Development of the E-Portal for the Design of Freeform Varifocal Lenses Using Shiny/R Programming Combined with Additive Manufacturing

Abstract

1. Introduction

1.1. Freeform Surface Design of Varifocal Lens

1.2. The Role of 3D Printing in Lens’s Customised Design

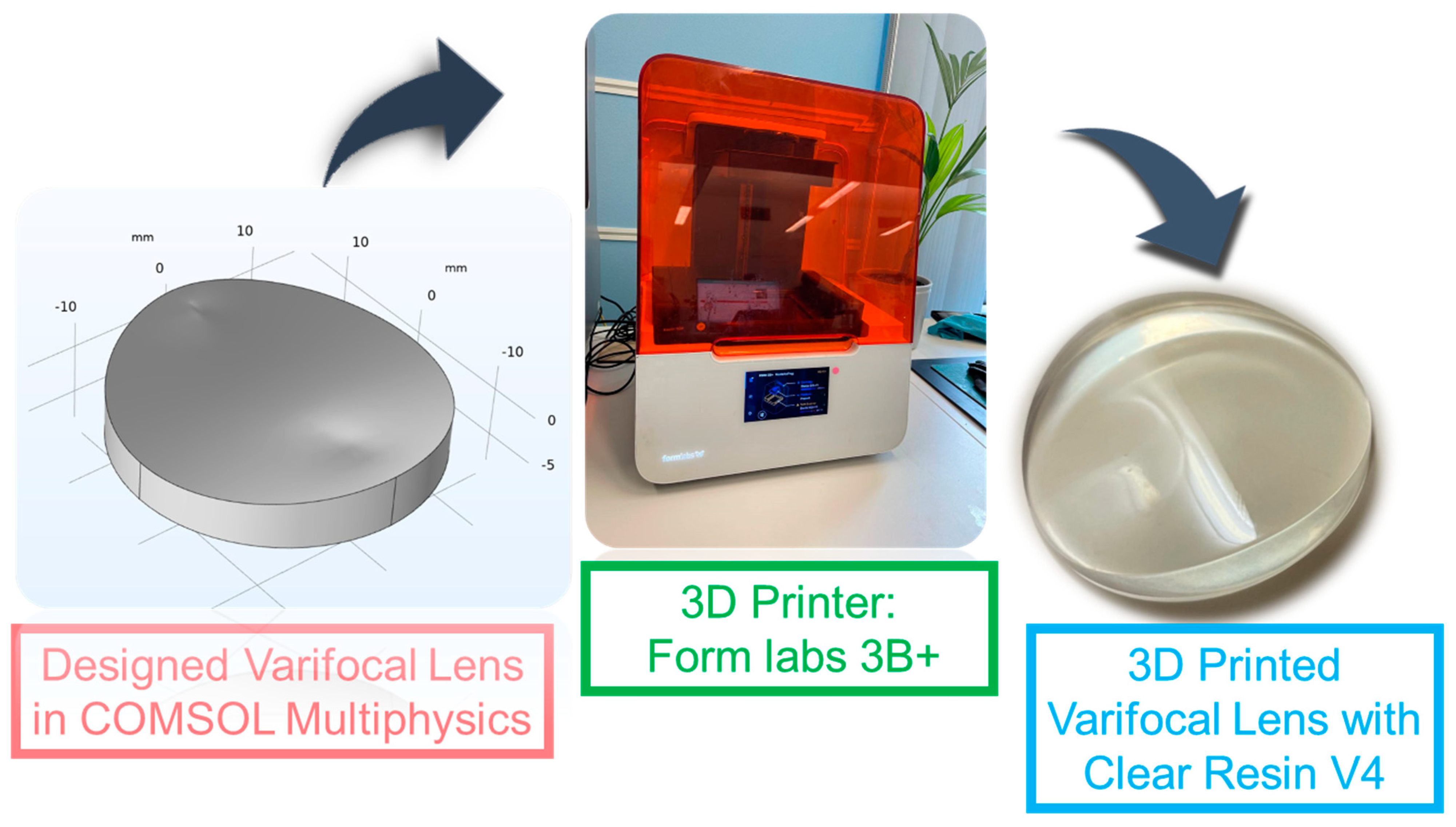

- Designing the lens using CAD software (COMSOL-Multiphysics 6.2).

- Converting the designed model to a 3D printer file format.

- Optimising the printer settings.

- Material selection for the 3D-printed model.

