Investigation of the Layer Effects Formed by W-EDM on Electrochemical Grooving of Stellite 21

Abstract

1. Introduction

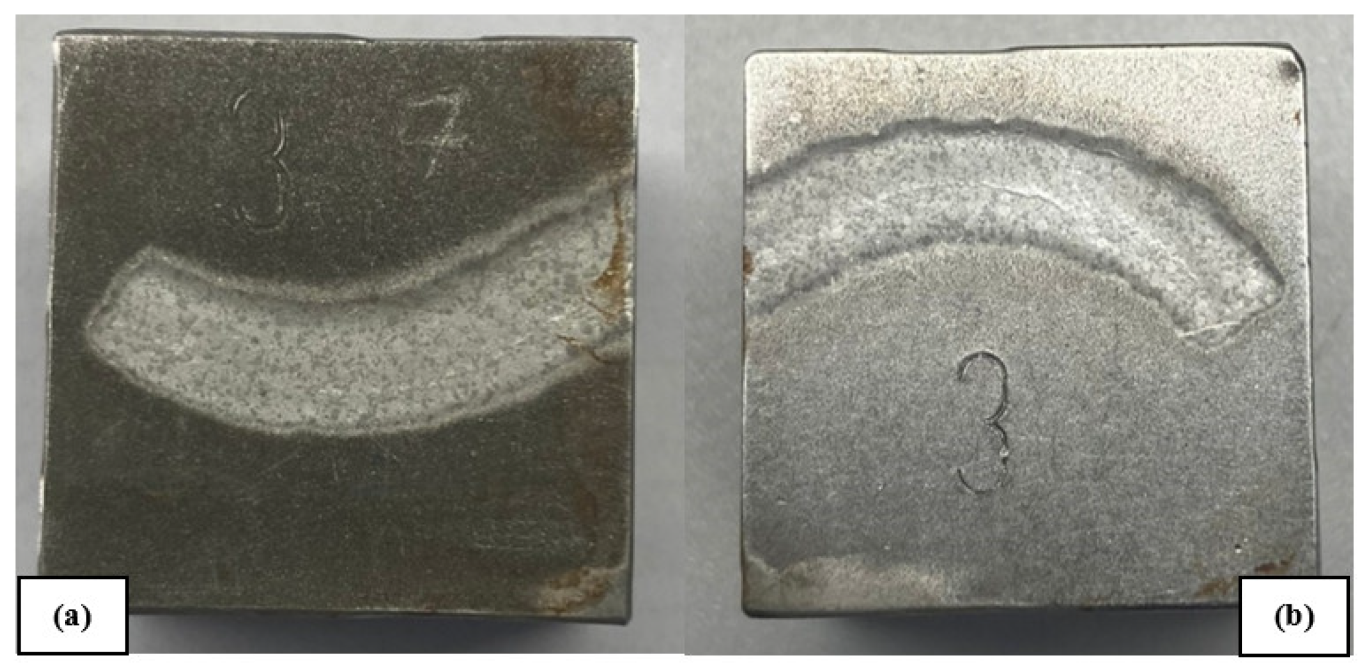

