Research on Quasi-Static Transmission Error Measurement of Spur Gears Based on the Acceleration Method

Abstract

1. Introduction

2. Measuring Principle

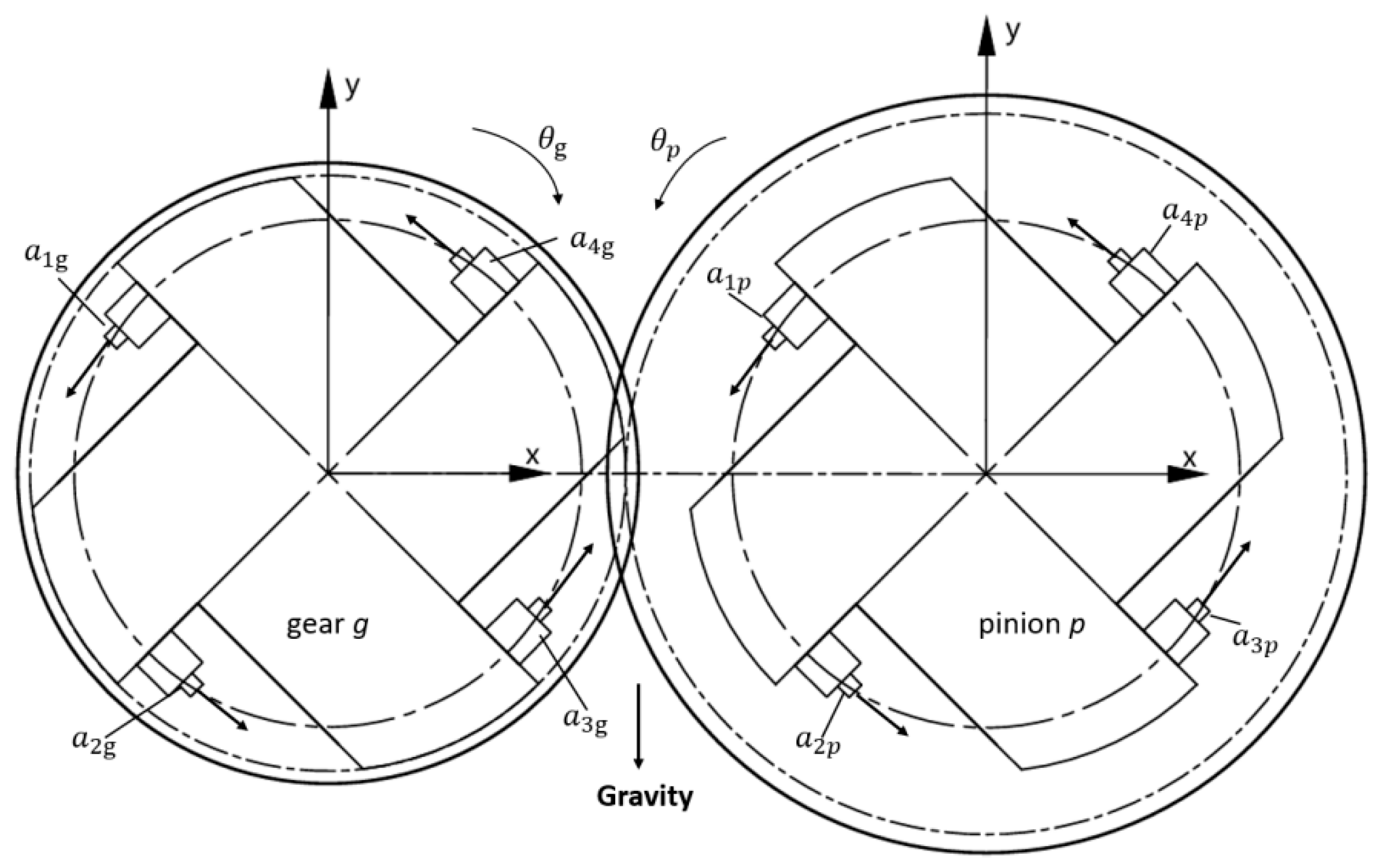

2.1. Acceleration Method

2.2. Theoretical Calculation Method of Material Mechanics

2.3. Magnetic Grating Detection Method

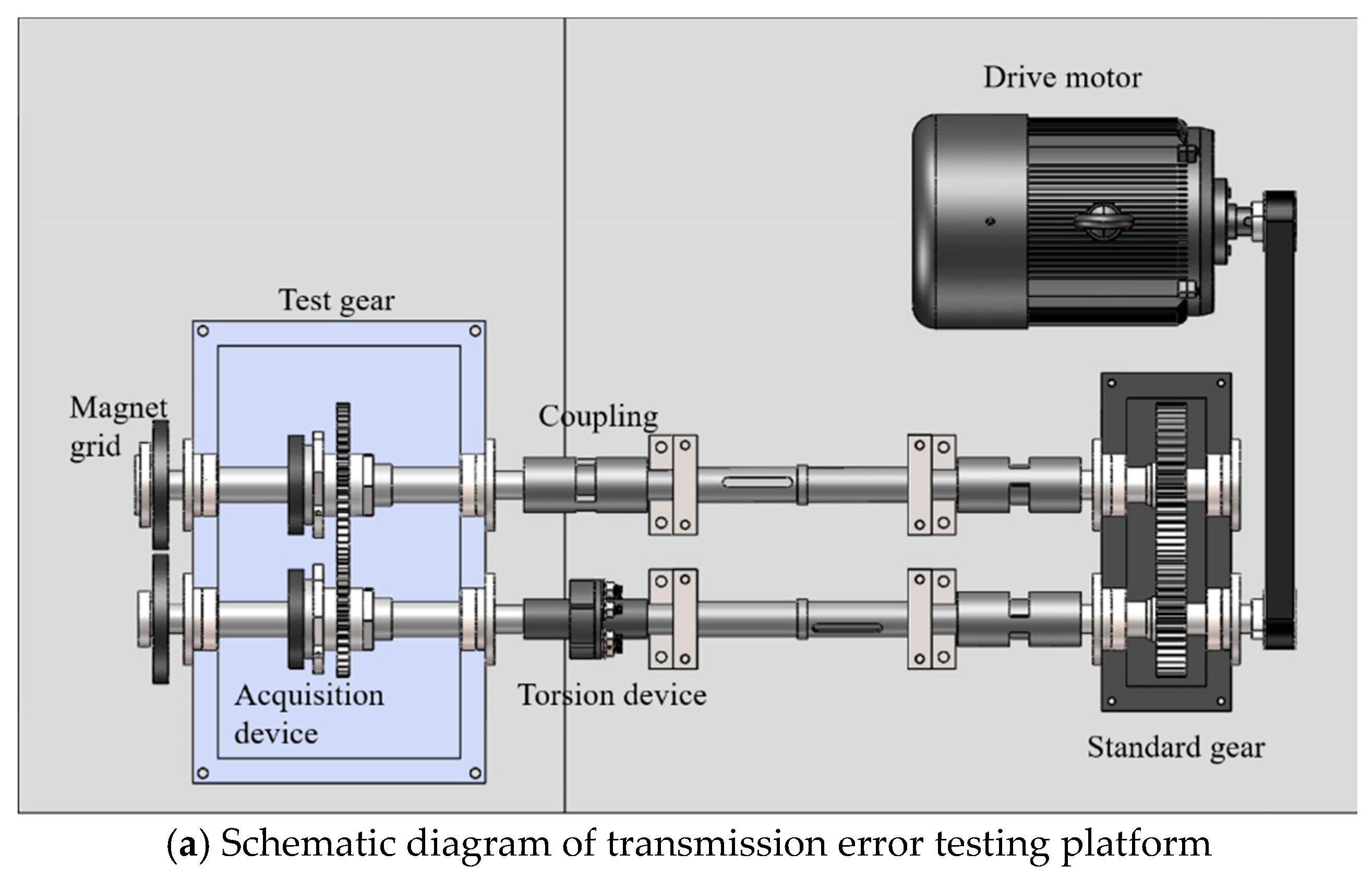

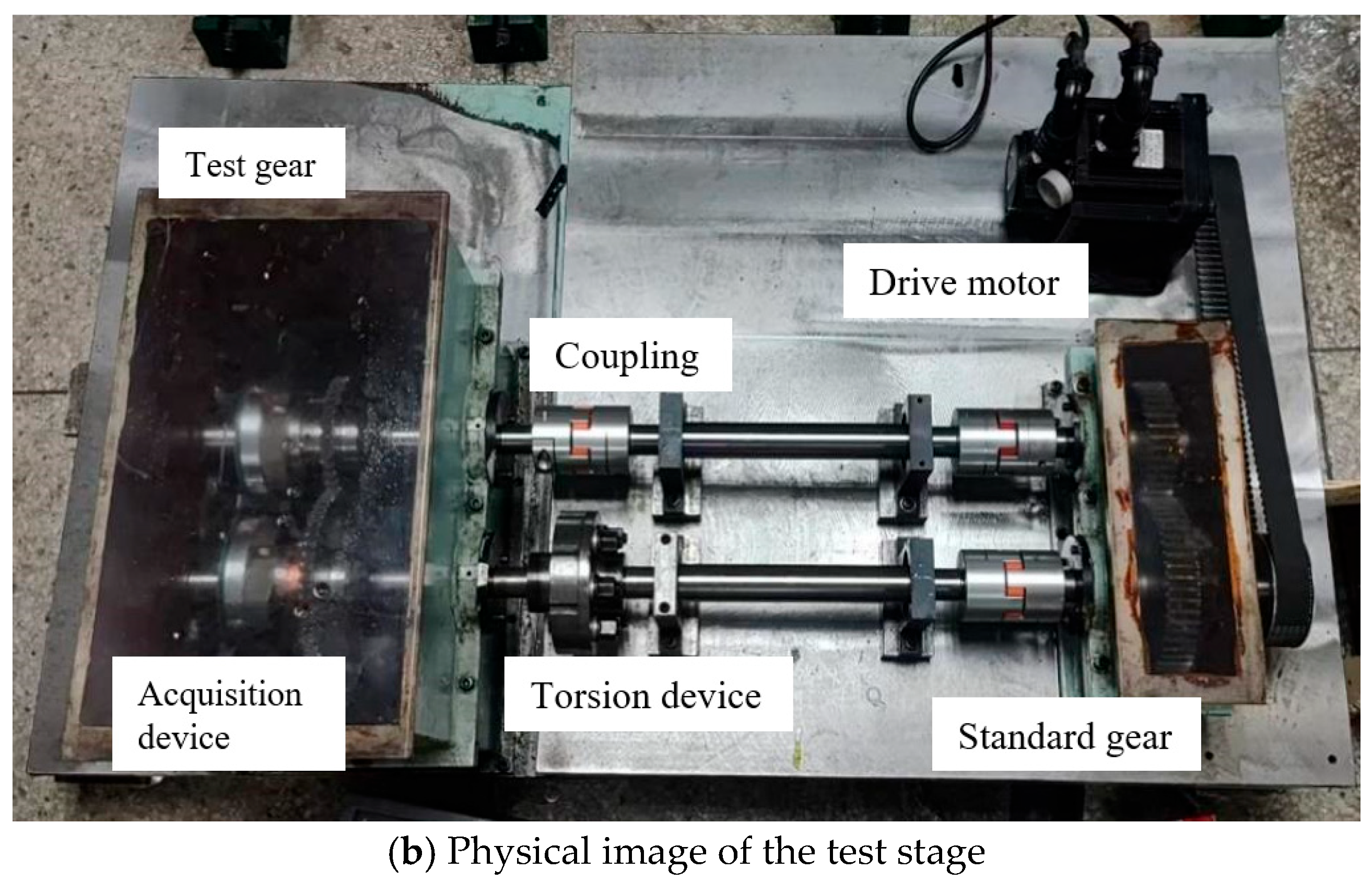