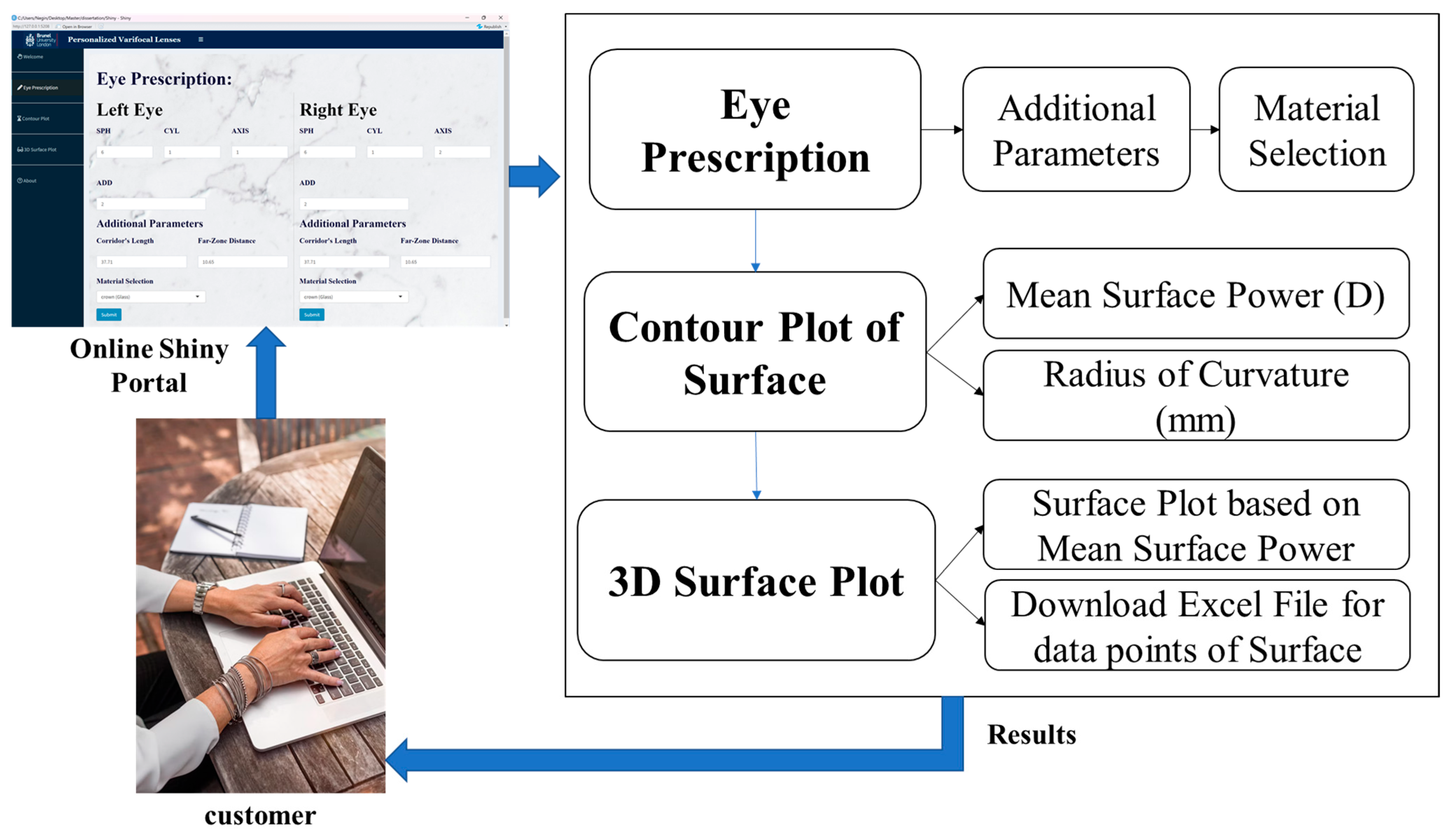

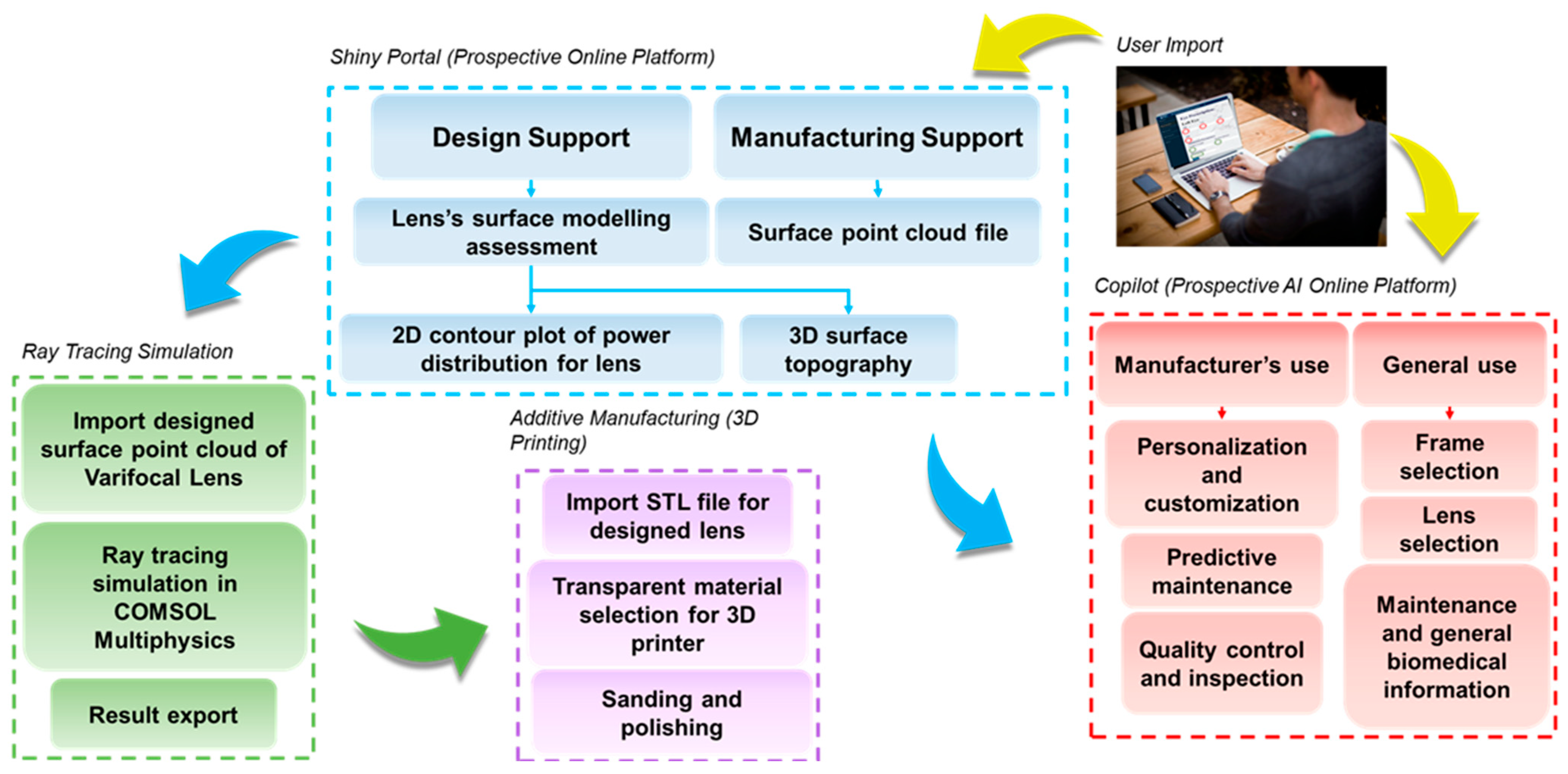

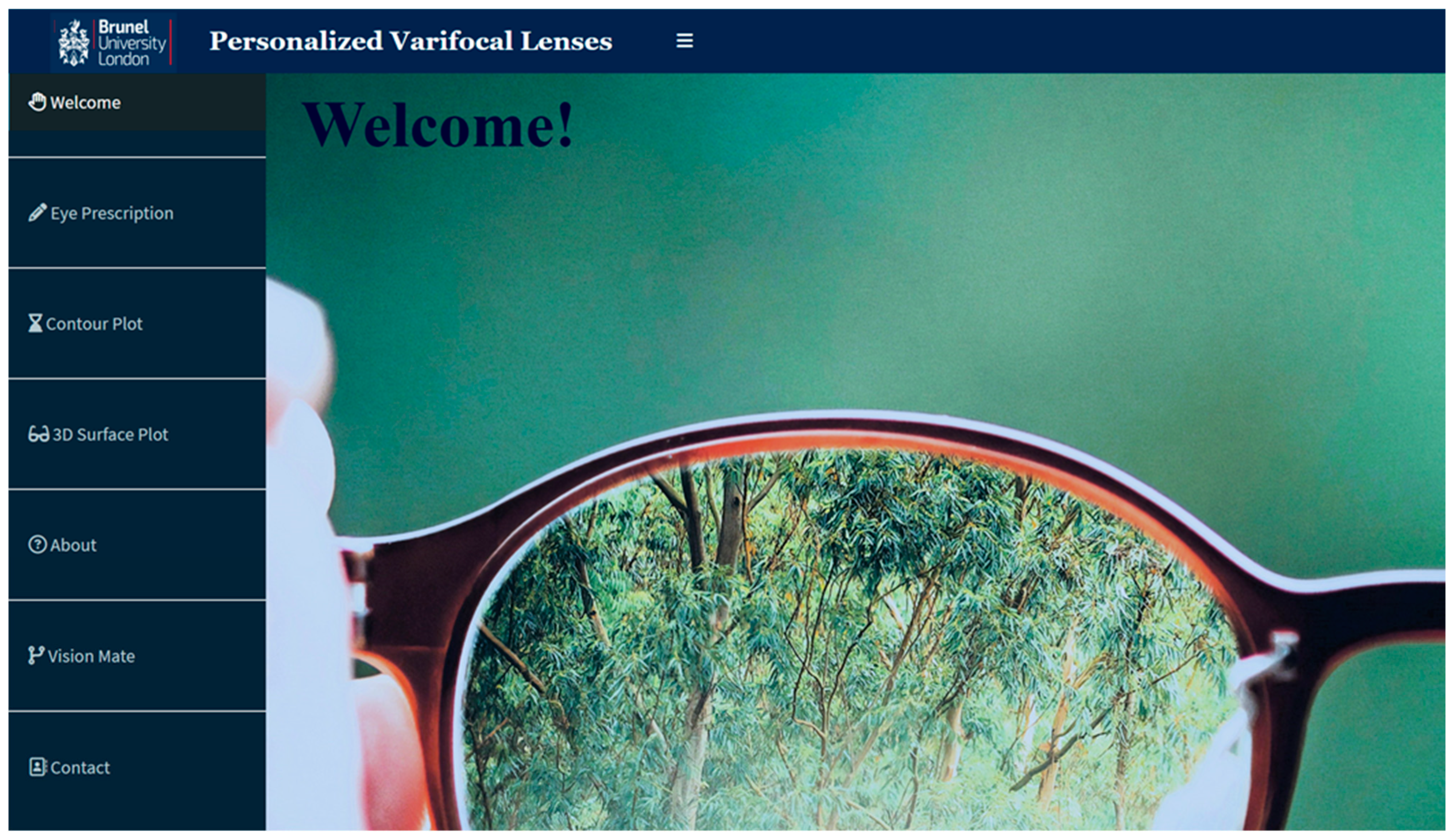

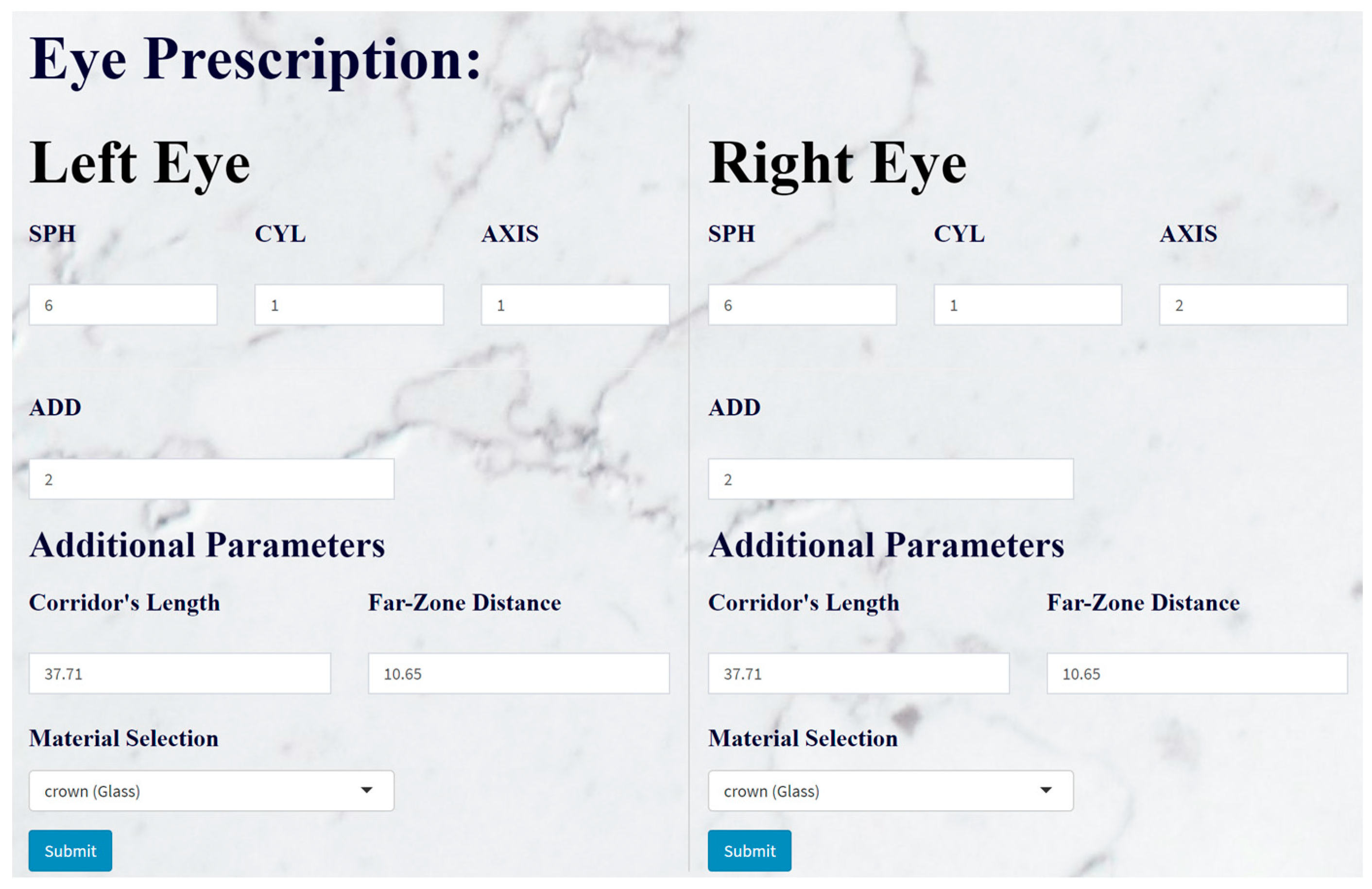

