1. Introduction

In the field of robotics, mobile robots are increasingly finding applications in various human services, including collaboration and task support. Bipedal walking robots such as Boston Dynamics’s Atlas are advancing in technology by performing challenging movements, including navigating rough terrains and executing parkour-like actions [

1,

2]. Specifically, wheeled-bipedal robots have overcome certain challenges encountered by bipedal walking robots by capitalizing on their inherently faster movement speeds and agility in directional changes [

3,

4,

5]. Recent studies have concentrated on integrating bipedal walking robots with wheels, aiming to optimize the advantages of each to achieve rapid and adaptable motion in challenging terrains, thereby enhancing mobility and stability [

6,

7,

8]. By combining technical elements, the wheeled-bipedal robot adeptly maneuvers challenging terrains and inclines using a single leg [

9]. It overcomes obstacles through the flexion of leg joints and the rotation of wheels [

10]. Moreover, the wheeled-bipedal robot has shown the ability to overcome obstacles larger than its wheel radius by performing controlled jumps to reach a specific height [

11,

12,

13,

14].

In the field of robotics research focused on overcoming challenging terrains and obstacles, the Inverted Pendulum Robot showcased its capability to ascend stairs with heights ranging from 120 mm to 130 mm. It achieved this task by utilizing a wheeled mechanism that incorporated belts, pulleys, and arms, completing each step in approximately 2.4 s [

15]. Unlike jumping robots, the Inverted Pendulum Robot showcases its optimal performance on narrow staircases by surmounting them smoothly without requiring an acceleration phase over a fixed distance. Boston Dynamics’ Handle demonstrated its ability to transport a 45 kg box across uncomplicated terrains and overcome gaps as high as 1.2 m utilizing a hydraulic-driven system [

16]. Moreover, Handle maintained a stable posture while navigating snow-covered slopes and swiftly traversing various staircases [

17]. The Ascento robot successfully overcame a 10 cm step by accelerating and jumping over a distance of 90 cm [

18,

19]. Furthermore, the Ascento robot defines the states of fallen robots as “laying, sitting, planking, sideways”, and has developed a system that enables it to recover from these situations, achieving fall recovery in complex terrains.

To enhance jumping performance, Direct Drive Technology Ltd conducted research and introduced the Diablo robot, which incorporates a parallel four-bar linkage wheel-leg mechanism design to generate the energy required for jumping [

20]. This mechanism adeptly adjusts the trajectory and height of the jump by modulating the energy release, which is contingent on alterations in the linked angles. EPFL’s Jumper aimed to enhance jumping performance through the mechanical design of a cam structure [

21]. The cam structure stores spring energy by decreasing the angle of the torsion spring connected to the leg joints while the cam rotates. When the cam reaches its critical point, the leg link in contact with the cam reverts to its original position, immediately releasing the stored torsion spring energy. This cam structure design effectively maintains the torsion spring force by adhering to physical laws, instead of relying on motor power adjustments.

Despite these advancements, challenges remain. A significant limitation is the necessity for both wheels of a wheeled-bipedal robot to maintain contact with the ground during both movement and stationary poses. In terrains where the height difference between the two wheels in contact with the ground varies, or in narrow passages where both wheels cannot pass through, the wheels of the wheeled-bipedal robot do not maintain contact with the ground, and one of the wheels loses contact with the ground surface. Wheeled-bipedal robots primarily focus on balance control in the direction of travel, lacking control methods for lateral movement perpendicular to the direction of travel. When only one wheel is in contact with the ground, the uneven weight distribution increases the likelihood of wheeled-bipedal robots tipping or flipping in complex terrains. Consequently, these robots are currently limited to simple tasks, such as logistics processing, in indoor environments due to stability concerns. Moreover, in order to improve jumping performance, robots utilize compact motors and gear ratios to maintain their weight low. However, this approach necessitates extended waiting times for repeated jumps. Finally, wheeled-bipedal robots utilize various control modes depending on the situation (e.g., driving mode, jumping mode), requiring frequent adjustments in control systems, and joint mobility is constrained by the behavioral limitations defined in each control mode.

