Integral Linear Quadratic Regulator Sliding Mode Control for Inverted Pendulum Actuated by Stepper Motor

Abstract

1. Introduction

- In existing CIP systems, DC motors are widely employed to drive the cart. Typically, these motors require gearboxes to increase torque and reduce speed in practical applications. However, mechanical gearboxes contain small gaps between gear teeth to avoid binding and reduce maintenance needs. These gaps cause delayed responses and generate position errors when the rotation direction reverses, a phenomenon known as backlash. This is an undesirable phenomenon in mechanical systems, especially in applications that require high accuracy control. When a DC motor is employed in CIP systems, the motor’s torque is transmitted through the mechanical system, converting rotational motion into a linear force that acts on the cart to balance the pendulum. Controlling this force is essential, because the dynamic model of the CIP depends on the force exerted on the cart to stabilize the pendulum in its upright position. While most controllers were designed to control this force in CIP systems, such an approach is less practical in industrial applications, where control strategies based on velocity or acceleration output are typically preferred. This preference arises because the force output of a motor, which refers to the strength of the motor to move or push something, is often less accurate than the velocity or acceleration output, which determines how quickly the motor speeds up or slows down [34]. Although DC motors offer some advantages, such as high speed control and a wide torque range, stepper motors are particularly appealing in control engineering due to their simplicity, accurate acceleration control, and ease of control in small-scale, low-speed control systems. Since a CIP system usually operates under limited acceleration, stepper motors are suitable for such a implementation. This justifies the use of stepper motors in CIP system designs, where controlling the cart acceleration plays a vital role in stabilizing the pendulum in the upright position.

