Optimized Energy Management Control of a Hybrid Electric Locomotive

Abstract

1. Introduction

2. Materials and Methods

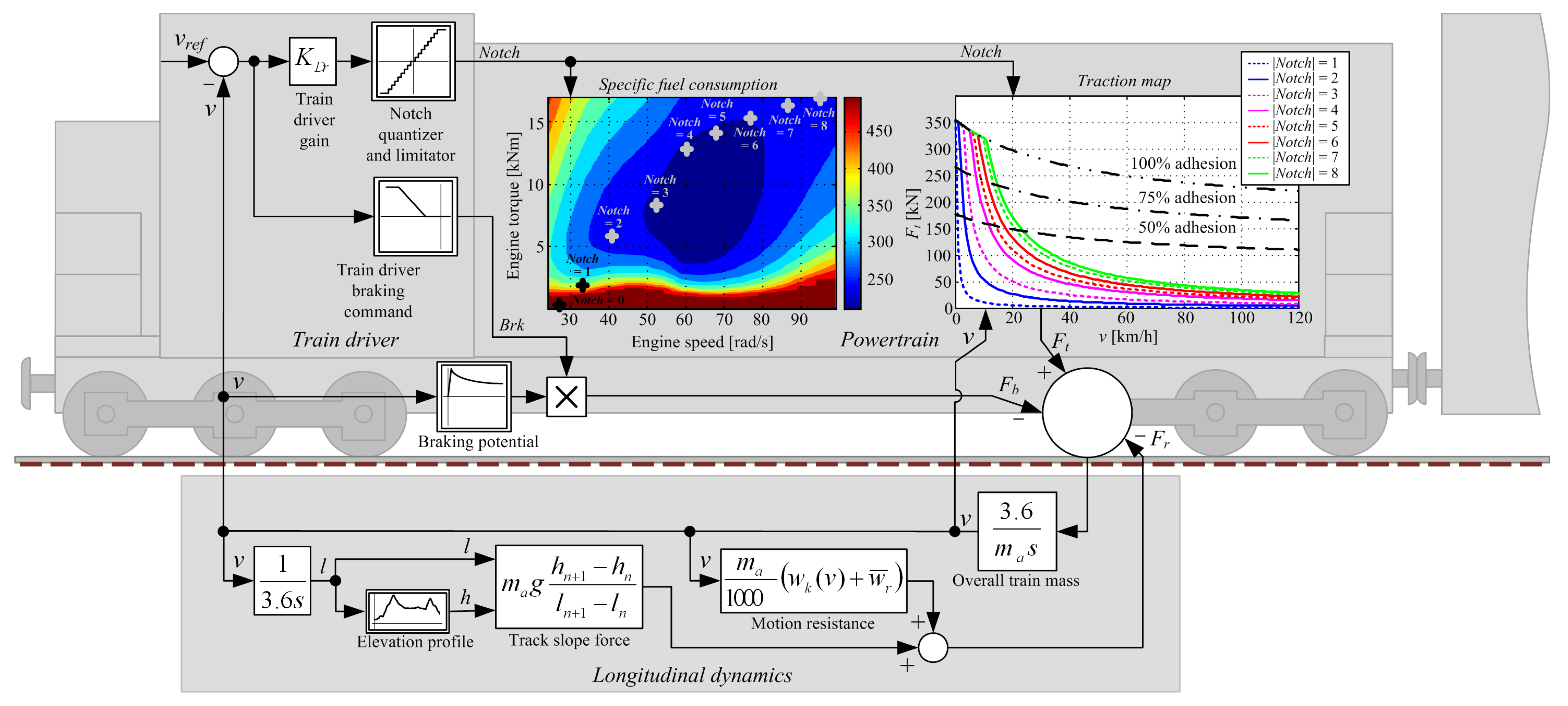

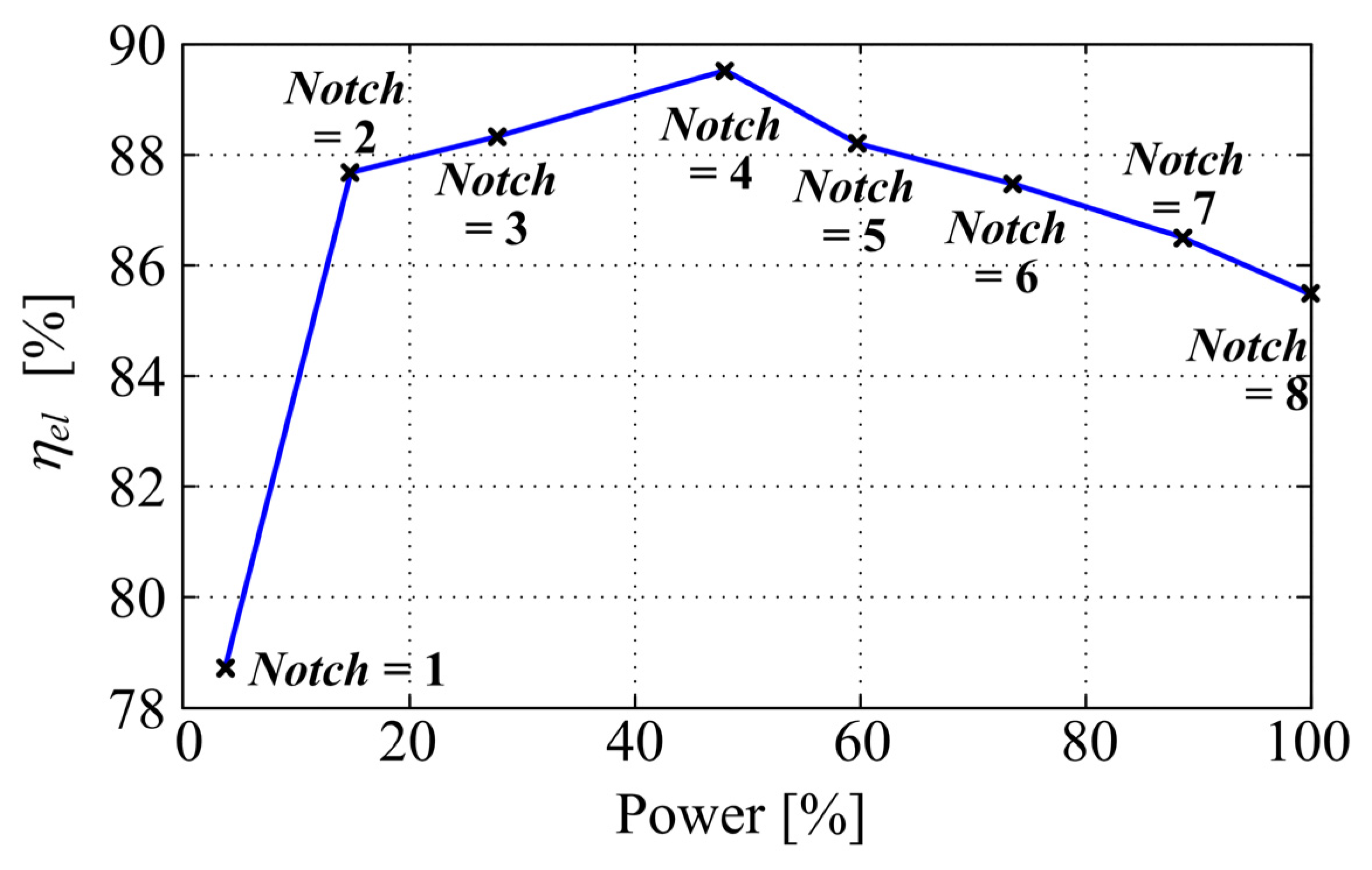

2.1. Conventional Diesel–Electric Locomotive Model

2.2. Hybrid–Electric Locomotive Model with Battery Energy Storage

2.3. Optimization Procedure

2.3.1. Optimization Problem Formulation

2.3.2. Outline of Dynamic Programming Algorithm

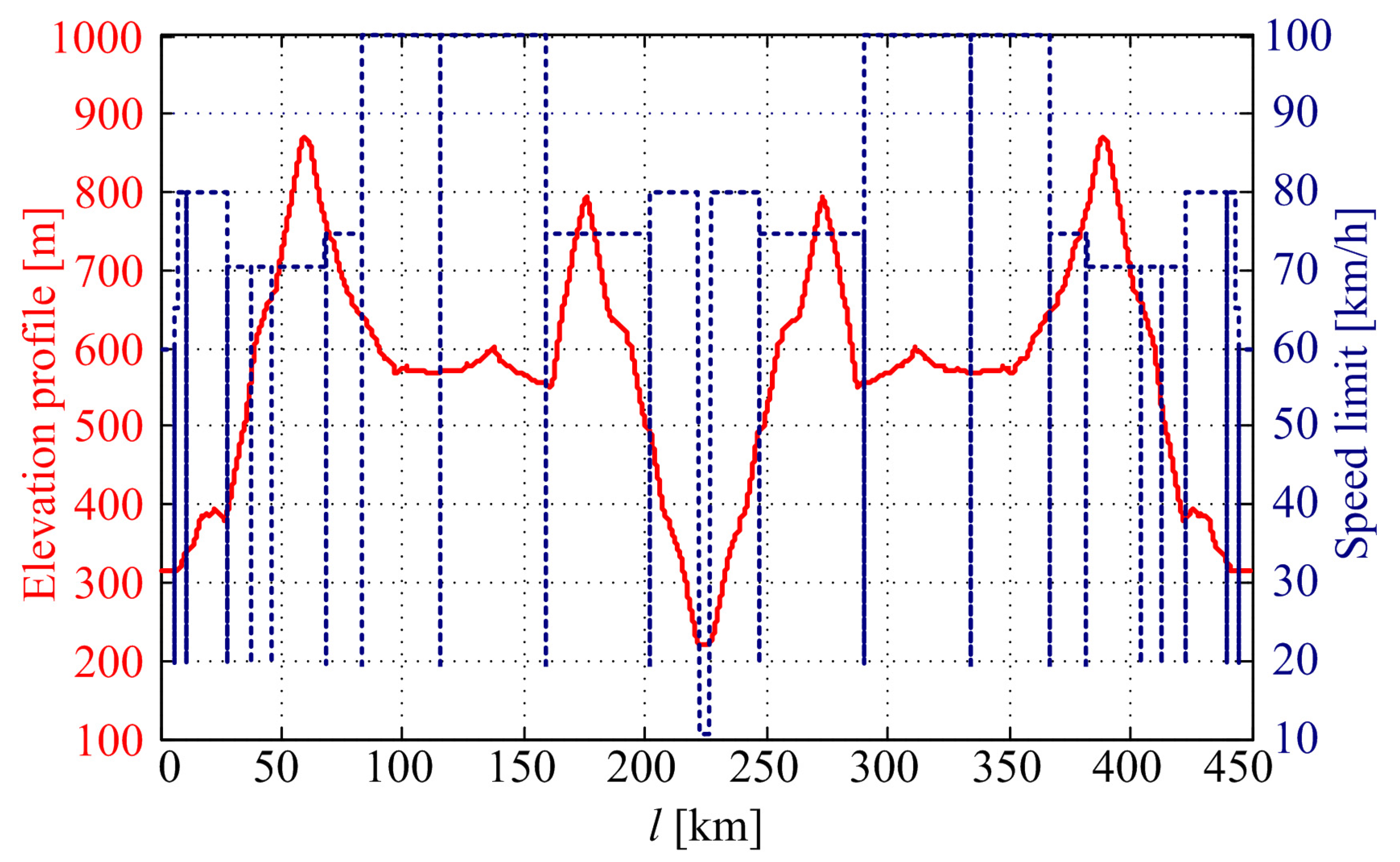

