Comparative Analysis of Dry, Minimum Quantity Lubrication, and Nano-Reinforced Minimum Quantity Lubrication Environments on the Machining Performance of AZ91D Magnesium Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experiments

2.3. Experimental Measurement Procedures

3. Results

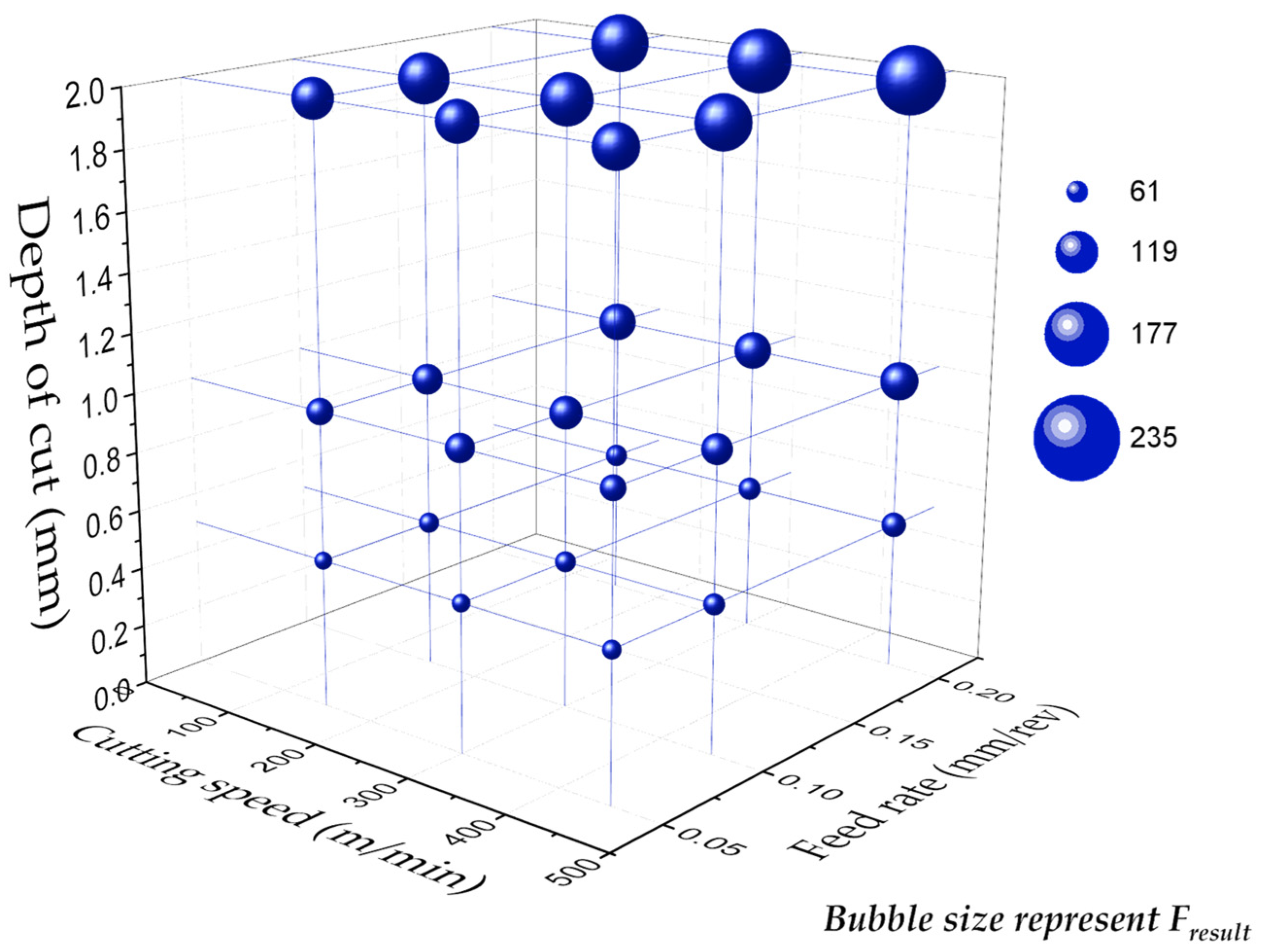

3.1. Analysis of Machining Forces

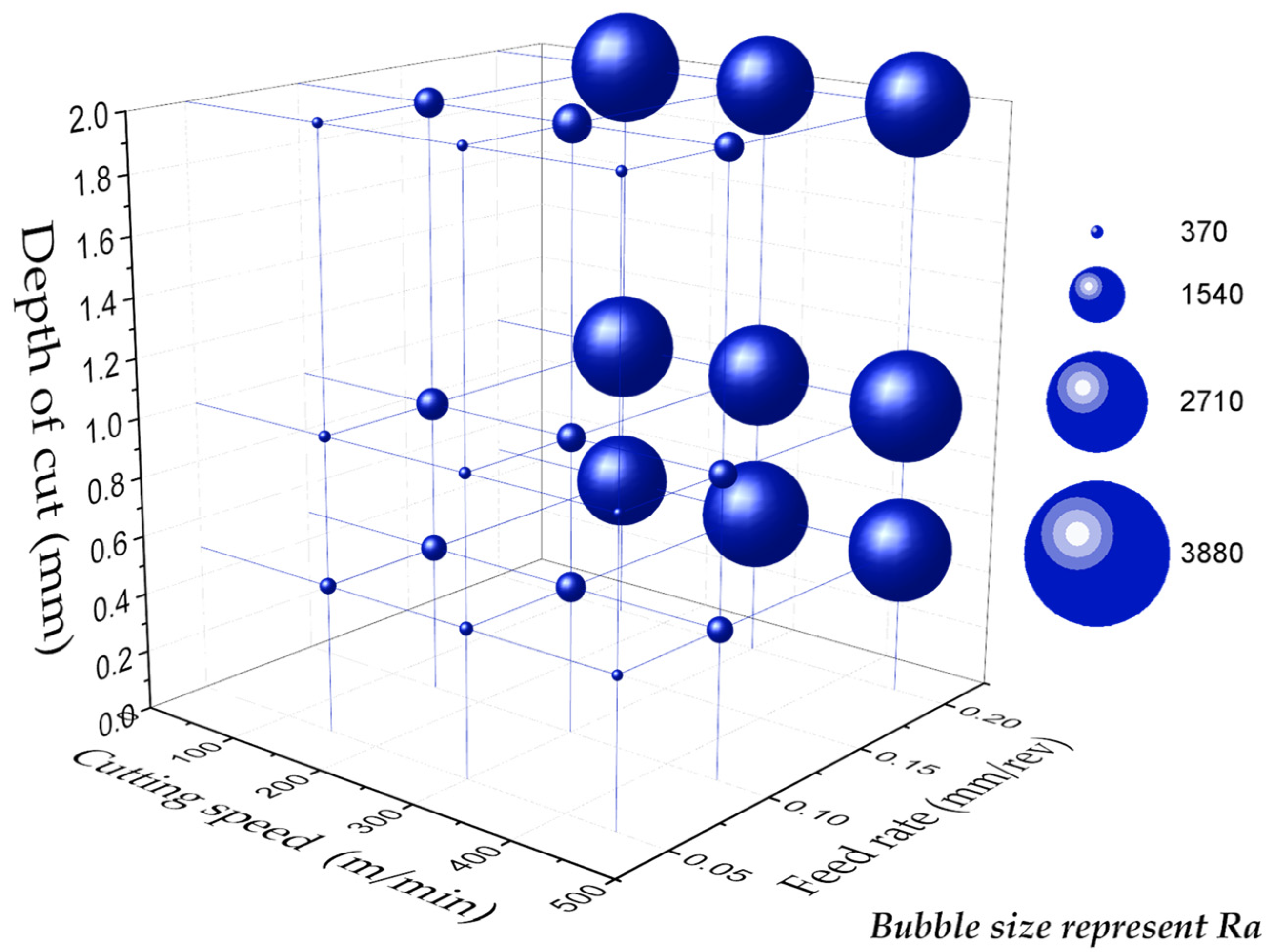

