Research on Vehicle Road Noise Prediction Based on AFW-LSTM

Abstract

1. Introduction

1.1. Background

1.2. Research Status of Road Noise

1.3. Contributions and Structure

- In order to further improve the prediction accuracy of the model, an adaptive feature weight layer is added to the traditional neural network model, which effectively improves the accuracy of the model prediction results.

- In order to simultaneously predict the multi-frequency interior noise performance under different working conditions, LSTM, CNN-LSTM, AFW-CNN and AFW-LSTM methods are used to predict the multi-frequency interior noise.

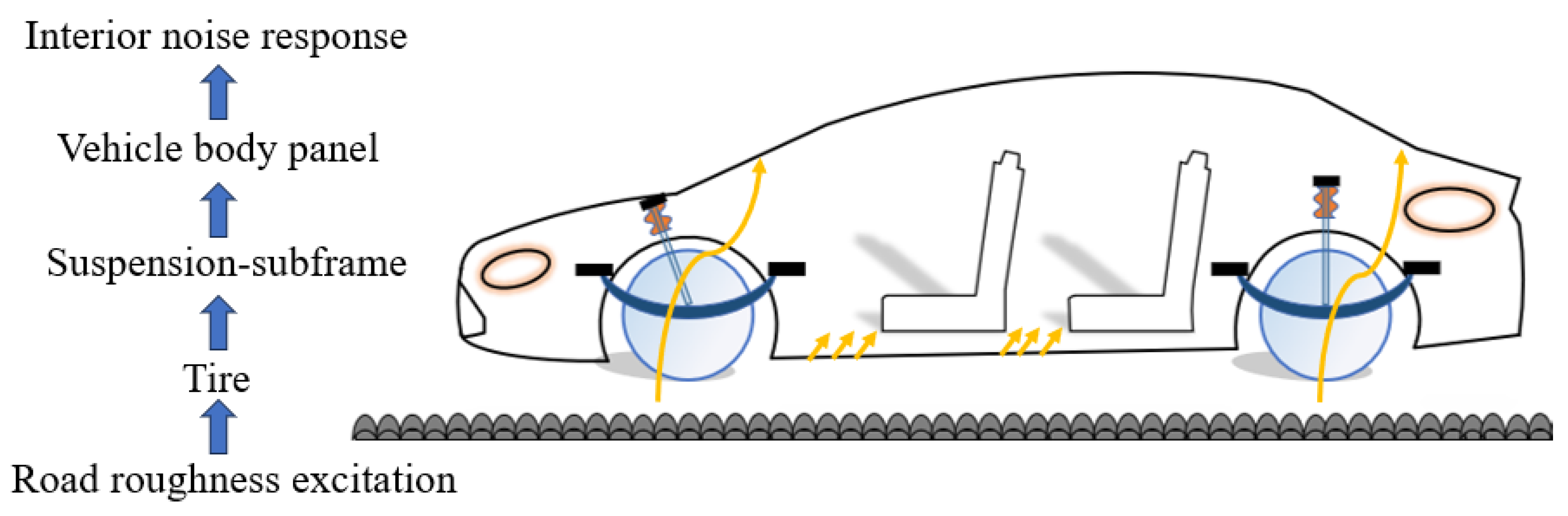

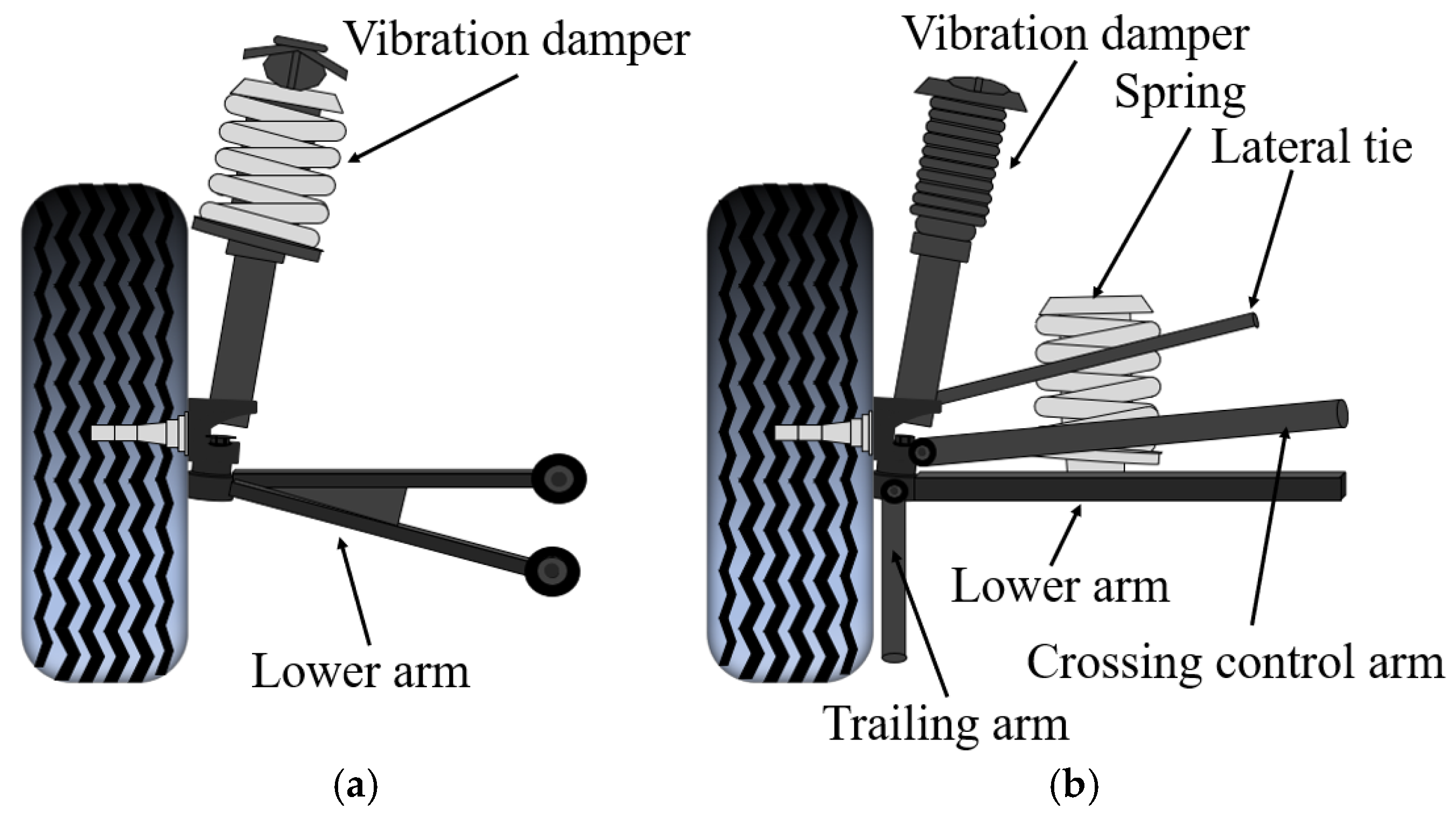

- By analyzing the structure with large noise contribution in the road noise transmission path, the structure with significant influence is defined, the components and quantitative indicators of each level are determined, and the road noise decomposition framework is established.