2.4. Considered Driving Mission

3. Optimization and Simulation Results

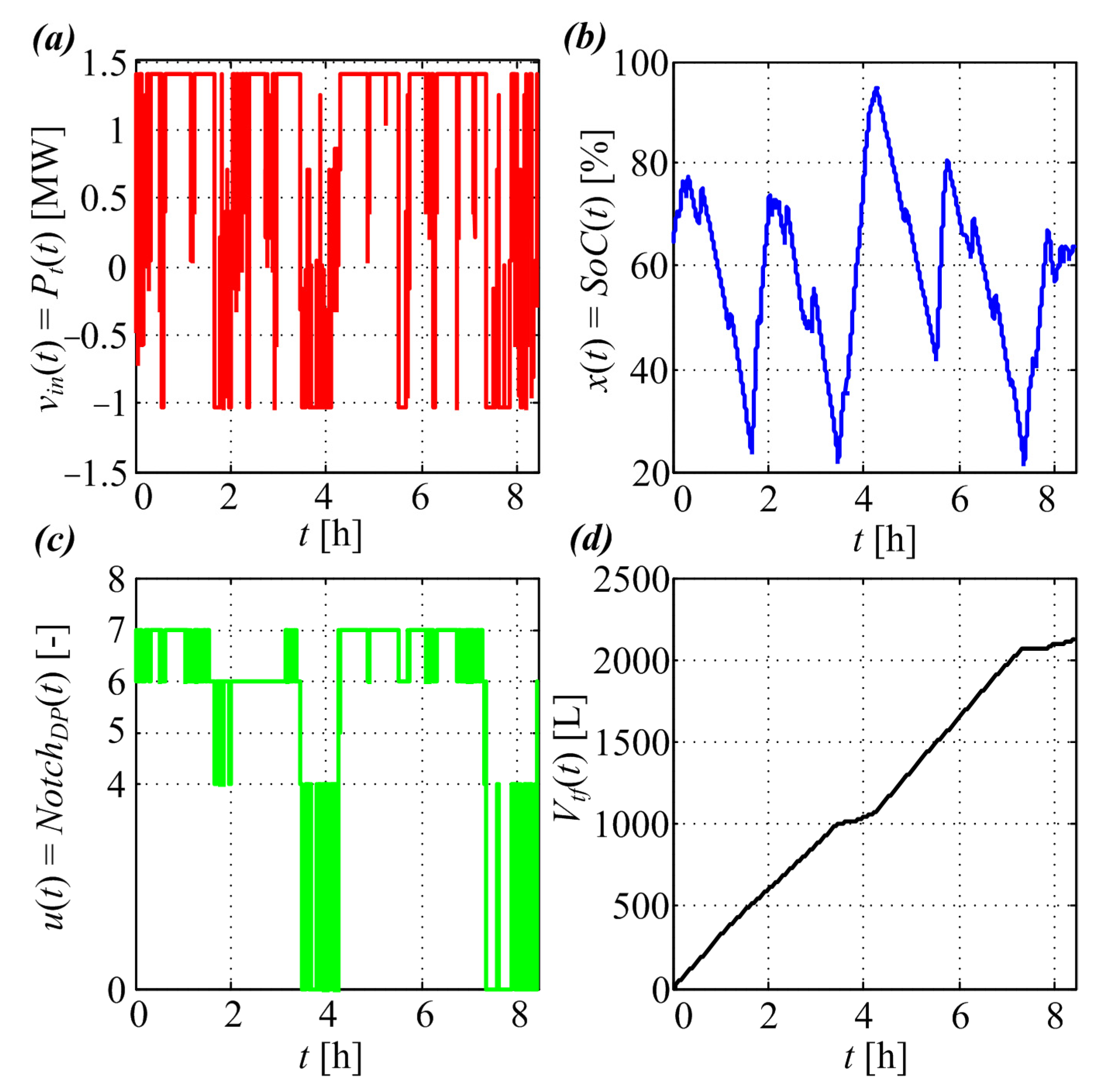

3.1. Optimization Results

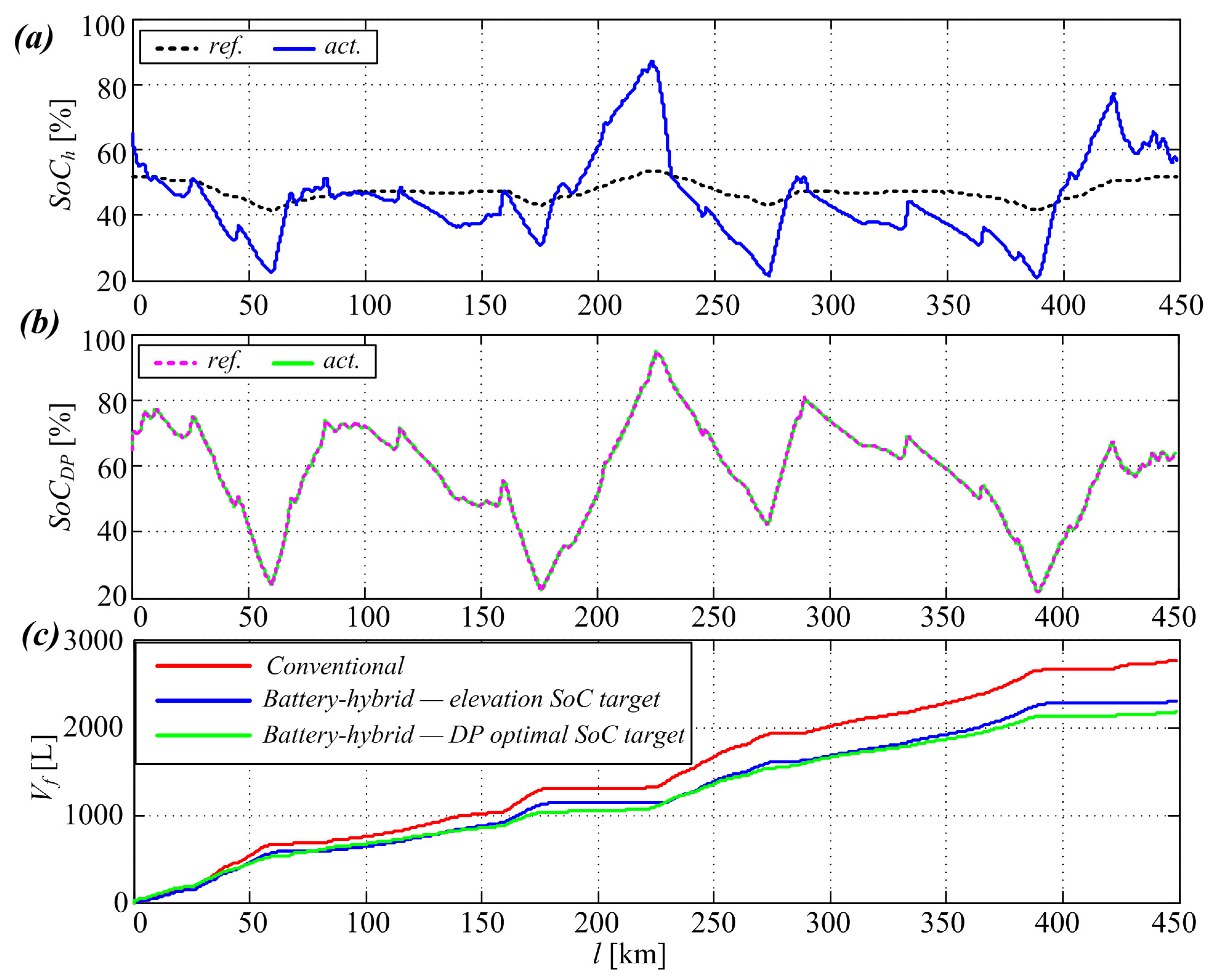

3.2. Simulation Results for the Case of Battery-Hybrid Locomotive

4. Discussion

- The model can predict the effect of different SoC target values on fuel consumption;

- For the optimized SoC target values, the controller can maintain battery SoC within the prescribed bounds while honoring the SoC boundary condition, while simultaneously achieving optimal fuel consumption;