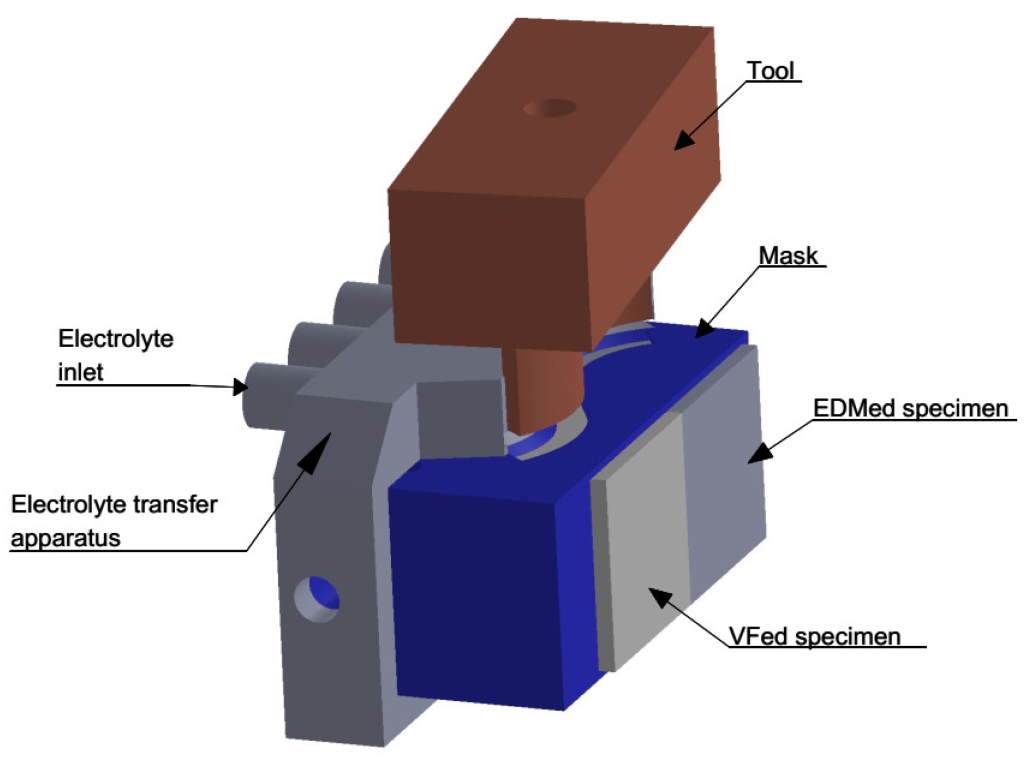

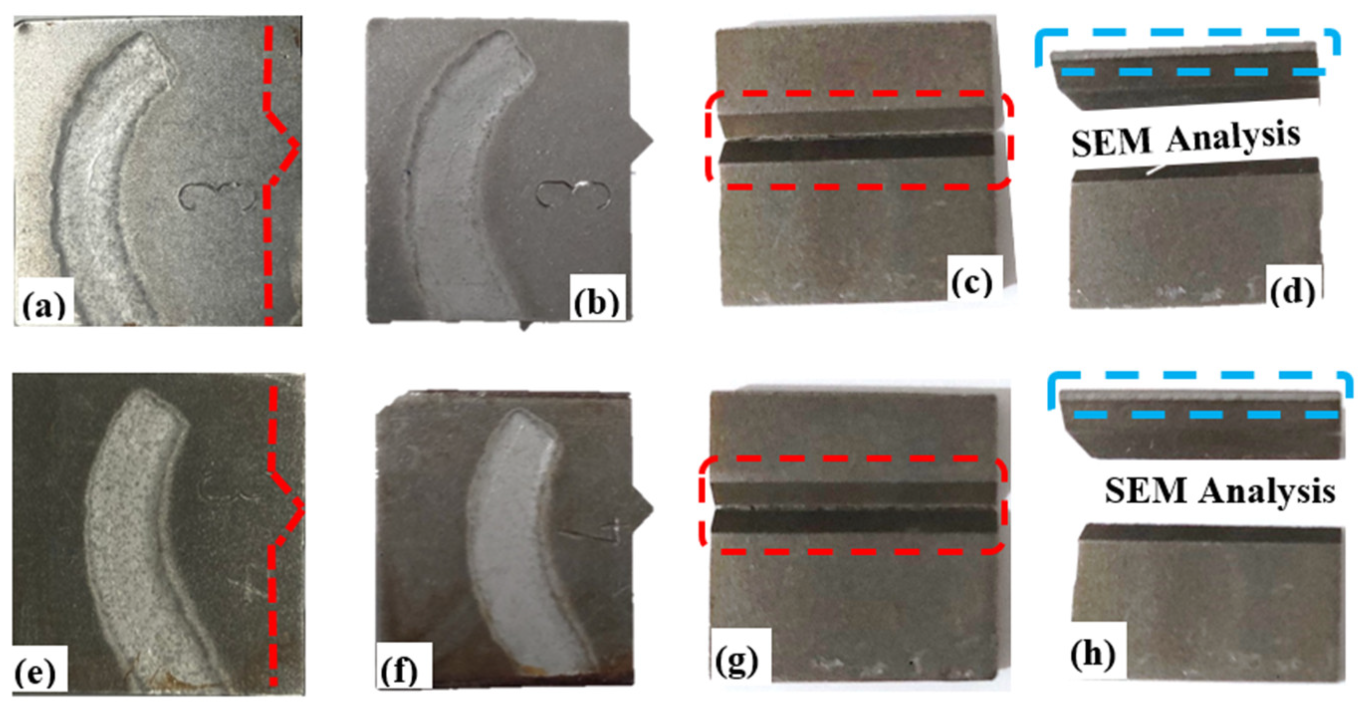

2. Materials and Methods

3. Results

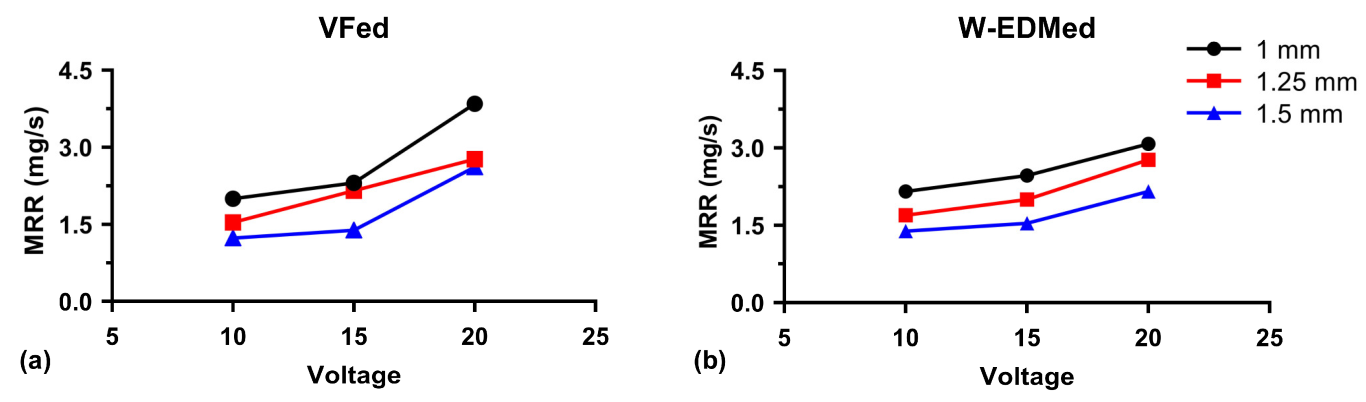

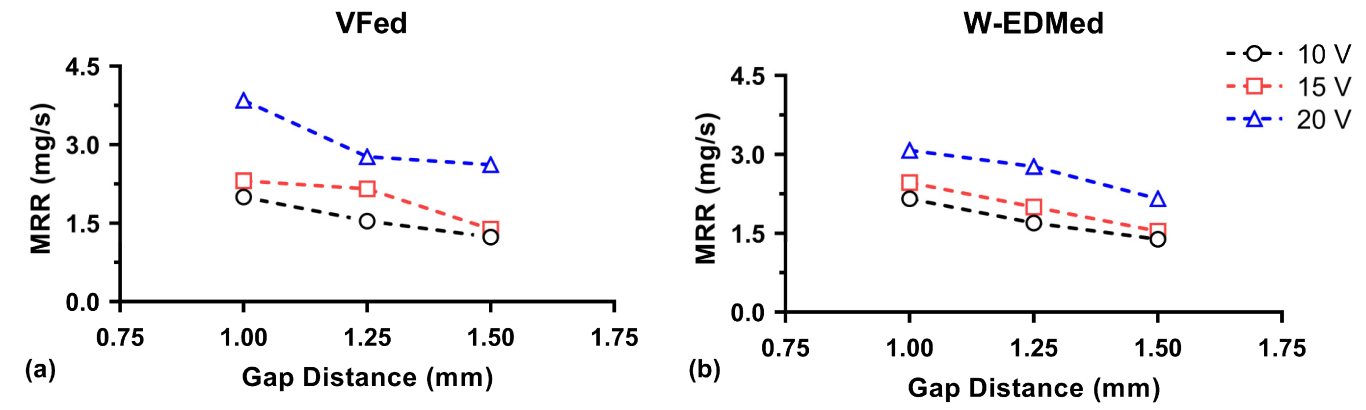

