1. Introduction

Satellites, fundamental to a broad spectrum of applications from scientific observations to communication and navigation, require fast and accurate attitude control for optimal performance on three axes. One of the main mechanisms employed to supply this control torque is reaction wheels (RWs), underscoring the importance of their reliability and accuracy for the success of space missions. Consequently, the need for robust RWs’ fault diagnosis and prognosis is critical. This foregrounds the urgent requirement for improved fault detection and mitigation strategies in RWs [

1]. The system-level prognostics approach for failure prediction of reaction wheels, which is presented in [

1], while valuable, may not capture the detailed component-level behaviors and complex temporal patterns associated with individual RWs. This can lead to less accurate fault detection and may not adequately address unforeseen anomalies or data scarcity issues. This foregrounds the urgent requirement for improved fault detection and mitigation strategies in RWs. In recent years, the application of deep learning techniques for fault detection and control in satellite attitude control systems has been recognized as a promising solution [

2]. It offers the capability to effectively analyze complex, high-dimensional data, facilitating faster and more accurate fault detection and reducing the need for human intervention [

3]. Thus, it significantly enhances mission success rate while minimizing mission risks. For example, Chen et al. [

4] conducted a study where the implementation of deep learning-based fault diagnosis improved the detection accuracy compared to traditional methods, which can contribute to higher mission success rates due to early and accurate fault detection. The present paper presents an approach for fault detection in satellite attitude control systems focusing on RWs. We propose a method based on Long Short-Term Memory (LSTM)-driven deep learning, which capitalizes on LSTM’s proficiency in handling time-series data, complemented by advanced torque allocation algorithms and denoising autoencoders to mitigate false alarms. By detecting subtle temporal changes in system behavior, our approach improves fault detection accuracy and enhances system reliability and performance.

Satellite attitude control systems encompass diverse components: sensors, actuators, and controllers. The function of the sensors is to gauge the spacecraft’s attitude relative to a reference framework. Actuators, on the other hand, generate the force needed to modify the spacecraft’s position or attitude, respectively. Controllers obtain sensor data and ascertain the appropriate corrective actions to stabilize or alter the spacecraft’s attitude. Common actuators in satellite attitude control systems are control moment gyroscopes (CMGs) and reaction wheels (RWs) [

3,

5,

6]. RWs are rotational instruments used in satellites to yield control torques for precise spacecraft alignment. Devices of this kind generate twisting forces by altering the rotational inertia of a flywheel. This is made possible through an electric motor and is attached to the framework of the space vehicle through a bearing mechanism. To provide a backup for orientation control in case of wheel failure, numerous spacecraft are equipped with an assembly of multiple reaction wheels (RWs), often more than three, arranged in a non-planar configuration known as a reaction-wheel assembly (RWA). Strategies for torque mapping are utilized to apportion the necessary control torques to the RWs in a non-unique fashion [

7]. Various methods for torque mapping have been suggested, such as the pseudo-inverse method [

8,

9,

10], which aims to minimize a specific norm of the apportioned RW torques, and the L∞-norm method [

11,

12,

13], which strives to minimize the highest RW torque in the RWA for a given slew maneuver [

14]. Satellite reaction-wheel fault detection is dependent on torque allocation algorithms because these algorithms ensure the optimal distribution of torque to reaction wheels, which directly affects their performance and reliability. Any anomalies in the allocated torque can indicate potential faults or impending failures in the reaction wheels, thereby making the torque allocation algorithm a component of the fault detection process [

3,

15].

In recent years, several methods for reaction-wheel fault detection have been proposed [

16,

17,

18]. In one of the latest achievements, Hedayati et al. [

19] used Generative Adversarial Networks (GAN) with Long Short-Term Memory (LSTM) to mitigate data scarcity in reaction-wheel fault diagnosis. These approaches include model-based methods and data-driven methods. Model-based methods rely on mathematical models of the satellite and reaction-wheel dynamics to detect faults [

20,

21]. One such method was proposed by Rahimi et al. [

22], who introduced an innovative approach for the detection of RWs malfunctions in satellite attitude control systems, utilizing an adaptive unscented Kalman filter that models the RWs’ dynamics. Model-based fault detection faces challenges in accurately capturing complex system dynamics and handling uncertainties, which can result in reduced sensitivity to faults and increased false alarms. Accordingly, data-driven methods are receiving more attention during the recent years. Data-driven methods utilize machine learning algorithms and statistical methods to identify faults based on historical or real-time data. For example, Ibrahim et al. [

23] proposed a fault detection method using support vector machines, while Abd-Elhay et al. employed a deep learning-based approach for reaction-wheel fault diagnosis [

18]. Data-driven fault detection can also struggle with limited or noisy data, which can impede learning accuracy.

Addressing the aforementioned challenges, deep learning techniques have recently demonstrated promising results in diverse fault detection applications, exhibiting enhanced accuracy and efficiency compared to traditional methodologies. Convolutional Neural Networks (CNNs) have been applied to image-based fault detection [

24], while Recurrent Neural Networks (RNNs), specifically LSTMs, have been utilized for time-series data fault detection [

10]. In comparison, while Convolutional Neural Networks (CNNs) are effective for image-based fault detection due to their spatial feature extraction capabilities [

24], they are less suitable for sequential data. Moreover, Gated Recurrent Units (GRUs) offer computational efficiency but may not capture long-term dependencies as effectively as LSTMs [

24]. LSTMs, a subclass of RNNs, have proven effective in managing long-term dependencies and complex temporal patterns, rendering them suitable for fault detection and control in satellite attitude control systems where learning temporal relationships is crucial [

24,

25]. Their unique architecture includes memory cells and gating mechanisms that allow them to retain information over extended periods, which is essential for detecting faults that develop gradually over time. This advantage makes LSTMs more adept at handling the temporal dynamics inherent in satellite systems compared to other deep learning methods.