2. Research Methods

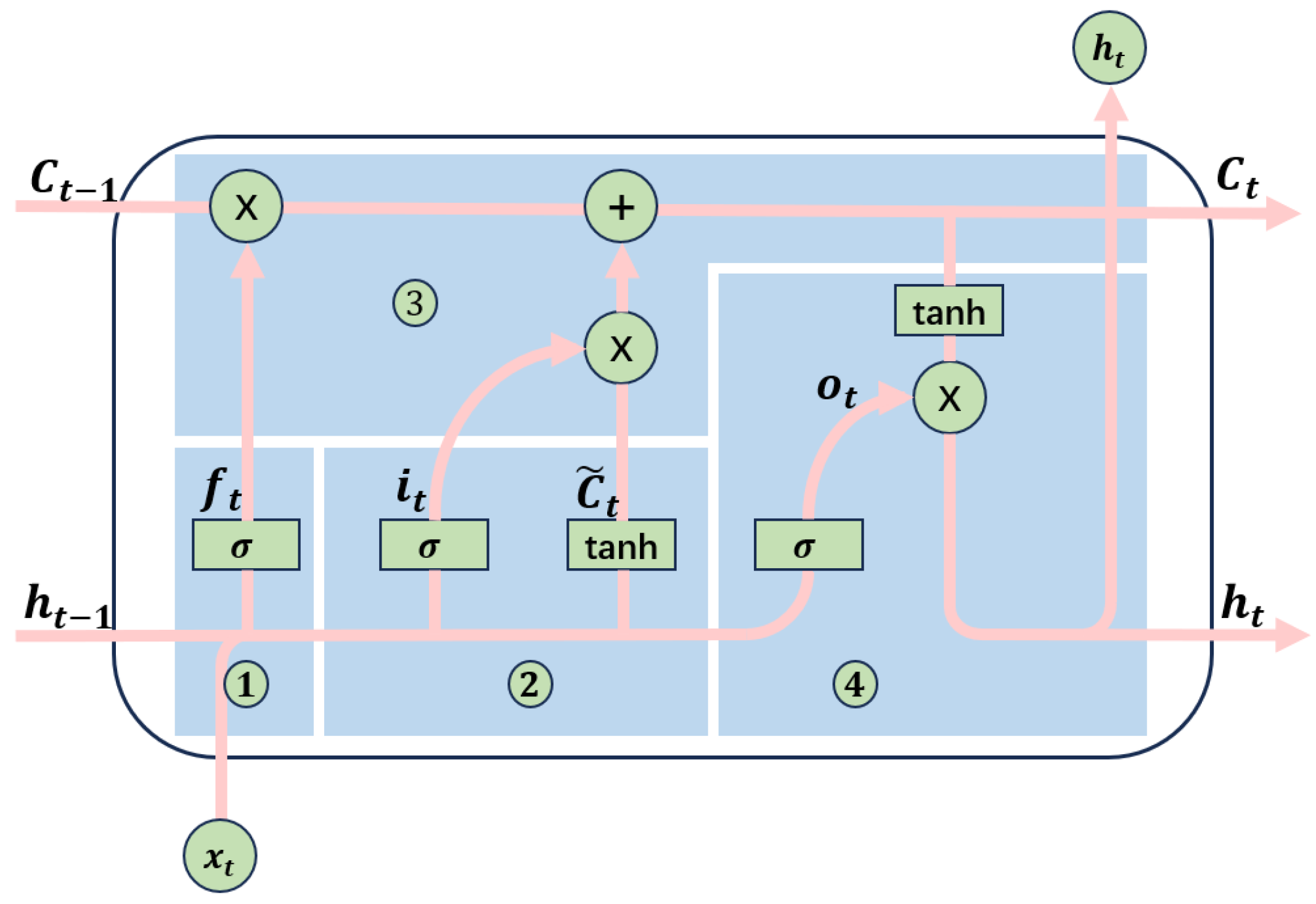

2.1. LSTM Neural Network

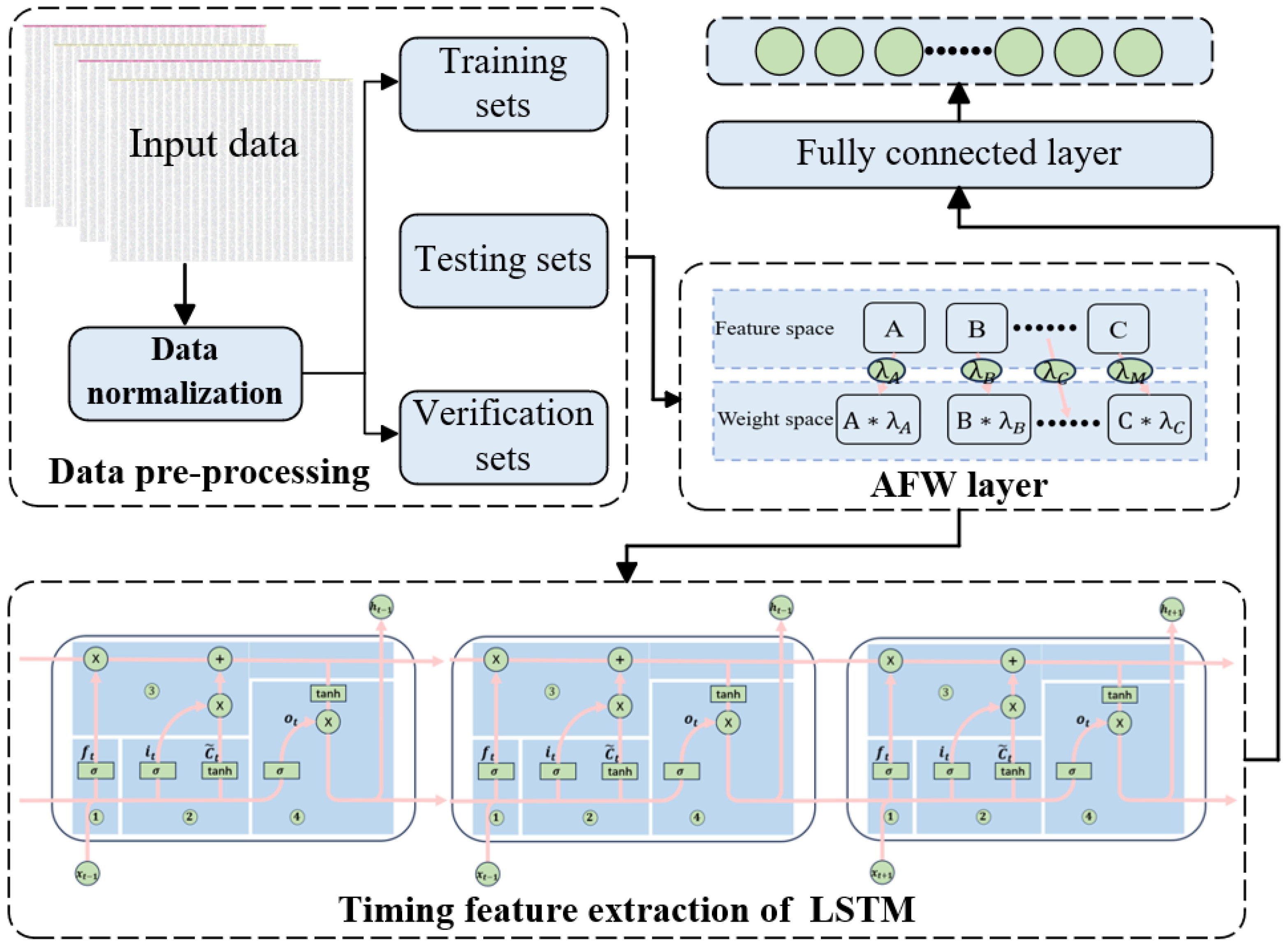

2.2. AFW-LSTM Proposed

3. Data Collection and Processing

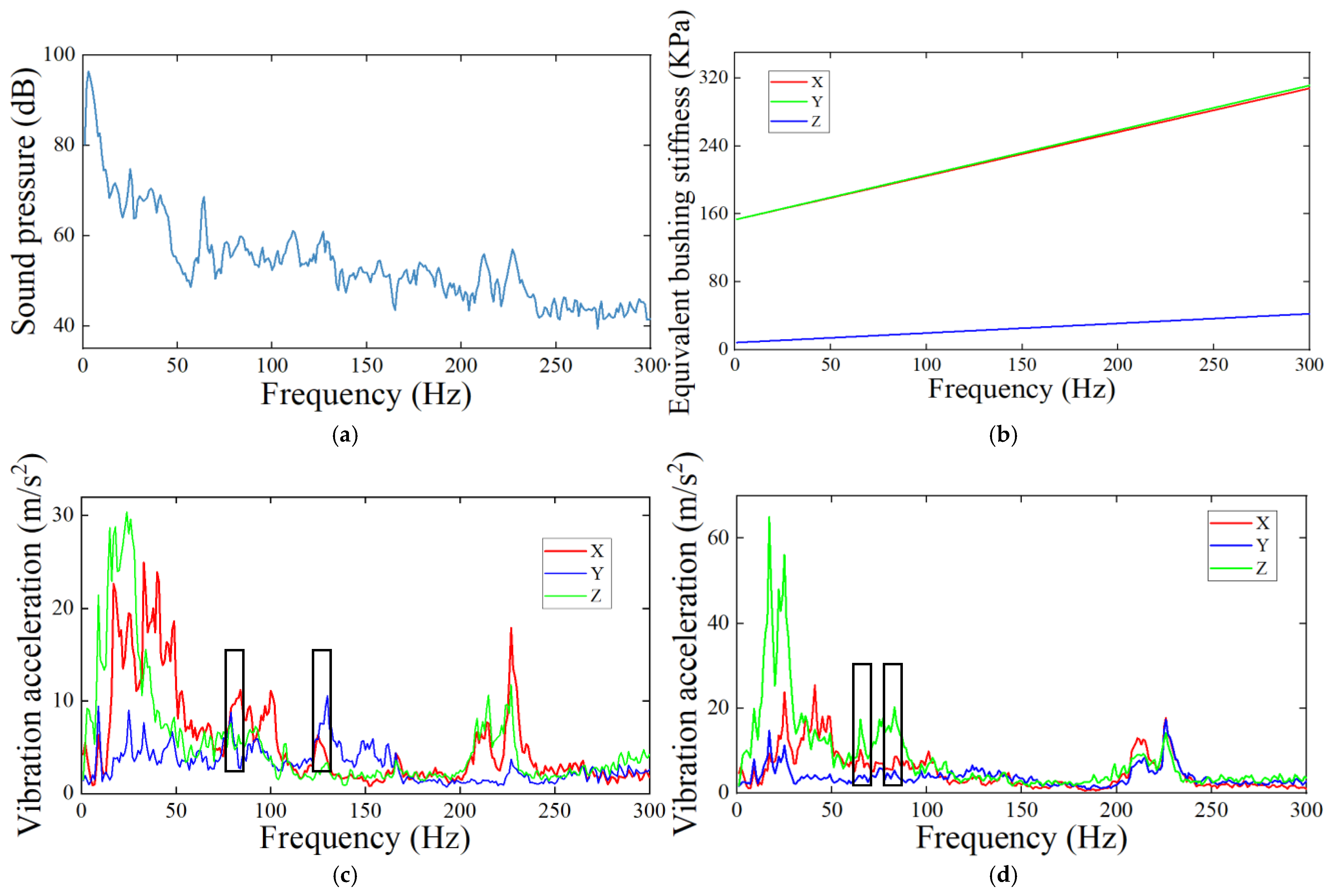

3.1. Analysis of Key Influencing Factors of Road Noise

3.2. Data Collection

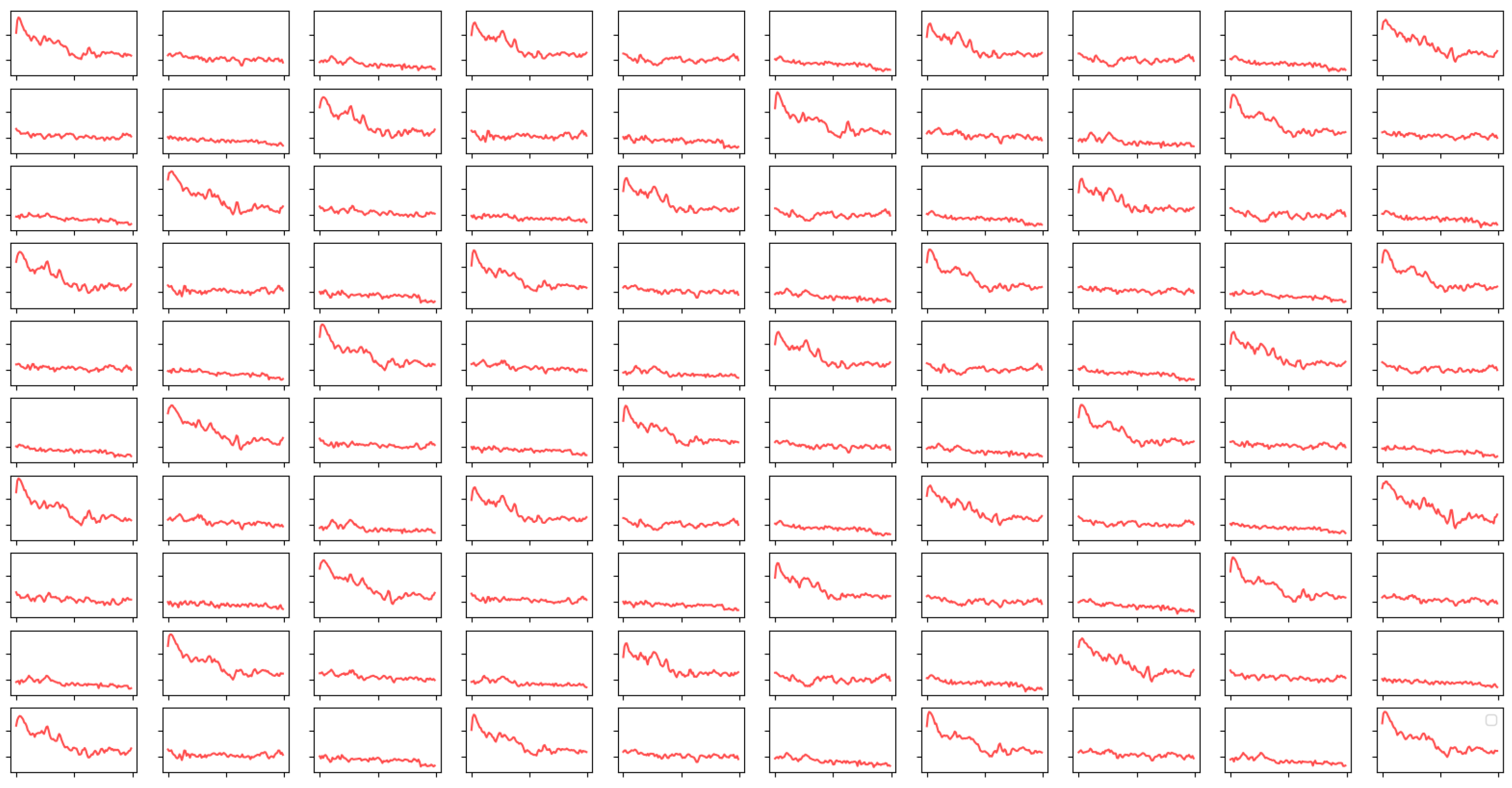

3.3. Data Augmentation

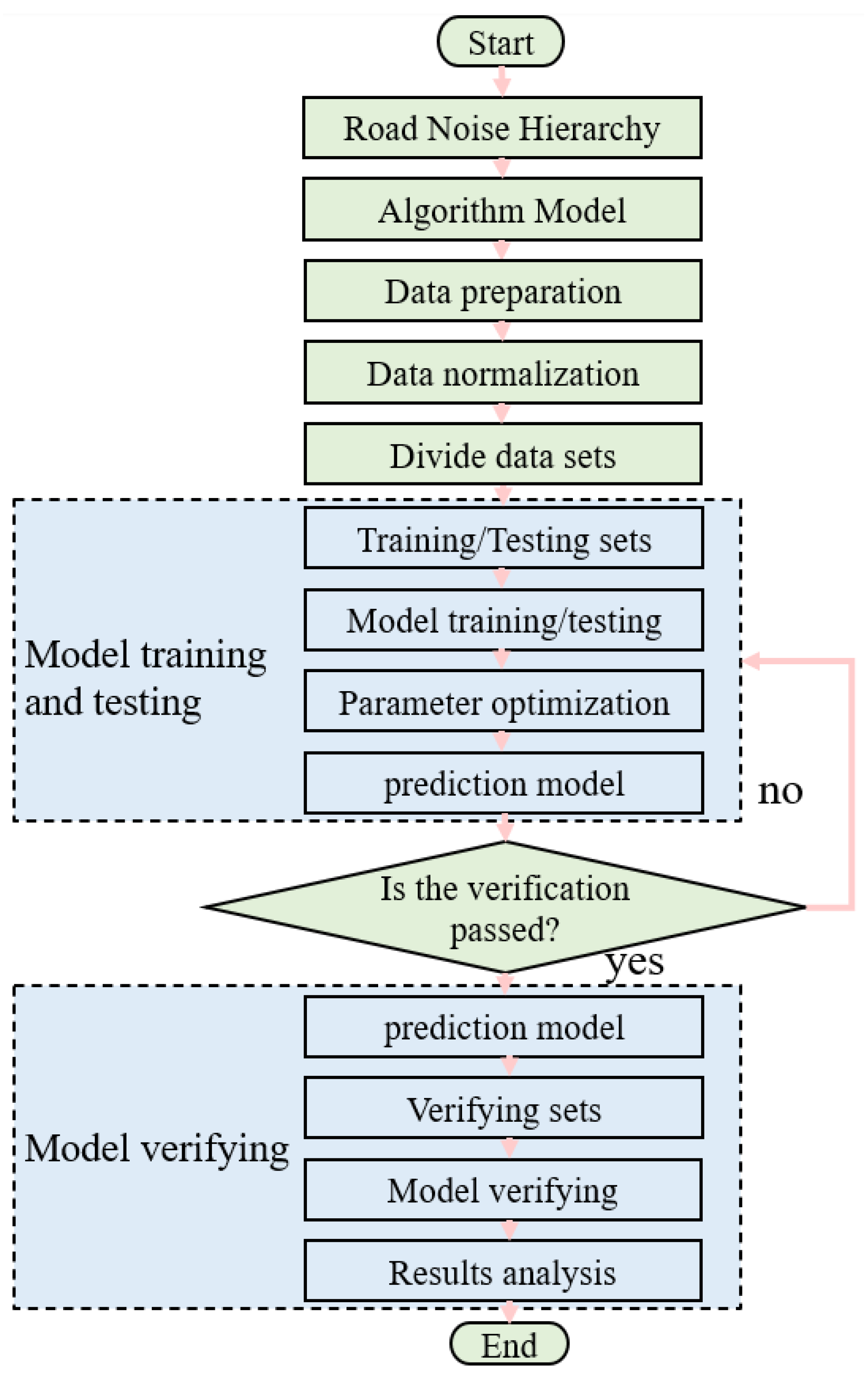

4. Road Noise Prediction Model

4.1. Construction of AFW-LSTM Road Noise Model

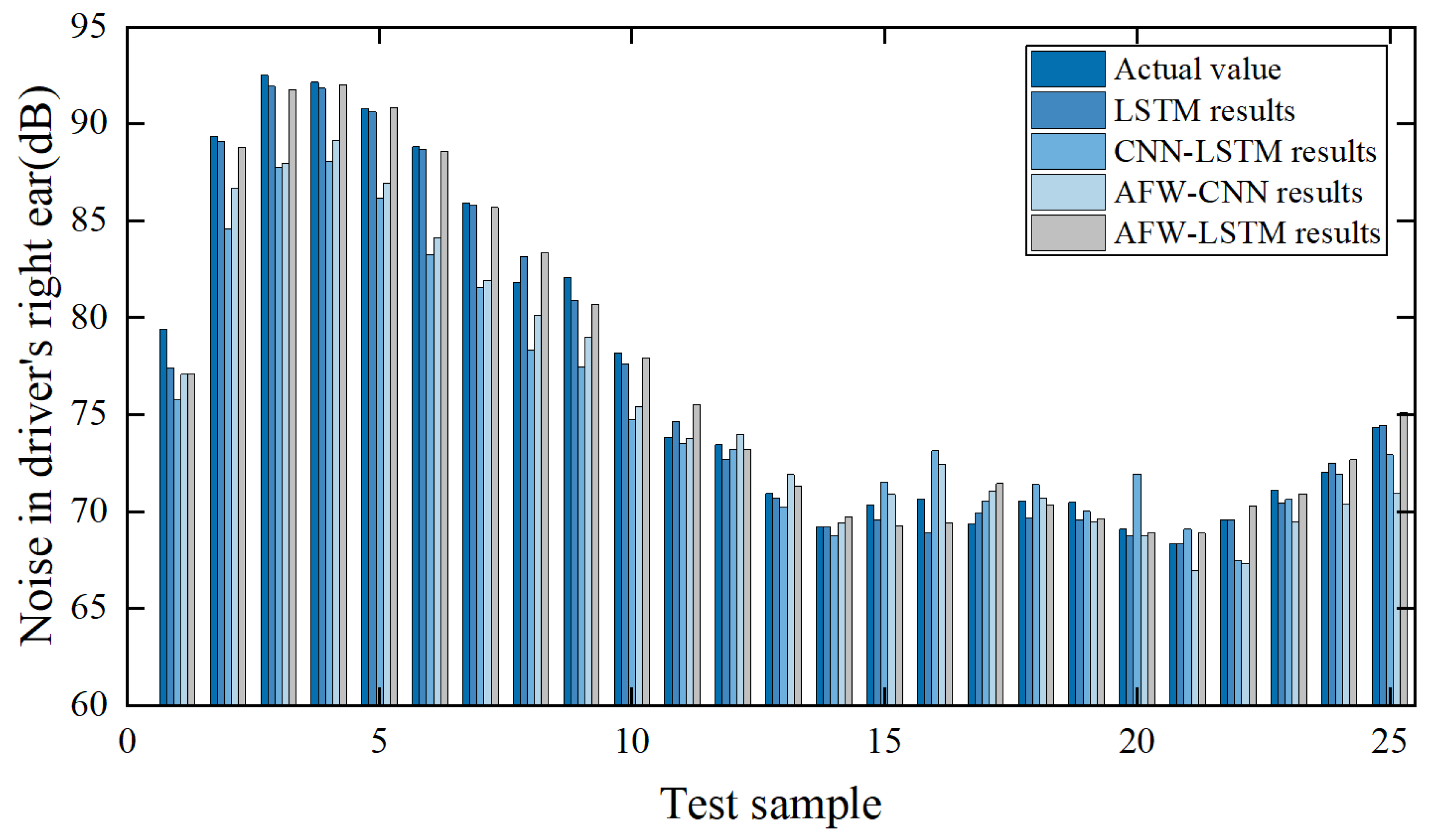

4.2. AFW-LSTM Road Noise Model Prediction and Results Comparison

4.3. Verification of Prediction Results of AFW-LSTM Road Noise Model

5. Conclusions

- Based on the theory of road noise transfer path, the factors and paths that have significant influence on road noise such as steering knuckle, suspension and shock absorber are analyzed, and a two-level decomposition framework of road noise with key influencing factors as input and driver’s right ear noise as output is established. Based on the hierarchical structure of road noise, the road test is carried out, and 