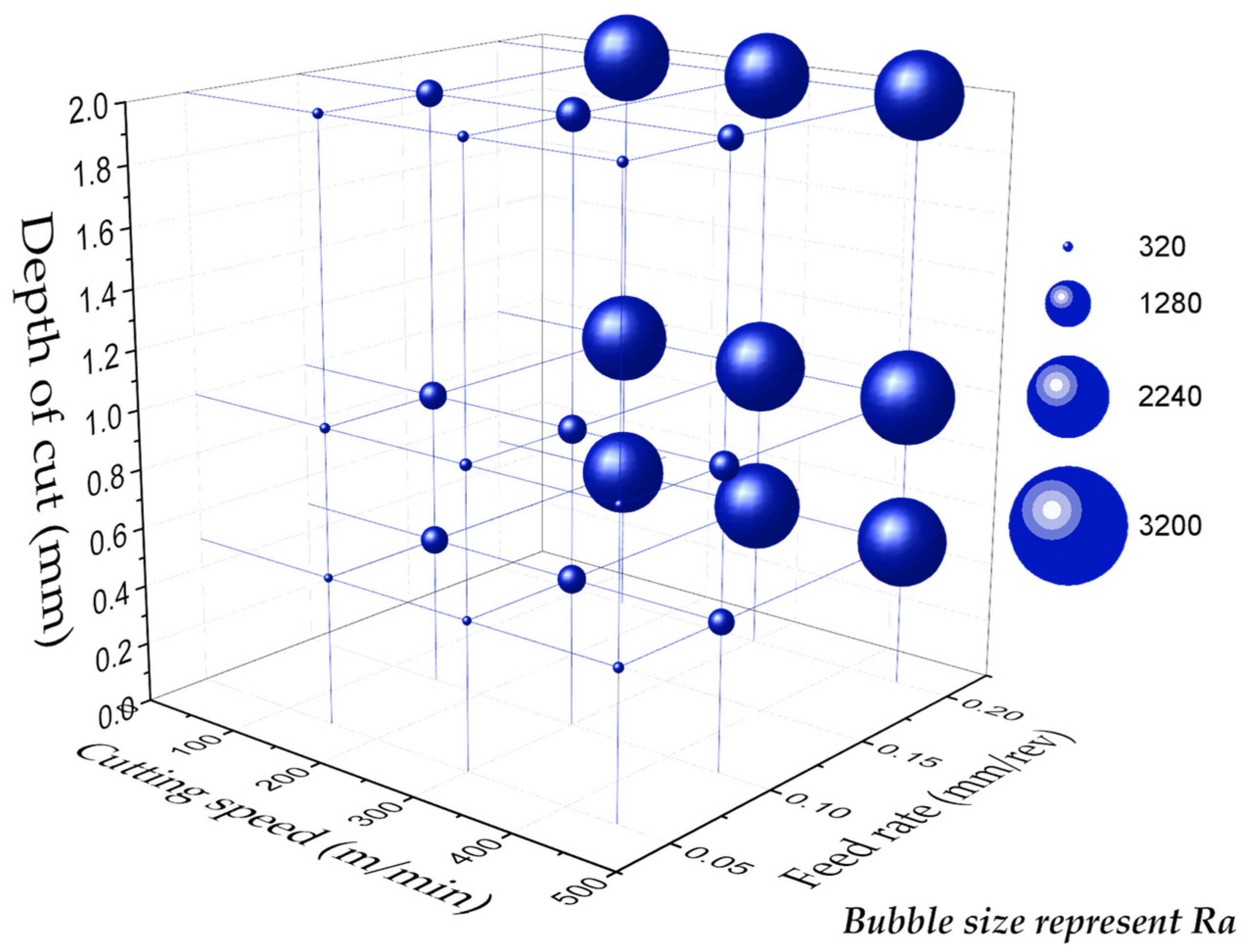

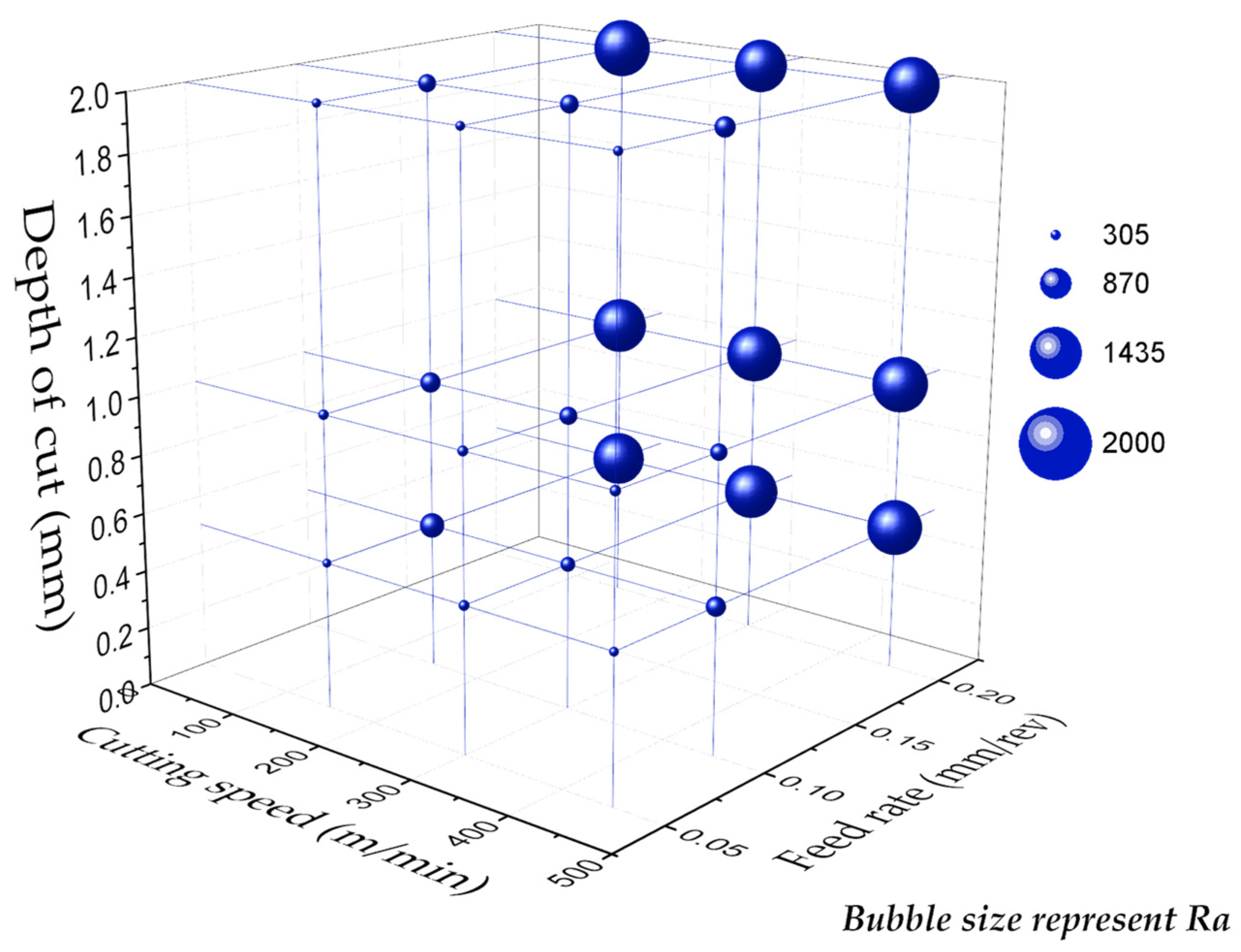

3.2. Surface Roughness Evaluation

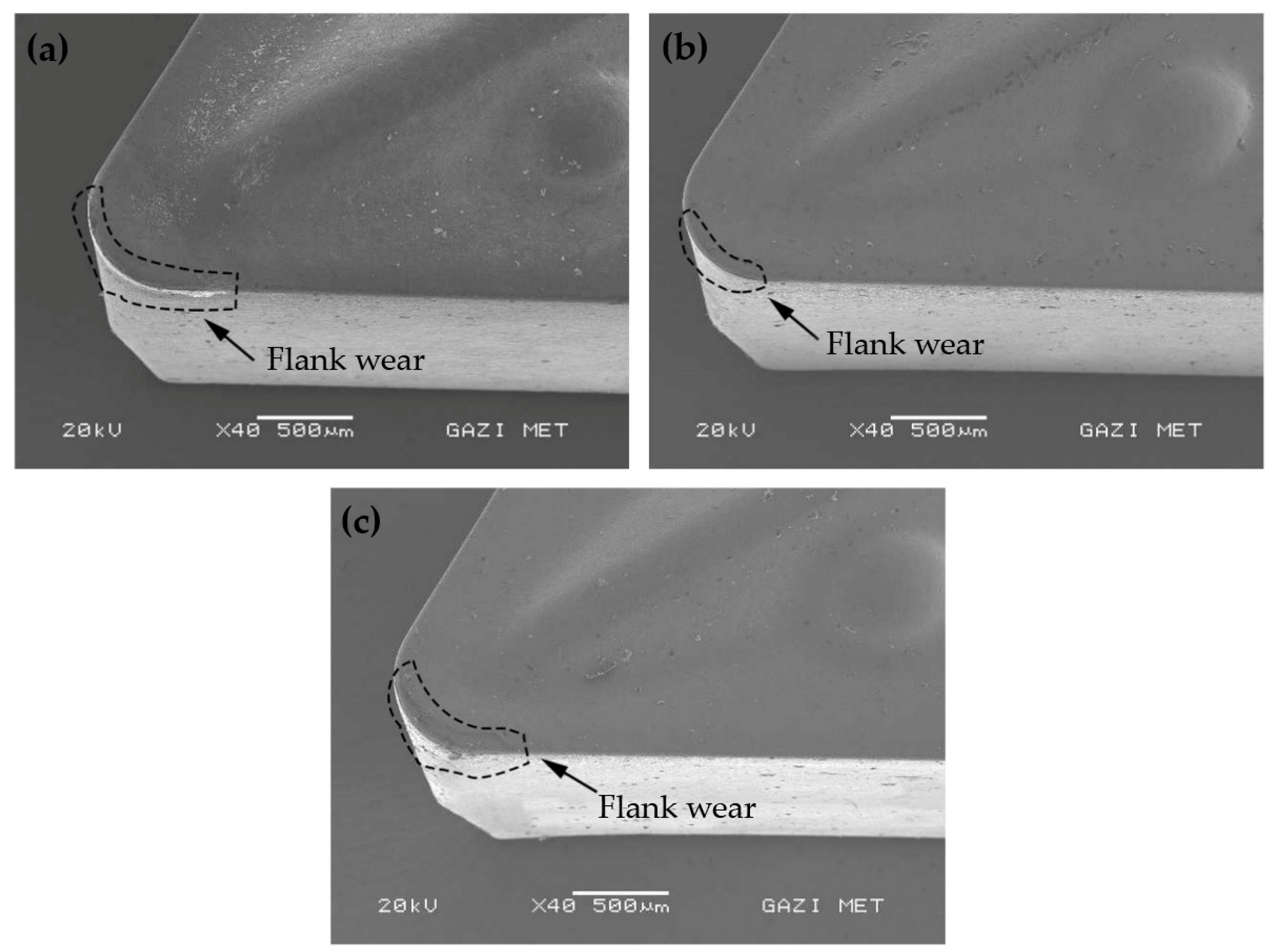

3.3. Tool Wear Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Y.; Xiong, X.; Chen, J.; Peng, X.; Chen, D.; Pan, F. Research advances of magnesium and magnesium alloys worldwide in 2022. J. Magnes. Alloys 2023, 11, 2611. [Google Scholar] [CrossRef]

