Kinematic Analysis of a Spatial Cable-Driven Mechanism and Its Equivalent Hybrid Mechanism for Elliptical Trajectory

Abstract

1. Introduction

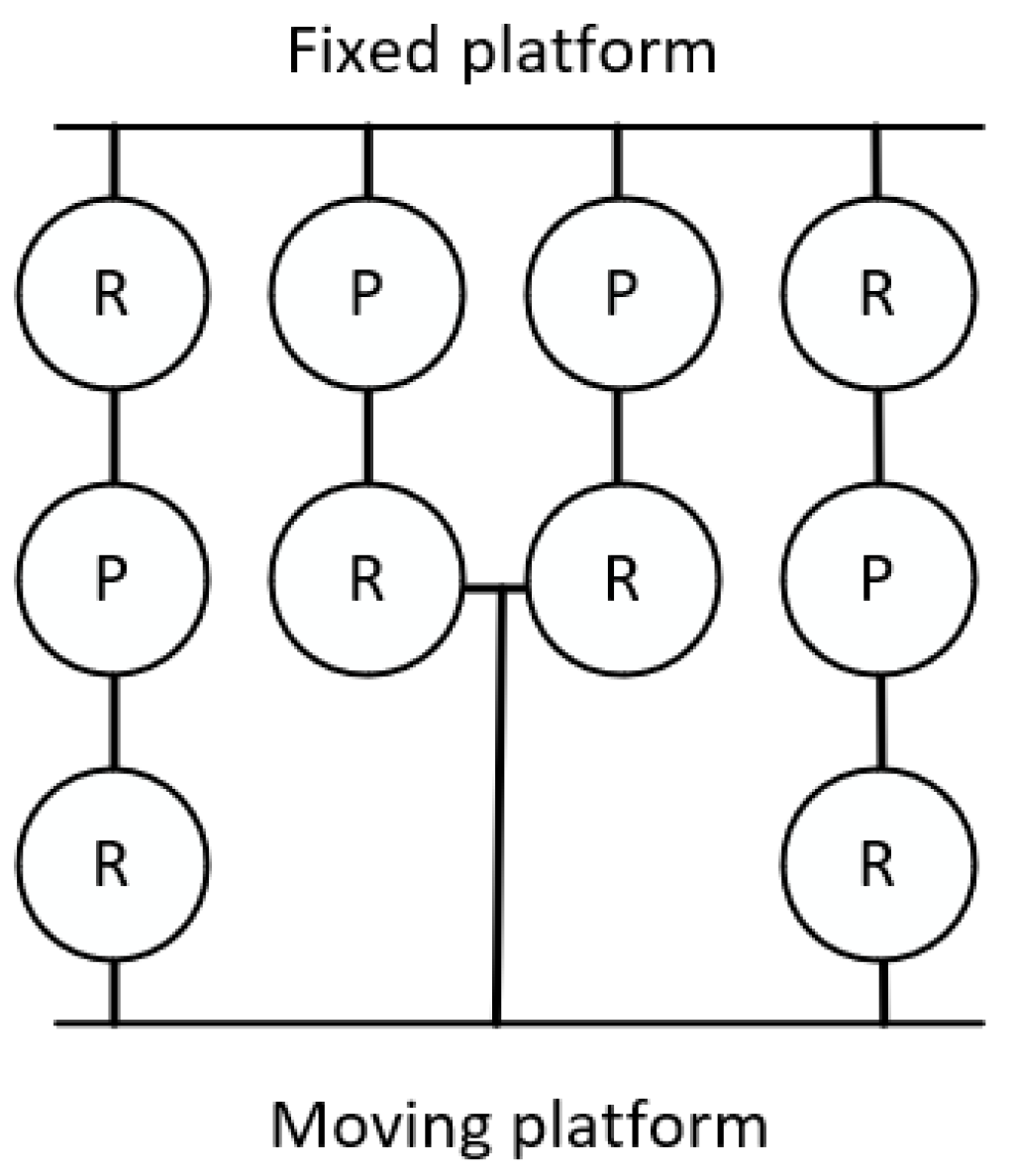

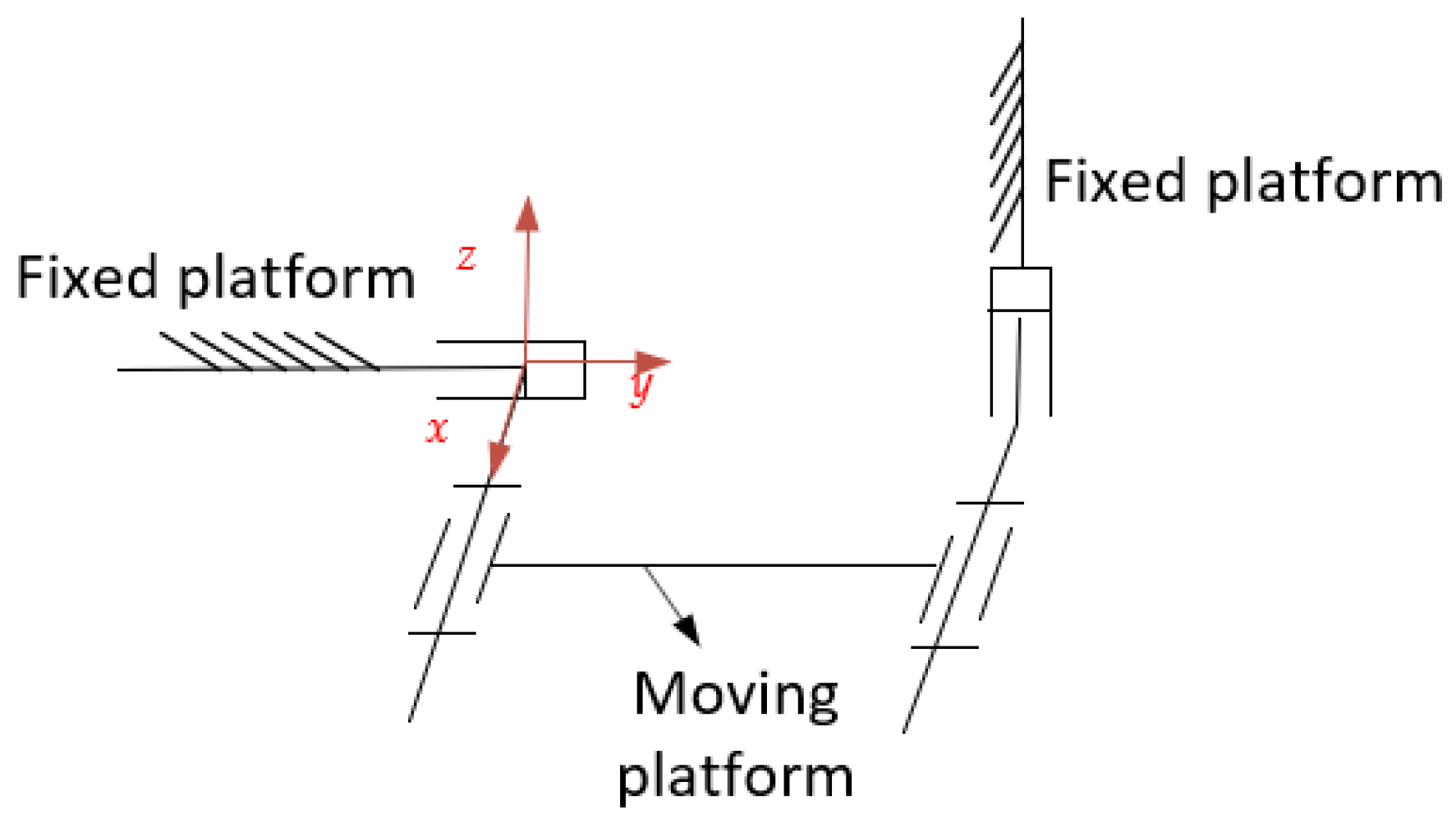

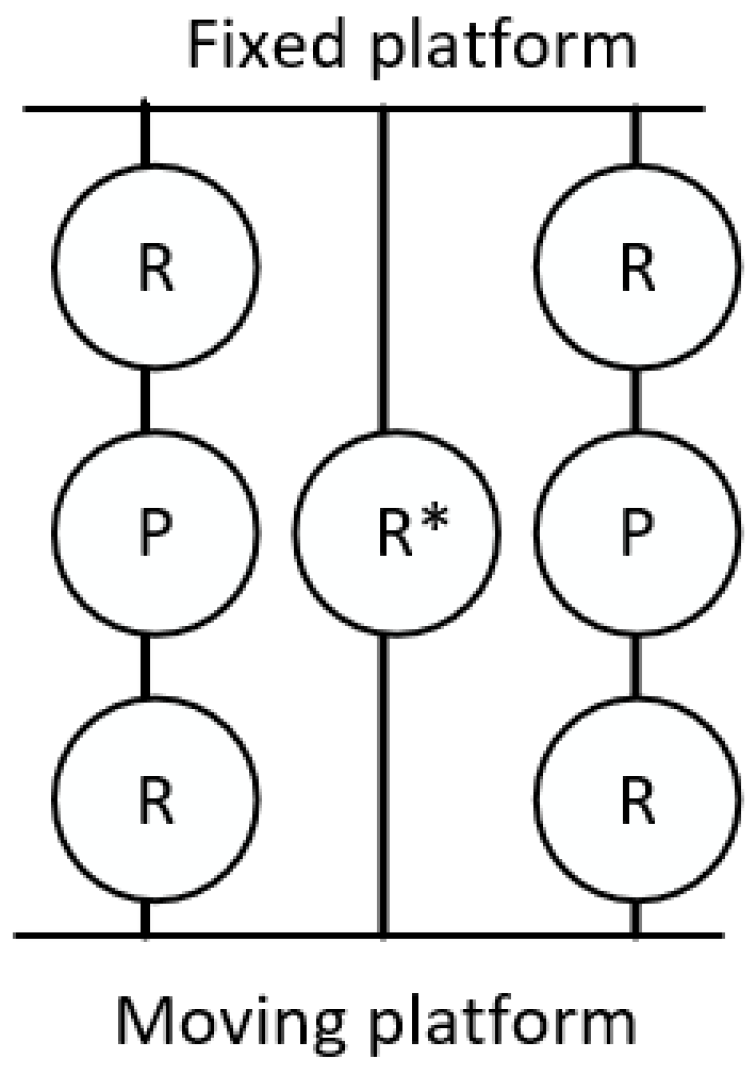

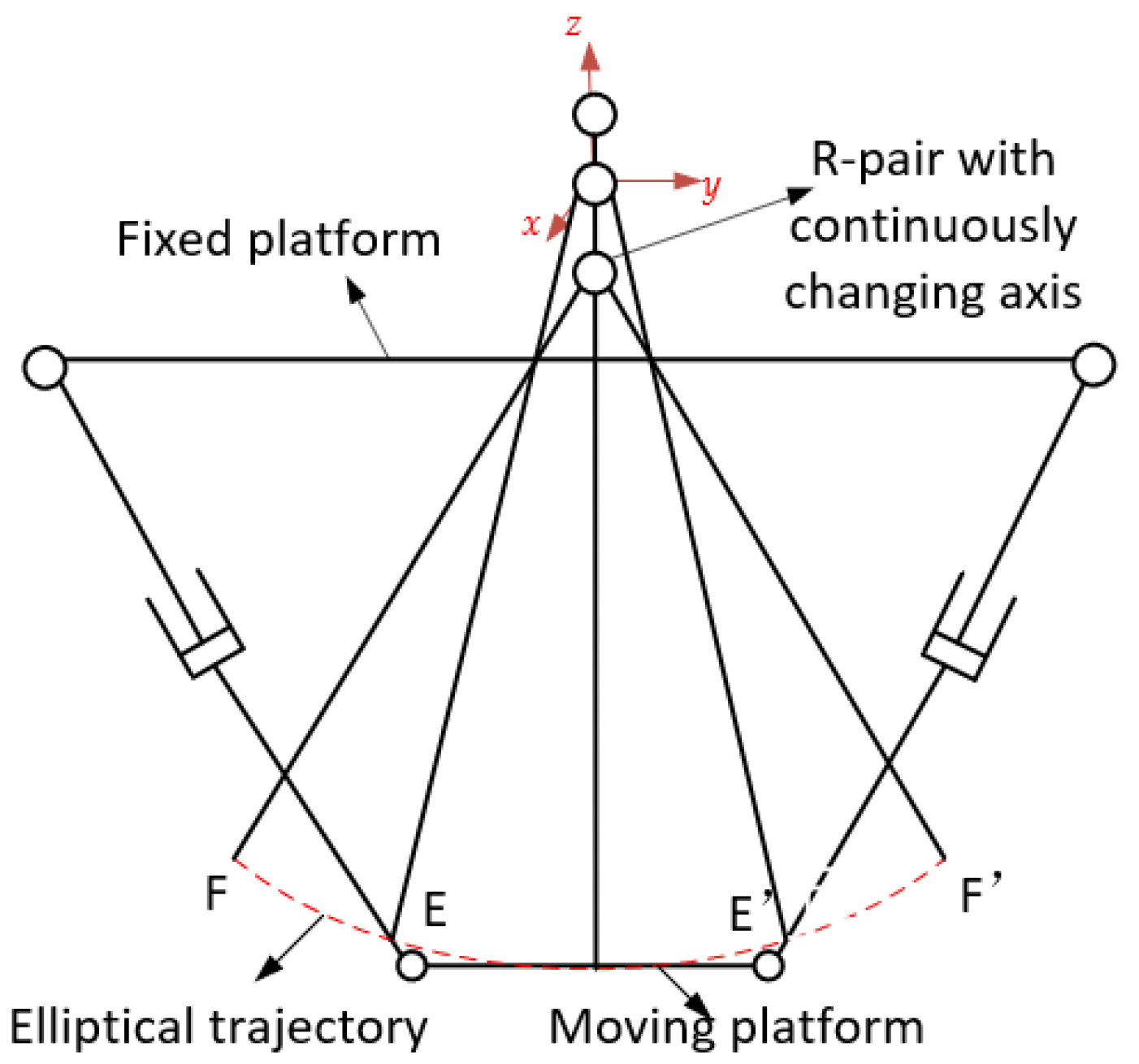

