Time-Varying Meshing Stiffness Calculation and Dynamics Simulation of Multi-Spalling Gear

Abstract

1. Introduction

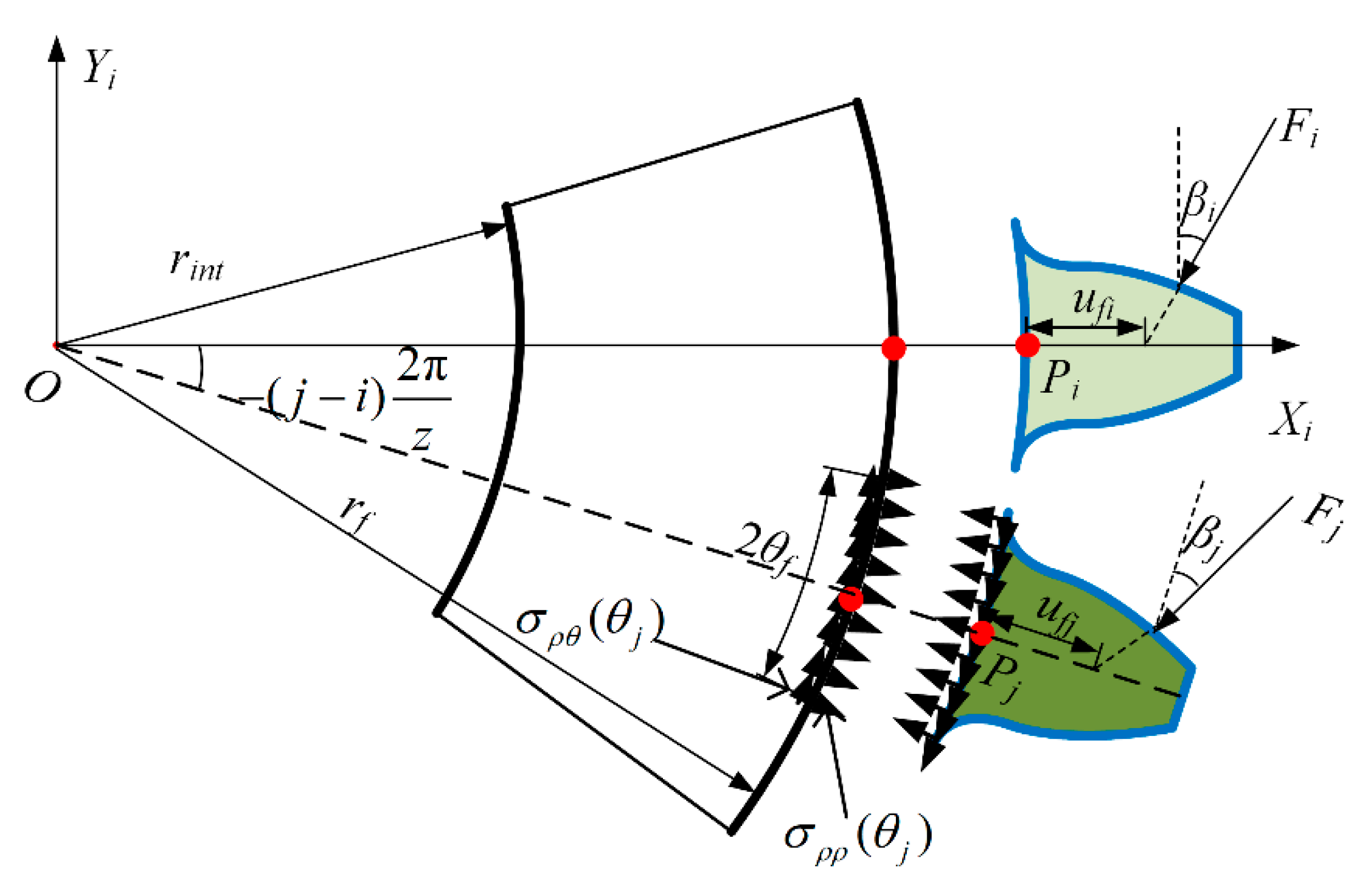

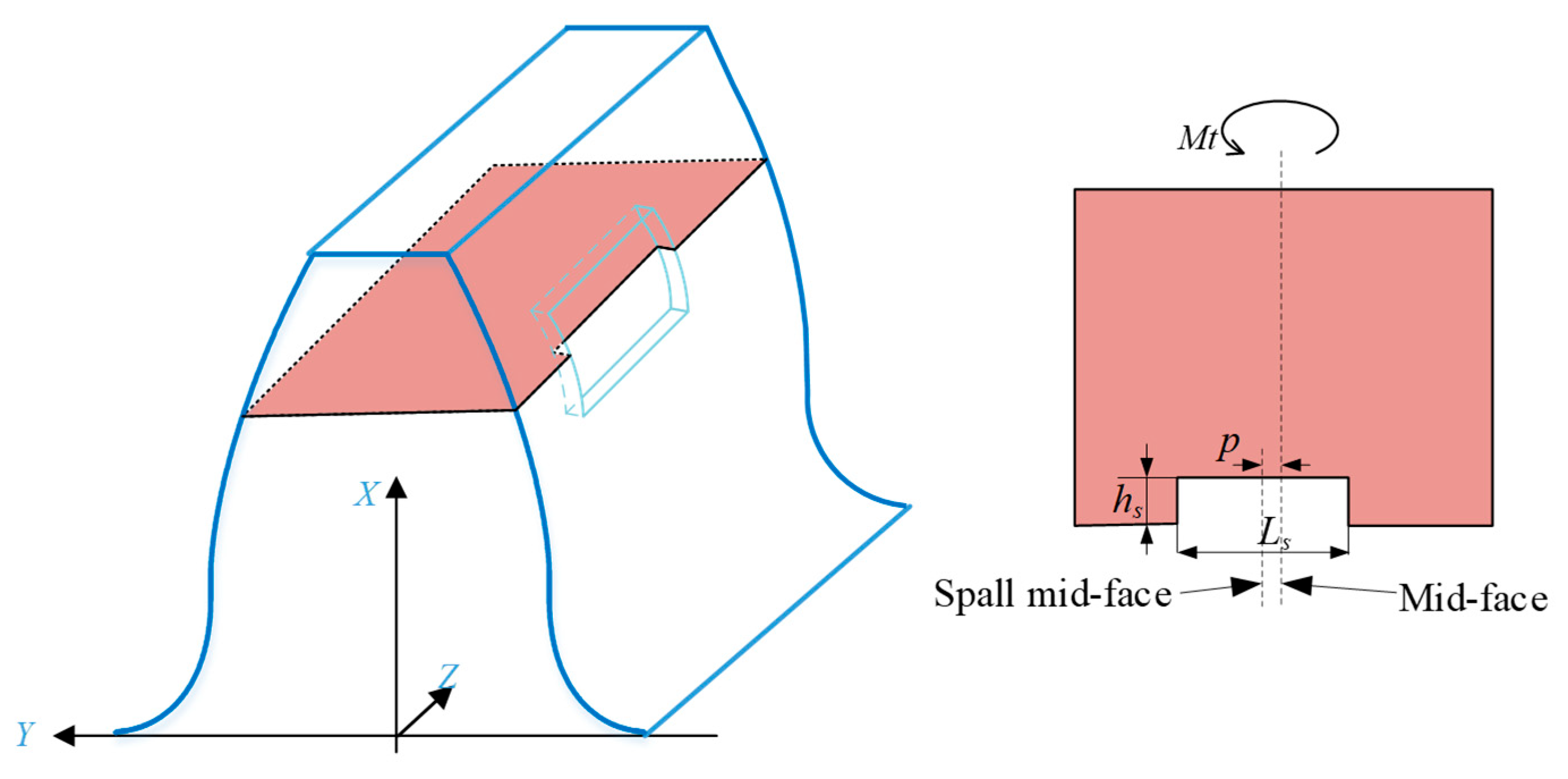

2. Improved TVMS Method for a Spalled Gear

3. Dynamic Modeling of Spur-Gear System

4. Results and Discussion

4.1. Model Validation

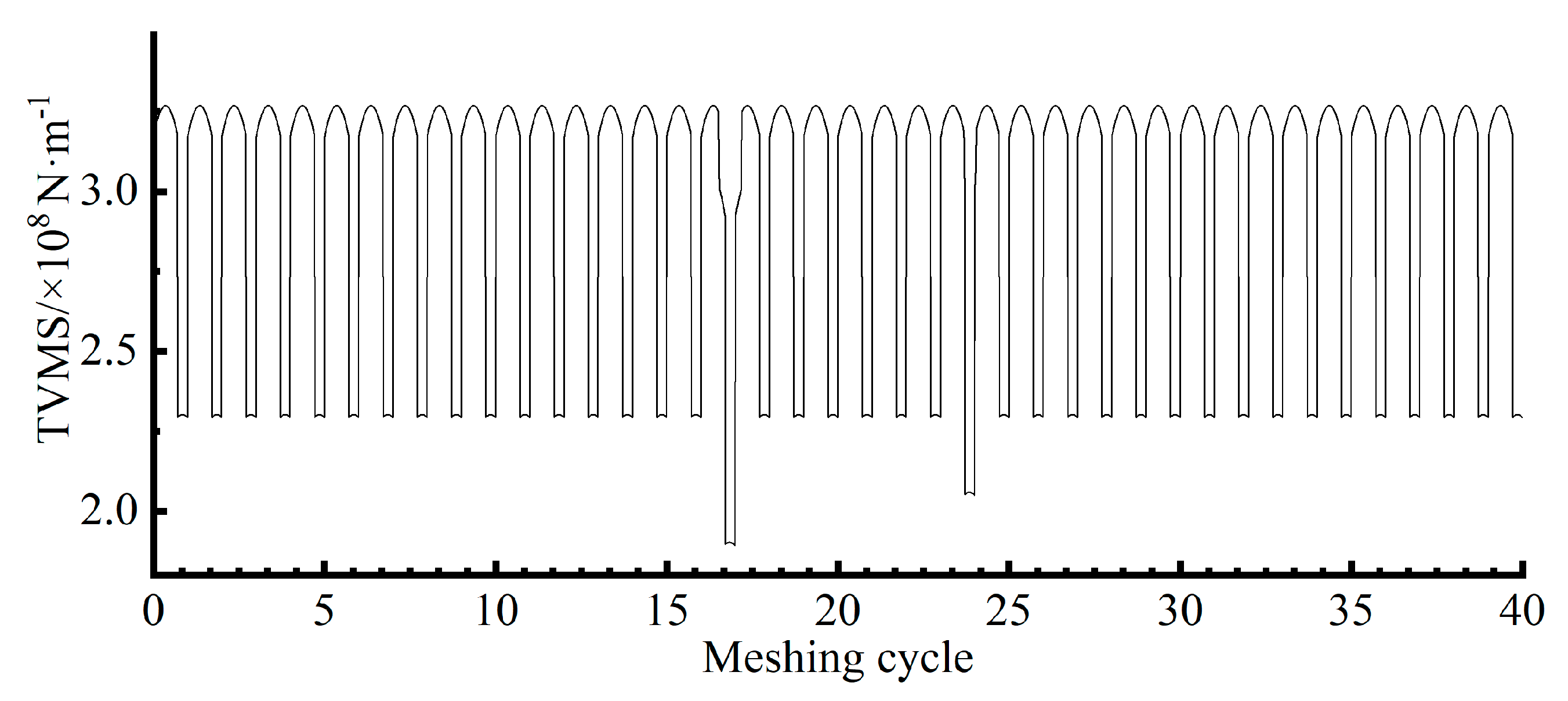

4.2. Multi-Spalling TVMS Calculation

4.2.1. Multi-Spalling on Non-Adjacent Teeth Within a Gear

4.2.2. Multi-Spalling on the Same Tooth Within a Gear

4.2.3. Multi-Spalling on Different Gears

