Effects of Matching between the Inducer and the Impeller of a Centrifugal Pump on Its Cavitation Performance

Abstract

1. Introduction

2. Methodology

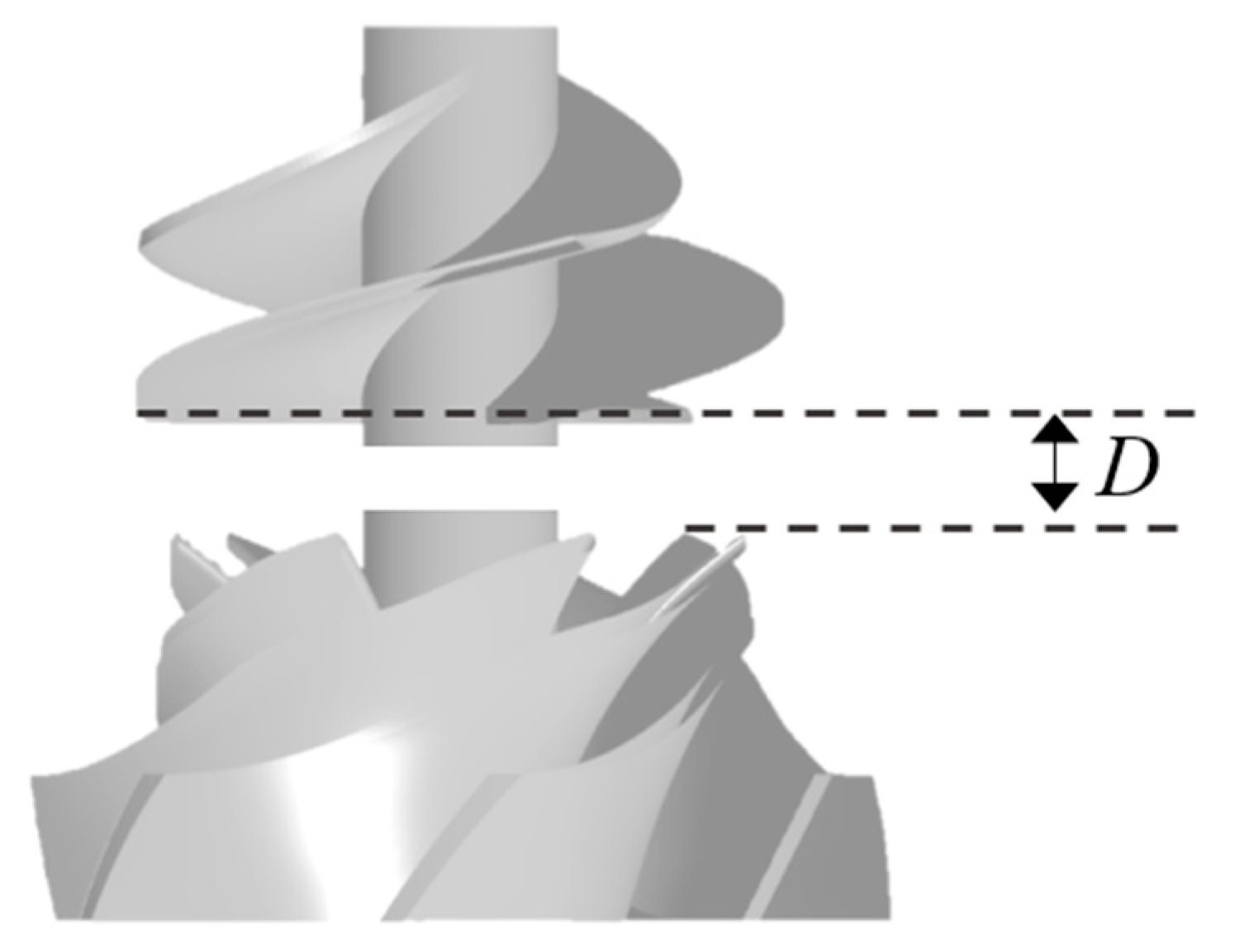

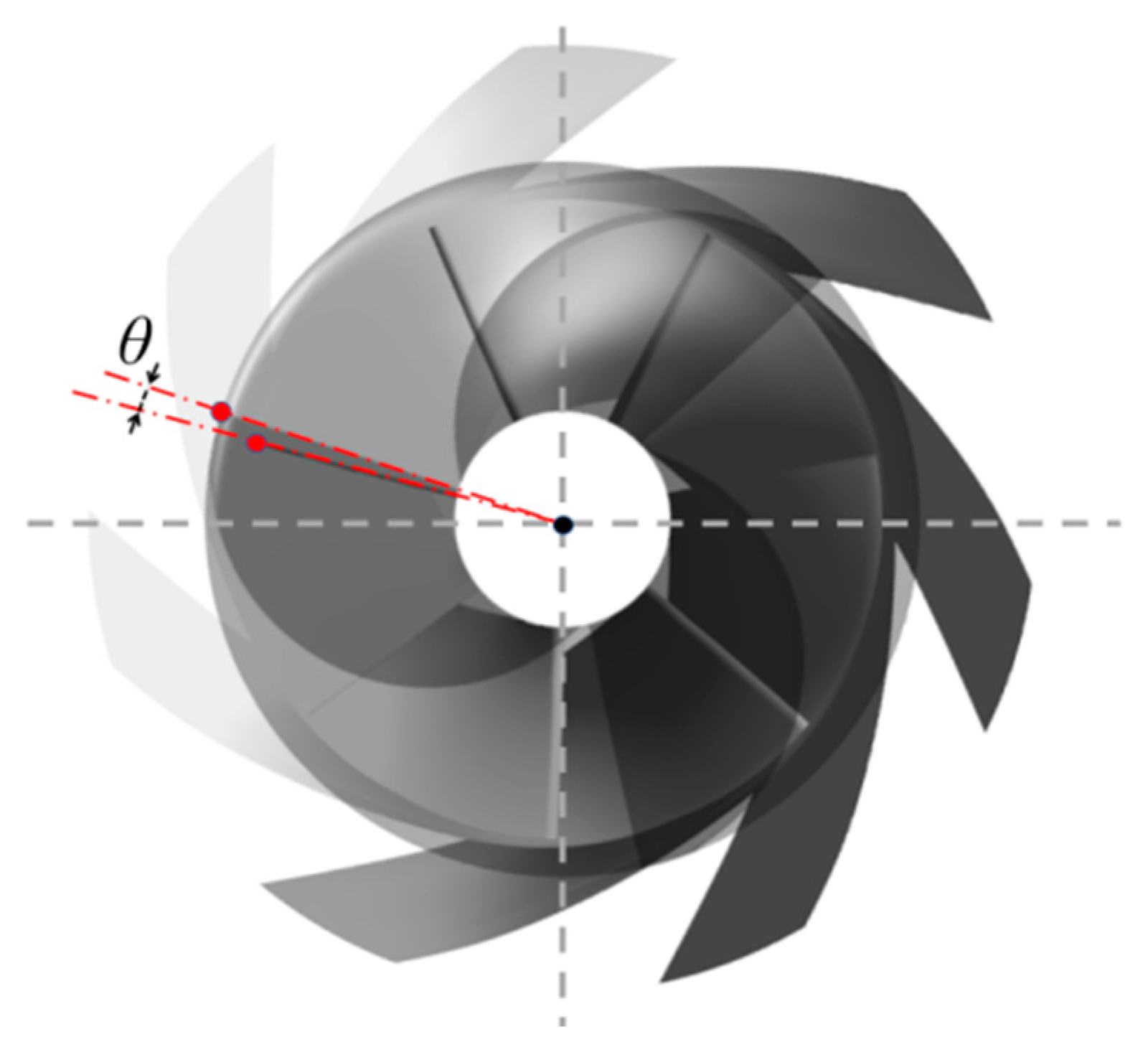

2.1. Inducer and Impeller Parameters

2.2. Meshing, Numerical Calculation Methods and Boundary Conditions