2. Preliminary on Screw Theory

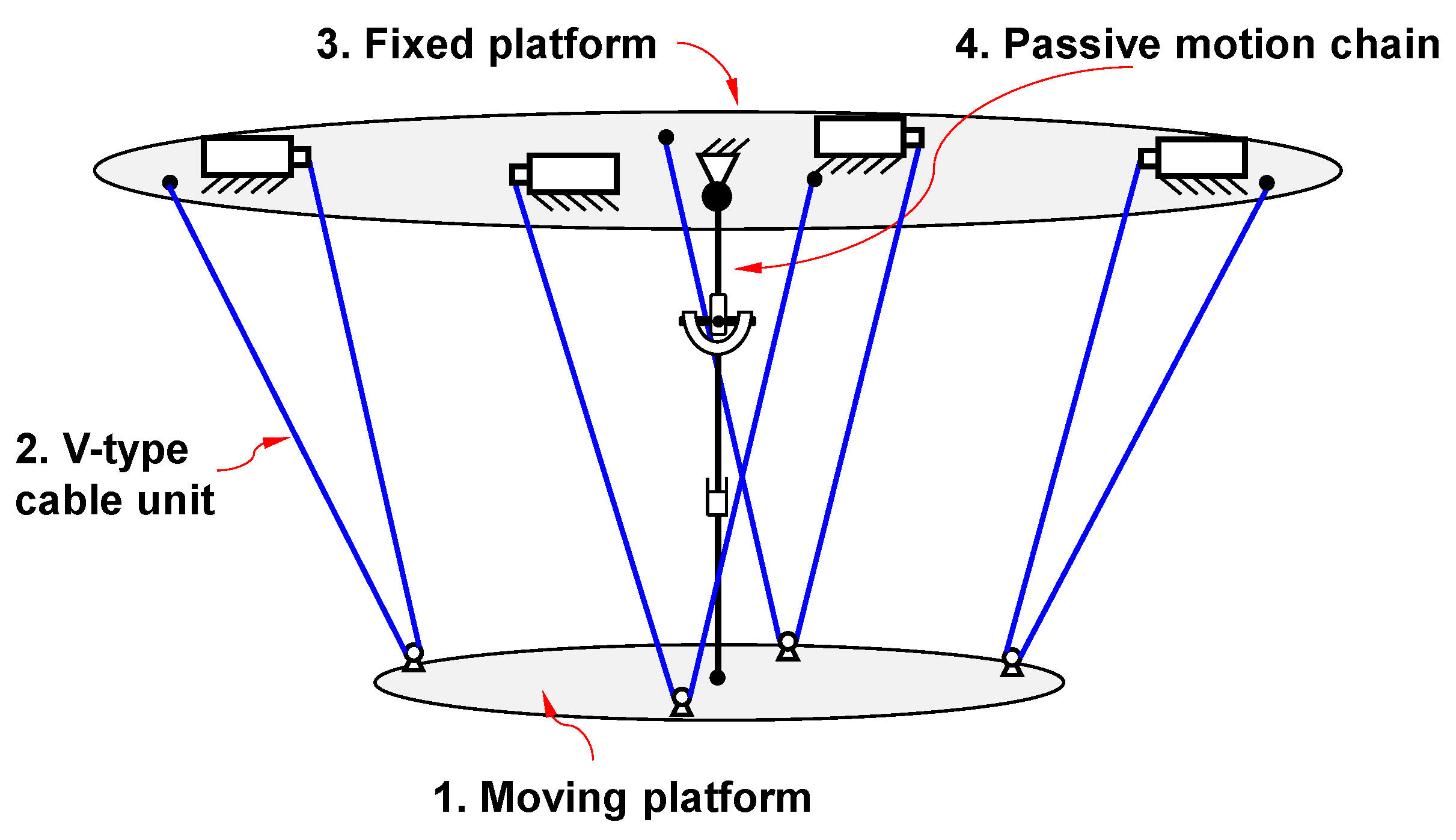

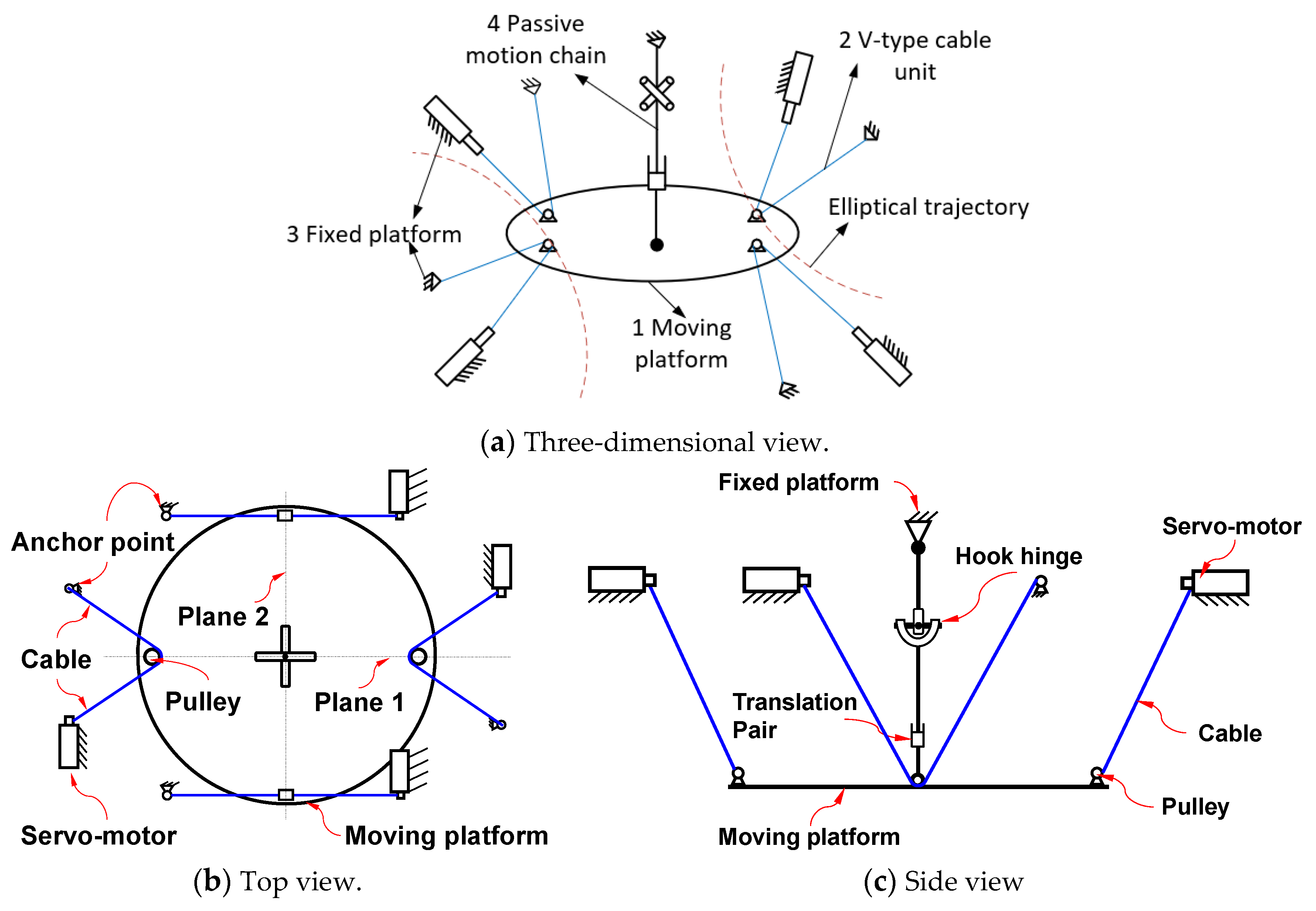

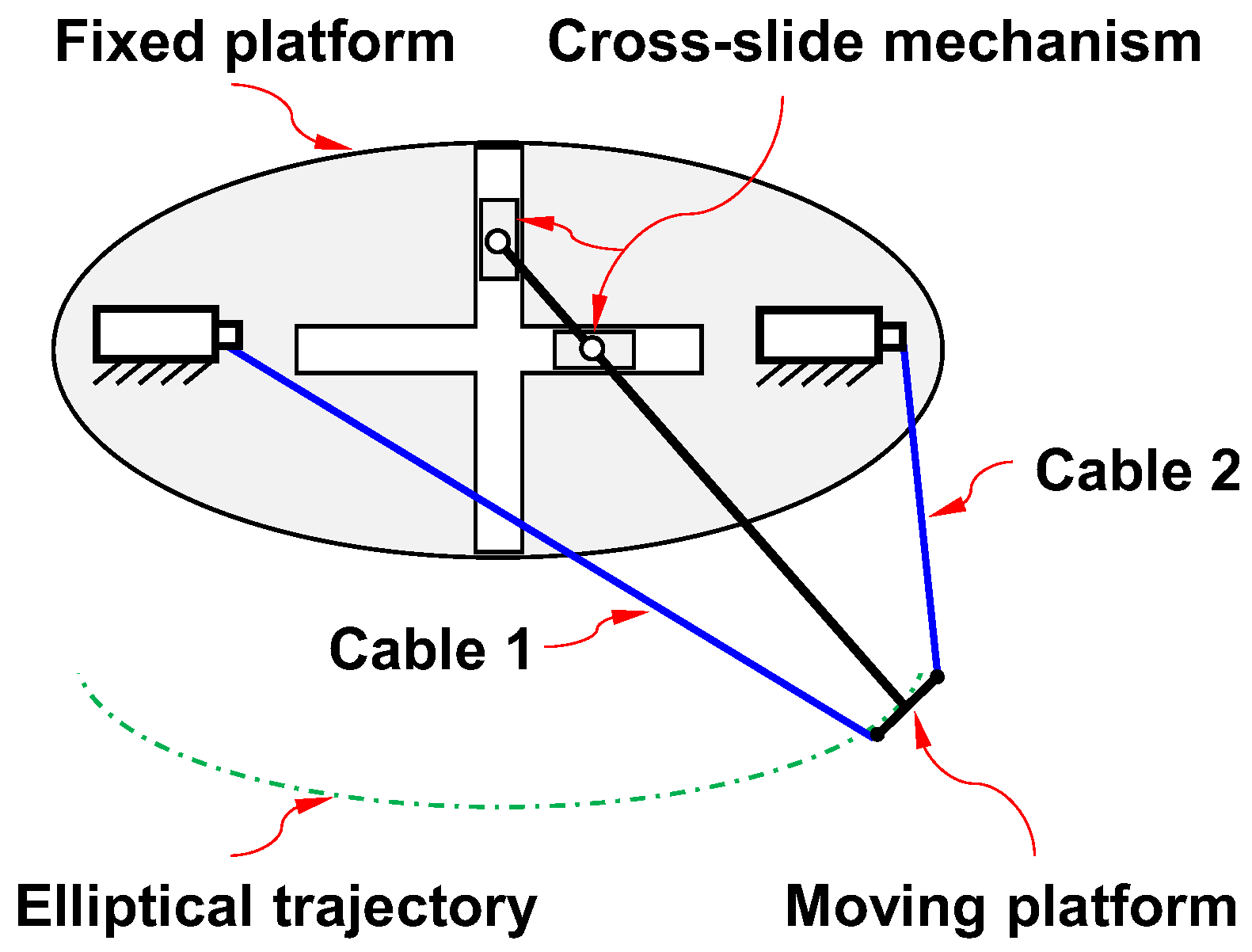