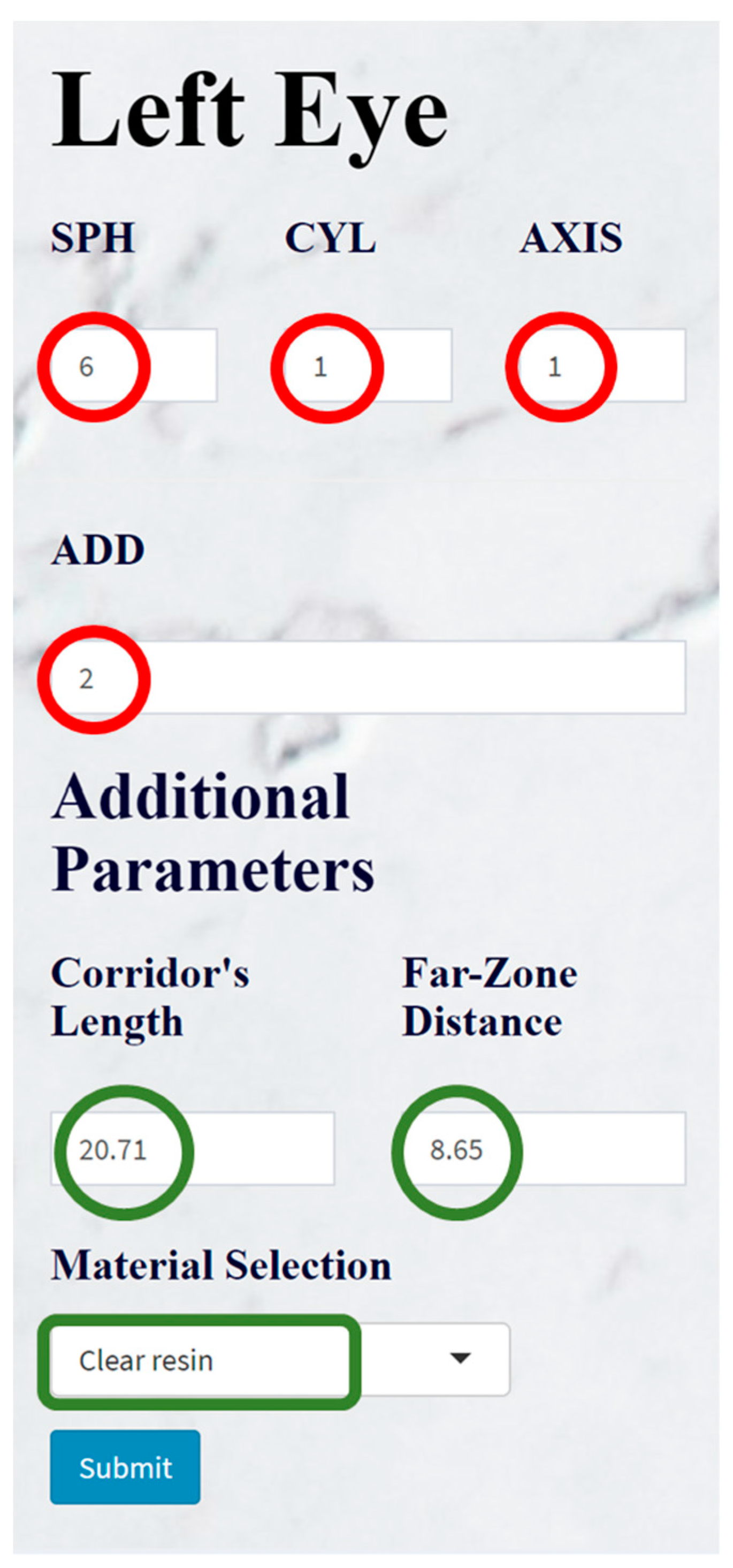

2. Module Structures and Development

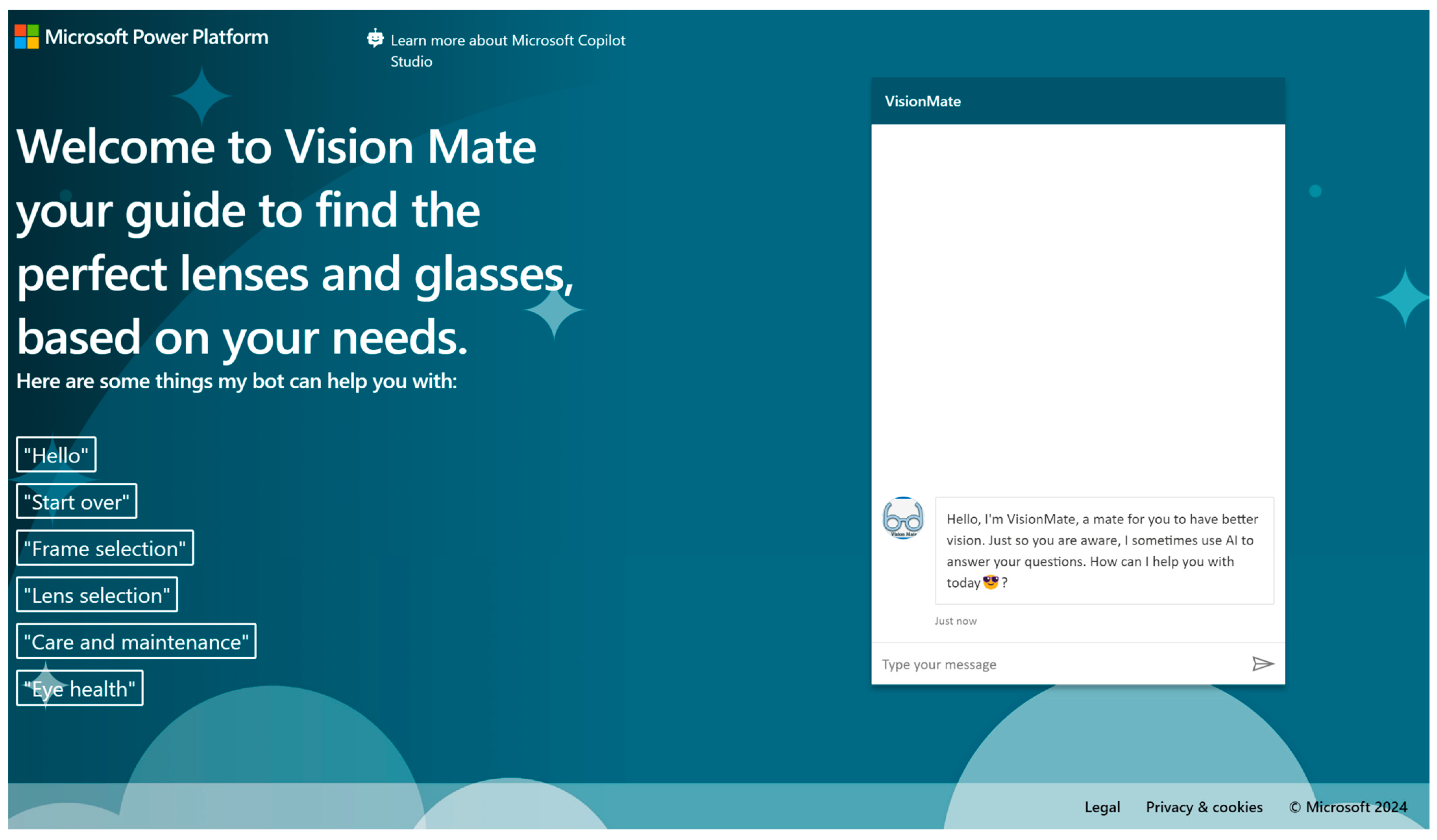