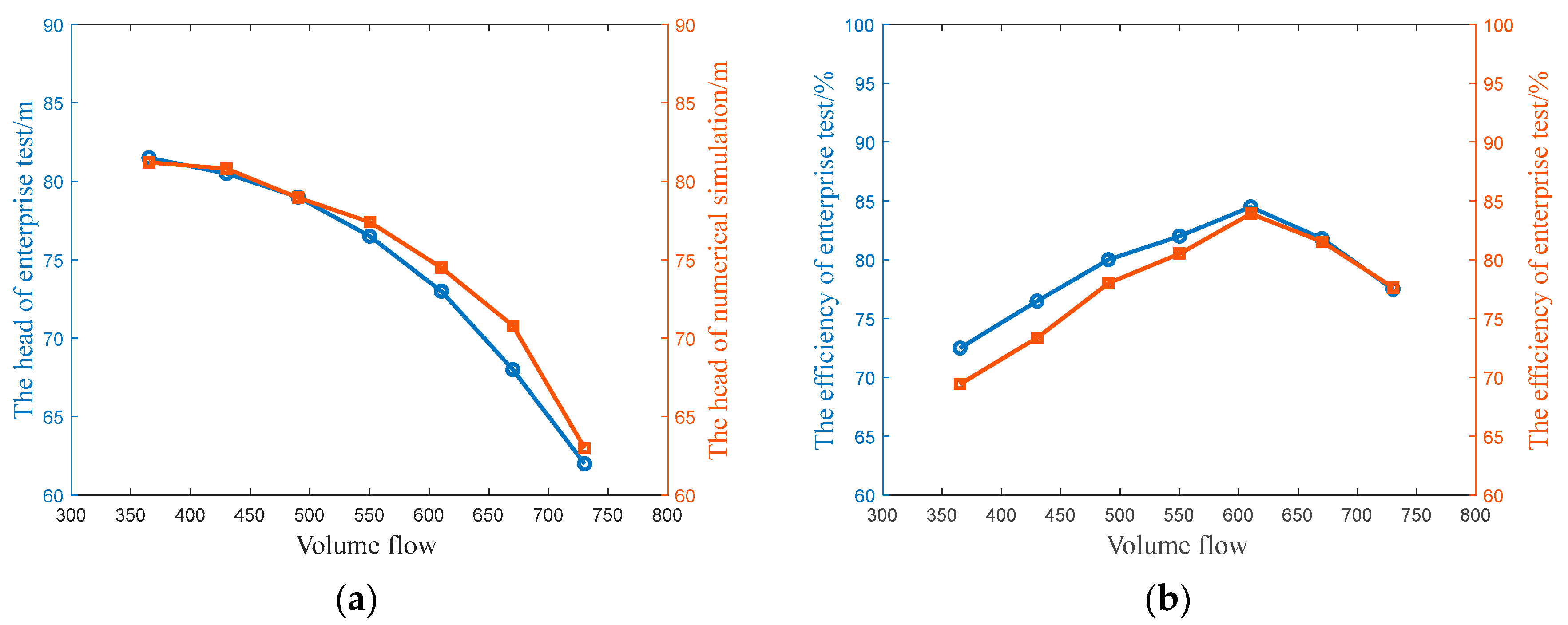

2.3. Model Validation

3. Results and Discussion

3.1. Analysis of Numerical Simulation Results of External Performances

3.2. The Effect of the Inducer on Incipient Cavitation

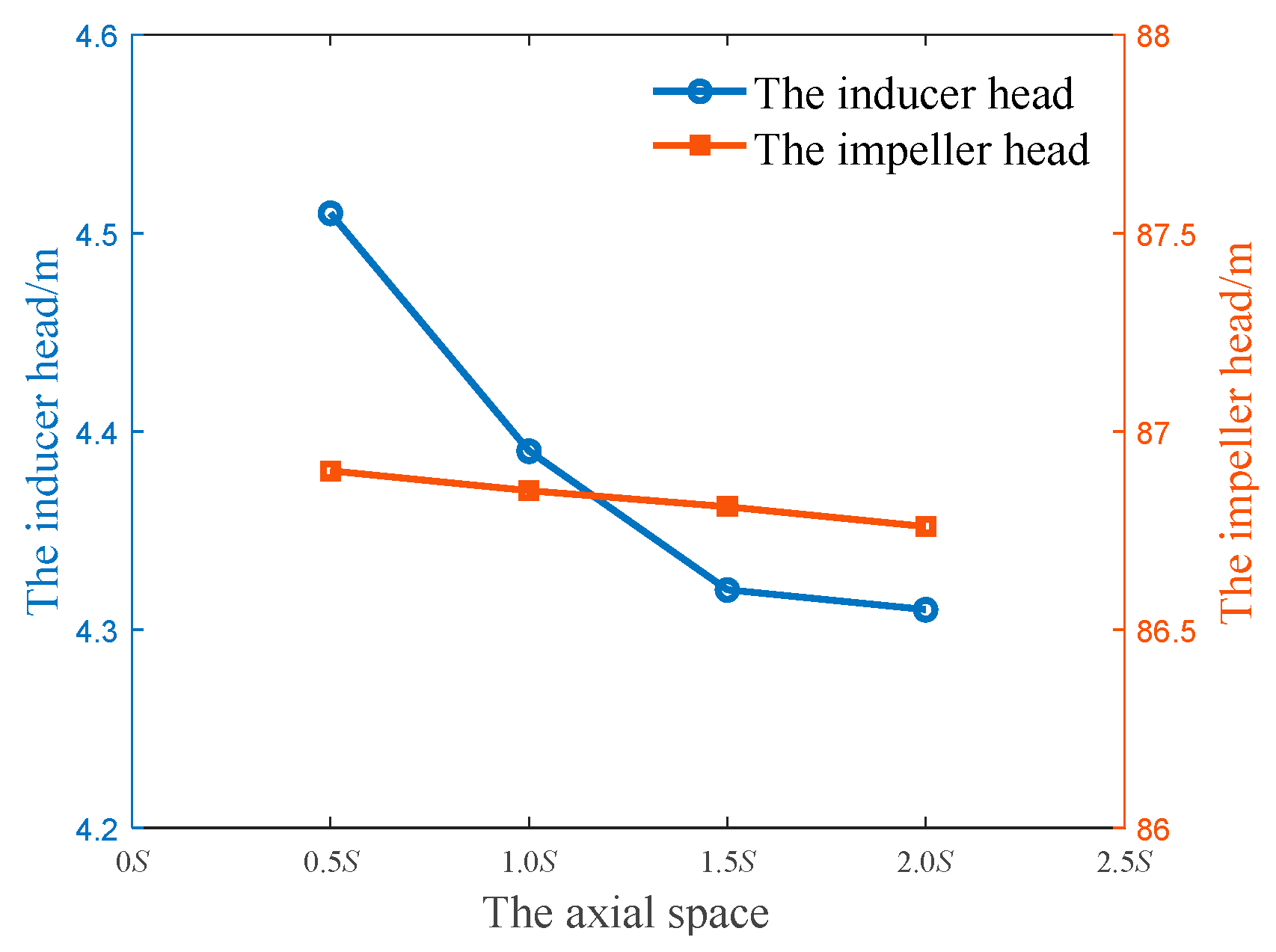

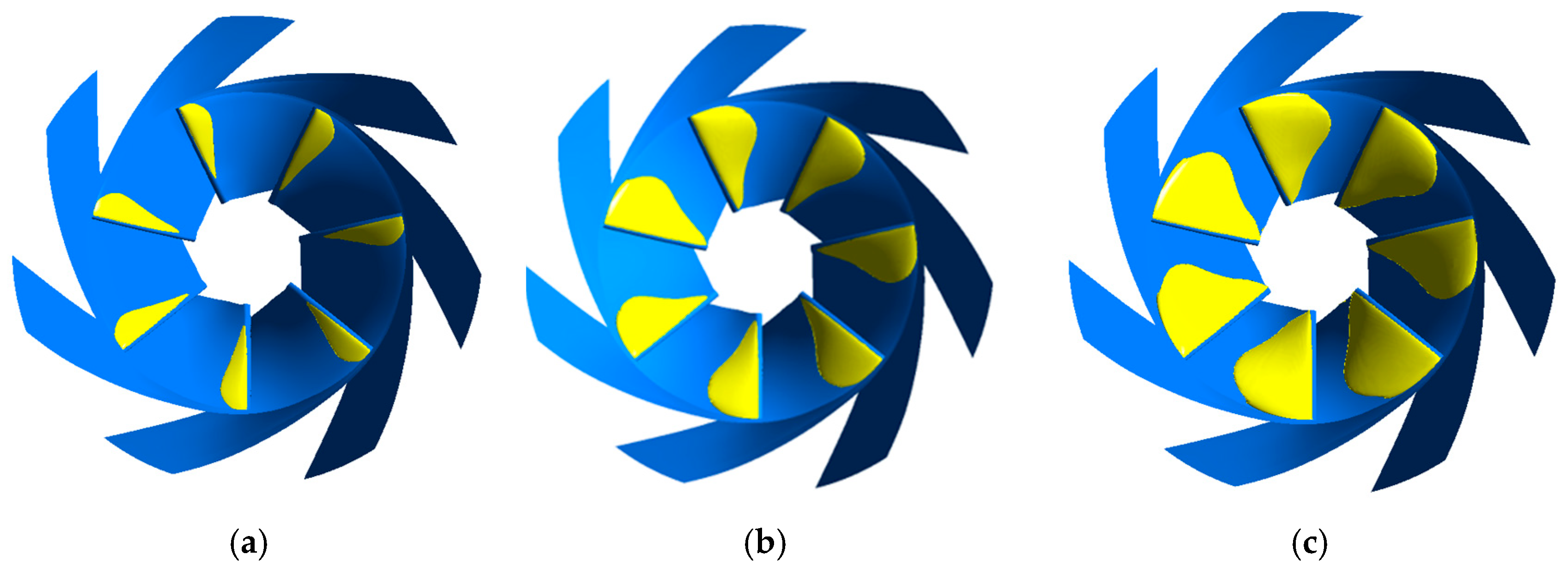