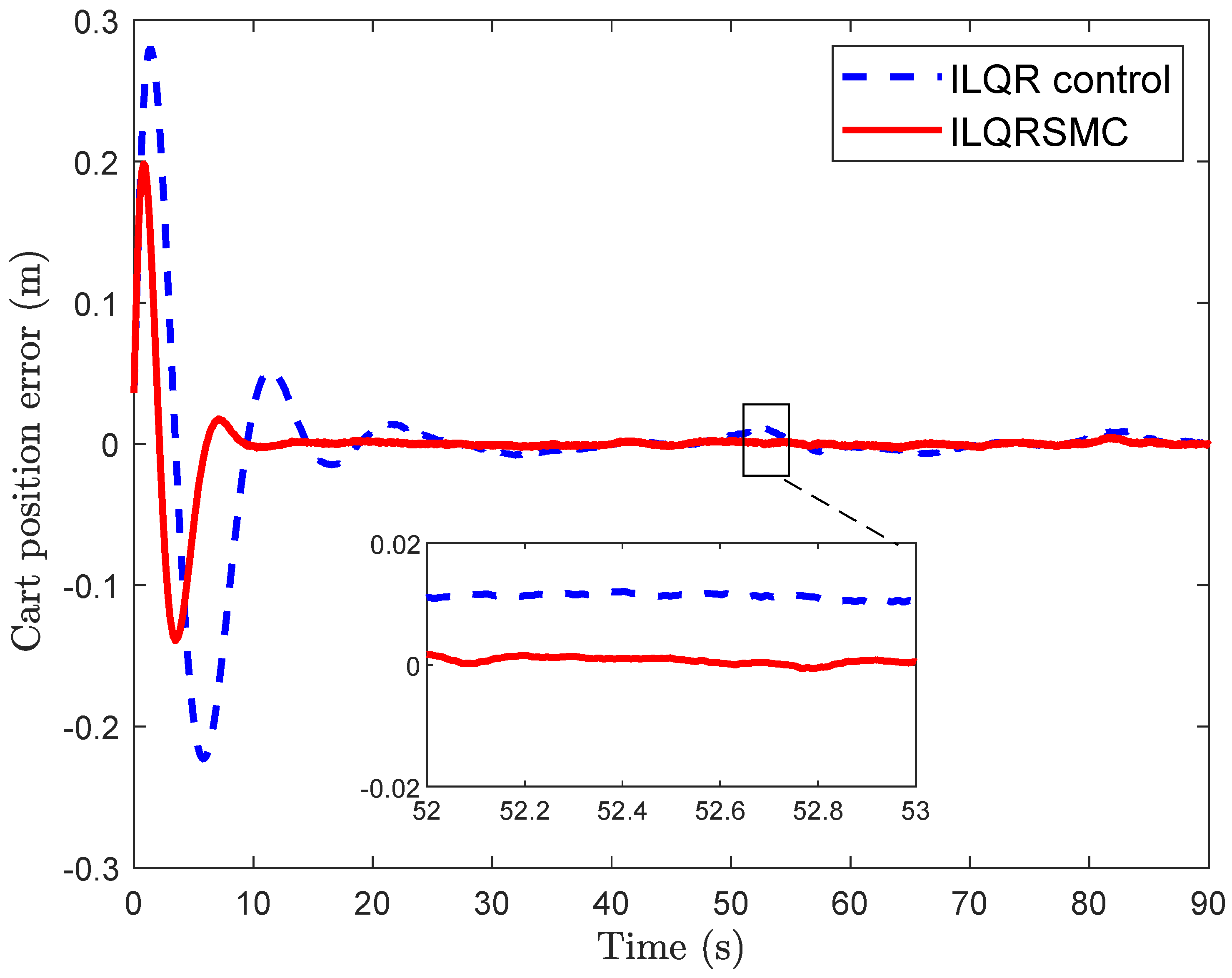

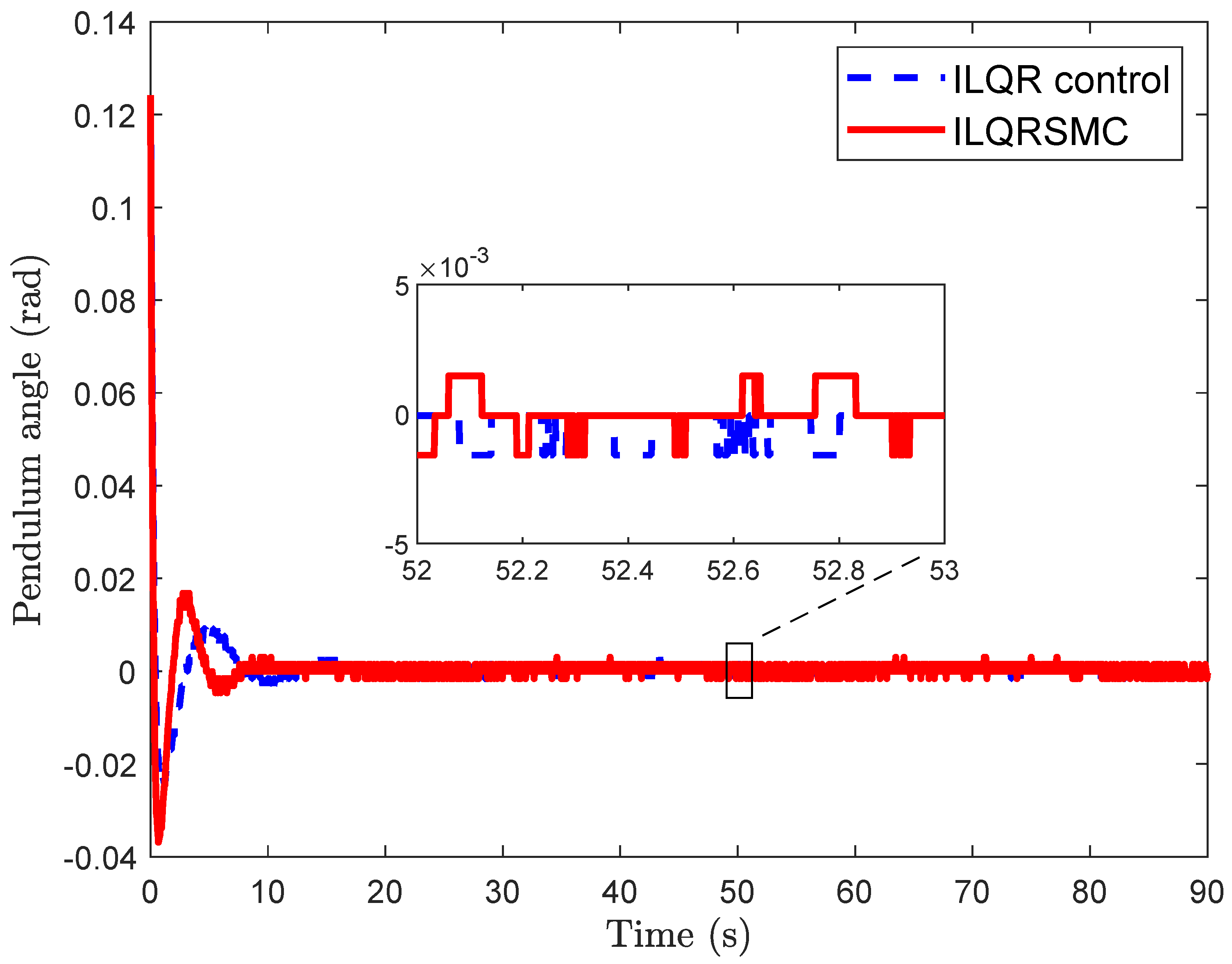

- In practice, achieving correct calibration of the pendulum angle at the equilibrium upright position is challenging, often leading to an offset of cart position errors [35]. Existing sliding mode controllers have not considered this problem, resulting in significant steady cart errors during implementation [36,37]. To solve this problem, we designed an augmented model of a CIP, comprising integral cart error. The proposed control is designed for this model, inheriting the merits of ILQR control and SMC control, while ensuring ease of parameter selection for practical engineer applications.

- The aim was to enhance the convergent speed and tracking accuracy of cart position and pendulum angle for both stabilization and tracking problems. The effectiveness and implementation were proved through experimental validation.

