Abstract

Heavy machinery has evolved significantly in productivity, efficiency, and safety over the past century and a half, where most technological advances occurred after the 1990s. The field of multibody dynamics has significantly contributed to this development. The objective of this study is to introduce the historical evolution of heavy machinery and to analyze the general role of multibody dynamics in this evolution. The latter part of the objective is the novel contribution of this study. The historical evolution of heavy machinery is presented from the ancient times of 30–20 BC to the modern innovations of 2024. The general role of multibody dynamics in heavy machinery is identified and analyzed in five phases, from using simple kinematic models in the 1970s to real-time simulations and autonomous systems in the 2020s. This study can serve as a benchmark for future work.

1. Introduction

Heavy machinery has come a long way from the ancient Roman cranes to modern computerized machinery. In the last century and a half, heavy machinery has significantly evolved with improved productivity, efficiency, and safety. Most technological advances in heavy machinery have been made in the late 1900s and 2000s. Among various factors, the field of multibody dynamics has significantly advanced the development of heavy machinery, particularly after the introduction of computers that enabled the complete characterization of multibody dynamics. Multibody dynamics can be defined as the study of mechanical systems that are defined as a collection of bodies connected using kinematic joints that operate under the influence of force elements.

Heavy machinery can be considered a wide range of mechanical systems designed for agriculture, construction, and industrial purposes [1]. Generally, such machines are designed to perform tasks that require significant power, precision, and durability, such as excavation, material handling, and earthmoving [2]. Their specialized design and robust construction allow them to perform tasks that are otherwise impossible or inefficient with manual labor or small-scale machines [3]. Historically, heavy machinery has been pivotal in the development of large-scale infrastructure, resource extraction, and manufacturing processes crucial to modern industry [4].

Heavy machinery can be broadly classified according to its primary function in categories such as agricultural machinery, earthmoving equipment, forest equipment, and material handling equipment [5]. Examples of agricultural machinery include tractors and wheel loaders; earthmoving equipment includes excavators and bulldozers; forest equipment includes harvesters and forwarders; and material handling equipment includes cranes and forklifts [1]. Each type of machinery is specifically designed to meet various industrial demands [6], varying in size, power, and mobility to optimize functionality. The diversity of design and functionality indicates the importance of machine selection [7,8], as each type is crucial to efficiently meet industrial needs.

The design and functionality of heavy machinery are based on the principles of mechanical and hydraulic engineering, often powered by internal combustion engines or electric motors [9]. Various subsystems allow these machines to handle demanding tasks that require immense force, endurance, and adaptability [10]. For example, hydraulic systems provide immense force with precision [11], while advanced materials and designs ensure durability, and diesel engines provide the energy necessary for operation under harsh conditions [12]. In addition, recent advances in sensors [13], automation, and materials have further increased the efficiency, safety, and environmental compatibility of heavy machinery [14].

In recent years, the incorporation of digital technologies into heavy machinery has revolutionized the corresponding industry [15]. Advances in telematics, automation, and machine learning have enabled autonomous operations, predictive maintenance, and remote monitoring in this field [16]. These innovations improve operational efficiency and address key challenges [17] such as minimizing downtime, increasing safety, and optimizing fuel consumption [18]. The integration of traditional heavy machinery with digital intelligence represents a paradigm shift toward more advanced and interconnected machinery [19].

In digital frameworks, multibody dynamics [20] provides computational tools to simulate and analyze heavy machinery in detail, allowing the manufacturer to implement and test various innovations and minimize development costs [21]. Multibody dynamics [22] has been used in heavy machinery simulation by incorporating the number of bodies, joints, force elements, and environmental modeling [23]. Bodies can be rigid or flexible, and joints can be of various types, such as revolute joints, translational joints, and spherical joints [24]. Force elements may include springs, dampers, actuators, or external forces [25]. The multibody approach has been utilized in the study of heavy machinery [26,27] and various engineering applications [28].

Despite previous research efforts, there are two limitations to the current state of the art. First, although there are various studies on heavy machinery, a brief history of heavy machinery has been overlooked. Second, although multibody dynamics has been utilized in the study of heavy machinery, a brief overview of the general role of multibody dynamics in heavy machinery has not been studied. Therefore, this study aims to overcome these research gaps by investigating studies on heavy machinery and listing the impact of multibody simulation on them.

The objective of this study is to introduce the historical evolution of heavy machinery and to analyze the general role of multibody dynamics in this evolution. The novel contribution here is a conceptual overview of the use of multibody dynamics as a simulation tool in the design and development of heavy machinery. This study advances the state-of-the-art by addressing the unique combination of heavy machinery with multibody dynamics that is seldom explored in the literature. To this end, the historical evolution of heavy machinery is presented from the ancient times of 30–20 BC to the modern innovations of 2024. The general role of multibody dynamics in the study of heavy machinery is divided into five phases, from the early 1970s to the present 2020s. This study provides a general overview designed to serve as a valuable synthesis for both academic and industry readers, rather than a systematic literature review or a detailed technical analysis.

2. Historical Evolution of Heavy Machinery

Heavy machinery plays a crucial role in shaping the core infrastructure of human society. Heavy machinery was originally used for agriculture; however, its application has evolved to be used for construction and mining in the last century and a half. This study covers wide range of machines from various heavy machinery industries, such as agricultural machinery (tractors and wheel loaders), earthmoving equipment (excavators and bulldozers), forest equipment (harvesters and forwarders), and material handling equipment (cranes and forklifts). There have been favorable and challenging periods in the evolution of heavy machinery.

