

is a basis function vector,

, and the

are hidden Gaussian functions, which satisfy:

where the

are the centers of the receptive field and the width of Gaussian function, respectively.

Therefore, approximate smooth functions

could be estimated by RBFNN as follows:

To minimize the approximation error, the optimal weight value ‘

’ of the RBFNN was defined [

30]:

As a result, a tiny positive design error

could have occurred:

where

and

.

The “centers and widths” of the RBFNN were chosen based on a range of input values. Therefore, we applied a gradient descent learning algorithm to obtain the optimal RBFNN parameters such as the centers , widths , and number of nodes .

The backstepping control was organized into four backstepping control steps, as follows.

Step 1: Sprung mass velocity

The control coordinate

was defined as:

To stabilize the controller, let us consider a quadratic Lyapunov function candidate

The Lyapunov derivative function

of step 1 becomes:

To stabilize the system, the derivative control coordinate

becomes:

where

is a positive constant.

Then, the virtual control function

is:

Substitute

into

:

Step 2: Sprung mass dynamic acceleration

We can define the virtual control coordinate

as:

Lemma 1: The control derivative functionproduces two parts, namely, a countable partand an uncountable part [

31].

The is defined.Then, the partial derivative of the function is:Therefore, the uncountable part consists of unknown smooth functions:The countable part is a smooth function described as:Thus, the total unknown functions at step i-1 are defined:The unknown function can be represented by the RBFNN as follows:Therefore, the Lyapunov function candidate design is selected:By applying Lemma 1, the Lyapunov derivative function candidate becomes:The adaptive RBFNN law is defined [

32,

33]:

where the is a positive definite matrix and the is a positive constant. Therefore, the selected virtual controlis:By substituting Equations (35) and (36) into the Lyapunov derivative function:

The functionis moved to the next step. Step 3: Hydraulic actuator dynamic system

The virtual control coordinate

is:

Hence, the

derivative function becomes

The Lyapunov function candidate

design is selected:

By applying Lemma 1, the Lyapunov derivative function candidate

becomes:

Therefore, the selected virtual control

is:

By substituting Equation (42) into the Lyapunov derivative function

:

The right-side terms in are moved to the last step.

Step 4: Servovalve dynamic system

In this step, the control signal design

is designed and the overall Lyapunov candidate stability is guaranteed. The virtual control coordinate

is selected:

The time derivative

is:

The overall Lyapunov candidate function

is selected as follows:

where

is a positive constant.

By using Lemma 1, the overall Lyapunov derivative function

Equation (46) becomes:

Thus, the design control signal

is selected:

The RBF neural network adaptive law

is expressed as:

The adaptive control law

is designed by the triangularity condition. The triangularity condition technique of the adaptive law is applied to estimate the unknown coefficient of the control signal

. The lower and upper bound known values of the uncertain parameter

is defined as

and

, which satisfies:

Hence, to guarantee

, a projection-type adaptive law

is applied [

32]:

According to the control signal

compact set, the

is a function of the state variables

. To ensure the Gaussian basis function mapping, the constant scaling factors of the operational hydraulic pressure

and the servovalve area

are applied as follows:

Therefore, the RBFNN input variable has nine input variables.

Applying inequality [

33] for term

in Equation (51):

The RBFNN error function

is satisfied:

where

is a designed positive error.

Applying Young’s inequality [

34]:

We apply the completing squares for each step [

35] as follows:

where the factors

and

are positive values with

,

, and the

being the maximum eigenvalue of the positive definite matrix

.

By integrating the overall Lyapunov derivative function

in Equation (56), we obtain:

where the

and

are the positive matrices.

The is thus bounded. Therefore, , goes to zero automatically when .

In conclusion, the

guarantee Barbalat’s Lemma [

36] and the

are uniformly bounded.

3.3. Zero Dynamics’ System

In

Section 3.2, the fourth-order error systems

existed to design the adaptive neural networks’ backstepping control system. On the other hand, there were nine state-space modelings for the active suspension system in Equation (18). The zero dynamics system can find the other five closed-loop systems of the ninth-order error system. In order to obtain the control output

, the minimization force transmits to the sprung mass can be equivalent, as follows:

In order to find zero dynamics closed-loop system of the other state-space system

, the control output

and first and second output derivative functions

must be zeros, as follows:

Substitute Equations (59)–(61) into state-space Equation (18). The zero dynamics’ state-space modeling system becomes:

The nonlinear derivative functions of

and

satisfy:

and the

is a static tire deflection defined as:

The positive nonlinear function

is a function of the suspension travel and the tire liftoff as follows:

Zero dynamic Lyapunov candidate is designed to guarantee its stability. Let us consider the linearized state-space model as:

The Lyapunov candidate

is suggested:

Therefore, the zero dynamics’ Lyapunov candidate derivative function

is:

In the previous equation

, we applied the Young’s inequality for the second term on the right side:

Applying inequality, for term

in Equation (69):

Therefore, the Lyapunov derivative function

becomes:

where

is a positive tunable factor:

By integrating the overall Lyapunov derivative function

into Equation (72), we obtain:

Hence, is uniformly bounded.