3. Vision Mate and Its Implementation

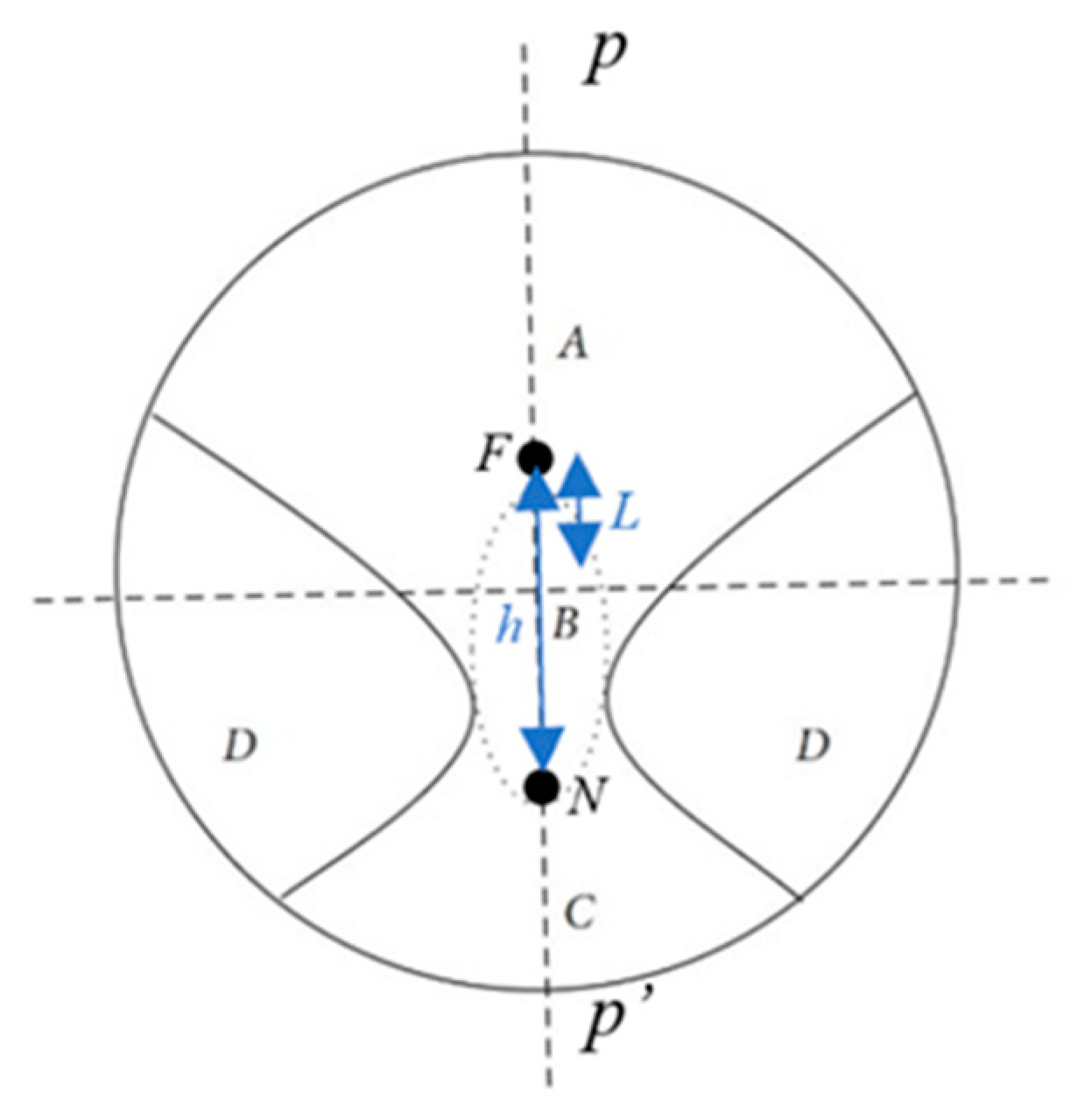

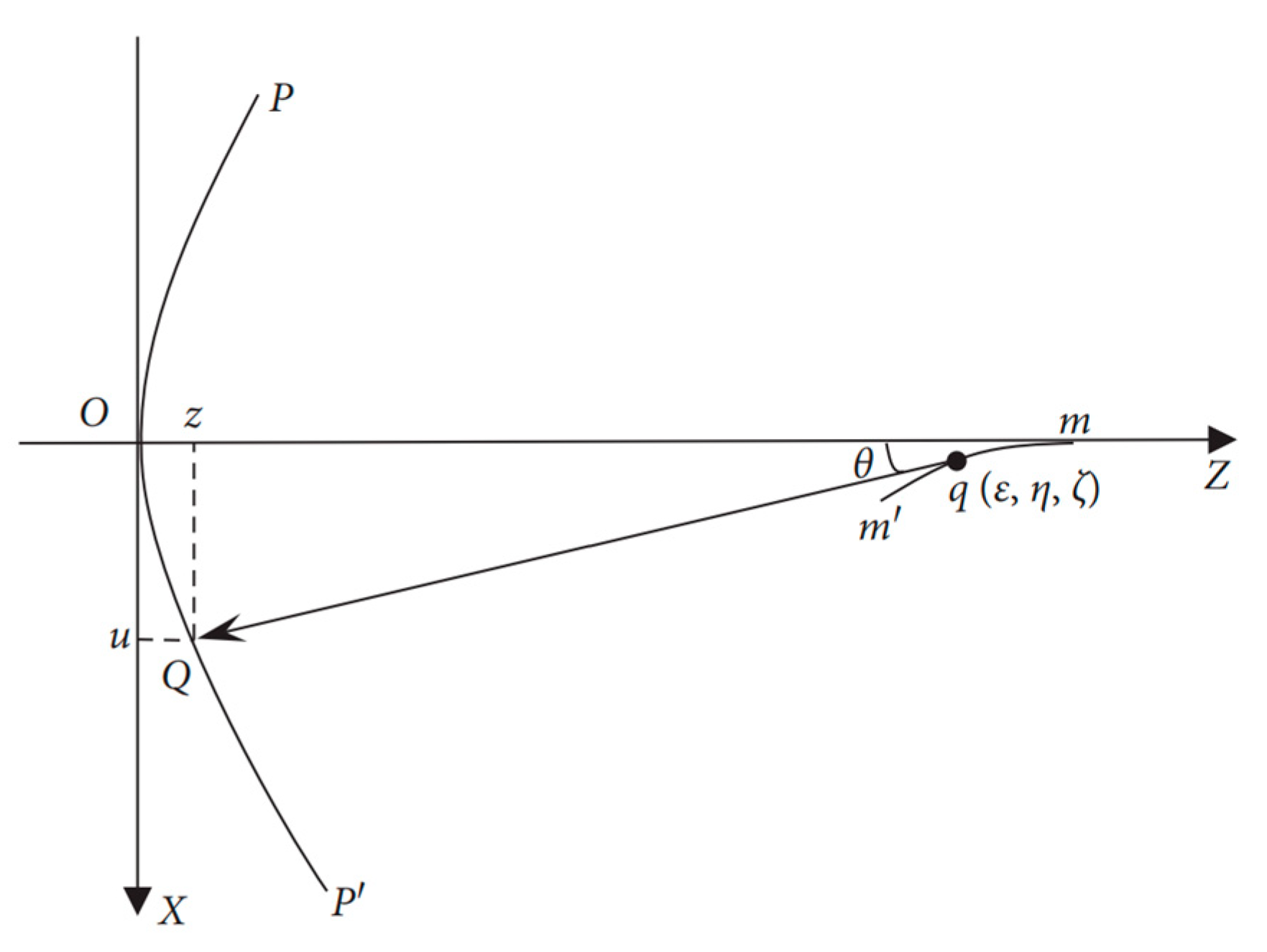

4. Freeform Surface Modelling

5. Lens Surface Assessment

- The 2D contour plots and 3D surface plots, which are representations of the designed surfaces for varifocal lenses.

