1. Introduction

Unmanned Aerial Vehicles (UAVs), popularly known as drones, have revolutionized numerous industries with their unmatched versatility and efficiency [

1]. These aerial vehicles are pivotal in optimizing crop management and resource utilization in precision agriculture. By capturing high-resolution imagery and multispectral data, drones facilitate precise monitoring of crop health, pest infestations, and overall field conditions [

2,

3]. This study delves into the intersection of advanced design methods and materials applied to the design of quadcopter drone chassis, aiming to propel advancements in precision agriculture [

4]. In the context of existing research, integrating generative design principles with materials and 3D printing represents an innovative approach [

5,

6].

This introduction aims to contextualize the study, emphasizing its significance in pushing the boundaries of drone technology for agricultural applications. At its core, this research seeks to address gaps in current designs, paving the way for high performance and increased power-to-weight and thrust-to-weight ratios, resulting in a more efficient, cost-effective, and sustainable approach to precision agriculture. Increasing the thrust-to-weight and power-to-weight ratios in lightweight drone designs enhance performance and agility. A higher thrust-to-weight ratio leads to quicker acceleration and improved maneuverability, while a higher power-to-weight ratio facilitates faster climbs and better handling in flying conditions. These improvements result in the increased responsiveness of the drone and overall flight capabilities that can benefit flight quality and time.

The following sections will unravel the complexities of 3D-printed generative design, culminating in insights that hold promise for the evolution of intelligent agricultural practices. At the forefront of precision agriculture, the synergy between data-driven farming and advanced drone technology promises transformative outcomes. Leveraging data for precise decision-making, drones facilitate precision crop monitoring, enabling issue detection and informed decision-making [

7]. This dynamic process ensures optimal crop health and feeds into an efficient resource management strategy where resources are judiciously allocated. The culmination of these practices represents a paradigm shift towards efficient farming, blending innovative techniques with data insights for heightened productivity and sustainability [

8].

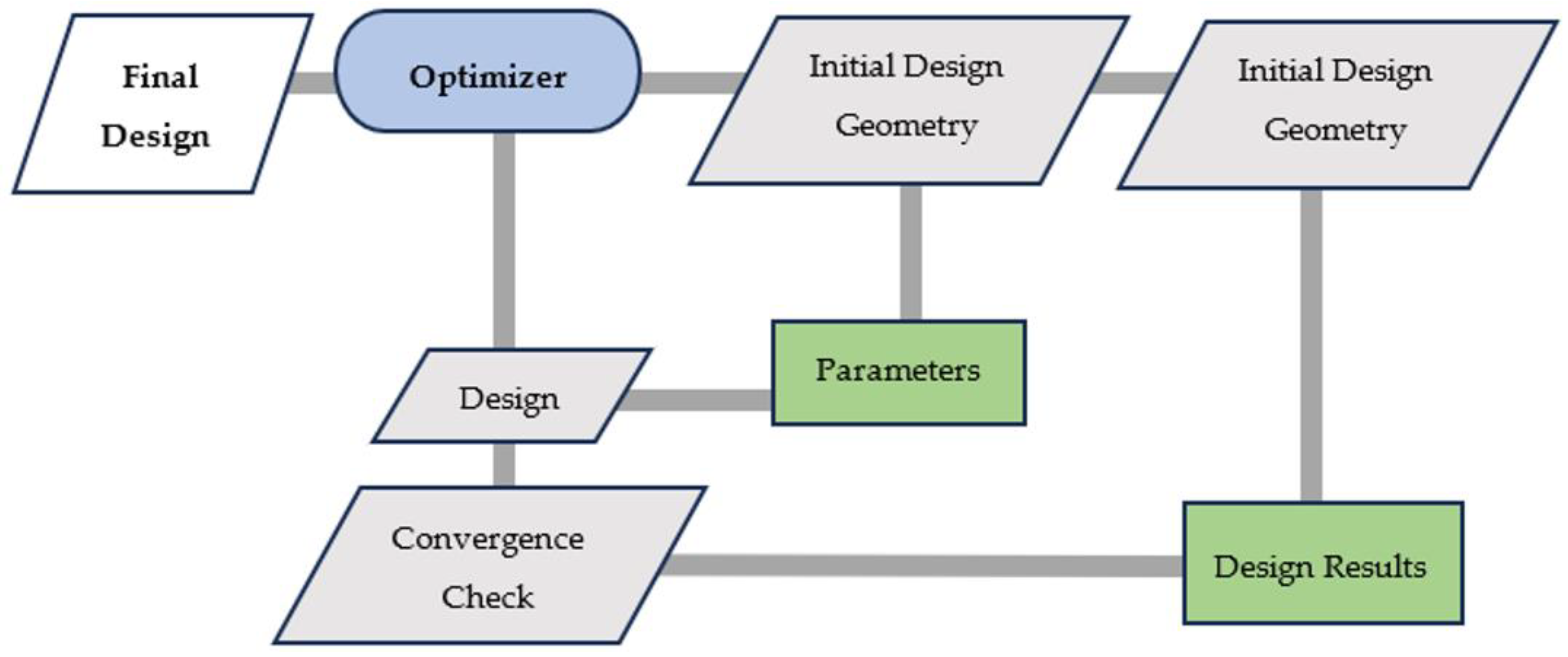

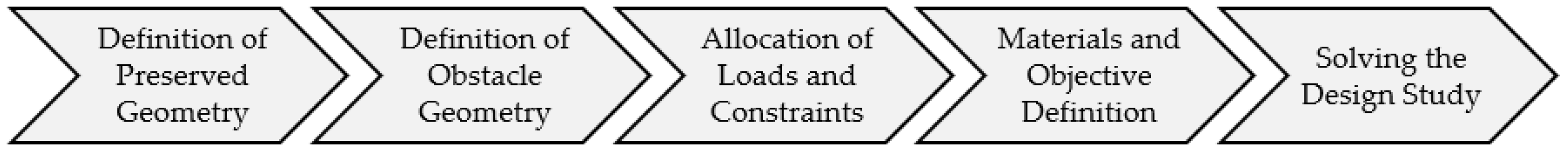

In the pursuit of advancing the design technology, Autodesk Fusion 360 Generative Design technology has been utilized, which allows for optimization of the parameters and provides the best possible results through topology optimization, guided by sophisticated algorithms, which emerges as a critical facet, strategically minimizing weight while maximizing structural integrity for various drone elements and their functionality, as listed in

Table 1. Autodesk Fusion 360 is a cloud-based C.A.E. software (v. 16.5. 0.2083), which is easy to run and requires no such special configurations of the device to run on, as it does not use the device’s internal graphics and memory, making it versatile and usable on any operating system and environment. The current study uses a device with 4 GB RAM and 512 GB internal memory, with Intel

® Core™ i5 processor (Acer Aspire 7, Acer India Private Limited, Puducherry, India.) with Windows 11 operating system, is utilized. The generative study performed on this software took around 15 to 20 min till convergence for the current design, which is variable for design type, complexity configurations and device specifications.