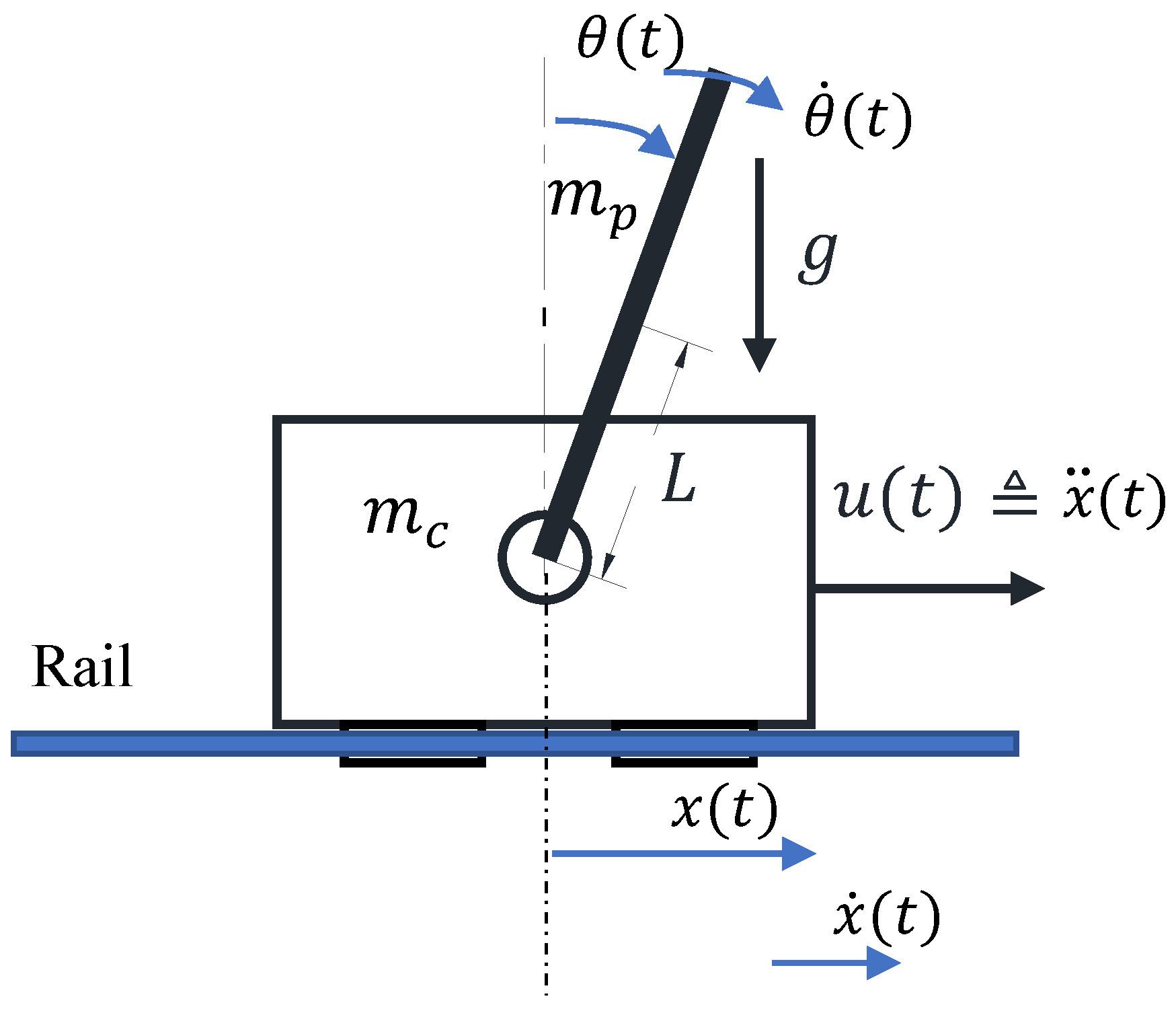

2. Modeling Cart Inverted Pendulum

2.1. Cart Inverted Pendulum Dynamic

2.2. Linearization

3. Integral Linear Quadratic Regulator Sliding Mode Control (ILQRSMC)