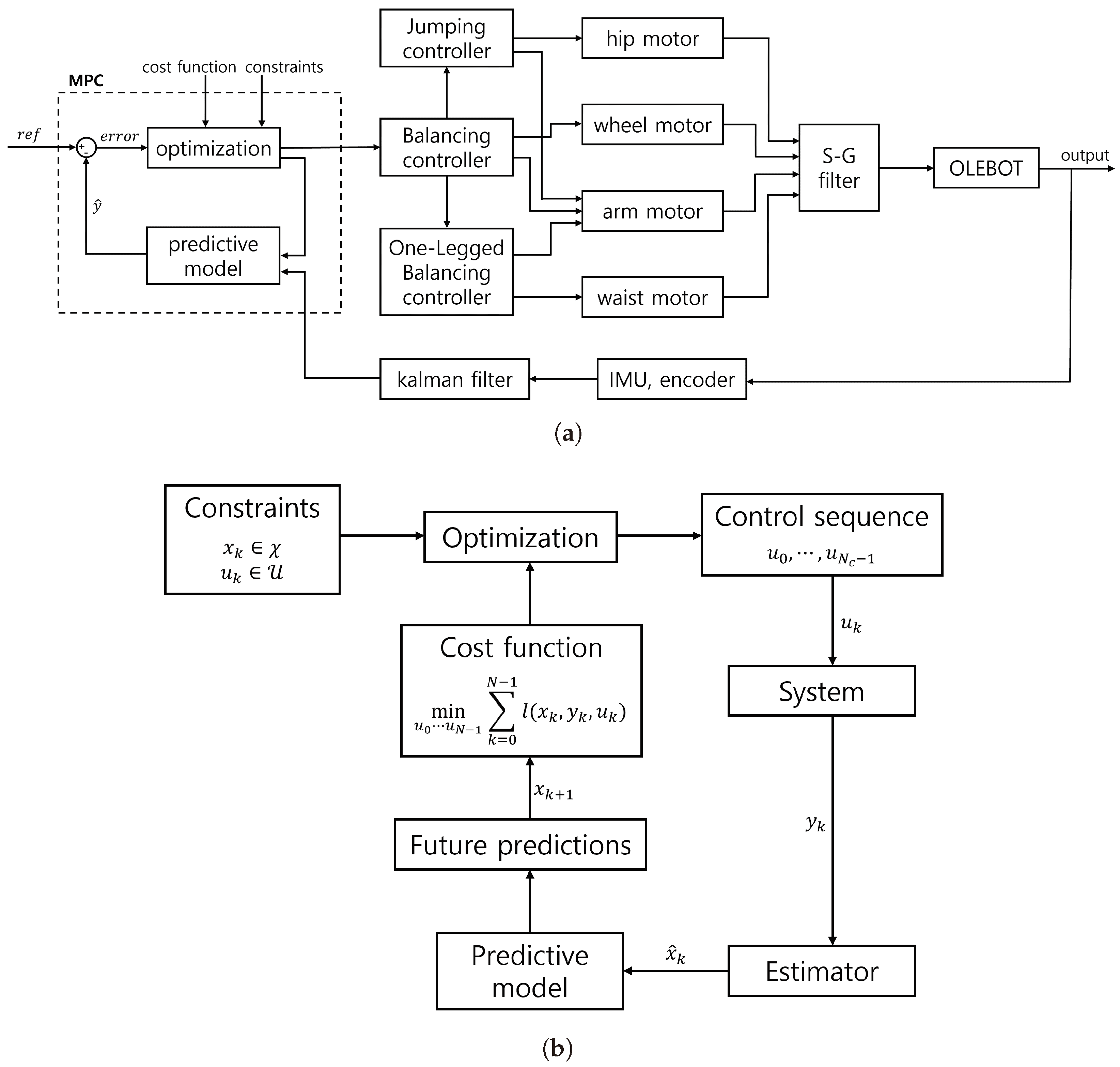

Therefore, this paper focuses on developing a wheeled-bipedal jumping robot equipped with a hand-fan-shaped end-effector capable of maintaining balance on a single leg, improving jumping performance over obstacles, and integrating control modes (OLEBOT). OLEBOT, drawing inspiration from traditional Korean tightrope walking as depicted in

Figure 1a, is crafted with a hand-fan-shaped end-effector to produce torque in the opposite direction of leaning while in a single-leg posture [