LSTM is a type of recurrent neural network (RNN) that is commonly used for analysis of time-series data, including fault detection in industrial processes [

26]. In fault detection applications, LSTM can be trained on historical sensor data from a machine or industrial process to learn patterns of normal behavior. The LSTM model can then be used to predict the expected sensor readings at each time step based on the previous readings. During operation, if the sensor readings deviate significantly from the LSTM’s predictions, it may indicate the presence of a fault or anomaly. The LSTM can be used to generate an alarm or trigger a maintenance action. The LSTM can also be used in conjunction with other machine learning techniques, such as clustering and outlier detection, to improve the accuracy of fault detection. For example, the LSTM can be used to identify time periods where the sensor readings are abnormal, and clustering algorithms can be used to group the abnormal periods into different fault types.

Although LSTM can perform well for fault detection, LSTM networks are often sensitive to the presence of noise and outliers in the input data, which can negatively impact their performance in fault detection tasks [

27,

28]. The robustness of LSTM networks to noisy input data remains a significant area of concern, especially in satellite attitude control systems where signal corruption may occur due to various sources such as sensor noise, cosmic radiation, and communication channel disruptions. In this study, we propose a methodology for mitigating reaction-wheel (RW) disturbances in satellite attitude control systems through the implementation of an effective torque allocation algorithm. This algorithm capitalizes on redundant RWs to circumvent particular velocities that may generate torque perturbations, such as zero-speed crossings and resonant speeds. Furthermore, our research endeavors to establish a robust, a LSTM-based deep learning technique for fault detection in satellite attitude control systems, utilizing signals from the redundant RWs, which evade specific speed-induced torque disturbances, and thereby enhanced LSTM accuracy. Hence, the present investigation aims to address the constraints of prior methodologies, delivering a more precise and efficient solution for fault detection and management in satellite attitude control systems. In addition, we integrate denoising autoencoders within the LSTM architecture to ensure the optimal performance and robustness of the proposed LSTM-based fault detection approach.

To tackle issues related to RWs speeds and torque disturbances, which degrade LSTM’s efficiency, different algorithms, such as constrained PID controllers and null-space torque components, have been put forward [

7]. Islam et al. [

25] utilized a PID mechanism to wheel velocities to set benchmarks, with an objective to lengthen the periods between back-to-back momentum offload activities. Modifications to improve upon their technique were suggested by both Jalayer et al. [

26], and Belagoune et al. [

27]. These strategies mainly zeroed in on the general metrics of reaction-wheel performance, including energy usage, torque forces, and momentum holding capacity. However, none of these methods explored ways to dodge specific problematic wheel speeds, like zero speed that can cause static friction issues. Afshari et al. [

28] introduced a deep-learning based methods to find the probability of anomalies. However, this solution springs into action only when the wheel velocity exceeds a certain minimum, making its efficacy uncertain, especially during sequences of operations where subsequent shifts start from the concluding speeds of the prior movement. Wang and Xu [

29] scrutinized diverse setups of momentum retention systems, notably control moment gyroscopes, to gauge their impact on spacecraft steerability. They considered wheel alignment for the management of singularities and optimizing energy reserves, but they did not focus on particular wheel speed paths designed to minimize torque irregularities. In this project, we employed the Null-Space Torque Algorithm, leveraging redundant reaction wheels to pre-empt common disturbances. This method reduced attitude controllers’ settling time by around 40% compared to traditional techniques, and it showcases the interplay between reaction-wheel redundancy and configuration design, leading to an agile spacecraft. Using this algorithm enhances both fault tolerance and spacecraft agility, ultimately boosting the data collection rate and overall mission value [

7].

Figure 1 depicts the overall framework of our proposed algorithm. We provide a detailed description of the algorithm’s flowchart, exploring its intricacies. In

Section 1, we describe the dynamics of a spacecraft with faulty reaction wheels, highlighting associated challenges and characteristics.

Section 2 outlines the design and operation of the attitude control system, emphasizing its role in maintaining orientation. The core of our algorithm, presented in

Section 3, comprises an LSTM network tailored for fault detection in satellite systems. We explain the network’s structure and training methodology, emphasizing its effectiveness in detecting faults.

Section 5 showcases numerical tests and results, evaluating the algorithm’s fault detection performance. We discuss findings, conduct a comprehensive analysis, and address limitations and potential improvements. In the concluding remarks (

Section 5), we summarize our research’s key contributions and implications.

2. Dynamics of the Spacecraft with Faulty Reaction Wheel

In order to simulate the dynamics of a spacecraft with faulty reaction wheels, firstly we introduce the attitude dynamics of a spacecraft that uses a reaction-wheel assembly (RWA) for control torques. Such a dynamic model can be described in the rotating body frame. The governing equation for the attitude dynamics is as follows:

where the following is true:

is the inertia tensor of the spacecraft;

is the representation of the body-rate vector the body frame;

is the disturbance torque vector acting on the spacecraft in the body frame;

is the reaction wheels’ angular momentum vector in the body frame;

is the torque from the reaction wheels.

In this equation, represents the change in angular momentum of the spacecraft due to its inertia; accounts for the gyroscopic effects resulting from the spacecraft’s rotation and the angular momentum of the reaction wheels; denotes external disturbance torques acting on the spacecraft in the body frame, such as gravitational perturbations or atmospheric drag; and is the control torque generated by the reaction wheels in the body frame, used to adjust the spacecraft’s attitude. The following is noted: “We estimated that solar radiation pressure torque is less than N⋅m for our satellite, which is significantly smaller than the reaction-wheel torque capacity and the disturbances we modeled. Therefore, we omitted these terms to simplify the analysis without compromising the accuracy of the simulation results”.

Reaction wheels’ angular momentum vector in the body frame,

, can be expressed as follows:

where

is the reaction wheels’ configuration matrix;

is their inertia tensor in the reaction-wheel frame;

is the wheel speed vector for the entire RWA represented in the reaction-wheel frame. The inertia tensor and wheel speed vector can be written as follows:

and

These disturbance torques are modeled according to a referenced study [

29]. The attitude dynamics Equation (1) and the RWA angular momentum Equation (2) together provide a comprehensive representation of the spacecraft’s attitude dynamics in the presence of an RWA. This understanding is crucial for designing effective control strategies and ensuring accurate spacecraft orientation and stabilization.