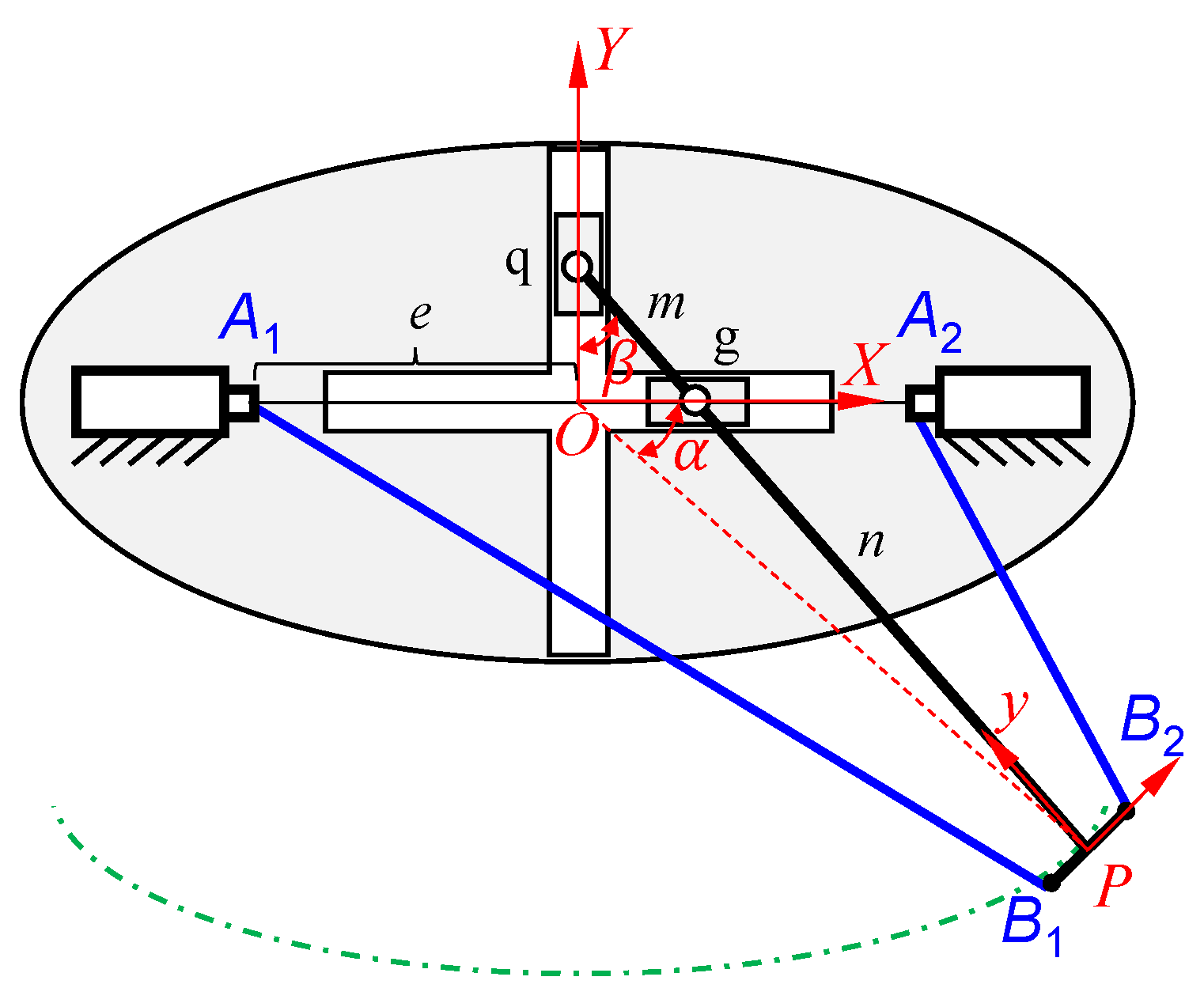

3. Equivalent Rigid Parallel Mechanism

- (1)

- List the motion screw system of each chain;

- (2)

- Find the reverse screw of (1);

- (3)

- The quadratic anti-screw of (2) is solved to obtain kinematic screws of the mechanism allowed by constraint screws.