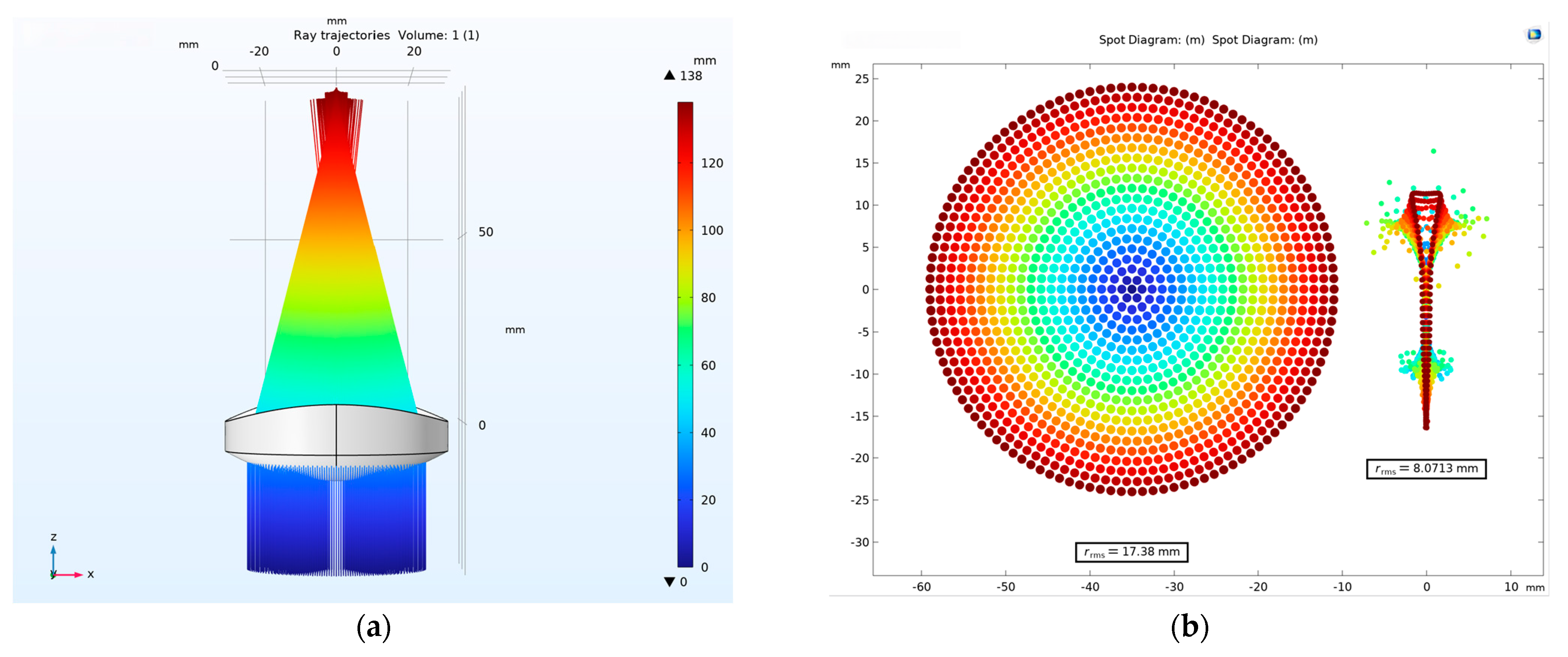

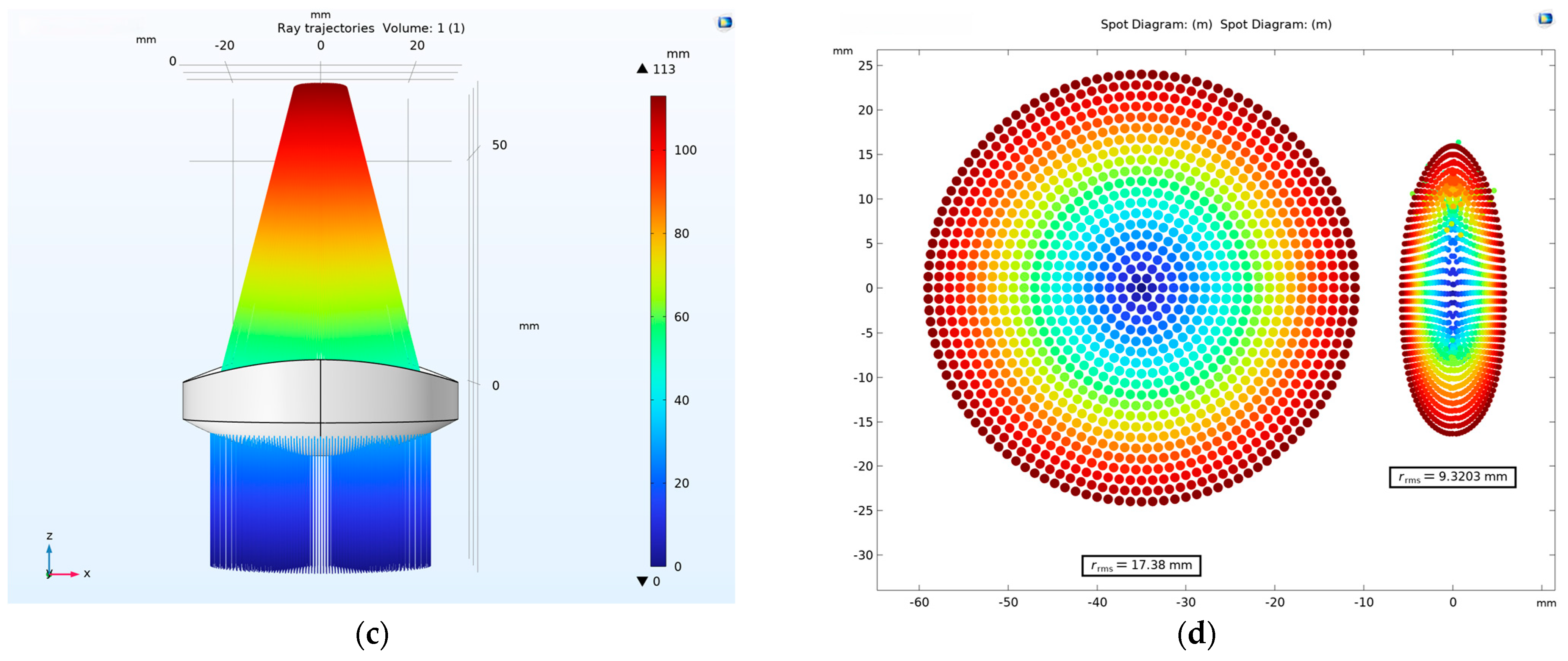

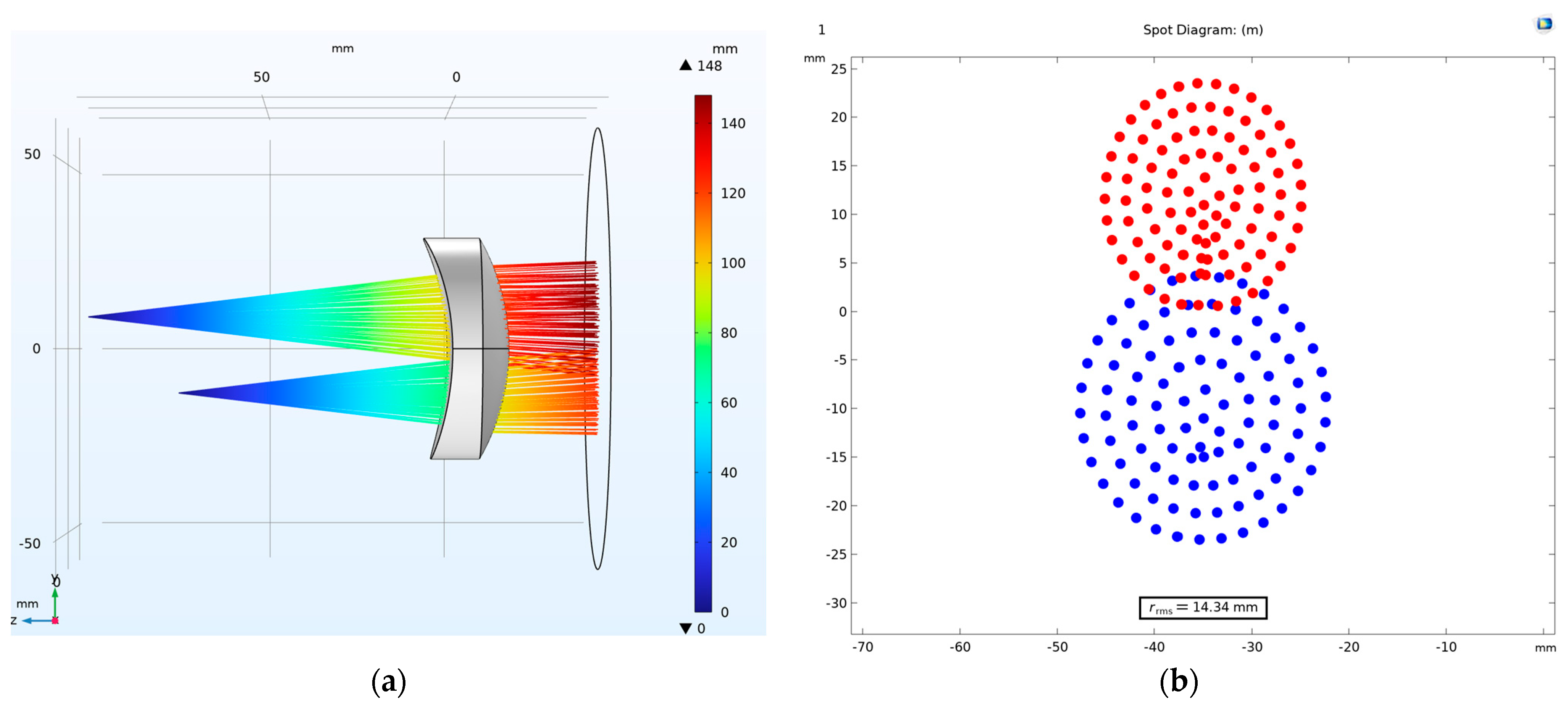

- Ray tracing assessment, which is based on the modelled surface in COMSOL Multiphysics 6.2—a powerful simulation modelling software that is widely used in engineering and scientific research—using the data points from the designed lens in the Shiny online web portal.

5.1. Results: PAL Surface for Varifocal Lenses Through the E-Portal

5.2. Lens Design

5.2.1. AM for Varifocal Lenses

5.2.2. Ray Tracing Assessment and Validation

6. Conclusions

- Development of an interactive intelligent e-portal that automates and streamlines the lens design and manufacturing workflow, increasing efficiency in optical engineering.

- A seamless fusion of design, additive manufacturing, and virtual assessment, which replaces traditional multi-step fabrication, creating benefits such as mass customisation, faster production cycles, and reduced material waste in order to save resources.

- Automated design and manufacturing processes that facilitate rapid prototyping and the customisation of lenses, enhancing the ability to meet individual customer needs and minimise process inconsistencies.

- Enhancing material selection and post-processing techniques to improve optical performance, enabling greater precision and durability in the final product.

- Experimental validation of the fabricated lenses, including surface accuracy, refractive index control, and other key optical properties.

- Incorporating AI-driven design optimisation into the e-portal to further streamline the design process and improve the customisation capabilities of the system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Toussaint, J.; Cheng, K. Implementation of design agility and manufacturing responsiveness on the web: Two case studies. Integr. Manuf. Syst. 2002, 13, 328–339. [Google Scholar]

- Cheng, K.; Bateman, R.J. e-Manufacturing: Characteristics, applications and potentials. Prog. Nat. Sci. 2008, 18, 1323–1328. [Google Scholar] [CrossRef]

- Liu, S.; Cheng, K.; Zhao, L. Development of the personalised manufacturing system framework for freeform vari-focal lenses and its implementation and application perspectives. Int. J. Mechatron. Manuf. Syst. 2023, 16, 1–21. [Google Scholar]

- Groover, M.P.; Jayaprakash, G. Automation, Production Systems, and Computer-Integrated Manufacturing, 4th ed.; Pearson: London, UK, 2016; Available online: https://go.exlibris.link/nclTmZ3v (accessed on 28 September 2024).

- Beeley, C. Web Application Development with R Using SHINY; Packt Publishing Ltd.: Birmingham, UK, 2016. [Google Scholar]

- Wei, Y.; Zhai, P.; Chen, X.; He, L. Study on design and diamond turning of optical freeform surface for progressive addition lenses. Math. Probl. Eng. 2020, 2020, 2850606. [Google Scholar]