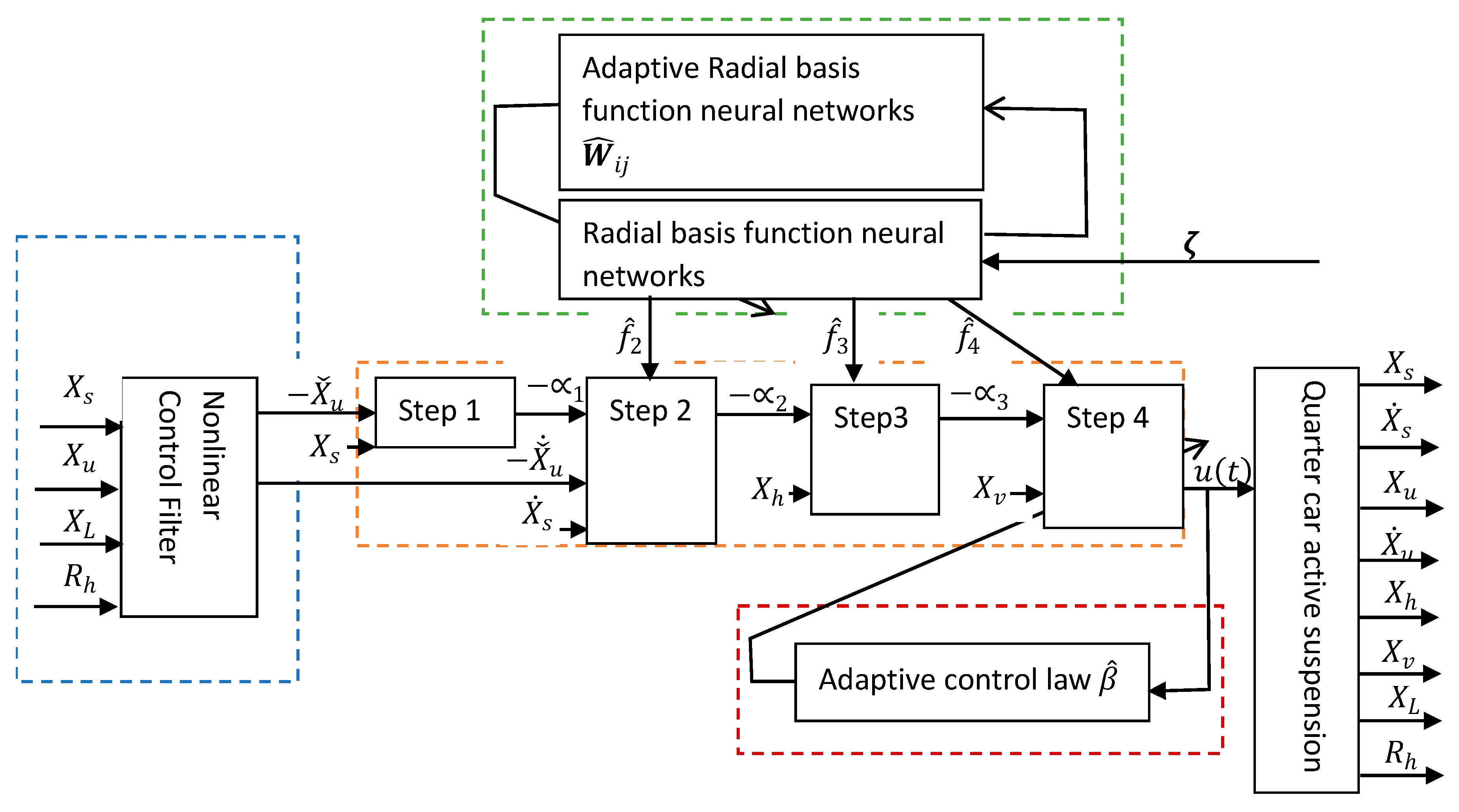

Finally, the flow pattern of the NAC design is sketched in

Figure 4. There were four control paths, which combined together to build the NAC system.

The path blue is the nonlinear control filter. The operational backstepping control system is shown in the orange bath. The unknown functions are approximated by using the green path for the radial basis function neural networks ‘RBFNN’ system. The fourth path is the adaptive control law to estimate .

4. Simulation and Results’ Discussion

To carry out the NAC control target successfully, we applied a comparative simulation between a filtered active suspension, an unfiltered active suspension, and passive suspension. By definition, the filtered active suspension was controlled by the novel adaptive control system (NAC), while for the unfiltered active suspension, the active suspension was only controlled by the adaptive neural networks control system (ANNC) with no coupling with the nonlinear control filter. To illustrate the comparative study, we considered several road perturbation designs and the active suspension simulation data. The simulation data of the active suspension system are presented in

Table 2. The ANNC and the active suspension setup data were selected from the control sensitivity and the literature review. The nonlinear control parameters were manually adjusted.

First, we analyzed a comparative study about control performance between the filtered active suspension NAC and another control system, which was investigated in [

37]. In [

37], a high gain observer-based integral sliding mode control ‘HGO’ was developed for quarter-vehicle active suspension. A bumpy road input design that was used in [

37] was applied for the comparative study.

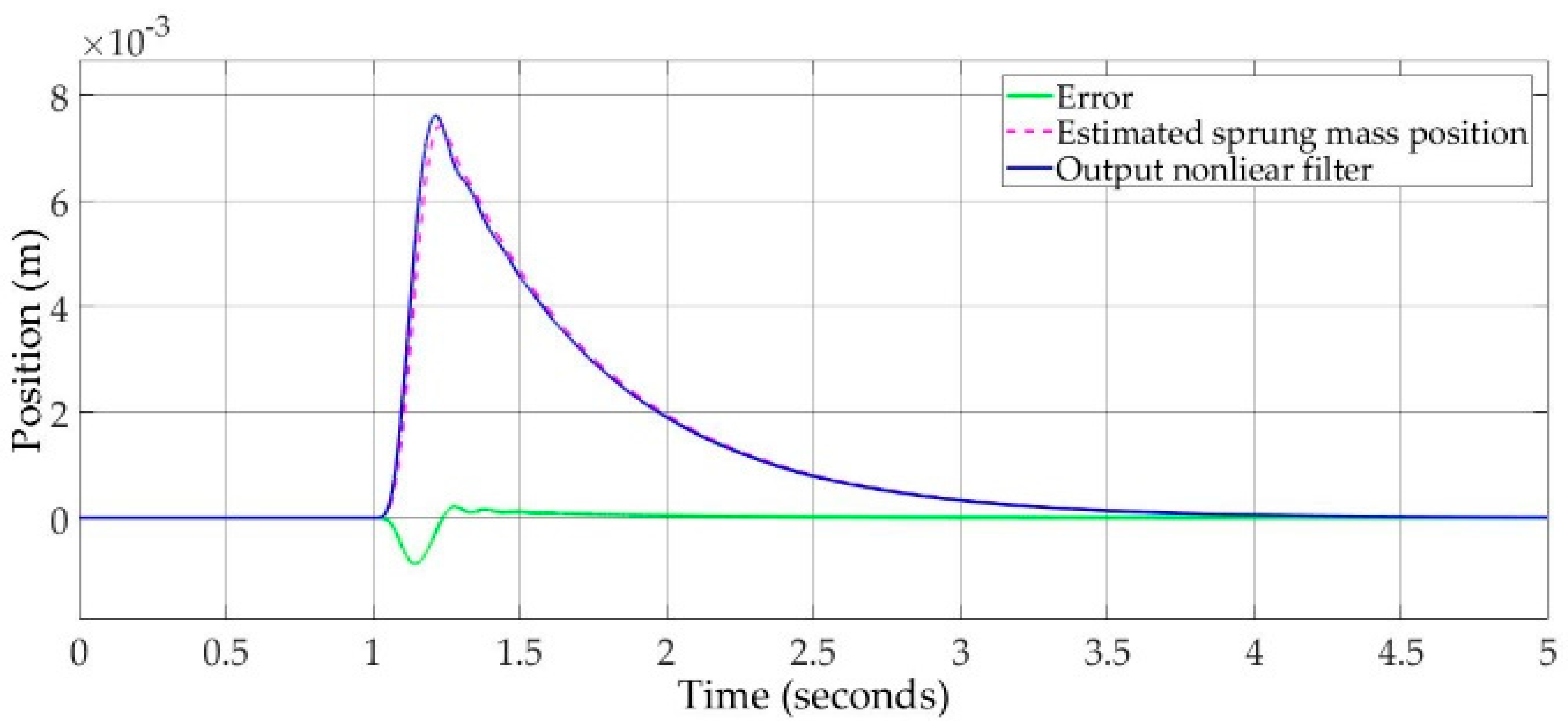

Figure 5 shows the output nonlinear control filter

the estimated sprung mass position

and their error. The maximum error of the NAC output was −0.009 m and its percentage of 10% at 1.2 s. In [

37], the results showed a high control performance that was less than 1% tracking position error.