4. Verification of DoFs of the Mechanism

5. Kinematic Analysis of Hybrid Mechanism

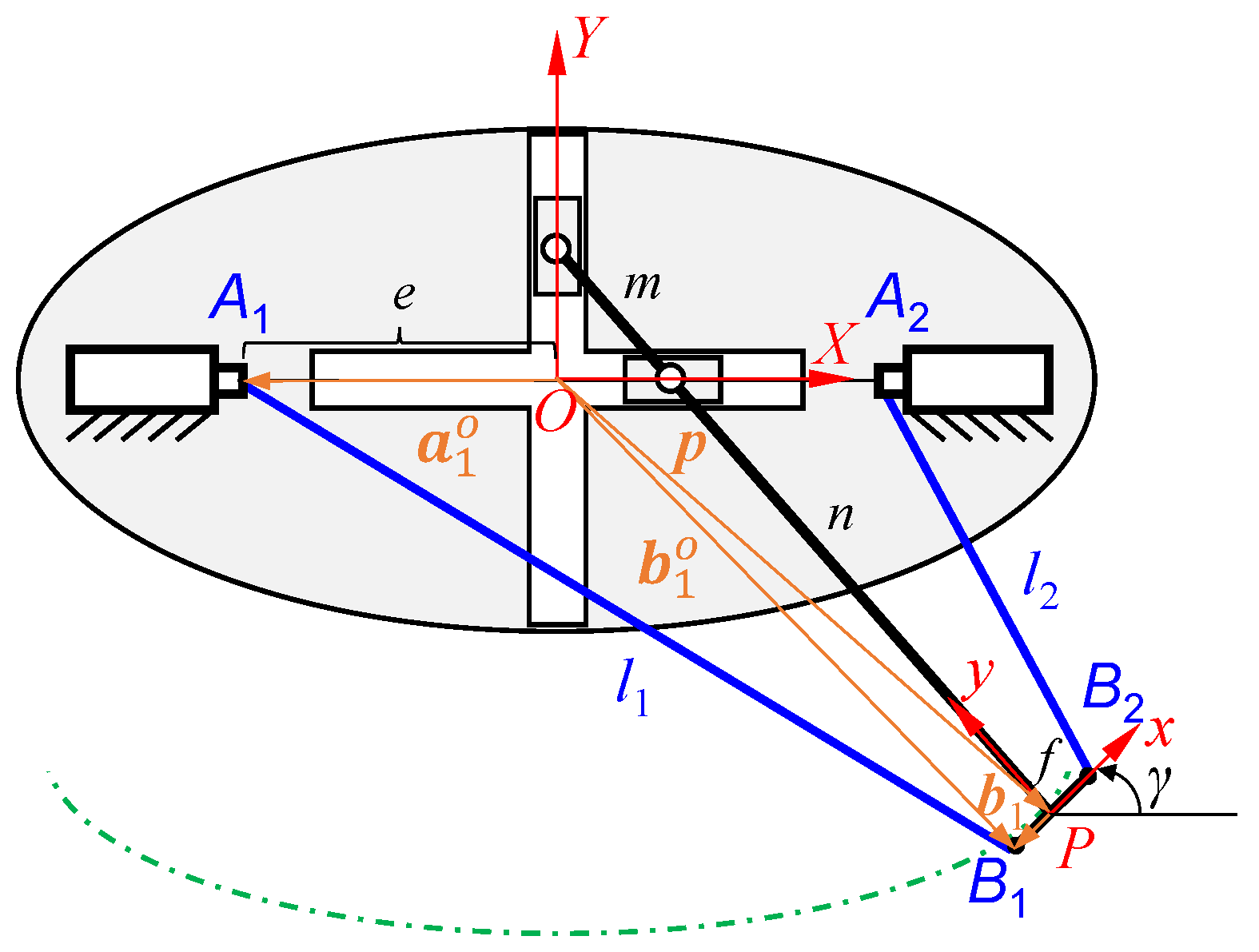

5.1. Position Analysis

5.2. Velocity Analysis

5.3. Acceleration Analysis

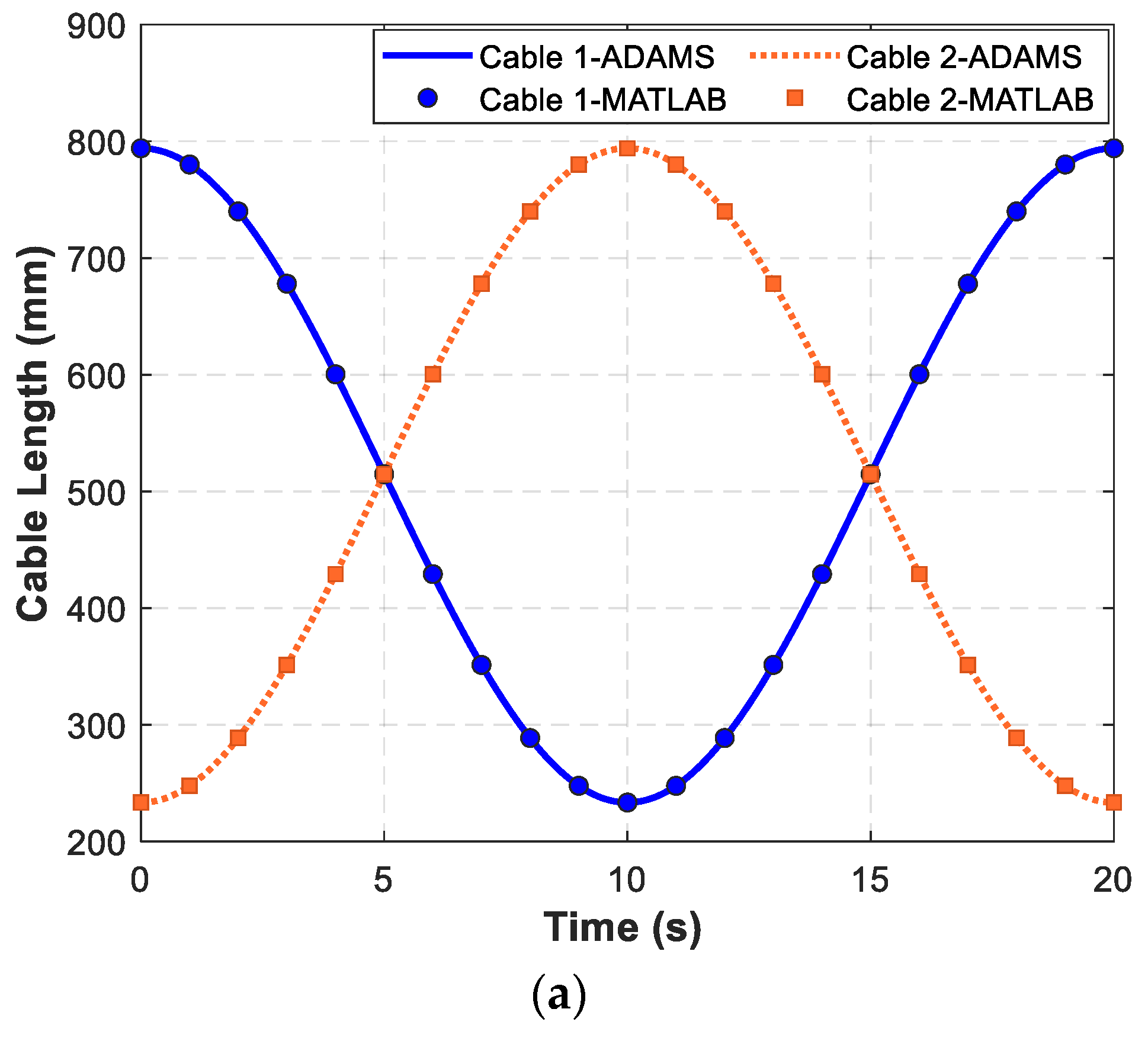

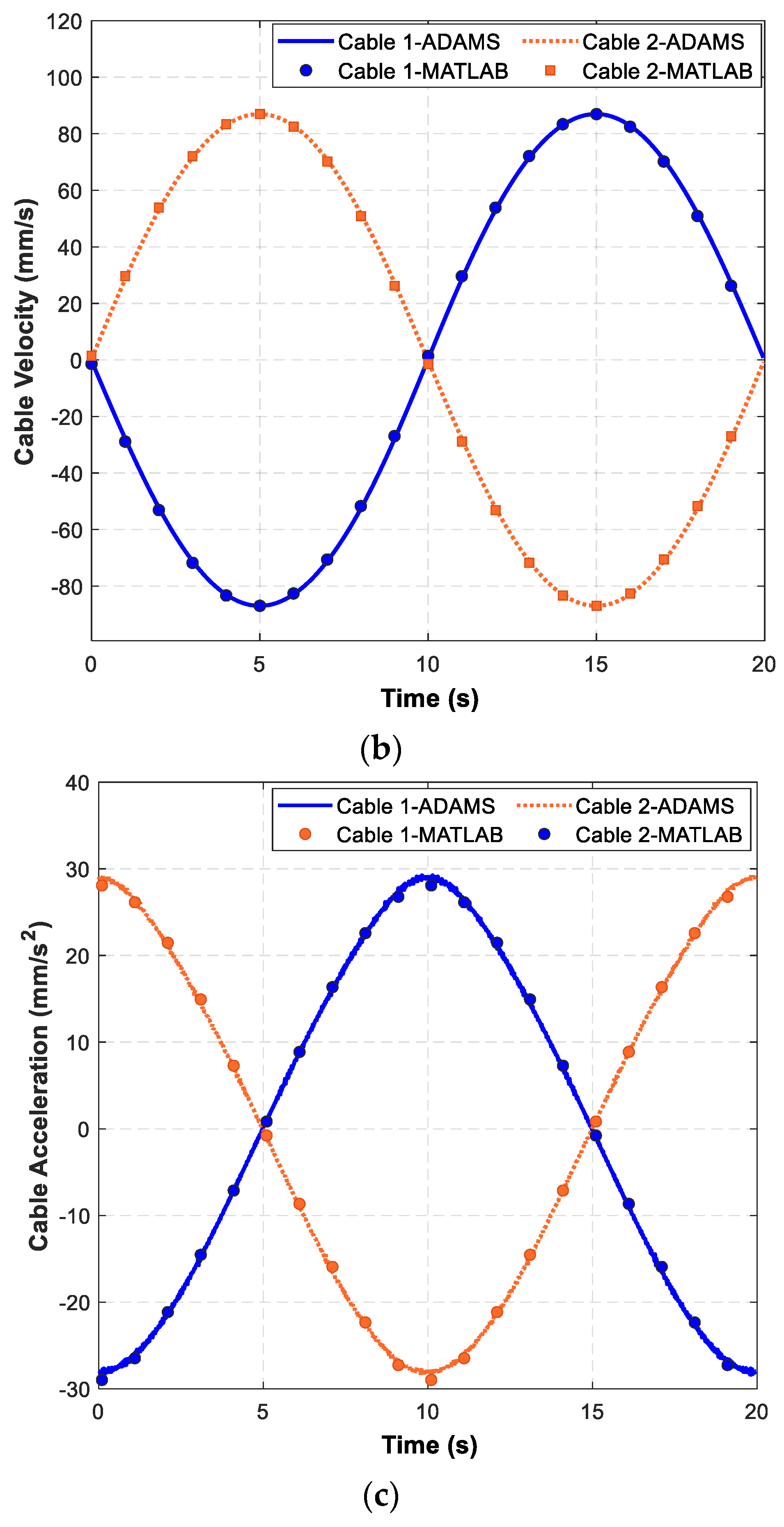

5.4. Kinematics Simulation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Shao, Z.; You, Z.; Tang, X.; Zi, B.; Yang, G.; Gosselin, C.; Caro, S. State-of-the-art on theories and applications of cable-driven parallel robots. Front. Mech. Eng. 2022, 17, 37. [Google Scholar] [CrossRef]

- Qian, S.; Zi, B.; Xu, Q. A review on cable-driven parallel robots. Chin. J. Mech. Eng. 2018, 31, 66. [Google Scholar]

- Tang, X. An overview of the development for cable-driven parallel manipulator. Adv. Mech. Eng. 2014, 6, 823028. [Google Scholar] [CrossRef]

- Tang, L.; Gouttefarde, M.; Sun, H.; Yin, L.; Zhou, C. Dynamic modelling and vibration suppression of a single-link flexible manipulator with two cables. Mech. Mach. Theory 2021, 162, 104347. [Google Scholar] [CrossRef]

- Rasheed, T.; Long, P.; Caro, S. Wrench-feasible workspace of mobile cable-driven parallel robots. J. Mech. Robot. 2020, 12, 031009. [Google Scholar] [CrossRef]