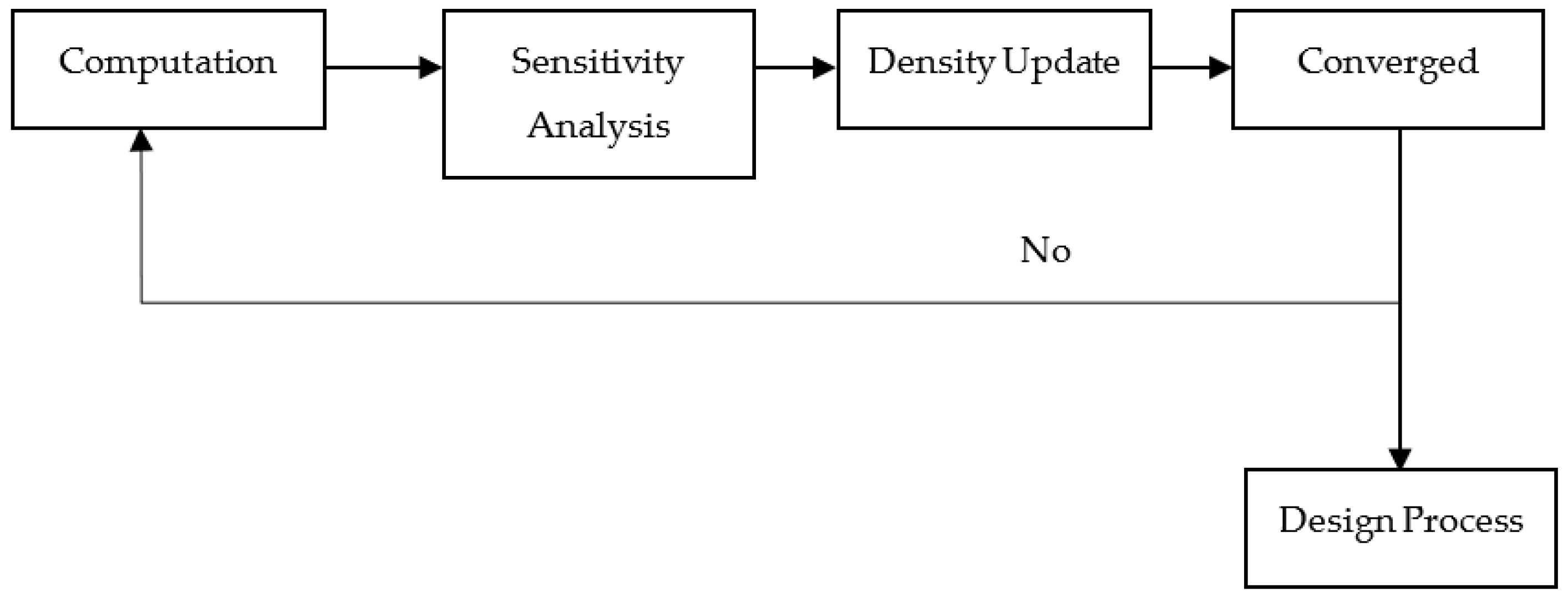

This optimization algorithm-based study of generative design enhances system performance by facilitating seamless collaboration between components [

9]. Optimization plays a pivotal role in driving efficiency and innovation in complex systems. It identifies the most effective solution from various choices, considering various goals, limitations, and uncertainties. It guarantees the most efficient use of resources within engineering and design, enhancing the systems’ performance, dependability, and eco-friendliness. The integration of rapid generation and evaluation of design alternatives through algorithmic iteration provides the best outcome from optimization. Generative design, a result of multidisciplinary optimization (M.D.O.) principles, transforms conventional design methods through the use of computational algorithms to examine vast design territories. It methodically creates and appraises countless design alternatives based on set objectives, restrictions, and performance standards. The concept of M.D.O. is based on tackling intricate design issues a notch higher by engaging multiple engineering areas. It considers the communication between different subsystems, intending to discover superior solutions that improve the entire system’s function. In M.D.O., various improvement strategies are utilized, which can be split into definite and uncertain methodologies. Precise optimization techniques, like algorithms based on gradients or line-based programming, depend on accurate math layouts to reach ideal solutions effectively. Such manners of problem-solving are suitable for well-structured issues with specific limits and goals [

10]. Like genetic algorithms, simulated annealing and particle swarm optimization are non-deterministic optimization techniques for dealing with complex and ill-defined problems. These methods are designed to explore the design space randomly, just like evolutionary processes or random searches do to find near-optimal solutions in the form of probabilistic models. In addition, errors must be considered during optimization procedures in realistic modeling and decision-making. For example, measurement inaccuracies, modeling assumptions, or environmental uncertainties may cause these errors. Therefore, taking into account the errors in the optimization process makes sure that the solutions obtained are robust and able to cope with practical conditions. This enhances the drone’s overall efficiency and aligns with the imperative for lightweight and robust aerial platforms in agricultural settings. Systematic integration algorithms further play a crucial role, ensuring cohesiveness among diverse drone elements. As we delve into the subsequent sections of this research, each of these components will be dissected and analyzed, shedding light on their specific contributions to the evolution of high-performance quadcopter drone chassis for precision agriculture.