- Risaliti, E.; Del Pero, F.; Arcidiacono, G.; Citti, P. Optimizing Lightweight Material Selection in Automotive Engineering: A Hybrid Methodology Incorporating Ashby’s Method and VIKOR Analysis. Machines 2025, 13, 63. [Google Scholar] [CrossRef]

- Tan, J.; Ramakrishna, S. Applications of magnesium and its alloys: A review. Appl. Sci. 2021, 11, 6861. [Google Scholar] [CrossRef]

- Maqbool, A.; Khan, N.Z.; Siddiquee, A.N. Towards Mg based light materials of future: Properties, applications, problems, and their mitigation. J. Manuf. Sci. Eng. 2022, 144, 030801. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, Z.; Han, S.; Gu, Y.; Zhu, Z.; Zhang, H. Evolution, limitations, advantages, and future challenges of magnesium alloys as materials for aerospace applications. J. Alloys Compd. 2024, 1008, 176707. [Google Scholar] [CrossRef]

- Manjunath, K.; Tewary, S.; Khatri, N.; Cheng, K. Monitoring and predicting the surface generation and surface roughness in ultraprecision machining: A critical review. Machines 2021, 9, 369. [Google Scholar] [CrossRef]

- Tiwari, A.; Singh, D.; Mishra, S. A review on minimum quantity lubrication in machining of different alloys and superalloys using nanofluids. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 112. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Effects of Minimum Quantity Lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Li, D.; Zhang, T.; Zheng, T.; Zhao, N.; Li, Z. A comprehensive review of minimum quantity lubrication (MQL) machining technology and cutting performance. Int. J. Adv. Manuf. Technol. 2024, 133, 2681. [Google Scholar] [CrossRef]

- Pu, Z.; Outeiro, J.C.; Batista, A.C.; Dillon, O.W., Jr.; Puleo, D.A.; Jawahir, I.S. Enhanced surface integrity of AZ31B Mg alloy by cryogenic machining towards improved functional performance of machined components. Int. J. Mach. Tools Manuf. 2012, 56, 17. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Zhang, Y.; Yang, M.; Li, B.; Jia, D.; Hou, Y.; Mao, C. Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. J. Clean. Prod. 2016, 127, 487. [Google Scholar] [CrossRef]

- Jouini, N.; Ruslan, M.S.M.; Ghani, J.A.; Che Haron, C.H. Sustainable high-speed milling of magnesium alloy AZ91D in dry and cryogenic conditions. Sustainability 2023, 15, 3760. [Google Scholar] [CrossRef]

- Zagórski, I.; Korpysa, J. Surface quality in milling of AZ91D magnesium alloy. Adv. Sci. Technol. Res. J. 2019, 13, 119. [Google Scholar] [CrossRef]

- Marakini, V.; Pai, S.P.; Bhat, U.K.; Thakur, D.S.; Achar, B.P. High-speed face milling of AZ91 Mg alloy: Surface integrity investigations. Int. J. Lightweight Mater. Manuf. 2022, 5, 528. [Google Scholar] [CrossRef]

- Cagan, S.C.; Buldum, B.B. A study on the machinability of environmentally friendly turning of titanium grade 2 alloy. J. Tribol. 2024, 146, 064201. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K. Nano lubricants in machining and tribology applications: A state of the art review on challenges and future trend. J. Mol. Liq. 2024, 407, 125261. [Google Scholar] [CrossRef]

- Tomac, N.; Tannessen, K.; Rasch, F.O. Machinability of particulate aluminium matrix composites. CIRP Ann. 1992, 41, 55. [Google Scholar] [CrossRef]

- Chu, A.; Li, C.; Zhou, Z.; Liu, B.; Zhang, Y.; Yang, M.; Gao, T.; Liu, M.; Zhang, N.; Dambatta, Y.S.; et al. Nanofluids minimal quantity lubrication machining: From mechanisms to application. Lubricants 2023, 11, 422. [Google Scholar] [CrossRef]

- Viswanathan, R.; Ramesh, S.; Subburam, V. Measurement and optimization of performance characteristics in turning of Mg alloy under dry and MQL conditions. Measurement 2018, 120, 107. [Google Scholar] [CrossRef]

- Ji, C.; Sheng, R.; Wu, H.; Zhou, Z.; Yan, X.; Dong, L.; Li, C. Bibliometric analysis and research trends in minimum quantity lubrication for reducing cutting forces. Int. J. Adv. Manuf. Technol. 2024, 135, 4995–5033. [Google Scholar] [CrossRef]