2.1. Faulty Reaction Wheel’s Mathematical Model

Having the general spacecraft attitude equation, as in Equation (1), we can introduce reaction-wheel faults into the dynamics model of the spacecraft with a reaction-wheel assembly (RWA). In this section, we formulate a model of an RW by taking into account its bearings as well as the motor. The RW torque originates from the motor torque and is influenced by disturbances such as static friction , rotor mass imbalance-induced resonance and viscous bearing friction . The following subsections elaborate on the torque models.

2.2. Motor’s Numerical Model and Fault Scenarios

The reaction wheel (RW) receives its input twisting forces from an electric motor, where the motor’s torque has a linear relationship with the electrical current, denoted as

i. The mathematical representation of the electric motor can be articulated as follows:

In this equation, and stand for the constants related to torque and counter-electromotive force, respectively. I and L correspond to the electrical resistance and inductance associated with the motor coils, respectively. V indicates the voltage input directed towards the motor coils. Within the context of this model, we aim to explore three distinct categories of malfunctions, which are presented in this study:

Reaction-Wheel Stiction

(1) The RW stiction arises from the static friction torque of the bearing, which consistently opposes the wheel speed direction. This stiction can result in significant tracking errors when the rotor alters its direction, causing an instantaneous change in the stiction direction. The stiction can be modeled by the following equation:

where

defines the stiction magnitude. It is noted that

is selected based on empirical data from reaction- wheel specifications provided by manufacturers. In this study, we use a value of

= 4 × 10

−3 N, which corresponds to typical static friction levels observed in small satellite reaction wheels [

29]. This value ensures that our simulations accurately reflect realistic operating conditions and the effects of stiction on the system’s dynamics.

Fault Scenario: The stiction magnitude in a faulty reaction wheel may change in several ways. In this study, we assume there is increased friction within the wheel’s bearings or other mechanical components, which increases the stiction magnitude. This could be caused by worn-out or damaged bearings, misalignment, or inadequate lubrication.

Reaction-Wheel Resonance

(2) Jitter is the term used for vibrational disturbances usually from a mass imbalance of a spinning RW. The jitter-induced resonance torque can be formulated as follows:

where

defines the jitter amplitude,

h is the resonance number, and

is a random phase within the range

. Additionally,

represents the wheel speed at resonance, and

is the amplification factor due to structural resonance, which we assume to be the maximum according to [

30].

Fault Scenario: We assume excessive vibration, characterized by increased . This could be due to an imbalance in the wheel, a worn-out bearing, or a software issue causing the wheel to spin at an inappropriate speed. The vibration results in jitter, which could interfere with sensitive instruments or equipment onboard the spacecraft, possibly leading to failure.

(3) Viscous Friction-based Fault

The Torque induced by viscous friction of a reaction wheel opposes the wheel speed, with its magnitude being proportional to the wheel speed:

where

is a constant to be calculated or given.

Fault Scenario: We assume there is an increase in the viscous friction within the reaction-wheel assembly due to a problem such as degraded lubrication or wear and tear in the bearings. This would be represented by an increase in the value of , which is typically constant in normal conditions. As increases, the opposing torque also increases for a given wheel speed . This increase in viscous friction causes the reaction wheel to consume more power in order to maintain the same wheel speed, potentially draining the spacecraft’s power reserves faster than expected. This can also generate excess heat, which could damage the wheel itself or other nearby components if not properly dissipated. Moreover, the increased torque due to viscous friction could also make the RW less responsive to control inputs, thereby affecting the spacecraft’s ability to maintain its desired attitude. Specifically, the spacecraft might start to drift from its desired orientation or fail to accurately point its instruments at its targets. If the lubrication issue or bearing wear worsens, the wheel might eventually seize or fail, which could lead to a loss of attitude control in the spacecraft, potentially causing mission failure.

2.3. Null-Space Algorithm

In this document, we discuss how issues like stiction and resonance in reaction wheels (RWs) are closely related to the rotational speed of the wheels. By carefully planning the speed profile for each wheel, one can steer clear of problematic speeds, specifically zero speed and the resonance velocity. We employ a specialized algorithm for optimal torque distribution that takes advantage of the extra degrees of freedom provided by the surplus RWs, in order to establish an appropriate wheel speed regimen. This, in turn, helps in maintaining the essential torques dictated by the control law. Mathematically, this concept can be formulated for a reaction-wheel assembly (RWA) composed of

n wheels as follows:

The optimization function J in Equation (11) is designed to minimize wheel speeds at problematic velocities, thereby reducing torque disturbances that can affect the spacecraft’s attitude control. In real-time control, this optimization directly influences the torque commands sent to the reaction wheels. By minimizing J, the algorithm actively avoids wheel speeds that could cause stiction or resonance, ensuring smoother and more reliable control responses. This proactive approach enhances the system’s ability to maintain precise attitude control, reduces the likelihood of control saturation, and improves overall mission performance by preventing potential disruptions caused by wheel-induced disturbances.

In this discussion, we explore how the prescribed speed for the i-th wheel and the critical avoidance speeds are factored into the model. These speeds can correspond to either zero speed (to circumvent stiction) or a specific resonant speed. The objective function incorporates constants and to adjust the weighting.

The function features an exponential component shaped like a bell curve, peaking at when the absolute value of matches . The term becomes negligible as diverges from . This implies that oscillations in the wheel’s structure could be triggered by either positive or negative speeds at the resonant frequency. The constant modulates the curve’s width, implying a noteworthy exponential term only if the wheel speed is situated within a specific boundary around termed the “impact zone”. The dimension of this zone inversely correlates with and can be adjusted based on the wheel’s resonant characteristics.

Furthermore, the exponential factor is scaled by the slew duration t. This allows for recovery time for the rate control mechanism in instances where avoiding is unfeasible, thus minimizing the settling period. This demonstrates that the optimization function penalizes wheel speeds near zero, effectively steering the wheel speeds away from the stiction region.