16 sets of complete road noise sample data are collected. The data set is enhanced by the CutMix method, where = 0.5, = 1.0, and 102 sets of sample data are generated.

- Based on the road noise hierarchical decomposition architecture, a data-driven model is built for the proposed AFW-LSTM method to reveal the quantitative relationship of the associated units in the hierarchical system. Data preprocessing involves data normalization, data set division, etc. The model training obtains the implicit mapping relationship between the levels of data and can obtain the data law of the frequency point analysis. At the same time, the prediction results of the data-driven model built by the four methods of LSTM, CNN-LSTM, AFW-CNN and AFW-LSTM are compared. The analysis results show that RMSE = 1.74 (dB), MAE = 2.6 (dB), = 0.924. Under the background of road noise, the prediction result of LSTM model is better than that of CNN prediction model, and the accuracy of LSTM model with AFW layer is better than that of single neural network model.

- The proposed method is tested by the sample data of the verification set obtained from the specific vehicle model. The results show that the predicted value is in good agreement with the true value, and the accuracy and robustness of the AFW-LSTM prediction model show obvious advantages. The RMSE = 1.84 (dB), MAE = 2.66 (dB), = 0.912 and other indicators obtained by the AFW-LSTM model are better than the models built by LSTM, CNN-LSTM, and AFW-CNN methods. Adaptive feature weight is conducive to the model to learn more important content, which can improve the efficiency and accuracy of the model to process data.

- The road noise prediction model only analyzes the influence of the suspension part on the driver’s right ear noise. The body part is still an important factor affecting the interior noise. In future research, the body parameters will be introduced to analyze the road noise problem. In addition, although the adaptive weight layer can enhance the network’s emphasis on key features under the premise of controllable actual engineering data and training, its comparative study with the current mainstream attention mechanism still needs to be further improved and expanded in the future.