- Dixit, U.S.; Sarma, D.; Davim, J.P. Environmentally Friendly Machining; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Kumar, A.; Gill, S.; Singh, G.; Sharma, S.; Dwivedi, S.; Mohammed, K.; Sharma, K.; Kozak, D.; Hunjet, A.; Abbas, M. Experimental investigation into machining performance of magnesium alloy AZ91D under dry, minimum quantity lubrication, and nano minimum quantity lubrication environments. High Temp. Mater. Process. 2024, 43, 20220328. [Google Scholar] [CrossRef]

- Cica, D.; Tesic, S.; Markovic, M.; Sredanovic, B.; Borojevic, S.; Zeljkovic, M.; Kramar, D.; Pušavec, F. Multi-Objective Optimization of Milling Ti-6Al-4V Alloy for Improved Surface Integrity and Sustainability Performance. Machines 2025, 13, 221. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Attia, H.; Biermann, D.; Duflou, J.; Klocke, F.; Meyer, D.; Newman, S.T.; Pusavec, F.; Putz, M.; Rech, J.; et al. Cryogenic manufacturing processes. CIRP Ann. 2016, 65, 713. [Google Scholar] [CrossRef]

- Srikant, R.R.; Rao, D.N.; Subrahmanyam, M.S.; Krishna, V.P. Applicability of cutting fluids with nanoparticle inclusion as coolants in machining. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2009, 223, 221. [Google Scholar] [CrossRef]

- Trent, E.M.; Wright, P.K. Metal Cutting; Butterworth-Heinemann: Oxford, UK, 2000. [Google Scholar]

- Singh, V.; Sharma, A.K.; Sahu, R.K.; Katiyar, J.K. State of the art on sustainable manufacturing using mono/hybrid nano-cutting fluids with minimum quantity lubrication. Mater. Manuf. Process. 2022, 37, 603. [Google Scholar] [CrossRef]

- Said, Z.; Gupta, M.; Hegab, H.; Arora, N.; Khan, A.M.; Jamil, M.; Bellos, E. A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int. J. Adv. Manuf. Technol. 2019, 105, 2057. [Google Scholar] [CrossRef]

- ISO 3685:1993; Tool Life Testing with Single-Point Turning Tools. International Organization for Standardisation: Geneva, Switzerland, 1993.

- Sousa, V.F.; Gil, J.; Silva, T.E.; de Jesus, A.M.; Silva, F.J.; Tavares, J.M.R. An Image Analysis Algorithm for Measuring Flank Wear in Coated End-Mills. Comput. Mater. Contin. 2025, 83, 177. [Google Scholar] [CrossRef]

- ImageJ Software, Image Processing and Analysis in Java. Available online: https://imagej.net/ij/ (accessed on 12 May 2025).

- Sun, S.; Brandt, M.; Dargusch, M.S. Characteristics of cutting forces and chip formation in machining of titanium alloys. Int. J. Mach. Tools Manuf. 2009, 49, 561. [Google Scholar] [CrossRef]

- Nouari, M.; List, G.; Girot, F.; Coupard, D. Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 2003, 255, 1359. [Google Scholar] [CrossRef]

- Mabrouki, T.; Girardin, F.; Asad, M.; Rigal, J.F. Numerical and experimental study of dry cutting for an aeronautic aluminium alloy (A2024-T351). Int. J. Mach. Tools Manuf. 2008, 48, 1187. [Google Scholar] [CrossRef]

- Dandekar, C.R.; Shin, Y.C.; Barnes, J. Machinability improvement of titanium alloy (Ti–6Al–4V) via LAM and hybrid machining. Int. J. Mach. Tools Manuf. 2010, 50, 174. [Google Scholar] [CrossRef]

- Davim, J.P. Design of optimisation of cutting parameters for turning metal matrix composites based on the orthogonal arrays. J. Mater. Process. Technol. 2003, 132, 340. [Google Scholar] [CrossRef]

- Shaw, M.C.; Cookson, J. Metal Cutting Principles; Oxford University Press: New York, NY, USA, 2005. [Google Scholar]

- Sallakhniknezhad, R.; Ahmadian, H.; Zhou, T.; Weijia, G.; Anantharajan, S.K.; Sadoun, A.M.; Abdelfattah, W.M.; Fathy, A. Recent Advances and Applications of Carbon Nanotubes (CNTs) in Machining Processes: A Review. J. Manuf. Mater. Process. 2024, 8, 282. [Google Scholar] [CrossRef]

- Carou, D.; Rubio, E.M.; Davim, J.P. Machinability of magnesium and its alloys: A review. Tradit. Mach. Process. 2015, 133–152. [Google Scholar] [CrossRef]

- Haghnazari, S.; Abedini, V. Effects of hybrid Al2O3–CuO nanofluids on surface roughness and machining forces during turning AISI 4340. SN Appl. Sci. 2021, 3, 203. [Google Scholar] [CrossRef]