3.1. Analysis of MRR

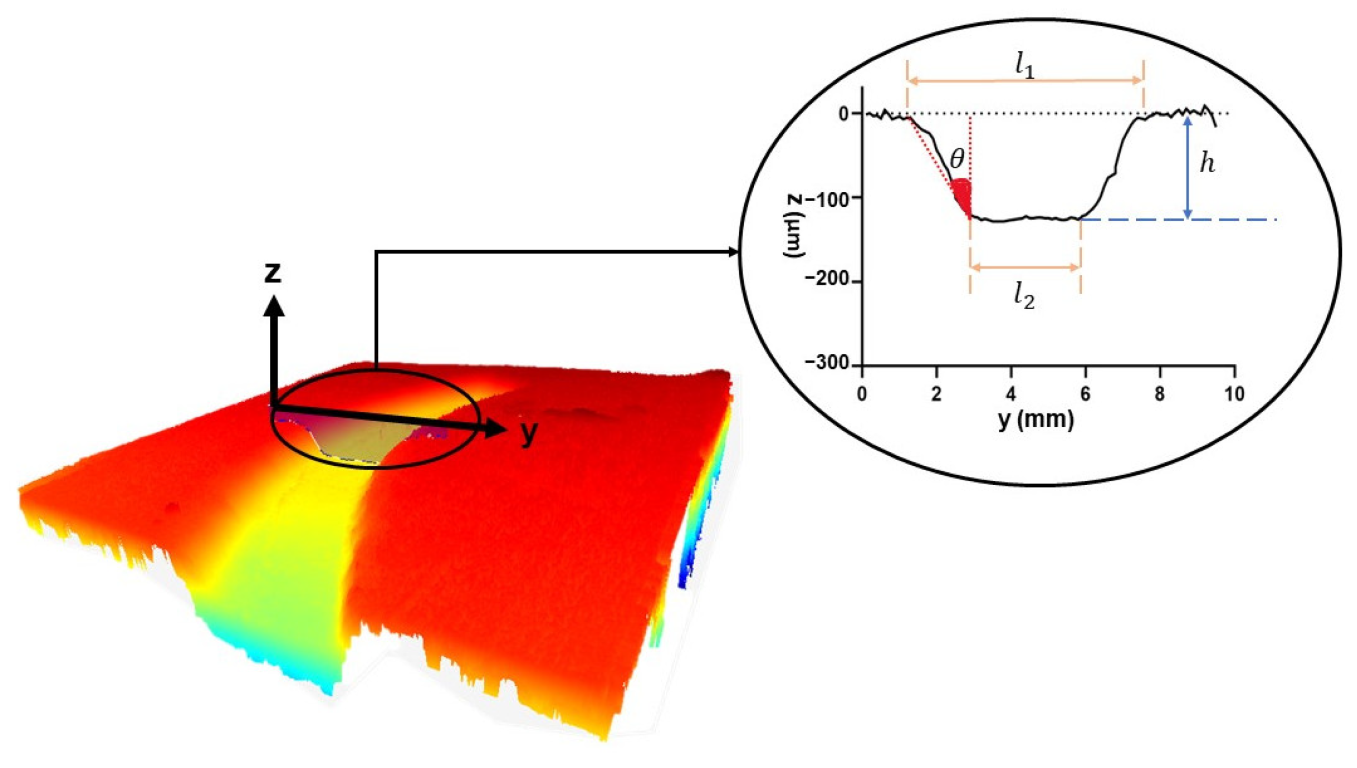

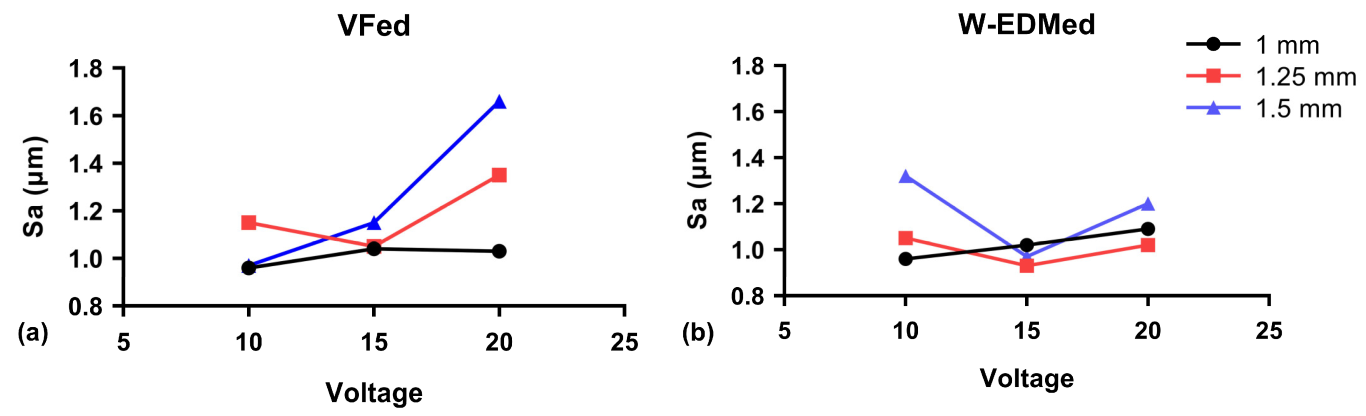

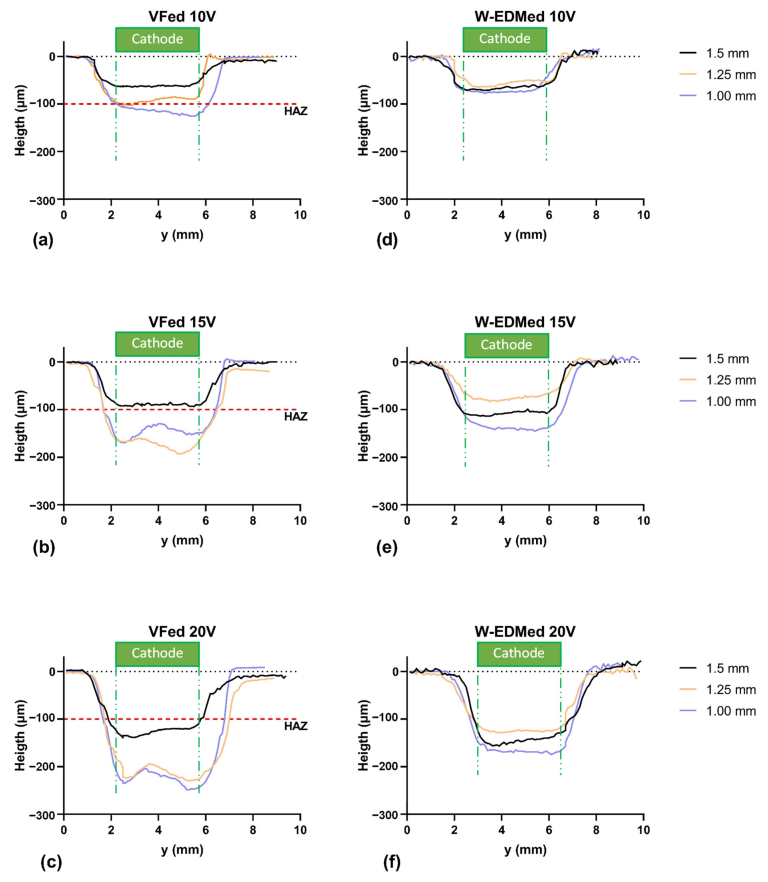

3.2. Analysis of Surface Roughness and Groove Profile

4. Conclusions

- Variation in MRR with voltage and gap distance shows a similarity to the results in literature on both surface types.