In

Figure 6, the estimated sprung mass velocity

, nonlinear filter output time derivative

and their error are displayed. The maximum absolute error was 0.01 m/s at 1.15 and 1.25 s. In [

37], the velocity tracking error was about 40 m/s at initial time and 18 m/s at 1.25 s.

Table 3 explains the control performance for both of the NAC and the HGO.

Even though the NAC had tiny tracking error in position compared with that in HGO, the NAC had better performance of tracking error velocity, as in

Figure 6.

Second, we implemented four road design cases in this study, as follows.

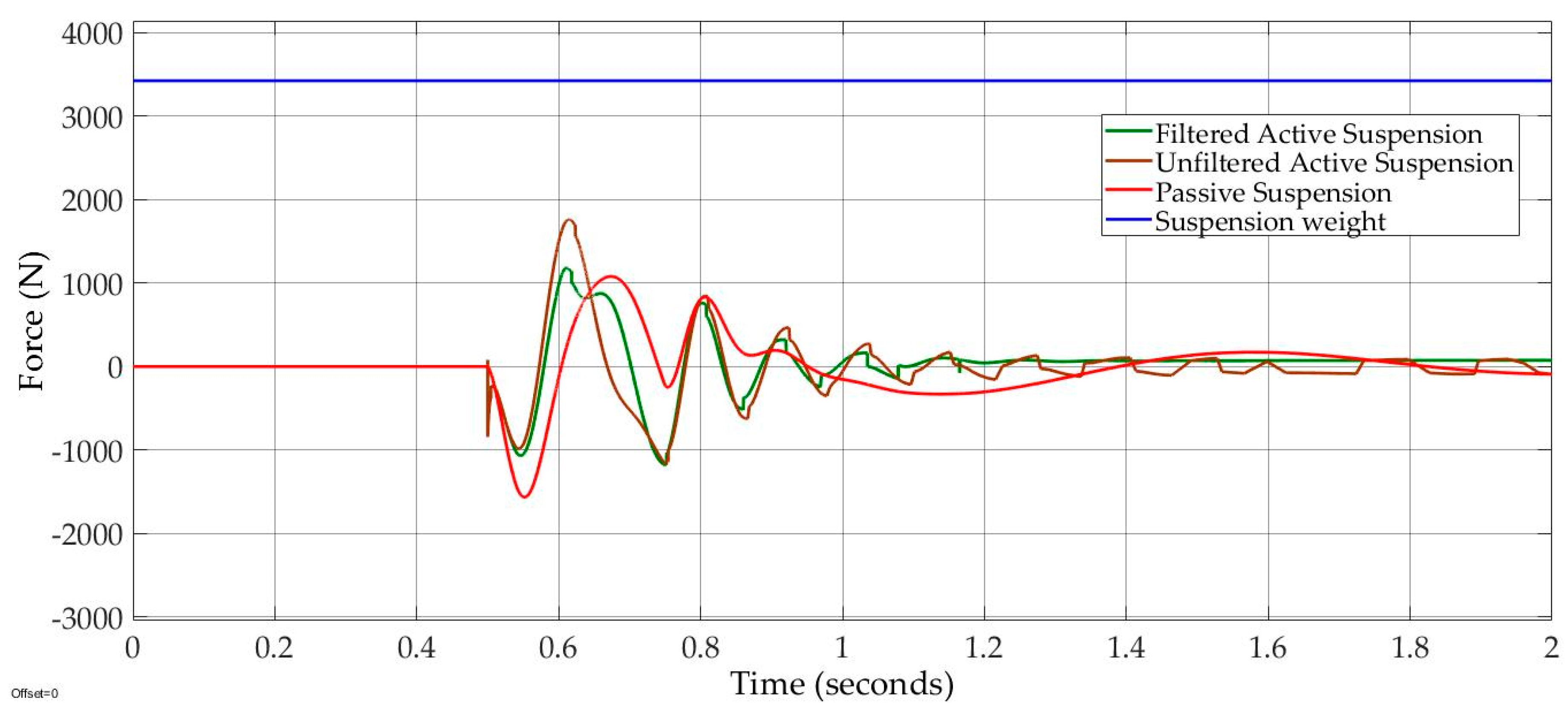

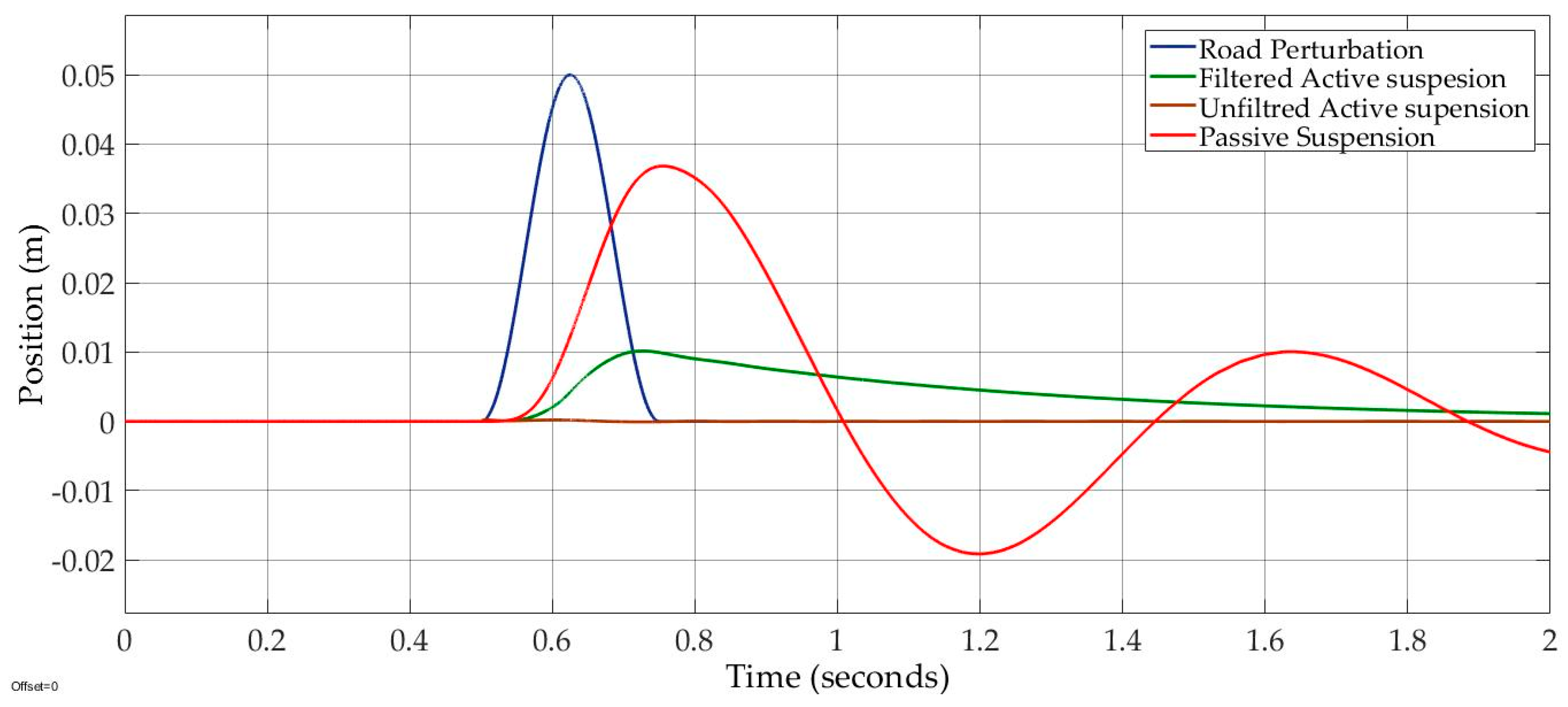

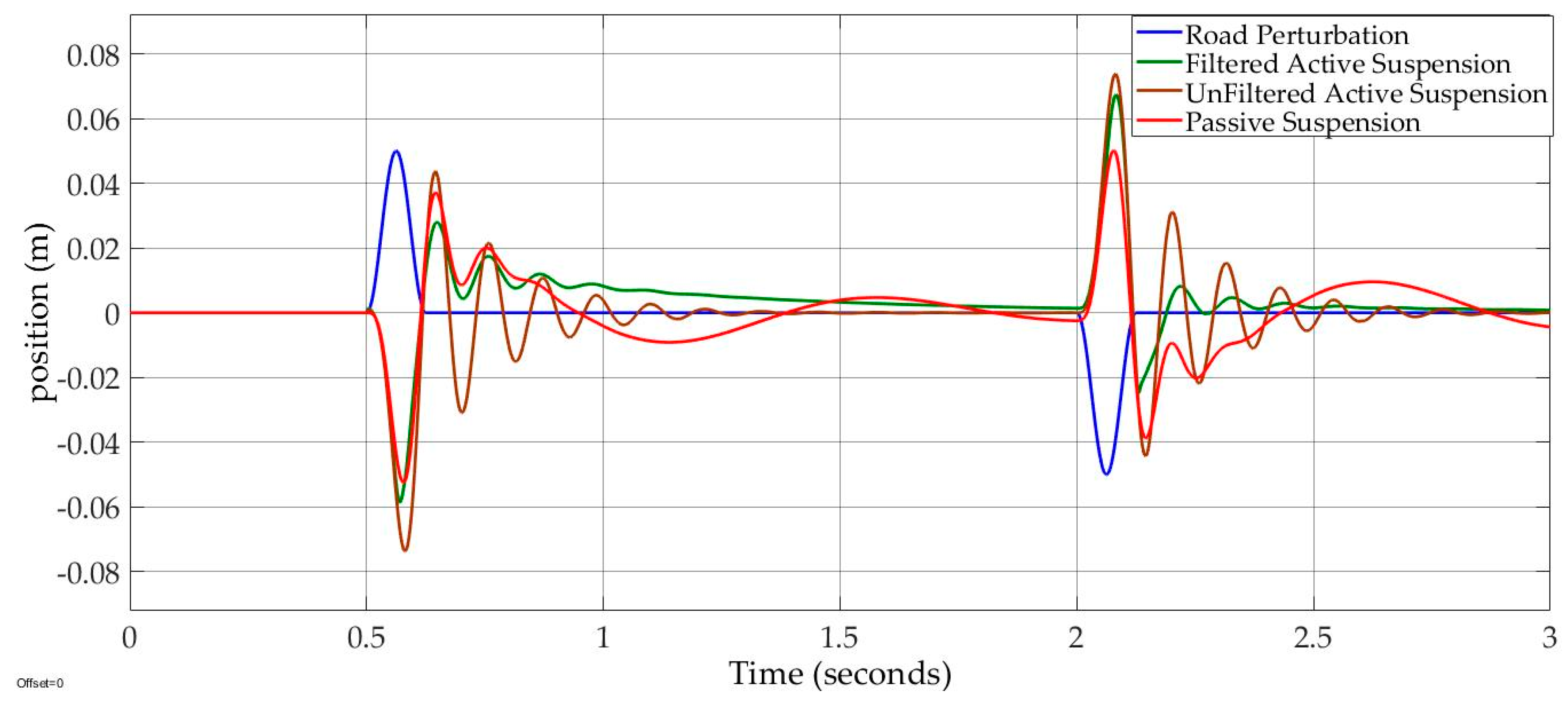

Case 1: Road design excitation “bumpy input” had an amplitude ofand a frequency of This case has been used by many researchers in order to stimulate active and passive suspensions. In

Figure 7, the maximum amplitudes of the dynamic tire force of the filtered active suspension, unfiltered active suspension, and passive suspension are smaller than the suspension weight by 68%, 48%, and 69%, respectively. Also, there was a 39% oscillation reduction in the filtered active suspension versus in the unfiltered active suspension. As result, all dynamic tire forces did not exceed the suspension weight; the filtered and the unfiltered active suspensions and passive suspension held on the road surface.