2.1. Early Phase of Heavy Machinery

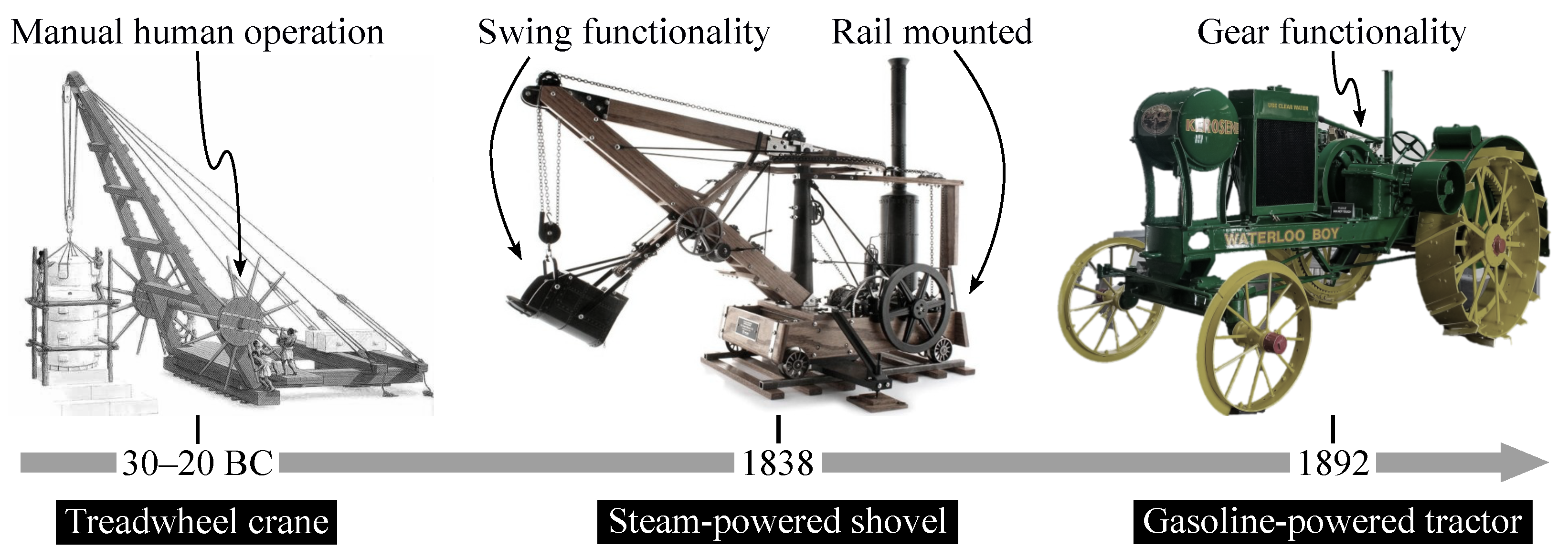

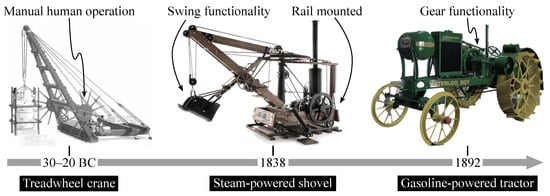

Egyptians pioneered the use of levers, pulleys, and cranes powered by humans and animals. An Egyptian chancellor, Imhotep, is believed to have employed ramps, rollers, and ropes to construct the step pyramid of Djoser circa 2670–2650 BC. The Romans used similar ramps and rollers to transport large stone blocks [29]. Human-powered treadwheel cranes, crafted from wood, facilitated the construction of Roman arches and other structures, as mentioned in “De Architectura” by a Roman architect, Marcus Vitruvius Pollio, circa 30–20 BC [4]. Engineered by the Song Dynasty’s Qiao Weiyue in China, the counterweight trebuchet was pivotal in enhancing siege weaponry between 960 and 1279 [30]. Figure 1 shows some key historical milestones in the early phase of heavy machinery.

Figure 1.

Some key historical milestones in the early phase of heavy machinery.

Despite the continued use of ancient machinery, the late 19th century marked a shift towards steam- and gasoline-powered machinery [31]. The first steam-powered shovel capable of partial swing functionality and rail operation was invented by an American inventor, William Otis, in 1838 [1]. The first steam-powered, leaning wheel, road grader capable of prairie road construction was invented by an American inventor, Joseph Adams, in 1876. The first combine harvester and the first steam-powered tractor capable of agriculture activities were created by an American inventor, Benjamin Holt, in 1886 and 1890, respectively [4]. The first gasoline-powered tractor capable of forward and reverse gears functionality was invented by an American inventor, John Froelich, in 1892.

During the 19th century, Western industrial powers significantly influenced the development of heavy machinery in Asia through both colonization and trade [30]. Steam engines, crushing mills, mechanized pumps, and railway locomotives were imported to facilitate infrastructure projects in regions such as British India, Dutch Indonesia, and Qing China. In contrast, between 1868 and 1912 in the Meiji era, Japan imported not only machinery but also Western engineers and educators [32]. This led to the use of heavy machinery in mining, railway construction, and military applications. Although Japan did not produce heavy machinery on a large scale during this period, it established a basis for skills in metalworking, steam engine repair, and mechanical replication [32].

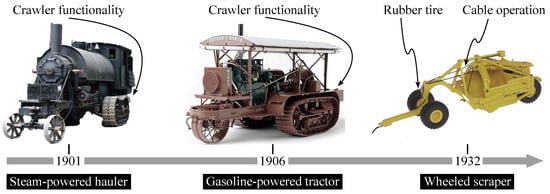

2.2. Increased Demand for Heavy Machinery

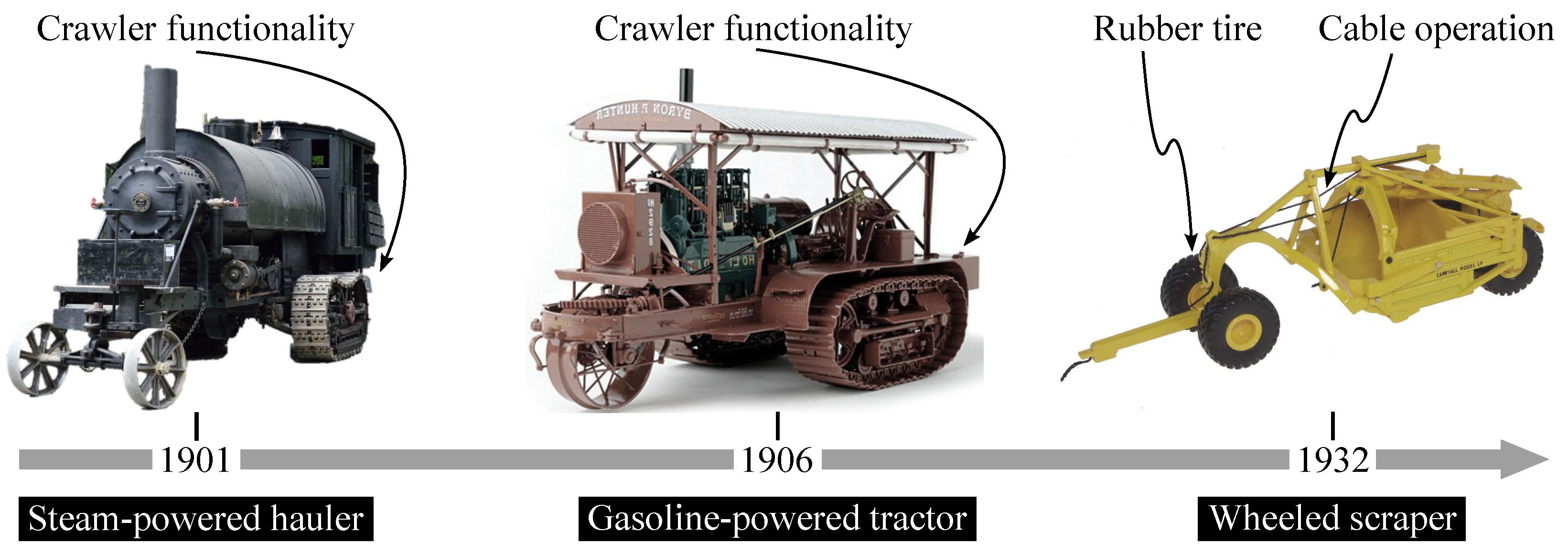

During the early 20th century, the Industrial Revolution sparked a significant demand for heavy machinery in numerous industries [33]. The first crawler-type steam hauler capable of effective log transportation was invented by an American inventor, Alvin Lombard, in 1901 (see Figure 2). Building on this idea, Benjamin Holt developed the first crawler-type gasoline tractor capable of preventing tractor sinkage on soft ground in 1906, which was later registered as the “Caterpillar” tractor in 1910 [34]. Various machines, such as motorized graders, steam and gasoline rollers, and wheel scrapers, capable of specific functionalities were engineered by an American manufacturer, Galion Iron Works, in 1907.

Figure 2.

Some key historical milestones in the increased demand phase for heavy machinery.

The crawler-type propulsion gained popularity in the 1910s and was subsequently used for military applications from then on [29]. The first crawler-type bull graders, now called bulldozers, capable of facilitating construction activities were developed in the 1920s. This decade also marked the creation of bucket and wheel excavators for surface excavation in the mining industry [1]. Tower cranes were developed and widely used during this period to build infrastructure in large cities, while the first tippers, now called dump trucks, were introduced [4]. The first cable-operated rubber-tired scraper was created by an American inventor, Robert LeTourneau, in 1932, which significantly impacted the design of heavy machinery over the next 30 years.