- Higher MRR values obtained for the VFed specimens show that the WL acts as a circuit element and decreases current efficiency. Also, in the W-EDMed surfaces, MRR is more predictable than in the VFed surfaces as the change in variation is lower (Figure 8).

- The effect of voltage on Sa for W-EDMed surfaces is unclear, whereas it increases Sa in VFed surfaces, particularly at the highest gap distance. This result shows that the WL has an effective role in the surface integrity of the EC grooved grooves.

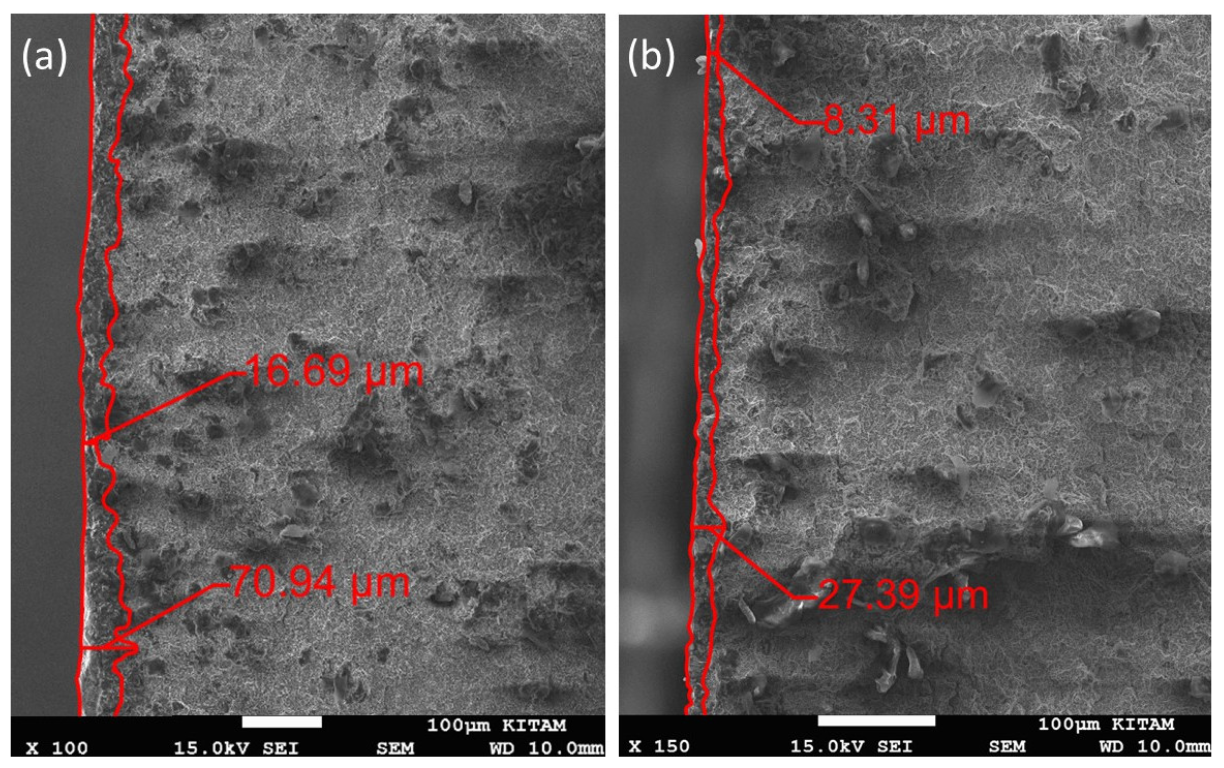

- The HAZ thicknesses in VFed parts are 50.21% and 61.39% less than in the W-EDMed parts, with the lowest and highest layer thickness values.

- At the highest voltage (20 V), the increment rate of Sa is 71.13% and 36.08% for the VFed and W-EDMed surfaces, respectively.