3. Experiment

Design of the Experiment Platform

4. Test Results

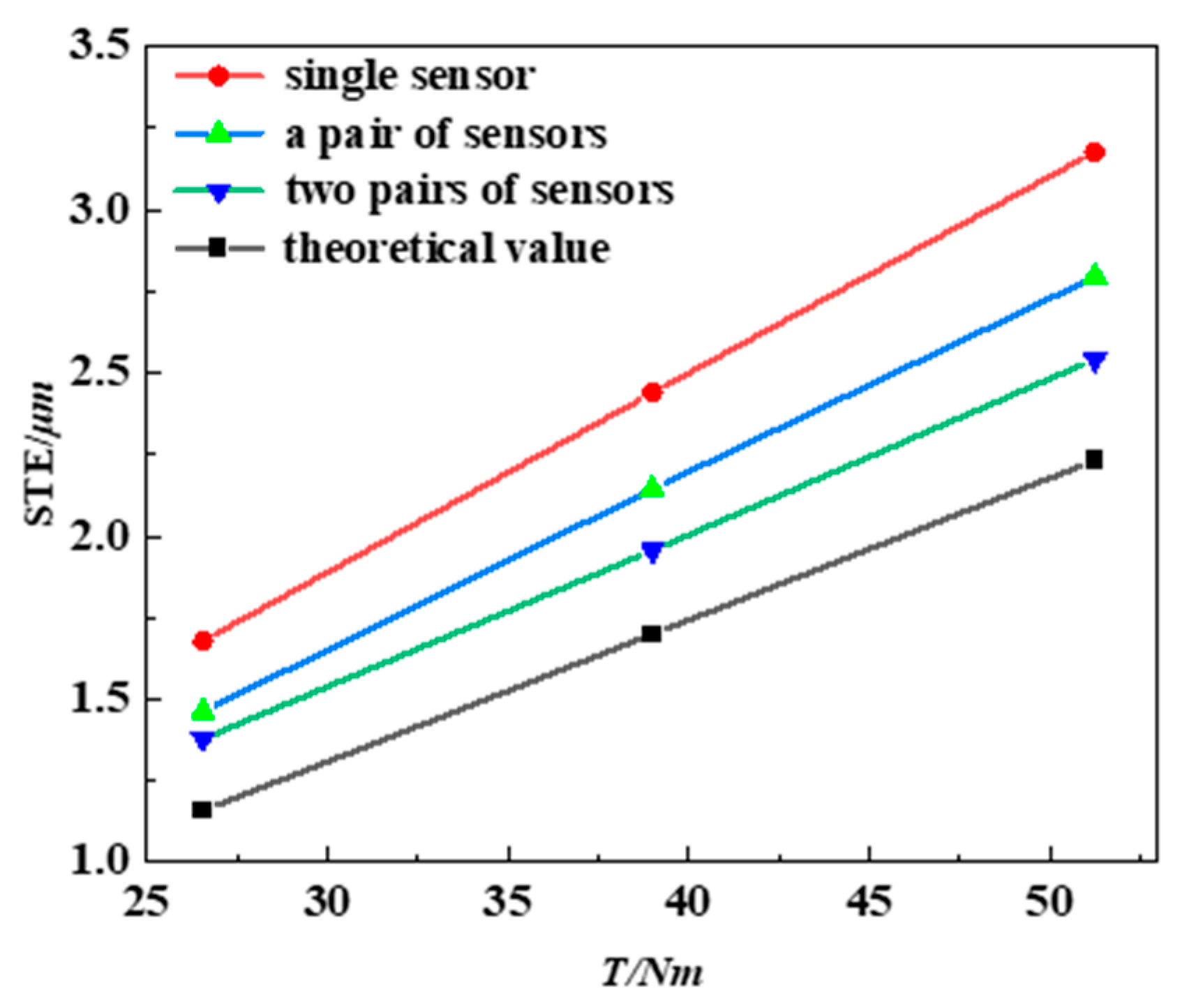

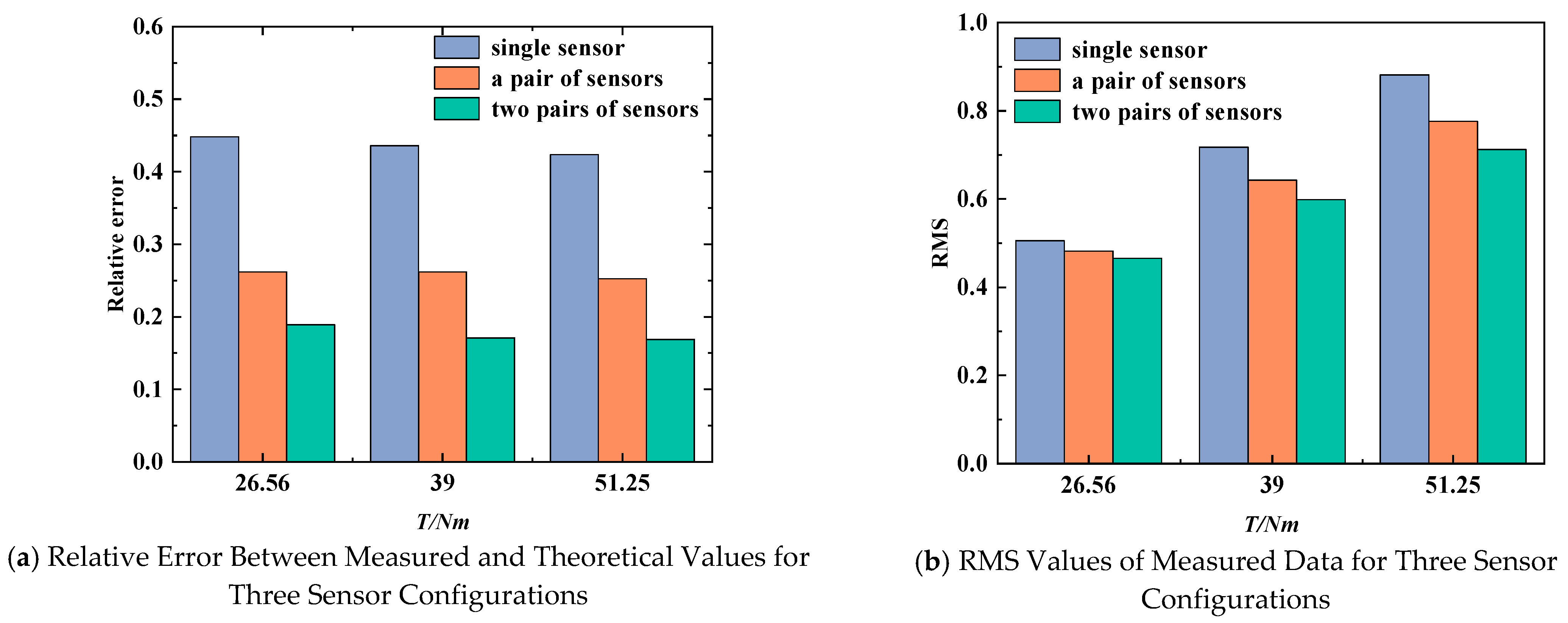

4.1. Comparison of Measurement Accuracy for Different Tangential Acceleration Sensor Configurations on Gears

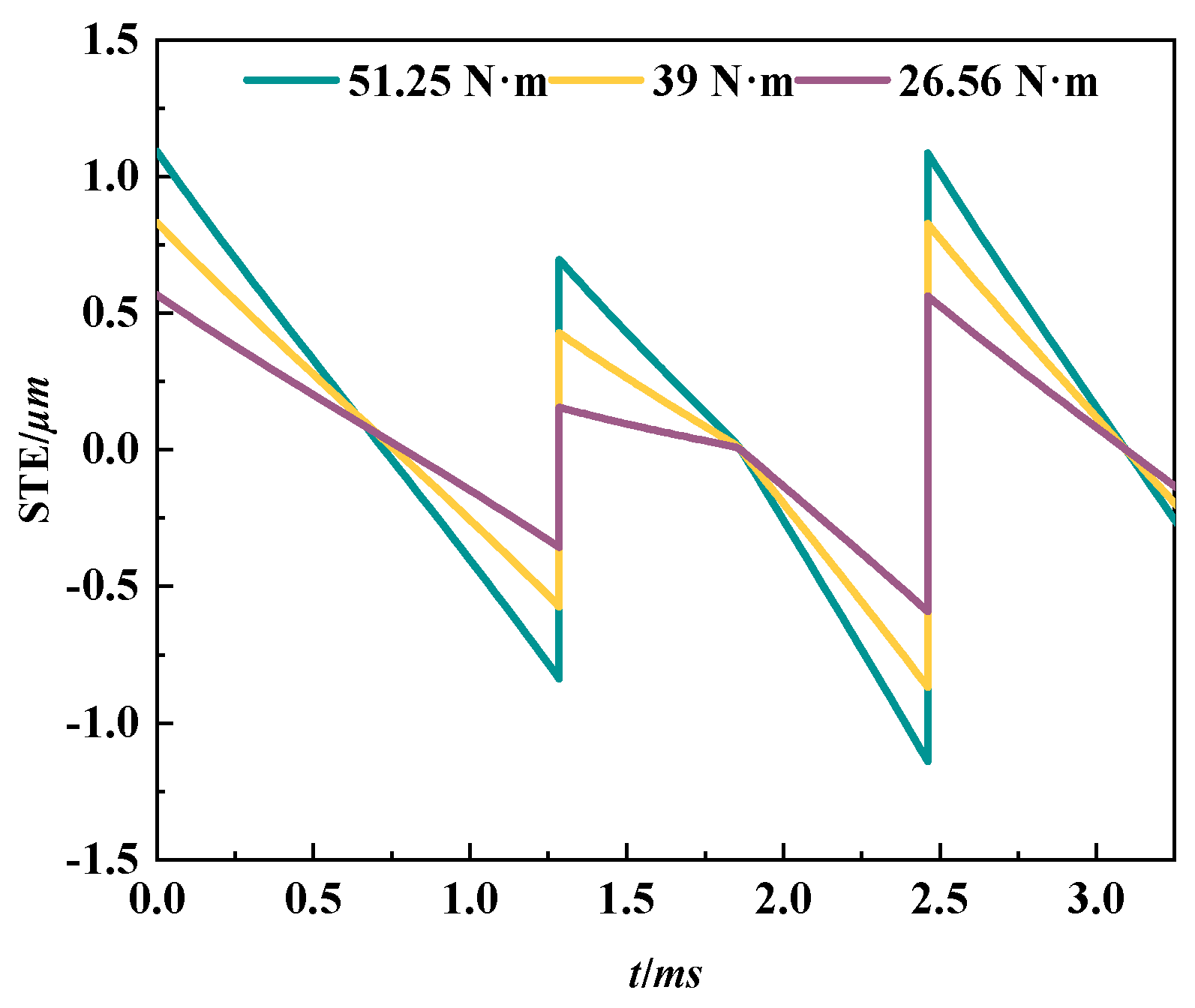

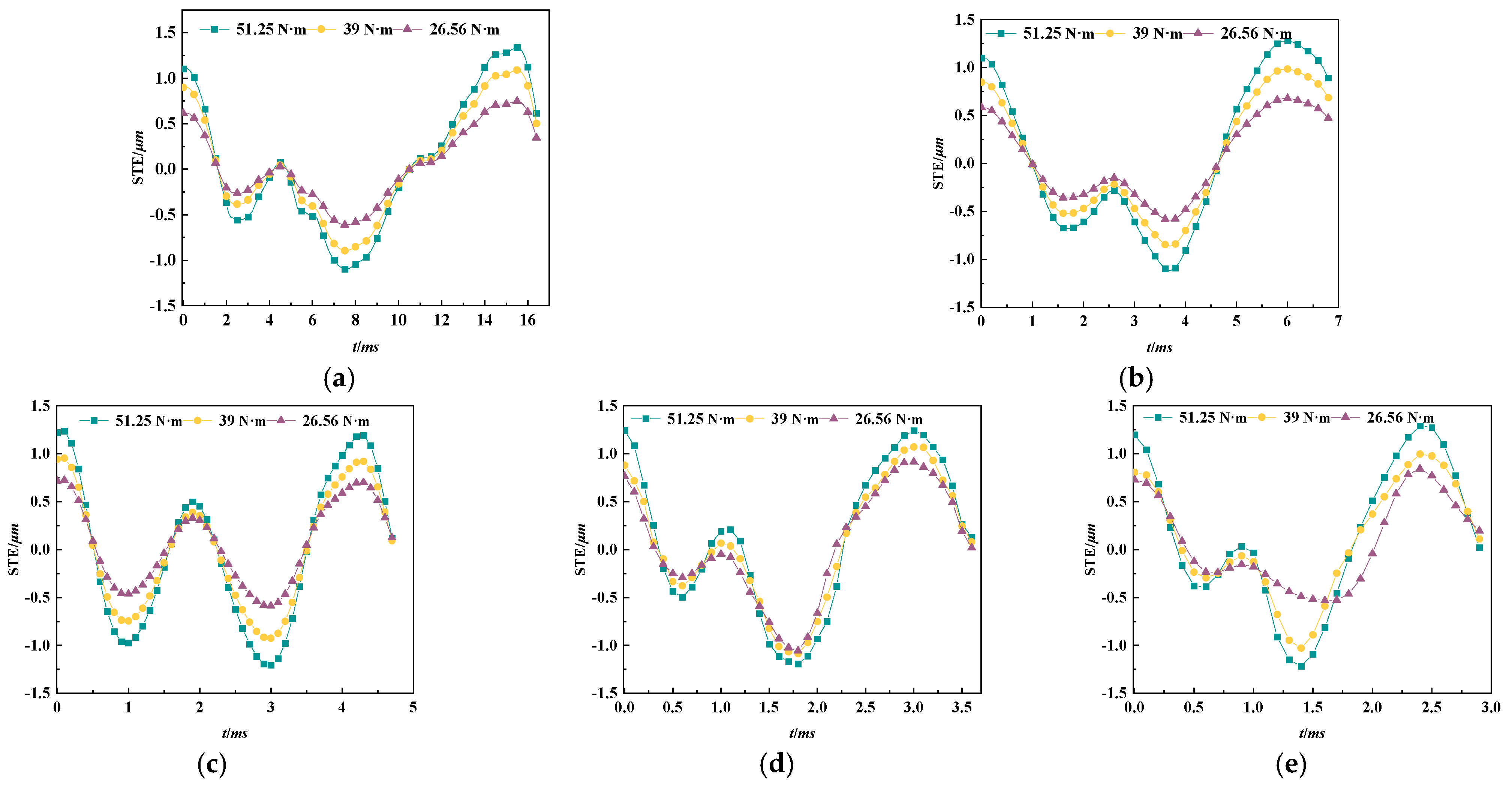

4.2. Experimental Results of Gear Elastic Deformation-Induced Transmission Error

