Mild Hybrid Powertrain for Mitigating Loss of Volumetric Efficiency and Improving Fuel Economy of Gasoline Vehicles Converted to Hydrogen Fueling

Abstract

1. Introduction

2. Materials and Methods

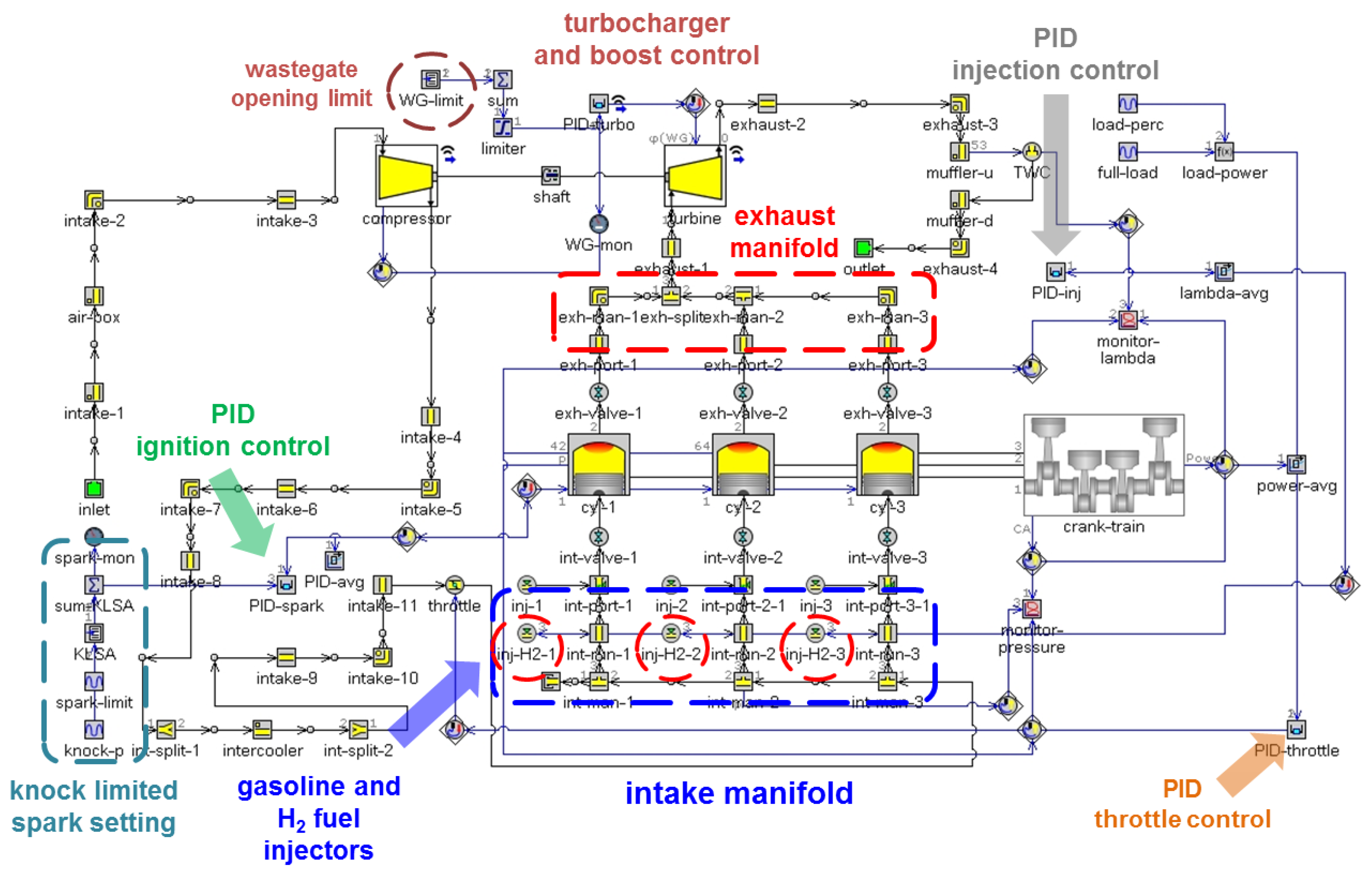

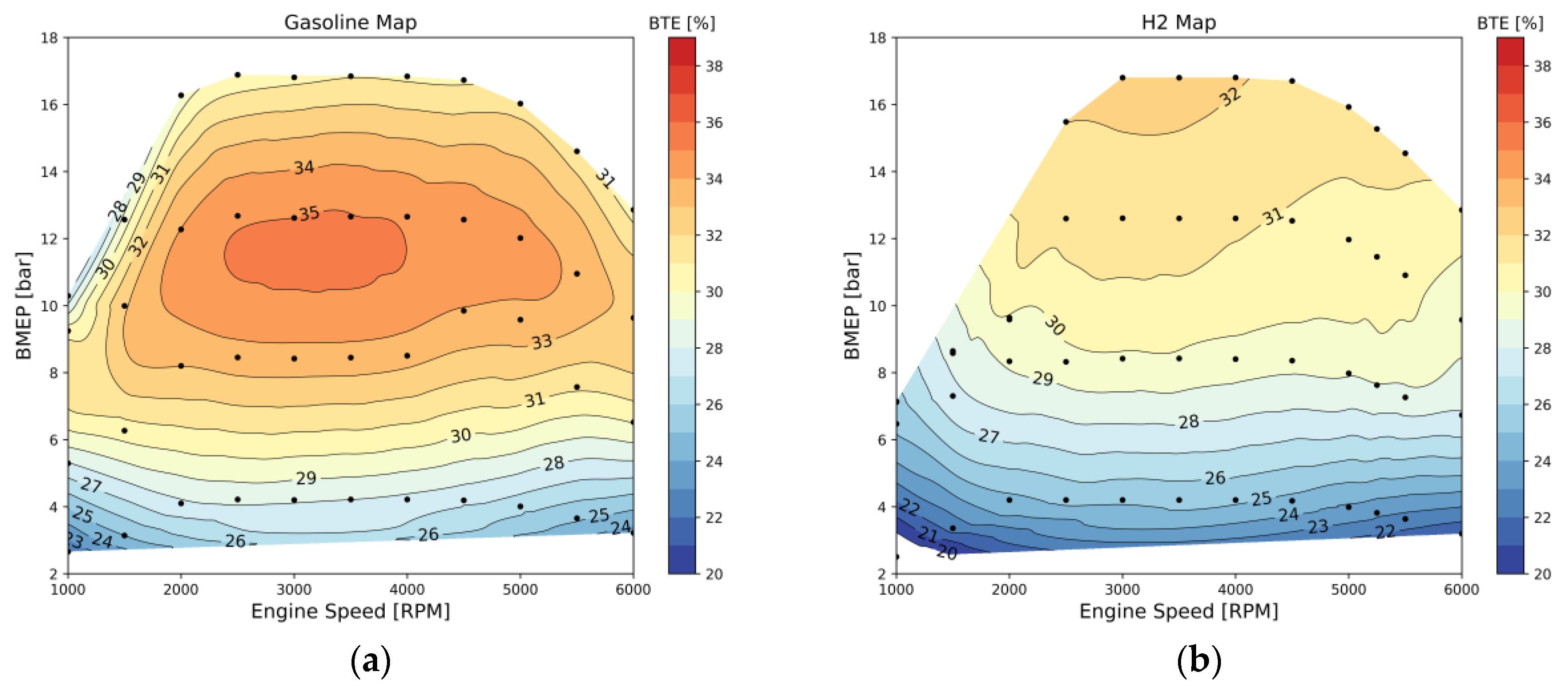

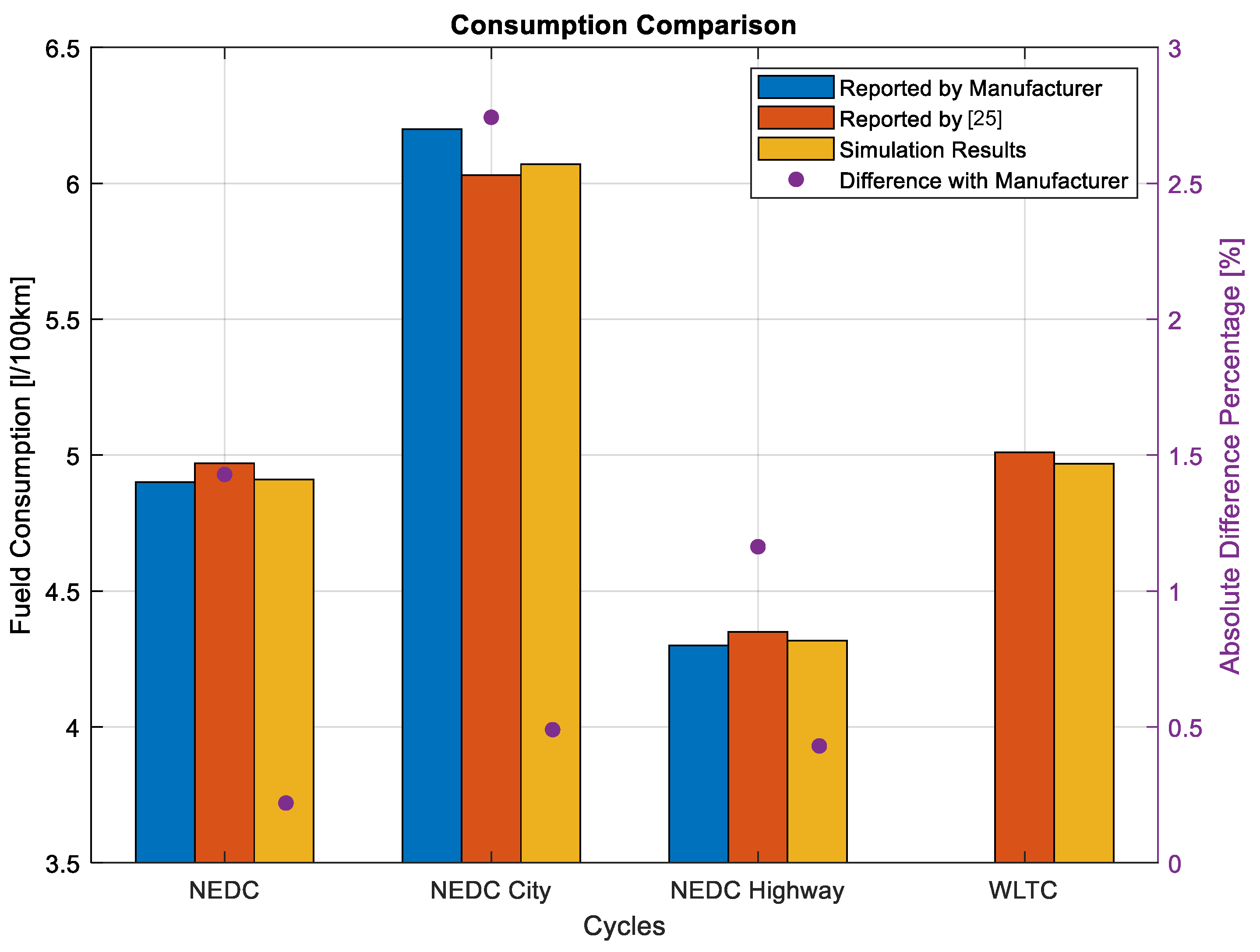

2.1. Hydrogen Engine Simulation

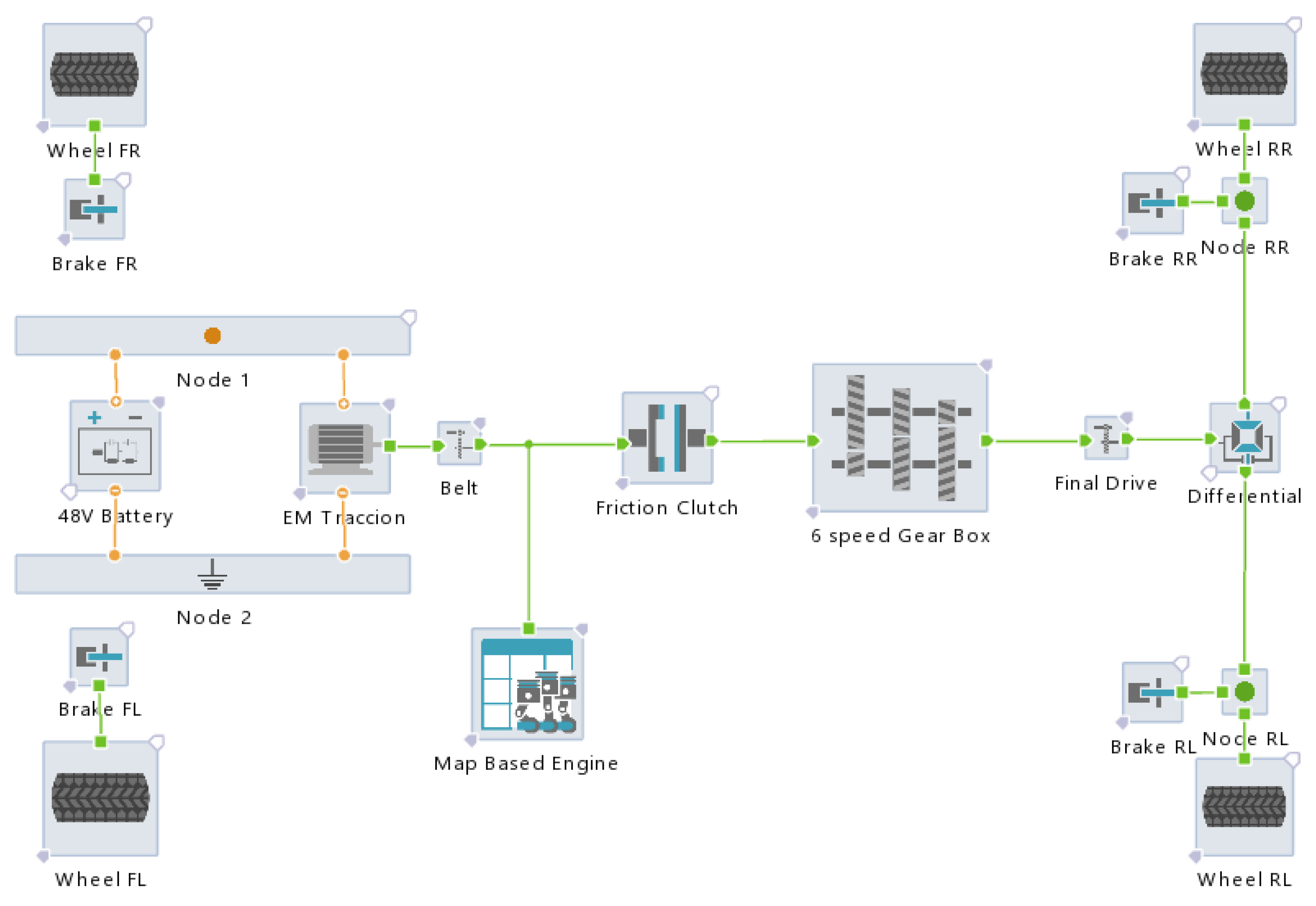

2.2. Mild Hybrid Vehicle Model

3. Results and Discussion

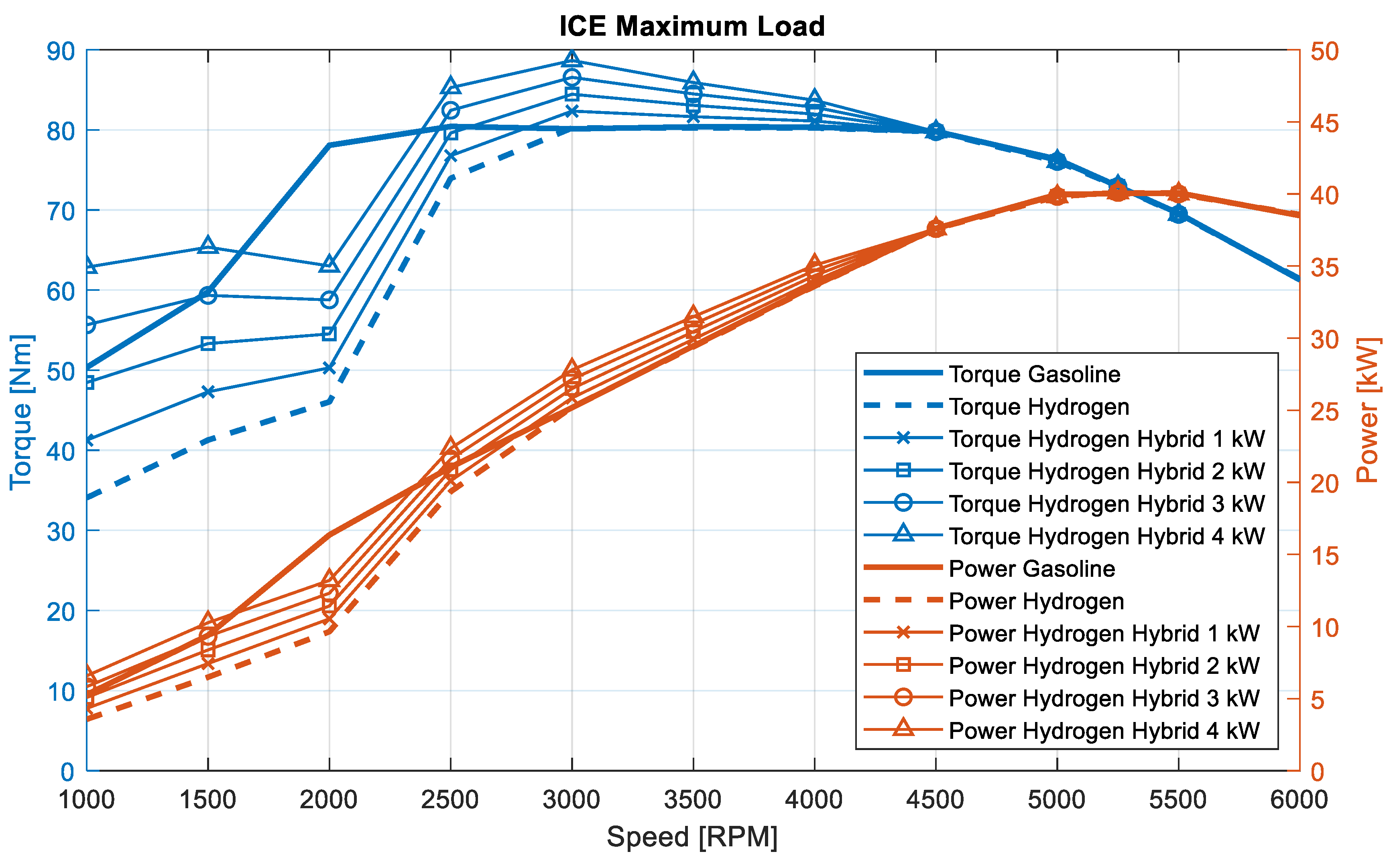

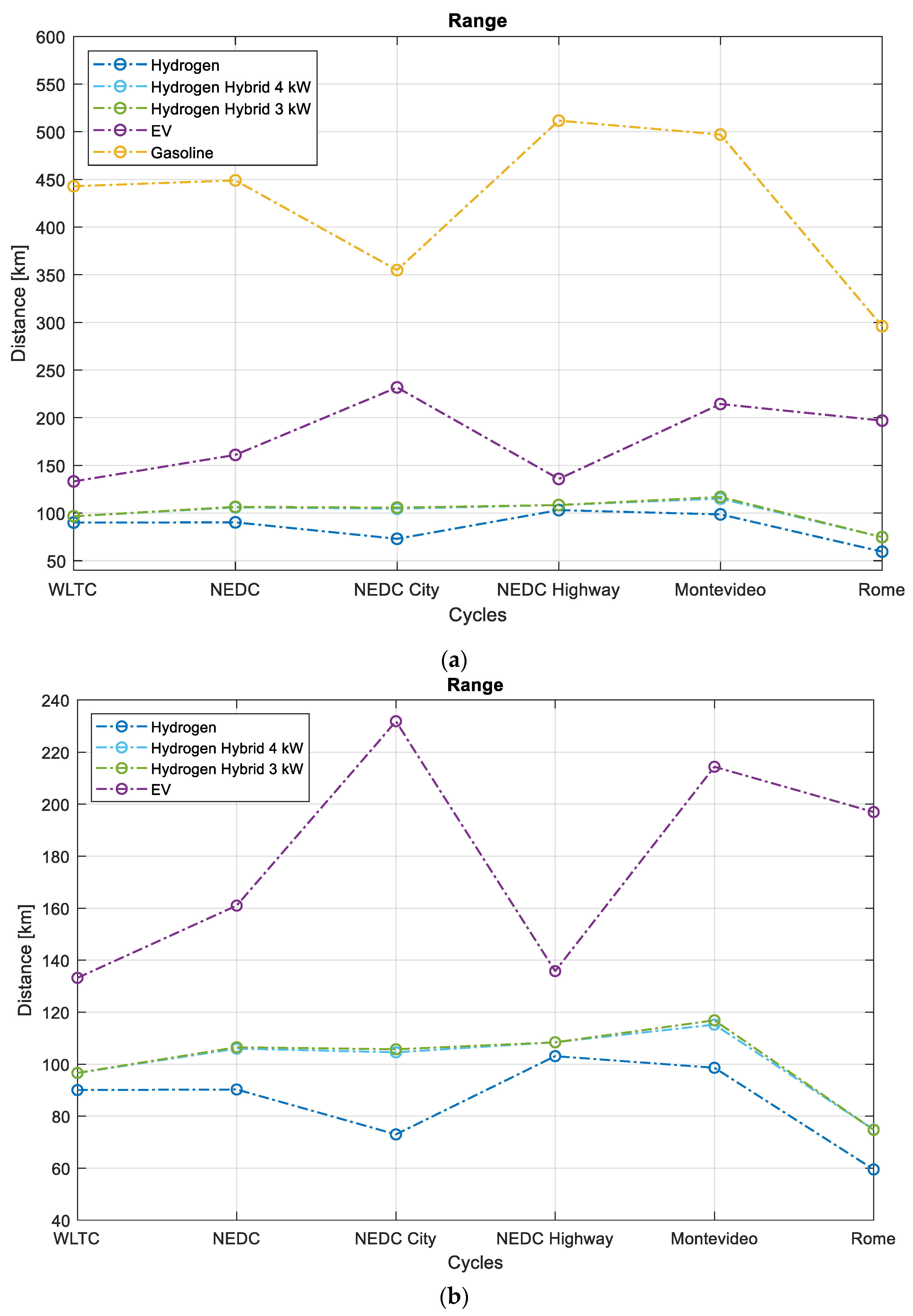

3.1. Performance