By visualizing the impact of the exponential term, we show how the optimization function shapes the wheel speed profile to minimize disturbances in practical applications

Besides sidestepping zero and resonant speeds, the model includes other variables in the objective function. For subsequent maneuvers to have adequate margins for error, the model aims to minimize the final wheel speeds after each action. Keeping the spacecraft’s stored momentum low benefits the performance of linear fine-pointing control systems. Also, in order to mitigate wheel speed saturation and control energy consumption, the model penalizes excessive wheel speeds. In summary, the complete objective function aims to optimize a host of variables, including critical avoidance speeds labeled as

, while also factoring in considerations like energy use and system responsiveness.

Because of the exponential term, the optimization function penalizes wheel speeds near zero, effectively steering the wheel speeds away from the stiction region. For example, let C1 = 5, C2 = 0.01, and ωs = 0 (to avoid zero speed); in such case, the exponential term peaks at , and it decreases rapidly as the wheel speed moves away from zero.

It is important to understand that evaluating Equation (12) needs the speeds for each reaction wheel (RW) within the reaction-wheel assembly (RWA), denoted as . These profiles can be estimated by calculating the integral of the predetermined wheel torques, acknowledging that small speed variations due to reactive torque are unpredictable. When a specific algorithm for torque distribution is utilized, the desired control torques for the spacecraft body, denoted as , are converted into the set torques for the wheel, . The control system then activates the electrical motors within the wheels to realize the anticipated torque, although the true torque output may also include unanticipated disturbances.

In this context, we employ a “null-space strategy”, which primarily uses the pseudoinverse method for torque allocation while also invoking null-space torques to counteract disturbances. Null-space torques become relevant when there are more than three RWs that are not aligned in a plane. These torques are characterized by a zero projection onto the body frame , where is the configuration matrix for the RWA, and is the null-space torque vector.

The null-space torques can be conveniently expressed as , where N is the null-space matrix, defined in terms of , and is a vector containing the scaling parameters for the null space. The value of A can be arbitrary since its projection in the body frame is consistently zero. In essence, the null-space matrix N is unique to a given RWA, implying that identifying the null-space torques is equivalent to determining the null-space scaling parameters A.

In this approach, the pseudoinverse method (also known as the Moore–Penrose inverse) is initially employed to guarantee that the RWA delivers the necessary control torque

. Subsequently, the null space is harnessed to fine-tune the wheel speed profiles to optimize the cost function. This is mathematically represented through the pseudoinverse operation on the configuration matrix

.

where

Note that

is a vector in the wheels frame that makes the required

in the body. Now, the control torques can be written as follows:

which yields the following wheel speed equation:

It should be noted that the commanded torques must fall in the range of the maximum and minimum torque capacity of the wheels, and final calculated speeds must also remain within the min/max range of the speeds:

In an ideal setting, the best null-space scaling parameters, denoted as

, would be calculated as a time-continuous function. Nonetheless, due to the objective function’s (Equation (11)) complex and discrete nature, finding individualized

values at every moment during the slew would not be practical for the majority of optimization algorithms. As a result, we compartmentalized

into four distinct regions, each characterized by a constant

value. These specific regions align with various stages of a standard trapezoidal-like slew, which is described as follows:

where

, and

are all vectors that can be calculated via the following minimization:

subject to the following constraints:

3. Attitude Control Approach

A key focus of this study delves into the influence of reaction wheel (RW)-generated disturbances on the spacecraft’s orientation management systems. For this investigation, we assume a commonly used hybrid control law that integrates both feedforward and feedback components, particularly when handling large-angle slews. We selected the hybrid control law over a pure PD (proportional-derivative) control strategy because it combines the benefits of feedforward planning and feedback correction, which is particularly advantageous for large-angle slews. The feedforward component allows the controller to anticipate the required torque to achieve the desired angular acceleration, improving efficiency and reducing the time to reach the target orientation. In contrast, a pure PD controller reacts only to errors without anticipating future states, which may result in longer settling times and potential overshoot, especially in large-angle maneuvers. The hybrid control law enhances performance by providing a planned torque profile while still correcting for disturbances and modeling inaccuracies through the feedback component.

By comparing the two approaches, we find that the hybrid control law offers improved agility, better disturbance rejection, and more precise control, making it more suitable for the demanding requirements of satellite attitude control during large-angle slews.

The torque in our control law is determined from the satellite’s orientation dynamic equations and the anticipated influence of the gravity gradient. Drawing on the frameworks discussed earlier in this paper, the feedforward torque variables, denoted as

, can be derived for a specified target spacecraft angular velocity

and angular acceleration

as follows:

The feedback control torque is designed to offset discrepancies originating from unforeseen disturbances, including those potentially generated by reaction wheels. During a slew, the feedback control mechanism functions in two separate phases: the rate-based slew controller and the fine-tuning pointing controller. The rate-based slew controller is engaged, while the pre-planned slew rate is non-zero, applying a conventional proportional-derivative (PD) control scheme to adhere to a designated angular velocity path , which eventually culminates in a precise pointing direction. This phase of control presumes that angular velocity is captured by gyroscopic sensors attached to the spacecraft, denoted as . It is also noted that Equation (21) includes the gravity gradient torque term , where μ is the Earth’s gravitational parameter, and is the position vector from the Earth’s center to the spacecraft in the body frame. The gravity gradient torque is significant primarily in low Earth orbits (LEO), where the Earth’s gravitational field exerts a noticeable torque on satellites with asymmetric mass distributions. It becomes less significant at higher altitudes due to the dependency. In our study, we consider gravity gradient torque because it can influence the spacecraft’s attitude, especially for missions requiring high pointing accuracy. By including this term, we ensure that the control system accounts for this disturbance when it is significant, enhancing the robustness and precision of the attitude control.

The fine-tuning pointing controller kicks in right after the rate-based slew controller concludes its trajectory at the planned angular velocity of zero. This controller also employs a PD control scheme with the goal of neutralizing any lingering angular discrepancies, depicted in quaternions, that may have accrued during the slew due to non-compensated disturbances. The overall control torque exerted, symbolized as , is a composite of the feedforward torques (which are non-zero only during the pre-planned slew) and the feedback torques .