- HSO. 2024. Available online: https://www.hso.com/ (accessed on 27 October 2024).

- Parnin, C.; Soares, G.; Pandita, R.; Gulwani, S.; Rich, J.; Henley, A.Z. Building your own product copilot: Challenges, opportunities, and needs. arXiv 2023, arXiv:2312.14231. [Google Scholar]

- Achiam, J.; Adler, S.; Agarwal, S.; Ahmad, L.; Akkaya, I.; Aleman, F.L.; Almeida, D.; Altenschmidt, J.; Altman, S.; Anadkat, S.; et al. Gpt-4 technical report. arXiv 2023, arXiv:2303.08774. [Google Scholar]

- Introducing Microsoft 365. 2024. Available online: https://www.microsoft.com/en-us/microsoft-365/blog/2023/03/16/introducing-microsoft-365-copilot (accessed on 15 November 2024).

- Huerta-Carranza, O.; Avendaño-Alejo, M.; Díaz-Uribe, R. Null screens to evaluate the shape of freeform surfaces: Progressive addition lenses. Opt. Express 2021, 29, 27921–27937. [Google Scholar]

- Alonso, J.; Gómez-Pedrero, J.A.; Quiroga, J.A. Modern Ophthalmic Optics; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Rolland, J.P.; Davies, M.A.; Suleski, T.J.; Evans, C.; Bauer, A.; Lambropoulos, J.C.; Falaggis, K. Freeform optics for imaging. Optica 2021, 8, 161–176. [Google Scholar]

- Fang, F.Z.; Zhang, X.D.; Weckenmann, A.; Zhang, G.X.; Evans, C. Manufacturing and measurement of freeform optics. Cirp Annals 2013, 62, 823–846. [Google Scholar] [CrossRef]

- Qin, L.; Zeng, C.; Qian, L.; Yu, J. Optimizing design of progressive addition lenses. In Proceedings of the 6th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Optical System Technologies for Manufacturing and Testing, SPIE, Bellingham, WA, USA, 11 October 2012; Volume 8420, pp. 325–329. [Google Scholar]

- Winthrop, J.T.; American Optical Corp. Progressive Power Ophthalmic Lenses. U.S. Patent 4,514,061, 30 April 1985. [Google Scholar]

- Maitenaz, B.F.; Lunetiers. Ophthalmic Lenses with a Progressively Varying Focal Power. U.S. Patent 3,687,528, 29 August 1972. [Google Scholar]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing: Principles and Applications (with Companion Media Pack)-of Rapid Prototyping; World Scientific Publishing Company: Hackensack, NJ, USA, 2014. [Google Scholar]

- Esmaeilian, B.; Behdad, S.; Wang, B. The evolution and future of manufacturing: A review. J. Manuf. Syst. 2016, 39, 79–100. [Google Scholar]

- Kai, C.C.; Fai, L.K.; Chu-Sing, L. Rapid Prototyping: Principles and Applications in Manufacturing; World Scientific Publishing Co., Inc.: Hackensack, NJ, USA, 2003. [Google Scholar]

- Brecher, C.; Lange, S.; Merz, M.; Niehaus, F.; Wenzel, C.; Winterschladen, M.; Weck, M. NURBS based ultra-precision free-form machining. CIRP Ann. 2006, 55, 547–550. [Google Scholar] [CrossRef]

- Essilor. 2024. Available online: https://www.essilor.com/us-en/ (accessed on 21 October 2024).