4. Experimental Results

4.1. Experimental Setup

4.2. Experimental Results

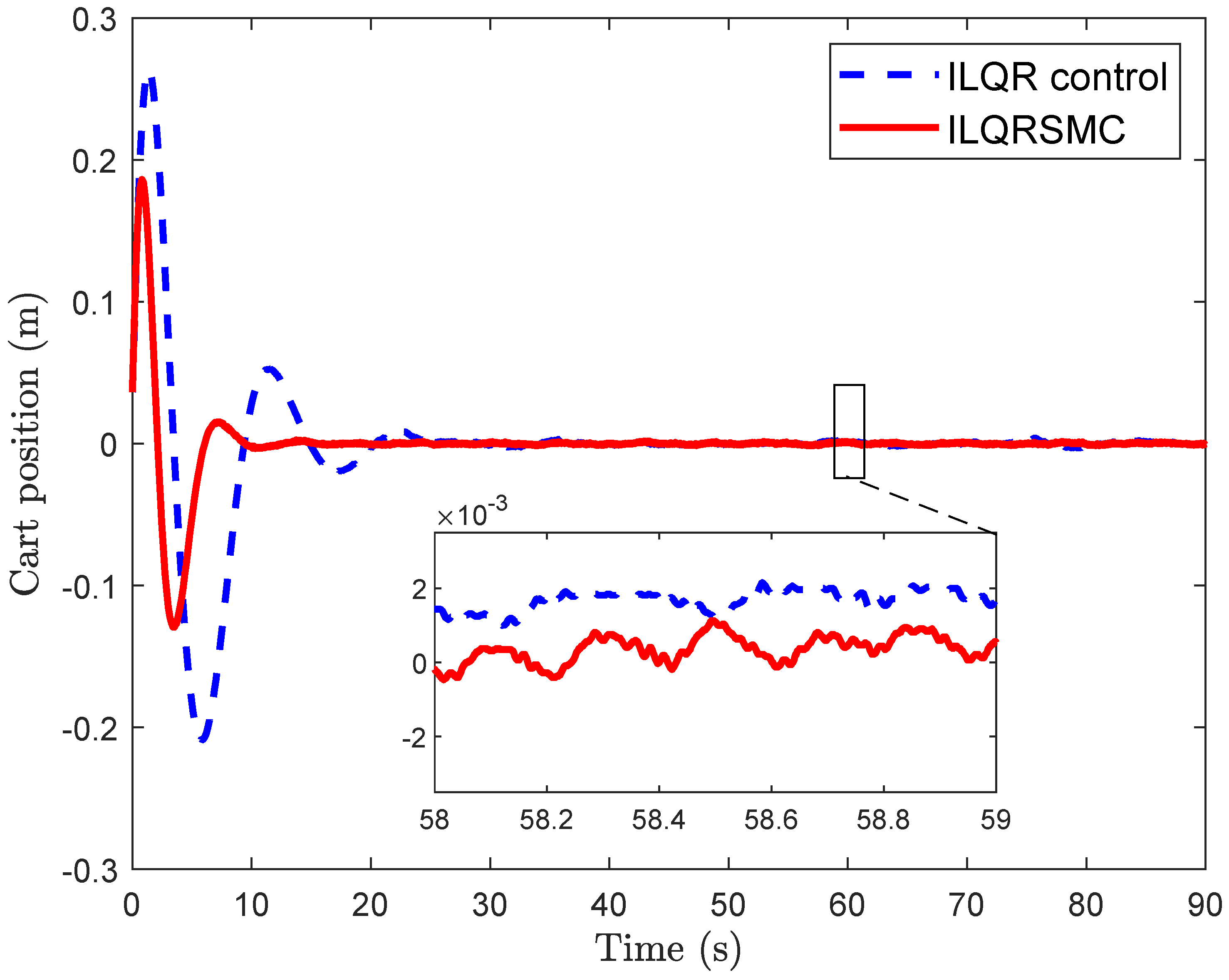

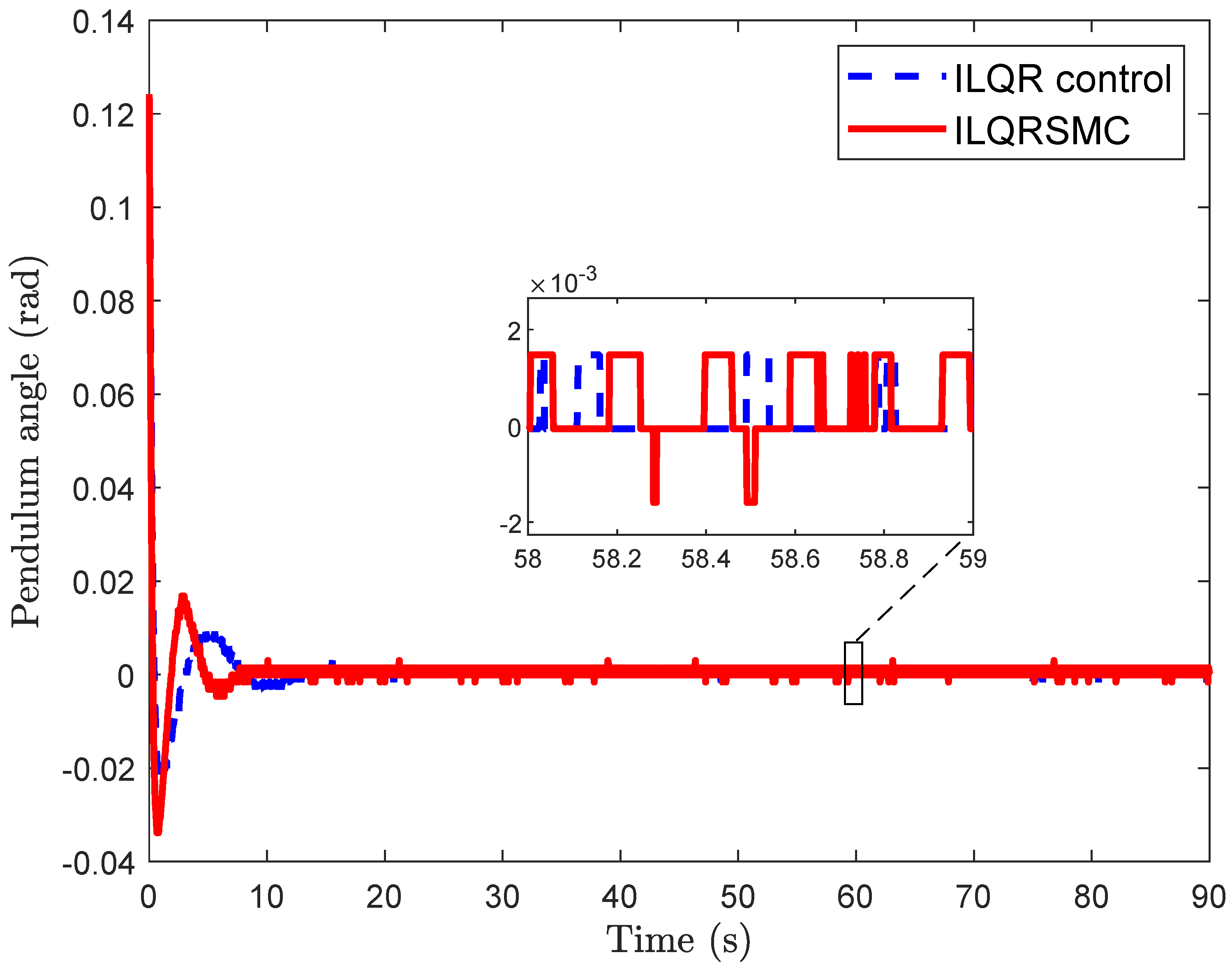

4.2.1. Stabilization Control of Cart Inverted Pendulum