22]. A hand-fan-shaped robotic arm, designed with a large surface area to maximize the inverse momentum, increases the contact area with the air, and the related torque generated when the hand fan is rotated can be enhanced. The hand-fan-shaped end-effector allows OLEBOT to execute motions akin to ice skating using single-leg control, resulting in greater maneuverability compared to wheeled-bipedal robots. Using a hand-fan-shaped end-effector for balance control enables finer movements than wheeled-bipedal robots such as ’Handle’ and ’Ascento’ by utilizing the rotational inertia of a robotic arm. Additionally, OLEBOT can fine-tune its jump performance by arm movements, similar to a human-like standing high jump. Unlike the previous jump system that relied solely on leg joints, this new approach leverages both arm and leg joints for improved control and precision. In addition, this paper proposes a leg system composed of a hip joint with a cam structure and a torsion spring at the knee joint. The cam structure efficiently releases energy from the torsion spring during jumping, minimizing losses and enhancing energy efficiency. To ensure that the overall center of gravity remains perpendicular to the ground while adjusting the leg angle, the leg structure is designed as a four-bar linkage comprising a driving link and a passive link in contact with the cam. Furthermore, the paper presents an MPC-based control system, consolidating various control modes such as basic balancing, jumping and landing, single-leg driving, single-leg stopping, and single-leg maintenance into a unified framework. OLEBOT enhances system stability by mitigating the effects of uncertainties and external factors through model predictive control. The integrated system allows for flexible and simultaneous execution of all possible movements. The paper is structured as follows: In

Section 2, we describe the operating principles and design of the hand-fan-shaped end-effector and cam-structured leg joint system. In

Section 3, we detail the overall kinematics and dynamics modeling of OLEBOT, along with the description of the MPC control architecture based on the modeling.

Section 4 presents simulation and real-world experimental results for MPC control based on the hand-fan-shaped end-effector and cam-structured leg joint. Finally,

Section 5 and

Section 6, we describe the performance differences between the conventional control methods and the proposed hand-fan-shaped end-effector, cam structure for leg joints, and integrated MPC control based on the experimental results. Furthermore, we discuss the areas for improvement and limitations of OLEBOT in these sections.

4. Experiments and Results

In this paper, we validate the control performance through experiments with OLEBOT in both a 3D simulation environment and a real-world setting. As shown in

Figure 6, the software development environment utilizes the Ubuntu 20.04 operating system and ROS2 Foxy, forming the node structure in the robot control system. Additionally, commands necessary for the ROS2 system are processed using Python 3.8 and C++ 23. Gazebo engine is employed for 3D physics simulation, and Arduino is used for communication with OLEBOT in the real environment, handling actuator and sensor signals. The designed STL files were converted into SDF format to be recognized within the Gazebo environment, and the resulting spawn into the Gazebo world is shown in

Figure 7. To acquire sensor data within the simulation environment, Gazebo-provided IMU and encoder plugins were utilized. To visually represent actuation within the Gazebo environment, a /joint_control_plugin was developed, allowing for the input of control values into the actuated joints [

30]. The sensor data and actuator input values are organized through a serial communication system involving two micro boards, as shown in

Figure S4.

We experiment with two distinct control methods for pitch control. The first method approach only wheels for pitch control, while the second method involves the first joint of a hand-fan-shaped arm to compensate for torque. The experiments are initialized with a pitch of 0 radians, a wheel speed of 0 rad/s, and all link joint angles set to a default position. As shown in

Figure 8a, the wheel speed converges to 0 within 0.25 s when controlling pitch without the use of the hand-fan-shaped end-effector. Conversely, when using the hand-fan-shaped end-effector for control, the wheel speed reaches zero within 0.21 s. This indicates that the control method, which combines both the wheels and the hand-fan-shaped end-effector, achieves converge 0.04 s faster than the method using only the wheels. Additionally, when using only wheels for control, the wheel’s maximum velocity was measured at 20.8891 rad/s. In contrast, when utilizing a hand-fan-shaped end-effector, the wheel’s maximum velocity was measured at 12.8101 rad/s. This shows that utilizing a hand-fan-shaped end-effector for control results in 40% reduction in the wheel motor’s maximum output compared to two-wheeled robot control approach. The decrease in wheel motor output, achieved by utilizing a hand-fan-shaped end-effector, ensures that the wheel output remains within the threshold required to maintain a stationary state. Consequently, this reduction leads to a decrease in fine movements, such as those observed in inverted pendulum motion.