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Huang, H.; Huang, X.; Ding, W.; Yang, M.; Yu, X.; Pang, J. Vehicle vibro-acoustical comfort optimization using a multi-objective interval analysis method. Expert Syst. Appl. 2023, 213, 119001. [Google Scholar] [CrossRef]

- Huang, H.; Wang, Y.; Wu, J.; Ding, W.; Pang, J. Prediction and optimization of pure electric vehicle tire/road structure-borne noise based on knowledge graph and multi-task ResNet. Expert Syst. Appl. 2024, 255, 124536. [Google Scholar] [CrossRef]

- Wang, H.; Liang, H.; Yu, D.; Hou, Q.; Zeng, W. A new urban road traffic noise exposure assessment method based on building land-use types and temporal traffic demand estimation. J. Environ. Manag. 2025, 376, 124604. [Google Scholar] [CrossRef] [PubMed]

- Petri, D.; Licitra, G.; Vigotti, M.A.; Fredianelli, L. Effects of Exposure to Road, Railway, Airport and Recreational Noise on Blood Pressure and Hypertension. Int. J. Env. Res. Public Health 2021, 18, 9145. [Google Scholar] [CrossRef]

- Fu, J.; Zhu, C.; Su, J. Research on the Design Method of Pure Electric Vehicle Acceleration Motion Sense Sound Simulation System. Appl. Sci. 2023, 13, 147. [Google Scholar] [CrossRef]

- Thakur, A.; Krishnan, K.; Ansari, A. Powering the transition: Examining factors influencing the intention to adopt electric vehicles. Smart Sustain. Built Environ. 2025, 14, 471–488. [Google Scholar] [CrossRef]

- Zhao, J.; Yin, Y.; Chen, J.; Zhao, W.; Ding, W. Evaluation and prediction of vibration comfort in engineering machinery cabs using random forest with genetic algorithm. SAE Int. J. Veh. Dyn. Stab. NVH 2024, 8, 491–512. [Google Scholar] [CrossRef]

- Jadhav, P.; Waghulde, K.; Bhortake, R. Test and CAE vibration results correlation and isolator design for improvement of car door vibrations. Int. J. Interact. Des. Manuf. 2024, 1–14. [Google Scholar] [CrossRef]

- Park, U.; Kang, Y. Operational transfer path analysis based on neural network. J. Sound Vib. 2024, 579, 118364. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, D.; Zhao, T. Electric vehicle interior noise contribution analysis. SAE Tech. Pap. 2016, 7. [Google Scholar] [CrossRef]