- The energy management strategy can be significantly enhanced by simply incorporating the desired battery SoC trajectory data obtained by means of the DP optimization.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ritchi McCollum, D.; Krey, V.; Kolp, P.; Nagai, Y.; Riahi, K. Transport electrification: A key element for energy system transformation and climate stabilization. Clim. Change 2014, 123, 651–664. [Google Scholar] [CrossRef]

- Saber, A.Y.; Venayagamoorthy, G.K. Plug-in Vehicles and Renewable Energy Sources for Cost and Emission Reductions. IEEE Trans. Ind. Electron. 2011, 58, 1229–1238. [Google Scholar] [CrossRef]

- Hansen, J.; Sato, M.; Kharecha, P.; Beerling, D.; Berner, R.; Masson-Delmotte, V.; Pagani, M.; Raymo, M.; Royer, D.L.; Zachos, J. Target atmospheric CO2: Where should humanity aim? Open Atmos. Sci. J. 2008, 2, 217–231. [Google Scholar] [CrossRef]

- Buzzonii, L.; Pede, G. New Prospects for Public Transport Electrification. In Proceedings of the International Conference on Electrical Systems for Aircraft, Railway and Ship Propulsion (ESARS), Bologna, Italy, 16–18 October 2012. [Google Scholar] [CrossRef]

- Shakya, S.R.; Shrestha, R.M. Transport sector electrification in a hydropower resource rich developing country: Energy security, environmental and climate change co-benefits. Energy Sustain. Dev. 2011, 15, 147–159. [Google Scholar] [CrossRef]