3.1. Architecture and Optimization of LSTM Network for Fault Detection in Satellite Systems

As articulated in

Section 1, LSTM with denoising can be a suitable approach for satellite fault detection of reaction wheels due to its capability to model complex temporal-spatial patterns in noisy, high-dimensional flight data. Denoising LSTMs are designed to filter out noise and capture underlying patterns in the data, making them well suited for identifying subtle changes in system behavior that could indicate potential faults. By processing the flight data with a denoising LSTM, it is possible to produce a denoised time series that is more suitable for fault detection. This denoised time series can then be analyzed using appropriate techniques to detect faults in the reaction wheels of the satellite, enabling timely maintenance and corrective action to be taken. In this research, we use the mentioned benefits of the LSTM for satellite reaction-wheel fault detection via the steps explained in the pseudocode presented in

Table 1. In the succeeding portion of this section, we delve into a detailed elucidation of the Long Short-Term Memory (LSTM) architecture, along with delineating the methodology for modeling time series data employing LSTM networks.

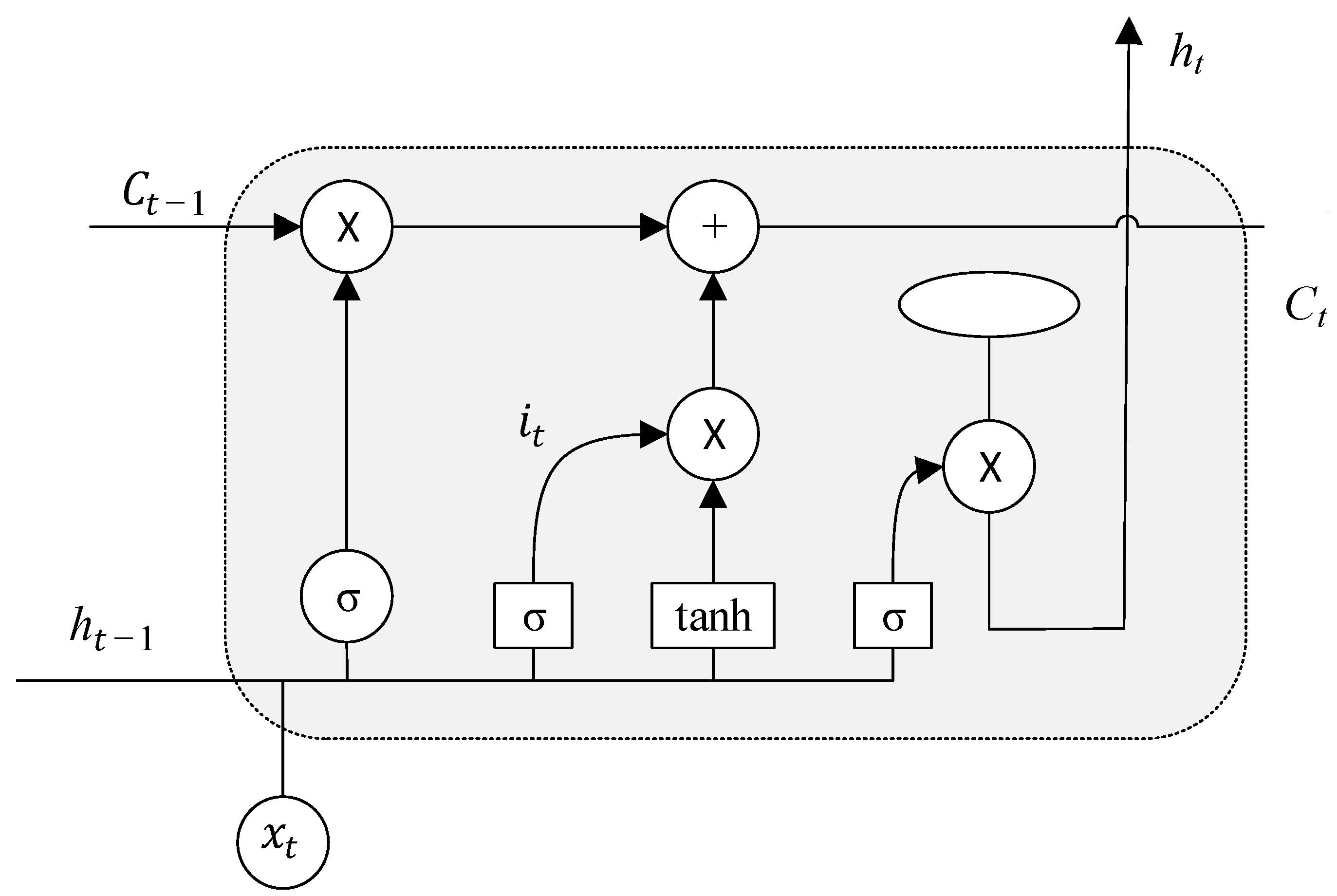

3.2. LSTM Network Architecture

In using LSTM to identify faults in satellite reaction wheels, the first step involves deciding what information from the sensor data to discard from the cell state. This is accomplished using a “forget gate”. Next, we need to determine what new information will be stored in the cell state from the sensor readings. This involves two parts. Firstly, an “input layer” decides which values will be updated. Then, a new set of candidate data, representing potential faults, is created to be added to the cell state. Following this, these two parts come together to update the state. The previous state is adjusted by the forget gate value to disregard irrelevant information. Then, we add the new candidate data from the input gate, providing an updated state reflecting potential faults. Finally, we must decide what will be outputted to potentially signal a fault. This output is a filtered version based on our updated cell state. Firstly, a layer decides which parts of the cell state will be outputted. Then, we take the cell state, process it through a function (giving values between −1 and 1), and multiply it by the output of the previous layer. The parts we decide to output will be the final output, potentially signaling a fault in the satellite’s reaction wheels. For a visual understanding of this LSTM layer process, please refer to

Figure 2. In this figure,

represents the states,

is the input, each element in the cell state is represented by

, and the forget gate is shown as

f.In our study, we employed an LSTM network specifically adapted for fault detection in satellite attitude control systems. Rather than detailing standard LSTM operations like the forget gate and cell state, we focused on integration of denoising autoencoders within the LSTM framework. This adaptation enhances the network’s ability to handle noisy input data, which is a common challenge in satellite telemetry.