- Castelli, G.; Ottaviano, E.; Rea, P. A cartesian cable-suspended robot for improving end-users’ mobility in an urban environment. Robot. Comput.-Integr. Manuf. 2014, 30, 335–343. [Google Scholar] [CrossRef]

- Tang, L.; Shi, P.; Wu, L.; Wu, X.; Tang, X. Singularity analysis on a special class of cable-suspended parallel mechanisms with pairwise cable arrangement and actuation redundancy. J. Mech. Des. 2020, 142, 024501. [Google Scholar] [CrossRef]

- Barbazza, L.; Oscari, F.; Minto, S.; Rosati, G. Trajectory planning of a suspended cable driven parallel robot with reconfigurable end effector. Robot. Comput. -Integr. Manuf. 2017, 48, 1–11. [Google Scholar] [CrossRef]

- Tang, X.; Zhu, W.; Sun, C.; Yao, R. Similarity model of feed support system for FAST. Exp. Astron. 2011, 29, 177–187. [Google Scholar] [CrossRef]

- Yin, J.; Jiang, P.; Yao, R. An approximately analytical solution method for the cable-driven parallel robot in FAST. Res. Astron. Astrophys 2021, 21, 46–60. [Google Scholar] [CrossRef]

- Yao, R.; Jiang, P.; Sun, J.-H.; Yu, D.-J.; Sun, C. A motion planning algorithm for the feed support system of FAST. Res. Astron. Astrophys 2020, 20, 68. [Google Scholar] [CrossRef]

- Khakpour, H.; Birglen, L.; Tahan, S. Synthesis of differentially driven planar cable parallel manipulators. IEEE Trans. Robot. 2014, 30, 619–630. [Google Scholar] [CrossRef]