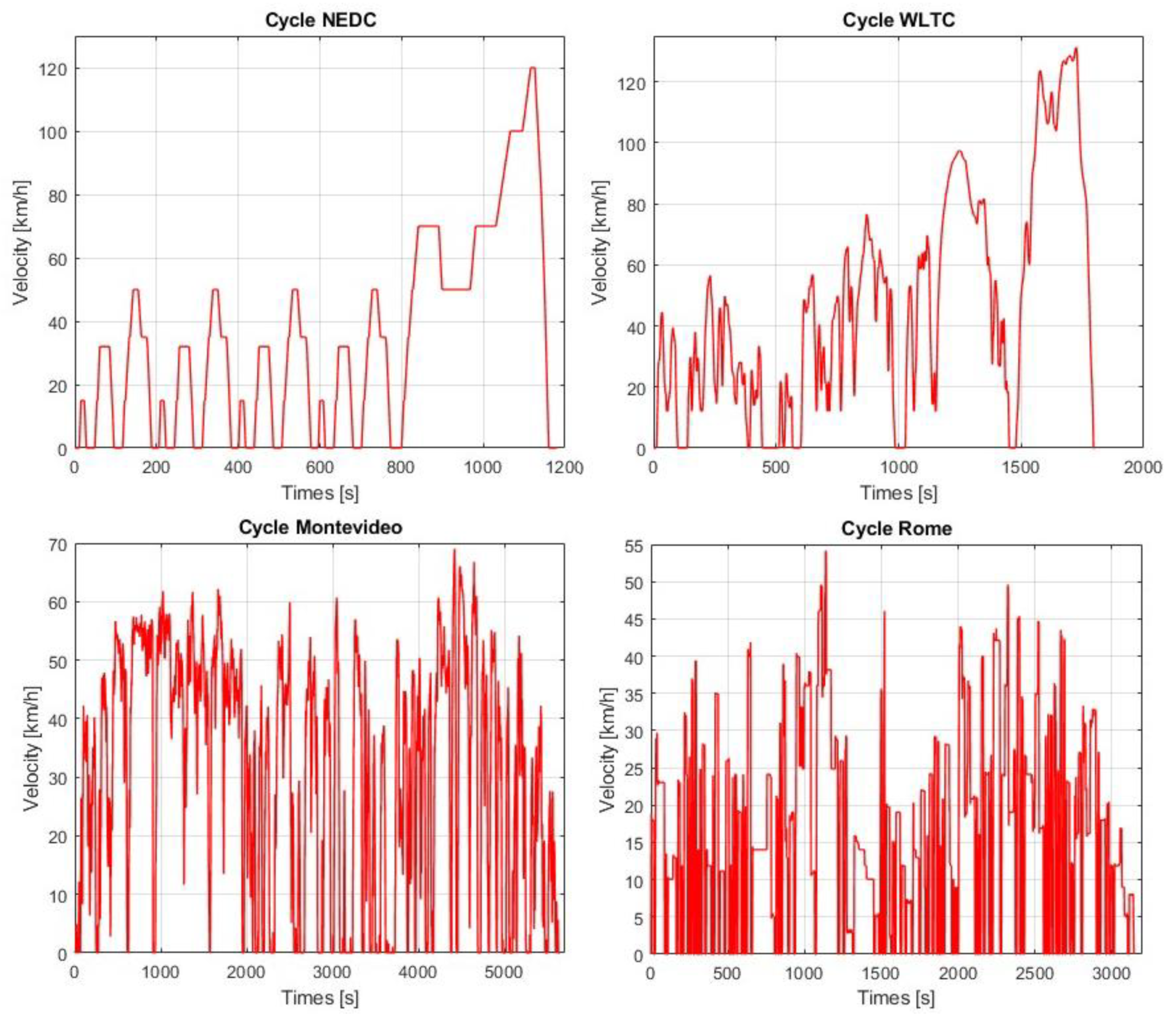

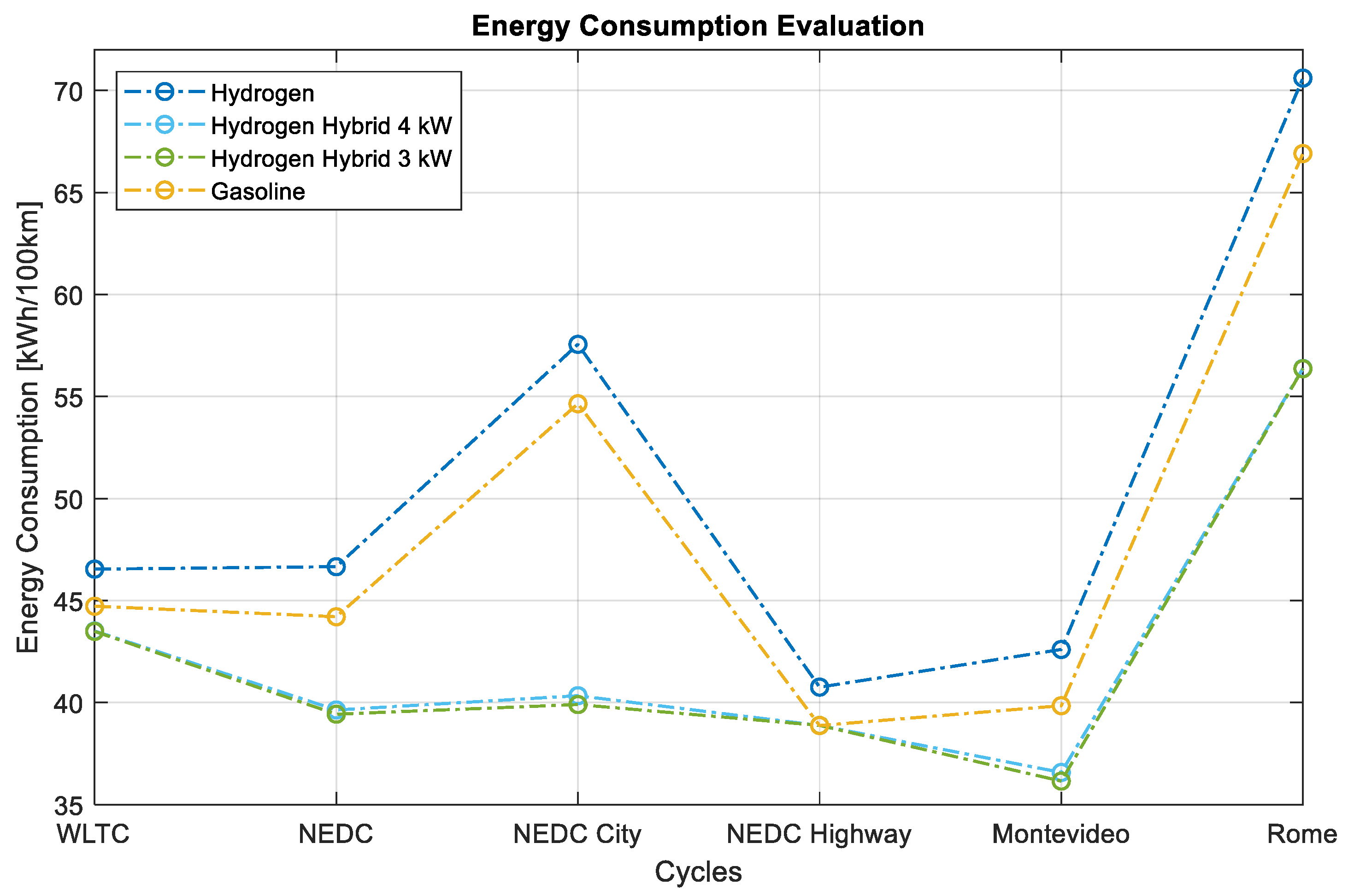

3.2. Real Driving Cycles Evaluation

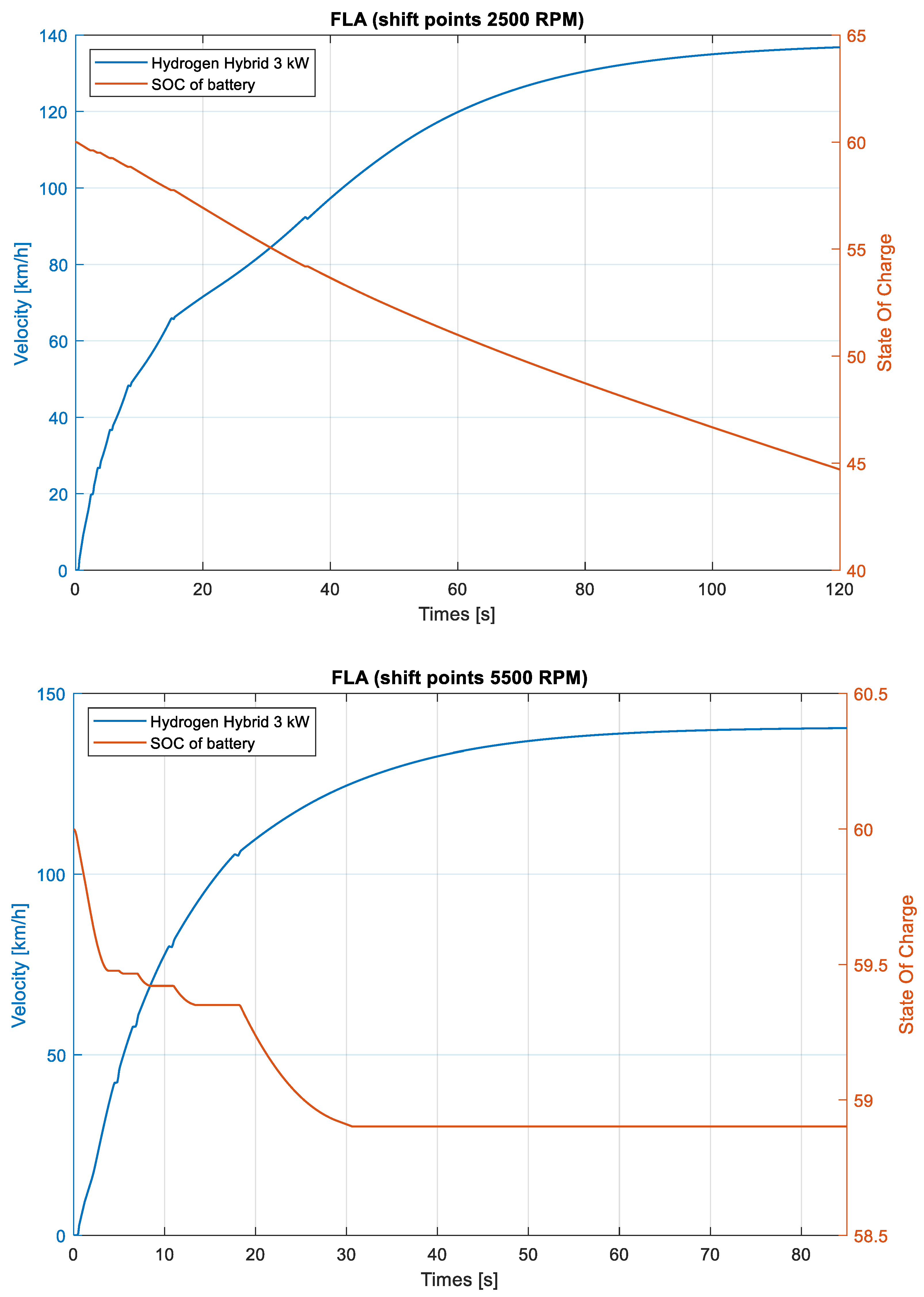

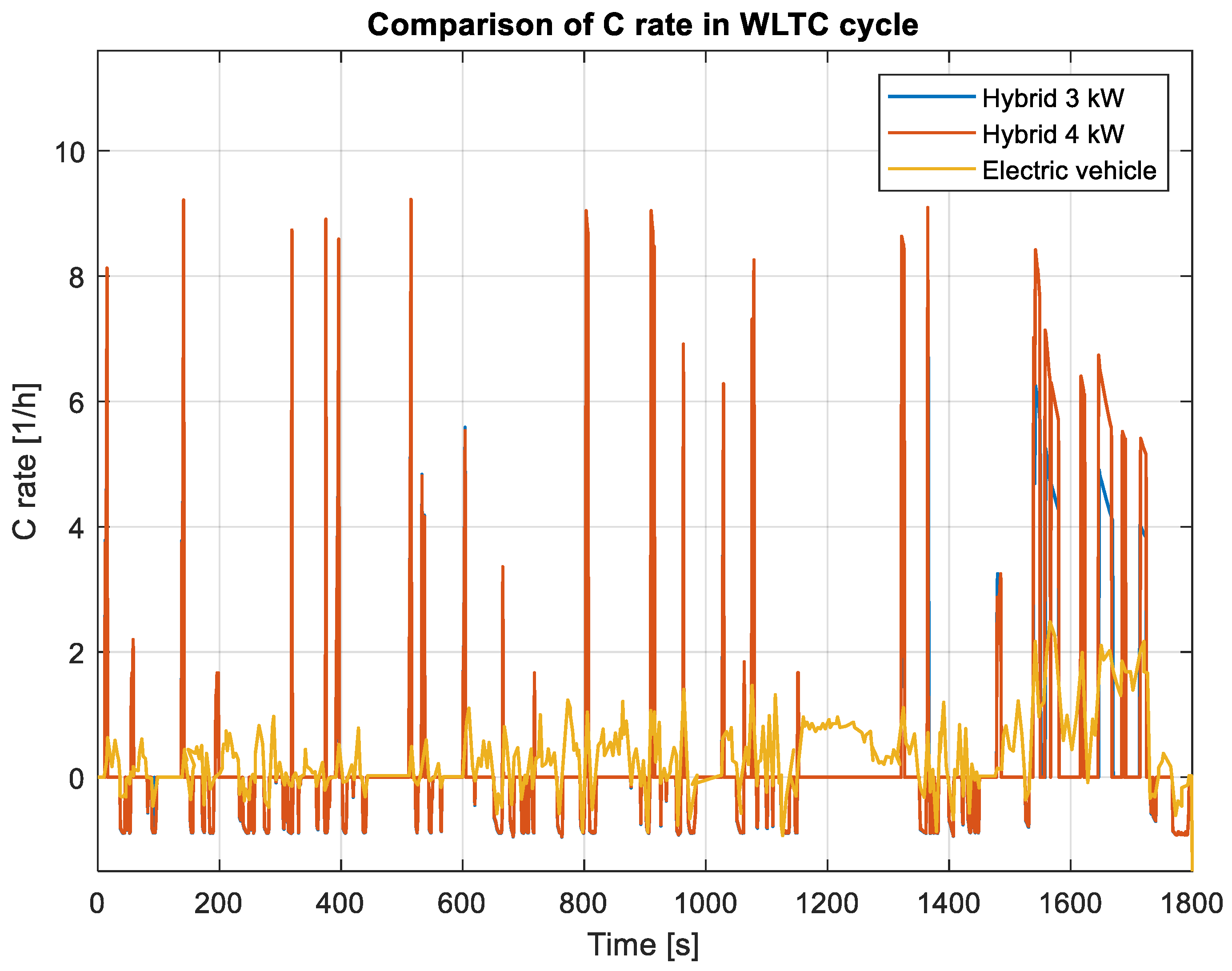

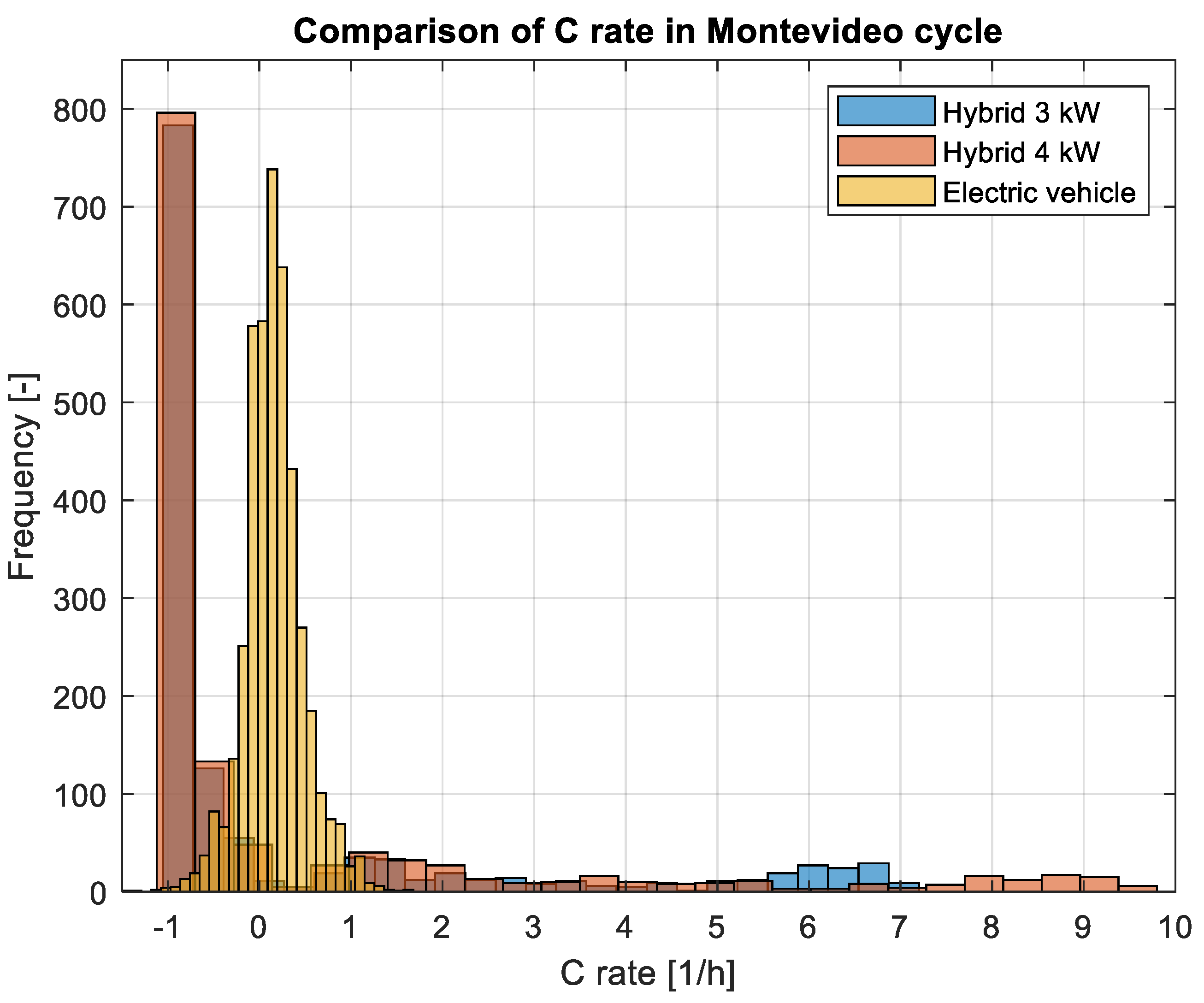

3.3. Battery Behavior under Different Driving Cycles

- Regeneration Module: This module calculates the torque needed for electromagnetic (EM) braking to generate energy for the battery. It uses the brake pedal position to determine proportional torque, which is limited by the motor’s maximum