In our study, we used an LSTM network along with the SGDM (Stochastic Gradient Descent with Momentum) optimizer for finding faults in satellite reaction wheels (as presented in [

31]). The SGDM optimizer is a bit different from the usual Stochastic Gradient Descent (SGD). While SGD changes the network settings like weights and biases little by little, going against the direction of the loss function’s gradient, SGDM makes this process better by adding momentum.

3.3. Time Series Modeling Utilizing LSTM Networks

The objective of time series modeling is to construct a prognostic model that harnesses historical data to project future values. In the context of an LSTM-based fault detection methodology, discrepancies from these anticipated values could potentially indicate a fault. Within the purview of this study, we employed LSTM to predict the satellite’s body rates. By leveraging the mean squared error between the predicted value and the simulated response, we can discern the operational status of the system’s reaction wheels, thereby identifying potential faults. In this work, we implement Long Short-Term Memory (LSTM) for time series prediction, as illustrated by the schematic in

Figure 2. The LSTM is designed to handle sequences, making it ideal for time series data.

In the LSTM architecture depicted, the state at each time step t is represented by , the input at each time step is , and each element in the cell state is represented by . The forget gate, crucial to LSTM operation, is represented by . The operations within an LSTM cell are summarized as follows:

- (1)

The forget gate

decides what information to discard from the cell state. This is determined by a sigmoid function, which outputs a value between 0 and 1 for each number in the cell state

:

- (2)

An input gate

decides what new information to store in the cell state, and a tanh layer creates new candidate values

, which could be added to the state:

The cell state

is updated to the new state:

Finally, the output gate

decides what part of the cell state is going to be outputted:

In the above equations, represents the weight matrix for the forget gate in the LSTM cell. This matrix, when multiplied by the concatenated matrix of the previous hidden state and the current input and then added to the bias term (), is passed through the sigmoid function to decide which information should be kept (and which should be forgotten) in the cell state. Using these operations, the LSTM can predict the time series by learning these patterns over the input sequence x, and the output h represents the prediction for the next time step. Discrepancies between these predictions and actual sensor readings can signal potential faults in the satellite’s reaction wheels.

To illustrate how the LSTM output is used for fault detection, consider a scenario where the network predicts the satellite’s body rates. Under normal conditions, the predicted body rate closely matches the actual body rate yt. However, when a fault occurs, this prediction deviates significantly.

In tuning our LSTM network, we considered trade-offs between computational efficiency and model accuracy. Increasing the number of units or layers can enhance the network’s capacity to learn complex patterns but at the cost of longer training times and higher computational demands. Conversely, a smaller network is faster but may underfit the data. We conducted a grid search over hyperparameters such as the number of LSTM units, learning rate, and batch size. Ultimately, we selected a model configuration that balances accuracy and efficiency, using 64 LSTM units and a learning rate of 0.001, which provided robust fault detection without prohibitive computational costs.

The synthetic data generated for our simulations include realistic noise profiles and disturbances to emulate actual satellite operating environments. We incorporated sensor noise characteristics based on specifications from space-grade gyroscopes and reaction wheels. Additionally, we modeled environmental disturbances such as solar radiation pressure, magnetic field interactions, and cosmic radiation effects. These considerations ensure that our LSTM network is trained and tested on data that closely mirror the conditions encountered during satellite missions.

4. Numerical Simulations and Results

Numerical simulations were performed to evaluate the proposed LSTM-based fault prediction algorithm algorithms. This section describes the tests and their results.

4.1. Test Setup

In this research, a nano-satellite was employed as the representative spacecraft to showcase the techniques. The assumed inertia tensor of the satellite was denoted as

. The maximum speed of the wheels taken into account was 1200 rad/s, and further details regarding the reaction wheels (RWs) can be found in

Table 2. The parameters listed in

Table 2, such as stall torque and rotor, were sourced from the specifications of commercially available small satellite reaction wheels, such as those provided by Blue Canyon Technologies and Sinclair Interplanetary. By using actual hardware specifications, we ensured that our simulations and results are relevant to real-world satellite systems. It should be emphasized that all RWs utilized in the experiments were presumed to be identical, with an initial wheel speed of 5 rad/s.

Table 3 presents the constants employed for the objective function in this study. It is important to acknowledge that the occurrence of disturbances in RW torque may lead to extended settling durations. To establish a basis for comparison, this investigation defines a controller as settled on a given target once the norm of the pointing error falls below 0.001 rad. At this stage, the controller can commence the subsequent slew. One advantageous aspect of the torque allocation approach is its capability to optimize wheel speed patterns across multiple slews, thereby enhancing the spacecraft’s agility and reducing the total time required to maneuver towards and stabilize at a series of designated pointing targets.

Our technique is designed to detect faults within the operational limits of small satellite reaction wheels, as specified in

Table 2. We simulated faults such as increased stiction torque up to

, resonance effects at critical speeds, and viscous friction coefficients up to ten times the nominal value. The method is effective for faults that manifest as deviations in torque output or wheel speed within these ranges. Extremely severe faults leading to immediate wheel failure or faults outside these specifications may require additional detection methods.

In order to assess the efficacy of the torque allocation approach, a comparison was made against the conventional pseudoinverse solution utilizing a reaction-wheel assembly (RWA) consisting of four wheels, with a configuration matrix defined in Equation (28). The evaluation comprised commanding a series of five sequential slews, each highlighting distinct wheel speed profiles. The initiation of each new slew was contingent upon the successful settling of the preceding one, adhering to the specified settling criteria outlined in the previous section.