2.3. Challenging Period Followed by Growth

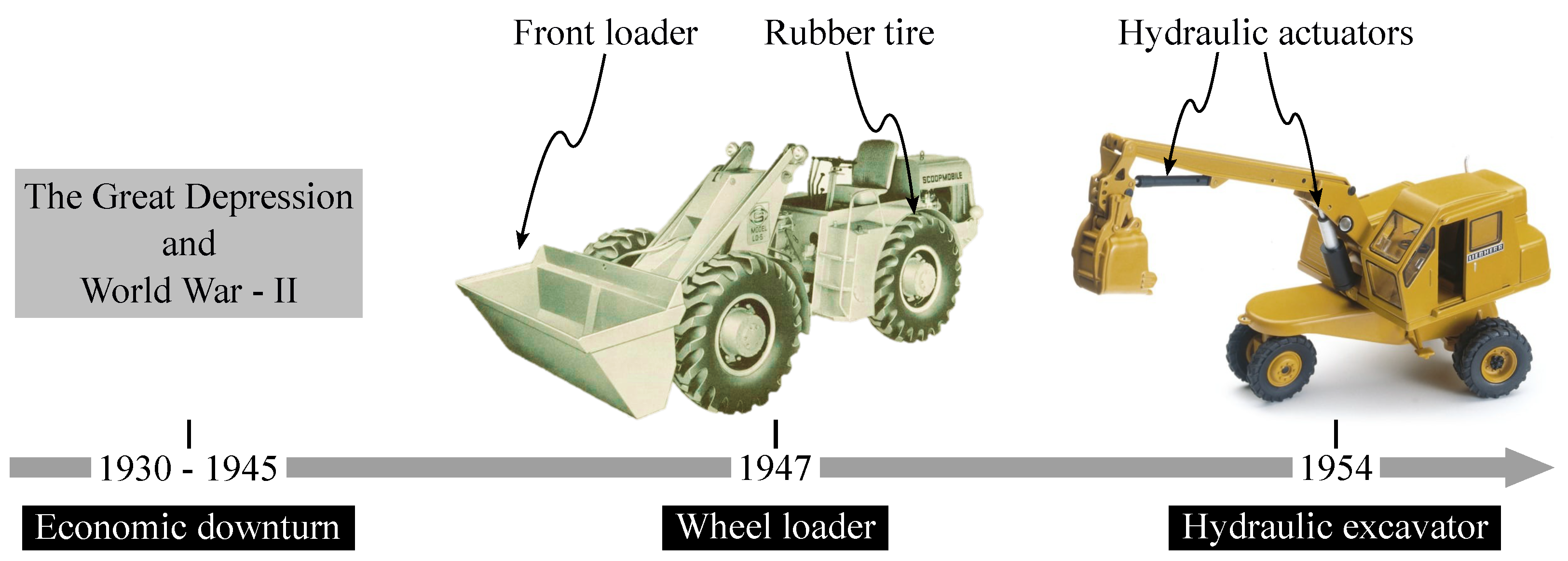

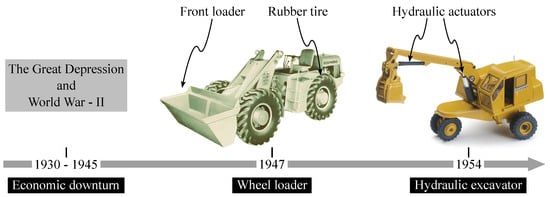

The economic downturn triggered by the Great Depression in the 1930s led to a slowdown in the development of heavy machinery. Despite its negative impact on the industry, heavy machinery played a crucial role in the construction of iconic structures [33]. In addition, machine manufacturers focused on government contracts for supplying war materials during the Second World War years (1939–1945), further halting the development of heavy machinery. However, the heavy machinery industry recovered rapidly after the war years [29]. Figure 3 shows some key historical milestones in the challenging period followed by growth.

Figure 3.

Some key historical milestones in the challenging period followed by growth.

The first front-end rubber-tired wheel loader capable of versatile mobility, speed, and efficient process cycles was developed by an American entrepreneur, Frank Hough, in 1947. Hydraulic-driven operations began to dominate cable-driven operations in the late 1940s [11], and Europe’s first hydraulic-driven excavator capable of improved precision and power was introduced by a German-Swiss manufacturer, Liebherr, in 1954. The large-scale infrastructure demands in the 1950s and 1960s led to the growth of the heavy machinery industry [10], and machinery grew in both size and complexity to meet those demands. Machine manufacturers prioritized improving productivity, safety, and reducing noise and emissions [31]. The first hydro-pneumatic suspension struts capable of better load retention compared to conventional leaf springs was introduced in mining trucks by an American manufacturer, Westinghouse Air Brake Company, in 1958.

2.4. Progress and Development in Technology

The demand for heavy machinery increased in the 1970s, especially due to the significant need for coal excavation during the oil crisis of 1973 [4]. In contrast, the economic recession of the 1980s led to a decline in the industry; however, the commercial success of computers and microelectronics revolutionized the further development of heavy machinery [31]. From this period on, machine manufacturers began to use computer simulations to significantly advance developments, such as improved machine control and monitoring [20]. The economic recession caused the merger of numerous machine manufacturers to sustain their operations in the industry.

The demand for versatile and agile heavy machinery in the 1990s led machine manufacturers to develop compact and efficient designs for heavy machinery [35]. These machines incorporated advanced technologies, such as GPS navigation, to improve productivity and maintenance [31]. Advances in computers allowed manufacturers to test complex operations using simulations. Furthermore, the use of diesel engines in heavy machinery increased carbon emissions and negatively affected the environment [36]. Consequently, the use of eco-friendly and fuel-efficient engines became an obligation from the 1990s onward to reduce emissions and comply with regulatory standards, such as the Tier 1 regulation of the US EPA.

2.5. Continuous Progression of Technology

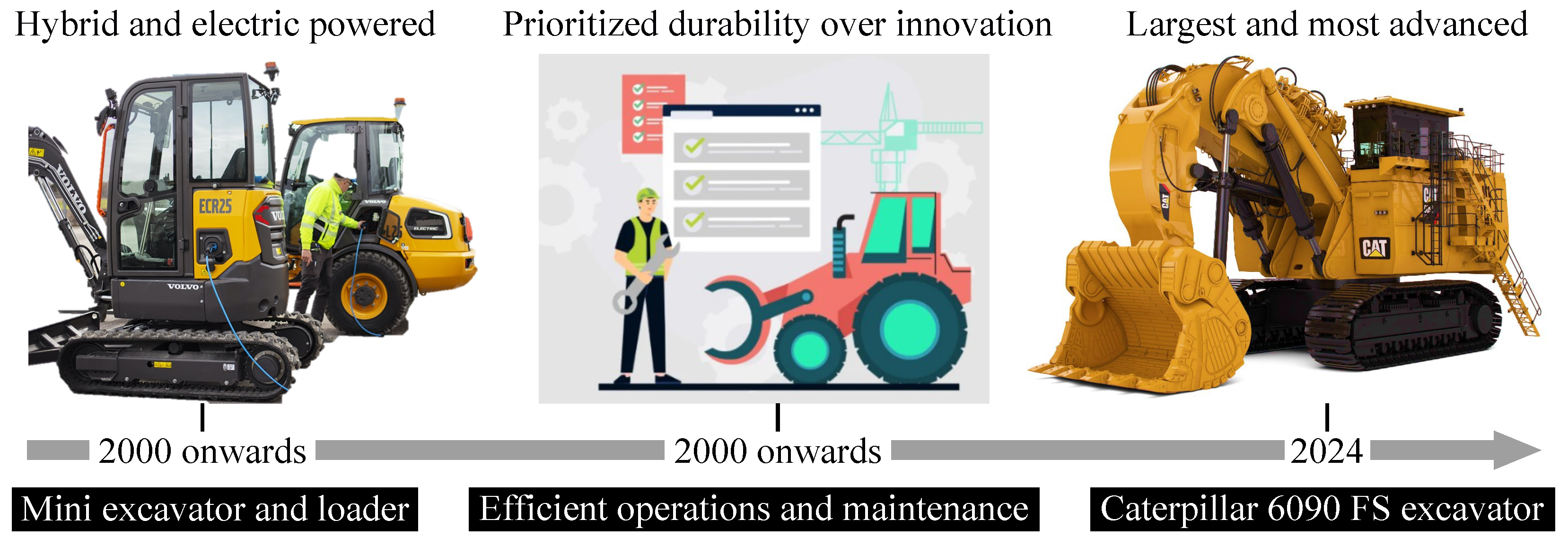

In the early 21st century, the heavy machinery industry experienced steady growth, with Caterpillar becoming a global leader [37], as shown in Table 1. This period marked a shift towards hybrid- and electric-powered machinery to reduce emissions [36] and comply with new regulatory standards, such as the Tier 2 regulation of the US EPA. Figure 4 shows some key historical milestones in the continuous progression of the technology phase. In the 2000s, the industry focus shifted to equipment rental over purchases, leading manufacturers to prioritize durability over innovation [35]. For durable machines, manufacturers focused on efficient operations and timely maintenance, and computer simulations played an important role in this development [38].