- Deur, J.; Škugor, B.; Cipek, M. Integration of Electric Vehicles into Energy and Transport Systems. Autom. J. Control. Meas. Electron. Comput. Commun. 2015, 56, 395–410. [Google Scholar] [CrossRef]

- Spiryagin, M.; Cole, C.; Sun, Y.Q.; McClanachan, M.; Spiryagin, V.; McSweeney, T. Design and Simulation of Rail Vehicles; Taylor & Francis Group, LLC: Abingdon, UK, 2014; ISBN 978-11-380-7370-8. [Google Scholar]

- Frey, S. Railway Electrification Systems & Engineering, 1st ed.; White Word Publications: New Delhi, India, 2012; ISBN 978-81-323-4395-0. [Google Scholar]

- Mandić, M.; Uglešić, I.; Milardić, V.; Filipović-Grčić, B. Application of Regenerative Braking on Electrified Railway Lines in AC Traction Systems 25 kV, 50 Hz. In Proceedings of the 12th Symposium HRO CIGRÉ, Šibenik, Croatia, 8–11 November 2015. [Google Scholar]

- Electrified Railway Lines—European Commission. Available online: https://ec.europa.eu/transport/facts-fundings/scoreboard/compare/energy-union-innovation/share-electrified-railway_en#2016 (accessed on 20 April 2020).

- Isler, C.A.; Blumenfeld, M.; Roberts, C. Assessment of railway infrastructure improvements: Valuation of costs, energy consumption and emissions. Sustain. Energy Technol. Assess. 2022, 52 Pt B, 102179. [Google Scholar] [CrossRef]

- Roskilly, A.P.; Palacin, R.; Yan, J. Novel technologies and strategies for clean transport systems. Appl. Energy 2015, 157, 563–566. [Google Scholar] [CrossRef]

- Verma, S.; Upadhyay, R.; Shankar, R.; Pandey, S.P. Performance and emission characteristics of micro-algae biodiesel with butanol and TiO2 nano-additive over diesel engine. Sustain. Energy Technol. Assess. 2023, 55, 102975. [Google Scholar] [CrossRef]

- Dominković, D.F.; Bačeković, I.; Pedersen, A.S.; Krajačić, G. The future of transportation in sustainable energy systems: Opportunities and barriers in a clean energy transition. Renew. Sustain. Energy Rev. 2018, 82, 1823–1838. [Google Scholar] [CrossRef]

- Cosic, A. Hybrid Locomotive, SUSTRAIL—FP7 Project Deliverable 3.2.1, 265740 FP7—THEME [SST.2010.5.2-2.]. 2014. Available online: https://www.sustrail.eu/IMG/pdf/d3.2-v1-hybrid_locomotive-final_version.pdf (accessed on 24 May 2023).

- Rastegarzadeh, S.; Mahzoon, M.; Mohammadi, H. A novel modular designing for multi-ring flywheel rotor to optimize energy consumption in light metro trains. Energy 2020, 206, 118092. [Google Scholar] [CrossRef]

- Liu, H.; Chen, G.; Xie, C.; Li, D.; Wang, J.; Li, S. Research on energy-saving characteristics of battery-powered electric-hydrostatic hydraulic hybrid rail vehicles. Energy 2020, 205, 118079. [Google Scholar] [CrossRef]

- Meinert, M.; Prenleloup, P.; Schmid, S.; Palacin, R. Energy storage technologies and hybrid architectures for specific diesel driven rail duty cycles: Design and system integration aspects. Appl. Energy 2015, 157, 619–629. [Google Scholar] [CrossRef]

- Yang, J.; Xu, X.; Peng, Y.; Zhang, J.; Song, P. Modeling and optimal energy management strategy for a catenary battery-ultracapacitor based hybrid tramway. Energy 2019, 183, 1123–1135. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, Y.; Li, S. Design and downhill speed control of an electric-hydrostatic hydraulic hybrid powertrain in battery-powered rail vehicles. Energy 2019, 187, 115957. [Google Scholar] [CrossRef]

- Sun, Y.; Cole, C.; Spiryagin, M.; Godber, T.; Hames, S.; Rasul, M. Conceptual designs of hybrid locomotives for application as heavy haul trains on typical track lines. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 439–452. [Google Scholar] [CrossRef]

- Cipek, M.; Pavković, D.; Kljaić, Z.; Mlinarić, T.J. Assessment of Battery-Hybrid Diesel-electric Locomotive Fuel Savings and Emission Reduction Potentials based on a Realistic Mountainous Rail Route. Energy 2019, 173, 1154–1171. [Google Scholar] [CrossRef]

- Technical Report: Hybrid Locomotive—SUSTRAIL, FP7 No. 265740, Deliverable 3.2.1. 2014. Available online: http://www.sustrail.eu/IMG/pdf/d3.2-v1-hybrid_locomotive-final_version.pdf (accessed on 20 April 2020).