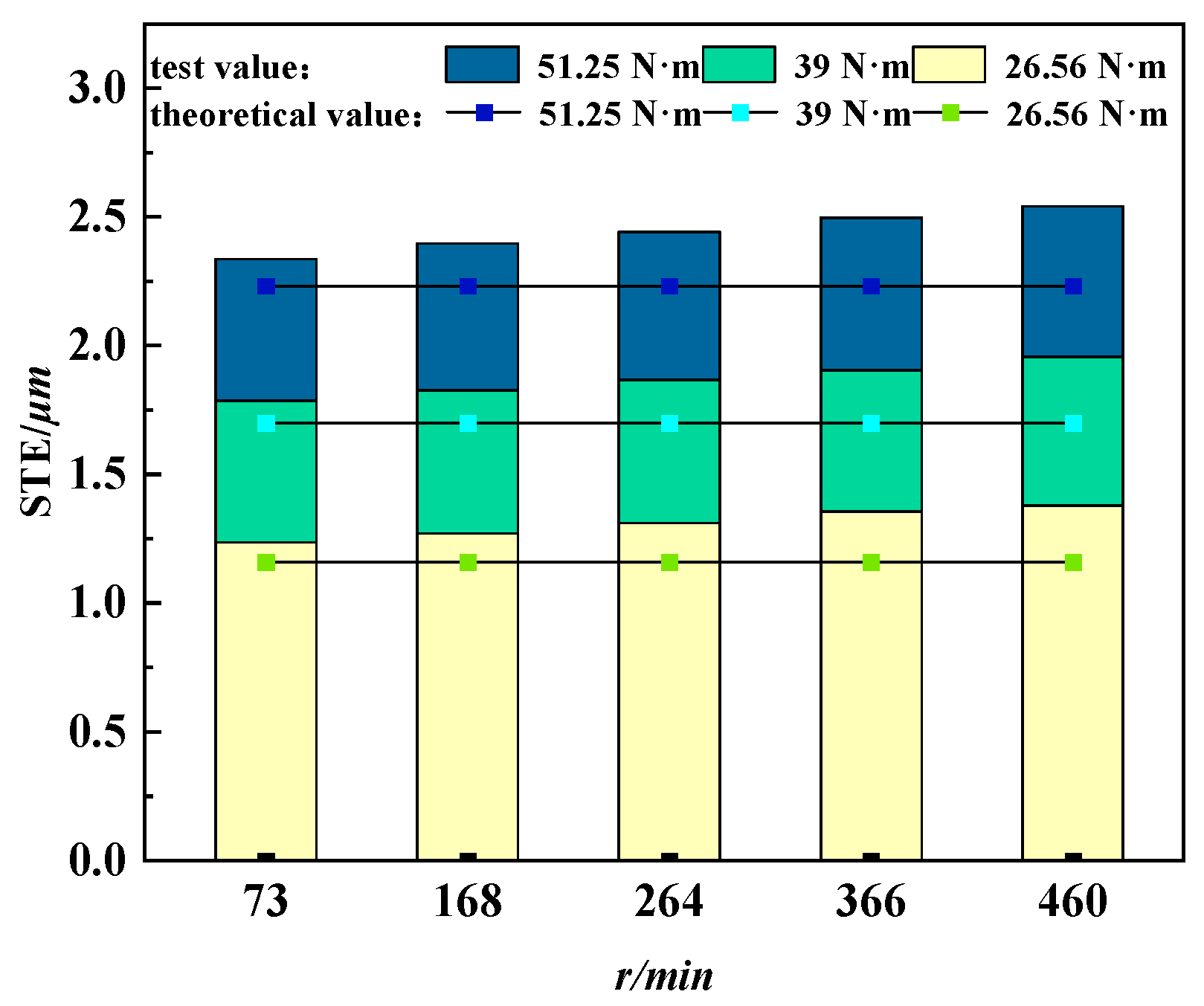

4.3. Comparative Analysis of Acceleration-Based Quasi-Static Transmission Error Measurements Versus Magnetic Grating Method Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, J.; Wei, P.; Zhu, C.; Zhang, P.; Liu, H. Development and Application of High Strength Gears. Int. J. Adv. Manuf. Technol. 2024, 132, 3123–3148. [Google Scholar] [CrossRef]