regeneration torque to prevent battery damage. If speed exceeds 5 km/h, regenerative braking is utilized.

- Traction Module: Designed to assist the Internal Combustion Engine (ICE) at low rotational speeds, it activates the EM to support the ICE when the required torque approaches its full load. EM’s maximum torque is restricted by battery discharge C-rate (<10 1/h) and EM limitations.

- Control Module: Receives signals from previous modules and dictates EM actions based on vehicle state. It operates in four states determined by battery charge level:

- Normal operation mode (charge > 20%): EM operates in regenerative mode and traction as per driver’s needs.

- Battery charging mode (charge < 20%): EM exclusively regenerates.

- Charging mode (charge < 60%): Maintains charging until battery reaches 60%.

- Normal operation mode (charge ≥ 60%): EM functions in both regenerative and traction modes.

4. Conclusions

- Performance: The hybridization of the hydrogen model demonstrates a remarkable achievement, nearly equating or surpassing the performance when compared to the gasoline model. The electric motor with a maximum power of 3 kW boosting the H2 ICE is the best compromise between performance and cost. The MHEV H2 concept equips a 1 kWh battery. This allows less lithium-ion materials than the EV version (18 kWh).

- Energy Consumption: The implemented modifications yield a more efficient vehicle, manifesting in lower energy consumption across nearly all evaluated driving cycles. The average improvement (five cycles tested) is around 11% with respect to the gasoline version and 19% with respect to the conventional powertrain. The latter is the best suited option only for the highway cycles.

- Vehicle Range: Hybridization introduces notable improvements in the range of the configurations and particularly in urban cycles. Even if as an absolute value, range is lower for H2-fueled versions, it is comparable to the BEV, and when considering the refilling time, it is an extremely attractive choice compared to the difficulties correlated with extensive charging times. Consequently, hybridization stands out as a viable solution for the decarbonization of the light vehicle fleet.