- Donnelly, F.W.; Cousineau, R.L.; Horsley, R.N.M. Hybrid Technology for the Rail Industry, Rail Conference, 2004. In Proceedings of the 2004 ASME/IEEE Joint, Baltimore, MD, USA, 6–8 April 2004. [Google Scholar] [CrossRef]

- Gao, Y.; Ehsani, M.; Miller, J.M. Hybrid Electric Vehicle: Overview and state of the Art. In Proceedings of the IEEE International Symposium on Industrial Electronics, Dubrovnik, Croatia, 20–23 June 2005; pp. 307–315. [Google Scholar]

- Guzzella, L.; Sciarretta, A. Vehicle Propulsion Systems—Introduction to Modeling and Optimisation, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Cipek, M.; Kasać, J.; Pavković, D.; Zorc, D. A novel cascade approach to control variables optimization for advanced series-parallel hybrid electric vehicle power-train. Appl. Energy 2020, 276, 115488. [Google Scholar] [CrossRef]

- Bellman, R.E.; Dreyfus, S.E. Applied Dynamic Programming; Princeton University Press: Princeton, NJ, USA, 1962. [Google Scholar]

- Hofman, T.; Van Druten, R.; Serrarens, A.; Steinbuch, M. Rule-based energy management strategies for hybrid vehicles. Int. J. Electr. Hybrid Veh. 2007, 1, 71–94. [Google Scholar] [CrossRef]

- Zhou, Y.; Ravey, A.; Péra, M.-C. Multi-mode predictive energy management for fuel cell hybrid electric vehicles using Markov driving pattern recognizer. Appl. Energy 2020, 258, 114057. [Google Scholar] [CrossRef]

- Hou, D.; Sun, Q.; Bao, C.; Cheng, X.; Guo, H.; Zhao, Y. An all-in-one design method for plug-in hybrid electric buses considering uncertain factor of driving cycles. Appl. Energy 2019, 253, 113499. [Google Scholar] [CrossRef]

- Hou, J.; Song, Z. A hierarchical energy management strategy for hybrid energy storage via vehicle-to-cloud connectivity. Appl. Energy 2020, 257, 113900. [Google Scholar] [CrossRef]

- Mahmoudimehr, J.; Sebghati, P. A Novel Multi-objective Dynamic Programming Optimization Method: Performance Management of a Solar Thermal Power Plant as a Case Study. Energy 2018, 168, 796–814. [Google Scholar] [CrossRef]

- Hajipour, E.; Mohiti, M.; Farzin, N.; Vakilian, M. Optimal Distribution Transformer Sizing in a Harmonic Involved Load Environment via Dynamic Programming Technique. Energy 2016, 120, 92–105. [Google Scholar] [CrossRef]

- Mia, S.; Podder, A.K.; Kumar, M.N.; Bhatt, A.; Kumar, K. Experimental verification of a dynamic programming and IoT-based simultaneous load-sharing controller for residential homes powered with grid and onsite solar photovoltaic electricity. Sustain. Energy Technol. Assess. 2023, 55, 102964. [Google Scholar] [CrossRef]

- Fritz, S.G. Evaluation of Biodiesel Fuel in an EMD GP38-2 Locomotive, NREL REPORT/PROJECT NUMBER: SR-510-33436, May 2004. Available online: https://www.nrel.gov/docs/fy04osti/33436.pdf (accessed on 24 May 2023).

- Valter, Z. Diesel-Electric Locomotives; Školska knjiga Zagreb: Zagreb, Croatia, 1985; ISBN 978-953-0-30697-4. (In Croatian) [Google Scholar]

- Škrobonja, D.; Beraković, T.; Božunović, A.; Ljubaj, Z.; Ljubaj, N. Applicative Monitoring of Locomotive Diesel Engine Oil, Professional paper. Fuels Lubr. 2004, 43, 291–309. Available online: https://hrcak.srce.hr/7174 (accessed on 19 January 2023).