- Anichowski, B.; Kahraman, A.; Talbot, D. Dynamic Transmission Error Measurements from Spur Gear Pairs Having Tooth Indexing Errors. In Proceedings of the ASME 2017 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Cleveland, OH, USA, 6–9 August 2017. [Google Scholar]

- Hotait, M.; Kahraman, A. Experiments on the Relationship between the Dynamic Transmission Error and the Dynamic Stress Factor of Spur Gear Pairs. Mech. Mach. Theory 2013, 70, 116–128. [Google Scholar] [CrossRef]

- Zhang, J.; Lv, C.; Li, Z. Investigation of High-Speed Dynamic Transmission Error Testing Using Gear Strain. Machines 2023, 11, 956. [Google Scholar] [CrossRef]

- Benatar, M.; Handschuh, M.J.; Kahraman, A.; Talbot, D. Static and Dynamic Transmission Error Measurements of Helical Gear Pairs with Various Tooth Modifications. J. Mech. Des. 2019, 141, 103301. [Google Scholar] [CrossRef]

- Kang, M.R.; Kahraman, A. Measurement of vibratory motions of gears supported by compliant shafts. Mech. Syst. Signal Process. 2012, 29, 391–403. [Google Scholar] [CrossRef]

- Gregory, R.W.; Harris, S.L.; Munro, R.G. A method of measuring transmission error in spur gears of 1:1 ratio. J. Sci. Instrum. 1963, 40, 5–9. [Google Scholar] [CrossRef]