4.3. Dynamic Simulation Analysis and Experimental Verification

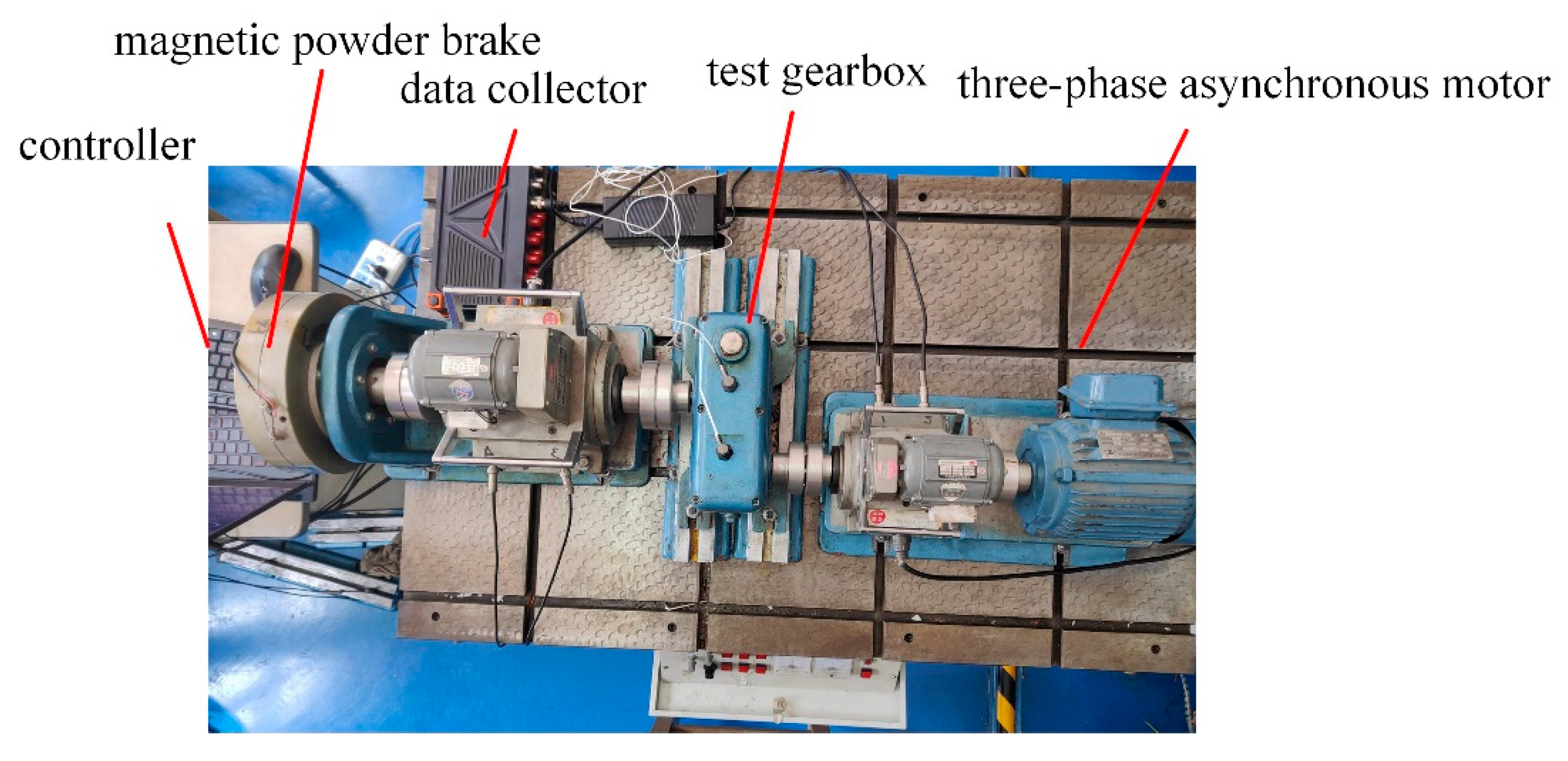

4.3.1. Experimental Equipment

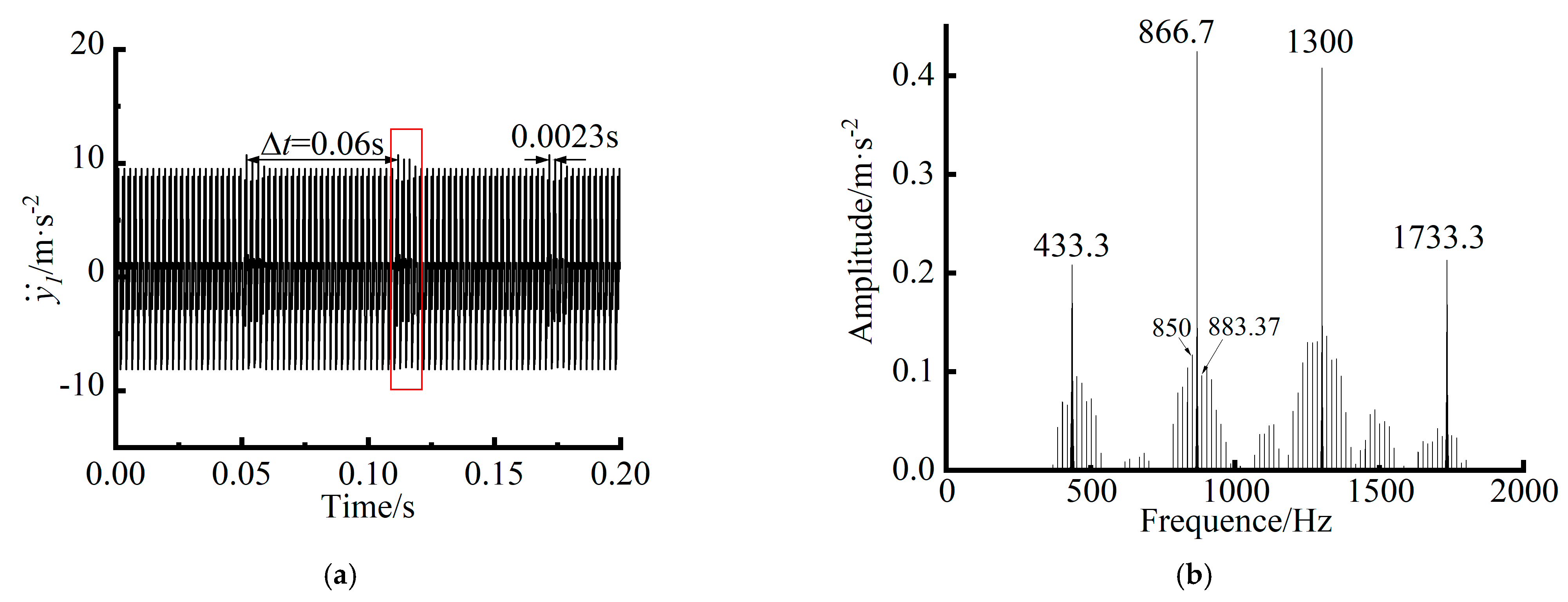

4.3.2. Multi-Spalling on Adjacent Teeth of the Driving Gear

4.3.3. Multi-Spalling on Different Gears

5. Conclusions

- (1)

- The proposed method can accurately calculate the TVMS of multi-spalling gears. Compared with traditional methods, it offers superior accuracy and greater generality. Therefore, the method shows strong potential for application in gear fault diagnosis.

- (2)