Table 1.

Leading manufacturers of heavy machinery worldwide in 2023 [37].

Figure 4.

Some key historical milestones in the continuous progression of technology phase.

The heavy machinery industry has experienced rapid expansion since the 2010s, with forecasts indicating a global annual growth rate of 6.2% in the coming years [39]. Today, modern machinery incorporates advanced technologies, such as telematics, electromobility, the Internet of Things, remote operations, and automation, to improve productivity, efficiency, and safety [15,40]. The largest and most advanced excavator in the world is the Caterpillar 6090 FS, with an operating weight of 1102 tons and a bucket capacity of 52 m3. Recent industry efforts focus on autonomous technology, sustainable materials, improved efficiency, and customer-focused solutions [40,41]. Leading heavy machine manufacturers, such as Caterpillar, Komatsu, and John Deere, have a strong focus on innovation and sustainability, dominating the global market, as indicated in Table 1. Future machines will prioritize compliance with emission standards, such as the Tier 4 regulation.

3. General Role of Multibody Dynamics

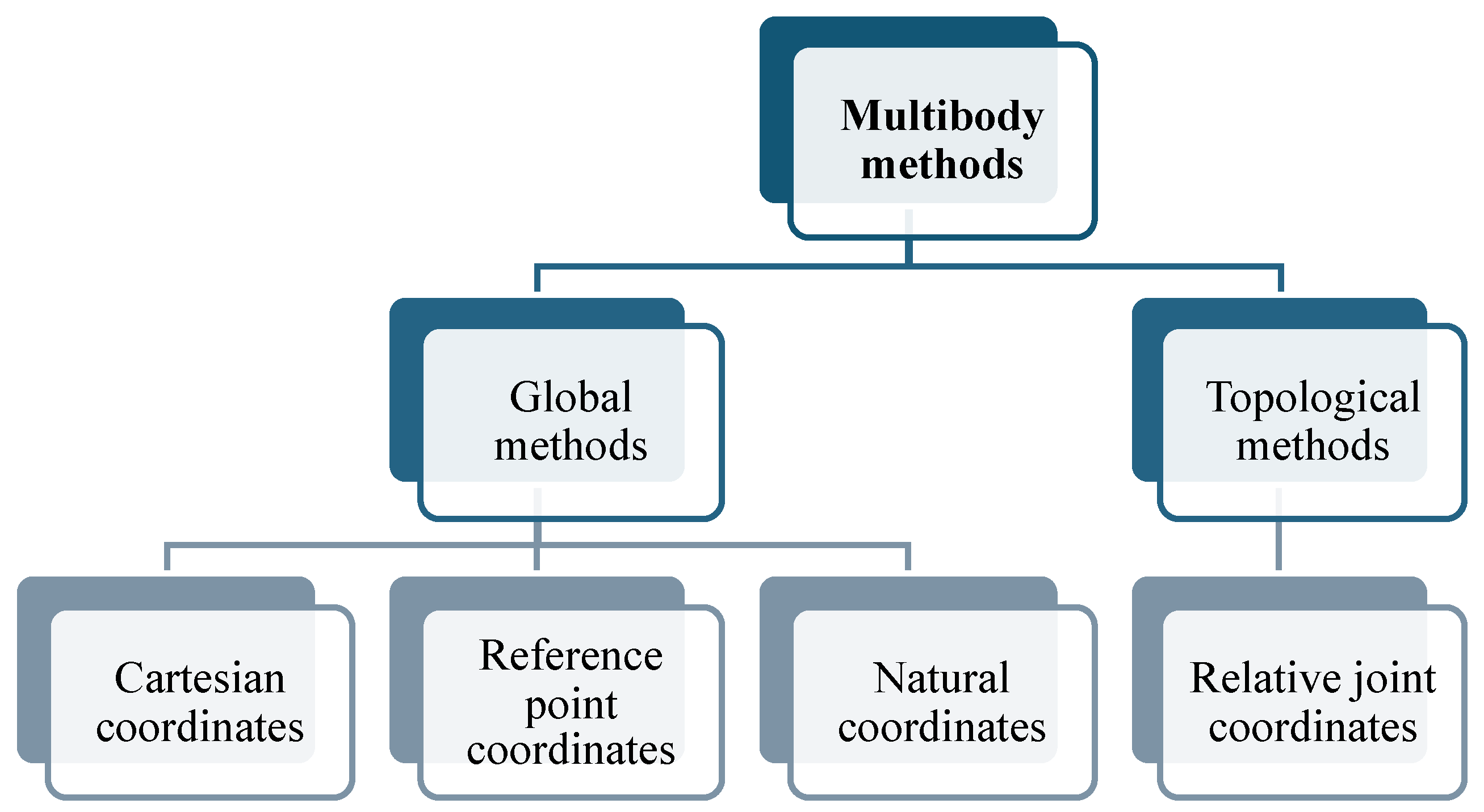

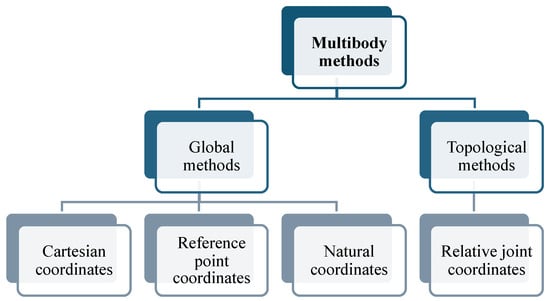

Multibody dynamics [25,42] can be broadly divided into global and topological methods [43,44], as shown in Figure 5. Global methods define each body in a kinematic chain using absolute/global coordinates related to the inertial frame [45], without considering the system topology [46,47]. The dynamic terms for each body are specified individually, allowing a straightforward system assembly. Topological methods define each body in a kinematic chain based on the previous body using relative joint coordinates [48,49]. The kinematic and dynamic terms for each body are defined recursively, considering the system topology [46,50], and the methods can be fully recursive or semi-recursive [51]. Global methods generally offer easy implementation [52] at the cost of solving a large set of coordinates [53], while topological methods involve intricate implementation [54,55] but demand fewer coordinate solutions [56,57].

Figure 5.

Categorization of various methods in multibody dynamics.

Multibody dynamics allows for detailed investigation of heavy machinery using comprehensive simulation models and advanced controls [25]. This has significantly transformed the design, testing, and optimization of heavy machinery. The general role of multibody dynamics in the study of heavy machinery is divided into five phases from the 1970s to the 2020s, as shown in Table 2. This study is limited to a conceptual overview that aims to offer an insightful synthesis for academic and industry audiences, excluding detailed multibody formulations.

Table 2.

Overview of multibody dynamics role in the study of heavy machinery.

3.1. Early Applications Using Analytical Models

The early application of multibody dynamics in heavy machinery utilized rigid body dynamics and fundamental kinematic models [20]. The poor computation power limited the studies to analytical models, heavily relying on simplifications. The models typically assumed only rigid bodies with limited degrees of freedom for kinematic studies, leading to elementary mathematical models. Research conducted during the 1970s and 1980s focused primarily on the early exploration of machine designs, with a limited focus on static or quasi-static conditions [58].

3.2. Emergence of Computational Tools

The progress in computing power led to the emergence of computational tools based on multibody dynamics. This allowed the application to shift from analytical models to numerical models and to study machine dynamics at the system level [59]. Although the models primarily assumed rigid bodies, the early exploration of flexible bodies offered valuable insights into system dynamics. Research conducted during the 1980s and 1990s focused primarily on effective machine designs and safety measures, with a focus on interaction forces, joint constraints, and component movements [60,61].