- Akyüz, B. Wear and machinability properties of AS series magnesium alloys. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 701. [Google Scholar] [CrossRef]

- Manikanta, J.E.; Abdullah, M.; Ambhore, N.; Kotteda, T.K. Analysis of machining performance in turning with trihybrid nanofluids and minimum quantity lubrication. Sci. Rep. 2025, 15, 12194. [Google Scholar] [CrossRef]

- Vardhanapu, M.; Chaganti, P.K.; Tarigopula, P. Characterization and machine learning-based parameter estimation in MQL machining of a superalloy for developed green nano-metalworking fluids. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 154. [Google Scholar] [CrossRef]

- Sharma, V.S.; Dogra, M.; Suri, N. Cooling techniques for improved productivity in turning. Int. J. Mach. Tools Manuf. 2009, 49, 435. [Google Scholar] [CrossRef]

- Aslan, A.; Salur, E. Applications of nanofluids in minimum quantity lubrication machining. Nanomater. Manuf. Process. 2022, 53–84. [Google Scholar] [CrossRef]

- Kanth, V.K.; Sreeramulu, D.; Srikiran, S.; Kumar, M.P.; Jagdeesh, K.E.; Govindh, B. Experimental investigation of cutting parameters using nano lubrication on turning AISI 1040 steel. Mater. Today Proc. 2019, 18, 2095. [Google Scholar] [CrossRef]

- Patole, P.B.; Kulkarni, V.V.; Bhatwadekar, S.G. MQL Machining with nano fluid: A review. Manuf. Rev. 2021, 8, 13. [Google Scholar] [CrossRef]

- Altaf, S.F.; Parray, M.A.; Khan, M.J.; Bhat, F.A. Machining with minimum quantity lubrication and nano-fluid MQL: A review. Tribol. Online 2024, 19, 209. [Google Scholar] [CrossRef]

- Xu, M.; Ali, S.; Kurniawan, R.; Gautam, R.K.S.; Sundaresan, T.K.; Ahmad, K. Nanoparticle-based lubrication during machining: Synthesis, application, and future scope—A critical review. Int. J. Adv. Manuf. Technol. 2025, 136, 4141. [Google Scholar] [CrossRef]

| Parameters | Units | Levels | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| Cutting Speed | m/min | 150 | 300 | 450 |

| Feed rate | mm/rev | 0.05 | 0.1 | 0.2 |

| Depth of Cut | mm | 0.5 | 1 | 2 |

| Cooling environments | - | Dry | MQL | NanoMQL |

| Exp No. | Cutting Speed | Feed Rate | Depth of Cut | Fx (N) | Fy (N) | Fz (N) | Fresult (N) |