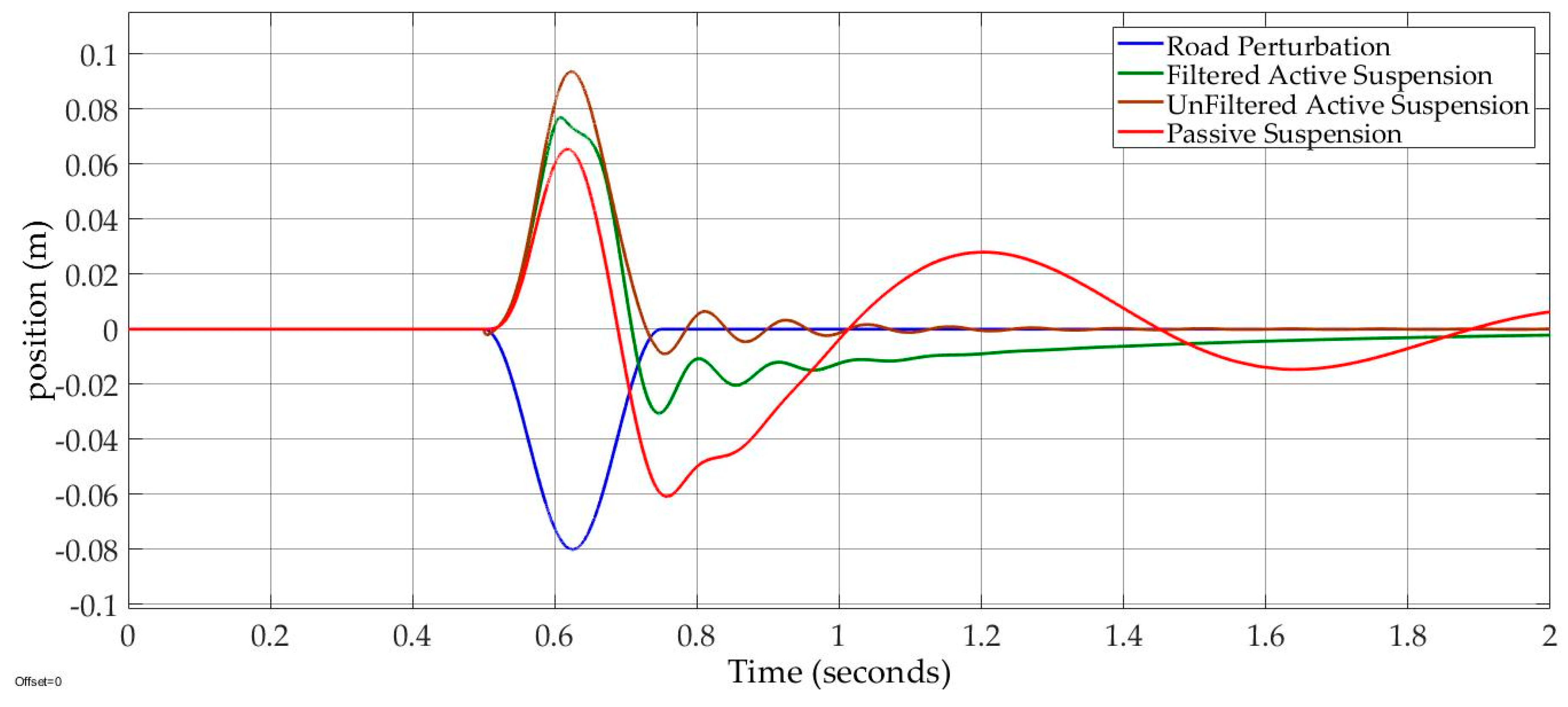

The comparative transient response of both filtered and unfiltered active suspensions are shown in

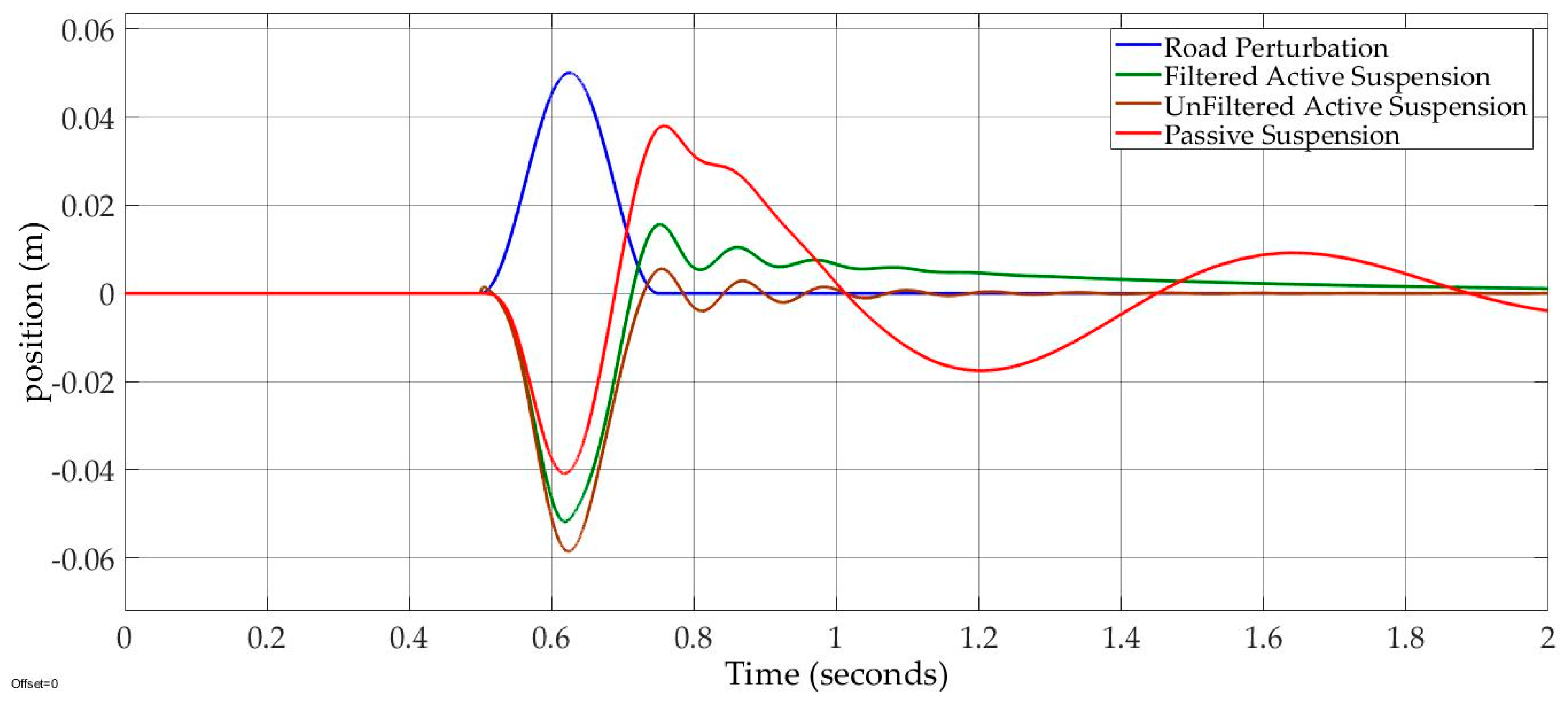

Figure 8. Although the sprung mass position of filtered active suspension provided 80% road compensation, as compared to 99.6% with the unfiltered active suspension, the filtered active suspension smoothly decayed to the origin.

Also, the filtered active suspension provided 75% improvement compensation of that in passive suspension. Therefore, passenger comfort was improved as compared to the case with the passive suspension. In

Figure 9, there is an improvement in suspension travel for the filtered active suspension versus the unfiltered suspension, in which the maximum values of the filtered and unfiltered suspension travels were −0.052 m at 0.62 s and −0.059 m at 0.62, respectively. The filtered suspension travel oscillation was reduced by 85%, versus 50% with the passive suspension.

In conclusion, both filtered and unfiltered active suspensions obtained good transit responses. The filtered active suspension provided better suspension travel oscillation and a smaller suspension travel compared to the unfiltered active suspension. Also, the reduced suspension travel oscillation with the filtered active suspension was improved by 35% over what was seen in the passive suspension. The vehicle road stability could not be indicated by Case 1, which cannot generate tire liftoff phenomenon. Therefore, we introduced Case 2 for bumpy and pothole impulse road design. The frequency of this case was 16π rad/s, and its amplitude was the same as that in Case 1.