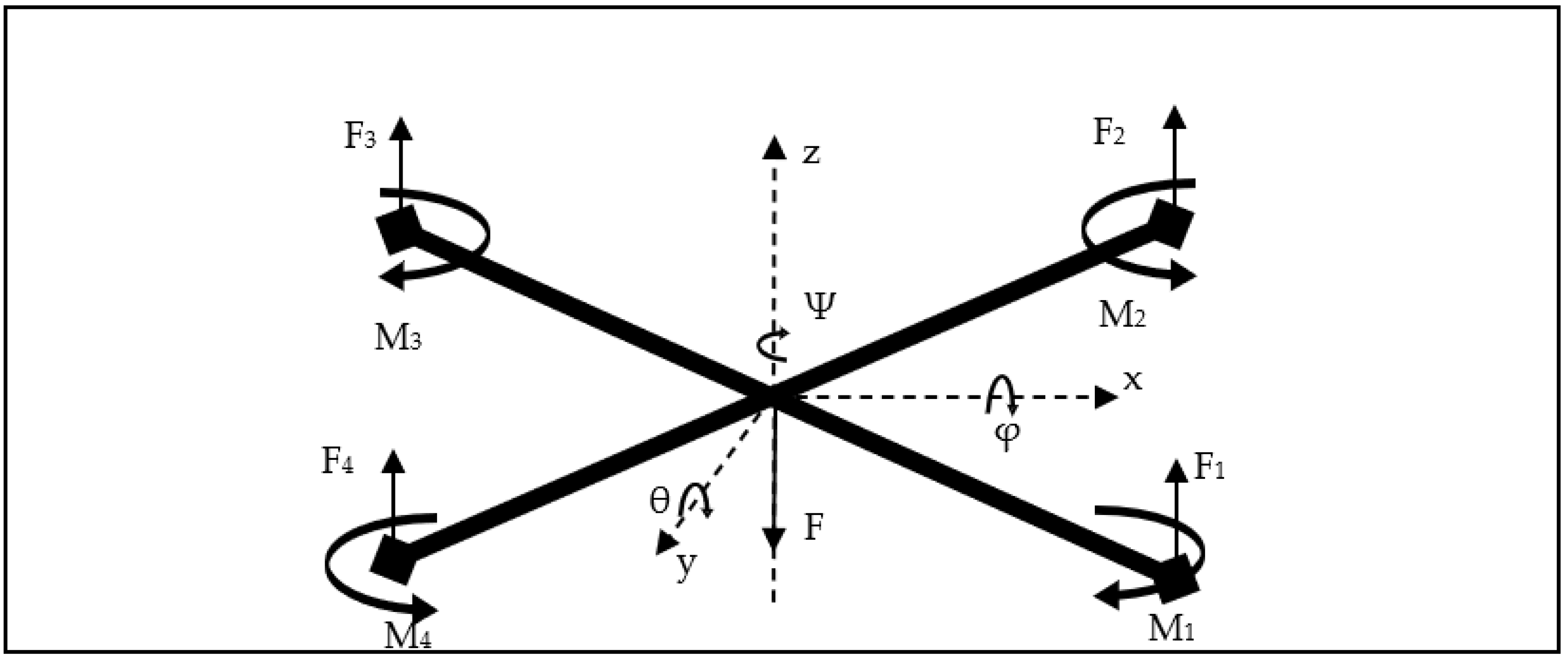

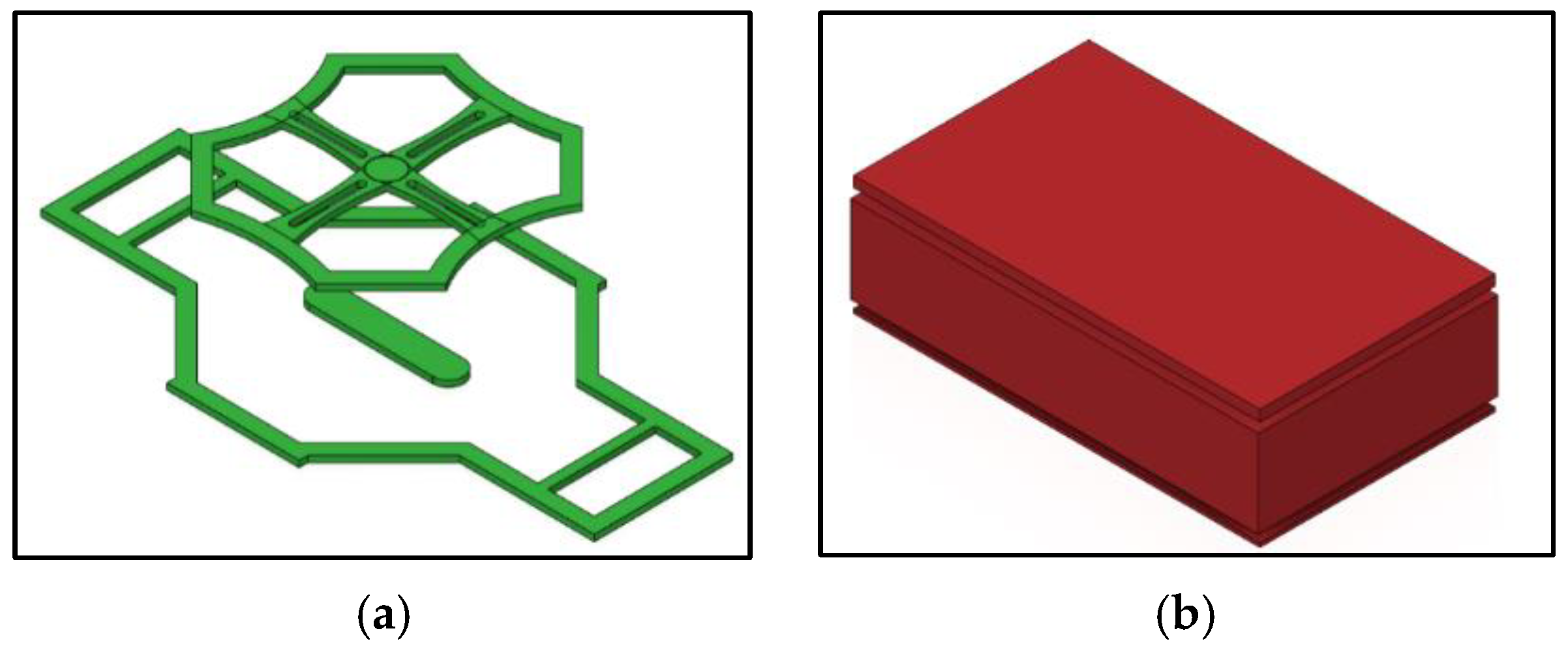

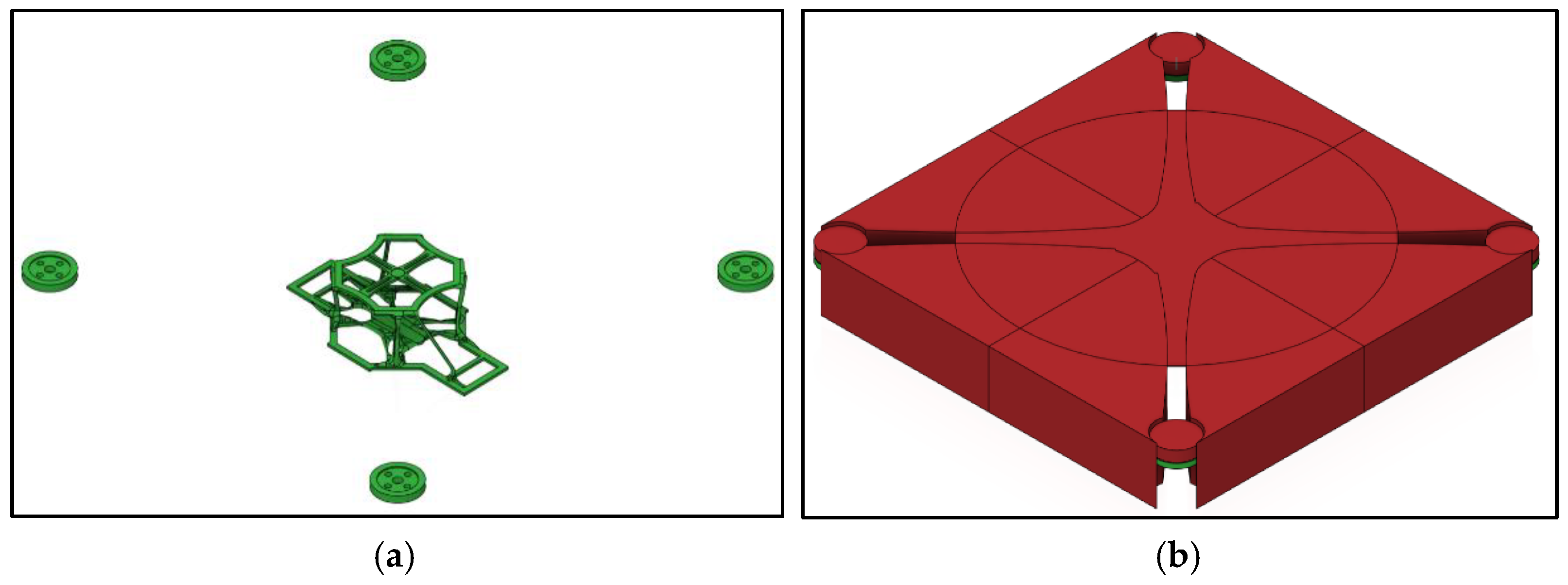

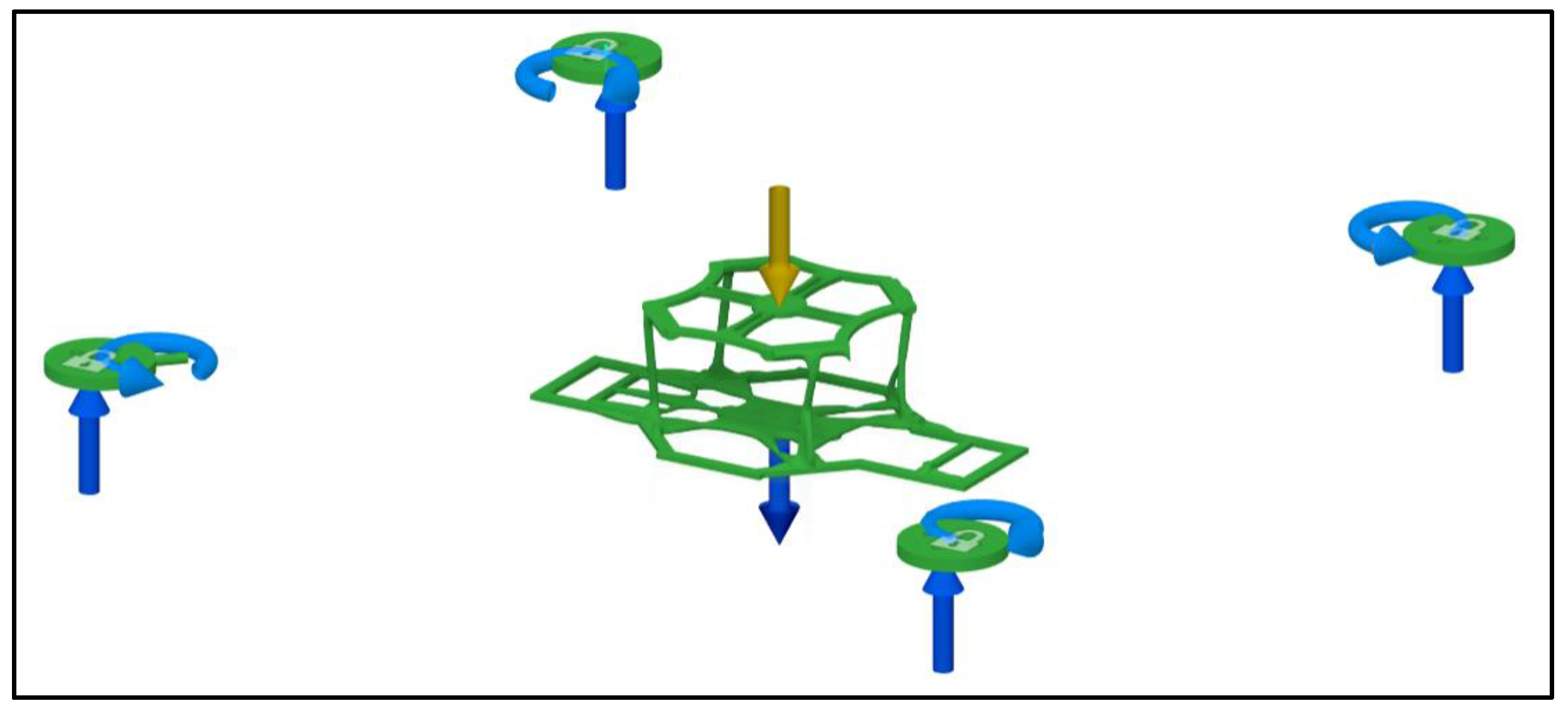

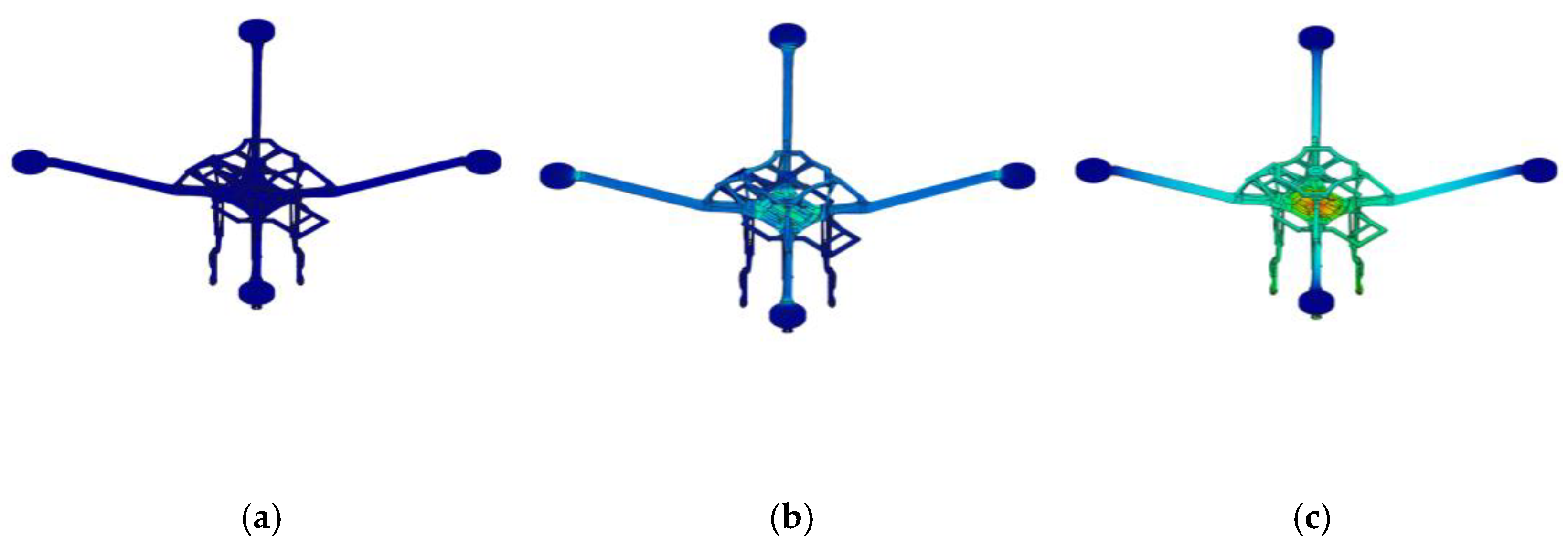

Figure 1 shows a typical quadcopter design for the specified application, including the components listed in

Table 1. Pushing the boundaries of quadcopter technology, this study delves into a thorough design exploration with well-defined goals, which starts with the meticulous design of a quadcopter chassis characterized by diagonal dimensions of 500 mm and a height of 55 mm [

11], with recommended landing gears of about 110 mm [

12]. Prioritizing structural integrity, the chassis is engineered to accommodate a load of up to 2.5 kg (2.5 kg or 2500 g), including a 1 kg (1000 g) payload, while maintaining a minimum Factor of Safety of 1.2 [

4]. Adhering to contemporary aerospace engineering principles, the chassis is designed to be lightweight without compromising robustness, optimizing both power-to-weight and thrust-to-weight ratios. These objectives underscore a commitment to precision and efficiency, ensuring the quadcopter meets the specific demands and establishes a benchmark for reliability and performance.