Figure 8b,c show the outcomes of wheel torque and arm torque when maintaining a stationary posture under the influence of a 1 kg·f external force applied in the x-axis direction, comparing arm fixation control and control utilizing robotic arms. Before applying an external force, the OLEBOT remains a stationary state using a balancing controller. In the external force stability experiments, OLEBOT maintained a stationary state without utilizing the hand-fan-shaped end-effector, using a maximum wheel torque of 4.5 N·m. In contrast, OLEBOT utilizing the hand-fan-shaped end-effector used a maximum wheel torque of 2.1 N·m. This shows the capability of the compensation torque and the center of gravity shifting mechanism of the hand-fan-shaped end-effector to reduce the wheel torque by approximately 2.4 N·m. Moreover, the control method utilizing the hand-fan-shaped end-effector stopped after moving 15 cm upon the application of external force and reached a stable threshold within 0.4 s. On the other hand, the control method with the hand-fan-shaped end-effector fixed resulted in the system stopping after moving 24 cm and reaching a stable threshold within 0.6 s. These results show that the control method using a hand-fan-shaped end-effector is faster and more efficient than the conventional two-wheeled robot control method.

In this paper, we conducted experiments on a jumping scenario, where the second joint of a hand-fan-shaped robotic arm was fixed, and jump control was performed with the arms extended. Furthermore, we simultaneously conducted experiments with the application of the proposed jump control mechanism in this paper. The initial conditions for this experiment were set with a hip joint angle of 0 radians and the center height of the wheel at 0.05 m.

As shown in

Figure 9b, the hip joint rotated from 0.6 to 1.05 radians during the leg-folding process, with an average measurement error of 0.02 radians. Additionally, when the driven leg link passed the critical point of the cam and initialized, we observed that the error momentarily increased but quickly converged to the reference value within 0.1 s.

When the second joint of the hand fan-shped robotic arm was fixed, enabling the arm to extend for jump control, the maximum jump height measured was 0.1 m. As shown in

Figure 9a, the wheel velocity reached convergence within 0.8 s after the jump, indicating stable control performance. Furthermore, as shown in

Figure 9c, the first joint angle of the hand-fan-shaped robot arm converged within 2 s after the jump. These results demonstrate the significant effect of the compensatory torque and center of mass shifting mechanism of the hand-fan-shaped robot arm in achieving stable posture control of OLEBOT after landing.

In the experiment applying the jump control mechanism, a maximum jump height of 0.14 m was measured. This result demonstrated that OLEBOT, through a human-like jumping posture, achieved a jump height 0.04 m higher than a fixed-arm jump. However, as shown in

Figure 10a, the wheel velocity converged within 0.7 s after the jump, showing little difference compared to the results with the hand-fan-shaped robot arm fixed.

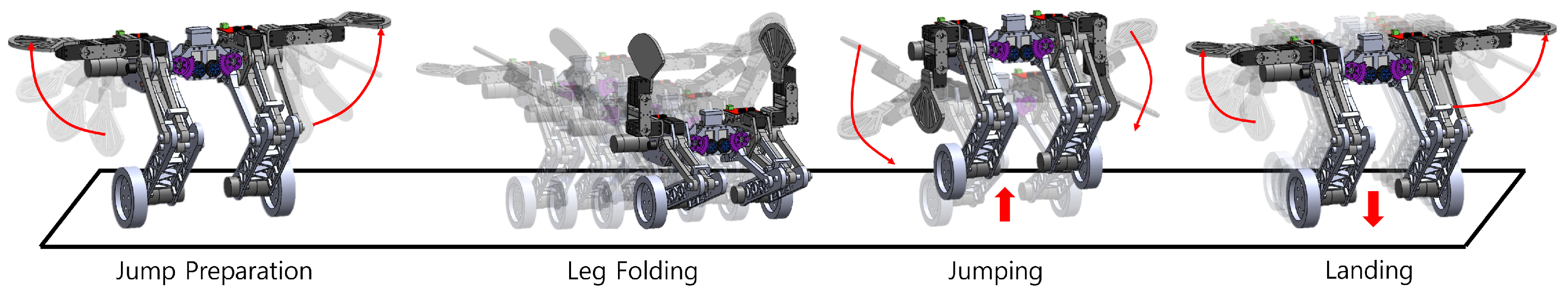

As shown in

Figure 10b, in the jump preparation section, it can be observed that the second joint angle of the robot arm rotated by 1.57 radians from the initial posture to extended the arm. Furthermore, in the leg folding section, the robot arm rotated by 3.14 radians to position the hand-fan-shaped robot arm upward towards the sky. In the jumping section, the second joint of the hand-fan-shaped robot arm momentarily rotated to the initial angle of 0 radians and generated a maximum torque of 0.7, as shown in

Figure 10c. This torque generated by the robot arm indicates the application of compensatory force that enables a higher jumping capability than the original jump force. Lastly, in the landing section, it was confirmed that by rotating the second joint of the hand-fan-shaped robot arm by 1.57 radians when the wheels made contact with the ground, extending the arms apart in both directions, stable landing and posture maintenance were achieved.