- When two adjacent teeth are spalled, the TVMS experiences a significant reduction. Asymmetric spalling causes a more substantial decrease in TVMS than symmetric spalling, even when the parameters are the same. The effect of multiple spalling teeth on the TVMS depends on the specific spalling parameters. Additionally, spalling on different gears results in eight distinct stiffness components.

- (3)

- The dynamic behavior of a multi-spalling gear system is influenced not only by individual spalling teeth but also by the combined effects of the distribution and degree of spalling. Different spalling modes can significantly change the system’s dynamic behavior. When teeth with spalling faults mesh, the vibration response exhibits more pronounced shocks. The FFT spectrum of the gear system modulates the meshing frequency, incorporating the corresponding rotational frequencies of gears with spalling faults. This study provides a solid foundation for understanding the dynamic behavior of spalled gear systems, revealing their dynamic characteristics and failure mechanisms.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DOFs | degrees of freedom |

| TVMS | time-varying meshing stiffness |

| FEM | finite element method |

| Hg-Hp | healthy tooth on the gear mesh with healthy tooth on the pinion |

| Sg-Hp | spalling tooth on the gear mesh with healthy tooth on the pinion |

| Hg-Sp | healthy tooth on the gear mesh with spalling tooth on the pinion |

| Sg-Sp | spalling tooth on the gear mesh with spalling tooth on the pinion |

References

- Liang, X.; Zhang, H.; Zuo, M.J.; Qin, Y. Three new models for evaluation of standard involute spur gear mesh stiffness. Mech. Syst. Signal Process. 2018, 101, 424–434. [Google Scholar] [CrossRef]

