Abstract

Functional electrical stimulation (FES) has been widely used to treat spinal cord injury (SCI) patients. Many research studies employ a closed-loop FES system to monitor the stimulated muscle response and provide a precise amount of charge to the muscle. However, most closed-loop FES devices perform poorly and sometimes fail when muscle nonlinearity effects such as fatigue, time delay response, stiffness, spasticity, and subject change happen. The poor performance of the closed-loop FES device is mainly due to discrepancies in the feedback control algorithms. Most of the existing feedback control algorithms were not designed to adapt to new changes in patients with different nonlinearity effects, resulting in early muscle fatigue. Therefore, this research proposes an adaptive sliding mode (SM) feedback control algorithm that could adapt and fine-tune internal control settings in real-time according to the current subject’s nonlinear and time-varying muscle response during the rehabilitation (knee extension) exercise. The adaptive SM feedback controller consists mainly of system identification, direct torque control, and tunable feedback control settings. Employing the system identification unit in the feedback control algorithm enables real-time self-tuning and adjusting of the SM internal control settings according to the current patient’s condition. Initially, the patient’s knee trajectory response was identified by extracting meaningful information, which included time delay, rise time, overshoot, and steady-state error. The extracted information was used to fine-tune and update the internal SM control settings. Finally, the performance of the proposed adaptive SM feedback control algorithm in terms of system response time, stability, and rehabilitation time was analysed using a nonlinear knee model. The findings from the simulation results indicate that the adaptive SM feedback controller demonstrated the best control performance in accurately tracking the desired knee angle movement by having faster response times, smaller overshoots, and lower steady-state errors when compared with the conventional SM across four reference angle settings (20°, 30°, 40°, and 76°). The adaptive feedback SM controller was also observed to compensate for muscle nonlinearities, including fatigue, stiffness, spasticity, time delay, and other disturbances.

1. Introduction

Spinal cord injury (SCI) is caused by diseases or accidents that destroy the neural tissue of the spinal cord, as well as trauma that compresses, stretches, or tears this tissue. SCI is often irreversible, resulting in a partial or total loss of sensory function, paralysis, or both in areas of the body below the level of the lesion. An electrical current can be applied to excitable tissue to support or replace lost function in people with neurological disabilities. The electronic appliance that generates these electrical current pulses is a functional electrical stimulation (FES) device. The FES device causes an action potential in the neuronal axons by transmitting an electrical stimulation charge into the neural tissue. The administered stimulus charge depolarizes the neuron membrane artificially, producing an action potential that induces muscle contraction in the motor neurons [1]. The neurons are stimulated by a series of brief electrical pulses delivered via electrode pads [2]. Applying electrical currents to the motors of intact peripheral nerves makes it possible to contract paralysed or paretic muscles.

One of the essential areas in the healthcare industry is the rehabilitation of SCI patients using FES-assisted devices. The intervention of the FES-assisted device in rehabilitation exercises enables muscle movement through electrical stimulation to build voluntary strength. FES systems used to restore the loss of neurological control are also known as neuroprostheses. Examples of neuroprosthetic devices used in rehabilitation exercises are gripping, elbow extension, standing, walking, cycling, rowing, knee extension, and sitting down from a standing posture [3]. Over the last three decades, FES-assisted exercise has piqued the interest of doctors, engineers, and researchers. The development of such systems continues, with new technologies and methodologies being developed [4,5,6,7,8].

A stimulator controller is essential to any FES-assisted exercise system as it affects exercise efficiency. The FES device’s stimulation charge is administered directly to the targeted muscle to produce muscle force. It is considered a success if the stimulator controller can adapt to unpredicted muscle behaviour. However, the significant challenges faced in the design of an FES-assisted system are the nonlinearity of the musculoskeletal system and the rapid change in muscle properties due to fatigue [5,6], imprecise muscle force/torque control [6], spasticity [3,9], time-varying delay [10,11,12], and day-to-day variation [5,6,13,14,15]. As a result, more research is needed to design a control technique or algorithm that provides satisfactory tracking performance; is robust against time-varying properties of muscle dynamics, day-to-day variations, subject-to-subject variations, muscle fatigue, and external disturbances; and is simple to apply across experiment sessions [3,5,12,16,17]. Therefore, to design a robust controller for an FES-assisted device, all of the factors mentioned above must be fully considered for further investigation.

Most FES devices on the market use an open-loop stimulation strategy for neuromuscular applications to achieve the desired movement. Open-loop control systems, which need continual trial-and-error input from the operator, ultimately result in an early onset of muscle fatigue [4,18]. This is because the conventional stimulation technique of the current FES device, which typically employs a single open-loop stimulation channel, delivers a fixed stimulation pattern on the same motor unit synchronously, which results in the motor unit being overworked [3,5]. Furthermore, because of existing parameter variations (e.g., muscle fatigue), inherent time variation, time delay, and strong nonlinearities in the neuromuscular-skeletal system, the open-loop control FES performance was found to be unsatisfactory for accurate movement control [3,19]. Therefore, a feedback controller is needed to precisely control the generated movement due to the underlying neuromusculoskeletal system’s highly nonlinear and time-varying nature. A closed-loop FES system, which uses a feedback controller to monitor the stimulated muscle response and deliver the appropriate amount of charge to the muscle, has been proposed by numerous researchers as a solution to the open-loop control system problem in FES [4,5,6,17,20]. Several types of feedback controllers have been commonly used in the closed-loop FES system, which include proportional−integral−derivative (PID) [3,21,22], fuzzy logic (FL) [4,5,6,23], neuro-fuzzy [24], sliding mode (SM) [3,5,9,19], gain scheduling (GS) [3,25], and artificial neural network (ANN) [26,27].

Among the existing feedback control algorithms, the PID controller is mainly used by researchers in FES applications due to its simplicity, ease of implementation and tuning, and high degree of familiarity. However, the comparative study of closed-loop controllers conducted by a few researchers has indicated that the performance of PID controllers was degraded when muscle nonlinearity effects were included in the simulation [3,23]. The presented results demonstrate that the classical PID controller alone was not a suitable technique for practical FES applications due to its inferior performance in successfully regulating electrically stimulated muscle contractions when nonlinearity effects were considered [3,23]. An intelligent controller such as fuzzy logic is very popular, has a better capability of adapting to the dynamic characteristics of the muscles, and has long been recognised for its ability to manage a complex nonlinear system without creating a complex mathematical system model [6,23]. The fuzzy logic (FL) controller could also be tuned in real time, has less chattering, and performs better than the PID controller [28,29]. However, the FL controller has lower control bandwidth and convergence limitations, which result in slow joint movements in FES [30,31]. Furthermore, the FL controller is incapable of generalizing, or it only responds to what is written in its rule base and is not robust concerning topological changes in the system. Such changes in the system would necessitate changes in the FL controller rule base and limitations in updating the membership function and consequent parameters to obtain reasonable results [32,33]. Artificial neural networks (ANNs) are an attractive control technique for FES applications because they mimic how the brain is assumed to regulate muscle contractions. However, these techniques typically do not guarantee stability, which should be considered a mandatory control requirement for a system that interfaces with human users, such as FES applications. Another disadvantage of neural networks is that they are too slow for online adaptation, which requires lots of data in which the expected nonlinear conditions must be present during data training to make them work effectively, and thus need to be trained offline [19]. In the case of parameter variation, when FES is applied to different subjects, neural networks often need to be retrained, which is a time-consuming procedure [19]. Furthermore, when the network is overtrained, it suffers from overfitting, which results in poor generalisation when unseen data patterns are introduced to the system or when the system complexity is greater than the training data [34].

A modern controller such as sliding mode (SM) is also known for its robustness in dealing with uncertainties, nonlinearities, unmodeled dynamics, quickly varying parameters, and external disturbances [3,5,9]. Additionally, the SM controller was found to provide fast tuning and exhibit the best sinusoidal tracking performance [3]. However, the disadvantages of this SM controller are that it suffers from chattering [3,9,35] and requires a mathematical model to design the sliding surface [19,21]. The performance of this controller might be improved by using a more accurate model of the stimulated muscle response that includes nonlinearities or by using a different method to overcome the chattering problem. The gain scheduling (GS) controller works acceptably well for FES systems, but choosing a suitable scheduling variable that captures the system’s nonlinear behaviour is challenging. Moreover, the GS controller involves a lengthy tuning process because it uses multiple local controllers. This tuning process may have to be repeated daily to accommodate variations in the response of the stimulated muscles [3].

Although numerous types of feedback control algorithms have been used in the FES system for knee extension, Cheryl et al. (2012), Jazernik et al. (2004), and Montazeri et al. (2021) concluded that none of these feedback controllers was ready for real-world FES applications yet [3,5,19]. While it is expected that closed-loop control will improve the control performance, the actual performance of closed-loop controllers is insufficient for real-world applications because most feedback controllers exhibit a significantly degraded performance when real-world nonlinear effects of muscle, such as time-varying delay response, fatigue, stiffness, and spasticity, are considered [2,3,5,17,19]. This is because most existing feedback control algorithms were not designed with a system identification feature and an automatic tuning mechanism that can detect and quickly adapt to new system changes according to the subject’s muscle response and other nonlinear disturbances such as muscle fatigue, time delay, stiffness, and spasticity [13,14,15,17,20]. The feedback controllers were tuned only during the simulation design stage, where fatigue and other nonlinear disturbances were either not included or represented by a single predicted value to represent the nonlinear response of the muscle model [14,17]. However, the nonlinear effects of actual human muscles vary with time, and different subjects have different nonlinear muscle responses. Therefore, any new changes or disturbances that occur when a closed-loop FES system is in operation, such as different human subjects, nonlinear time-varying muscle response, and other disturbances (fatigue, stiffness, and spasticity), will cause changes in the FES system. This resulted in the internal control settings of the feedback control algorithm, which were obtained during the design phase, being no longer accurate and suitable for the real-world closed-loop FES controller [17]. The nonlinear muscle response causes the overall system to change, resulting in the feedback controller having an under performance and providing an inaccurate amount of stimulus charge to the patient [3,5,19]. The inaccurate amount of charge might lead to overstimulation, early muscle fatigue, and, consequently, muscle damage [36].