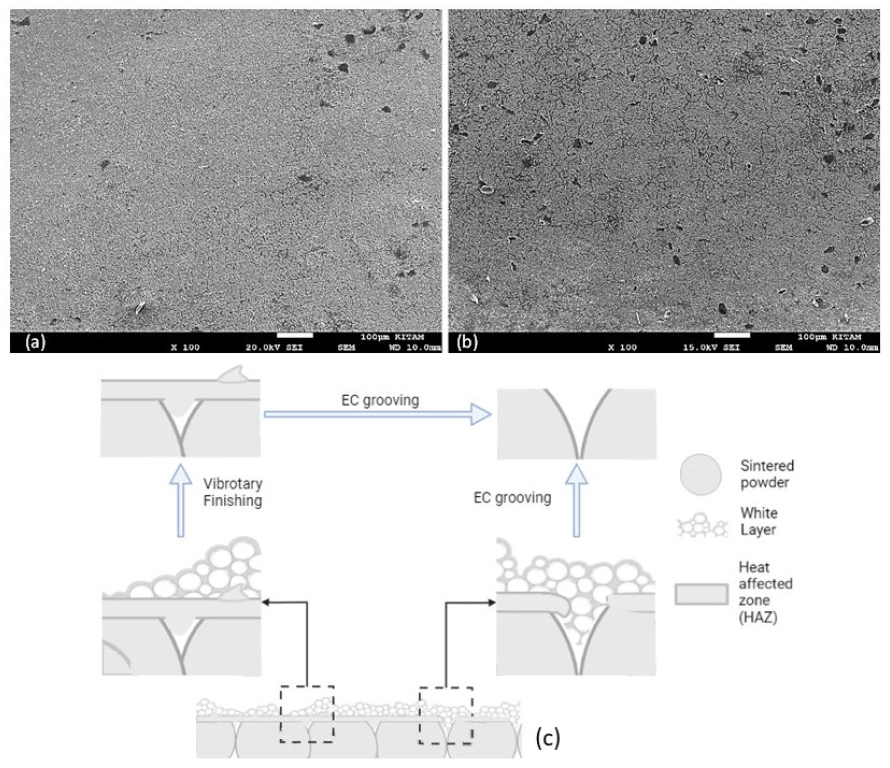

- As seen from the groove profiles (Figure 13), after approximately 100 µm, the groove loses its flatness at the bottom for the VFed surfaces. This result shows that after removing the HAZ layer via the different electrochemical dissolution rates (HAZ and surface texture), turbulence occurs in the groove. However, for the W-EDMed surfaces, the depth of the groove increases up to approximately 180 µm, and the flatness does not change substantially. This result can be attributed to the WL thickness that prevents current transition, leading to the non-removal of the HAZ layer from the machining area.

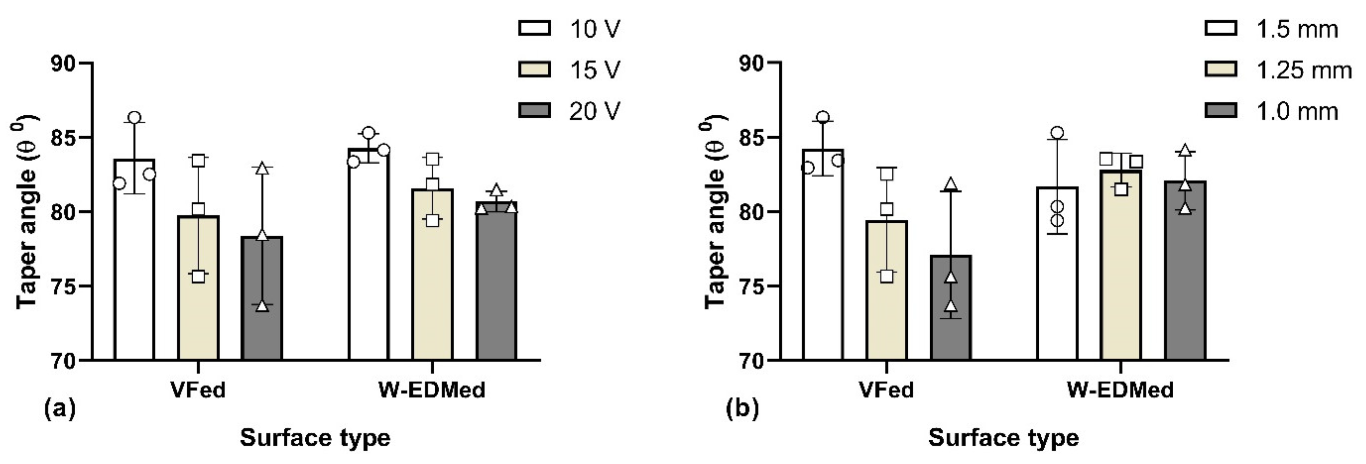

- Increases in voltage cause a decrease in taper angle for both surface types, but the range of variation is higher for the VFed surface, which is similar to MRR.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ablyaz, T.R.; Shlykov, E.S.; Muratov, K.R.; Osinnikov, I.V.; Bannikov, M.V.; Sidhu, S.S. Investigation of Plasma-Electrolytic Processing on EDMed Austenitic Steels. Materials 2023, 16, 4127. [Google Scholar] [CrossRef] [PubMed]

- Fonda, P.; Nakamoto, K.; Heidari, A.; Yang, H.-A.; Horsley, D.; Lin, L.; Yamazaki, K. A Study on the Optimal Fabrication Method for Micro-Scale Gyroscopes Using a Hybrid Process Consisting of Electric Discharge Machining, Chemical Etching or Micro-Mechanical Milling. CIRP Ann. 2013, 62, 183–186. [Google Scholar] [CrossRef]

- Mohd Abbas, N.; Solomon, D.G.; Fuad Bahari, M. A Review on Current Research Trends in Electrical Discharge Machining (EDM). Int. J. Mach. Tools Manuf. 2007, 47, 1214–1228. [Google Scholar] [CrossRef]

- Hsue, A.W.; Huang, Z.-Y. Deionized Water Electrochemical Machining Hybridized with Alumina Powder Polishing for Microcavity of M-333 Mold Steel. Processes 2022, 10, 152. [Google Scholar] [CrossRef]