4.2. Simulation Platform and Training Data Generation

To overcome the challenges of obtaining substantial fault data from real satellite missions, we implemented a simulation-based approach using MATLAB (R2023b). This study focused on generating synthetic data from satellite reaction wheels under various fault conditions, including reaction-wheel (RW) stiction, resonance, and viscous friction, as discussed in

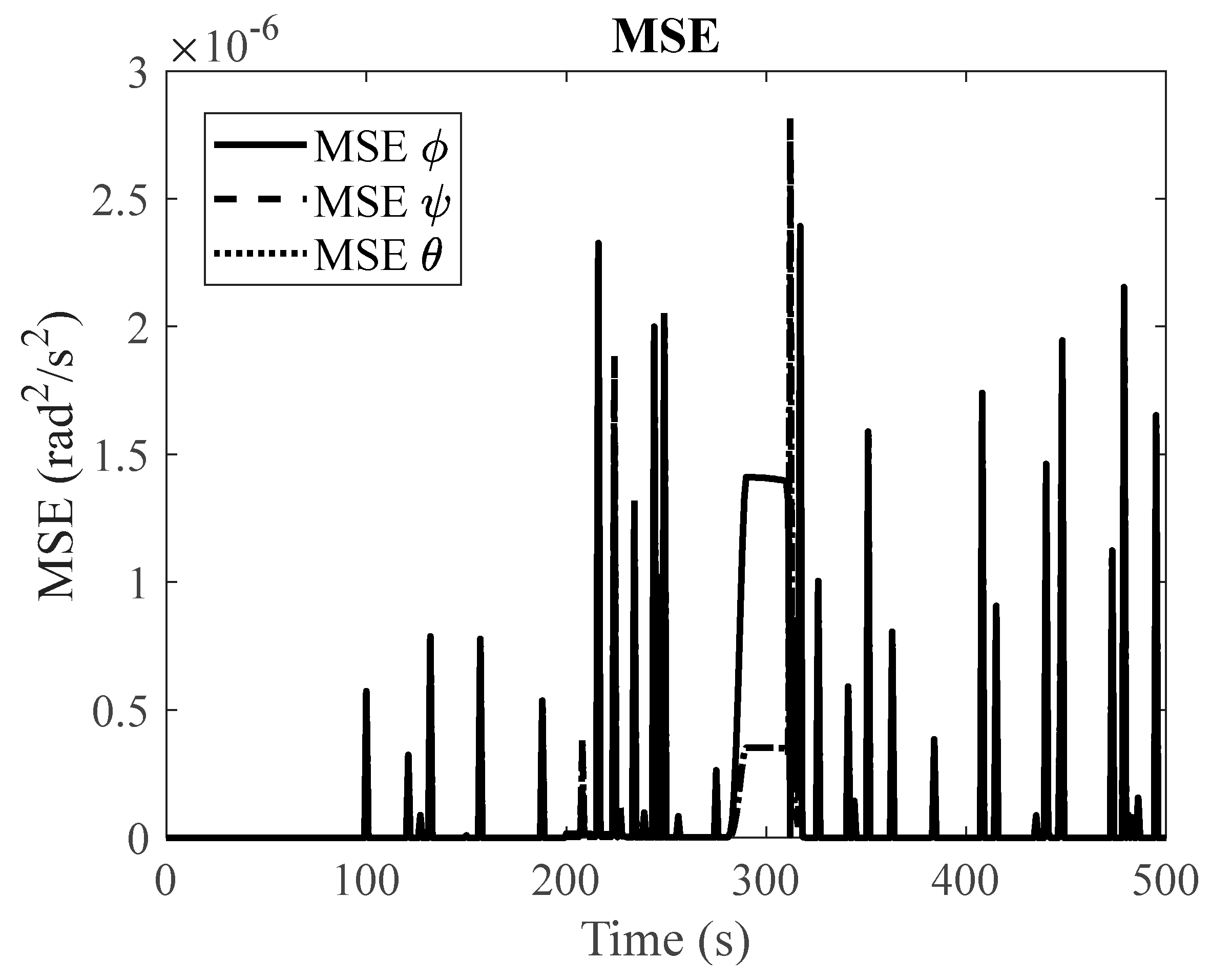

Section 2.1. The synthetic data, with a time step of 20 ms, consisted of the body rates of the satellite that are instrumental in detecting faults. The LSTM network served as the core of our fault detection system. By utilizing the simulated satellite sensor data, both with and without faults, the network learned to identify faults based on patterns in the body rates. This ability was then tested on the unseen dataset, providing a practical measure of its performance. At the end, we applied the Mean Squared Error (MSE) as a key metric to judge the quality of the LSTM predictions. In specific terms, we measured the MSE between the predicted and simulated body rate responses. If the MSE exceeded a predetermined threshold, the reaction wheel was classified as faulty.

4.3. Simulation Results

The satellite system delineated in

Section 2 served as the experimental testbed for evaluating the performance of our LSTM-based fault detection system. Through simulations, the temporal variations in reaction-wheel speed were plotted for both the pseudoinverse method and the null-space method with their corresponding satellite body rates under varying fault scenarios as well as in the absence of faults. Notably, for the LSTM network training, 1000 body rate values were utilized as input. The trained LSTM network was subsequently employed to predict the nominal response, which was then compared with the simulated responses, both faulty and healthy. The findings obtained from this process are systematically presented in the ensuing section.

(1) Null-Space Algorithm: To assess the effectiveness of our proposed algorithm, which employs an LSTM-based fault detection method with redundant reaction wheels, we began by simulating the satellite system’s slew performance under normal operating conditions. In addition, we conducted simulations for three distinct fault scenarios. When encountering faulty conditions, we generated graphical representations that display the Mean Squared Error (MSE) between the LSTM-based predicted response and the simulated faulty response. If the MSE exceeded the fault threshold, it served as an indication of a potential fault within the system.

Figure 3 and

Figure 4 showcase the slew performance of the Null-Space Algorithm, illustrating the reaction-wheel speeds and body rates, respectively.

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12 and

Figure 13 present the simulation results for faulty reaction wheels, with three different faults, along with the LSTM prediction and their corresponding MSE.