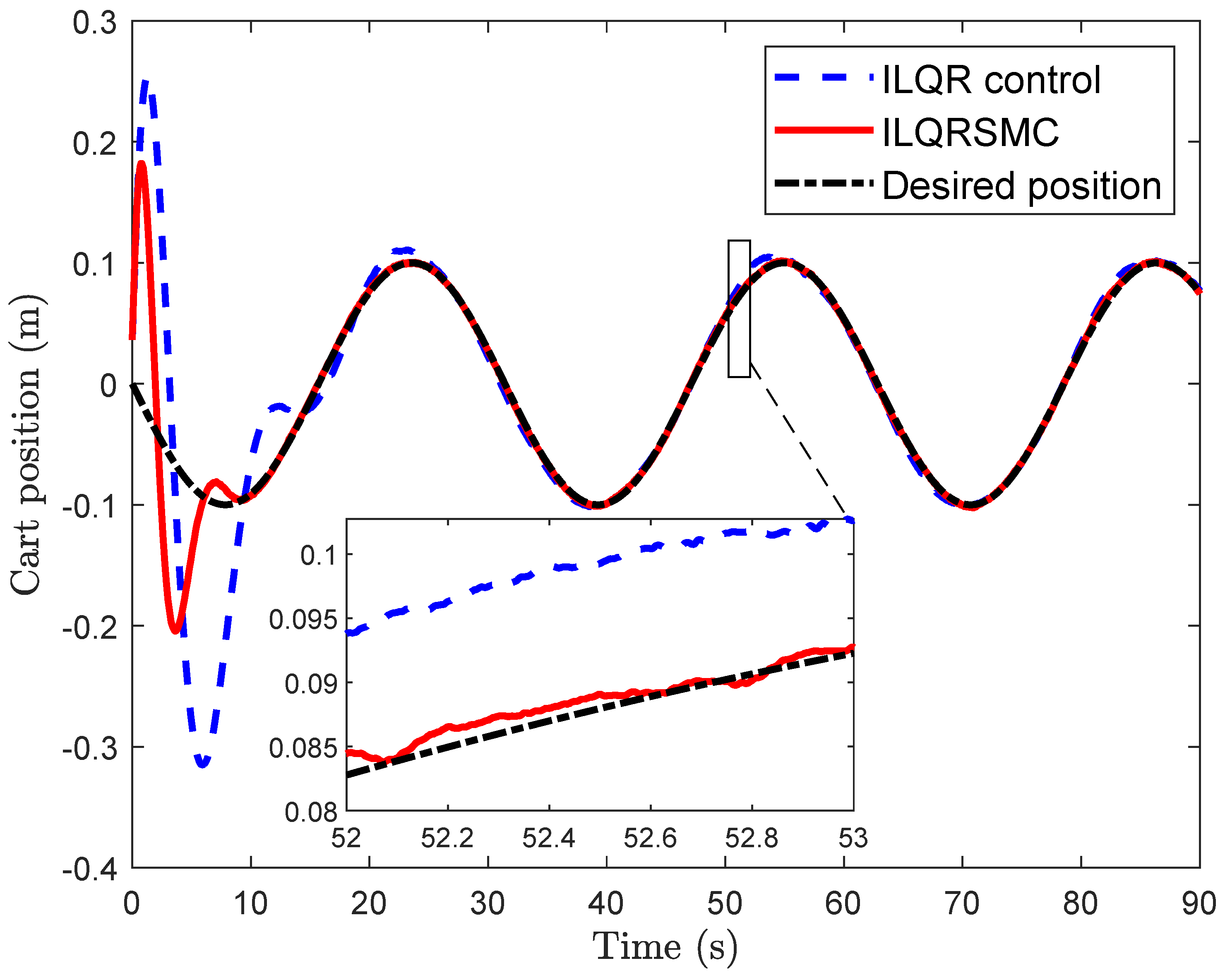

4.2.2. Tracking Control of Cart Inverted Pendulum

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| UMS | under-actuated mechanical systems |