- Vaitkus, D.; Tcherniak, D.; Brunskog, J. Application of vibro-acoustic operational transfer path analysis. Appl. Acoust. 2019, 154, 201–212. [Google Scholar] [CrossRef]

- Zhu, Y.; Lu, C.; Liu, Z.; Song, W.; Xie, L.; Shen, J. Simulated Operational Path Analysis Method for the Separation of Intake and Exhaust Noises. Acoust. Aust. 2020, 48, 261–270. [Google Scholar] [CrossRef]

- Zhu, H.; Zhao, J.; Wang, Y.; Ding, W.; Pang, J.; Huang, H. Improving of pure electric vehicle sound and vibration comfort using a multi-task learning with task-dependent weighting method. Measurement 2024, 233, 114752. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F. Innovative Approaches for Noise Management in Smart Cities: A Review. Curr. Pollut. Rep. 2018, 4, 143–153. [Google Scholar] [CrossRef]

- Fredianelli, L.; Carpita, S.; Bernardini, M.; Del Pizzo, L.; Brocchi, F.; Licitra, G. Traffic Flow Detection Using Camera Images and Machine Learning Methods in ITS for Noise Map and Action Plan Optimization. Sensors 2022, 22, 1929. [Google Scholar] [CrossRef]

- Su, J.; Lou, J.; Jiang, X. Research on optimization control of vehicle road noise performance. IOP Conf. Ser. Earth Environ. Sci. 2021, 769, 042055. [Google Scholar] [CrossRef]

- Gerwin, P.; Georg, J.; Joerg, B. Numerical Transfer Path Analysis for NVH System-Simulation Models. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1097, 012008. [Google Scholar] [CrossRef]

- Cao, C.; Meng, D.; Zhao, Y.; Shu, Y.; Zhang, M.; Zhang, L. Prediction and Optimization of Full-Vehicle Road Noise Based on Random Response Analysis. J. Phys. Conf. Ser. 2021, 1828, 012166. [Google Scholar] [CrossRef]

- Yu, W. Analysis and Optimization of Low-Speed Road Noise in Electric Vehicles. Wirel. Commun. Mob. Comput. 2021, 2021, 5537704. [Google Scholar] [CrossRef]

- Shang, Z.; Hu, F.; Zeng, F.; Wei, L.; Xu, Q.; Wang, J. Research of transfer path analysis based on contribution factor of sound quality. Appl. Acoust. 2021, 173, 107693. [Google Scholar] [CrossRef]

- Li, M.; Zhou, W.; Liu, J.; Zhang, X.; Pan, F.; Yang, H.; Luo, D. Vehicle interior noise prediction based on Elman neural network. Appl. Sci. 2021, 11, 8029. [Google Scholar] [CrossRef]

- Pang, J.; Mao, T.; Jia, W.; Jia, X.; Dai, P.; Huang, H. Prediction and Analysis of Vehicle Interior Road Noise Based on Mechanism and Data Series Modeling. Sound Vib. 2024, 58, 59–80. [Google Scholar] [CrossRef]

- Huang, X.; Huang, H.; Wu, J.; Yang, M.; Ding, W. Sound quality prediction and improving of vehicle interior noise based on deep convolutional neural networks. Expert Syst. Appl. 2020, 160, 113657. [Google Scholar] [CrossRef]

- Wang, X.; Lin, J.; Liang, H.; Wang, H. A regional road network traffic noise limit prediction method based on design elements. J. Acoust. Soc. Am. 2025, 157, 527–537. [Google Scholar] [CrossRef]

- Wang, H.; Wu, Z.; Wu, Z.; Hou, Q. Urban network noise control based on road grade optimization considering comprehensive traffic environment benefit. J. Environ. Manag. 2024, 364, 121451. [Google Scholar] [CrossRef]

- Li, D.; Li, M.; Han, G.; Li, T. A combined deep learning method for internet car evaluation. Neural Comput. Appl. 2021, 33, 4623–4637. [Google Scholar] [CrossRef]

- Liao, Y.; Qian, F.; Zhang, R.; Kumar, P. Long short-term memory (LSTM) neural networks for predicting dynamic responses and application in piezoelectric energy harvesting. Smart Mater. Struct. 2024, 33, 075005. [Google Scholar] [CrossRef]

- Noh, S. Analysis of Gradient Vanishing of RNNs and Performance Comparison. Information 2021, 12, 442. [Google Scholar] [CrossRef]

- Guo, H.; Chen, L.; Wang, Z.; Lin, L. Day-ahead prediction of electric vehicle charging demand based on quadratic decomposition and dual attention mechanisms. Appl. Energy 2025, 381, 125198. [Google Scholar] [CrossRef]

- Li, T.; Ren, H.; Li, C. Intelligent electric vehicle trajectory tracking control algorithm based on weight coefficient adaptive optimal control. Trans. Inst. Meas. Control 2024, 46, 2647–2663. [Google Scholar] [CrossRef]

- Huang, H.; Huang, X.; Ding, W.; Yang, M.; Fan, D.; Pang, J. Uncertainty optimization of pure electric vehicle interior tire/road noise comfort based on data-driven. Mech. Syst. Signal Process. 2022, 165, 108300. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, X.; Huang, H.; Wu, Y.; Ding, W.; Yang, M. Multi-Objective Prediction and Optimization of Vehicle Acoustic Package Based on ResNet Neural Network. Sound Vib. 2023, 57, 73–95. [Google Scholar] [CrossRef]

- Yang, M.; Dai, P.; Yin, Y.; Wang, D.; Wang, Y.; Huang, H. Predicting and optimizing pure electric vehicle road noise via a locality-sensitive hashing transformer and interval analysis. ISA Trans. 2024, 157, 556–572. [Google Scholar] [CrossRef] [PubMed]

- Lu, X.; Chen, H.; He, X. A Frequency Domain Fitting Algorithm Method for Automotive Suspension Structure under Colored Noise. World Electr. Veh. J. 2024, 15, 410. [Google Scholar] [CrossRef]

- GB/T 18697-2002[S]; National Acoustic Standardization Technical Committee. Interior Noise Measurement Method of Acoustic Vehicle. China Standards Publishing House: Beijing, China, 2002.