In this study, we compare and analyze the effects of using a hand-fan-shaped robotic arm control method for performing one-legged balancing in OLEBOT of a stationary state. The experiment establishes the initial conditions by setting all joint angles of the robot arm to default posture and controlling the waist angle to 60 degrees to raise the right leg of the OLEBOT. In this experiment, we compare the effects of control using only one arm and control using both arms. As shown in

Figure 11a, in the one-legged balancing situation, OLEBOT maintained an average angle of −0.45 radians. Control using only one arm was able to maintain one-legged balancing for 2.4 s, while control using both arms was able to maintain it for 3 s, indicating that using both arms allowed for 0.6 s longer one-legged balance. As shown in

Figure 11b, the wheel velocity in the one-legged control state was controlled based on the pitch direction’s inclination change. In particular, a phenomenon of momentary wheel velocity of up to 3.5 m/s occurring with a period of approximately 0.4 s was observed. The dynamic movement of the wheel showed similarities to the momentary compensatory torque generated by the periodic motion of the robot arm, indicating that the robot arm’s movement plays a crucial role in one-legged pitch control situations.

Furthermore, in this experiment, we compare the joint torques of control using only the right hand-fan-shaped robotic arm and control using both hand-fan-shaped robotic arms. As shown in

Figure 11c, when using only the right hand-fan-shaped robotic arm, a maximum force of 7 N·m was used to generate compensatory torque. On the other hand, as shown in

Figure 11d,e, when using both hand-fan-shaped robotic arms, the left robotic arm exhibited a maximum force of 2.5 N·m, and the right robotic arm exhibited a maximum force of 4 N·m, resulting in more torque generation by the right robotic arm. This result indicates that the movement of the robotic arm on the side where the lifted leg is located has a significant influence on the control performance in one-legged control, and the robotic arm or leg in contact with the ground assists in aligning the weight center of OLEBOT with the vertical axis of the ground through fine movements. Furthermore, control using both hand-fan-shaped robotic arms generated small joint torques for each arm compared to control using only one arm. This result minimizes the movement of the robotic arm by reducing the inertia caused by arm rotation, enabling more stable control and improving OLEBOT’s ability to maintain balance.

The purpose of this experiment is to measure the operation of the hand-fan-shaped robot arm and the compensatory torque generated during the maintenance of balance while performing single-leg cross motion in place. During the experiment, OLEBOT alternates legs at intervals of 0.5 s, rotating the waist angle by 60 degrees during leg replacement. As shown in

Figure 12a, the hand-fan-shaped robot arm moved the arm similar to a tightrope walker. The robot arm on the side where the leg is lifted exhibited a large range of motion towards the upward direction, while the robot arm on the side in contact with the opposite ground performed fine adjustments within a range similar to the initial posture. This movement pattern evokes the motion of ice skating and demonstrates that OLEBOT can maintain balance and move. Additionally, as shown in

Figure 12b, it is observed that the torque generated by the inclination to the left and right is compensated for by the robot arm, with a root mean square error (RMSE) measured at 2.16. This indicates that the error falls within an acceptable range for maintaining balance while alternating legs at 0.5-s intervals. Despite the differences in the error range, the results of this experiment demonstrate the possibility of maintaining balance in place through continuous leg replacement.

In this experiment, we compared and analyzed the performance of OLEBOT’s driving using the conventional two-wheel balancing method and the single-leg cross driving method using skating motion. The experiments were conducted in the Gazebo world coordinate system, with the starting point set at . The experiments involved OLEBOT moving forward by 2 m in the y-axis direction and moving backward by −2 m. In these experiments, the desired pitch angle of OLEBOT was set to 0.2 radians for forward motion and −0.3 radians for backward motion.