The nonlinear response of human muscle and other disturbance factors such as muscle fatigue, stiffness, and spasticity during FES-assisted activities has led to a time-varying delay response in the FES system. The large time delay in the real-world FES application will result in a poor performance of the closed-loop FES controller due to oscillation and stability issues. The time-varying delay becomes more obvious as the fatigue increases [13,37]. Most existing feedback controllers have no specific method to handle this large time-varying delay response.

Therefore, besides providing an accurate nonlinear knee model during the simulation stage, the design of feedback control algorithms in a closed-loop FES system must be significantly improved before they can be implemented in real-world applications [3,5,16,17]. Real-world FES devices must be able to accurately adjust the electrical stimulation pulse in real time to account for nonlinear muscle effects, such as time-varying delay responses, fatigue, spasticity, and retraining effects [3]. The conventional controller can only perform control loops to maintain the control variables at a dedicated set point. However, once the process starts to operate beyond such variables, the changes in functionality can be carried out by employing adaptive control [38]. To overcome the limitations of existing feedback control algorithms, much of the current research uses adaptive control methods in the FES closed-loop system [9,15,22,35,39,40,41,42]. Adaptive control is the control method a controller uses to adapt to a controlled system with parameters that vary or are initially uncertain [43].

The adaptive controller can be divided into a few categories, which are gain scheduling [3,25], self-tuning regulators [44,45], iterative learning controllers [46,47], feedforward controllers [48,49], model reference adaptive controllers (MRAC), and model identification adaptive controllers (MIAC) [50,51]. These last two adaptive controllers (MRAC and MIAC) utilise several feedback control units, such as PID, FL, NN, SM, and others, as part of their systems. The MIAC controller has a system identification to identify the status of the controlled system and to determine the relevant control laws and gain so that adjustments can be made to the feedback control unit settings [39,52]. Meanwhile, the MRAC type compares the observer and actual system outputs to adjust the system’s state variable under control. An observer can also be used in the MIAC type of adaptive controller, becoming a hybrid of the MIAC and MRAC adaptive controllers [50,51,52].

Several adaptive feedback control algorithms have recently been published to overcome the limitations of existing closed-loop FES. Kobravi and Erfanian (2012) used fuzzy logic as part of the adaptive system and the second-order SM controller in a complete adaptive system dealing with unknown and dynamic nonlinearities to control standing [35]. Fuzzy logic was used as a state variable representation. Sharma et al. (2017) employed integrator backstepping with a neural network used to estimate the state variables and the second-order SM controller to control knee extension in the presence of unknown dynamic nonlinearities and specific nonlinearities of fatigue and spasticity [53]. Cousin et al. (2022) used an SM with a feedforward neural network as an adaptive admittance controller for cadence rehabilitation to deal with unknown and dynamic nonlinearities [42]. Ajoudani and Erfanian (2009) used a neuro-sliding mode adaptive controller for controlling paralysed limbs in knee extension. Two neural networks were used to represent state variables to eliminate chattering [9]. Cousin (2020) employed two neural networks for adaptive admittance control of hybrid exoskeletons for the knee and ankle joints to deal with disturbances and unknown nonlinearities. The Lyapunov method was also used for stability [15]. Naoual et al. (2014) used an adaptive Takagi-Sugeno fuzzy SM for two-link robot exoskeletons against nonlinearities of dynamics, uncertainties, and disturbances of the exoskeleton’s motors [41]. Riani et al. (2018) used an integral terminal SM to eliminate singularities and dynamic uncertainties, resulting in less output chattering due to changes in person [40]. Wang et al. (2013) used an adaptive controller made of PD and a neural network to compensate for unstructured uncertainties [54]. JoAnne Riess (2000) employed a neural network and PD in combination as an adaptive feedforward, whereby the neural network was used to generate stimulation patterns to tackle the dynamic uncertainties of a nonlinear system of the shank [55]. Asadi and Erfanian (2012) used two adaptive neuro-fuzzy sliding modes to control rat ankles for flexor and extensor muscles in dynamic uncertainties [24]. Belkadi et al. (2017) reported that the adaptive PID controller with the modified PSO algorithm provided satisfactory results in tracking the desired trajectories in position and velocity [21]. Bkekri et al. (2019) reported that the robust adaptive SM controller for human-driven knee joint orthoses had a good tracking performance [56]. Li et al. (2020) used an adaptive controller to incorporate human and robot capabilities for knee-climbing trajectories [57]. Montazeri et al. (2021) successfully designed and simulated the fuzzy adaptive sliding mode controller to track the reference trajectories in the presence of time-varying system parameters, external disturbances, muscle fatigue, and unmodeled dynamics [5].

Although several authors have claimed success for the proposed adaptive feedback controller and control techniques or algorithms, no detailed analyses have been provided on how the proposed controller could handle specific nonlinearities such as fatigue, stiffness, spasticity, and time delay. Additionally, none of the published works has proven in detail that the proposed adaptive feedback control algorithms could still maintain their performance and compensate for each specific nonlinearity effect, which includes stiffness, spasticity, external disturbance, and time delay. To the best of the authors’ knowledge, no published work has demonstrated that the proposed feedback controller can optimize, maximize, or extend the duration of rehabilitation exercise and compensate for fatigue by adaptively changing the reference angle during the exercise. Therefore, many areas for improvement can still be studied and investigated for lower limb rehabilitation, such as knee extension involving FES. For instance, the adaptive type of MIAC controller has not been studied or found in the literature.

This paper proposes an adaptive SM feedback control algorithm for a closed-loop FES system that could monitor the progress of knee extension movement and ensure the closed-loop FES delivers an appropriate amount of stimulus charge according to the status of the patient under treatment. The adaptive SM feedback control algorithm was designed to automatically adjust the relevant internal control settings for self-tuning in real time to fit the condition of patients undergoing rehab treatment. The adaptive self-tuning of the feedback control algorithm ensures the closed-loop FES device delivers a precise amount of charge, indirectly preventing early muscle fatigue and consequently prolonging the rehabilitation exercise. The adaptive SM feedback controller consists mainly of a main control unit with a system identification feature and a tuneable SM feedback control unit. Initially, three conventional feedback control units (FCUs)—namely, PID, FL, and SM—were developed and tuned using particle swarm optimization (PSO). Then, the performances of the three FCUs regarding rise time, overshoot, steady-state error, and oscillation were evaluated. The SM feedback control unit was chosen for the adaptive feedback controller implementation in this work because it performed the best out of the three FCUs. Two types of knee extensions, namely physical-based and numerical models, were designed and developed with muscle nonlinearities such as fatigue, time delay, stiffness, and spasticity. The feedback controllers and the knee extension model were designed and developed in the MATLAB Simulink (Mathworks, Portola Valley, CA, USA) environment. Finally, the performance of the adaptive SM feedback controller in terms of system response time, stability, steady-state error, and rehabilitation time was analysed using the developed nonlinear knee extension model.

This paper is organised as follows: Section 2 presents the design methodology for the adaptive feedback control algorithm’s implementation. The explanation starts with a system overview of the closed-loop FES with an adaptive feedback controller for the knee extension application. After that, the implementation of the nonlinear knee extension models, the design of FCUs (PID, FL, and SM), and an adaptive SM feedback controller are elucidated. Each design phase is explained in detail, starting from modelling the nonlinear knee model using a physical-based model and numerical computation method, designing FCUs (PID, FL, and SM), tuning the designed FCUs using PSO, designing the adaptive SM feedback control algorithm, extracting the essential features from the knee response, and establishing the control laws and look-up table (LUT) of data after the optimization process. Section 3 discusses the performance of the three FCUs (PID, FL, and SM) from the obtained simulation results, and the performance of the adaptive SM feedback controller. In this section, the performance of the designed adaptive SM feedback controller is discussed and compared with the conventional SM feedback controller and from other research work. Finally, Section 4 presents the conclusion of the research work.

2. Materials and Methods

This section discusses the design methodology of the nonlinear knee extension model, the design and fine-tuning process of conventional FCUs (PID, FL, and SM) using PSO, and the implementation of an adaptive SM feedback controller. In this research, three main design phases were executed to implement an adaptive SM feedback controller for a nonlinear knee extension model. All design phases were implemented and tested using the MATLAB Simulink environment. The design process started with modelling the nonlinear knee extension for a closed-loop FES knee extension application. For performance comparison purposes, three FCUs, including SM, PID, and FL, were initially developed and fine-tuned at a reference angle of 40° using PSO. During the tuning phase, the key performance indicators of these FCUs in terms of rise time, overshoot, steady-state error, and oscillation were evaluated using a digital signal processing method to obtain the optimised gain settings (for SM and PID) and membership function (for FL). After the optimised gain and membership function settings were obtained, the three FCUs were tested with the nonlinear knee model. During the testing phase, the FCU that demonstrated the smallest value for rise time, settling time, overshoot, and steady-state error was selected for the adaptive feedback controller implementation. Additionally, the FCU that performed well at four reference angles (20°, 30°, 40°, and 76°), and that was robust against disturbances and nonlinearities was also taken into consideration as the best controller. Finally, among the three FCUs (PID, FL, and SM), the one with the best performance was chosen for the adaptive feedback controller implementation. The SM FCU, which exhibited the best performance, was fine-tuned once more to achieve optimal gains at a few ranges of reference angles (20°, 30°, 40°, and 76°) for adaptive controller implementation. Once the fine-tuning process of the SM feedback controller was completed, the optimised gains at different reference angle settings were stored in a look-up table (LUT) for reference. The adaptive SM feedback controller was then tested with the nonlinear knee extension model for performance evaluation. The following subsections provide detailed explanations of the nonlinear knee extension model development, the development of three FCUs (SM, PID, and FL), the tuning and performance evaluation of three FCUs (SM, PID, and FL) using PSO, and finally the design and testing of an adaptive SM feedback controller.