- Chen, Z.; Zhai, W.; Wang, K. Dynamic investigation of a locomotive with effect of gear transmissions under tractive conditions. J. Sound. Vib. 2017, 408, 220–233. [Google Scholar] [CrossRef]

- Saxena, A.; Parey, A.; Chouksey, M. Time varying mesh stiffness calculation of spur gear pair considering sliding friction and spalling defects. Eng. Fail. Anal. 2016, 70, 200–211. [Google Scholar] [CrossRef]

- Ma, H.; Li, Z.; Feng, M.; Feng, R.; Wen, B. Time-varying mesh stiffness calculation of spur gears with spalling defect. Eng. Fail. Anal. 2016, 66, 166–176. [Google Scholar] [CrossRef]

- Luo, Y.; Baddour, N.; Han, G.; Jiang, F.; Liang, M. Evaluation of the time-varying mesh stiffness for gears with tooth spalls with curved-bottom features. Eng. Fail. Anal. 2018, 92, 430–442. [Google Scholar] [CrossRef]

- Luo, W.; Qiao, B.; Zhixian, S.; Yang, Z.; Chen, X. Time-varying mesh stiffness calculation of a planetary gear set with the spalling defect under sliding friction. Meccanica 2020, 55, 245–260. [Google Scholar] [CrossRef]

- Cheng, Z.; Huang, K.; Xiong, Y.; Han, G. An improved model for dynamic characteristics analysis of high-contact-ratio spur gears considering localised tooth spall defect. Eng. Fail. Anal. 2022, 140, 106600. [Google Scholar] [CrossRef]

- Wu, X.; Luo, Y.; Li, Q.; Shi, J. A new analytical model for evaluating the time-varying mesh stiffness of helical gears in healthy and spalling cases. Eng. Fail. Anal. 2022, 131, 105842. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Song, H.; Zhu, R.; Ma, H. Time-varying mesh stiffness calculation of spiral bevel gear with spalling defect. Mech. Mach. Theory 2024, 193, 105571. [Google Scholar] [CrossRef]

- Hou, J.; Yang, S.; Li, Q.; Liu, Y. Effect of a Novel Tooth Pitting Model on Mesh Stiffness and Vibration Response of Spur Gears. Mathematics 2022, 10, 471. [Google Scholar] [CrossRef]

- Jin, Y.; Zhang, Q.; Chen, Y.; Zu, T. A shape-independent analytical method for gear mesh stiffness with asymmetric spalling defects. Sci. Rep. 2024, 14, 15545. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, F.; Gao, J.; Li, Z. Improved mesh stiffness model of spur gear considering spalling defect influenced by surface roughness under EHL condition. Mech. Based Des. Struct. Mach. 2024, 52, 8865–8889. [Google Scholar] [CrossRef]

- Lu, Z.; Chen, Y.; Zu, T.; Zhang, W. A spalling evolution model for time-varying mesh stiffness evaluation and service life prediction of gears. Mech. Syst. Signal Process. 2023, 193, 110227. [Google Scholar] [CrossRef]

- Han, L.; Qi, H. Influences of tooth spalling or local breakage on time-varying mesh stiffness of helical gears. Eng. Fail. Anal. 2017, 79, 75–88. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, R. An improved mesh stiffness model for double-helical gear pair with spalling defects considering time-varying friction coefficient under mixed EHL. Eng. Fail. Anal. 2021, 121, 105174. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, W.; Song, C.; Lin, T.; Duan, M. Analysis of time-varying meshing stiffness of helical gear pair with tooth surface spalling. J. Phys. Conf. Ser. 2021, 1820, 012131. [Google Scholar] [CrossRef]

- Luo, Y.; Baddour, N.; Liang, M. Dynamical modeling and experimental validation for tooth pitting and spalling in spur gears. Mech. Syst. Signal Process. 2019, 119, 155–181. [Google Scholar] [CrossRef]

- Yang, L.; Chen, Q.; Yin, L.; Wang, L.; Shao, Y. Dynamic characteristic of spur gear system with spalling fault considering tooth pitch error. Qual. Reliab. Eng. Int. 2022, 38, 2921–2938. [Google Scholar] [CrossRef]

- Wang, L.; Deng, C.; Xu, J.; Yin, L.; Yu, W.; Ding, X.; Shao, Y.; Huang, W.; Yang, X. Effects of spalling fault on dynamic responses of gear system considering three-dimensional line contact elasto-hydrodynamic lubrication. Eng. Fail. Anal. 2022, 132, 105930. [Google Scholar] [CrossRef]