- Hatefi, S.; Abou-El-Hossein, K. Review of single-point diamond turning process in terms of ultra-precision optical surface roughness. Int. J. Adv. Manuf. Technol. 2020, 106, 2167–2187. [Google Scholar] [CrossRef]

- Ananyev, V. Waveguides by 3D-Printing. Master’s Thesis, Itä-Suomen yliopisto, Kuopio, Finland, 2020. [Google Scholar]

- Liu, Q.; Zhou, X.; Xu, P. A new tool path for optical freeform surface fast tool servo diamond turning. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1721–1726. [Google Scholar] [CrossRef]

- Ge, Q.; Li, Z.; Wang, Z.; Kowsari, K.; Zhang, W.; He, X.; Zhou, J.; Fang, N.X. Projection micro stereolithography based 3D printing and its applications. Int. J. Extrem. Manuf. 2020, 2, 022004. [Google Scholar] [CrossRef]

- Christopher, J.; Rooney, L.M.; Donnachie, M.; Uttamchandani, D.; McConnell, G.; Bauer, R. Low-cost 3D printed lenses for brightfield and fluorescence microscopy. Biomed. Opt. Express 2024, 15, 2224–2237. [Google Scholar]

- Shinydashboard. 2024. Available online: https://rstudio.github.io/shinydashboard/index.html (accessed on 15 March 2024).

- Ibm.com. 2024. Available online: https://www.ibm.com/think/topics/ai-in-manufacturing?utm_source=chatgpt.com (accessed on 22 September 2024).

- IOT Lenses. 2024. Available online: https://iotlenses.com/ (accessed on 21 October 2024).

- SpecSavers. 2024. Available online: https://www.specsavers.co.uk/ (accessed on 21 October 2024).

- Vision Express. 2024. Available online: https://www.visionexpress.com/ (accessed on 21 October 2024).

- Cakmakci, O.; Moore, B.; Foroosh, H.; Rolland, J.P. Optimal local shape description for rotationally non-symmetric optical surface design and analysis. Opt. Express 2008, 16, 1583–1589. [Google Scholar] [CrossRef]

- Meister, D.J.; Fisher, S.W. Progress in the spectacle correction of presbyopia. Part 2: Modern progressive lens technologies. Clin. Exp. Optom. 2008, 91, 251–264. [Google Scholar] [CrossRef]

- Form Labs. Manuals; Documentation (SLA). 2024. Available online: https://support.formlabs.com/s/article/Manuals-and-documentation/ (accessed on 18 September 2024).

- Creating 3D Printed Lenses and a 3D Printed Camera with Stereolithography. 2024. Available online: https://formlabs.com/blog/creating-camera-lenses-with-stereolithography/ (accessed on 12 September 2024).

- Berglund, G.D.; Tkaczyk, T.S. Fabrication of optical components using a consumer-grade lithographic printer. Opt. Express 2019, 27, 30405–30420. [Google Scholar] [CrossRef]

- Reynoso, M.; Gauli, I.; Measor, P. Refractive index and dispersion of transparent 3D printing photoresins. Opt. Mater. Express 2021, 11, 3392–3397. [Google Scholar]

- ISO8980-1:2017; Ophthalmic Optics—Uncut Finished Spectacle Lenses. Part 1: Specifications for Single-Vision and Multifocal Lenses. International Organization for Standardization: Geneva, Switzerland, 2017.

- Liu, S.; Cheng, K.; Dianat, N. Development of a Web-Based e-Portal for Freeform Surfaced Lens Design and Manufacturing and Its Implementation Perspectives. Machines 2025, 13, 59. [Google Scholar] [CrossRef]

- Schwendeman, F.J.; Ogden, B.B.; Horner, D.G.; Thibos, L.N. Effect of sphero-cylinder blur on visual acuity. Optom. Vis. Sci. 1997, 74, 80. [Google Scholar]

| Optical Parameters | |

|---|---|

| Symbol | Definition |

| Spherical power of the lens | |

| Cylindrical power of the lens | |

| Astigmatism correction angle | |

| Power of near-vision zone | |

| Geometrical Parameters | |

|---|---|

| Symbol | Definition |

| Far-zone distance | |

| Lens corridor length | |

| Refractive Index | |

| Radius of curvature | |

| Lens near power | |

| Lens distant power | |

| Material Properties | |

|---|---|

| Selected material | Clear Resin V4 (RS-F2-GPCL-04) |

| Type | Plastic |

| Refractive index | |

| ) | 56.44 |

| Design Parameters | |

| 3D printer type | Stereolithography (SLA) |

| Lens diameter | |

| Maximum thickness | |

| Minimum thickness | |

| Surface roughness | < |

| Form accuracy | <5 (μm) |

| Parameter | Value | Description |

|---|---|---|

| Lens diameter | ||

| Radius of the curvature for the outer surface of the lens | ||

| Incident ray direction, x direction | ||

| Incident ray direction, y direction | ||

| Incident ray direction, z direction | ||

| Ray wavelength | ||

| Refractive index | ||

| Focal length for far-view zone | ||

| Focal length for near-view zone |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dianat, N.; Liu, S.; Cheng, K.; Lu, K. Development of the E-Portal for the Design of Freeform Varifocal Lenses Using Shiny/R Programming Combined with Additive Manufacturing. Machines 2025, 13, 298. https://doi.org/10.3390/machines13040298

Dianat N, Liu S, Cheng K, Lu K. Development of the E-Portal for the Design of Freeform Varifocal Lenses Using Shiny/R Programming Combined with Additive Manufacturing. Machines. 2025; 13(4):298. https://doi.org/10.3390/machines13040298

Chicago/Turabian StyleDianat, Negin, Shangkuan Liu, Kai Cheng, and Kevin Lu. 2025. "Development of the E-Portal for the Design of Freeform Varifocal Lenses Using Shiny/R Programming Combined with Additive Manufacturing" Machines 13, no. 4: 298. https://doi.org/10.3390/machines13040298

APA StyleDianat, N., Liu, S., Cheng, K., & Lu, K. (2025). Development of the E-Portal for the Design of Freeform Varifocal Lenses Using Shiny/R Programming Combined with Additive Manufacturing. Machines, 13(4), 298. https://doi.org/10.3390/machines13040298