- Wu, X.; Li, S.; Jia, Z.; Xin, B.; Yin, X. Using WECM to Remove the Recast Layer and Reduce the Surface Roughness of WEDM Surface. J. Mater. Process. Technol. 2019, 268, 140–148. [Google Scholar] [CrossRef]

- Klocke, F.; Hensgen, L.; Klink, A.; Ehle, L.; Schwedt, A. Structure and Composition of the White Layer in the Wire-EDM Process. Procedia CIRP 2016, 42, 673–678. [Google Scholar] [CrossRef]

- Azam, M.; Jahanzaib, M.; Abbasi, J.A.; Abbas, M.; Wasim, A.; Hussain, S. Parametric Analysis of Recast Layer Formation in Wire-Cut EDM of HSLA Steel. Int. J. Adv. Manuf. Technol. 2016, 87, 713–722. [Google Scholar] [CrossRef]

- Han, Y.; Liu, Z.; Cao, Z.; Kong, L.; Qiu, M. Mechanism Study of the Combined Process of Electrical Discharge Machining Ablation and Electrochemical Machining in Aerosol Dielectric. J. Mater. Process. Technol. 2018, 254, 221–228. [Google Scholar] [CrossRef]

- Ayesta, I.; Izquierdo, B.; Flaño, O.; Sánchez, J.A.; Albizuri, J.; Avilés, R. Influence of the WEDM Process on the Fatigue Behavior of Inconel® 718. Int. J. Fatigue 2016, 92, 220–233. [Google Scholar] [CrossRef]

- Wu, S.; Liu, G.; Zhang, W.; Chen, W.; Wang, C. Formation Mechanism of White Layer in the High-Speed Cutting of Hardened Steel under Cryogenic Liquid Nitrogen Cooling. J. Mater. Process. Technol. 2022, 302, 117469. [Google Scholar] [CrossRef]

- Wälder, G.; Richard, J. Removal of the Heat Affect Zone Created by EDM with Pico-Second LASER Machining. Procedia CIRP 2016, 42, 475–480. [Google Scholar] [CrossRef]

- Srivastava, V.; Pandey, P.M. Study of Ultrasonic Assisted Cryogenically Cooled EDM Process Using Sintered (Cu-TiC) Tooltip. J. Manuf. Process. 2013, 15, 158–166. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, Y.; Bian, H.; Wang, G.; Ji, L. Investigation of Electrochemical Dissolution Behavior of Ni(γ)/Ni3Al(γ’) and Co(γ)/Co3Al(γ’) Superalloys in NaNO3 Solution. Corros. Sci. 2022, 208, 110622. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Z.; Liu, J.; Tang, X. Real-Time Vision-Assisted Electrochemical Machining with Constant Inter-Electrode Gap. J. Manuf. Process. 2021, 71, 384–397. [Google Scholar] [CrossRef]

- Wang, D.; Li, J.; He, B.; Zhu, D. Analysis and Control of Inter-Electrode Gap during Leveling Process in Counter-Rotating Electrochemical Machining. Chin. J. Aeronaut. 2019, 32, 2557–2565. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, X.; Zhou, Z.; Qin, P.; Zhu, D. Electrochemical Machining of High-Temperature Titanium Alloy Ti60. Procedia CIRP 2016, 42, 125–130. [Google Scholar] [CrossRef]

- Anasane, S.S.; Bhattacharyya, B. Experimental Investigation into Micromilling of Microgrooves on Titanium by Electrochemical Micromachining. J. Manuf. Process. 2017, 28, 285–294. [Google Scholar] [CrossRef]

- Klocke, F.; Zeis, M.; Klink, A.; Veselovac, D. Technological and Economical Comparison of Roughing Strategies via Milling, Sinking-EDM, Wire-EDM and ECM for Titanium- and Nickel-Based Blisks. CIRP J. Manuf. Sci. Technol. 2013, 6, 198–203. [Google Scholar] [CrossRef]

- Kurita, T.; Hattori, M. Development of New-Concept Desk Top Size Machine Tool. Int. J. Mach. Tools Manuf. 2005, 45, 959–965. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Rahman, M.; Wong, Y.S. Simultaneous Micro-EDM and Micro-ECM in Low-Resistivity Deionized Water. Int. J. Mach. Tools Manuf. 2012, 54–55, 55–65. [Google Scholar] [CrossRef]

- Skoczypiec, S.; Ruszaj, A. A Sequential Electrochemical-Electrodischarge Process for Micropart Manufacturing. Precis. Eng. 2014, 38, 680–690. [Google Scholar] [CrossRef]

- Kurita, T.; Hattori, M. A Study of EDM and ECM/ECM-Lapping Complex Machining Technology. Int. J. Mach. Tools Manuf. 2006, 46, 1804–1810. [Google Scholar] [CrossRef]

- Steuer, P.; Rebschläger, A.; Weber, O.; Bähre, D. The Heat-Affected Zone in EDM and Its Influence on a Following PECM Process. Procedia CIRP 2014, 13, 276–281. [Google Scholar] [CrossRef][Green Version]

