Thermal Elastohydrodynamic Analysis of a Worm Gear

Abstract

1. Introduction

2. Methods

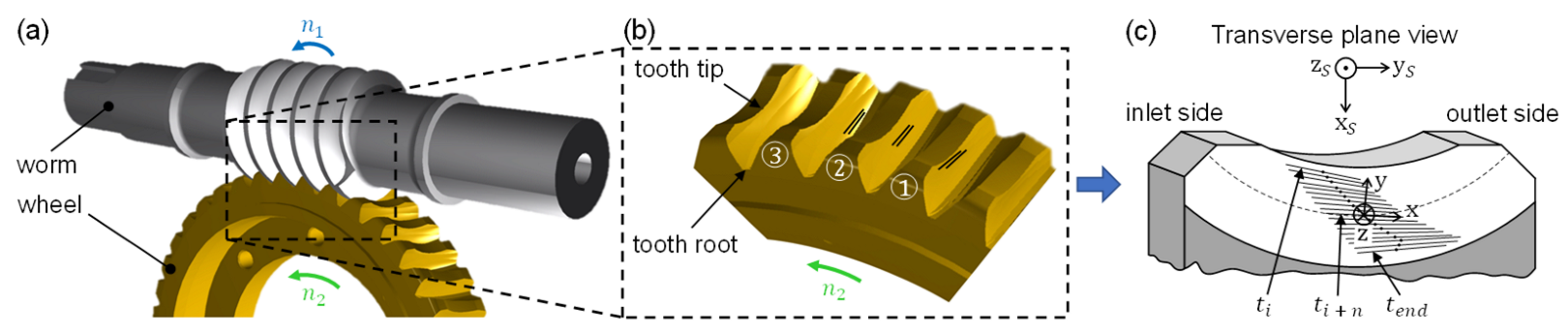

2.1. Object of Investigation

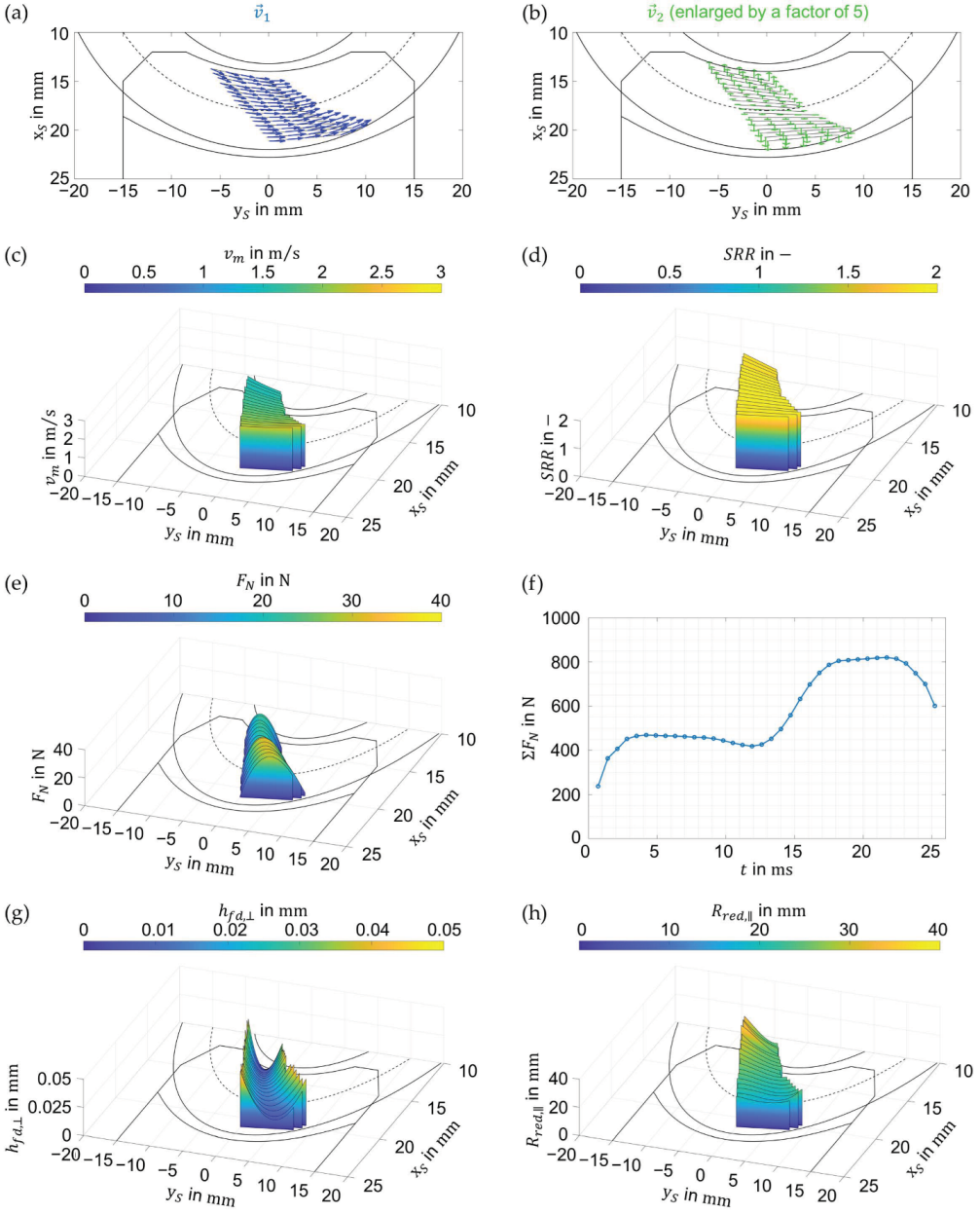

2.1.1. Tooth Contact Analysis

2.1.2. Implementation of Contact Conditions in EHL Model

2.1.3. Solid Contact Analysis

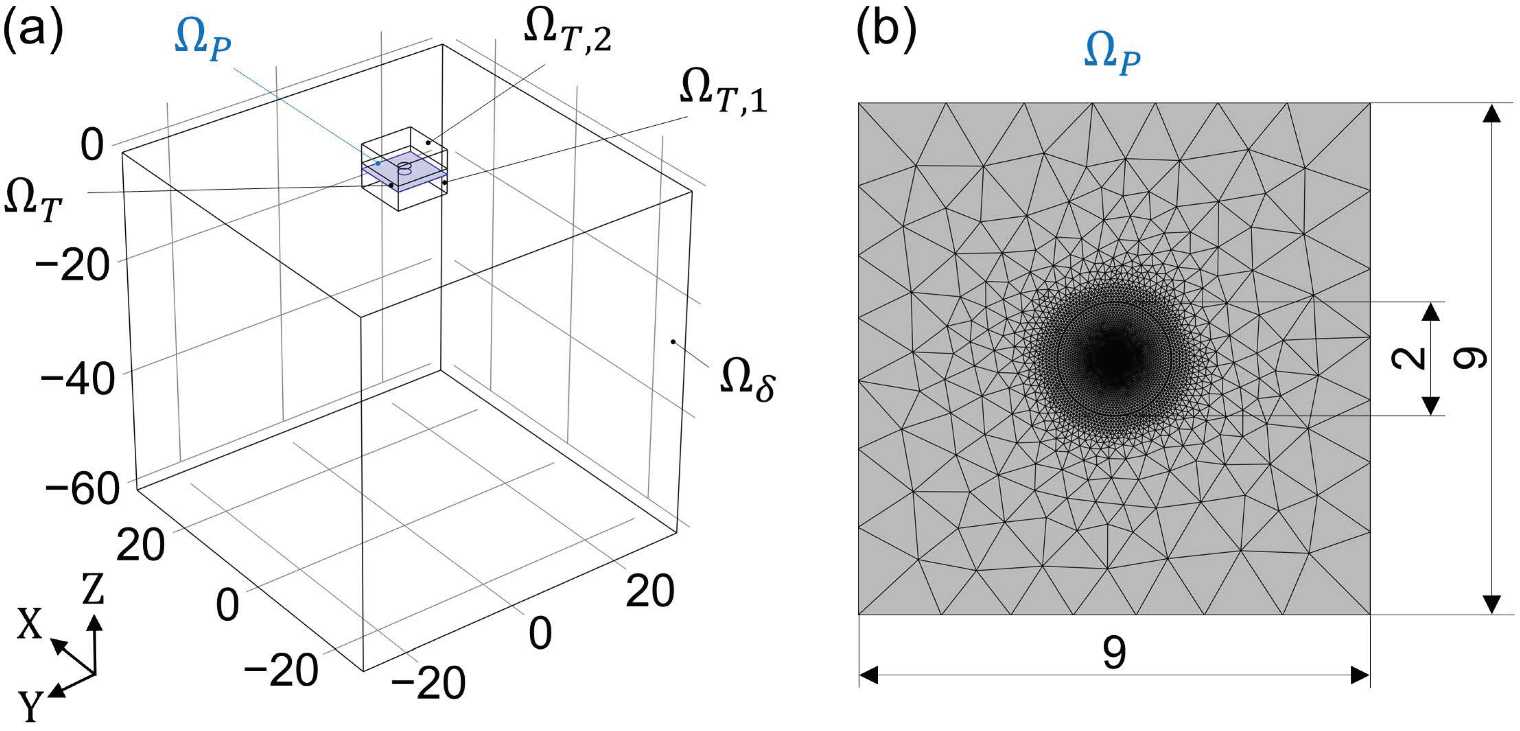

2.2. Thermal Elastohydrodynamic Lubrication Model

2.2.1. Governing Equations

2.2.2. Dimensionless Formulation