- Battery management: One key aspect of the hybrid configurations is that despite the small size of the 48V battery pack that results in numerous charging–discharging cycles, the lifetime should be fully compatible with that expected for the entire vehicle. The full throttle acceleration simulations can be ensured at the end of an event starting from standstill and running up to top speed with an SoC above 35% if starting from 50% initial charge. This can be further mitigated by changing the gear shift strategy, further enhancing management margins. These suggests that even in worst-case scenarios, “normal” battery management can ensure extensive lifetime, even if cycling is much heavier compared to the BEV version.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ICE | internal combustion engine |

| EM | electric motor |

| FLA | full load acceleration |

| OEM | original equipment manufacturer |

| MHEV | mild hybrid electric vehicle |

| LHV | lower heating value |

| NEDC | New European Driving Cycle |

| WLTC | Worldwide Harmonized Light Vehicles Test Procedure |

| RPM | Revolution Per Minute |

| BTE | brake thermal efficiency |

| GHG | greenhouse gases |

| FCEV | fuel cell electric vehicles |

| FC | fuel cell |

| H2 | hydrogen |

| SMR | steam reforming |

| DOE | United States Department of Energy |

| EV | electric vehicle |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| S | sulfur |

| NH3 | ammonia |

| NOx | nitrogen oxidizer |

| H2ICE | hydrogen-fueled Internal Combustion Engines |

| EU | European Union |

| SOI | Start of Injection |

| EGR | Exhaust Gas Recirculation |

| BMEP | Brake Mean Effective Pressure |

| PFI | Port Fuel Injected |

| DI | Direct Injection |

| CCV | cycle-to-cycle variability |

| e-fuels | green fuels |

| SOC | state of charge |

| HCNG | hydrogen-enriched compressed natural gas |

References

- Molina, S.; Novella, R.; Gomez-Soriano, J.; Olcina-Girona, M. Impact of medium-pressure direct injection in a spark-ignition engine fueled by hydrogen. Fuel 2024, 360, 130618. [Google Scholar] [CrossRef]

- De Colvenaer, B.; Castel, C. The fuel cells and hydrogen joint undertaking (FCH JU) in Europe. Int. J. Low-Carbon Technol. 2012, 7, 5–9. [Google Scholar] [CrossRef]

- Novas, N.; Garcia Salvador, R.M.; Portillo, F.; Robalo, I.; Alcayde, A.; Fernández-Ros, M.; Gázquez, J.A. Global Perspectives on and Research Challenges for Electric Vehicles. Vehicles 2022, 4, 1246–1276. [Google Scholar] [CrossRef]

- Usmanov, U.; Ruzimov, S.; Tonoli, A.; Mukhitdinov, A. Modeling, Simulation and Control Strategy Optimization of Fuel Cell Hybrid Electric Vehicle. Vehicles 2023, 5, 464–481. [Google Scholar] [CrossRef]

- Chojnowski, J.; Dziubak, T. Multi-Criteria Analysis of Semi-Trucks with Conventional and Eco-Drives on the EU Market. Energies 2024, 17, 1018. [Google Scholar] [CrossRef]

- Düzgün, M.T.; Dorscheidt, F.; Krysmon, S.; Bailly, P.; Lee, S.Y.; Dönitz, C.; Pischinger, S. Virtual Multi-Criterial Calibration of Operating Strategies for Hybrid-Electric Powertrains. Vehicles 2023, 5, 1367–1383. [Google Scholar] [CrossRef]

- Martinez-Boggio, S.; Di Blasio, D.; Fletcher, T.; Burke, R.; García, A.; Monsalve-Serrano, J. Optimization of the air loop system in a hydrogen fuel cell for vehicle application. Energy Convers. Manag. 2022, 283, 116911. [Google Scholar] [CrossRef]

- Ruffini, E.; Wei, M. Future costs of fuel cell electric vehicles in California using a learning rate approach. Energy 2018, 150, 329–341. [Google Scholar] [CrossRef]

- Papadias, D.D.; Ahmed, S.; Kumar, R.; Joseck, F. Hydrogen quality for fuel cell vehicles—A modeling study of the sensitivity of impurity content in hydrogen to the process variables in the SMR-PSA pathway. Int. J. Hydrogen Energy 2009, 34, 6021–6035. [Google Scholar] [CrossRef]

- Murugan, A.; Brown, A.S. Review of purity analysis methods for performing quality assurance of fuel cell hydrogen. Int. J. Hydrogen Energy 2015, 40, 4219–4233. [Google Scholar] [CrossRef]

- Zhou, P.; Gao, S.; Wang, B.; Wang, Y.; Li, C.; Wang, Y.; Sun, B. Influence of hydrogen fuel cell temperature safety on bus driving characteristics stack heating mode. Int. J. Hydrogen Energy 2022, 48, 11541–11554. [Google Scholar] [CrossRef]

- Ahmadi, P.; Khoshnevisan, A. Dynamic simulation and lifecycle assessment of hydrogen fuel cell electric vehicles considering various hydrogen production methods. Int. J. Hydrogen Energy 2022, 47, 26758–26769. [Google Scholar] [CrossRef]

- Evangelisti, S.; Tagliaferri, C.; Brett, D.J.L.; Lettieri, P. Life cycle assessment of a polymer electrolyte membrane fuel cell system for passenger vehicles. J. Clean. Prod. 2017, 142, 4339–4355. [Google Scholar] [CrossRef]

- Molina, S.; Novella, R.; Pla, B.; Lopez-Juarez, M. Optimization and sizing of a fuel cell range extender vehicle for passenger car applications in driving cycle conditions. Appl. Energy 2020, 285, 116469. [Google Scholar] [CrossRef]

- Nakagawa, K.; Yamane, K.; Ohira, T. Potential of large output power, high thermal efficiency, near-zero NOx emission, supercharged, lean-burn, hydrogen-fuelled, direct injection engines. Energy Procedia 2012, 29, 455–462. [Google Scholar] [CrossRef]

- Naganuma, K.; Honda, T.; Yamane, K.; Takagi, Y.; Kawamura, A.; Yanai, T.; Sato, Y. Efficiency emissions-optimized operating strategy of a high-pressure direct injection hydrogen engine for heavy-duty trucks. SAE Int. J. Engines 2010, 2, 132–140. [Google Scholar] [CrossRef]

- Engels, M.; Jakoby, M.; Fahrbach, T.; Andert, J. Hybridisation Concept of Light Vehicles Utilising an Electrified Planetary Gear Set. Vehicles 2023, 5, 1622–1633. [Google Scholar] [CrossRef]

- Bao, L.; Sun, B.; Luo, Q. Optimal control strategy of the turbocharged direct-injection hydrogen engine to achieve near-zero emissions with large power and high brake thermal efficiency. Fuel 2022, 325, 124913. [Google Scholar] [CrossRef]

- Verhelst, S. Recent progress in the use of hydrogen as a fuel for internal combustion engines. Int. J. Hydrogen Energy 2014, 39, 1071–1085. [Google Scholar] [CrossRef]

- White, C.M.M.; Steeper, R.R.R.; Lutz, A.E.E. The hydrogen-fueled internal combustion engine: A technical review. Int. J. Hydrogen Energy 2006, 31, 1292–1305. [Google Scholar] [CrossRef]

- Kyjovský, Š.; Vávra, J.; Bortel, I.; Toman, R. Drive cycle simulation of light duty mild hybrid vehicles powered by hydrogen engine. Int. J. Hydrogen Energy 2023, 48, 16885–16896. [Google Scholar] [CrossRef]

- Martinez, S.; Merola, S.S.; Irimescu, A. Flame Front and Burned Gas Characteristics for Different Split Injection Ratios and Phasing in an Optical GDI Engine. Appl. Sci. 2019, 9, 449. [Google Scholar] [CrossRef]

- Verhelst, S.; Sierens, R.; Verstraeten, S. A Critical Review of Experimental Research on Hydrogen Fueled SI Engines; SAE Technical Paper 2006-01-0430; SAE: Warrendale, PA, USA, 2006. [Google Scholar] [CrossRef]