| CIP | cart inverted pendulum |

| PID | proportion integral derivative |

| LQR | linear quadratic regulator |

| ILQR | integral linear quadratic regulator |

| SMC | sliding mode control |

| LHSMC | linear hierarchical sliding mode control |

| LSS | linear sliding surface |

| HNTSMC | hierarchical nonsingular terminal sliding mode control |

| HRNTSMC | hierarchical recursive nonsingular terminal sliding mode control |

| LMI | linear matrix inequality |

| IAE | integrated absolute error |

References

- Emran, B.J.; Najjaran, H. A review of quadrotor: An underactuated mechanical system. Annu. Rev. Control 2018, 46, 165–180. [Google Scholar] [CrossRef]

- Kumar, E.V.; Jerome, J. Robust LQR controller design for stabilizing and trajectory tracking of inverted pendulum. Procedia Eng. 2013, 64, 169–178. [Google Scholar] [CrossRef]

- Boubaker, O.; Iriarte, R. The Inverted pendulum in Control Theory and Robotics: From Theory to New Innovations; Technical Report; IET: Stevenage, UK, 2017. [Google Scholar]

- Boubaker, O. The inverted pendulum benchmark in nonlinear control theory: A survey. Int. J. Adv. Robot. Syst. 2013, 10, 233. [Google Scholar] [CrossRef]

- Wang, J.J. Stabilization and tracking control of X–Z inverted pendulum with sliding-mode control. ISA Trans. 2012, 51, 763–770. [Google Scholar] [CrossRef]

- Dwivedi, P.; Pandey, S.; Junghare, A.S. Stabilization of unstable equilibrium point of rotary inverted pendulum using fractional controller. J. Frankl. Inst. 2017, 354, 7732–7766. [Google Scholar] [CrossRef]

- Saleem, O.; Mahmood-Ul-Hasan, K. Indirect adaptive state-feedback control of rotary inverted pendulum using self-mutating hyperbolic-functions for online cost variation. IEEE Access 2020, 8, 91236–91247. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, H.H.; Voyles, R.M. Optimal fractional-order proportional–integral–derivative control enabling full actuation of decomposed rotary inverted pendulum system. Trans. Inst. Meas. Control 2023, 45, 1986–1998. [Google Scholar] [CrossRef]

- Yang, X.; Zheng, X. Swing-up and stabilization control design for an underactuated rotary inverted pendulum system: Theory and experiments. IEEE Trans. Ind. Electron. 2018, 65, 7229–7238. [Google Scholar] [CrossRef]

- Abdullah, M.; Amin, A.A.; Iqbal, S.; Mahmood-ul Hasan, K. Swing up and stabilization control of rotary inverted pendulum based on energy balance, fuzzy logic, and LQR controllers. Meas. Control 2021, 54, 1356–1370. [Google Scholar] [CrossRef]

- Chacko, S.J.; Abraham, R.J. On LQR controller design for an inverted pendulum stabilization. Int. J. Dyn. Control 2023, 11, 1584–1592. [Google Scholar] [CrossRef]

- Maciejowski, J.M. Multivariable Feedback Design; Electronic Systems Engineering Series; Addison-Wesley: Boston, MA, USA, 1989. [Google Scholar]

- Safonov, M.; Athans, M. Gain and phase margin for multiloop LQG regulators. IEEE Trans. Autom. Control 1977, 22, 173–179. [Google Scholar] [CrossRef]

- Mahapatra, C.; Chauhan, S. Tracking control of inverted pendulum on a cart with disturbance using pole placement and LQR. In Proceedings of the 2017 International Conference on Emerging Trends in Computing and Communication Technologies (ICETCCT), Dehradun, India, 17–18 November 2017; pp. 1–6. [Google Scholar]

- Chantarachit, S. Development and Control of Rotary Inverse Pendulum by LQR with Integral Action. IOP Conf. Ser. Mater. Sci. Eng. 2019, 639, 012022. [Google Scholar] [CrossRef]

- Dai Le, H.; Nestorović, T. Integral Linear Quadratic Regulator for Inverted Pendulum System Actuated by a Step Motor. In Proceedings of the 2024 10th International Conference on Control, Decision and Information Technologies (CoDIT), Valetta, Malta, 1–4 July 2024; pp. 367–370. [Google Scholar]