The experimental results showed that when using the conventional posture, it took 3.651 s to reach the target point during forward motion, while it took 5.847 s when using the skating motion. Therefore, the conventional posture reached the target point approximately 2.196 s faster than the skating motion. Similar results were observed in the backward experiments, with the conventional posture taking 3.627 s and the skating motion taking 5.856 s to reach the target point. This indicates that the conventional posture reached the target point approximately 2.229 s faster than the skating motion during backward motion. The speed difference between forward and backward motion was not significant, indicating that the weight distribution of OLEBOT’s front and rear centers of gravity was balanced. However, as shown in

Figure 13a,b, the analysis of OLEBOT’s movement path revealed significant differences between the movement paths when using the conventional posture and the skating motion. When driving with the conventional posture, OLEBOT accurately followed the reference path by controlling the speeds of the two wheels in contact with the ground according to the yaw value. On the other hand, when driving with the skating motion, it was difficult to control the lateral movement with only one wheel in contact with the ground, resulting in the inability to adjust the direction. This led to errors and increased the total travel distance.

In

Figure 13c,d, the speed analysis results also showed significant differences between the conventional posture and the skating motion. When driving with the conventional posture, both wheels were in contact with the ground, resulting in minimal disturbances and allowing OLEBOT to move quickly at a maximum speed of 4.2 m/s, following the desired pitch angle. In contrast, when driving with the skating motion, OLEBOT experiences significant vibrations and a high level of disturbances, causing its maximum speed to decrease to 3.5 m/s. This represents a reduction of approximately 16.7% compared to when it is driven in a normal posture. Additionally, reverse rotation of wheel or stopping was observed to maintain pitch balance. These results indicate that driving with the conventional posture allows for faster movement compared to skating motion driving.

5. Discussion

In this paper, we presented the results of using a hand-fan-shaped end-effector for pitch and one-legged balancing control, a cam-structure-based leg joint system for jumping, and MPC for OLEBOT. The one-legged balancing control method, where only single wheel touches the ground, exposed its limitations in lateral control. Particularly, in the moment when both legs made contact with the ground during the single-leg cross-driving process, continuous directional correction using both wheels was essential for maintaining the desired direction of OLEBOT. Additionally, we observed instances where OLEBOT made contact with the ground using the edges of the wheels instead of the wheel surface during one-legged balancing control, which added significant difficulty to the directional correction process. It is expected that designing the wheel with a surface structure instead of edges could alleviate these issues and enable more stable control.

In one-legged balancing control, multiple control variables are introduced, including robot arm joints. These variables can lead to computational speed degradation during the MPC optimization process. Considering that the average reaction time for an adult is 0.02 s and accounting for the 6.8-fold scale difference between OLEBOT and human proportions, the ideal data transmission time for OLEBOT would be within 0.136 s. However, experimental results indicate that the average time for data to be input into OLEBOT’s actuators is as long as 0.253 s. This suggests that delays in computational speed may impact OLEBOT’s real-time responsiveness. Therefore, simplifying OLEBOT’s modeling and controller can enhance MPC computational speed and allow for faster data transmission, ultimately improving OLEBOT’s driving performance and stability.

The results of the gazebo simulation and actual OLEBOT performance for jumping showed some discrepancies. OLEBOT jumped 0.14 m in the simulation, while it jumped 0.1 m in the real environment. The simulation environment was set to be similar to the actual environment in terms of OLEBOT’s mass, friction coefficient, and torsion spring constant. However, factors that additionally affect the real environment, such as the weight of micro boards and wires, were not considered. The most significant cause of the difference in jumping performance between simulation and the real environment was the variation in torsion spring elasticity. Torsion springs find it challenging to recover elasticity when exposed to a load for an extended period. OLEBOT, even in situations where the torsion spring is not driven, is exposed to a significant force on the knee joint, leading to spring aging in many experimental processes. Therefore, periodic replacement of the torsion spring is necessary to maintain jumping performance, and modular design for easy replacement of the torsion spring is required in OLEBOT’s design.

The success rate for maintaining a stable posture after jumping was 80% in the simulation environment and 70% in the real environment. Unstable landings varied significantly depending on changes in pitch angle in the posture just before jumping. In the stable pitch angle range just before jumping, the pitch angle is between −0.21 radians and 0.11 radians. If leaping occurs outside this angle range, OLEBOT cannot maintain its posture stably upon landing, as the center of gravity does not remain perpendicular to the ground. If the pitch angle and ref angle differ by more than 0.14 radians at the landing point, OLEBOT could not maintain a stable posture and balance after jumping. Therefore, to increase the success rate of maintaining a stable posture after jumping, it is necessary to limit the range of the error between the ref pitch angle and pitch in the posture just before jumping and improve the algorithm for OLEBOT to jump when it is within a stable error range.