- Huyskens, P.; Van Oost, S.; Goemaere, P.; Bertels KPecqueur, M. The Technical Implementation of a Retrofit Hydrogen PFI System on a Passenger Car; SAE Technical Paper 2011-01-2004; SAE: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Irimescu, A.; Vaglieco, B.; Merola, S.; Zollo, V.; De Marinism, R. Conversion of a Small Size Passenger Car to Hydrogen Fueling: Focus on Rated Power and Injection Phasing Effects; SAE Technical Paper 2022-24-0031; SAE: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Ha, J.; Park, J.; Kwon, O.B.; Lim, I.G.; Yun, J.H.; Keel, S.I.; Park, H.Y.; Kim, T.H. Flame extinction in interacting CO-air and syngas-air premixed flames. J. Mech. Sci. Technol. 2015, 29, 419–428. [Google Scholar] [CrossRef]

- Molina, S.; Ruiz, S.; Gomez-Soriano, J.; Olcina-Girona, M. Impact of hydrogen substitution for stable lean operation on spark ignition engines fueled by compressed natural gas. Results Eng. 2022, 17, 100799. [Google Scholar] [CrossRef]

- Szamrej, G.; Karczewski, M. Exploring Hydrogen-Enriched Fuels and the Promise of HCNG in Industrial Dual-Fuel Engines. Energies 2024, 17, 1525. [Google Scholar] [CrossRef]

- Martinez, S.; Merola, S.S.; Curto, P.; Vaglieco, B.M.; Irimescu, A. Conversion of a Small Size Passenger Car to Hydrogen Fueling: Focus on Vehicle Dynamics and ECU Remapping Requirements; SAE Technical Paper 2023-24-0065; SAE: Warrendale, PA, USA, 2023. [Google Scholar]

- Demuynck, J.; De Paepe, M.; Huisseune, H.; Sierens, R.; Vancoillie, J.; Verhelst, S. On the applicability of empirical heat transfer models for hydrogen combustion engines. Int. J. Hydrogen Energy 2011, 36, 975–984. [Google Scholar] [CrossRef]

- Nagappa, M.; Hebbur Rameshbabu, A. Comparison of Predictive Gasoline Combustion Models Using GT-Power. Master Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- Smart EQ Fortwo Coupe 60 kW Tech Specs. Available online: https://autocatalogarchive.com/wp-content/uploads/2021/09/Smart-ForTwo-EQ-ForFour-EQ-2021-UK.pdf (accessed on 13 November 2023).

- Smart-City-Coupe-55. Available online: www.ultimatespecs.com (accessed on 2 December 2023).

- Mallon, K.R.; Assadian, F.; Fu, B. Analysis of On-Board Photovoltaics for a Battery Electric Bus and Their Impact on Battery Lifespan. Energies 2017, 10, 943. [Google Scholar] [CrossRef]

- Pramanik, S.; Anwar, S. Predictive Optimal Control of Mild Hybrid Trucks. Vehicles 2022, 4, 1344–1364. [Google Scholar] [CrossRef]

- Smart EQ Fortwo Coupe (2020–2023) Price and Specifications—EV Database. Available online: https://ev-database.org/car/1230/Smart-EQ-fortwo-coupe (accessed on 15 November 2023).

- Jaguemont, J.; Van Mierlo, J. A comprehensive review of future thermal management systems for battery-electrified vehicles. J. Energy Storage 2020, 31, 101551. [Google Scholar] [CrossRef]

- Pinto, C.; Barreras, J.V.; de Castro, R.; Araújo, R.E.; Schaltz, E. Study on the combined influence of battery models and sizing strategy for hybrid and battery-based electric vehicles. Energy 2017, 137, 272–284. [Google Scholar] [CrossRef]

- Atalay, S.; Sheikh, M.; Mariani, A.; Merla, Y.; Bower, E.; Widanage, W.D. Theory of battery ageing in a lithium-ion battery: Capacity fade, nonlinear ageing and lifetime prediction. J. Power Sources 2020, 478, 229026. [Google Scholar] [CrossRef]

| Item | Value |

|---|---|

| Displacement | 599 cm3 |

| Number of cylinders | 3 |

| Bore × stroke | 63.5 × 63 mm |

| Compression ratio | 9.5:1 |

| Number of valves | 2 per cylinder |

| Rated power | 40 kW @5250 RPM |

| Air filling | turbocharger |

| Fuel system | port fuel injection at 3.5 bar for gasoline and 5 bar for hydrogen |

| Ignition system | inductive discharge, 2 spark plugs per cylinder |

| Vehicle Type [-] | Non-Hybrid | MHEV | EV |

|---|---|---|---|

| Vehicle | small size passenger car 2-seater | ||

| Vehicle Drag Coefficient [-] | 0.37 | ||

| Frontal Area [m2] | 1.99 | ||

| Tires Size [mm/%/inch] | 175/55 R15 | ||

| Rolling resistance factor [%] | 1.1 | ||

| Top speed [km/h] | 135 | 130 | |

| Base vehicle Mass [kg] | 720 | 765 | 1095 |

| Passenger and Cargo Mass [kg] | 75 | ||

| Differential ratio [-] | 4.21:1 | 9.9221:1 | |

| Primary Energy Source [-] | Gasoline | Hydrogen | Lithium-Ion Battery |

| Second Energy Source [-] | None | Lithium-Ion Battery | None |

| Fuel tank [L] | 22 | 30 | None |

| Lithium-Ion Battery Size [kWh] | None | 0.98 | 17.6 |

| Lithium-Ion Battery mass [kg] | None | 5.4 | 180 |

| Lithium-Ion Battery Volume [L] | None | 4.0 | 100 |

| Electric machine Power [kW] | None | TBD | 60 |

| Country/City | Route Type | Total Distance [km] | Time [min] | Vapos95 [m2/s3] |

|---|---|---|---|---|

| NEDC | Mixed | 11.03 | 19.67 | 7.4 |

| Uruguay/Montevideo | Urban—Avenue | 47.4 | 94 | 18.3 |

| Italy/Rome | Urban—City | 13.5 | 52.4 | 23.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bibiloni, S.; Irimescu, A.; Martinez-Boggio, S.; Merola, S.; Curto-Risso, P. Mild Hybrid Powertrain for Mitigating Loss of Volumetric Efficiency and Improving Fuel Economy of Gasoline Vehicles Converted to Hydrogen Fueling. Machines 2024, 12, 355. https://doi.org/10.3390/machines12060355

Bibiloni S, Irimescu A, Martinez-Boggio S, Merola S, Curto-Risso P. Mild Hybrid Powertrain for Mitigating Loss of Volumetric Efficiency and Improving Fuel Economy of Gasoline Vehicles Converted to Hydrogen Fueling. Machines. 2024; 12(6):355. https://doi.org/10.3390/machines12060355

Chicago/Turabian StyleBibiloni, Sebastian, Adrian Irimescu, Santiago Martinez-Boggio, Simona Merola, and Pedro Curto-Risso. 2024. "Mild Hybrid Powertrain for Mitigating Loss of Volumetric Efficiency and Improving Fuel Economy of Gasoline Vehicles Converted to Hydrogen Fueling" Machines 12, no. 6: 355. https://doi.org/10.3390/machines12060355

APA StyleBibiloni, S., Irimescu, A., Martinez-Boggio, S., Merola, S., & Curto-Risso, P. (2024). Mild Hybrid Powertrain for Mitigating Loss of Volumetric Efficiency and Improving Fuel Economy of Gasoline Vehicles Converted to Hydrogen Fueling. Machines, 12(6), 355. https://doi.org/10.3390/machines12060355