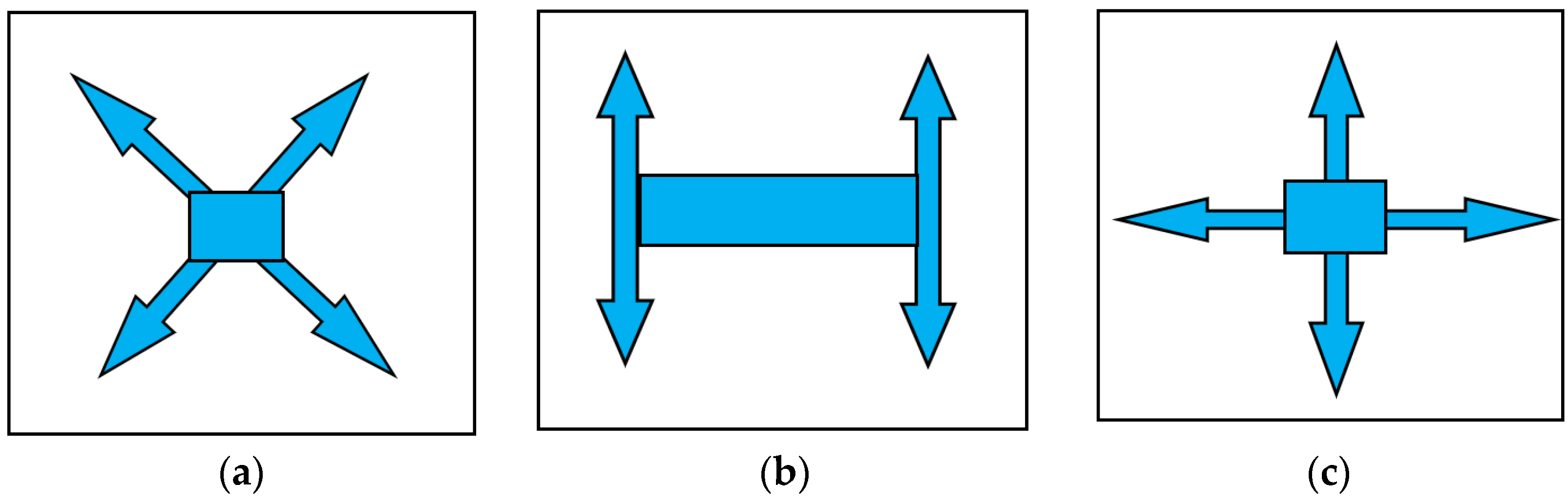

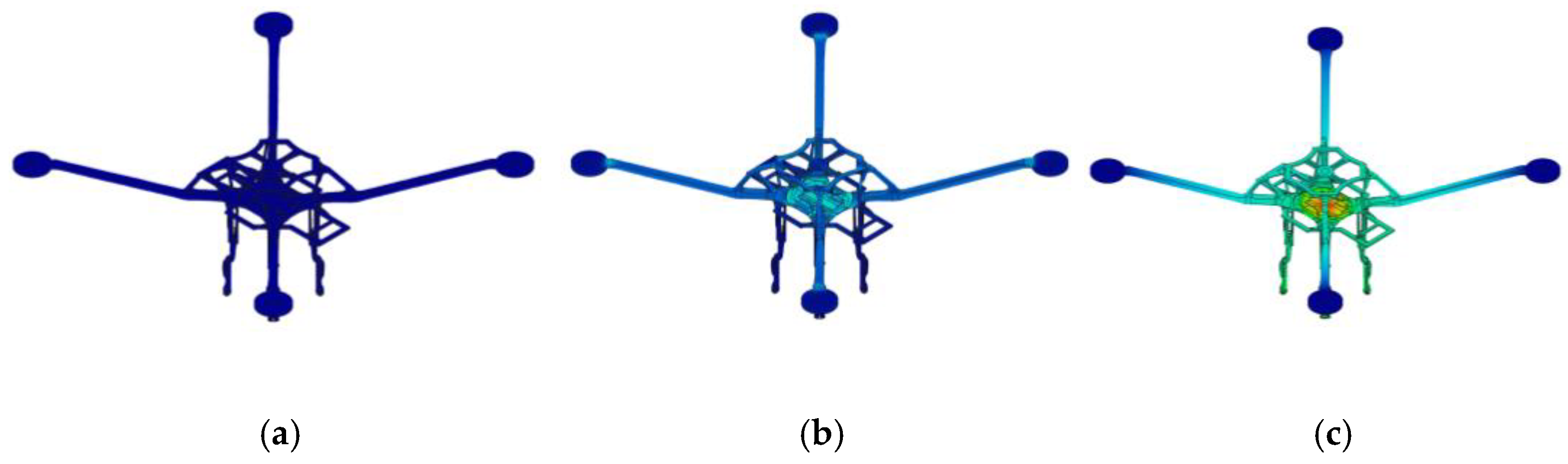

Figure 2 shows different drone configurations: the H, X, and + designs. Each has its unique set of advantages and applications [

14]. The X configuration, which has four rotors forming a symmetrical X shape, is the most versatile in the case of precision agriculture. Its inherent stability and agility make it well-suited for navigating the intricacies of agricultural landscapes. The symmetrical layout facilitates balanced thrust, providing enhanced maneuverability and precise positioning.

In contrast, the H configuration, with arms extending vertically and horizontally, offers stability but may sacrifice some agility in specific scenarios, with being heavy as a disadvantage. The + configuration, with arms extending horizontally, lacks behind from X regarding symmetrical thrust distribution characteristics. Considering all these variations, the X configuration’s versatility and balanced thrust make it an optimal choice in agricultural settings where precision is paramount. While the H and + configurations may excel in stability, the nuanced requirements of precision agriculture underscore the unique advantages of the X design in delivering reliable and accurate results [

15].