3.3. Expansion into Real-World Scenarios

Further advancements in computing power led to sophisticated multibody models of complex machinery that incorporated real-world scenarios. This allowed investigation of environmental interactions and realistic load simulations in complex operations [62]. The models incorporated a level of flexibility at the component level to account for bending and vibrations and supported cyclic loading to analyze component fatigue. Research conducted during the 1990s and 2000s focused primarily on improving operational reliability, evaluating stability analyses, and developing safer machine designs [63].

3.4. Integration with FEA and Control Systems

Multibody dynamics progressed into the incorporation of finite element analysis (FEA) and this revolutionized simulation studies of heavy machinery. This allowed investigation of the flexible dynamics of machine parts at the component level [64]. Mechanical models incorporated hydraulics and controls to comprehensively study the dynamics of heavy machinery, both at the system and component levels, and explored the initial use of real-time simulation [65]. Research conducted during the 2000s and 2010s focused primarily on improving machine durability, optimizing operational performance, and implementing safety measures in challenging and uncertain environments [66].

3.5. Progression into Real-Time Simulation and Automation

Advanced computing power and modern state-of-the-art methods have enabled multibody dynamics to evolve into real-time simulations [23] and autonomous systems [67] in recent years. This allowed the integration of actual machine data into multibody models, ensuring their alignment with actual machines [68]. The models exhibit significant sophistication, incorporating detailed heavy machinery characteristics alongside machine learning algorithms. Research conducted during the 2010s and 2020s focused primarily on real-time machine monitoring, predicting machine failures, anticipating maintenance needs, and executing autonomous functions to fulfill industrial demands [38]. Table 3 lists the simulation tools based on multibody dynamics, which are utilized in the study of heavy machinery.

Table 3.

List of simulation tools based on multibody dynamics.

4. Discussion and Future Work

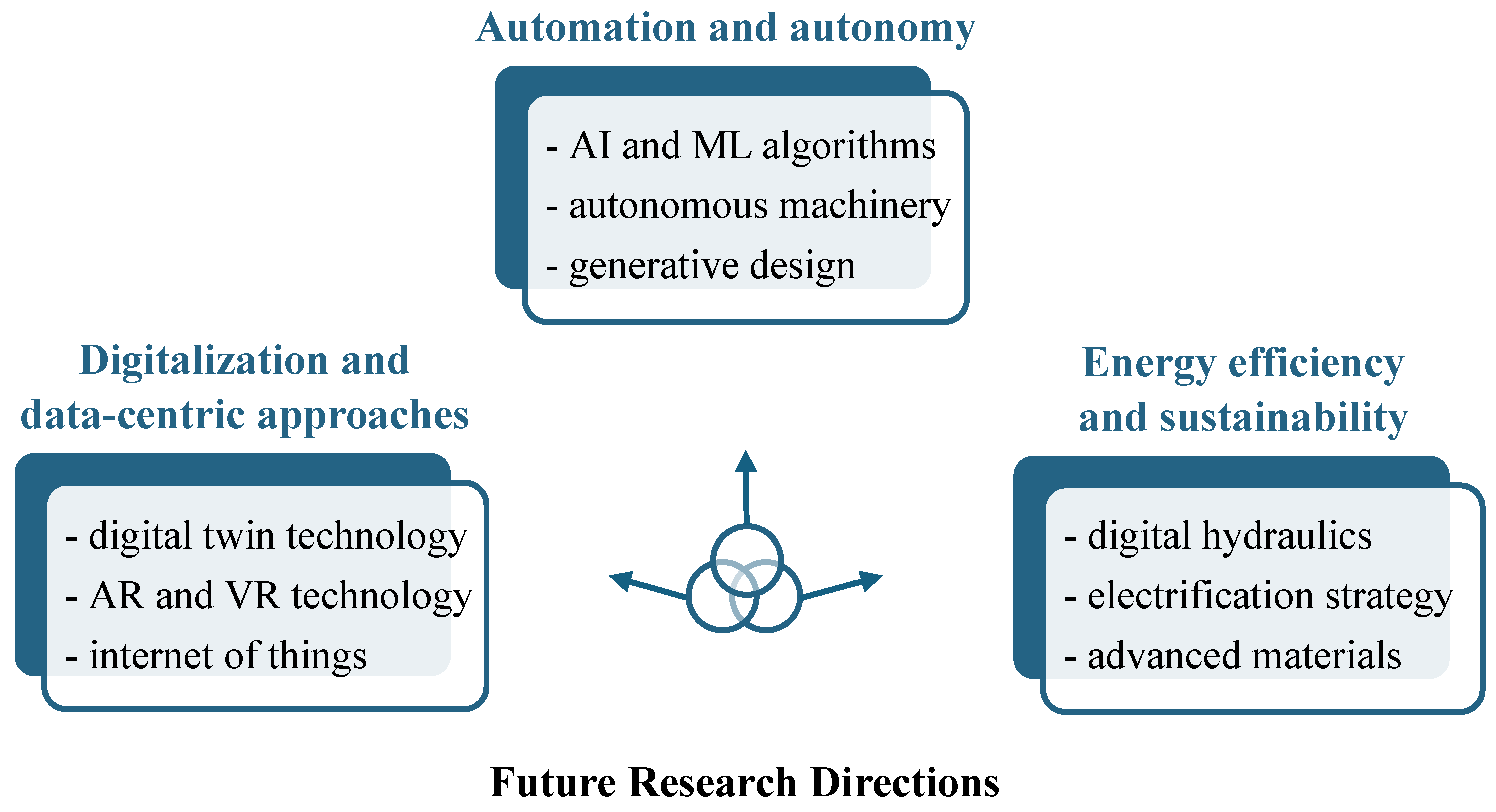

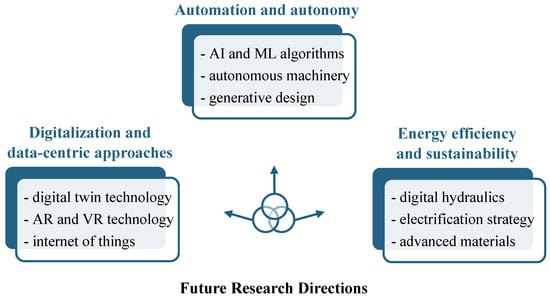

The general role of multibody dynamics in heavy machinery has evolved from offering basic analytical models to advanced real-time simulation and automation, integrating multiple disciplines and practical scenarios. This has helped manufacturers improve the design, testing, and optimization of heavy machinery. Based on existing research gaps, future work in heavy machinery can go in three directions: (i) digitalization and data-centric approaches, (ii) automation and autonomy, and (iii) energy efficiency and sustainability. Figure 6 presents a visual representation of these future research directions.

Figure 6.

Future research directions in heavy machinery using multibody dynamics.

In digitalization and data-centric approaches, heavy machinery can incorporate modern technologies, such as digital twin (DT), augmented reality (AR) and virtual reality (VR), and the Internet of Things (IoT). DT technology provides a virtual machine model that mirrors the real machine in real-time, offering the ability to simulate scenarios, optimize operations, and anticipate maintenance requirements. AR and VR technologies replicate real-world environments and provide immersive training experiences, offering the ability to train machine operators, remotely support field technicians, and assist in machine maintenance. The IoT enables the collection of data from machine sensors in real-time, offering the ability to monitor performance, assist with predictive maintenance, and support data fleet management. An example of future work in this category is that physics-based digital twin models can be aligned with machine sensor data to facilitate predictive maintenance, as proposed in [38,69].