- Khodadadi, N.; Hosseini, M.I.; Khalilpour, S.A.; Taghirad, H.D.; Cardou, P. Multiobjective optimization of a cable-driven robot with parallelogram links. In Cable-Driven Parallel Robots. CableCon 2021; Gouttefarde, M., Bruckmann, T., Pott, A., Eds.; Springer International Publishing: Cham, Switzerland, 2021; Volume 104, pp. 170–181. [Google Scholar]

- Nuchkrua, T.; Chen, S. Precision contouring control of five degree of freedom robot manipulators with uncertainty. Int. J. Adv. Robot. Syst. 2017, 14, 1729881416682703. [Google Scholar] [CrossRef]

- Dimentberg, F. The Screw Calculus and Its Applications to Mechanics; Clearinghouse for Federal Scientific & Technical Information: Online, 1968. [Google Scholar]

- Hunt, K. Kinematic Geometry of Mechanisms; Clarendon Press: Oxford, UK, 1978. [Google Scholar]

- Sugimoto, K.; Duffy, J. Application of Linear Algebra to Screw Systems. Mech. Mach. Theory 1982, 17, 73–83. [Google Scholar] [CrossRef]

- Mohamed, M.G.; Duffy, J. A direct determination of the instantaneous kinematics of fully parallel robot manipulators. J. Mech. Des. 1985, 107, 226–229. [Google Scholar] [CrossRef]

- Huang, Z. Modelling formulation of 6-dof Multi-loop Parallel Manipulators, Part 1-Kinematic Influence Matrix. In Proceedings of the 4th IFToMM Conference on Mechanisms and CAD, Bucharest, Romania, 27–30 September 1985; Volume 2, pp. 163–170. [Google Scholar]

- Huang, Z.; Liu, J.; Zeng, D. A general methodology for mobility analysis of mechanisms based on constraint screw theory. Sci. China Ser. E-Technol. Sci. 2009, 52, 1337–1347. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, J.; Li, Y. Mobility of Mechanisms; Science Press: Beijing, China, 2011. [Google Scholar]

- Yang, T.; Shen, H.; Liu, A.; Dai, J. Review of the Formulas for Degrees of Freedom in the Past Ten Years. J. Mech. Eng. 2015, 51, 69–80. [Google Scholar] [CrossRef]

- Hervé, J.M. The mathematical group structure of the set of displacements. Mech. Mach. Thoery 1994, 29, 73–81. [Google Scholar] [CrossRef]

- Huang, Z.; Li, Q. General methodology for type synthesis of lower-mobility symmetrical parallel manipulators and several novel manipulators. Int. J. Robot. Res. 2002, 21, 131–145. [Google Scholar] [CrossRef]

- Yang, T.; Liu, A.; Luo, Y.; Hang, L.; Shen, H.; Shi, Z. Basic principles, main characteristics and development tendency of methods for robot mechanism structure synthesis. J. Mech. Eng. 2010, 46, 1–11. [Google Scholar] [CrossRef]

- Hu, B. Kinematically identical manipulators for the Exechon parallel manipulator and their comparison study. Mech. Mach. Theory 2016, 103, 117–137. [Google Scholar] [CrossRef]

- Hu, B.; Huang, Z. Kinematically identical manipulators of a 2-RPU+UPR parallel manipulator and their kinematics analysis. In Proceedings of the 14th IFToMM World Congress, Taipei, Taiwan, China, 25–30 October 2015; pp. 310–319. [Google Scholar]

- Hu, B. Theoretical Study of Limited-Dof Parallel Manipulators and Serial-Parallel Manipulators Based on Constrained Force/Torque. Ph.D. Thesis, Yanshan University, Qinhuangdao, China, 2010. [Google Scholar]

- Li, W.; Xiao, Y.; Bi, S.; Du, G. Automatic elliptical trajectory planning algorithm for pick and place operation. In Proceedings of the 2013 International Conference on Advanced Mechatronics Systems, Luoyang, China, 19–22 February 2013. [Google Scholar]

- Fallahtafti, F.; Pfeifer, C.M.; Buster, T.W.; Burnfield, J.M. Effect of motor-assisted elliptical training speed and body weight support on center of pressure movement variability. Gait Posture 2020, 81, 138–143. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Dai, J. Bifurcated configurations and their variations of an 8-bar linkage derived from an 8-kaleidocycle. Mech. Mach. Theory 2018, 121, 745–754. [Google Scholar] [CrossRef]

- Wang, R.; Song, Y.; Dai, J. Reconfigurability of the origami-inspired integrated 8R kinematotropic metamorphic mechanism and its evolved 6R and 4R mechanisms. Mech. Mach. Theory 2021, 161, 104245. [Google Scholar] [CrossRef]

- Shi, C.; Guo, H.; Zhang, S.; Liu, R.; Deng, Z. Configuration synthesis of linear foldable over-constrained deployable unit based on screw theory. Mech. Mach. Theory 2021, 156, 104163. [Google Scholar] [CrossRef]

- Khakpour, H.; Birglen, L.; Tahan, S.-A. Analysis and optimization of a new differentially driven cable parallel robot. J. Mech. Robot. 2015, 7, 034503. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, L.; Liu, X.; Wang, M.; Zhao, D.; Tang, L. Kinematic Analysis of a Spatial Cable-Driven Mechanism and Its Equivalent Hybrid Mechanism for Elliptical Trajectory. Machines 2023, 11, 710. https://doi.org/10.3390/machines11070710

Wu L, Liu X, Wang M, Zhao D, Tang L. Kinematic Analysis of a Spatial Cable-Driven Mechanism and Its Equivalent Hybrid Mechanism for Elliptical Trajectory. Machines. 2023; 11(7):710. https://doi.org/10.3390/machines11070710

Chicago/Turabian StyleWu, Li, Xuan Liu, Mingjun Wang, Dengbiao Zhao, and Lewei Tang. 2023. "Kinematic Analysis of a Spatial Cable-Driven Mechanism and Its Equivalent Hybrid Mechanism for Elliptical Trajectory" Machines 11, no. 7: 710. https://doi.org/10.3390/machines11070710

APA StyleWu, L., Liu, X., Wang, M., Zhao, D., & Tang, L. (2023). Kinematic Analysis of a Spatial Cable-Driven Mechanism and Its Equivalent Hybrid Mechanism for Elliptical Trajectory. Machines, 11(7), 710. https://doi.org/10.3390/machines11070710