4. Discussion

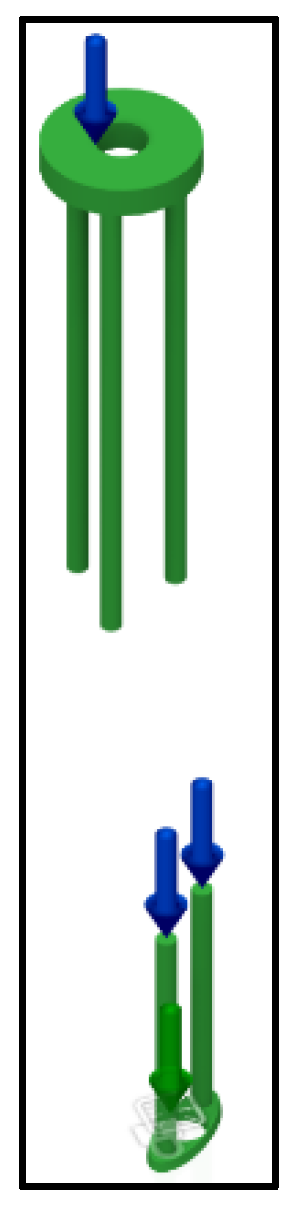

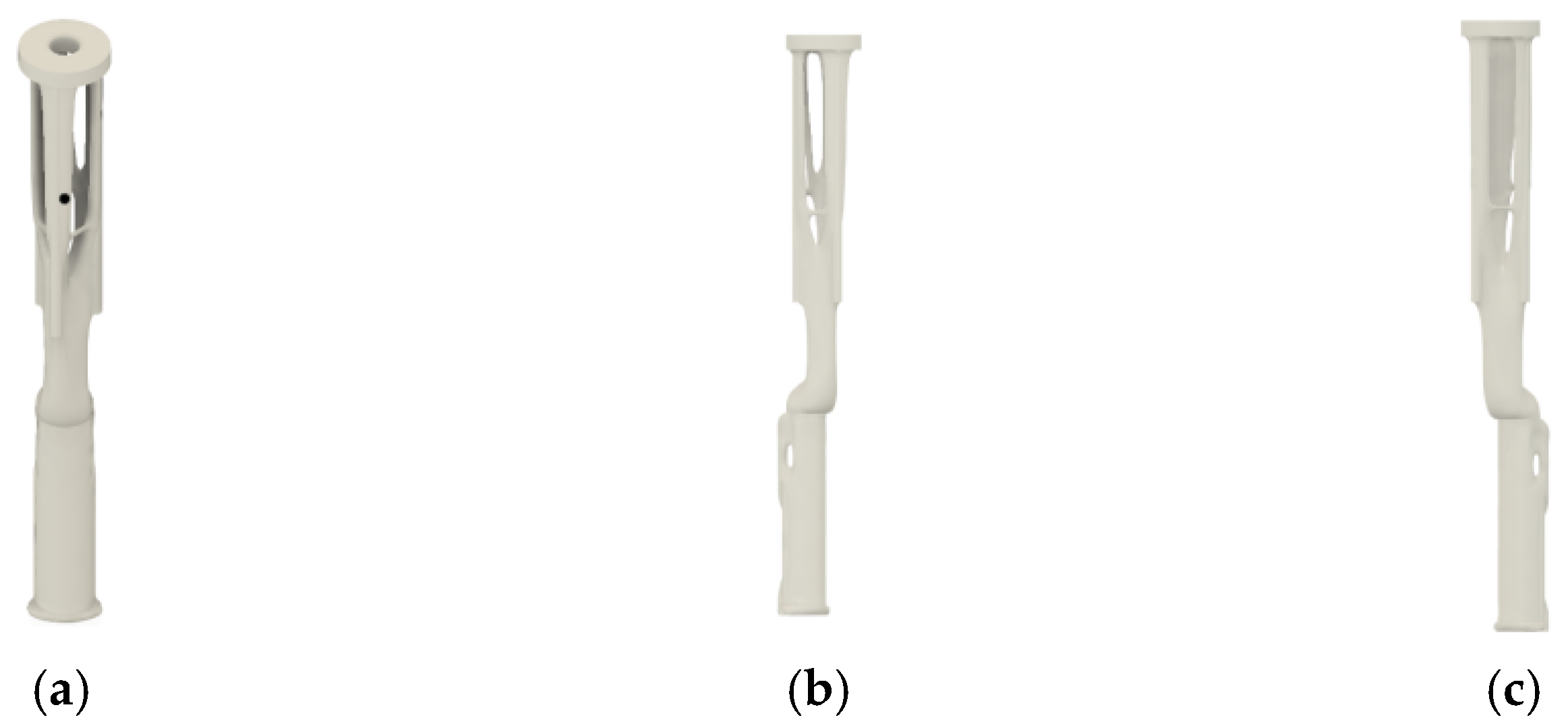

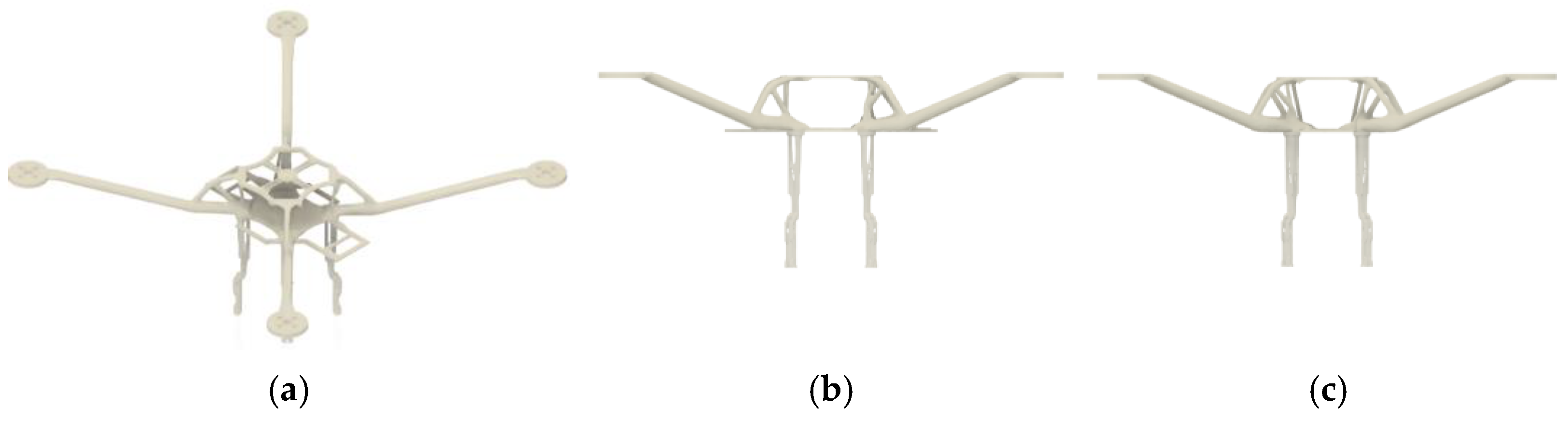

The results of this research exhibit a significant gain in drone design, where all components have been meticulously crafted with the most optimized parameters through topology optimization-integrated generative-design methodology using Autodesk Fusion 360. This approach, with potential design constraints such as structural integrity, durability, and standards and choosing the relevant materials, yielded a quadcopter chassis that outperforms the well-established DJI F450, a prominent commercial drone. The optimized topology enhances the structural integrity of individual components and contributes to a more cohesive and efficient overall design. The superior performance metrics, including power-to-weight and thrust-to-weight ratios, underscore the success of our generative design approach. This comparative advantage over a widely recognized commercial drone highlights the potential of our methodology to push the boundaries of drone technology, particularly in the realm of precision agriculture, where the demand for enhanced performance and agility is paramount. The following discussion will delve into the nuanced aspects of these results, elucidating the specific advantages and implications for the field.

The design of the quadcopter, as it was meant to be lightweight, has good structural conduct and is efficient; the selections made for every component were very logical. These selections were made after accounting for all possible considerations. For the central part of the drone base, A.B.S. material is prioritized over P.L.A., as A.B.S. is stiffer. However, A.B.S.’s light weight also tends to make the material bend a bit, protecting against breakage in times of unexpected loadings.

Table 4 of

Section 3.3 shows that the properties achieved in A.B.S. are very similar to those of P.L.A., with the advantages of being lightweight, easily accessible and cost-effective.

For the arm’s section of the quadcopter, the materials of A.B.S., P.L.A. and Nylon 6/6 are considered, but with P.L.A. being stiffer and heavier, it is not recommended for our purposes, as discussed in previously referred studies. Therefore, the design outcomes of A.B.S. and Nylon 6/6 were processed and then analyzed based on the variations in their properties. It was observed that both materials do not differ much in terms of body mass, von Mises Stresses, and body global displacement, as shown in

Table 5 of

Section 3.3.