- Malkapure, H.G.; Chidambaram, M. Comparison of two methods of incorporating an integral action in linear quadratic regulator. IFAC Proc. Vol. 2014, 47, 55–61. [Google Scholar] [CrossRef]

- Baumann, W.; Rugh, W. Feedback control of nonlinear systems by extended linearization. IEEE Trans. Autom. Control 1986, 31, 40–46. [Google Scholar] [CrossRef]

- Utkin, V. Variable structure systems with sliding modes. IEEE Trans. Autom. Control 1977, 22, 212–222. [Google Scholar] [CrossRef]

- Zhao, H.; Zong, G.; Zhao, X.; Wang, H.; Xu, N.; Zhao, N. Hierarchical Sliding-Mode Surface-Based Adaptive Critic Tracking Control for Nonlinear Multiplayer Zero-Sum Games Via Generalized Fuzzy Hyperbolic Models. IEEE Trans. Fuzzy Syst. 2023, 31, 4010–4023. [Google Scholar] [CrossRef]

- Wang, W.; Yi, J.; Zhao, D.; Liu, D. Design of a stable sliding-mode controller for a class of second-order underactuated systems. IEE Proc.Control Theory Appl. 2004, 151, 683–690. [Google Scholar] [CrossRef]

- Hwang, C.L.; Chiang, C.C.; Yeh, Y.W. Adaptive fuzzy hierarchical sliding-mode control for the trajectory tracking of uncertain underactuated nonlinear dynamic systems. IEEE Trans. Fuzzy Syst. 2013, 22, 286–299. [Google Scholar] [CrossRef]

- Hwang, C.L.; Wu, H.M. Trajectory tracking of a mobile robot with frictions and uncertainties using hierarchical sliding-mode under-actuated control. IET Control Theory Appl. 2013, 7, 952–965. [Google Scholar] [CrossRef]

- Yue, S.; Niu, B.; Wang, H.; Zhang, L.; Ahmad, A.M. Hierarchical sliding mode-based adaptive fuzzy control for uncertain switched under-actuated nonlinear systems with input saturation and dead-zone. Robot. Intell. Autom. 2023, 43, 523–536. [Google Scholar] [CrossRef]

- Yan, M.-X.; Jing, Y.-W. Terminal sliding mode decomposed control for a class of nonlinear systems. In Proceedings of the 2008 Chinese Control and Decision Conference, Yantai, China, 2–4 July 2008; pp. 4988–4991. [Google Scholar]

- Bayramoglu, H.; Komurcugil, H. Nonsingular decoupled terminal sliding-mode control for a class of fourth-order nonlinear systems. Commun. Nonlinear Sci. Numer. Simul. 2013, 18, 2527–2539. [Google Scholar] [CrossRef]

- Edwards, C.; Shtessel, Y.B. Adaptive continuous higher order sliding mode control. Automatica 2016, 65, 183–190. [Google Scholar] [CrossRef]

- Le, H.D.; Nestorović, T. A Novel Hierarchical Recursive Nonsingular Terminal Sliding Mode Control for Inverted Pendulum. Actuators 2023, 12, 462. [Google Scholar] [CrossRef]

- Utkin, V. Methods for constructing discontinous planes in multidimensional variable structure systems. Autom. Remote Control 1977, 31, 1466–1470. [Google Scholar]

- Edwards, C. A practical method for the design of sliding mode controllers using linear matrix inequalities. Automatica 2004, 40, 1761–1769. [Google Scholar] [CrossRef]

- Pang, H.P.; Tang, G.Y. Optimal Sliding Manifold Design for Nonlinear Systems Based on Sensitivity Approach. In Proceedings of the 2006 IEEE International Conference on Systems, Man and Cybernetics, Taipei, Taiwan, 8–11 October 2006; Volume 2, pp. 1371–1376. [Google Scholar]

- Patil, M.; Kurode, S. Stabilization of RDIP using sliding modes. In Proceedings of the 2018 Indian Control Conference (ICC), Kanpur, India, 4–6 January 2018; pp. 119–124. [Google Scholar]

- Singh, S.; Swarup, A. Control of Rotary Double Inverted Pendulum using Sliding Mode Controller. In Proceedings of the 2021 International Conference on Intelligent Technologies (CONIT), Hubli, India, 25–27 June 2021; pp. 1–6. [Google Scholar]

- Lu, B.; Fang, Y. Online trajectory planning control for a class of underactuated mechanical systems. IEEE Trans. Autom. Control 2023, 69, 442–448. [Google Scholar] [CrossRef]

- Block, D.; Astrom, K.; Spong, M. The Reaction Wheel Pendulum; Morgan & Claypool Publishers: San Rafael, CA, USA, 2007. [Google Scholar]

- Dotoli, M.; Maione, B.; Naso, D.; Turchiano, B. Fuzzy sliding mode control for inverted pendulum swing-up with restricted travel. In Proceedings of the 10th IEEE International Conference on Fuzzy Systems (Cat. No. 01CH37297), Melbourne, Australia, 2–5 December 2001; Volume 2, pp. 753–756. [Google Scholar]