- Huangfu, Y.; Chen, K.; Ma, H.; Li, X.; Han, H.; Zhao, Z. Meshing and dynamic characteristics analysis of spalled gear systems: A theoretical and experimental study. Mech. Syst. Signal Process. 2020, 139, 106640. [Google Scholar] [CrossRef]

- Shi, L.; Wen, J.; Pan, B.; Xiang, Y.; Zhang, Q.; Lin, C. Dynamic Characteristics of a Gear System with Double-Teeth Spalling Fault and Its Fault Feature Analysis. Appl. Sci. 2020, 10, 7058. [Google Scholar] [CrossRef]

- Wu, J.; Yang, Y.; Cheng, J. A novel estimation method of friction coefficient for evaluating gear pitting fault. Eng. Fail. Anal. 2021, 129, 105715. [Google Scholar] [CrossRef]

- Liu, Z.; Shang, E.; Huangfu, Y.; Ma, H.; Zhu, J.; Zhao, S.; Long, X.; Li, Z. Vibration characteristics analysis of flexible helical gear system with multi-tooth spalling fault: Simulation and experimental study. Mech. Syst. Signal Process. 2023, 201, 110687. [Google Scholar] [CrossRef]

- Xiang, L.; An, C.; Zhang, Y.; Hu, A. Failure dynamic modelling and analysis of planetary gearbox considering gear tooth spalling. Eng. Fail. Anal. 2021, 125, 105444. [Google Scholar] [CrossRef]

- Luo, W.; Qiao, B.; Shen, Z.; Yang, Z.; Cao, H.; Chen, X. Investigation on the influence of spalling defects on the dynamic performance of planetary gear sets with sliding friction. Tribol. Int. 2021, 154, 106639. [Google Scholar] [CrossRef]

- Sun, Z.; Tang, J.; Chen, S.; Li, H.; Tao, X.; Hu, Z. Dynamical modeling and characteristics analysis of tooth spalling in gear system with weight reduction structure. Mech. Mach. Theory 2023, 189, 105429. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, H.; Shi, J.; Yang, S.; Baddour, N.; Liang, M. Fault feature analysis and detection of progressive localized gear tooth pitting and spalling. Meas. Sci. Technol. 2022, 33, 115002. [Google Scholar] [CrossRef]

- Bai, W.; Zhou, X.; Wang, Y.; Zeng, Q.; Zhan, S.; Hua, X.; Bao, G. Vibration Analysis of the Electric Drive System with Inter-turn Short-Circuit and Gear Spalling Faults. J. Vib. Eng. Technol. 2023, 11, 3595–3605. [Google Scholar] [CrossRef]

- Dai, P.; Lu, J.; Liang, X.; Wang, J.; Wang, F. Dynamic behavior analysis for cages in gear-bearing system with spalling failure on tooth surface. Eng. Fail. Anal. 2023, 154, 107657. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.W.; Li, Q.; Niu, X.J.; Li, W. Dynamic Characteristics Analysis of High-Speed Fixed-Axis Gear Pair with Spalling Fault for a Wind Turbine Gearbox Considering Friction and Flash Temperature. Mech. Solids 2024, 59, 1154–1179. [Google Scholar] [CrossRef]

- Yan, S.; Dai, P.; Shu, D.; Wang, J.; Wei, S.; Liu, P.; Zhang, D.; Li, H. Deformation and Response Analysis of Spur Gear Pairs with Flexible Ring Gears and Localized Spalling Faults. Machines 2022, 10, 560. [Google Scholar] [CrossRef]

- Liang, X.-H.; Liu, Z.-L.; Pan, J.; Zuo, M.J. Spur Gear Tooth Pitting Propagation Assessment Using Model-based Analysis. Chin. J. Mech. Eng. 2017, 30, 1369–1382. [Google Scholar] [CrossRef]

- Tavakoli, M.S.; Houser, D.R. Optimum profile modifications for the minimization of static transmission errors of spur gears. J. Mech. Transm. Autom. Des. 1986, 108, 86–94. [Google Scholar] [CrossRef]