2.1. System Overview of Adaptive Feedback Controller

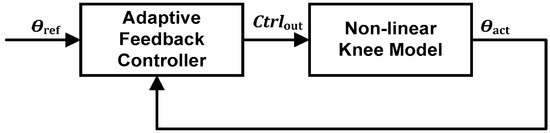

The proposed adaptive feedback controller was designed to control and generate an appropriate FES signal to maintain knee extension at a specific angle over long periods of rehabilitation exercise, to maintain control performance at different reference angles, to compensate for nonlinearity effects, and to be robust against external (sensors, FES device, power supply noise), and internal (model mismatch, muscle nonlinearities, and unknown dynamics) disturbances. Figure 1 depicts the basic system overview of an adaptive feedback controller with a nonlinear knee model.

Figure 1.

System overview of an adaptive feedback controller.

The position error obtained from the comparison between the reference angle ( and the actual angle ( is calculated internally in the adaptive feedback controller to determine the appropriate control output signal (Ctrlout) or stimulus pulse that needs to be provided to the knee model.

2.2. Knee Movements and Maximum Muscle Torque for Knee Extension Model

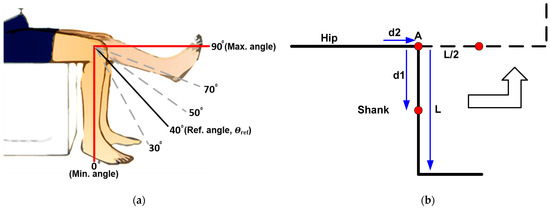

The knee angle depicted in Figure 2 indicates the estimated knee movement of an SCI patient and its equivalent model using the closed-loop FES device.

Figure 2.

Knee extension body mechanics: (a) knee extension; (b) knee extension equivalent model.

An illustration of knee movements from a resting position (0°) to a fully extended position (90°) is shown in Figure 2a. The knee angle is 0° in rest mode and remains in that position until the FES device provides a stimulus charge to the quadriceps muscles. The muscle contracts due to the administered stimulation charge, resulting in a knee extension movement. The angle (θact) generated by the limb’s movement is used as a feedback input by the adaptive feedback controller to calculate the amount of charge that must be adjusted throughout the stimulation operation. An example of a knee extension movement targeted to achieve a 40° reference knee angle (θref) is shown in Figure 2. Two types of input data can be derived from θref and θact. The first input datum is error (e), which is the difference between θref and θact. The second input datum is the change in error (de), which is the difference between the current and previous errors. The error (e) and error change (de) can be specified using Equations (1) and (2):

The adaptive feedback controller uses these input data ( and ) to calculate the amount of charge (pulse width duration) required to meet the targeted reference angle (θref). While negative denotes overstimulation of the charge, positive indicates that the applied charge is still insufficient. As a result, the feedback controller adjusts the stimulus pulse width (ΔT) appropriately (increasing or decreasing) until the desired target angle is reached [4]. Details of input data ( and ) processed by the feedback controller are explained in the following sections.

The body mechanics of the knee movement are then illustrated in Figure 2b for muscle torque calculation. The maximum muscle torque of a knee extension model is calculated by considering the human body weight of 117 kg with a lower leg weight of about 7 kg. Muscle torque is calculated by considering the body mechanics of knee movement. For knee extension modelling, a weight of 7 kg for the lower leg is used, and the centre of mass is 0.16 m of the total shank length (L), as shown in Figure 2b. The distance from the muscle pivot to the end of the muscle tendon (d2) is averaged at 1/5 of the shank length (L), which is 0.064 (0.32/5) metres. Consider the sum of moments at the knee pivot (A) for muscle torque calculation, as shown in Figure 2b. The muscle torque output calculations are shown in Equations (3)–(11), as listed below:

where,

| TA | : | Summation of torque at point A |

| m | : | Shank weight (7 kg) |

| g | : | Gravity (9.81 m/s2) |

| d1 | : | Half of the shank length |

| d2 | : | Muscle pivot |

| F | : | Force |

| L | : | Shank length |

| Tq | : | Muscle torque = F × d2 |

In this work, the muscle torque needed to lift a 7 kg weight with a lower leg from rest (0°) to full extension (90°) was calculated to be 10.99 Nm. Thus, the maximum muscle torque of 10.99 Nm was used as a reference for the maximum knee extension of 90°.

2.3. Nonlinear Knee Extension Model Development

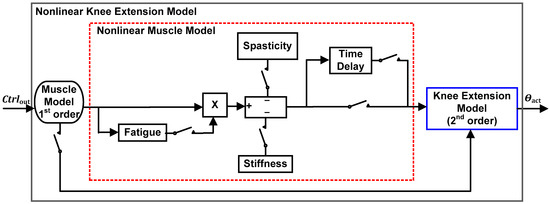

Figure 3 depicts the internal block diagram of the nonlinear knee extension model. The developed nonlinear knee extension model consists mainly of the first-order muscle model (torque), the basic second-order Veltink’s knee extension model, and the nonlinear muscle models, which include time delay, fatigue, stiffness, and spasticity. The basic second-order knee extension model was designed following the Veltink et al. (1992) model [58], and the nonlinear muscle model parameters (time delay, fatigue, stiffness, and spasticity) were developed following the Lynch and Popovic (2012) and Ferrarin and Pedotti (2000) methods [3,59]. One new parameter for the nonlinear muscle model was time delay.

Figure 3.

The internal architecture of the nonlinear knee extension model.

The overall nonlinear knee extension model was first designed and developed using a physical-based model and later converted into a numerical model using Taylor series computation. This is because the conventional physical-based model may take some time to converge during tuning when running with the optimization tool. To increase the convergence’s speed while maintaining the system’s accuracy, the knee model is best represented in discrete form or numerical computation [60]. Therefore, the conversion of the physical-based model into a numerical computation model was done to increase convergence speed during the fine-tuning process using PSO.

When applied to the first-order muscle model, the feedback controller’s output (Ctrlout), in terms of stimulus pulse width, generates force, which is later converted into muscle torque. The muscle torque causes the knee extension movement after the second-order knee model. The muscle model’s nonlinear components, including fatigue, spasticity, time delay, and stiffness, were also modelled and incorporated into the system for feedback controller development, testing, and analysis purposes. Detailed explanations for each internal block are provided in the following subsections.

2.3.1. Second-Order Knee Extension Model

The second-order knee extension movement was modelled based on the mechanics of the human body using Veltink et al.’s (1992) control model [58]. As depicted in Figure 2, muscle force is required to lift the lower leg with no other load for the knee extension movement. The muscle force to lift the lower leg is converted into muscle torque by multiplying the muscle force by the acted muscle tendon distance. The Veltink et al. (1992) knee extension control model represents the limb parts, as shown in Figure 2a. The movement is described by a second-order equation that relates the torque and angle, as defined in Equation (12):

The physical-based model can be formed as in Equation (13):

where,

| M | : | Joint torque |

| θ | : | Joint angle |

| : | Joint angle velocity | |

| : | Joint angle acceleration | |

| θnom | : | The angle at which the steady-state torque equals zero |

| I | : | Inertia |

| B | : | Damping |

| C | : | Compliance with the load = |

| m | : | Shank Weight (7 kg) |

| l | : | Length to the centre of the shank |

| g | : | Gravity (9.81 m/s2) |

The Veltink et al. (1992) second-order knee extension control model is much simpler to implement and more linear, as it does not contain any nonlinear functions of sin or cosine in its mathematical model [58]. The mathematical model of the Ferrarin and Pedotti (2000) knee extension model has a sine function, which makes the system nonlinear [59]. The muscle models designed by Reiner et al. (1996 and 2002) focused on the muscle without the biomechanics of the knee extension model [7,8].

2.3.2. Nonlinear Muscle Model

The muscle nonlinearity effects, which include fatigue, time delay, stiffness, and spasticity, are incorporated into the knee model for accurate knee model representation. In this work, the muscle nonlinearities’ equations are combined to form a physical-based model and later converted into numerical computation. The muscle can also be modelled using a non-mathematical approach, such as fuzzy logic, genetic algorithm, and ANFIS, as reported by Ibrahim et al. (2011) [61] and Salleh et al. (2013) [62]. Detailed muscle nonlinearities, which include fatigue, time delay, stiffness, and spasticity, are explained in the following subsections.

- Fatigue

The fatigue effect causes muscle torque to decrease over time, and when the overstimulation effect persists, the fatigue effect increases [53]. Fatigue is implemented as a multiplier that modifies the electrically stimulated quadricep muscles’ torque [3]. The value of the fatigue waveform ( ranges between 0 and 1 in the time domain, with 1 corresponding to no fatigue and 0 corresponding to no measurable response to stimulation [3]. The higher the fatigue effect, the faster the torque input decreases. Equations (14) and (15) represent the fatigue effect in the time domain for mild and severe fatigue [63].

- 2.

- Stiffness

The muscle stiffness was designed based on Lynch and Popovic (2012) [3] and Ferrarin and Pedoti’s (2000) [59] models. The stiffness effect is according to Equation (16).

Stiffness causes a reduction in muscle torque when the movement starts from a standstill and disappears when the knee trajectory angle reaches a certain degree of resting elastic knee angle () [3].

- 3.

- Time Delay

The muscle time delay nonlinearity is challenging as it can cause the system to become uncontrollably unstable. The transfer function first order plus time delay () is given by Equation (17). The exponential term represents a time delay [64].

where,

| τs | : | Time constant |

| K | : | System gain |

| θS | : | Delay angle (in transfer function format) |

The Pade approximation was used to represent the time delay, allowing the root locus, bode plot, linear quadratic regulator (LQR), and H infinity controllers to work. In this work, the time-delay effects were developed using MATLAB Simulink transportation delay in the range of 10 ms (minimum) to 260 ms (maximum) [11,12,30,65].

- 4.

- Spasticity

The spastic hamstring torque is expressed as in Equation (18) [3].

where is the hamstring tension resulting from the spasm. We assumed that = 5 cm was the distance between the centre of rotation of the knee and the insertion point of the biceps femoris on the fibula. The angle between the longitudinal axis of the hamstrings and the axis of the shank can be expressed as in Equations (19) and (20).

The hamstring tension was determined by

where Td = 40 ms was the delay between the stretch and the onset of the resulting contraction, and was the maximum spastic torque elicited at the maximum knee angular velocity [3].