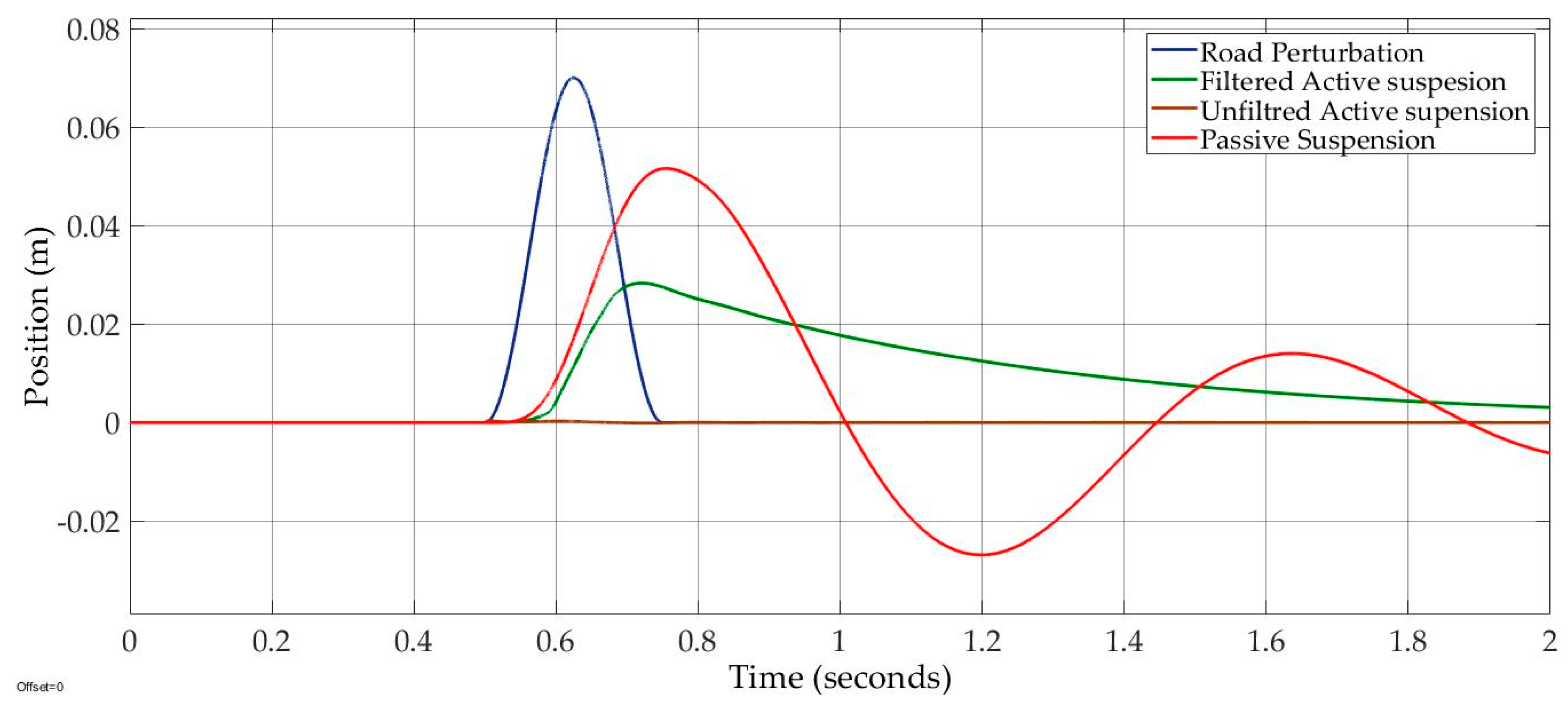

Case 2: Road design excitation “bumpy input” had an amplitude 2.5 cm and a frequency.