- Pichlík, P.; Zděnek, J. Overview of Slip Control Methods Used in Locomotives. Trans. Electr. Eng. 2014, 3, 38–43. [Google Scholar]

- Kljaić, Z.; Cipek, M.; Pavković, D.; Mlinarić, T.J. Assessment of Railway Train Energy Efficiency and Safety Using Real-time Track Condition Information. J. Sustain. Dev. Energy Water Environ. Syst. 2021, 9, 1080352. [Google Scholar] [CrossRef]

- Bin, Y.; Li, Y.; Feng, N. Nonlinear dynamic battery model with boundary and scanning hysteresis. In Proceedings of the ASME 2009 Dynamic Systems and Control Conference, Hollywood, CA, USA, 12–14 October 2009; No. DSCC2009-2745. pp. 245–251. [Google Scholar] [CrossRef]

- Ouyang, T.; Wang, C.; Xu, P.; Ye, J.; Liu, B. Prognostics and health management of lithium-ion batteries based on modeling techniques and Bayesian approaches: A review. Sustain. Energy Technol. Assess. 2023, 55, 102915. [Google Scholar] [CrossRef]

- Malla, S.G.; Bhende, C.N. Enhanced operation of stand-alone “Photovoltaic-Diesel Generator-Battery” system. Electr. Power Syst. Res. 2014, 107, 250–257. [Google Scholar] [CrossRef]

- GPS Visualizer: Freehand Drawing Utility: Draw on a Map and Save GPX Data. Available online: https://www.gpsvisualizer.com/draw/ (accessed on 19 January 2023).

- OpenRailwayMap. Available online: https://www.openrailwaymap.org/ (accessed on 19 January 2023).

- Pavković, D.; Cipek, M.; Kljaić, Z.; Mlinarić, T.J. A fuzzy logic-based classifier for railway track condition estimation and tractive effort conditioning using data from remote sensors. In Proceedings of the XXIV International Conference on Material Handling, Constructions and Logistics—MHCL ’22, Belgrade, Serbia, 21–23 September 2022. [Google Scholar]

| Throttle Position | Main Engine Power Pmg (kW) | Generator Power Pg (kW) | |

|---|---|---|---|

| P0—IDLE | 6.43 | 0 | 2.5704 |

| P1—Notch 4 | 632.77 | 566.49 | 40.8315 |

| P2—Notch 5 | 787.15 | 694.13 | 51.6475 |

| P3—Notch 6 | 965.83 | 844.70 | 64.2834 |

| P4—Notch 7 | 1161.70 | 1004.73 | 79.8195 |

| P5—Notch 8 | 1312.80 | 1121.67 | 94.4690 |

| Parameter | Value |

|---|---|

| Lower SoC bound SoCmin | 0.20 (20%) |

| Upper SoC bound SoCmax | 0.95 (95%) |

| Grid points with respect to time Nt | 30694 |

| Grid points with respect to control input Nu | 6 |

| Grid points with respect to state variable Nx | 200 |

| Locomotive | Battery SoC [%] | Fuel Consumption [L] | |

|---|---|---|---|

| SoC(t0) | SoC(tf) | Vf | |

| Conventional | - | - | 2761 |

| Hybrid (SoCh) | 64.79 | 56.73 | 2295 |

| Hybrid (SoCDP) | 64.79 | 63.81 | 2130 |

| Hybrid (SoCDPO) | 64.79 | 63.70 | 2119 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cipek, M.; Pavković, D.; Kljaić, Z. Optimized Energy Management Control of a Hybrid Electric Locomotive. Machines 2023, 11, 589. https://doi.org/10.3390/machines11060589

Cipek M, Pavković D, Kljaić Z. Optimized Energy Management Control of a Hybrid Electric Locomotive. Machines. 2023; 11(6):589. https://doi.org/10.3390/machines11060589

Chicago/Turabian StyleCipek, Mihael, Danijel Pavković, and Zdenko Kljaić. 2023. "Optimized Energy Management Control of a Hybrid Electric Locomotive" Machines 11, no. 6: 589. https://doi.org/10.3390/machines11060589

APA StyleCipek, M., Pavković, D., & Kljaić, Z. (2023). Optimized Energy Management Control of a Hybrid Electric Locomotive. Machines, 11(6), 589. https://doi.org/10.3390/machines11060589