2.4. Design and Development of Feedback Control Units

The three FCUs, namely PID, FL, and SM, were first developed using MATLAB Simulink. Details for each controller are explained in the following subsections.

2.4.1. Design and Implementation of PID Control Unit

The PID controller was developed based on the mathematical equations represented in the Laplace transform, shown in Equations (21)–(25). From the equations, represents the PID controller’s output signal (Ctrlout) or stimulus pulse that needs to be provided to the knee model.

where,

| Kp | : | Proportional controller gain |

| Ki | : | Integral controller gain |

| Kd | : | Derivative controller gain |

| Td | : | Derivative time |

| Ti | : | Integration time |

| u(t) | : | Controller output in the time domain |

| e(t) | : | Error in the time domain |

| u(s) | : | Controller output in s domain |

| e(s) | : | Error in s domain |

The PID controller’s final gain settings ( were determined during PSO tuning optimization. The PID equations were then transformed into an algorithm that works on discrete controllers.

2.4.2. Design and Implementation of FL Control Unit

As indicated in Figure 2, the angle (θact) generated from the limb’s movement serves as the feedback input to the FL control unit to determine the required amount of charge during the stimulation operation. The error () and change of error () shown in Equations (1) and (2) are initially calculated for the FL control unit’s input data. The FL control unit processes these input data ( and ) to determine the amount of charge (pulse width duration) required to meet θref.

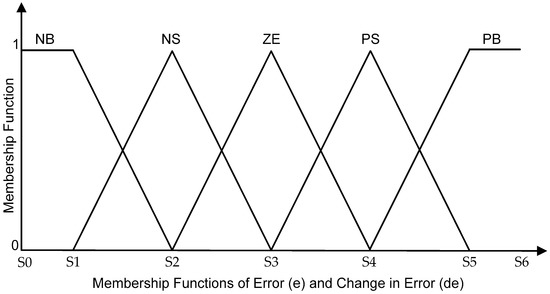

Trapezoidal and triangular shapes are used to define the membership function (MF) and degree of MF. The MFs for errors () and changes in errors (), which include the negative big (NB), negative small (NS), zero (ZE), positive small (PS), and positive big (PB), are shown in Figure 4. As depicted in Figure 4 and described in Table 1, the limits of the triangle MFs for error (e) and change in error (de) are equally divided.

Figure 4.

Membership function (MF) of error (e) and change in error (de). The input MFs are negative big (NB), negative small (NS), zero (ZE), positive small (PS), and positive big (PB).

Table 1.

Membership function (MF) of error (e) and change of error (de). The input MFs are negative big (NB), negative small (NS), zero (ZE), positive small (PS), and positive big (PB).

The Takagi–Sugeno singleton method was employed to represent the output of the MF due to its simplicity and reduced computational complexity [4]. In this Takagi–Sugeno model, the singleton MFs of fuzzy output are represented as values of 1 at a single location and 0 at all other locations. Figure 5 depicts the singleton MF of the fuzzy output at a reference angle of 40°. As listed in Table 2, the 25 rules (min 1–min 25) are developed because the FL control unit has two inputs (error () and change in error ()) and five MFs (NB, NS, ZE, PS, and PB) for each input. Any combination of two linguistic variables triggers at least one rule. The 25 fuzzy singleton outputs are also referred to as c1–c25.

Figure 5.

MF of fuzzy output (reference angle = 40°). The singleton output MFs are zero (ZE), small (SM), medium (ME), big (BG), and very big (VB).

Table 2.

Fuzzy rule-based table mapping for two inputs, error (e) and change in error (de), and singleton outputs. The input MFs are negative big (NB), negative small (NS), zero (ZE), positive small (PS), and positive big (PB). The singleton output MFs are zero (ZE), small (SM), medium (ME), big (BG), and very big (VB).

Examples of fuzzy rules in IF−THEN statements for min 1–min 5 using the Takagi-Sugeno method are shown in Equations (26)–(30). These equations are generated based on the set of rules from Table 2. Similar IF−THEN statements are also applicable for min 6–min 25.

The MF output grades of each rule are accumulated into a single value to represent the final fuzzy output signal. The defuzzy output was computed using the centre of gravity (COG) approach. The advantage of this COG approach is that it can lower computational complexity and generate quick results [4]. This COG technique was implemented by multiplying the final accumulated fuzzy output from the MF output grades by its associated singleton value, then dividing this multiplied value with the final accumulated fuzzy outputs from the MF output grades, as shown in Equation (31). The defuzzy output (crisp output) represents the output signal (Ctrlout) or stimulus pulse that the FL control unit must deliver to the knee model.

2.4.3. Design and Implementation of SM Control Unit

The sliding mode (SM) control, which is one of the variable structure control (VSC) approaches, is usually used in a system for excellent disturbance rejection and set point tracking [5,66]. VSC has nonlinear feedback, which is discontinuous. SM control is nonlinear because the input switches rapidly between two or more control limits. The system’s structure can be changed or switched as it crosses each discontinuity surface, using this control as the feedback. When the trajectory moves on the sliding surface, the equivalent control operates internally and controls the system. Two types of SM controls were developed: conventional SM and second-order unchattered sliding mode (USM). The mathematical equations for the conventional SM and USM are shown in Method 1 and Method 2 below:

- Method 1: Conventional SM Control Unit

The simplest form of SM mathematical equations is listed in Equations (32)–(35) in their canonical form. The sliding surface is defined as in Equations (36) and (37); the final implementation and controller output are as in Equation (38) [3,5,9]. The gain setting for λ can be determined using trial and error, or PSO.

u represents sliding input, y represents knee angle, represents the state variable, is the state variable representing knee angle acceleration, and defines the state variable representing knee angle velocity.

Define sliding surface (s) as in Equation (36)

Define the equivalent sliding surface as in Equation (37), where is rate of error, is the gain constant, and is the error.

The derivative of Equation (37) is shown in Equation (38).

Using control law [67], u = , the controller is designed as in Equation (39)

The term is nullified by the first order, and will always go to zero in finite time. In this work, the SM controller’s final gain setting for from Equation (39) was set equal to the maximum muscle torque (), and the final gain setting for λ from Equation (37) is 0.5, which was determined during PSO tuning optimization.

- 2.

- Method 2: Unchattered SM (USM) Second order

The second-order SM is one of the best sliding mode control algorithms, significantly reducing the chattering effect [56,68]. It has good resistance against external force disturbances during knee movement and provides good tracking of the desired trajectory set by the therapist or the subject [56]. The system can be converted into canonical form, as shown in Equation (40). Feeding in state variables and parameters results in Equations (40) and (41).

where,

| I | : | Inertia () |

| B | : | Damping () |

| D | : | State variable constant (D = ) |

| M | : | Joint torque (10.99 Nm) |

| m | : | Shank weight (7 kg) |

| l | : | Length to the centre of the shank (0.16) |

| g | : | Gravity (9.81 m/s2) |

The conversion of a state-space model to a transfer function model was done using the MATLAB Simulink function (ss2tf) [69].

The sliding mode controller must be transformed into a state-space controllable form. Thus, the linear differential in Equation (12) can be written in transfer function in the time domain, as shown in Equation (43). Equations (44)–(47) are the state space in canonical form.

where

| : | knee angle | |

| : | knee velocity | |

| : | State variable | |

| : | State variable |

The state space model in the controllable canonical form [69] is shown in Equation (48).

As shown in Equation (48), the state space model has been tested using the quadratic local Lyapunov function for stability evaluation [70]. The obtained values of the P11 matrix (1.954) and determinant (0.053) are greater than 0. Therefore, the system is considered stable.

Then, the sliding surface is determined as shown in Equation (49)

e denotes tracking error and λ must be greater than zero (0). The tracking error and its derivatives can be expressed by Equations (50)–(52)

where denotes the desired position (reference angle ) and θ denotes the actual position (actual angle ). The Lyapunov function is defined by Equation (53).

To ensure stability, the derivative of the Lyapunov function must satisfy V < 0, as shown in Equation (54)

The derivation of the sliding mode function is shown in Equations (55)–(57).

Thus, the derivation of the Lyapunov function is shown in Equation (58) [66].

Substituting Equation (59) into (58), Equation (60) is obtained.

where

The controller is designed, as in Equation (60), to meet the condition of , as stated in Equation (54).

2.5. Tuning and Testing Feedback Control Units

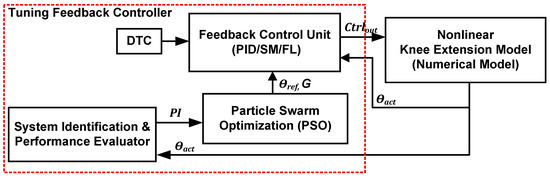

The developed FCUs (SM, PID, and FL) were first tuned using PSO to obtain the best performance for four reference angles: 20°, 30°, 40°, and 76°. Figure 6 illustrates the tuning of three FCUs (SM, PID, and FL) using PSO with the assistance of system identification and performance evaluator units. For the FCUs’ tuning, the previously developed knee extension model using a physical-based method was first transformed into a numerical computation model using Taylor series computation for fast convergence [70].

Figure 6.

Tuning feedback control units (FCUs) using PSO, system identification, and the knee extension model.

The system identification was used to extract essential features from the acquired knee trajectory output response (, which include rise time, steady-state error, and overshoot, for system performance evaluation during the tuning phase in order to find the best gain settings for the FCUs (SM, PID, and FL).

The PSO used 50 particles, representing the possible gains for each FCU at a reference angle of 40°. Details of the parameter settings’ range used for each FCU are listed in Table 3. This work used a reference angle of 40° to represent the medium knee angle reference during the rehabilitation exercise. Each particle was tested for 100 iterations. Therefore, for 50 particles, 5000 steps of iterations are required for each FCU. The performance of the designed FCUs (SM, PID, and FL) was evaluated in terms of their time response, overshoot, steady-state error, and oscillation. Each parameter has a performance indicator (PI) setting of 0% as the lowest mark and 25% as the highest mark. The grading performance for each parameter setting ranging from 0 to 25% is listed in Table 4. For example, the rise time is graded 0% for a duration above 5 s and 25% for a duration less than 3.3 s. Between 3.3 s and 5 s, the rise time is graded accordingly to determine the percentage mark. Similarly, for the other parameters (overshoot, steady-state error, and oscillation), specific value settings are used to grade the performance between 0% and 25%. Therefore, the combination of four parameters (rise time, overshoot, steady-state error, and oscillation) accumulates into one single PI that ranges from 0 to 100%. The highest PI represents the best performance for the tested FCU. The optimised gain (G) or MF was saved in a look-up table (LUT), and adaptive control laws were formulated for the FCU references.