- Li, T.H.S.; Shieh, M.Y. Switching-type fuzzy sliding mode control of a cart–pole system. Mechatronics 2000, 10, 91–109. [Google Scholar] [CrossRef]

- Furuta, K.; Kajiwara, H.; Kosuge, K. Digital control of a double inverted pendulum on an inclined rail. Int. J. Control 1980, 32, 907–924. [Google Scholar] [CrossRef]

- Goldstein, H.; Poole, C.; Safko, J. Classical Mechanics; Addison and Wesley: San Francisco, CA, USA, 2003. [Google Scholar]

- Ogata, K. Modern Control Engineering, 5th ed.; Pearson: London, UK, 2010. [Google Scholar]

- Castanos, F.; Fridman, L. Analysis and design of integral sliding manifolds for systems with unmatched perturbations. IEEE Trans. Autom. Control 2006, 51, 853–858. [Google Scholar] [CrossRef]

- Utkin, V.I. Sliding Modes in Control and Optimization; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Chen, Y.P.; Chang, J.L. A new method for constructing sliding surfaces of linear time-invariant systems. Int. J. Syst. Sci. 2000, 31, 417–420. [Google Scholar] [CrossRef]

- Gao, W. Variable structure control of nonlinear systems: A new approach. IEEE Trans. Ind. Electron. 1993, 40, 45–55. [Google Scholar]

- Fridman, L.; Poznyak, A.; Bejarano, F.J. Robust Output LQ Optimal Control Via Integral Sliding Modes; Springer: New York, NY, USA, 2014. [Google Scholar]

- Draženović, B.; Milosavljević, Č.; Veselić, B. Comprehensive approach to sliding mode design and analysis in linear systems. In Advances in Sliding Mode Control: Concept, Theory and Implementation; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1–19. [Google Scholar]

- Le, H.D.; Nestorović, T. Adaptive Proportional Integral Derivative Nonsingular Dual Terminal Sliding Mode Control for Robotic Manipulators. Dynamics 2023, 3, 656–677. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Q.; Zhou, L.; Zhang, Y.; Li, X.; Zhang, J. Velocity profile algorithm realization on FPGA for stepper motor controller. In Proceedings of the 2011 2nd International Conference on Artificial Intelligence, Management Science and Electronic Commerce (AIMSEC), Dengfeng, China, 8–10 August 2011; pp. 6072–6075. [Google Scholar]

- Apkarian, J.; Lacheray, H.; Martin, P. Linear inverted pendulum experiment for matlab/simulink users. Quanser Student Workbook; Quanser Inc.: Markham, ON, Canada, 2012. [Google Scholar]

- Yu, L.; He, G.; Wang, X.; Zhao, S. Robust fixed-time sliding mode attitude control of tilt trirotor UAV in helicopter mode. IEEE Trans. Ind. Electron. 2021, 69, 10322–10332. [Google Scholar] [CrossRef]

- Mohd Haziq Norsahperi, N.; A Danapalasingam, K. A comparative study of LQR and integral sliding mode control strategies for position tracking control of robotic manipulators. Int. J. Electr. Comput. Eng. Syst. 2019, 10, 73–83. [Google Scholar] [CrossRef]

- Gaing, Z.L. A particle swarm optimization approach for optimum design of PID controller in AVR system. IEEE Trans. Energy Convers. 2004, 19, 384–391. [Google Scholar] [CrossRef]

| Controller | Tuning Parameters |

|---|---|

| ILQR | . |

| Proposed control | . |

| IAE of Cart Position (m) | IAE of Pendulum Angle (rad) | IAC | |

|---|---|---|---|

| ILQR | 1.6714 | 0.1209 | 7.8814 |

| Proposed control | 0.6233 | 0.1292 | 16.0692 |

| IAE of Cart Position (m) | IAE of Pendulum Angle (rad) | IAC | |

|---|---|---|---|

| ILQR | 1.9151 | 0.1303 | 7.5683 |

| Proposed control | 0.7005 | 0.1348 | 15.3816 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, H.D.; Nestorović, T. Integral Linear Quadratic Regulator Sliding Mode Control for Inverted Pendulum Actuated by Stepper Motor. Machines 2025, 13, 405. https://doi.org/10.3390/machines13050405

Le HD, Nestorović T. Integral Linear Quadratic Regulator Sliding Mode Control for Inverted Pendulum Actuated by Stepper Motor. Machines. 2025; 13(5):405. https://doi.org/10.3390/machines13050405

Chicago/Turabian StyleLe, Hiep Dai, and Tamara Nestorović. 2025. "Integral Linear Quadratic Regulator Sliding Mode Control for Inverted Pendulum Actuated by Stepper Motor" Machines 13, no. 5: 405. https://doi.org/10.3390/machines13050405

APA StyleLe, H. D., & Nestorović, T. (2025). Integral Linear Quadratic Regulator Sliding Mode Control for Inverted Pendulum Actuated by Stepper Motor. Machines, 13(5), 405. https://doi.org/10.3390/machines13050405