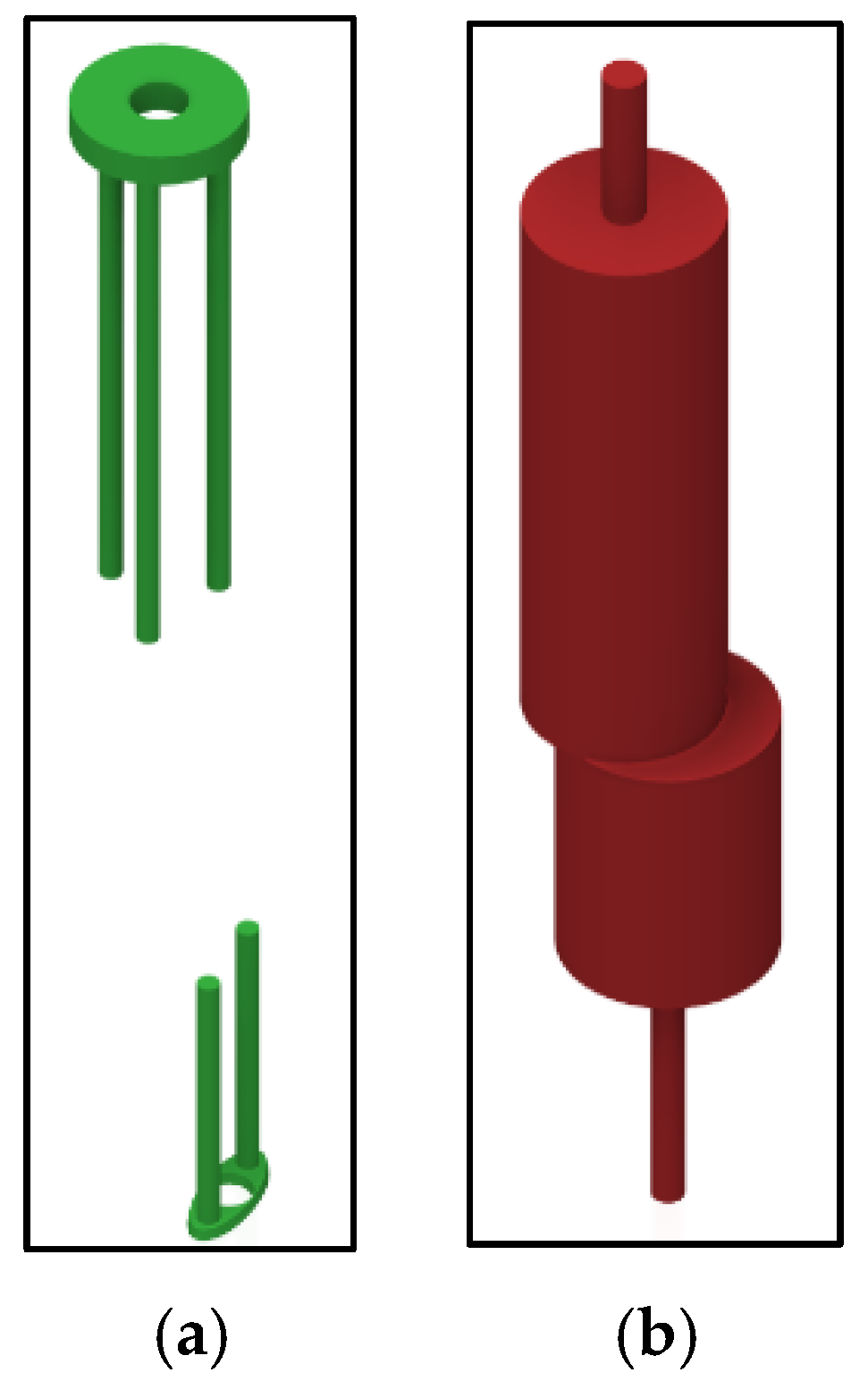

In the case of the landing gear, the body part must be strong enough to sustain the upper body’s load during landings and act as a protective part in rough terrains and surroundings. It is imperative to make the design stronger yet lighter in weight, so the components made from P.L.A. and A.B.S. were exclusively taken under the study’s consideration. Also, these materials were strongly suggested by previous researchers, so when applied to the study, they provided similar results. Still, P.L.A. surpassing A.B.S. in some fields with the same body mass makes it a better choice for the landing gear.

So, with the chosen materials, parameters and designs of the sections of the quadcopter chassis, a whole assembly was created that provided outperforming results in each domain, with surpassed factor of safety values, lesser stress values, lighter body frames, and better results in every aspect than the market’s popular drone chassis, as listed in

Table 7 of

Section 3.4. The drone chassis for both materials was able to provide outstanding thrust-to-weight and power-to-weight ratios with the designated load conditions and application domain. However, the design of the chassis is associated with some constraints, such as the utilization of the chassis within the limitations of precision agriculture tasks like field mapping, monitoring, and pesticide distribution (up to 1 kg as payload), which are small but tedious tasks for humans. Also, the generative design produces an organic design manufactured by non-conventional processes, i.e., subtractive or conventional manufacturing processes would not be able to compensate for any modification or repair in the design if required. Although the generative study facilitates the application of manufacturing constraints as a specific process to achieve a significant weight reduction, these very non-conventional processes, such as additive manufacturing and materials, should be utilized.

Further research in the future for this subject will include the experimental testing of the generative design in real-world scenarios, i.e., testing in actual agriculture fields with real-time conditions, considering practical agricultural applications and various outdoor environmental factors such as wind speed and temperature as noted above, which will significantly impact drone performance. A systematic comparison of the generated drone performance in real-world conditions in full functionality with all components and payload with the experimental and field tests of DJI F450 will also be considered in the future scope of the study. Also, improving the power-to-weight and thrust-to-weight ratios for greater payload capacities will be considered within the same volumetric limits to further improve its performance. Heavy-duty applications will also be included in future studies.

5. Conclusions

The generative design employed in our research demonstrated superior performance across multiple dimensions compared to traditional designs, surpassing currently available drones in the market that enjoy widespread usage. The results for various parameters, directly affecting the stability, flight time, efficiency, mass production rates and cost of the drones, were achieved to be well advanced from DJI F450, a well-known commercial drone. The values of generated topology-optimized chassis have reduced weight values of 50%, which directly result in reduced costs up to similar extents, i.e., 50%, with power-to-weight and thrust-to-weight ratios increased by 6.06% and 6.75%, respectively, and incremental improvements of at least 11.8% in terms of factor of safety and 70% in reduced stress values. The design also exhibits shorter production times as additive manufacturing favours it.

These substantial positive outcomes have far-reaching implications for the drone industry. First and foremost, the enhanced design contributes to better operational efficiencies, allowing for more precise and agile manoeuvres during flight. The optimization achieved through generative design also translates into longer flight times, a critical factor in applications such as precision agriculture, where extended aerial coverage is paramount. Additionally, the reduced power consumption inherent in our design prolongs the drone’s operational duration and aligns with sustainability goals, making it environmentally friendly. The prospect of mass production with cost-efficient availability is another significant benefit, enabling broader access to advanced drone technology. Our generative design approach aims to revolutionize the drone industry, offering a holistic enhancement that extends beyond individual components to benefit users through improved efficiency, sustainability and cost-effectiveness.