Table 3.

The range of gain and membership function settings for each feedback control unit (FCU).

Table 4.

The minimum and maximum ratings for each parameter.

After the tuning process, the FCUs (SM, PID, and FL) were tested again on the four reference angles (20°, 30°, 40°, and 76°) using the nonlinear knee extension model. The knee muscle model nonlinearities, which include stiffness, fatigue, spasticity, and time delay, were included in the FCUs’ performance evaluation. The FCU incorporated a direct torque control technique (DTC) when a higher time delay (260 ms) was detected. The FCU that manifested the best performance (smallest values of rise time, overshoot, steady-state error, and oscillation) was chosen for the final implementation of the adaptive feedback controller design. The SM exhibited the best performance among the three FCUs in this work. Details of the performance analysis are provided in the Results and Discussion sections.

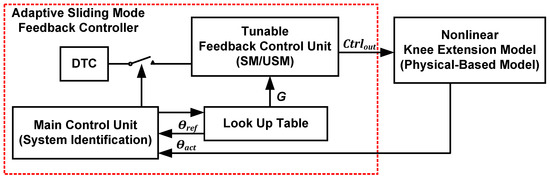

2.6. Adaptive Sliding Mode Feedback Controller

Figure 7 depicts the adaptive SM feedback controller’s internal architecture, consisting of a main control unit with a system identification feature, tuneable SM and USM feedback control units, a DTC, and a LUT.

Figure 7.

The internal architecture of the adaptive SM feedback controller.

The function of the main control unit is to monitor and supervise the overall operation of the adaptive SM feedback controller. The function of the system identification feature incorporated in the main control unit is to extract essential features such as rise time, time delay, steady-state error, and overshoot from the acquired knee trajectory output response to identify the patient’s knee muscle status during the testing phase. The two types of employed FCUs, namely SM and USM, are activated according to the patient’s condition. DTC is incorporated into the adaptive controller and is activated when a larger system time delay (260 ms) is detected. LUT is used to store the optimised gain (G) and reference angle (

The adaptive SM feedback control algorithm has two primary operations, namely open-loop and closed-loop stimulations. The adaptive SM feedback controller’s operation begins with an open-loop stimulation. The main control unit initiates open-loop stimulation by sending a preset pulse width value (corresponding to a medium reference angle of 45°) to the nonlinear knee extension model. The nonlinear knee extension model generates knee movement with a certain trajectory angle in response to the delivered stimulus pulse or control output signal (Ctrlout) from the adaptive SM feedback controller. During the open-loop operation, the knee trajectory output response ( was acquired and stored in three memory units for the system identification process, where the status of a patient under treatment was identified. The system identification unit extracted and processed important features (rise time, time delay, steady-state error, and overshoot) from the knee trajectory output response during the open-loop operation. Based on the extracted features from the acquired knee response of the tested nonlinear knee model (or patient’s knee in the real-world closed-FES application), the appropriate gain setting, reference angle, and control laws were determined for the tunable FCU (SM or USM). The FCU (SM or USM) was then tuned accordingly by modulating the stimulus pulse width or control output signal (Ctrlout) to provide an accurate amount of stimulus charge to the nonlinear knee model (or patient’s knee in the real-world closed-FES application).

Thereafter, the closed-loop stimulation begins, and the main control unit starts to monitor time delay, stiffness, spasticity, and fatigue. An example of a pseudocode for the monitoring control laws is shown in Algorithm 1. The monitoring control laws start with checking the time delay nonlinearity, followed by lower muscle torque, spasticity, stiffness, and fatigue. If a time delay in the system is detected, the main control unit will select the appropriate FCU (SM or USM), DTC, reference angle (Ref. angle), and gain based on the time delay duration. If stiffness or spasticity is detected, the main control unit will determine the appropriate reference angle (Ref. angle) and gain setting for SM. If fatigue is detected, the main control unit will adapt to the patient’s condition by changing the appropriate reference angle (Ref. angle) and gain settings to prolong the rehabilitation exercise.

| Algorithm 1. Monitoring Control Laws Algorithm | |

| 1. | #1. Check for time delay and control settings. |

| 2. | If time delay > 0.26 s. |

| 3. | Activate USM and DTC; Ref. angle = Steady state; Gain = Time delay × constant |

| 4. | If 0.05 s < time delay < 0.26 s |

| 5. | Activate USM; Ref. angle = Steady state; Gain = Time delay × constant |

| 6. | If time delay < 0.05 s |

| 7. | Activate SM; Ref. angle = Steady state; Gain = Time delay × constant |

| 8. | #2. Check for lower muscle torque and control settings. |

| 9. | If the steady state value is lower than (45°/2) |

| 10. | Activate SM; Ref. angle = Steady state − 10°; Gain = 4 |

| 11. | #3. Check for spasticity and control settings. |

| 12. | If spasticity detected |

| 13. | Activate SM; Ref. angle = Steady state; Gain = 24 |

| 14. | #4. Check for stiffness and control settings. |

| 15. | If stiffness detected |

| 16. | Activate SM; Ref. angle = Steady state; Gain = 14 |

| 17. | #5. Check for fatigue and control settings. |

| 18. | If fatigue (Tfat(t)) detected during an open loop |

| 19. | Activate SM; Ref. angle = Steady state/2; Gain = 4 |

| 20. | If fatigue (Tfat(t)) detected during closed-loop |

| 21. | Tfat(t) < −0.01; Ref. angle = Ref. angle −10; Gain = 4 |

| 22. | Tfat(t) < −0.03; Ref. angle = Ref. angle −12.5; Gain = 4 |

| 23. | Tfat(t) < −0.06; Ref. angle = Ref. angle −15; Gain = 4 |

| 24. | #6. Control settings for a condition without any nonlinearities |

| 25. | Else |

| 26. | Activate SM; Ref. angle = steady state; Gain = 2 |

Details of the system identification operations, processes, and algorithms are explained in the following subsection.

2.6.1. System Identification

System identification was used to extract essential features (time delay, rise time, overshoot, and steady-state error) from the acquired knee response during the fine-tuning and testing phases. During the tuning phase, the extracted features (rise time, overshoot, steady-state error, and oscillation) from the system identification process were used to evaluate the performance of the three FCUs (SM, PID, and FL) and finally obtain the optimised gain setting, reference angle, and control laws. During the testing phase, the extracted features (time delay, rise time, overshoot and steady-state error, stiffness, spasticity, and fatigue) from the system identification process were used to determine the status of the patients under treatment and to select appropriate control laws, gain settings, and reference angles. An example of system identification flow during the testing phase is indicated in Algorithm 2. A three-point moving average method consisting of three memory units (M1, M2, and M3) and an internal counter were used to extract the essential features (time delay, rise time, overshoot, steady-state error, stiffness, spasticity, and fatigue) from the knee response. The following subsections explain the details and illustrations of each feature extraction operation.

| Algorithm 2. System Identification Algorithm (During Testing Phase) | |

| 1. | #1. Calculate the time delay. |

| 2. | FES System starts to operate and activate the internal counter |

| 3. | Acquire knee angle data every 0.05 ms and store in three memory units (M1, M2, and M3) |

| 4. | Use the three-point (M1, M2, and M3) moving average and counter to calculate the time delay |

| 5. | Calculate the time delay if M3>M2 and M1 = 0 |

| 6. | #2. Calculate the rise time |

| 7. | If the acquired knee angle is >10% and <90% of the target angle (45°), calculate the rise time using a counter that counts when the knee angle hits 10% and stops when it reaches 90% |

| 8. | #3. Calculate the steady-state value, error, and time |

| 9. | If time delay and rise time have been calculated and the counter value > 50 |

| 10. | Check three points (M1, M2, and M3) moving average |

| 11. | If the difference between M1, M2, and M3 is 0.1 then calculate the steady state value |

| 12. | Then calculate the steady-state error: Reference angle − steady state value angle |

| 13. | Calculate steady state time: Counted value x internal time delay (0.01 s) |

| 14. | #4. Calculate overshoot |

| 15. | Find the maximum peak using moving averages of three points (M1, M2, and M3) |

| 16. | If M2 > M1 and M2 > M3, then store the maximum peak value (M2) |

| 17. | Calculate overshoot: Maximum peak (M2) − steady state value |

| 18. | #5. Detection of stiffness, spasticity, and fatigue |

| 19. | Convert the acquired knee response to a rate of change response |

| 20. | Find the maximum and minimum peaks using three points (M1, M2, and M3) moving average |

| 21. | If there is only one maximum peak, then the knee response has no nonlinearities |

| 22. | If there are two maximum peaks and one minimum peak, stiffness is detected |

| 23. | If there are several maximum and minimum peaks, spasticity is detected |

| 24. | If the acquired knee rate of change response goes below zero, fatigue is detected |

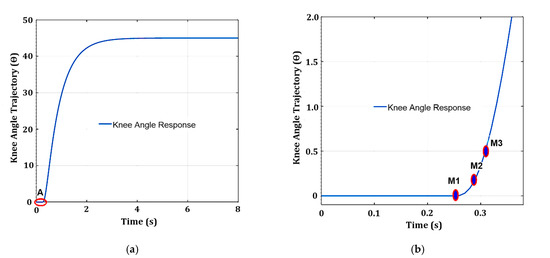

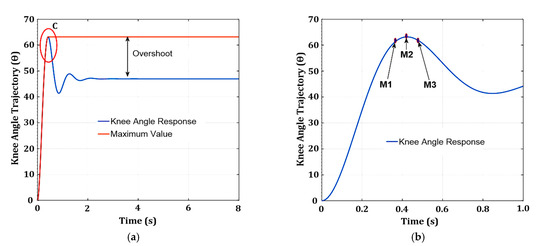

- Extraction of Time Delay from Knee Angle Response

Figure 8 illustrates the extraction of time delay from the acquired knee angle trajectory using a three-point moving average method. The acquired knee angle data are stored in the three memory units (M1, M2, and M3) separated by a 0.05 ms time interval. When the FES starts to operate in an open-loop stimulation, an internal counter is activated to begin counting immediately at 0.01 s intervals. The knee angle data are acquired every 0.05 ms and stored in three memory units (M1, M2, and M3). Every new point of acquired data is stored in M3, while the previous points in M3 and M2 are shifted to M2 and M1, respectively. The values stored in the three memory units are checked and compared. The internal counter is stopped if the value stored in M3 is greater than that in M2 and the value stored in M1 is zero. As shown in Equation (62), the time delay is calculated by multiplying the internal counter-counted value by the time interval (0.01 s) and subtracting the acquired two-point interval.