|---|---|---|---|---|---|---|---|

| 1 | 150 | 0.05 | 0.5 | 28.36 | 23.75 | 51.84 | 63.685 |

| 2 | 150 | 0.05 | 1 | 52.22 | 23.64 | 69.41 | 90.020 |

| 3 | 150 | 0.05 | 2 | 91.93 | 20.44 | 102.85 | 139.453 |

| 4 | 150 | 0.1 | 0.5 | 30.23 | 23.74 | 59.38 | 70.735 |

| 5 | 150 | 0.1 | 1 | 57.37 | 24.41 | 85.82 | 106.077 |

| 6 | 150 | 0.1 | 2 | 100.97 | 23.51 | 135.7 | 170.769 |

| 7 | 150 | 0.2 | 0.5 | 31.36 | 27.14 | 72.78 | 83.767 |

| 8 | 150 | 0.2 | 1 | 67.35 | 24.59 | 115.64 | 136.064 |

| 9 | 150 | 0.2 | 2 | 98.67 | 25.02 | 183.17 | 209.554 |

| 10 | 300 | 0.05 | 0.5 | 28.7 | 19.95 | 49.82 | 60.858 |

| 11 | 300 | 0.05 | 1 | 58.9 | 26.27 | 71.04 | 95.948 |

| 12 | 300 | 0.05 | 2 | 89.29 | 21.92 | 101.17 | 136.706 |

| 13 | 300 | 0.1 | 0.5 | 31.04 | 27.38 | 61.04 | 73.750 |

| 14 | 300 | 0.1 | 1 | 64.42 | 24.65 | 88.94 | 112.552 |

| 15 | 300 | 0.1 | 2 | 105.51 | 22.37 | 136.72 | 174.141 |

| 16 | 300 | 0.2 | 0.5 | 30.1 | 24.91 | 74.49 | 84.115 |

| 17 | 300 | 0.2 | 1 | 61.92 | 32.95 | 114.06 | 133.901 |

| 18 | 300 | 0.2 | 2 | 116.78 | 27.82 | 187.79 | 222.882 |

| 19 | 450 | 0.05 | 0.5 | 30.46 | 24.2 | 50.42 | 63.684 |

| 20 | 450 | 0.05 | 1 | 48.83 | 19.42 | 66.75 | 84.953 |

| 21 | 450 | 0.05 | 2 | 98.91 | 21.44 | 102.89 | 144.323 |

| 22 | 450 | 0.1 | 0.5 | 31.87 | 25.43 | 60.83 | 73.230 |

| 23 | 450 | 0.1 | 1 | 54.74 | 23.74 | 84.2 | 103.197 |

| 24 | 450 | 0.1 | 2 | 107.99 | 22.99 | 136.02 | 175.191 |

| 25 | 450 | 0.2 | 0.5 | 41.12 | 30.4 | 71.89 | 88.222 |

| 26 | 450 | 0.2 | 1 | 59.36 | 29.23 | 111.94 | 130.033 |

| 27 | 450 | 0.2 | 2 | 131.53 | 30.6 | 191.62 | 234.424 |

| Cutting Speed | Feed Rate | Depth of Cut | Ra (Dry, μm) | Ra (MQL, μm) | Ra (NanoMQL, μm) |

|---|---|---|---|---|---|

| 150 | 0.05 | 0.5 | 0.587 | 0.322 | 1.910 |

| 150 | 0.05 | 1 | 0.405 | 0.356 | 2.660 |

| 150 | 0.05 | 2 | 0.399 | 0.360 | 2.386 |

| 150 | 0.1 | 0.5 | 0.933 | 0.966 | 4.393 |

| 150 | 0.1 | 1 | 1.137 | 0.986 | 3.784 |

| 150 | 0.1 | 2 | 1.007 | 0.940 | 4.018 |

| 150 | 0.2 | 0.5 | 3.353 | 3.042 | 8.098 |

| 150 | 0.2 | 1 | 3.703 | 3.128 | 8.424 |

| 150 | 0.2 | 2 | 3.897 | 3.084 | 9.965 |

| 300 | 0.05 | 0.5 | 0.492 | 0.348 | 2.535 |

| 300 | 0.05 | 1 | 0.421 | 0.423 | 2.578 |

| 300 | 0.05 | 2 | 0.382 | 0.389 | 2.208 |

| 300 | 0.1 | 0.5 | 1.01 | 0.954 | 3.766 |

| 300 | 0.1 | 1 | 0.964 | 0.958 | 3.827 |

| 300 | 0.1 | 2 | 1.251 | 1.121 | 4.308 |

| 300 | 0.2 | 0.5 | 3.833 | 3.053 | 8.463 |

| 300 | 0.2 | 1 | 3.557 | 3.168 | 8.429 |

| 300 | 0.2 | 2 | 3.386 | 2.924 | 8.809 |

| 450 | 0.05 | 0.5 | 0.391 | 0.380 | 2.110 |

| 450 | 0.05 | 1 | 0.39 | 0.397 | 2.600 |

| 450 | 0.05 | 2 | 0.377 | 0.387 | 2.160 |

| 450 | 0.1 | 0.5 | 0.885 | 0.893 | 3.744 |

| 450 | 0.1 | 1 | 0.946 | 0.964 | 3.032 |

| 450 | 0.1 | 2 | 0.921 | 0.842 | 3.959 |

| 450 | 0.2 | 0.5 | 3.571 | 3.062 | 8.190 |

| 450 | 0.2 | 1 | 3.815 | 3.210 | 7.929 |

| 450 | 0.2 | 2 | 3.498 | 2.993 | 8.728 |

| Lubrication Condition | Average Flank Wear (VB, μm) |

|---|---|

| Dry | 163 ± 4 |

| MQL | 94 ± 7 |

| NanoMQL | 58 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buldum, B.B.; Leksycki, K.; Cagan, S.C. Comparative Analysis of Dry, Minimum Quantity Lubrication, and Nano-Reinforced Minimum Quantity Lubrication Environments on the Machining Performance of AZ91D Magnesium Alloy. Machines 2025, 13, 430. https://doi.org/10.3390/machines13050430

Buldum BB, Leksycki K, Cagan SC. Comparative Analysis of Dry, Minimum Quantity Lubrication, and Nano-Reinforced Minimum Quantity Lubrication Environments on the Machining Performance of AZ91D Magnesium Alloy. Machines. 2025; 13(5):430. https://doi.org/10.3390/machines13050430

Chicago/Turabian StyleBuldum, Berat Baris, Kamil Leksycki, and Suleyman Cinar Cagan. 2025. "Comparative Analysis of Dry, Minimum Quantity Lubrication, and Nano-Reinforced Minimum Quantity Lubrication Environments on the Machining Performance of AZ91D Magnesium Alloy" Machines 13, no. 5: 430. https://doi.org/10.3390/machines13050430

APA StyleBuldum, B. B., Leksycki, K., & Cagan, S. C. (2025). Comparative Analysis of Dry, Minimum Quantity Lubrication, and Nano-Reinforced Minimum Quantity Lubrication Environments on the Machining Performance of AZ91D Magnesium Alloy. Machines, 13(5), 430. https://doi.org/10.3390/machines13050430