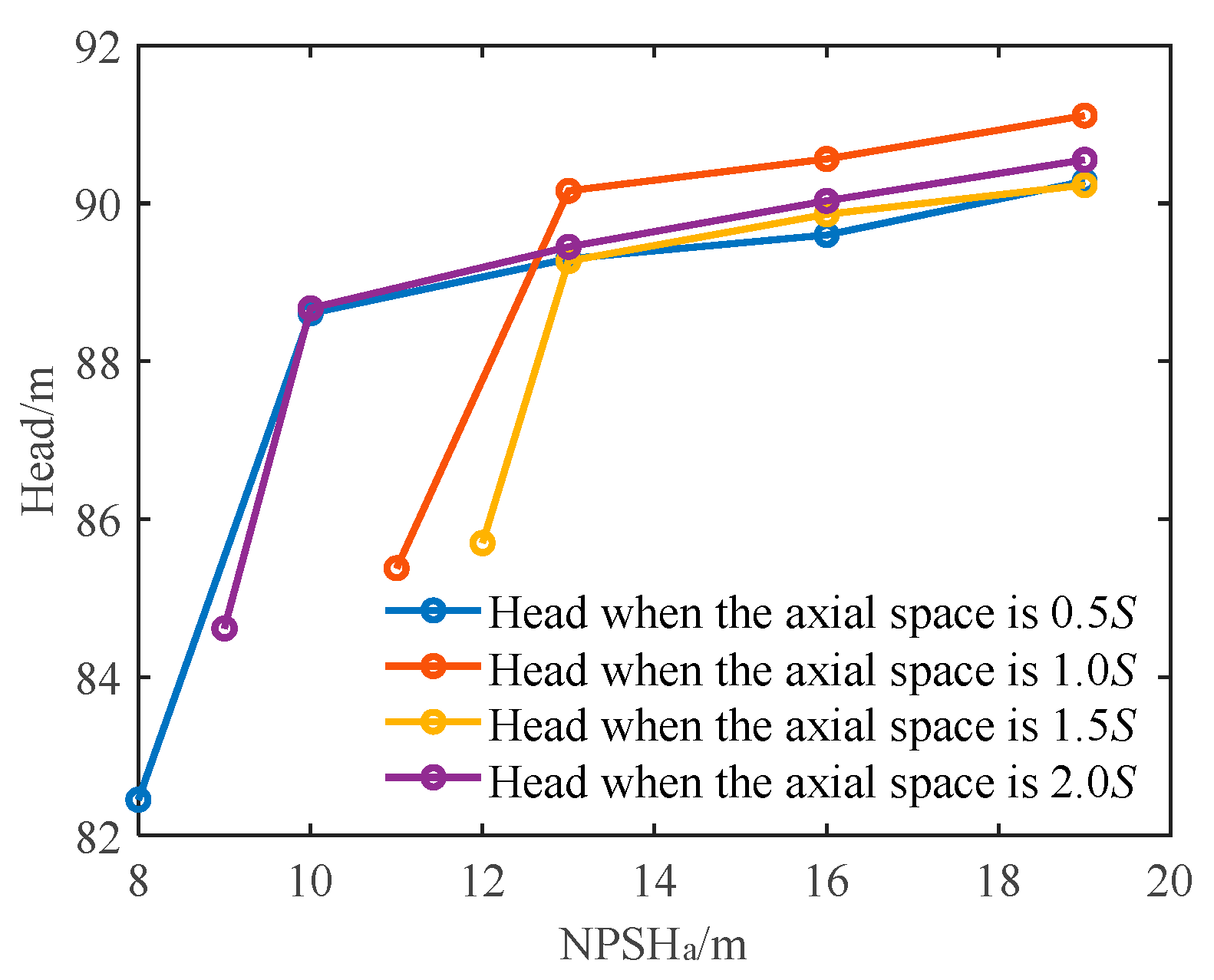

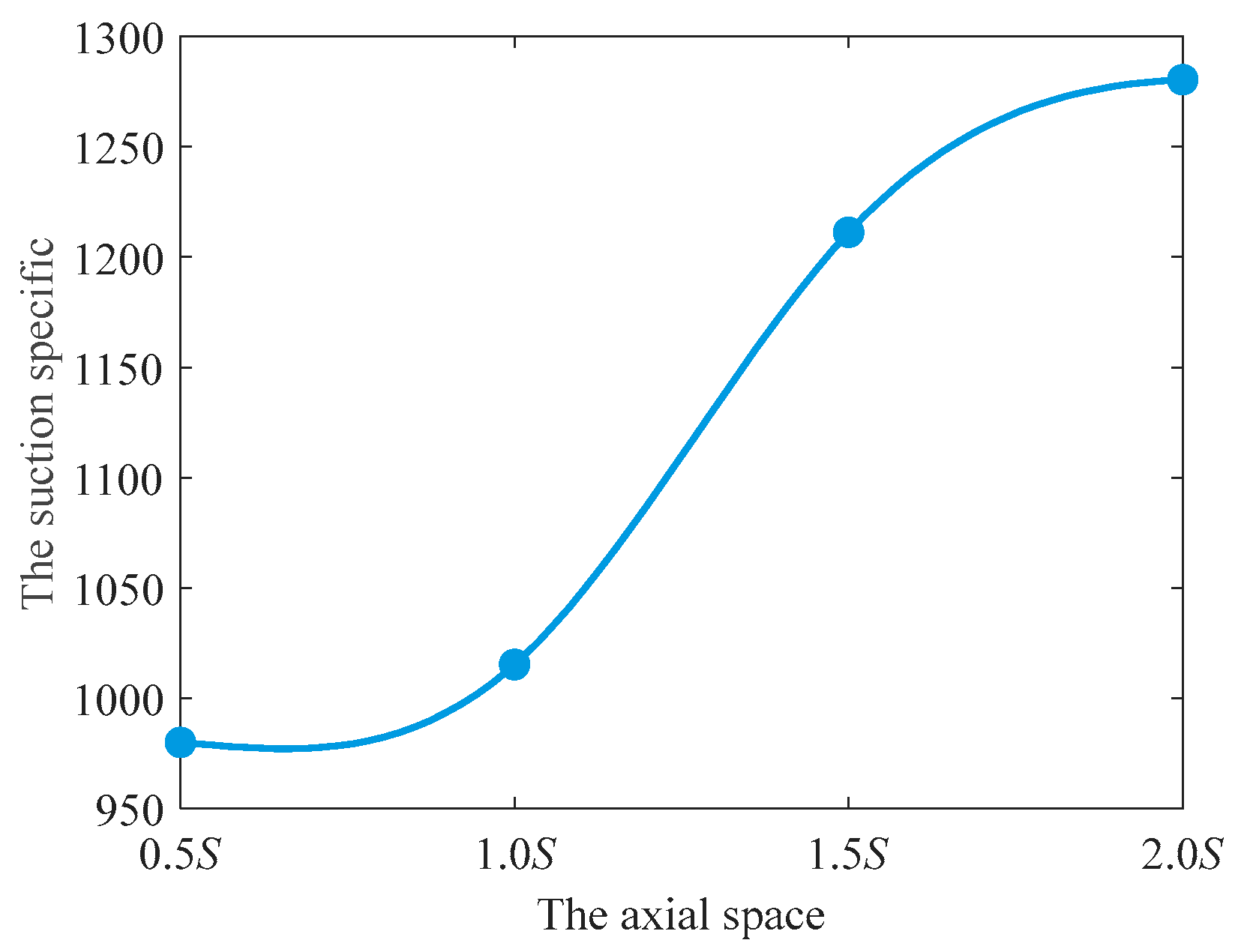

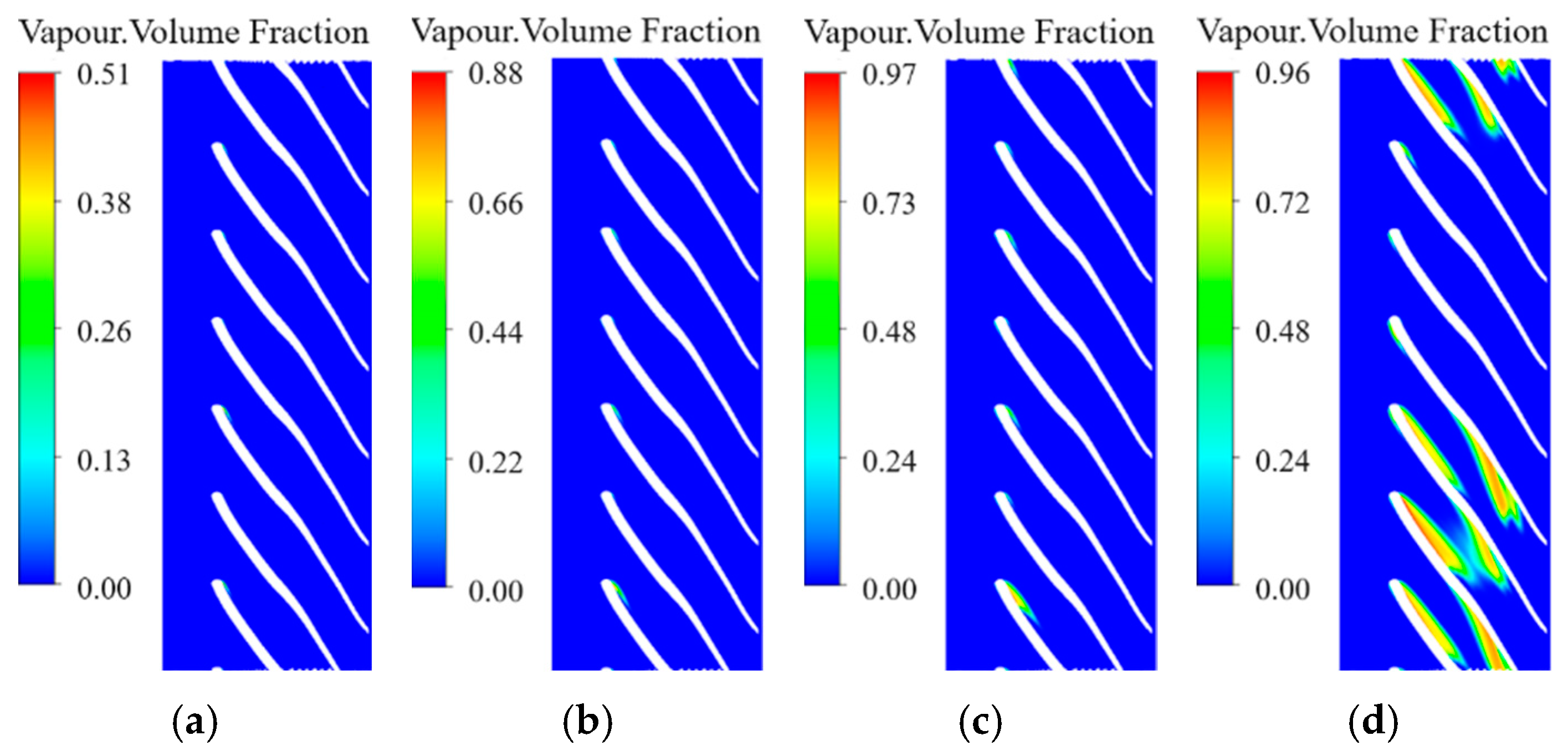

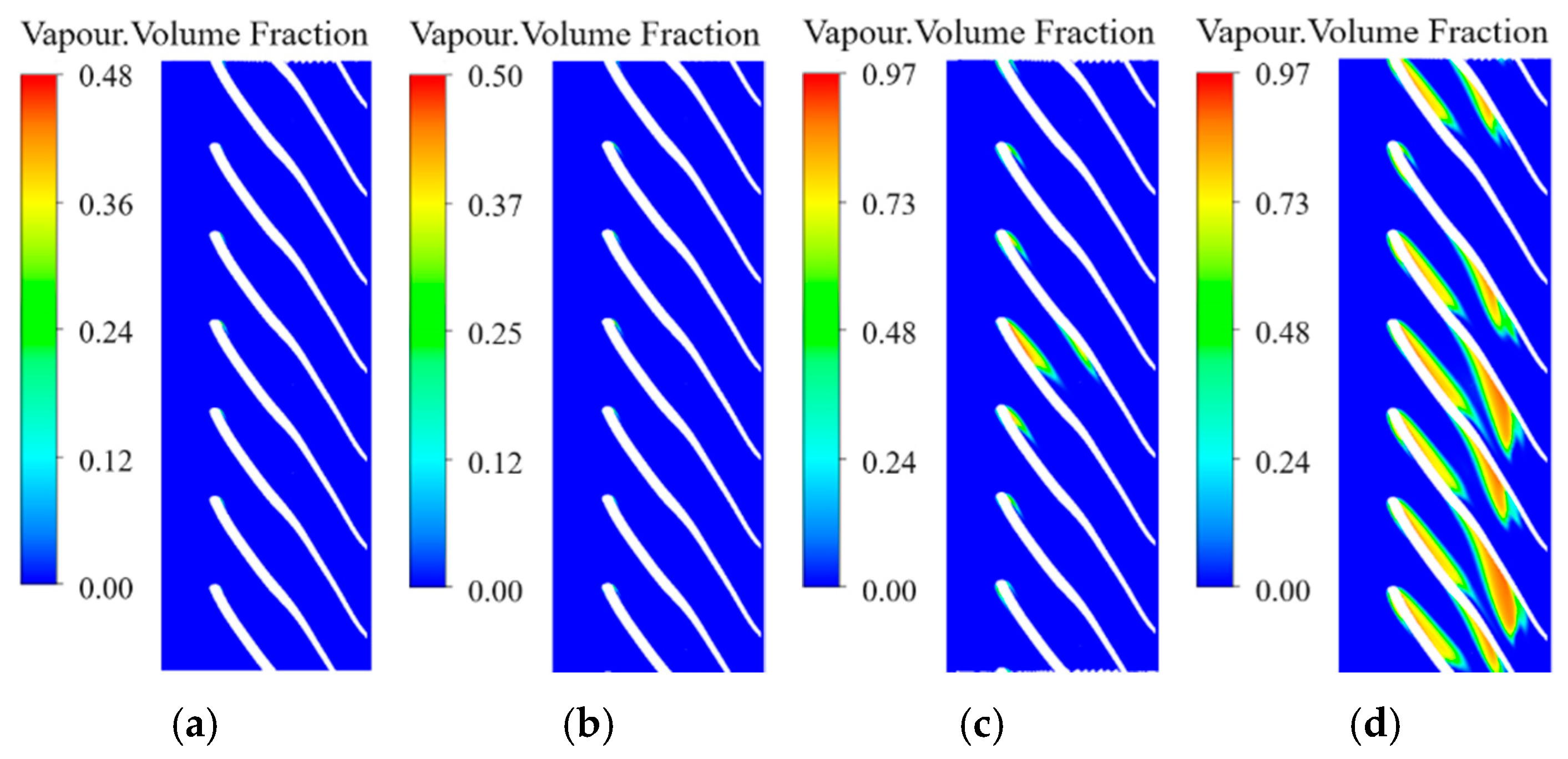

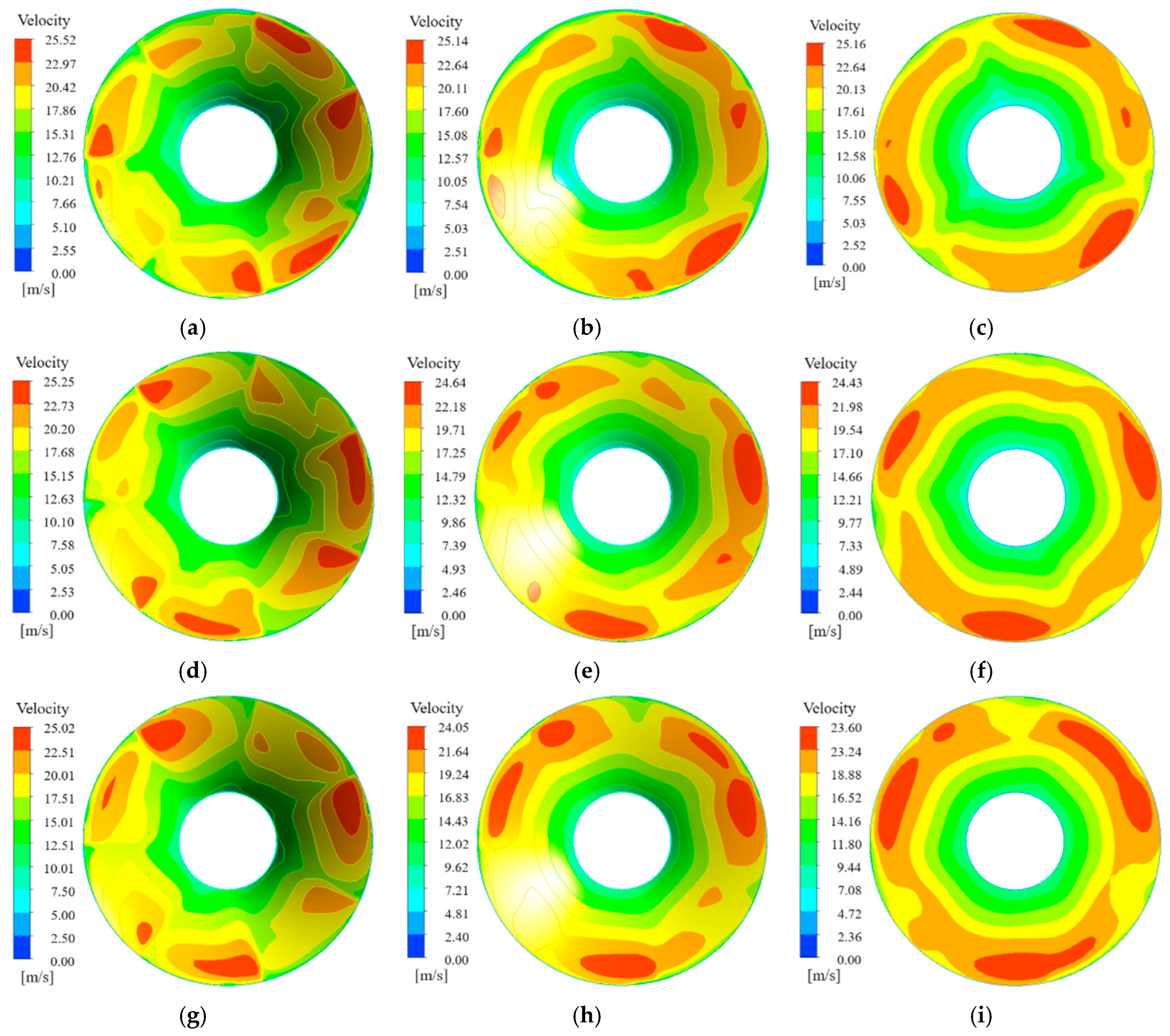

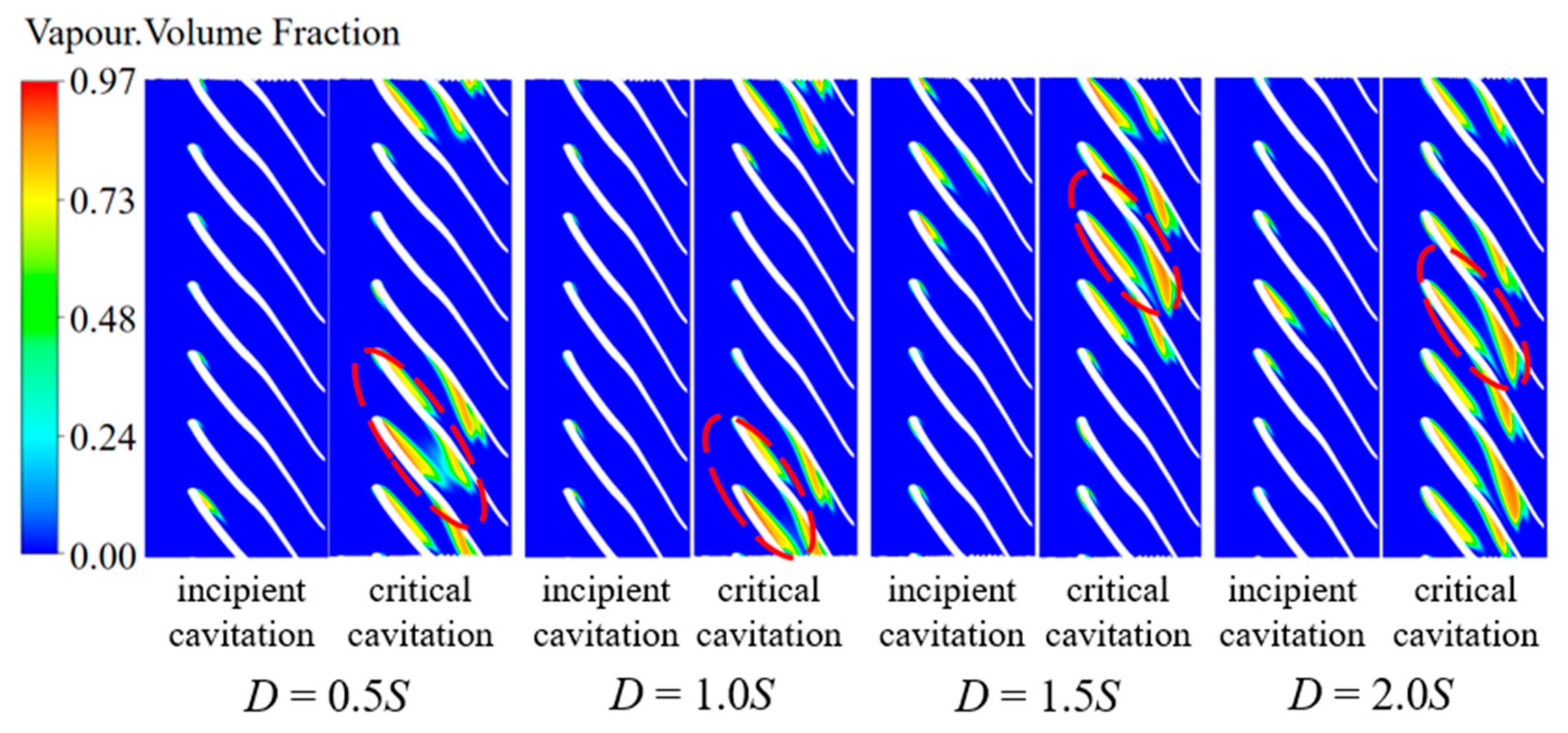

3.3. The Effect of the Axial Space on Cavitation Development