- Muskhelishvili, N.I. Some Basic Problems of the Mathematical Theory of Elasticity; Springer: Dordrecht, The Nederlands, 1977. [Google Scholar]

- Xie, C.; Hua, L.; Han, X.; Lan, J.; Wan, X.; Xiong, X. Analytical formulas for gear body-induced tooth deflections of spur gears considering structure coupling effect. Int. J. Mech. Sci. 2018, 148, 174–190. [Google Scholar] [CrossRef]

- Luo, Y.; Baddour, N.; Liang, M. A shape-independent approach to modelling gear tooth spalls for time varying mesh stiffness evaluation of a spur gear pair. Mech. Syst. Signal Process. 2019, 120, 836–852. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, K.; Zhao, B.; Ma, H.; Kong, X. An analytical-finite-element method for calculating mesh stiffness of spur gear pairs with complicated foundation and crack. Eng. Fail. Anal. 2018, 94, 339–353. [Google Scholar] [CrossRef]

- Xia, Q.; Ping, X.; Lizhong, J.; Jianwei, Y.; Peng, L. Bending and free vibration and analysis of laminated plates on Winkler foundations based on meshless layerwise theory. Mech. Adv. Mater. Struct. 2022, 29, 6168–6187. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Number of teeth/z1, z2 | 40, 40 |

| Module (mm)/m | 3 |

| Tooth width (mm)/L | 20 |

| Pressure angle (°)/α0 | 20 |

| Hub hole radius (mm) | 20, 20 |

| Parameter | Value |

|---|---|

| Number of teeth/z1, z2 | 26, 31 |

| Module (mm)/m | 3 |

| Teeth width (mm)/L | 25 |

| Pressure angle (°)/α0 | 20 |

| Mass (kg)/m1, m2 | 0.988, 1.02 |

| Backlash (μm)/2b | 40 |

| Eccentricity (mm)/ρ1, ρ2 | 1 × 10−3, 2 × 10−3 |

| Mass moment of inertia (kg·m2)/I1, I2 | 1.81 × 10−3, 1.87 × 10−3 |

| Mass moment of inertia (kg·m2)/Jg, Jp | 2 × 10−3, 2.5 × 10−3 |

| Bending stiffness (N·m−1)/ks1, ks2 | 1 × 107, 1.5 × 107 |

| Torsional stiffness (N·m−1)/kt1, kt2 | 1.5 × 107, 2 × 107 |

| Bearing stiffness (N·m−1)/kx1, ky1, kx2, ky2 | 1 × 108, 1 × 108, 1 × 108, 1 × 108 |

| Bearing damping (N·m−1·s−1)/cx1, cy1, cx2, cy2 | 1 × 105, 1 × 105, 1 × 105, 1 × 105 |

| 0.1 | |

| 0.05, 0.05 | |

| (i = 1, 2, 3, 4) | 0.5 |

| Hub hole radius (mm) | 20, 20 |

| Spall 1/2/3/4 | |

| lmax (mm) | 3/3/3/2 |

| hs (mm) | 2/2/2/1 |

| p (mm) | 2.5/4/3.2/5.5 |

| xcenter (mm) | 40/40/40/41 |

| θs (°) | 30/30/30/40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, X.; Yuan, Y.; Sun, S.; Xin, Y.; Meng, Q. Time-Varying Meshing Stiffness Calculation and Dynamics Simulation of Multi-Spalling Gear. Machines 2025, 13, 299. https://doi.org/10.3390/machines13040299

Kong X, Yuan Y, Sun S, Xin Y, Meng Q. Time-Varying Meshing Stiffness Calculation and Dynamics Simulation of Multi-Spalling Gear. Machines. 2025; 13(4):299. https://doi.org/10.3390/machines13040299

Chicago/Turabian StyleKong, Xiangxi, Ye Yuan, Shuai Sun, Yi Xin, and Qiang Meng. 2025. "Time-Varying Meshing Stiffness Calculation and Dynamics Simulation of Multi-Spalling Gear" Machines 13, no. 4: 299. https://doi.org/10.3390/machines13040299

APA StyleKong, X., Yuan, Y., Sun, S., Xin, Y., & Meng, Q. (2025). Time-Varying Meshing Stiffness Calculation and Dynamics Simulation of Multi-Spalling Gear. Machines, 13(4), 299. https://doi.org/10.3390/machines13040299