Figure 8.

Extraction of time delay using a three-point (M1, M2, and M3) moving average method from knee angle response. (a) knee angle response with a time delay at point A; (b) zoomed view into the marked area A of the knee angle response with a three-point average (M1, M2, and M3).

The time delay is calculated for every new patient in real time. This value is used to determine the types of FCUs to be used. The SM FCU is used for small time delays (0–0.06 s). For moderate time delays (0.07–0.13 s), the USM FCU unit is used. For high-time delays (above 0.26 s), the USM FCU with DTC is used. The results section explains detailed analyses and justifications for using SM or USM FCU according to the time delay duration.

- 2.

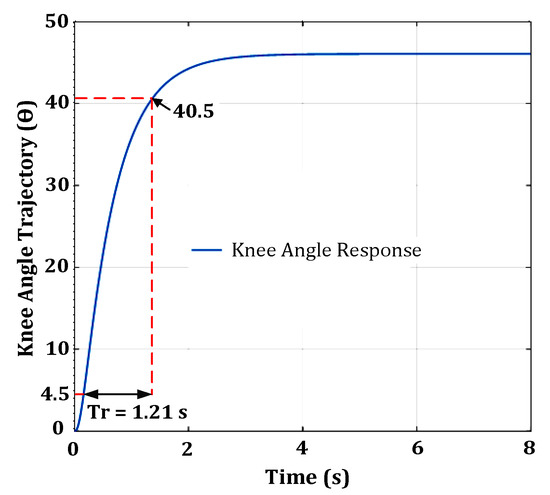

- Extraction of Rise Time from Knee Angle Response

In this work, during the open-loop stimulation, the knee torque output is set to operate at a target angle of 45°. Figure 9 illustrates the extraction of the rise time from the acquired knee angle trajectory response using an internal counter. Once the FES open loop system starts to operate, the internal counter is activated when the acquired knee angle is at 10% (4.5°) of the target angle (45°). The counter stops counting when the acquired knee angle reaches 90% (40.5°) of the target angle (45°). Therefore, once the acquired knee angle reaches a value of 40.5°, the internal counter stops counting, and the rise time is calculated by multiplying the counted value by its time interval (0.01 s). The calculated rise time is 1.21 s (121 counted values × 0.01 s).

Figure 9.

Extraction of rise time using an internal counter from the knee angle response.

The calculated rise time is used to determine the suitable reference angle and the SM gain for that patient. A smaller SM gain will be required for a fast rise time, and a higher SM gain will be required for a slow rise time.

- 3.

- Extraction of Overshoot from Knee Angle Response

The overshoot is calculated by subtracting the steady-state value from the maximum peak value, as depicted in Figure 10a and shown in Equation (63). The maximum peak value is calculated using the three-point (M1, M2, and M3) moving average method, as shown in Figure 10b in the zoomed view. The peak point is determined when M2 is greater than M1 and M3, as illustrated in Figure 10b. The calculated overshoot value is used to determine a suitable SM gain setting during the closed-loop operation. When an overshoot occurs, a lower SM gain setting will be used.

Figure 10.

Extraction of overshoot using a three-point (M1, M2, and M3) moving average method from the knee angle response: (a) knee angle response with overshoot; (b) zoomed view into marked area C of knee angle response with the three-point (M1, M2, and M3) moving average.

- 4.

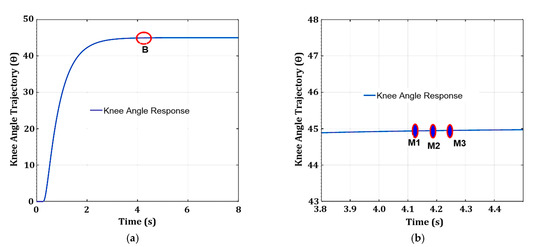

- Extraction of Steady State Value, Error, and Time

The steady-state value is extracted using the three-point (M1, M2, and M3) moving average method, as illustrated in Figure 11. The three points (M1, M2, and M3) are separated by 0.05 ms, as shown in the zoomed view in Figure 11b. The steady-state value is extracted after the system passes the time delay calculation and the internal counter value is above 50. The steady-state value is determined when the three-point (M1, M2, and M3) values are almost similar and the differences among the three are less than 0.1. The steady-state value is used to determine the suitable reference angle setting for the system. Once the steady-state value is known, Equation (64) determines the steady-state error by subtracting the steady-state value from the reference angle.

Figure 11.

Extraction of steady-state value, error, and time using a three-point (M1, M2, and M3) moving average method from the knee angle response: (a) knee angle response with steady-state value at point B; (b) zoomed view into marked area B of the knee angle response with the three-point average (M1, M2, and M3).

Additionally, when the system reaches its steady-state value, the steady-state time is found by multiplying the counted value of the internal counter by the time interval of the counter delay (0.01 s), as shown in Equation (65).

After determining the steady-state value, error, and time, the closed-loop system can operate with the relevant reference angle setting.

- 5.

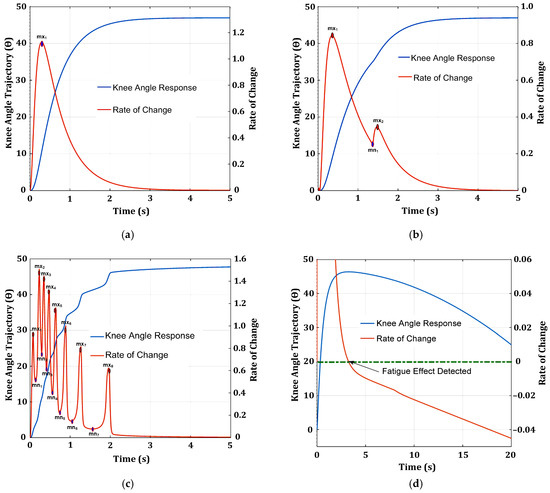

- Detection of Stiffness, Fatigue, and Spasticity from Knee Angle Response

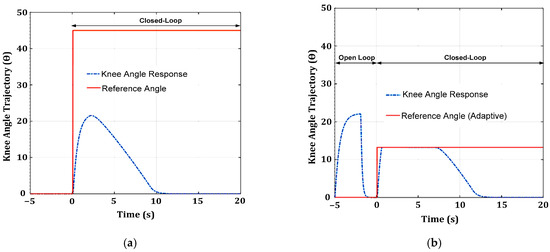

The stiffness, spasticity, and fatigue are detected by transforming the acquired knee angle response into a rate of change response. The rate of change response is obtained by subtracting the previously acquired knee angle data from the current knee angle data. For stiffness and spasticity, the internal minimum and maximum counters and the three-point (M1, M2, and M3) moving average method are used to determine the number of maximum and minimum peaks from the knee angle rate of change response. The three-point (M1, M2, and M3) moving average method determines the maximum or minimum value. The maximum peak point is determined when M2 is greater than M1 and M3. The minimum peak point is determined when M2 is smaller than M1 and M3. The maximum counter is increased whenever there is a maximum peak, and the minimum counter is increased whenever there is a minimum peak. As depicted in Figure 12a, for a normal knee angle response (without any nonlinearities), the rate of change has only one maximum peak value. When the knee angle rate of change response has two maximum peaks with one minimum peak in between, stiffness is detected, as illustrated in Figure 12b. However, spasticity is detected when the knee angle rate of change response has several maximum and minimum peaks, as shown in Figure 12c. Figure 12d shows that the knee angle rate of change response is less than zero when fatigue is present.

Figure 12.

Detection with and without nonlinearities from the knee angle response: (a) knee angle response without nonlinearities; (b) knee angle response with stiffness; (c) knee angle response with spasticity; (d) knee angle response with fatigue.

2.6.2. Tunable Feedback Control Unit (SM/USM)

The function of the tunable feedback control unit (SM or USM) is to provide an accurate amount of charge (pulse width) to stimulate the quadricep muscles for knee angle movement. Two types of FCUs, SM and USM, were designed for the adaptive feedback controller. These FCUs were designed to be tunable in real time or online in response to muscle nonlinearities, disturbances, and system changes. After the system identification process, the main control unit determines the appropriate gain, reference angle, and control law settings for the FCUs (SM and USM) according to the status of the patient under treatment. Based on the selected gain, reference angle, and control laws, the FCU (SM or USM) calculates the appropriate control output (Ctrlout) or stimulus pulse width that needs to be provided for stimulation purposes. If the system has a time delay, the main control unit activates the USM FCU when the time delay is above 0.05 s and turns on DTC (for time delays above 0.26 s) to reduce the oscillating effect of the time delay.

2.6.3. Direct Torque Control (DTC) for Time Delay System

DTC is used to deal with the system’s time delay problem in this adaptive feedback controller design. According to previous research [11], as the system’s time delay increases, the feedback controller system begins to oscillate and becomes unstable [64], and overshoots will also increase [10,11,30]. Therefore, when the time delay is calculated to be above 260 ms, DTC is activated to operate together with the USM FCU. DTC works very well when associated with the USM FCU.