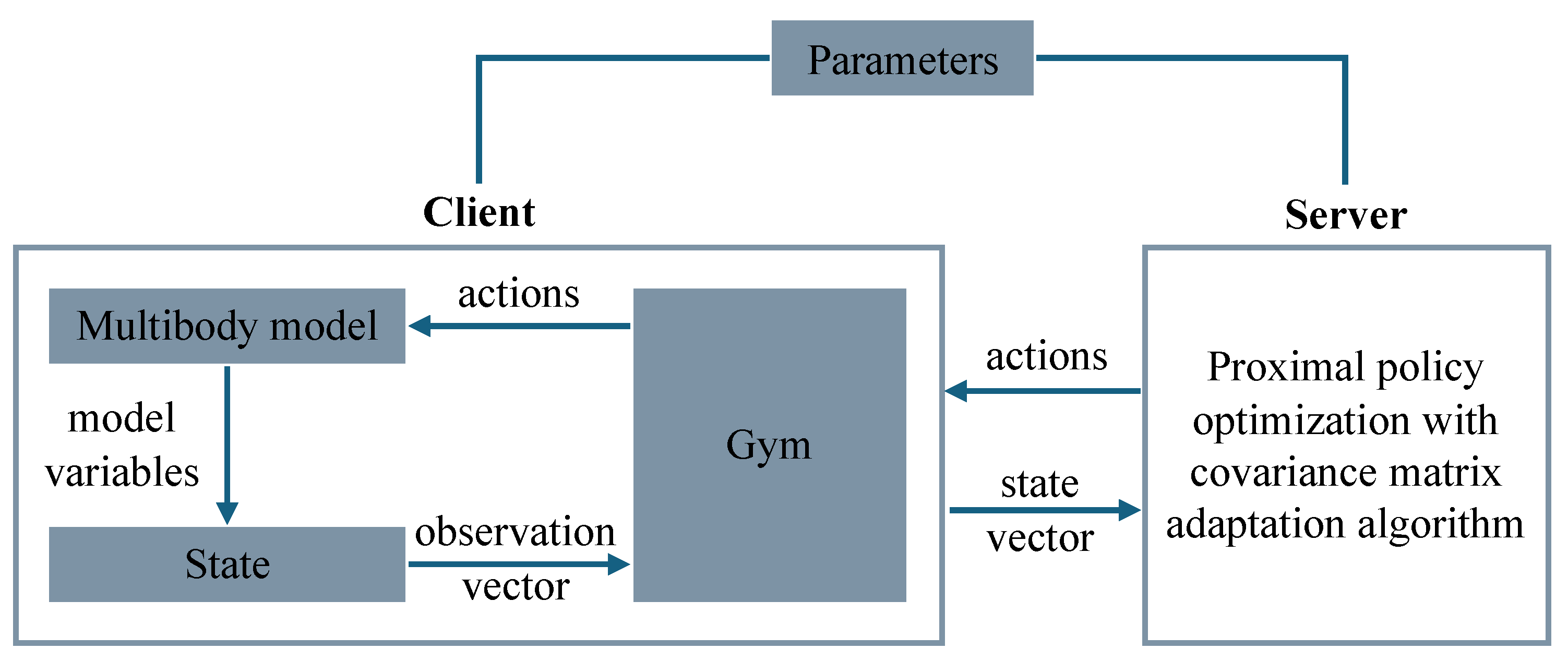

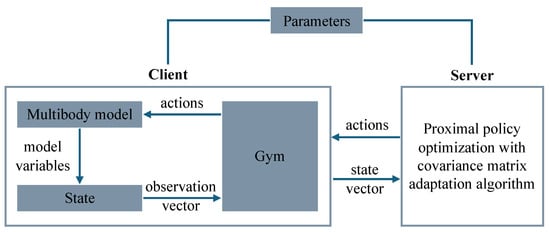

In automation and autonomy, heavy machinery can incorporate modern-day approaches, such as artificial intelligence (AI) and machine learning (ML), autonomous machinery, and generative design. Incorporation of AI and ML into heavy machinery allows machine data analysis, offering the ability to predict maintenance needs, minimize downtime, and support operators in decision making. Autonomous machinery refers to a machine that functions on its own without direct human oversight, offering the ability to operate around the clock, improve productivity, and minimize labor expenses. Generative design creates various design solutions that consider performance criteria, manufacturing methods, and material selection, offering the ability to develop durable, efficient, and practical designs, while using lightweight and sustainable materials. An example of future work in this category is that reinforcement learning can be combined with multibody models to optimize machine operations in complex environments, as the methodology (see Figure 7) is proposed for a simple operation in [67].

Figure 7.

Integration of a reinforcement learning algorithm with a multibody model as in [67].

In energy efficiency and sustainability, heavy machinery can integrate greener energy solutions and sustainable materials, such as electrification and advanced materials. Electrification strategies can replace diesel power sources with electric ones, offering the ability to reduce carbon emissions, minimize noise pollution, and improve energy efficiency. In addition, hydrogen fuel cells and modern batteries can offer efficient solutions for alternative energy sources. Advanced materials, such as composites, alloys, and nanomaterials, enable a combination of reduced weight, enhanced strength, and increased durability, offering the ability to resist high stress, corrosion, and wear. An example of future work in this category is that different hybrid electric powertrains can be tested in various heavy machines to explore energy-efficient solutions, as demonstrated for a tractor in [70,71].

5. Conclusions

This study has introduced the historical evolution of heavy machinery and analyzed the general role of multibody dynamics in this evolution. The novel contribution of this study is the impact of multibody dynamics on heavy machinery. The historical evolution of heavy machinery is presented from the ancient times of 30–20 BC to the modern innovations of 2024. The general role of multibody dynamics in the study of heavy machinery is divided into five phases, from the early 1970s to the present 2020s.

Heavy machinery has played a crucial role in shaping the core infrastructure of human society. Heavy machinery was originally used for agriculture and later evolved to be used for construction and mining. Over centuries, heavy machinery has evolved from human-powered treadwheel cranes in 30–20 BC, to the steam-powered shovel in 1838, to the gasoline-powered tractor in 1906, and finally to electric-powered excavators in the 2000s. Moreover, cable-driven operations were replaced by powerful and efficient hydraulic-driven operations by the late 1940s.

Multibody dynamics-based studies have helped manufacturers improve the design, testing, and optimization of heavy machinery. The early application of multibody dynamics in heavy machinery was limited to analytical models for kinematics studies in the 1970s–1980s and to numerical models for dynamics studies in the 1980s–1990s. Increased computational power allowed the investigation of environmental interactions and realistic load simulations in the 1990s–2000s and incorporation of finite element analysis for flexibility studies in the 2000s–2010s. The application of multibody dynamics in heavy machinery has evolved to real-time simulation and automation that allowed the investigation of failure predictions and predictive maintenance in the 2010s–2020s.

This study provided a conceptual framework on multibody dynamics applied to heavy machinery and is intended to present a valuable synthesis for both academic and industrial readers. The limitation of this study is that it ignored a systematic literature review and a deeper technical analysis on the topic, and the authors plan to cover it in their future research work. Future research will focus on particular multibody formulations and provide detailed mathematical descriptions. Future studies can focus on particular industries within heavy machinery, such as agriculture, earthmoving, mining, forestry, and material handling.

Author Contributions

Conceptualization, S.J.; methodology, S.J.; software, S.J.; validation, S.J.; formal analysis, S.J.; investigation, S.J.; resources, S.J.; data curation, S.J.; writing—original draft preparation, S.J.; writing—review and editing, S.J.; visualization, S.J.; supervision, M.P.; project administration, S.J.; funding acquisition, S.J. All authors have read and agreed to the published version of the manuscript.

Funding

This project has received funding from the European Union’s Horizon Europe research and innovation programme under the Marie Skłodowska-Curie grant agreement No 101107491.