4.4. Discussion

To verify the efficacy of our fault detection methods, we utilized three key performance metrics, namely the True-Positive Rate (TPR), False-Positive Rate (FPR), and overall Accuracy (Acc).

The True-Positive Rate (TPR), also known as sensitivity or recall, measures the proportion of actual positives that are correctly identified. In our context, this refers to the percentage of actual faults that our system correctly detects.

The False-Positive Rate (FPR), referred to as the fall-out, gauges the proportion of negative instances that are falsely flagged as positive. In our case, this indicates the percentage of non-fault events that our system incorrectly flags as faults.

The Accuracy (Acc) provides a holistic measure of the system’s performance. It calculates the proportion of total predictions (both positive and negative) that are correct.

Furthermore, we evaluated the system’s performance across varying fault intensities, specifically at 90%, 50%, and 30% of the maximum possible magnitude. These investigations, designed to emulate real-world variability, offer a thorough understanding of the system’s response to diverse fault scenarios. The outcomes from these evaluations are encapsulated in

Table 3. In most cases, we aim for a high TPR and a FPR. A high TPR is desirable, as it indicates that the system is effectively identifying true-positive instances; i.e., actual faults are accurately detected. A high TPR signifies a sensitive system capable of detecting most true faults. A low FPR is preferred, as it suggests that the system rarely makes false alarms; i.e., it does not frequently misclassify non-fault situations as faults. A low FPR implies a precise system that can correctly disregard most non-fault instances. However, the balance between TPR and FPR is highly dependent on the application and the costs associated with false positives and false negatives. For some applications, it may be more important to have a higher TPR (even at the cost of increasing FPR) if the consequences of not detecting a true positive are severe. Conversely, in other applications, maintaining a low FPR may be more crucial if the repercussions of false alarms are high. Therefore, it is always important to adjust the system based on specific requirements and contexts.

In our fault detection system, setting the threshold for anomaly detection is crucial in balancing the True-Positive Rate (TPR) and False-Positive Rate (FPR). We employed Receiver Operating Characteristic (ROC) curve analysis to determine the optimal threshold. By plotting TPR against FPR for various threshold values, we identified the point that offers the best trade-off. Adjusting the threshold upwards decreases FPR but may reduce TPR, potentially missing some faults. Conversely, lowering the threshold increases TPR but may result in more false alarms. Our chosen threshold maximizes the Area Under the ROC Curve (AUC), indicating a high level of overall diagnostic accuracy.

The Null-Space Algorithm leverages the redundancy in reaction-wheel assemblies with more than three wheels. It optimizes torque distribution not only to achieve the desired control torques but also to minimize wheel speeds that could lead to resonance. By incorporating an optimization objective that penalizes wheel speeds near known resonance frequencies, the Null-Space Algorithm actively avoids operating conditions that exacerbate resonance-induced disturbances. In contrast, the pseudoinverse method focuses solely on achieving the required control torques without considering individual wheel speeds or resonance avoidance. This can result in some wheels operating at speeds that trigger resonance, leading to increased vibrations and control issues. Therefore, the inherent design of the Null-Space Algorithm, which optimizes both torque allocation and wheel speed profiles, allows it to handle faults like resonance more effectively than the pseudoinverse method. Finally to show how the presented method performs as compared to some benchmarks, we have provided two tables.

Table 4. presents the fault detection accuracy in terms of some performance metrics and

Table 5. compares performance metric of the proposed method vs. the baseline methods in the literature.

From the results, we can see the use of deep learning techniques, specifically LSTM networks with denoising autoencoders, offers significant benefits in terms of improved fault detection accuracy and the ability to handle complex temporal patterns in noisy data. The main costs involve the computational resources required for training and the need for sufficient data to effectively train the models. However, considering the high value of satellite missions and the potential costs associated with undetected faults, the benefits of early and accurate fault detection outweigh the costs. Additionally, advances in computational hardware and optimization algorithms continue to reduce the barriers to implementing deep learning solutions in this domain.

5. Conclusions

In this study, we introduce a method based on LSTM deep learning to detect faults in satellite attitude control systems. Specifically, we focused on systems that rely on reaction wheels (RWs). Our approach effectively mitigated the negative impacts of torque disturbances related to velocity by integrating a torque allocation algorithm that utilizes redundant RWs. The results of our experiments demonstrated high accuracy in fault detection, improved system reliability, and enhanced performance. We validated the effectiveness of our proposed method in real-world scenarios, and we believe it can contribute to the existing range of fault detection and control techniques in satellite attitude control systems. To strengthen the robustness of our model in noisy data environments commonly encountered in space missions, we integrated denoising autoencoders within the LSTM architecture. This further improved its ability to function effectively. Our proposed method achieved a True-Positive Rate of 95% and a False-Positive Rate of 5%, outperforming traditional methods by approximately 7% in TPR and reducing FPR by 5%. Additionally, the Null-Space Algorithm reduced the attitude controller’s settling time by 40% compared to the pseudoinverse method. These results demonstrate the effectiveness of our approach in enhancing fault detection accuracy and improving system performance.

It is important to note that our model serves as a starting point and requires further refinements. For instance, its effectiveness under different operational circumstances and fault conditions needs extensive investigation. Nevertheless, our findings highlight the efficacy of advanced machine learning algorithms, specifically the LSTM-based approach, in enhancing fault detection for satellite attitude control systems. As a next step, we plan to validate our method using real satellite telemetry data obtained from CubeSat missions. This will enable us to assess the model’s performance in operational environments and refine it to handle the complexities of actual mission data. This signals an important era of intelligent and resilient space missions. Future research can focus on refining these methods and exploring their application in other subsystems of satellite technology. Through this paper, we aim to inspire further research in the integration of advanced machine learning techniques in space technology. We also intend to extend this fault detection framework to other satellite subsystems, such as power systems, thermal control units, and communication modules. Additionally, we will explore the detection of different fault types, including sensor degradation, actuator malfunctions, and software anomalies. By broadening the scope of our method, we aim to develop a comprehensive fault management system that enhances the reliability and resilience of satellite operations. This research has the potential to transform the way we conduct space missions by increasing reliability and efficiency.