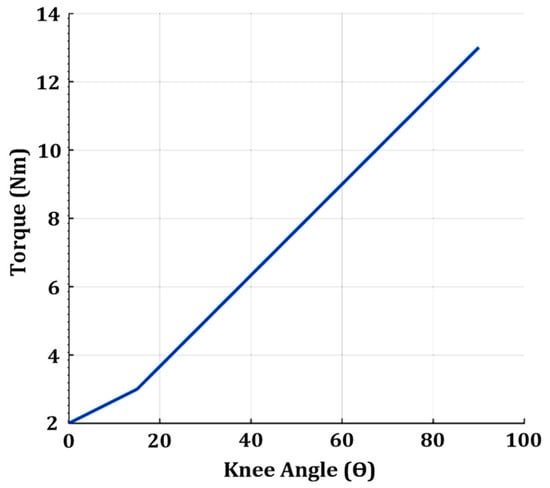

The DTC technique changes the control reference, originally based on the reference angle, into an equivalent torque, as shown in Figure 13. The converted equivalent torque has a smaller value compared with the knee angle. Therefore, the calculated error between the reference and actual angles is much smaller when the equivalent torque conversion values are used. These small errors keep the controller from acting quickly and roughly because it works at lower error rates. Hence, the DTC techniques prevent the controller from reaching its maximum output, which keeps it from oscillating [71].

Figure 13.

Angle to torque conversion look-up table (LUT) for direct torque control (DTC).

3. Results

This section discusses the performance of the three FCUs (SM, PID, and FL) when tested with and without nonlinearities (fatigue, time delay, stiffness, and spasticity). In this work, because the SM feedback control unit exhibited the best performance compared with PID and FL, SM was used for the adaptive feedback controller implementation. The performance of the adaptive SM feedback control algorithm tested with the nonlinear knee model is also discussed.

3.1. Three Feedback Control Units Performance Using Optimized Gain

This section discusses the simulation results of three FCUs (SM, PID, and FL) tested on a knee model with and without nonlinearities.

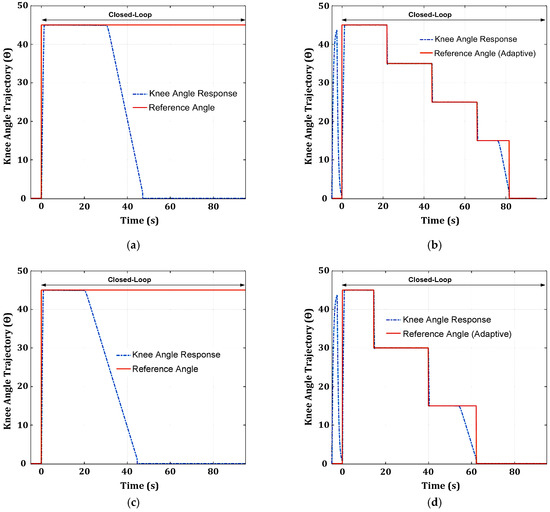

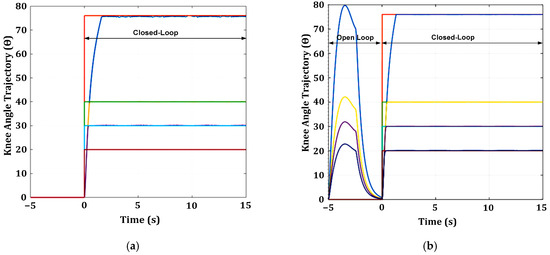

3.1.1. Knee Model without Nonlinearities

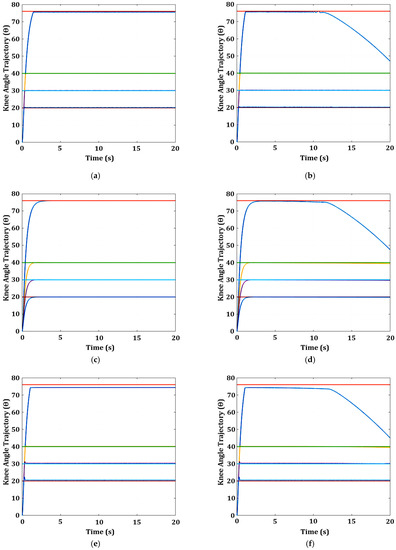

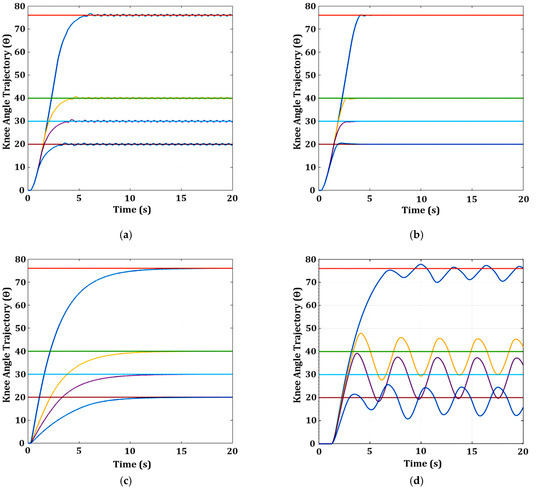

Figure 14 depicts the knee angle response at four reference angles (20°, 30°, 40°, and 76°) without nonlinearity and with fatigue nonlinearity for three FCUs (SM, PID, and FL). Figure 14a,c,e shows the knee angle responses of the SM, PID, and FL FCUs in the absence of any nonlinearity. Although the FCUs tuning was conducted only at 40°, all FCUs observed could meet the target angles except for FL, which exhibits the largest steady-state error at a reference angle of 76°. The PID feedback control unit has a smooth knee angle response at all reference angles.

Figure 14.

Knee angle response without nonlinearities and with fatigue nonlinearity using three FCUs (SM, PID, and FL): (a) knee angle response without nonlinearities for SM; (b) knee angle response with fatigue for SM; (c) knee angle response without nonlinearities for PID; (d) knee angle response with fatigue for PID; (e) knee angle response without nonlinearities for FL; (f) knee angle response with fatigue for FL. The reference angle (ref) and knee response (resp) are represented in different coloured lines as follows: (i) ref 76°: orange and resp: blue; (ii) ref 40°: light green and resp: yellow; (iii) ref 30°: light blue and resp: purple; (iv) ref 20°: red and resp: blue.

The key performance parameters of the three FCUs (SM, PID, and FL), which include rise time, settling time, overshoot, and steady-state error at four reference angles (20°, 30°, 40°, and 76°), are tabulated in Table 5. The tabulated results show that the rise time and settling time for the three FCUs (SM, PID, and FL) increase as the reference angles increase. The rise time and settling time for SM and FL are almost the same across all reference angles. PID is observed to have the highest values for rise time and settling time among the three FCUs across all reference angles. The overshoot for SM and FL is more pronounced at lower reference angles (20°, 30°, and 40°) and less so at a higher reference angle (76°). The steady-state error of FL is the highest (1.688°) among the three FCUs at a higher reference angle (76°).

Table 5.

FCU (SM, PID, and FL) performance (rise time, settling time, overshoot, and steady-state error) tested on the knee model (without nonlinearities) at four reference angles (20°, 30°, 40°, and 76°).

3.1.2. Knee Model with Fatigue Nonlinearity

When fatigue is incorporated into the knee model, as depicted in Figure 14b,d,f, the FCUs (SM, PID, and FL) maintain their performance at lower reference angles (20°, 30°, and 40°). However, the performance of the FCUs (SM, PID, and FL) starts to degrade around 12 s for the higher reference angle of 76°. At around 12 s, the performance of all FCUs (SM, PID, and FL) starts to decline, and the knee angle trajectories begin to drop significantly. Muscle fatigue results in small oscillations in the knee angle trajectory response for the SM FCU before the knee drops. The drop in knee angle trajectory after 12 s indicates that muscle fatigue significantly affects the knee angle trajectory at a higher reference angle (76°). Consequently, the steady-state error increases substantially after 12 s, reaching a value around 30° (76° − 46° = 30°) at the reference angle of 76°, as shown in Figure 14b,d,f. The steady-state error of FL is still the highest among the three FCUs across all times, at a reference angle of 76°.

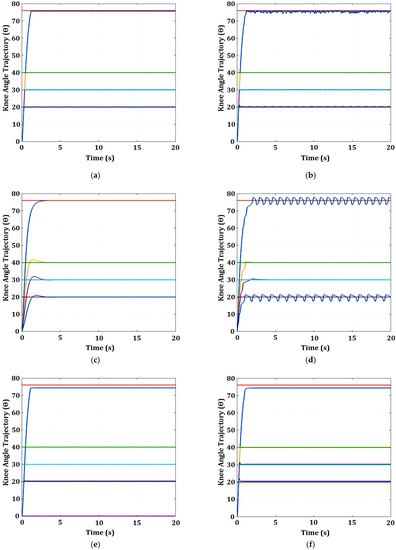

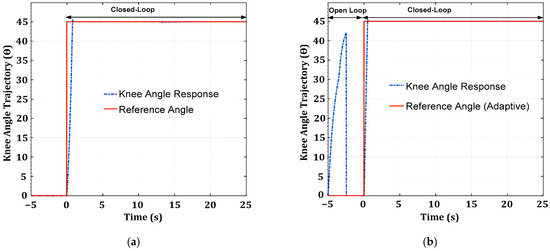

3.1.3. Knee Model with Stiffness Nonlinearity

The knee angle responses of three FCUs (SM, PID, and FL) with stiffness at four different reference angles (20°, 30°, 40°, and 76°) are shown in Figure 15a,c,e. It is observed that the SM FCU is robust and immune to the effect of stiffness because the knee responses are quite stable, with minimal steady-state errors (0.1° to 0.2°) at all reference angles. For the PID FCU, the stiffness effect causes overshoot around the value of 1° to 1.8° in the knee response, especially at lower reference angles (20°, 30°, and 40°). For FL FCU, the stiffness does not affect the knee response and still has a similar large steady-state error (1.69°) at a higher reference angle (76°). This is expected as the FL controller has a lower control bandwidth [30,31].

Figure 15.