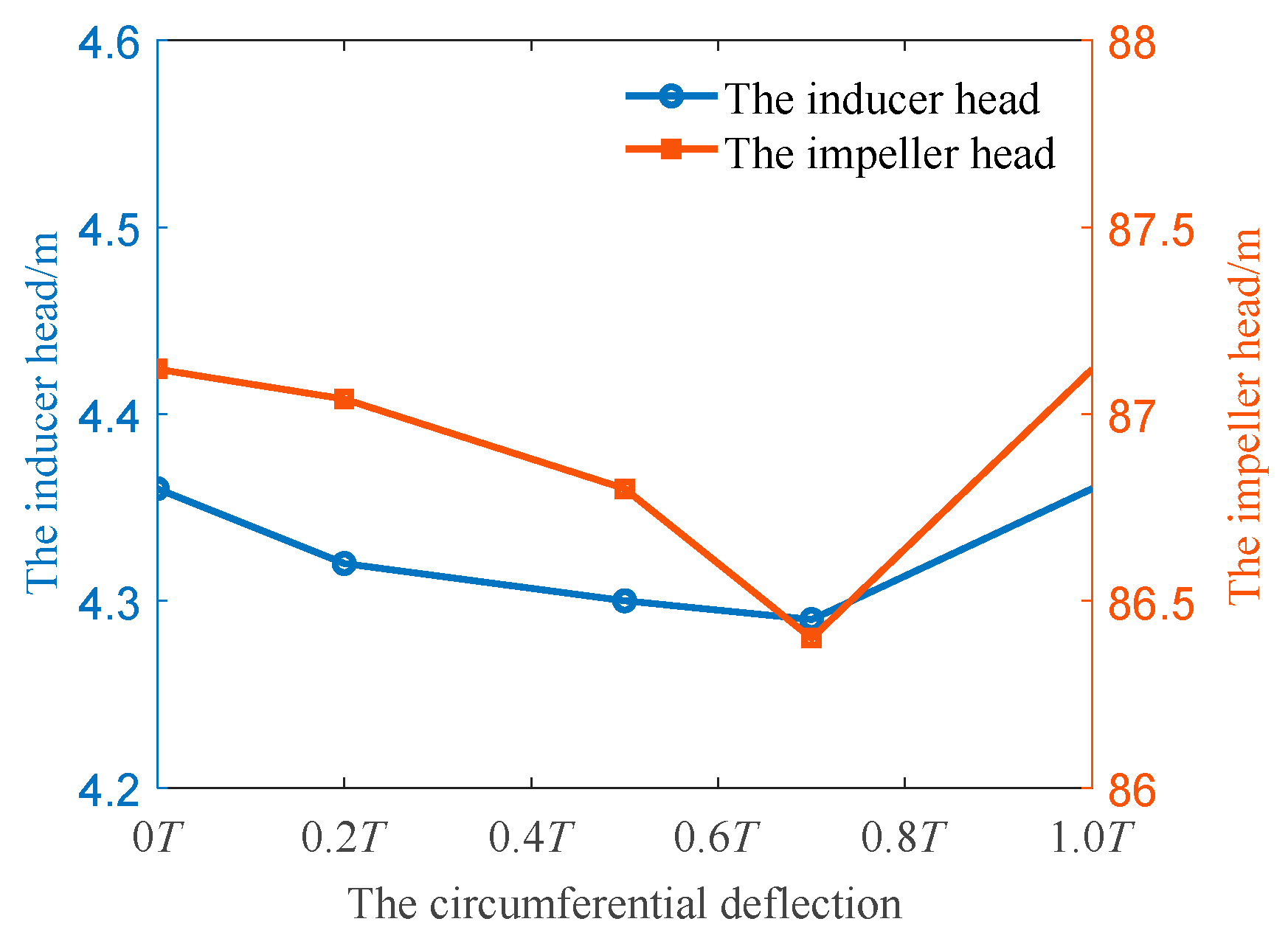

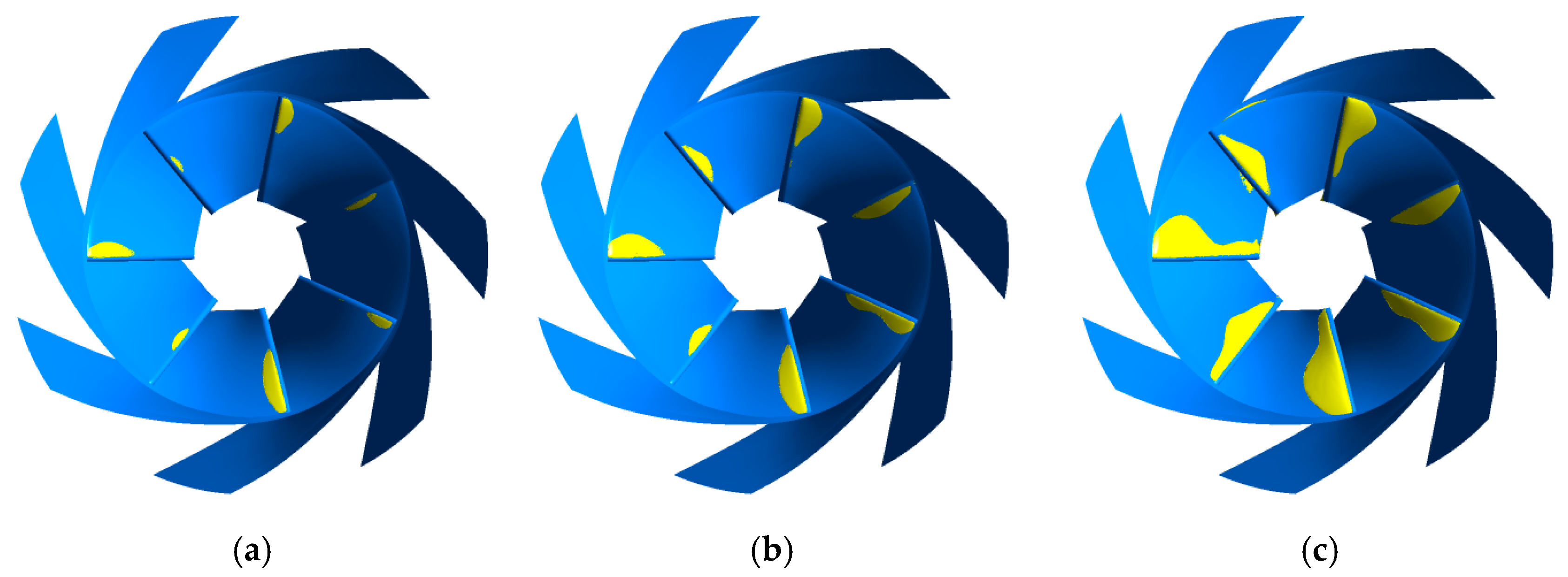

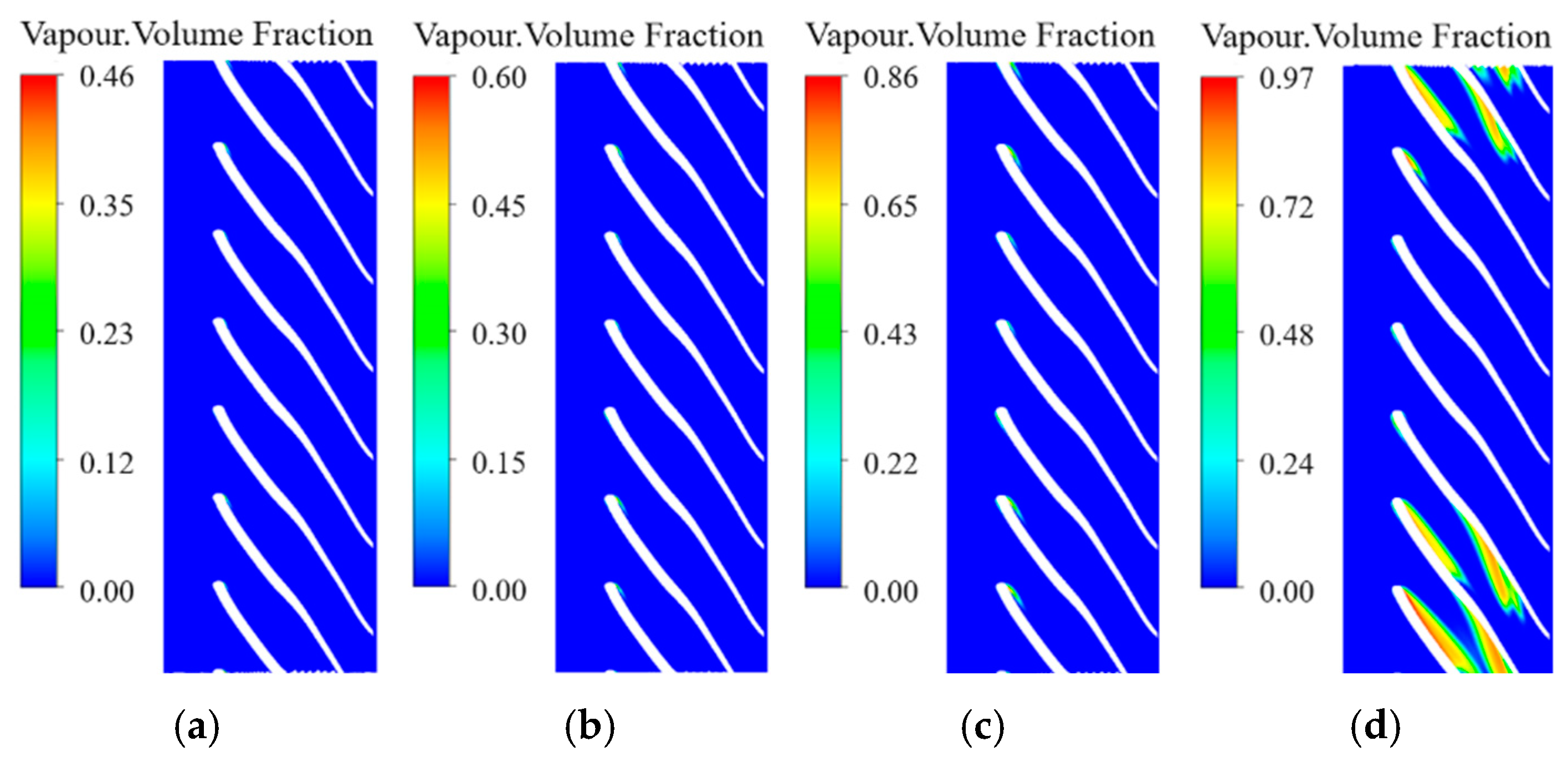

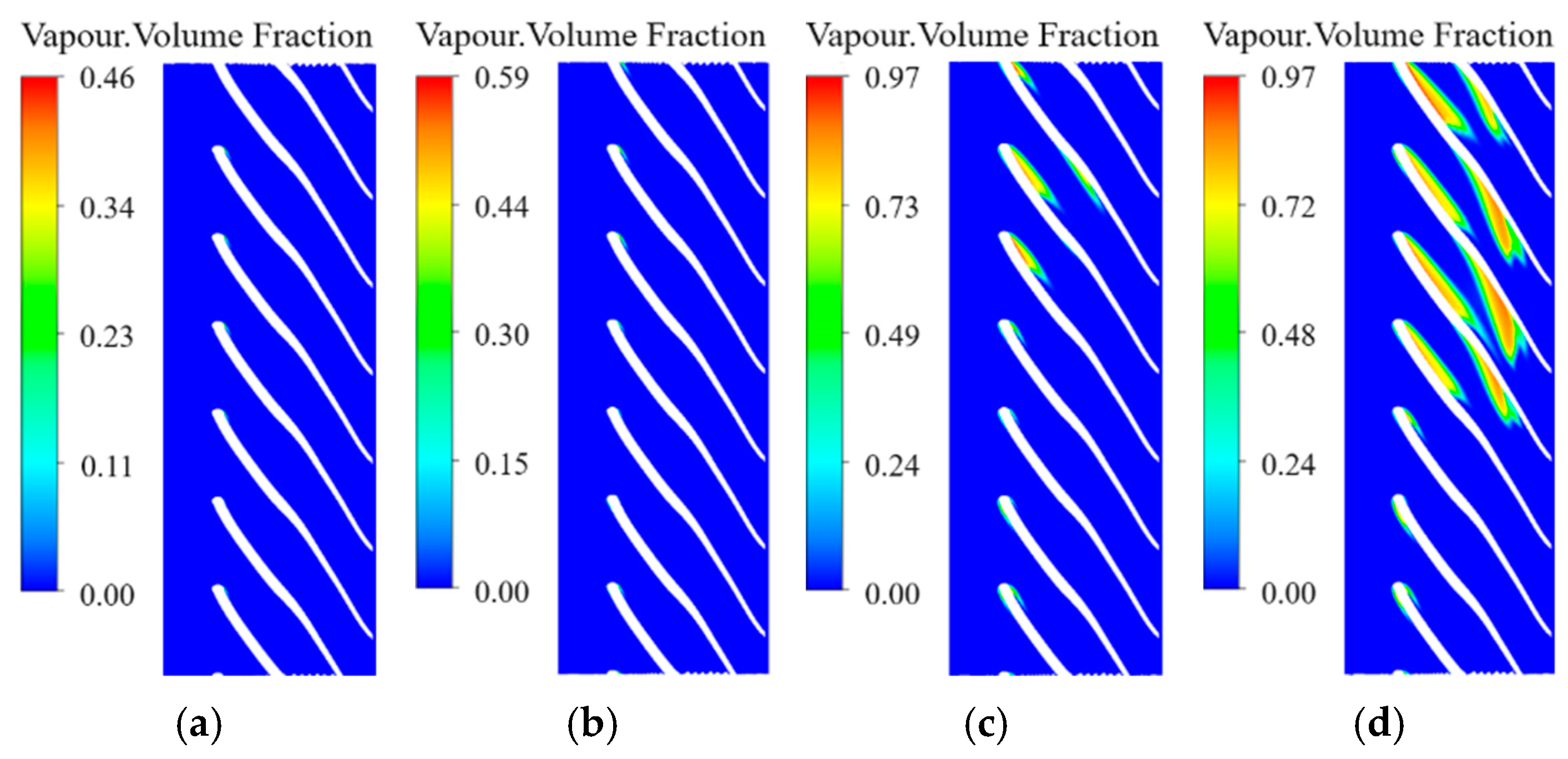

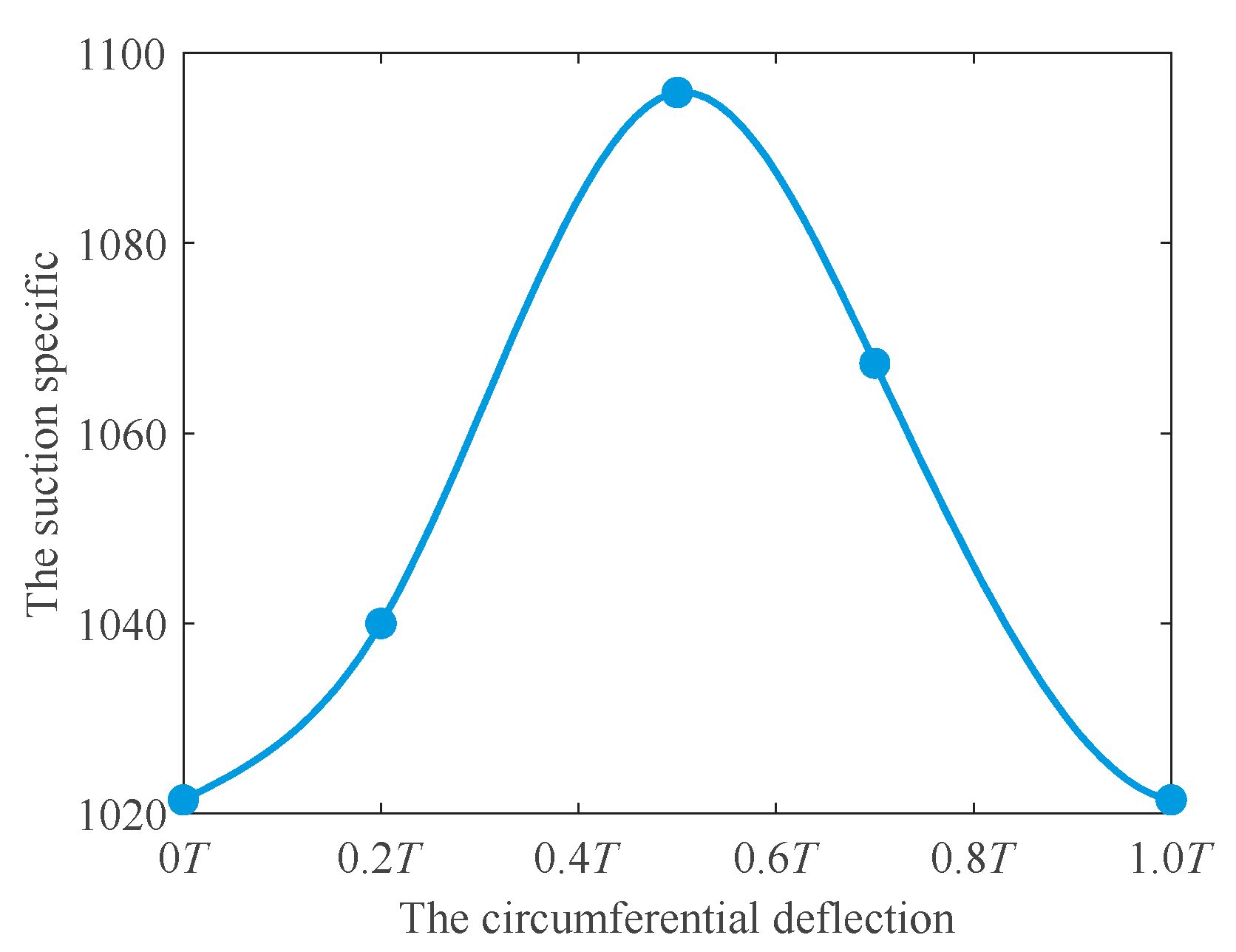

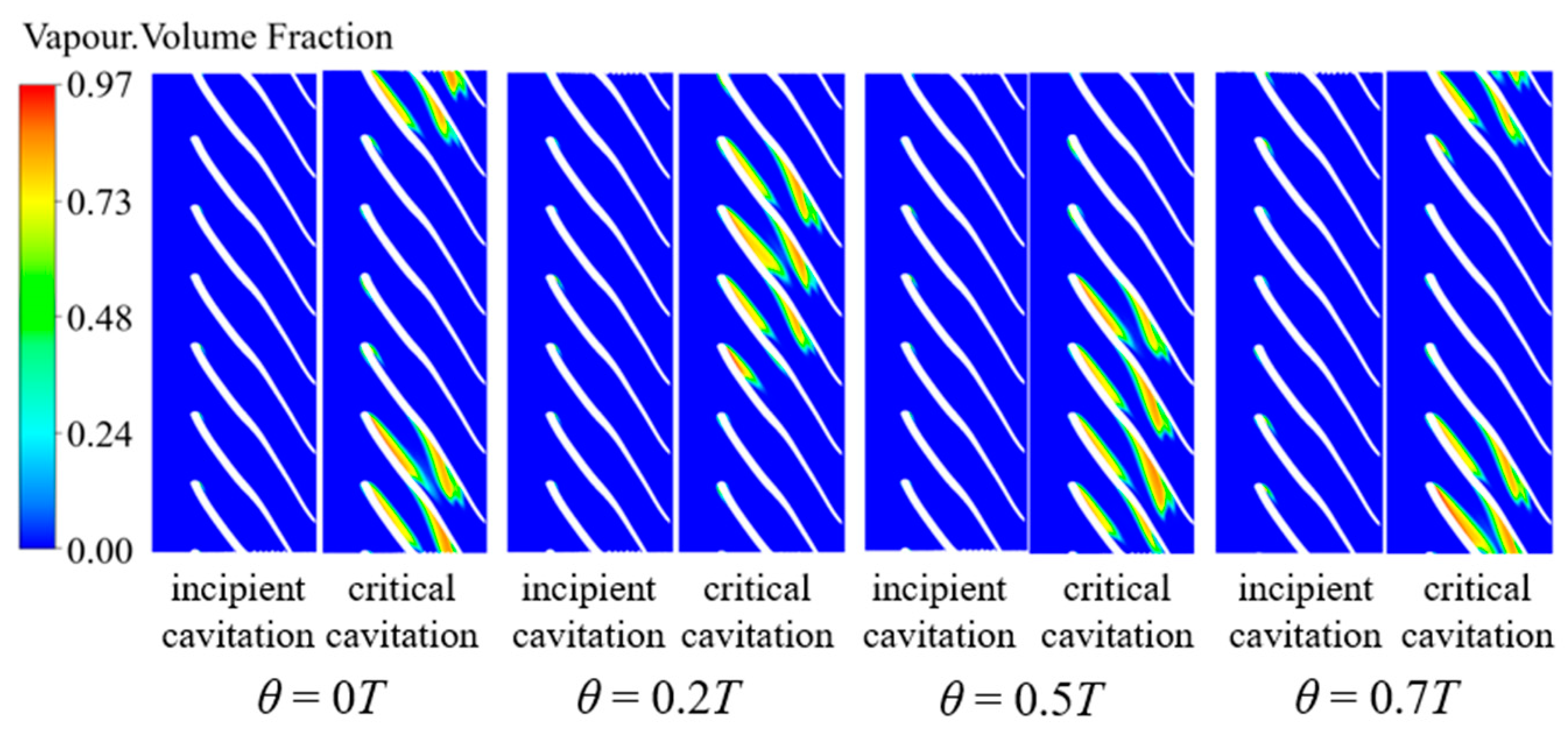

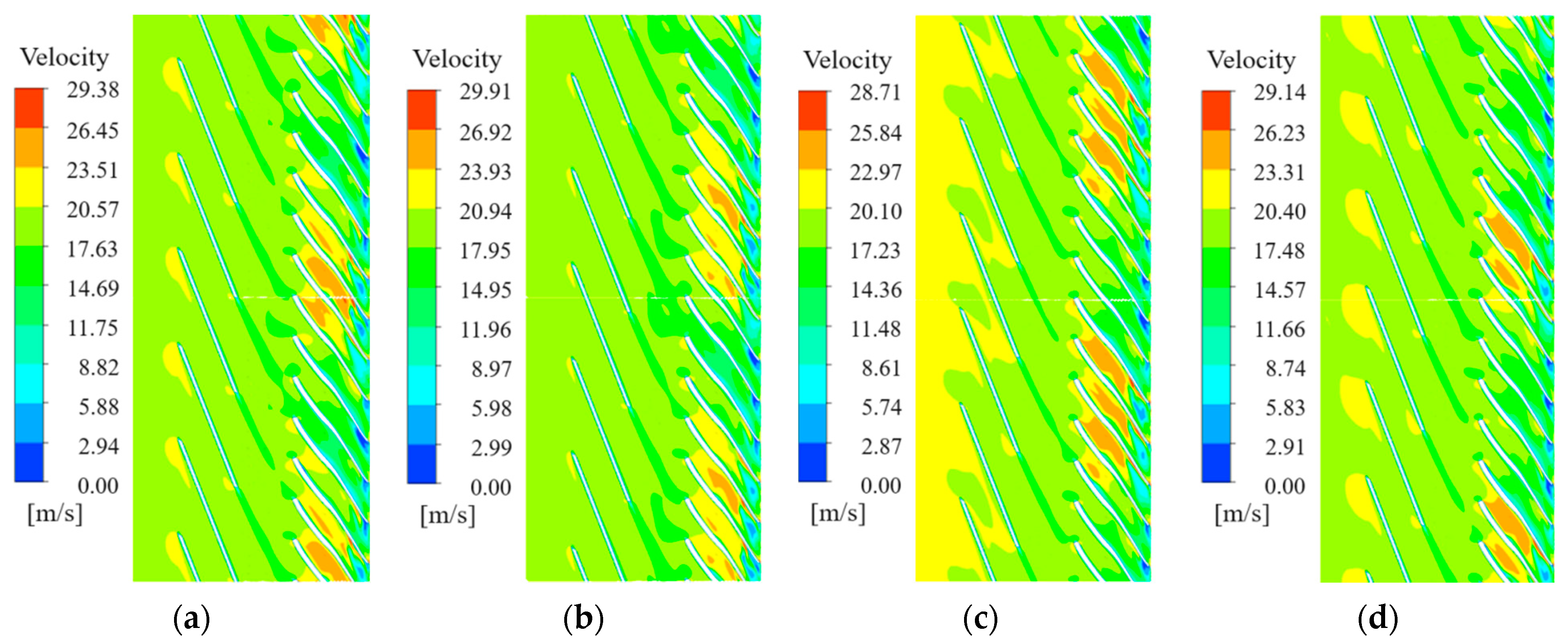