- Dwivedi, V.D.; Wahi, P. Influence of gravity on the vibration characteristics of a geometrically nonlinear McPherson-suspension model. Multibody Syst. Dyn. 2024, 61, 571–596. [Google Scholar] [CrossRef]

- Alizadeh, R.; Fataliyev, V.; Akhundov, E. Improving the Design of the Linkage Suspension of a Robotic Mobile Modular System. J. Mach. Manuf. Reliab. 2024, 53, 539–543. [Google Scholar] [CrossRef]

- Fan, D.; Dai, P.; Yang, M.; Jia, W.; Jia, X.; Huang, H. Research on maglev vibration isolation technology for vehicle road noise control. SAE Int. J. Veh. Dyn. Stab. NVH 2022, 6, 233–245. [Google Scholar] [CrossRef]

- Barnett, J.; Li, W.; Resmerita, E. Multiscale Hierarchical Decomposition Methods for Images Corrupted by Multiplicative Noise. J. Math. Imaging Vis. 2025, 67, 12. [Google Scholar] [CrossRef]

- Yun, S.; Han, D.; Oh, S.; Chun, S.; Choe, J.; Yoo, Y. Cutmix: Regularization strategy to train strong classifiers with localizable features. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Honolulu, HI, USA, 19–23 October 2019; p. 6023. [Google Scholar] [CrossRef]

- Zhang, H.; Cissé, M.; Dauphin, Y.; Lopez-Paz, D. Mixup: Beyond empirical risk minimization. arXiv 2017, arXiv:1710.09412. [Google Scholar] [CrossRef]

- Darkwah, Y.; Kang, D. Enhancing few-shot learning using targeted mixup. Appl. Intell. 2025, 55, 279. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, Y.; Yang, J.; Li, X. Automatic modulation classification based on Alex Net with data augmentation. J. China Univ. Posts Telecommun. 2022, 29, 51–61. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, S.; Qin, H.; Liu, Y.; Wang, J. MixCFormer: A CNN–Transformer Hybrid with Mixup Augmentation for Enhanced Finger Vein Attack Detection. Electronics 2025, 14, 362. [Google Scholar] [CrossRef]

- Liao, Y.; Huang, H.; Chang, G.; Luo, D.; Xu, C.; Wu, Y. Research on low-frequency noise control of automobiles based on acoustic metamaterial. Materials 2022, 15, 3261. [Google Scholar] [CrossRef]

- Wang, W.; Lu, Y. Analysis of the Mean Absolute Error (MAE) and the Root Mean Square Error (RMSE) in Assessing Rounding Model. IOP Conf. Ser. Mater. Sci. Eng. 2018, 324, 012049. [Google Scholar] [CrossRef]

- Huang, H.; Wu, J.; Lim, T.C.; Yang, M.; Ding, W. Pure electric vehicle nonstationary interior sound quality prediction based on deep CNNs with an adaptable learning rate tree. Mech. Syst. Signal Process. 2021, 148, 107170. [Google Scholar] [CrossRef]

- Nakagawa, S.; Schielzeth, H. A general and simple method for obtaining R sup2/sup from generalized linear mixed-effects models. Methods Ecol. Evol. 2013, 4, 133–142. [Google Scholar] [CrossRef]

- Sun, P.; Dai, R.; Li, H.; Zheng, Z.; Wu, Y.; Huang, H. Multi-Objective Prediction of the Sound Insulation Performance of a Vehicle Body System Using Multiple Kernel Learning–Support Vector Regression. Electronics 2024, 13, 538. [Google Scholar] [CrossRef]

- Marotta, R.; Strano, S.; Terzo, M.; Tordela, C. Multi-output physically analyzed neural network for the prediction of tire–road interaction forces. SAE Int. J. Veh. Dyn. Stab. NVH 2024, 8, 285–308. [Google Scholar] [CrossRef]

| Index | LSTM | CNN-LSTM | AFW-CNN | AFW-LSTM |

|---|---|---|---|---|

| RMSE (dB) | 1.91 | 1.90 | 1.76 | 1.74 |

| MAE (dB) | 2.69 | 2.72 | 2.61 | 2.60 |

| 0.901 | 0.890 | 0.913 | 0.924 |

| Index | LSTM | CNN-LSTM | AFW-CNN | AFW-LSTM |

|---|---|---|---|---|

| RMSE (dB) | 1.85 | 1.94 | 2.00 | 1.84 |

| MAE (dB) | 2.67 | 2.73 | 2.77 | 2.66 |

| 0.891 | 0.871 | 0.908 | 0.912 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Dai, R.; Liu, T.; Liu, J.; Yang, S.; Wang, J. Research on Vehicle Road Noise Prediction Based on AFW-LSTM. Machines 2025, 13, 425. https://doi.org/10.3390/machines13050425

Ma Y, Dai R, Liu T, Liu J, Yang S, Wang J. Research on Vehicle Road Noise Prediction Based on AFW-LSTM. Machines. 2025; 13(5):425. https://doi.org/10.3390/machines13050425

Chicago/Turabian StyleMa, Yan, Ruxue Dai, Tao Liu, Jian Liu, Shukai Yang, and Jingjing Wang. 2025. "Research on Vehicle Road Noise Prediction Based on AFW-LSTM" Machines 13, no. 5: 425. https://doi.org/10.3390/machines13050425

APA StyleMa, Y., Dai, R., Liu, T., Liu, J., Yang, S., & Wang, J. (2025). Research on Vehicle Road Noise Prediction Based on AFW-LSTM. Machines, 13(5), 425. https://doi.org/10.3390/machines13050425