Acknowledgments

Suraj Jaiswal would like to thank the European Commission for awarding him the prestigious Marie Skłodowska-Curie Postdoctoral Fellowship in 2023. This study is dedicated to the evolution of heavy machinery over the next 100 years.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Duffy, O.C.; Wright, G.; Heard, S.A. Fundamentals of Mobile Heavy Equipment; Jones & Bartlett Learning: Burlington, MA, USA, 2019. [Google Scholar]

- Parker, N.R.; Salcudean, S.E.; Lawrence, P.D. Application of force feedback to heavy duty hydraulic machines. In Proceedings of the IEEE International Conference on Robotics and Automation, Atlanta, GA, USA, 2–6 May 1993; pp. 375–381. [Google Scholar]

- Odeyar, P.; Apel, D.B.; Hall, R.; Zon, B.; Skrzypkowski, K. A review of reliability and fault analysis methods for heavy equipment and their components used in mining. Energies 2022, 15, 6263. [Google Scholar] [CrossRef]

- Haycraft, W.R. History of construction equipment. J. Constr. Eng. Manag. 2011, 137, 720–723. [Google Scholar] [CrossRef]

- Shin, Y.; Choi, Y.; Won, J.; Hong, T.; Koo, C. A new benchmark model for the automated detection and classification of a wide range of heavy construction equipment. J. Manag. Eng. 2024, 40, 04023069. [Google Scholar] [CrossRef]

- Day, D.A.; Benjamin, N.B. Construction Equipment Guide; John Wiley & Sons: Hoboken, NJ, USA, 1991. [Google Scholar]

- Zaneldin, E.; Sivaloganathan, S. A framework for the selection of heavy construction equipment. In Proceedings of the International Annual Conference of the American Society for Engineering Management, Huntsville, AL, USA, 18–21 October 2017; pp. 1–11. [Google Scholar]

- Shehadeh, A.; Alshboul, O.; Tatari, O.; Alzubaidi, M.A.; Salama, A.H.E.S. Selection of heavy machinery for earthwork activities: A multi-objective optimization approach using a genetic algorithm. Alex. Eng. J. 2022, 61, 7555–7569. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.; Liu, S.; Zhang, Q.; Han, Y. A comprehensive overview of hybrid construction machinery. Adv. Mech. Eng. 2016, 8, 1–15. [Google Scholar] [CrossRef]

- Key, J.M. Earthmoving and heavy equipment. J. Constr. Eng. Manag. 1987, 113, 611–622. [Google Scholar] [CrossRef]

- Ergur, H.S. The importance of hydraulic systems in the machinery manufacturing industry. In Innovative Technology Applications in Engineering Sciences; Jain, R., Gullu, A., Yalcinkaya, S., Eds.; Güven Publishing: Çayyolu Çankaya Ankara, Türkiye, 2021; pp. 249–269. [Google Scholar]

- Jog, G.M.; Brilakis, I.K.; Angelides, D.C. Testing in harsh conditions: Tracking resources on construction sites with machine vision. Autom. Constr. 2011, 20, 328–337. [Google Scholar] [CrossRef]

- Jiang, Y.; He, X. Overview of applications of the sensor technologies for construction machinery. IEEE Access 2020, 8, 110324–110335. [Google Scholar] [CrossRef]

- Quan, Z.; Ge, L.; Wei, Z.; Li, Y.W.; Quan, L. A survey of powertrain technologies for energy-efficient heavy-duty machinery. Proc. IEEE 2021, 109, 279–308. [Google Scholar] [CrossRef]

- Khan, A.U.; Huang, L.; Onstein, E.; Liu, Y. Overview of emerging technologies for improving the performance of heavy-duty construction machines. IEEE Access 2022, 10, 103315–103336. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2021, 122, 103517. [Google Scholar] [CrossRef]

- Chirumalla, K. Managing product introduction projects in operations: Key challenges in heavy-duty vehicle industry. J. Mod. Proj. Manag. 2018, 5, 108–118. [Google Scholar]

- Masih-Tehrani, M.; Ebrahimi-Nejad, S.; Dahmardeh, M. Combined fuel consumption and emission optimization model for heavy construction equipment. Autom. Constr. 2020, 110, 103007. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, F.; Gong, G.; Yang, H.; Han, D. Intelligent technologies for construction machinery using data-driven methods. Autom. Constr. 2023, 147, 104711. [Google Scholar] [CrossRef]

- Wittenburg, J. Dynamics of Systems of Rigid Bodies; Teubner: Stuttgart, Germany, 1977. [Google Scholar]

- Chen, S.; Keys, L.K. A cost analysis model for heavy equipment. Comput. Ind. Eng. 2009, 56, 1276–1288. [Google Scholar] [CrossRef]

- Nikravesh, P.E. Computer-Aided Analysis of Mechanical Systems; Prentice Hall: Upper Saddle River, NJ, USA, 1988. [Google Scholar]

- Jaiswal, S.; Åman, R.; Sopanen, J.; Mikkola, A. Real-time multibody model-based heads-up display unit of a tractor. IEEE Access 2021, 9, 57645–57657. [Google Scholar] [CrossRef]

- Flores, P.; Lankarani, H.M. Contact Force Models for Multibody Dynamics; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Garcia de Jalon, J.; Bayo, E. Kinematic and Dynamic Simulation of Multibody Systems: The Real-Time Challenge; Springer: Berlin/Heidelberg, Germany, 1994. [Google Scholar]

- Imanishi, E.; Nanjo, T.; Hirooka, E.; Sugano, N. Fast simulation on flexible multibody dynamics using domain decomposition technique. J. Syst. Des. Dyn. 2007, 1, 387–397. [Google Scholar] [CrossRef]

- Cha, J.H.; Roh, M.I.; Lee, K.Y. Dynamic response simulation of a heavy cargo suspended by a floating crane based on multibody system dynamics. Ocean Eng. 2010, 37, 1273–1291. [Google Scholar] [CrossRef]

- Eberhard, P.; Schiehlen, W. Computational dynamics of multibody systems: History, formalisms, and applications. J. Comput. Nonlinear Dyn. 2006, 1, 3–12. [Google Scholar] [CrossRef]

- Gamucci, P.G. The Italian heavy mechanical engineering industry. Proc. Inst. Mech. Eng. 1969, 184, 1146–1155. [Google Scholar] [CrossRef]

- Paz, E.B.; Ceccarelli, M.; Otero, J.E.; Sanz, J.L.M. A Brief Illustrated History of Machines and Mechanisms; Springer Science & Business Media: Berlin, Germany, 2010. [Google Scholar]

- Gross, A.C.; Weiss, D.D. Industry corner: The global demand for heavy construction equipment. Bus. Econ. 1996, 31, 54–58. [Google Scholar]

- Ohno, K. The History of Japanese Economic Development: Origins of Private Dynamism and Policy Competence; Taylor & Francis: Abingdon, UK, 2017. [Google Scholar]

- Hildenbrand, J. Developments in heavy construction equipment. In Proceedings of the 65th Annual Road School; Purdue University: West Lafayette, Indiana, 1979; pp. 124–140. [Google Scholar]

- Chapman, J.E. The use of telemetry in heavy equipment testing at Caterpillar Inc. In Proceedings of the International Telemetering Conference, Las Vegas, NV, USA, 27–30 October 1997; pp. 42–47. [Google Scholar]

- Gross, A.C.; Hester, E.D. Heavy construction equipment: Vitality in an “old economy” sector. Bus. Econ. 2000, 35, 66. [Google Scholar]

- Tan, D.; Tan, J.; Peng, D.; Fu, M.; Zhang, H.; Yin, H.; Ding, Y. Study on real-world power-based emission factors from typical construction machinery. Sci. Total Environ. 2021, 799, 149436. [Google Scholar] [CrossRef]

- Statista. World’s Largest Construction Machinery Manufacturers by Sales 2023. 2024. Available online: https://www.statista.com/statistics/280343/leading-construction-machinery-manufacturers-worldwide-based-on-sales/ (accessed on 22 December 2024).

- Verdugo-Cedeño, M.; Jaiswal, S.; Ojanen, V.; Hannola, L.; Mikkola, A. Simulation-based digital twins enabling smart services for machine operations: An industry 5.0 approach. Int. J. Hum.-Interact. 2024, 40, 6327–6343. [Google Scholar] [CrossRef]

- EMR. Global Heavy Construction Equipment Market Size Analysis: Market Share, Forecast Trends, and Outlook Report (2024–2032). 2024. Available online: https://www.expertmarketresearch.com/reports/heavy-construction-equipment-market (accessed on 22 December 2024).