- Demirtas, H.; Yilmaz, O.; Kanber, B. Development of a Desktop Size Electrochemical Machine for Micro/Macro Manufacturing. In Proceedings of the International Conference on Machine Design and Production, Bursa, Turkiye, 12–15 July 2016. [Google Scholar]

- Wang, D.; Yu, J.; Le, H.; Zhu, D. Localized Sinking Electrochemical Machining of Pre-Shaped Convex Structure on Revolution Surface Using Specifically Designed Cathode Tool. J. Manuf. Process. 2023, 99, 605–617. [Google Scholar] [CrossRef]

- Schaarschmidt, I.; Luther, F.; Steinert, P.; Richter, M.; Schubert, A. Simulation of the Magnetic Field Assisted Electrochemical Machining. Procedia CIRP 2023, 117, 249–256. [Google Scholar] [CrossRef]

- Natsu, W.; Terada, A. Approach to Detect and Control Gap-Width with Peak Current in Pulse ECM. Adv. Mater. Res. 2012, 482–484, 1973–1978. [Google Scholar] [CrossRef]

- Schneider, M.; Schubert, N.; Höhn, S.; Michaelis, A. Anodic Dissolution Behaviour and Surface Texture Development of Cobalt under Electrochemical Machining Conditions. Electrochim. Acta 2013, 106, 279–287. [Google Scholar] [CrossRef]

- Choi, S.H.; Kim, H.B.; Shin, H.S.; Chung, D.K.; Chu, C.N. Analysis of the Electrochemical Behaviors of WC-Co Alloy for Micro ECM. J. Mater. Process. Technol. 2013, 213, 621–630. [Google Scholar] [CrossRef]

- Das, M.K.; Kumar, K.; Barman, T.K.; Sahoo, P. Optimization of Surface Roughness and MRR in Electrochemical Machining of EN31 Tool Steel Using Grey-Taguchi Approach. Procedia Mater. Sci. 2014, 6, 729–740. [Google Scholar] [CrossRef]

- Shabgard, M.; Oliaei, S.; Seyedzavvar, M.; Najadebrahimi, A. Experimental Investigation and 3D Finite Element Prediction of the White Layer Thickness, Heat Affected Zone, and Surface Roughness in EDM Process. J. Mech. Sci. Technol. 2011, 25, 3173–3183. [Google Scholar] [CrossRef]

- Wang, G.Q.; Li, H.S.; Qu, N.S.; Zhu, D. Investigation of the Hole-Formation Process during Double-Sided through-Mask Electrochemical Machining. J. Mater. Process. Technol. 2016, 234, 95–101. [Google Scholar] [CrossRef]

- Shen, Z.-Y.; Tsui, H.-P. An Investigation of Ultrasonic-Assisted Electrochemical Machining of Micro-Hole Array. Processes 2021, 9, 1615. [Google Scholar] [CrossRef]

| Atomic Weight (%) | |||||

|---|---|---|---|---|---|

| Element | Co | Cr | Ni | Fe | Mo |

| Stellite 21 | Balance | 25–27 | 2.2–2.5 | 13–1.5 | 5.5–6.0 |

| Mechanical Properties | |||||

| Hardness (HRB) | Tensile Strength | Modulus of Elasticity | Thermal Conductivity | ||

| 103 | 724 MPa | 248 GPa | 14.7 W/mK | ||

| PLA | Apparatus | ||

|---|---|---|---|

| Density | 1.25 (g/cm3) | Size | 30 × 30 × 60 mm3 |

| Tensile strength | 45 MPa | Machining area | 46 × 3.5 mm2 |

| Pattern | Honeycomb | Pipe diameter | 8 mm |

| Infill rate | %100 | Electrolyte output | 1 mm |

| EC Grooving Parameter | |||||

|---|---|---|---|---|---|

| Voltage (V) | Gap (mm) | Surface | Conductivity (mS/cm) | Machining Time (s) | Flow Rate (lt/min) |

| 10–15–20 | 1–1.25–1.5 | W-EDMed VFed | 105 | 65 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anil, S.E.; Demirtas, H.; Kalayci, A.; Cebi, A. Investigation of the Layer Effects Formed by W-EDM on Electrochemical Grooving of Stellite 21. Machines 2023, 11, 823. https://doi.org/10.3390/machines11080823

Anil SE, Demirtas H, Kalayci A, Cebi A. Investigation of the Layer Effects Formed by W-EDM on Electrochemical Grooving of Stellite 21. Machines. 2023; 11(8):823. https://doi.org/10.3390/machines11080823

Chicago/Turabian StyleAnil, Semih Ekrem, Hasan Demirtas, Adnan Kalayci, and Abdulkadir Cebi. 2023. "Investigation of the Layer Effects Formed by W-EDM on Electrochemical Grooving of Stellite 21" Machines 11, no. 8: 823. https://doi.org/10.3390/machines11080823

APA StyleAnil, S. E., Demirtas, H., Kalayci, A., & Cebi, A. (2023). Investigation of the Layer Effects Formed by W-EDM on Electrochemical Grooving of Stellite 21. Machines, 11(8), 823. https://doi.org/10.3390/machines11080823