- Chun, X.; Siyu, C. Experimental Study of the Effect of Assembly Error on the Lightly Loaded Transmission Error of Spur Gear with Crown Modification. J. Low Freq. Noise Vib. Act. Control 2019, 39, 1039–1051. [Google Scholar] [CrossRef]

- Chin, Z.Y.; Smith, W.A.; Borghesani, P.; Randall, R.B.; Peng, Z. Absolute transmission error: A simple new tool for assessing gear wear. Mech. Syst. Signal Process. 2021, 146, 107070. [Google Scholar] [CrossRef]

- Yu, B.; Kou, H.; Shi, Z.; Sun, Y. A Virtual Measurement Method of the Transmission Error Based on Point Clouds of the Gear. Meas. Sci. Rev. 2022, 22, 92–99. [Google Scholar] [CrossRef]

- Tamminana, V.K.; Kahraman, A.; Vijayakar, S. A Study of the Relationship Between the Dynamic Factor and the Dynamic Transmission Error of Spur Gear Pairs. In Proceedings of the 2007 Asme International Design Engineering Technical Conferences & Computers & Information in Engineering Conference, Las Vegas, NV, USA, 4–7 September 2007. [Google Scholar]

- Rezayat, A.; Catera, P.G.; Capalbo, C.; Cosco, F.; Mundo, D. Numerical and experimental analysis of the transmission error in hybrid met-al-composite gears. Compos. Struct. 2022, 298, 116012. [Google Scholar] [CrossRef]

- Liu, C.; Shi, W.K.; Curá, F.M.; Mura, A. A novel method to predict static transmission error for spur gear pair based on accuracy grade. J. Cent. South Univ. 2020, 27, 3334–3349. [Google Scholar] [CrossRef]

- Tang, J.J.; Tang, J.Y. Transmission Error Calculation Based on Manufacturing Errors and Load. Adv. Mater. Res. 2014, 971–973, 848–851. [Google Scholar] [CrossRef]

- Cheng, J.H.; Liang, M.; Fan, F.L. Experiment Research and Analysis of Transmission Error of Gears. Adv. Mater. Res. 2012, 503–504, 1074–1077. [Google Scholar] [CrossRef]

- Wang, Y.N.; Sun, Z.L.; Yin, M.A. Considering Thermal Deformation in Gear Transmission Error Calculation. Appl. Mech. Mater. 2013, 281, 211–215. [Google Scholar] [CrossRef]

- Karagiannis, I.; Theodossiades, S. An Alternative Formulation of the Dynamic Transmission Error to Study the Oscillations of Automotive Hypoid Gears. J. Vib. Acoust. 2013, 136, 011001. [Google Scholar] [CrossRef]

- Lee, H.K.; Do, J.G.; Hong, S.M.; Yoo, D.K.; Won, K.M.; Chae, G.M.; Lee, T.H. Research for a Development of the Test Equipment for Transmission Error of the Planetary Gear Carrier Pack. Trans. Korean Soc. Noise Vib. Eng. 2014, 24, 549–554. [Google Scholar] [CrossRef]

- Morikawa, K.; Kumagai, K.; Komori, M.; Nakura, Y. Transmission Error Prediction Method of Planetary Gears Taking Account of Alignment Error. Proc. JSME Annu. Meet. 2012, 4, 513–525. [Google Scholar] [CrossRef][Green Version]

- Guo, C.H.; Yang, W.T.; Liu, Z.; Zhang, Z.M. Tooth Contact Analysis and Transmission Error Optimization for Klingelnberg Spiral Bevel Gear. Appl. Mech. Mater. 2013, 310, 323–327. [Google Scholar] [CrossRef]

- Sentoku, H.; Itou, T. Study on Transmission Error of Straight Bevel Gears. JSME Int. J. Ser. C 2004, 47, 391–397. [Google Scholar] [CrossRef]

- Mohamad, E.N.; Komori, M.; Murakami, H.; Kubo, A.; Fang, S. Effect of Convex Tooth Flank Form Deviation on the Characteristics of Transmission Error of Gears Considering Elastic Deformation. J. Mech. Des. 2010, 132, 101005. [Google Scholar] [CrossRef]

- Zachary, H.W. Loaded Transmission Error Measurement System for Spur and Helical Gears. Master’s Thesis, The Ohio State University, Columbus, OH, USA, 2009. [Google Scholar]

- Lu, H.; Zhang, J.; Pan, K.; Lv, C.; Hou, X.; Li, Z.; Zhang, H. Quasi-Static Transmission Error Measurement Using Micro-Deformation. Iran. J. Sci. Technol. Trans. Mech. Eng. 2023, 48, 723–731. [Google Scholar] [CrossRef]

| Material | E/Gpa | ν | ρ/(kg/m3) |

|---|---|---|---|

| Gear steel | 207 | 0.3 | 7800 |

| Parameter | Driving Gear | Driven Gear |

|---|---|---|

| Modulus (mm) | 3 | 3 |

| Number of teeth | 37 | 53 |

| Pressure angle (°) | 25 | 25 |

| Tooth width (mm) | 12 | 12 |

| Addendum height coefficient | 1 | 1 |

| Root height coefficient | 1.25 | 1.25 |

| Torque (N·m) | Acceleration Method (µm) | Magnetic Grating Method (µm) | MAE | Pearson R |