- Azar, E.R.; Kamat, V.R. Earthmoving equipment automation: A review of technical advances and future outlook. J. Inf. Technol. Constr. 2017, 22, 247–265. [Google Scholar]

- Blaettchen, P.; Taneri, N.; Hasija, S. Business model choice for heavy equipment manufacturers. Oper. Res. 2024, 72, 2263–2278. [Google Scholar] [CrossRef]

- Tseng, F.C.; Ma, Z.D.; Hulbert, G.M. Efficient numerical solution of constrained multibody dynamics systems. Comput. Methods Appl. Mech. Eng. 2003, 192, 439–472. [Google Scholar] [CrossRef]

- Schiehlen, W.; Guse, N.; Seifried, R. Multibody dynamics in computational mechanics and engineering applications. Comput. Methods Appl. Mech. Eng. 2006, 195, 5509–5522. [Google Scholar] [CrossRef]

- McPhee, J.; Redmond, S. Modelling multibody systems with indirect coordinates. Comput. Methods Appl. Mech. Eng. 2006, 195, 6942–6957. [Google Scholar] [CrossRef]

- Bayo, E.; Ledesma, R. Augmented Lagrangian and mass-orthogonal projection methods for constrained multibody dynamics. Nonlinear Dyn. 1996, 9, 113–130. [Google Scholar] [CrossRef]

- Cuadrado, J.; Dopico, D.; Naya, M.; Gonzalez, M. Real-time multibody dynamics and applications. In Simulation Techniques for Applied Dynamics; Arnold, M., Schiehlen, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 247–311. [Google Scholar]

- Cuadrado, J.; Dopico, D.; Gonzalez, M.; Naya, M. A combined penalty and recursive real-time formulation for multibody dynamics. J. Mech. Des. 2004, 126, 602–608. [Google Scholar] [CrossRef]

- Pan, Y.; Dai, W.; Xiong, Y.; Xiang, S.; Mikkola, A. Tree-topology-oriented modeling for the real-time simulation of sedan vehicle dynamics using independent coordinates and the rod-removal technique. Mech. Mach. Theory 2020, 143, 103626. [Google Scholar] [CrossRef]

- Pan, Y.; Xiang, S.; He, Y.; Zhao, J.; Mikkola, A. The validation of a semi-recursive vehicle dynamics model for a real-time simulation. Mech. Mach. Theory 2020, 151, 103907. [Google Scholar] [CrossRef]

- Garcia de Jalon, J.; Alvarez, E.; de Ribera, F.A.; Rodriguez, I.; Funes, F.J. A fast and simple semi-recursive formulation for multi-rigid-body systems. In Advances in Computational Multibody Systems; Ambrosio, J.A.C., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 1–23. [Google Scholar]

- Dopico, D.; Lopez Varela, A.; Luaces Fernandez, A. Augmented Lagrangian index-3 semi-recursive formulations with projections: Kinematics and dynamics. Multibody Syst. Dyn. 2021, 52, 377–405. [Google Scholar] [CrossRef]

- Bayo, E.; Garcia de Jalon, J.; Avello, A.; Cuadrado, J. An efficient computational method for real time multibody dynamic simulation in fully Cartesian coordinates. Comput. Methods Appl. Mech. Eng. 1991, 92, 377–395. [Google Scholar] [CrossRef]

- Rahikainen, J.; Mikkola, A.; Sopanen, J.; Gerstmayr, J. Combined semi-recursive formulation and lumped fluid method for monolithic simulation of multibody and hydraulic dynamics. Multibody Syst. Dyn. 2018, 44, 293–311. [Google Scholar] [CrossRef]

- Avello, A.; Jimenez, J.M.; Bayo, E.; Garcia de Jalon, J. A simple and highly parallelizable method for real-time dynamic simulation based on velocity transformations. Comput. Methods Appl. Mech. Eng. 1993, 107, 313–339. [Google Scholar] [CrossRef]

- Varela, A.L.; Dopico, D.; Fernandez, A.L. An analytical approach to the sensitivity analysis of semi-recursive ODE formulations for multibody dynamics. Comput. Struct. 2025, 308, 107642. [Google Scholar] [CrossRef]

- Bae, D.S.; Lee, J.K.; Cho, H.J.; Yae, H. An explicit integration method for real-time simulation of multibody vehicle models. Comput. Methods Appl. Mech. Eng. 2000, 187, 337–350. [Google Scholar] [CrossRef]

- Pan, Y.; Dai, W.; Huang, L.; Li, Z.; Mikkola, A. Iterative refinement algorithm for efficient velocities and accelerations solutions in closed-loop multibody dynamics. Mech. Syst. Signal Process. 2021, 152, 107463. [Google Scholar] [CrossRef]

- Haug, E.J. Computer-Aided Kinematics and Dynamics of Mechanical Systems; Allyn and Bacon: Boston, MA, USA, 1989. [Google Scholar]

- Ramon, H.; De Baerdemaeker, J. A modelling procedure for linearized motions of tree structured multibodies—2: Design of an active spray boom suspension on a spraying-machine. Comput. Struct. 1996, 59, 361–375. [Google Scholar] [CrossRef]

- Sheth, P.N.; Craig, K.C.; Mattice, M.; Banks, S. Design and development of a computer-aided engineering environment for controlled multibody systems. J. Eng. Des. 1991, 2, 175–195. [Google Scholar] [CrossRef]

- Moon, F.C. Applied Dynamics: With Applications to Multibody and Mechatronic Systems; Wiley: Hoboken, NJ, USA, 1998. [Google Scholar]

- Korkealaakso, P.; Rouvinen, A.; Moisio, S.; Peusaari, J. Development of a real-time simulation environment. Multibody Syst. Dyn. 2007, 17, 177–194. [Google Scholar] [CrossRef]

- Yoo, W.S.; Kim, O.J.; Kim, K.S.; Kang, D.K.; Yoon, K.H. Estimation of maximum lifting load capacities of a hydraulic excavator via multibody computer modeling and simulation. KSME Int. J. 1998, 12, 1090–1096. [Google Scholar] [CrossRef]

- Nanjo, T.; Sugano, N.; Imanishi, E. Fast simulation of flexible multibody dynamics using improved domain decomposition technique. In Proceedings of the Asian Conference on Multibody Dynamics, Kyoto, Japan, 23–27 August 2010; p. 56492. [Google Scholar]

- Sun, G.; Kleeberger, M. Dynamic responses of hydraulic mobile crane with consideration of the drive system. Mech. Mach. Theory 2003, 38, 1489–1508. [Google Scholar] [CrossRef]

- Baharudin, M.E.; Rouvinen, A.; Korkealaakso, P.; Mikkola, A. Real-time multibody application for tree harvester truck simulator. Proc. Inst. Mech. Eng. Part K J. Multibody Dyn. 2014, 228, 182–198. [Google Scholar] [CrossRef]

- Kurinov, I.; Orzechowski, G.; Hämäläinen, P.; Mikkola, A. Automated excavator based on reinforcement learning and multibody system dynamics. IEEE Access 2020, 8, 213998–214006. [Google Scholar] [CrossRef]

- Palomba, I.; Richiedei, D.; Trevisani, A.; Sanjurjo, E.; Luaces, A.; Cuadrado, J. Estimation of the digging and payload forces in excavators by means of state observers. Mech. Syst. Signal Process. 2019, 134, 106356. [Google Scholar] [CrossRef]

- Jaiswal, S.; Sanjurjo, E.; Cuadrado, J.; Sopanen, J.; Mikkola, A. State estimator based on an indirect Kalman filter for a hydraulically actuated multibody system. Multibody Syst. Dyn. 2022, 54, 373–398. [Google Scholar] [CrossRef]

- Goswami, G.; Tupitsina, A.; Jaiswal, S.; Nutakor, C.; Lindh, T.; Sopanen, J. Comparison of various hybrid electric powertrains for non-road mobile machinery using real-time multibody simulation. IEEE Access 2022, 10, 107631–107648. [Google Scholar] [CrossRef]

- Goswami, G.; Jaiswal, S.; Nutakor, C.; Sopanen, J. Co-simulation platform for simulating heavy mobile machinery with hydraulic actuators and various hybrid electric powertrains. IEEE Access 2022, 10, 105770–105785. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).