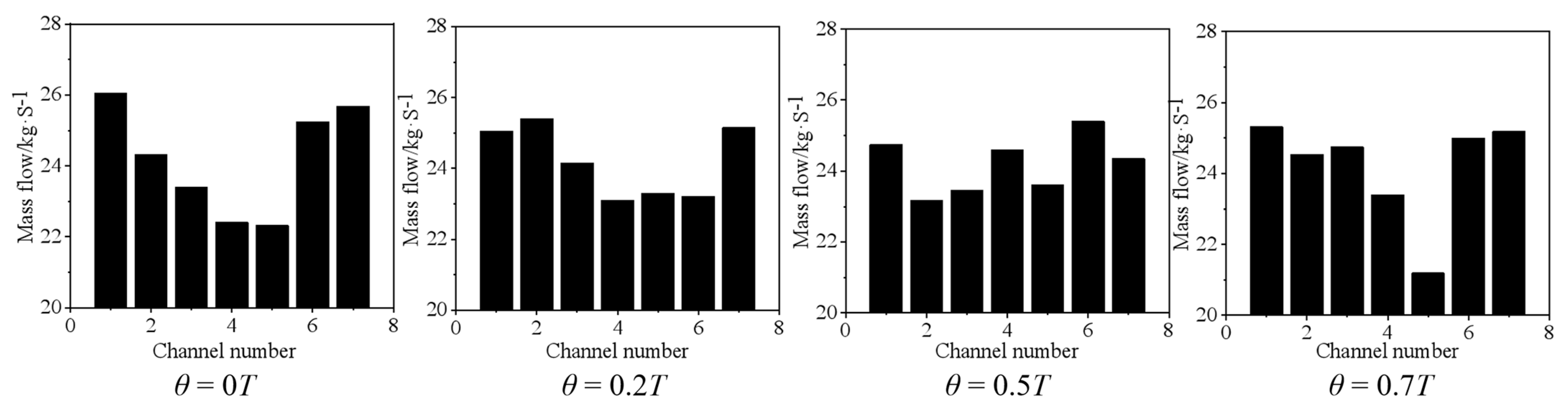

3.4. The Effect of the Circumferential Deflection on Cavitation Development

4. Conclusions

- Generally, it is believed that the inducer would maintain the propulsion performance and suppress the cavitation damage. In fact, the inducer does have an inhibition effect on the incipient cavitation, but whether the critical cavitation performance can be improved is closely related to the matching between the inducer and the impeller. This is because the inducer destroys the rotational symmetry of the flow at the impeller inlet, making the cavitation of some channels more serious than other channels. Once a channel is blocked due to cavitation, the adjacent channel will also be blocked. These channels under serious cavitation will limit the overall cavitation performance. Therefore, even if the inducer provides the flow with energy, it still may not improve the critical cavitation performance.