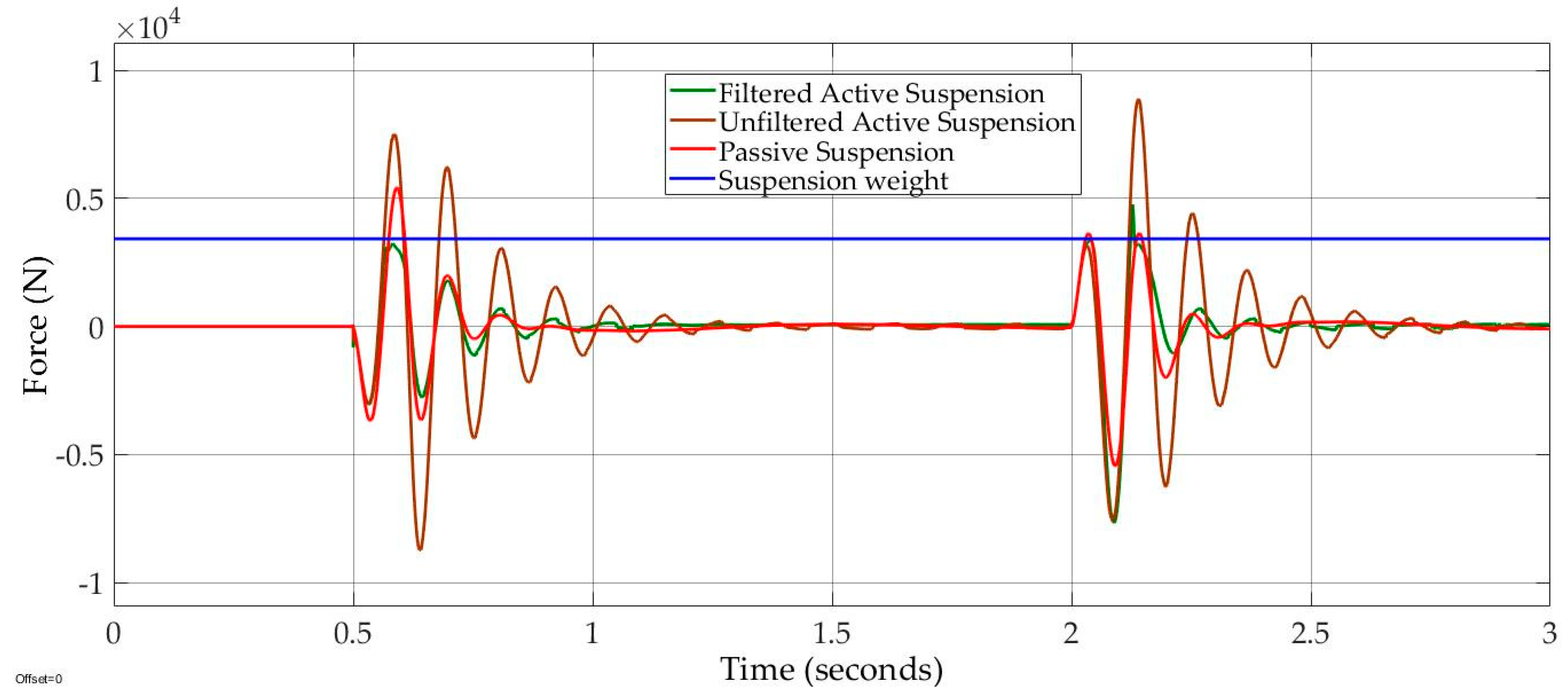

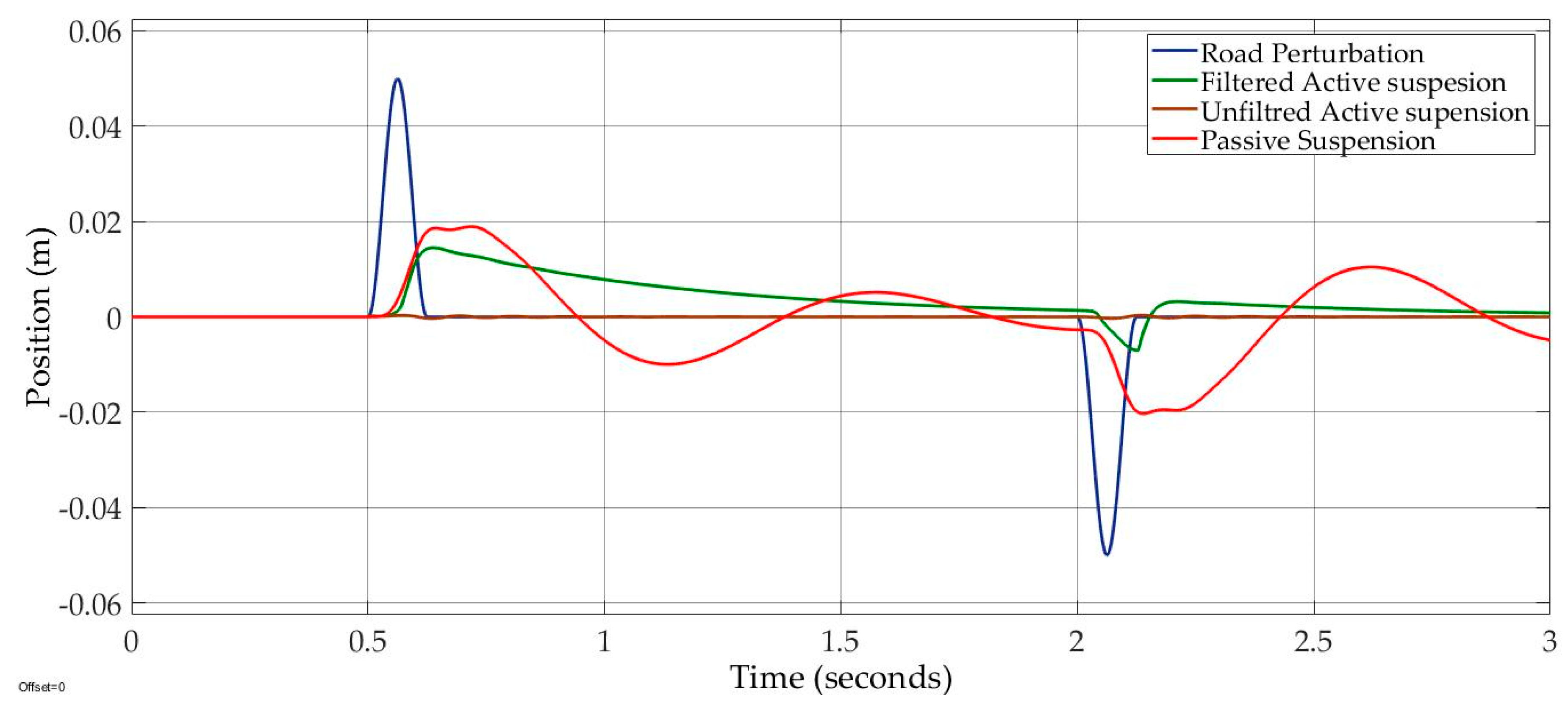

In

Figure 10, the filtered active suspension kept tire contact with the road surface despite tiny periods of tire liftoff at 0.68 and (2.12–2.13) seconds. On the other hand, the dynamic tire force of the unfiltered active suspension was greater than the suspension weight at four time periods (0.56–0.61), (0.68–0.72), (2.12–2.18), and (2.24–2.26) seconds. The passive suspension dynamic tire force was higher than the weight suspension at (0.57–0.61) seconds’ period.

Thus, both the unfiltered active suspension and passive suspension had tire liftoff phenomenon that may lose car–road stability. The sprung mass position of the filtered active suspension was compensated by 75% on bumpy road and by 88% on the pothole road, and smoothly decayed to origin, despite the road-holding compensation, as shown in

Figure 11.

On the other hand, the passive suspension was roughly compensated by about 60%. A frequency response estimation was applied to show the steady state of the filtered and unfiltered active suspension systems. The frequency response was estimated by using the Simulink tool frequency estimation with the sinusoidal road profile, as shown in

Figure 12.

The sensitive human frequency was about 18–50 rad/s [

38]. In

Figure 12, there is a compromise between road holding and passenger comfort, with the sprung mass acceleration of the filtered active suspension being higher at the sensitive human frequency domain. The reduction in suspension travel oscillation was also our control target. The suspension travel of the filtered active suspension oscillation was reduced by 87% as compared to 57% with the unfiltered active suspension, as can be seen in

Figure 13.

The benefits of reducing suspension travel oscillation include the possibility of preventing the suspension travel from reaching its limit, reducing wear in the mechanical suspension system, and saving energy.