Knee angle response with stiffness and spasticity using three FCUs (SM, PID, and FL): (a) knee angle response with stiffness for SM; (b) knee angle response with spasticity for SM; (c) knee angle response with stiffness for PID; (d) knee angle response with spasticity for PID; (e) knee angle response with stiffness for FL; (f) knee angle response with spasticity for FL. The reference angle (ref) and knee response (resp) are represented in different coloured lines as follows: (i) ref 76°: orange and resp: blue; (ii) ref 40°: light green and resp: yellow; (iii) ref 30°: light blue and resp: purple; (iv) ref 20°: red and resp: blue.

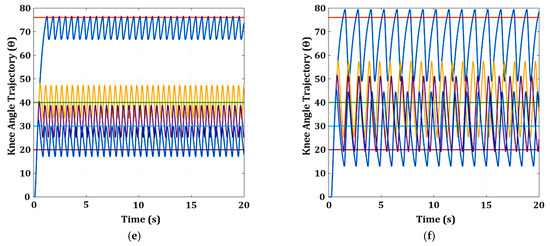

3.1.4. Knee Model with Spasticity Nonlinearity

The knee angle responses for the three FCUs (SM, PID, and FL) with spasticity at four different reference angles (20°, 30°, 40°, and 76°) are shown in Figure 15b,d,f. For SM and PID FCUs, the spasticity effect causes the knee response to oscillate at reference angles of 20° and 76°. The oscillation of the knee response for PID FCU is more prominent and more significant compared with the SM FCU at the lower reference angle (20°) and the higher reference angle (76°). The oscillation of the knee response for the SM FCU increases at a higher reference angle (76°). The knee response for the FL FCU is not affected much by the spasticity effect, except for small overshoots (0.4° to 0.5°) at lower reference angles (20° and 30°). The steady-state error of the FL FCU is still high (1.69°) at the reference angle of 76°. The PID FCU exhibits the worst performance, with a significant oscillation of knee response at smaller and higher reference angles (20° and 76°). PID FCU has the highest steady-state error (4°) at smaller and higher reference angles (20° and 76°). From the knee-angle trajectory oscillating response behaviour, it is observed that SM and PID controllers cannot compensate for the effect of spasticity, especially at smaller and higher reference angles (20° and 76°). FL FCU is found to be robust to the nonlinear spasticity effect.

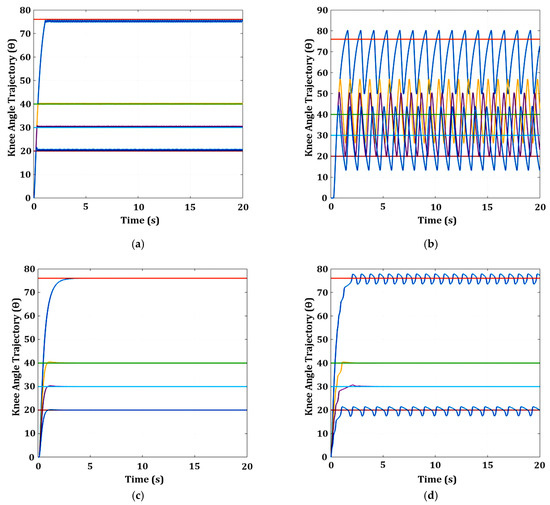

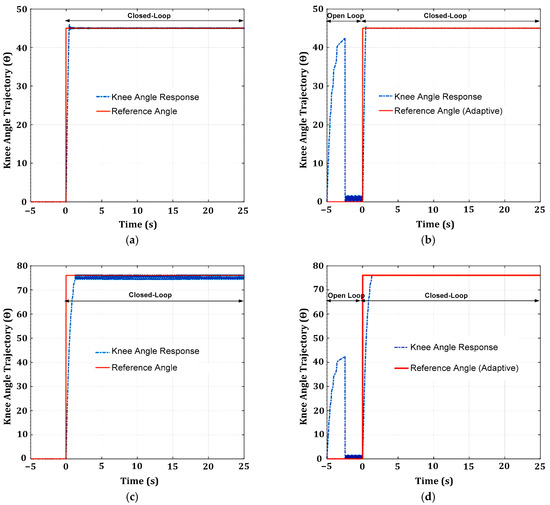

3.1.5. Knee Model with Time Delay (10 ms, and 260 ms) Nonlinearity

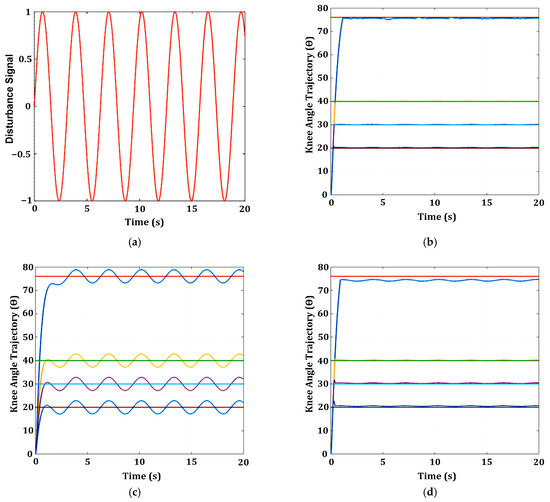

The knee angle responses of three FCUs (SM, PID, and FL) with a time delay of 10 ms at four different reference angles (20°, 30°, 40°, and 76°) are shown in Figure 16a,c,e. The knee response for the PID FCU seems relatively smooth, with no oscillation at any reference angles. The time delay causes small oscillations at all reference angles for the SM FCU. However, for the FL FCU, the time delay of 10 ms has a higher oscillation when compared with the SM FCU.

Figure 16.

Knee angle response with time delay 10 ms and 260 ms using three FCUs (SM, PID, and FL): (a) knee angle response with a time delay of 10ms for SM; (b) knee angle response with a time delay of 260 ms for SM; (c) knee angle response with a time delay of 10 ms for PID; (d) knee angle response with time a delay of 260 ms for PID; (e) knee angle response with a time delay of 10 ms for FL; (f) knee angle response with a time delay of 260 ms for FL. The reference angle (ref) and knee response (resp) are represented in different coloured lines as follows: (i) ref 76°: orange and resp: blue; (ii) ref 40°: light green and resp: yellow; (iii) ref 30°: light blue and resp: purple; (iv) ref 20°: red and resp: blue.

The knee angle responses of three FCUs (SM, PID, and FL) with a time delay of 260 ms at four different reference angles (20°, 30°, 40°, and 76°) are shown in Figure 16b,d,f. The large time delay (260 ms) causes bigger oscillations in the knee response for SM and FL FCUs at all reference angles. It is observed that the SM and FL FCUs could not eliminate the time delay effect at all reference angles and had a degraded closed-loop performance. SM FCU has the highest overshoot and steady-state errors in the range of 15° to 24° at all reference angles (20°, 30°, 40°, and 76°). FL FCU has the second-highest overshoot and steady-state errors in the range of 2° to 22° at all reference angles (20°, 30°, 40°, and 76°). The knee response for PID FCU also shows small oscillations at reference angles of 20° and 76°.

3.1.6. Knee Model with Time Delay Nonlinearity Using DTC (260 ms)

To overcome heavy oscillation in the knee response when a higher time delay exists in the system, DTC was employed in all FCUs (SM, PID, and FL). Additionally, to reduce the significant effect of chattering in the SM at a higher time delay, the SM was replaced with a USM FCU. The knee angle response with a time delay of 260 ms is shown in Figure 17a when USM FCU is used. The heavy oscillation is significantly reduced compared with the SM FCU (as shown in Figure 16b).

Figure 17.

Knee angle response with a 260 ms time delay using three FCUs (USM, PID, and FL): (a) knee angle response with a time delay of 260 ms for USM; (b) knee angle response with a 260 ms time delay for USM with DTC; (c) knee angle response with a 260 ms time delay for PID with DTC; (d) knee angle response with a 260 ms time delay for FL with DTC. The reference angle (ref) and knee response (resp) are represented in different coloured lines as follows: (i) ref 76°: orange and resp: blue; (ii) ref 40°: light green and resp: yellow; (iii) ref 30°: light blue and resp: purple; (iv) ref 20°: red and resp: blue.

Figure 17b–d depicts the knee angle response for the three FCUs (USM, PID, and FL) with DTC activation for a 260 ms time delay at four different reference angles (20°, 30°, 40°, and 76°). It is observed that the knee response of USM FCU with DTC (Figure 17b) activation is relatively smooth at four reference angles (20°, 30°, 40°, and 76°) when a time delay of 260 ms exists in the system. As shown in Table 6, USM FCU with DTC activation has a much faster rise time at a lower reference angle (20° and 30°) than the USM FCU operating alone. Although the PID FCU with DTC (Figure 17c) has a smooth knee response (no oscillation), the rise time at all reference angles is quite large (ranging from 5.26 s to 6.42 s) when compared with the PID FCU that operates alone (shown in Figure 16d). The knee response for the FL FCU with DTC (Figure 17d) still oscillates. However, the knee response has shown some reduction in the oscillation amplitude and frequency at four reference angles (20°, 30°, 40°, and 76°) with an increment in the rise time value when compared with the FL FCU that operates alone (shown in Figure 16f).

Table 6.

Rise time for USM, USM with DTC, PID with DTC, and FLC with DTC for the knee extension model with a time delay of 260 ms.

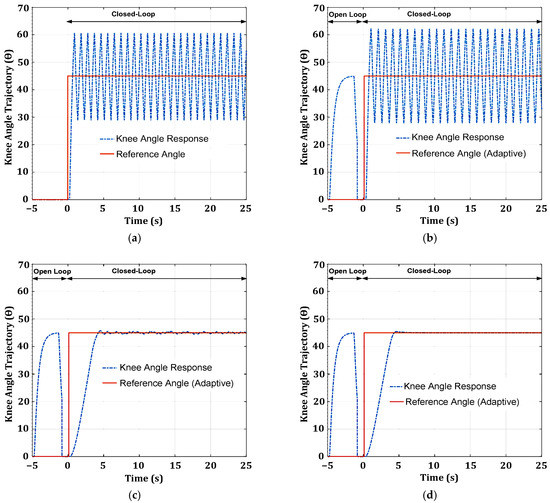

From the results of all the knee response simulations, USM FCU with DTC works best when the time delay in the system is high.