- A numerical simulation of a centrifugal pump with a critical cavitation ratio of 1024 was carried out. Under the premise of maintaining the same circumferential deflection, the suction-specific speed is increased by about 300 by adjusting the axial space. Under the premise of maintaining the same axial space, the suction-specific speed is increased by nearly 100 by adjusting the circumferential deflection.

- With the increase of axial space, the distribution of bubbles in each flow channel under the same NPSHa becomes more uniform. The flow in the channel with the most serious cavitation phenomenon is improved, and the cavitation performance of the pump becomes better. Meanwhile, for circumferential deflection, when the angle of attack is large, the flow velocity of the adjacent flow channel increases, and the pressure decreases. There is an optimal value of circumferential deflection to avoid large high-speed areas, which has the best cavitation performance. The axial space has a greater effect than the circumferential deflection on the cavitation performance of the pump.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ge, M.; Petkovšek, M.; Zhang, G.; Jacobs, D.; Coutier-Delgosha, O. Cavitation dynamics and thermodynamic effects at elevated temperatures in a small Venturi channel. Int. J. Heat Mass Transf. 2021, 170, 120970. [Google Scholar] [CrossRef]

- Ge, M.; Manikkam, P.; Ghossein, J.; Subramanian, R.K.; Coutier-Delgosha, O.; Zhang, G. Dynamic mode decomposition to classify cavitating flow regimes induced by thermodynamic effects. Energy 2022, 254, 124426. [Google Scholar] [CrossRef]

- Fan, Y.; Chen, T.; Liang, W.; Wang, G.; Huang, B. Numerical and theoretical investigations of the cavitation performance and instability for the cryogenic inducer. Renew. Energy 2022, 184, 291–305. [Google Scholar] [CrossRef]

- Kim, H.; Kim, C. A physics-based cavitation model ranging from inertial to thermal regimes. Int. J. Heat Mass Transf. 2021, 181, 121991. [Google Scholar] [CrossRef]

- Hou, X.Y.; Hu, J.; Yu, Y. Numerical Simulation and Evaluation of Attached Cavitation with Different Cavitation Models. Acta Armamentarii 2020, 41, 91–96. [Google Scholar]

- Hu, J.; Hou, X.Y.; Yu, Y. Improvement and Application of Zwart-Gerbera-Belamri CavitationModel with Local Flow Properties. Trans. Beijing Inst. Technol. 2021, 41, 388–394. [Google Scholar]

- Zhang, G.; Zhang, D.; Ge, M.; Shi, W. Experimental validation to Reboud empirical correction model of cavitation. J. Huazhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2022, 1–6. [Google Scholar] [CrossRef]

- Bakir, F.; Kouidri, S.; Noguera, R.; Rey, R. Experimental analysis of an axial inducer influence of the shape of the blade leading edge on the performance in cavitating regime. J. Fluids Eng. 2003, 125, 293–301. [Google Scholar] [CrossRef]

- Saha, S.L.; Kurokawa, J.; Matsui, J.; Imamura, H. Passive control of rotating stall in a parallel wall vaned diffuser by J-grooves. J. Fluids Eng. 2000, 122, 90–96. [Google Scholar] [CrossRef]

- Benoît, P.; Regiane, F.P.; Jean-Luc, R.; Pierre-Alain, L. Numerical analysis of cavitation instabilities in inducer blade cascade. J. Fluids Eng. 2008, 130, 1441–1448. [Google Scholar]

- Cui, B.L.; Zhu, Z.C.; Lin, Y.G. Numerical simulation of inner flow in equal-pitch inducer. J. Agric. Eng. 2010, 46, 158–163. [Google Scholar] [CrossRef]

- Qiu, N.; Wang, L.Q.; Kong, F.Y. Research on cavitation characteristic of inducer. IOP Conf. Ser. Mater. Sci. Eng. 2013, 52, 668–672. [Google Scholar] [CrossRef]

- Guo, X.M.; Li, Y.; Cui, B.L.; Zhu, Z.C. Research on the rotation cavitation performance of high-speed rotation centrifugal pump with different pre-positioned inducers. Acta Aeronaut. Astronaut. Sin. 2013, 34, 1572–1581. [Google Scholar]

- Kang, D.; Yokota, K. Analytical study of cavitation surge in a hydraulic system. J. Fluids Eng. 2014, 136, 1011031–10110310. [Google Scholar] [CrossRef]

- Zhang, A. Effect of the Geometric Parameters at Inlet of Inducer and Itself on Cavitation Characteristics of Centrifugal Pump. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China.

- Chen, X.; Yang, D.; Liu, J. Influence of annular groove position on cavitation performance of high-speed inducer. J. Drain. Irrig. Mach. Eng. 2021, 39, 548–554. [Google Scholar]

- Lu, X. Research on the effect of front-end flow stabilizer devices on high-speed inducer cavitation characteristics. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China.

- Wang, R. Study on optimization design and cavitation characteristics high-speed centrifugal pump with inducer. Master’s Thesis, Jiangsu University, Zhenjiang, China.

- Leng, H.F.; Yao, Z.F.; Tang, Y.; Wang, C.Y.; Zhao, H.R. Matching characteristics of axial distance between inducer and impeller of micro-centrifugal pump. Trans. Chin. Soc. Agric. Eng. 2020, 36, 47–53. (In Chinese) [Google Scholar]

- Li, R.N.; Bi, Z.; Li, Y.B.; Xiao, L.Q. Effect of inducer deflection angle on impeller cavitation performance in centrifugal pump. J. Drain. Irrig. Mach. Eng. 2016, 34, 461–469. [Google Scholar]

- Sun, Q.Q.; Jiang, J.; Zhang, S.S. Effects of variable pitch inducer on cavitation performance of high-speed centrifugal pumps. J. Drain. Irrig. Mach. Eng. 2017, 35, 856–862. [Google Scholar]

- Wang, W.T.; Chen, H.; Li, Y.P.; Du, Y. Matching research of inducer and impeller of high-speed centrifugal pump. J. Drain. Irrig. Mach. Eng. 2015, 33, 301–305. [Google Scholar]

- Lu, J.L.; Deng, J.; Xu, Y.R.; Feng, J.; Luo, X. Study on axial spacings between inducer and impeller of centrifugal pump. J. Hydroelectr. Eng. 2015, 34, 91–96. [Google Scholar]

- Cheng, X.; Liu, H.; Wu, C.; Wei, Y. Influence of matching of blade number of inducer with impeller on cavitation performance of pump. J. Lanzhou Univ. Technol. 2019, 45, 53–58. [Google Scholar]

- Liu, H. Research on the Matching Characteristics of Inducer and Impeller of Centrifugal Pump. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China.

- Guan, X.F. Morden Pumps Theory and Design, 1st ed.; Zhong Guo Yu Hang Chu Ban She: Beijing, China, 2011; pp. 455–470. [Google Scholar]

- Wang, F.J. Research progress of computational model for rotating turbulent flow in fluid machinery. Trans. Chin. Soc. Agric. Mach. 2016, 47, 1–14. [Google Scholar]

- Zhang, X.X.; Zhang, Z.T.; Zhang, W.F.; Chen, Z. Comparison of five eddy viscosity turbulence models in numerical simulation of flow over a two-dimensional square cylinder. Acta Aerodyn. Sin. 2018, 36, 339–349. [Google Scholar]

- Ren, Y.; Wu, D.; Mou, Y.; Li, X. Modification for Turbulence Model Considering Rotation and Curvature with Applications. J. Xi’an Jiaotong Univ. 2016, 50, 25–30. [Google Scholar]

- Patankar, S.V.; Spalding, D.B. A calculation pressure for heat, mass and momentum transfer in three-dimensional parabolic flows. In Numerical Prediction of Flow, Heat Transfer, Turbulence and Combustion; Pergamon: Oxford, England, 1983; pp. 54–73. [Google Scholar]

- Van Doormaal, J.P.; Raithby, G.D. Enhancement of the SIMPLE method for predicting incompressible fluid flows. Numer. Heat Transf. 1984, 7, 147–163. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Gao, B.; Chen, Y.; Pan, Y.; Luo, J.; Liu, L.; Wei, Q.; Liu, L. Effects of Matching between the Inducer and the Impeller of a Centrifugal Pump on Its Cavitation Performance. Machines 2023, 11, 142. https://doi.org/10.3390/machines11020142

Wang D, Gao B, Chen Y, Pan Y, Luo J, Liu L, Wei Q, Liu L. Effects of Matching between the Inducer and the Impeller of a Centrifugal Pump on Its Cavitation Performance. Machines. 2023; 11(2):142. https://doi.org/10.3390/machines11020142

Chicago/Turabian StyleWang, Daocheng, Bingwen Gao, Yunzhang Chen, Yufan Pan, Jinping Luo, Lei Liu, Qingxi Wei, and Lijun Liu. 2023. "Effects of Matching between the Inducer and the Impeller of a Centrifugal Pump on Its Cavitation Performance" Machines 11, no. 2: 142. https://doi.org/10.3390/machines11020142

APA StyleWang, D., Gao, B., Chen, Y., Pan, Y., Luo, J., Liu, L., Wei, Q., & Liu, L. (2023). Effects of Matching between the Inducer and the Impeller of a Centrifugal Pump on Its Cavitation Performance. Machines, 11(2), 142. https://doi.org/10.3390/machines11020142