|---|---|---|---|---|

| 26.56 | 35.345 | 45.337 | 8.913 | 0.999 |

| 39 | 52.158 | 62.042 | ||

| 51.25 | 67.512 | 76.377 |

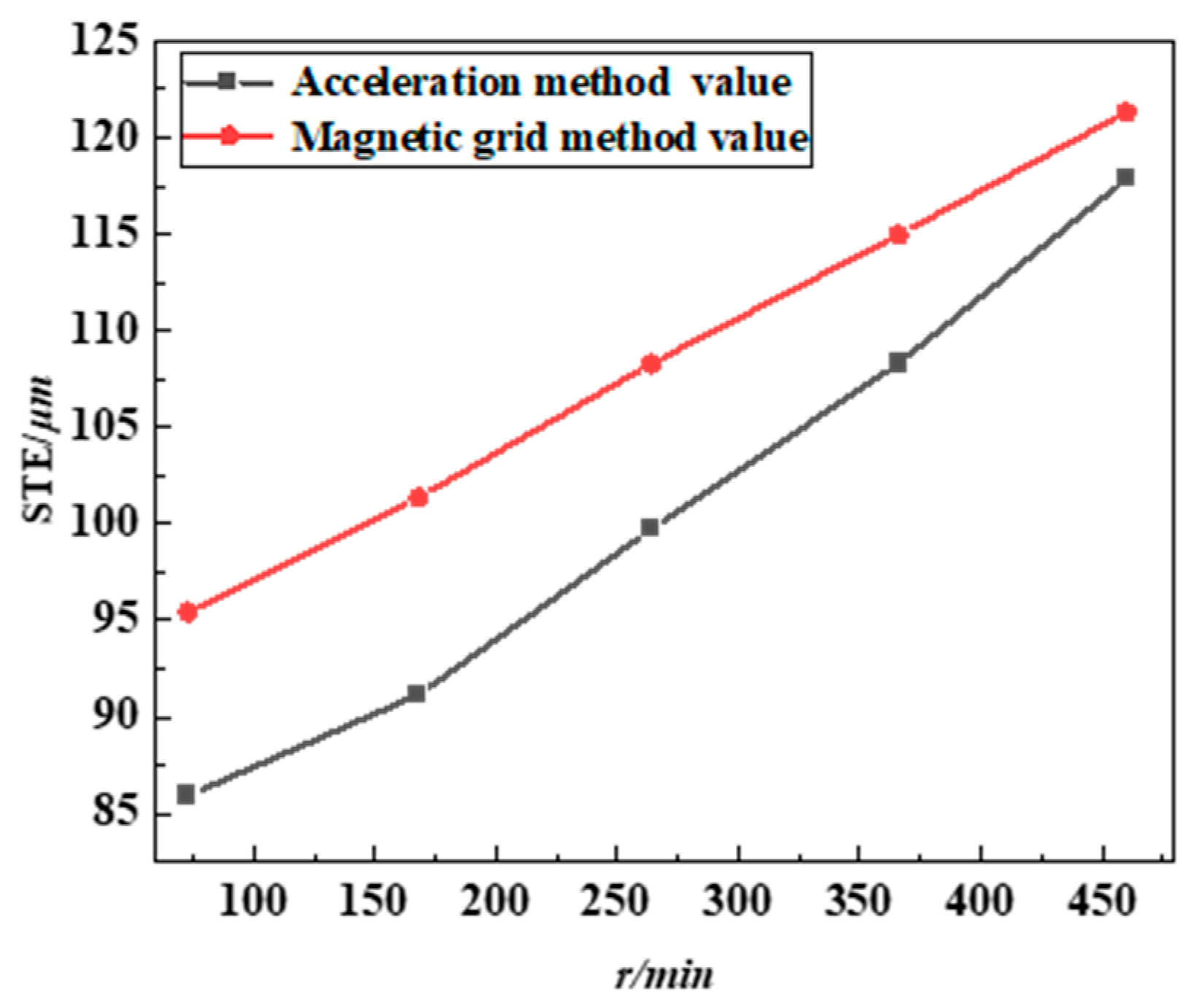

| Large Gear Speed (rev/min) | Acceleration Method (µm) | Magnetic Grating Method (µm) | MAE | Pearson R |

|---|---|---|---|---|

| 73 | 85.935 | 95.426 | 7.433 | 0.998 |

| 168 | 91.153 | 101.359 | ||

| 264 | 99.718 | 108.298 | ||

| 366 | 108.303 | 114.965 | ||

| 460 | 117.884 | 121.312 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, C.; Zhang, J.; Jian, J.; Lv, C.; Li, Z. Research on Quasi-Static Transmission Error Measurement of Spur Gears Based on the Acceleration Method. Machines 2025, 13, 941. https://doi.org/10.3390/machines13100941

Ji C, Zhang J, Jian J, Lv C, Li Z. Research on Quasi-Static Transmission Error Measurement of Spur Gears Based on the Acceleration Method. Machines. 2025; 13(10):941. https://doi.org/10.3390/machines13100941

Chicago/Turabian StyleJi, Chengcheng, Jian Zhang, Jiaxin Jian, Chuanmao Lv, and Zhengminqing Li. 2025. "Research on Quasi-Static Transmission Error Measurement of Spur Gears Based on the Acceleration Method" Machines 13, no. 10: 941. https://doi.org/10.3390/machines13100941

APA StyleJi, C., Zhang, J., Jian, J., Lv, C., & Li, Z. (2025). Research on Quasi-Static Transmission Error Measurement of Spur Gears Based on the Acceleration Method. Machines, 13(10), 941. https://doi.org/10.3390/machines13100941