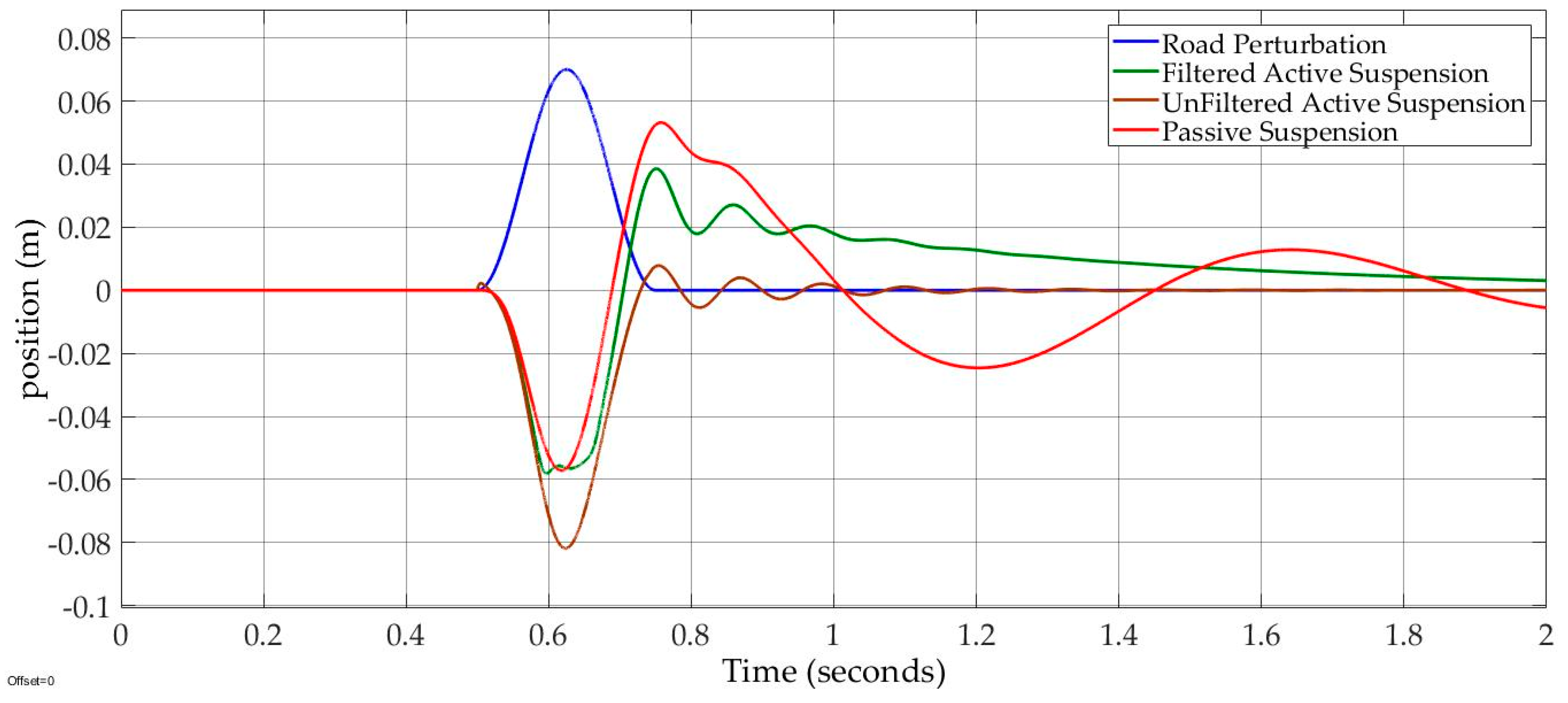

The third control objective was to prevent hitting the suspension contraction limit. Hence, we proposed a suspension contraction limit of −6 cm. The bumpy road design had an amplitude of 3.5 cm and a frequency of , as in the following case.

Case 3: The road excitation “bumpy input” had an amplitude 3.5 cm and a frequency.

Although there was a trade-off between passenger comfort and suspension deflection, the sprung mass position was compensated by 72% and smoothly decayed to its original position, as shown in

Figure 14.

The unfiltered active suspension provided the best compensation, of about 99%. In

Figure 15, the suspension travel analysis is scoped to indicate the filtered active suspension performance.

Accordingly, the filtered active suspension prevented hitting the suspension travel limit of −0.06 m, as shown in

Figure 15; otherwise, the unfiltered active suspension hit the suspension travel limit at the (0.58–0.68) seconds’ period.

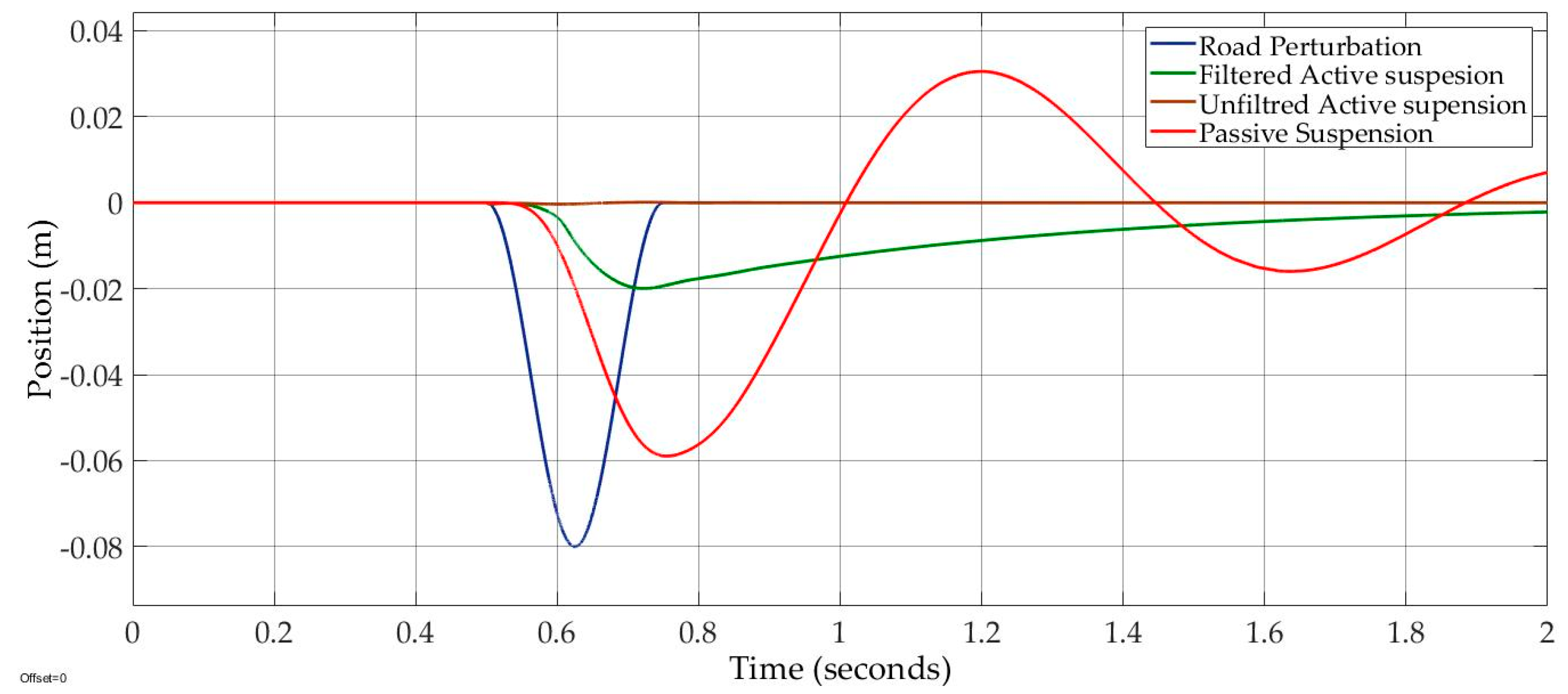

Finally, the fourth control objective was the constrained suspension expansion. The suspension travel expansion limit was rarely addressed in previous studies. In particular, depending on how the vehicle is loaded, the suspension travel expansion limit may not be the same magnitude of the suspension travel contraction limit. The suspension travel expansion limit is 0.08 m. Therefore, we proposed a suspension travel expansion limit of 8 cm. In Case 4, there were a pothole road perturbation magnitude at −3.5 cm and the frequency of , as follows:

Case 4: The pothole perturbation road design had an amplitude ofand a frequency of.

In

Figure 16, the filtered active suspension compensation is 75.5% and 22.5% for the passive suspension.

Even though the unfiltered active suspension had the best control compensation of 99%, the unfiltered active suspension travel hit its limitation at about (0.6–0.67) seconds’ period, as shown in

Figure 17. The suspension travel of the filtered active suspension avoided hitting the suspension travel expansion limit

of 0.08 m.

On the other hand, the suspension travel of the unfiltered active suspension hit the suspension travel limitation at the (0.06–0.062) seconds’ period.

In conclusion, the sprung mass position of the filtered active suspension was smoothly compensated by 75% in Case 1. The suspension travel oscillations were reduced as compared to the unfiltered active suspension. In Case 2, the filtered active suspension provided both passenger comfort and road holding, as shown in

Figure 10. On the other hand, the unfiltered active suspension and passive suspension failed to maintain road holding. The filtered active suspension prevented reaching the suspension travel limitations in both Case 3 and Case 4. Hence, the control objectives were successfully addressed.