2.2.3. Lubricant Equations

2.2.4. Numerical Modeling

3. Results and Discussion

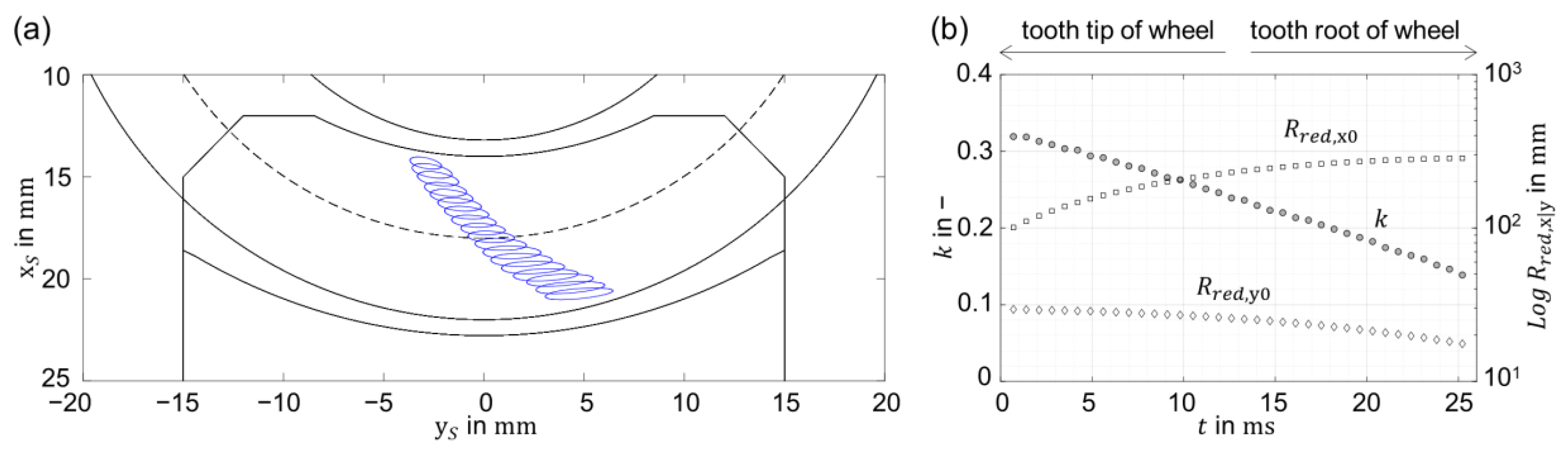

3.1. Dry Contact Analysis

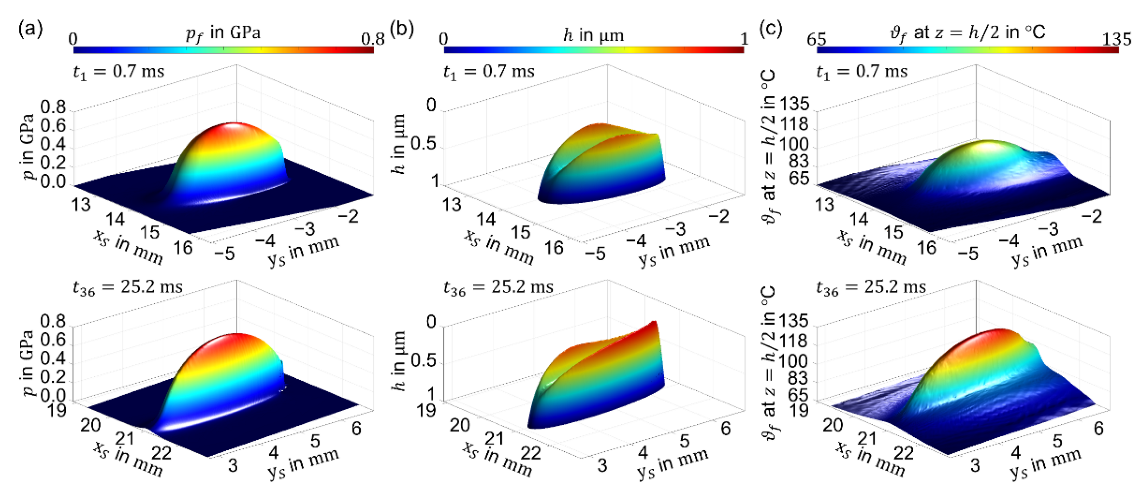

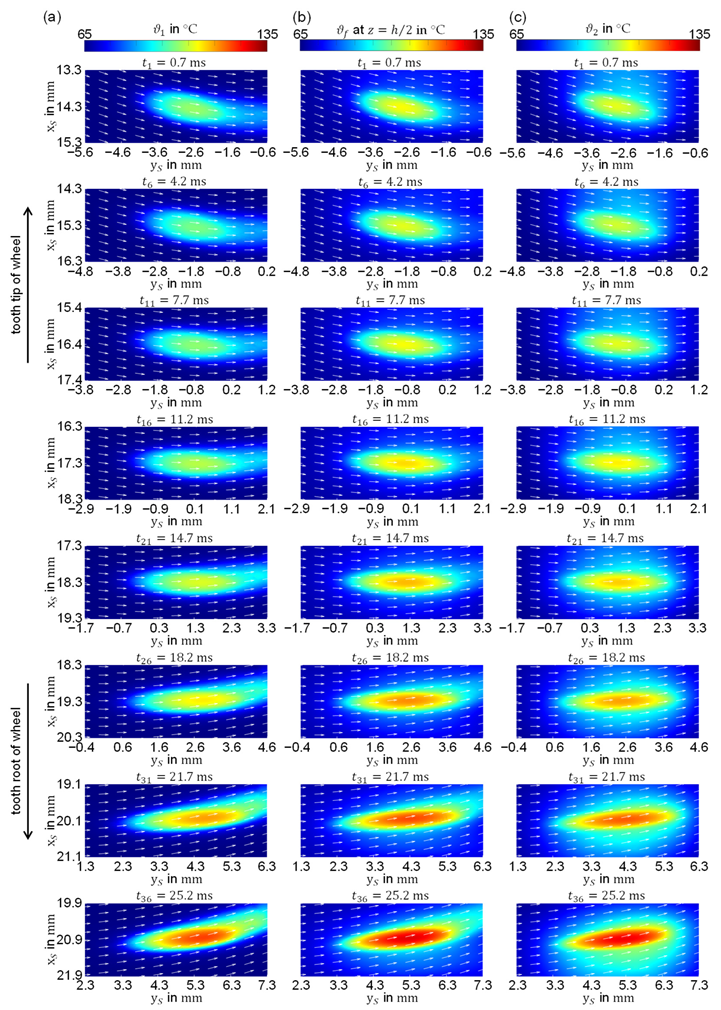

3.2. EHL Contact Analysis

3.3. Classification of Film Thickness Results

- calculation in worm gear contacts according to DIN 3996 (performed by SNETRA) [29];

- and formulae for point contacts with lubricant entrainment at some intermediate angle, by Chittenden et al. [27];

4. Conclusions

- Worm gears with nonconjugate meshing action are characterized by a slender-like elliptical contact with small ellipticity ratio.

- As the contact becomes slenderer toward the tooth root of the wheel, the quantity of the oil entrained in the contact decreases, and the side flow increases, which in turn results in a lower film thickness. In other words, as the worm gear contact becomes slenderer, the effect of entrainment speed on EHL film thickness diminishes.

- The positive effect of the increasing entrainment speed toward the tooth root of the wheel on EHL film thickness could be restored by making the contact less slender. This could be achieved by increasing conformity between the flanks in the transverse direction to the meshing position.

- The worm tooth flank is cooler than the wheel tooth flank, which is a consequence of more efficient heat removal via convection by the worm.

- In terms of analytical approaches, the film thickness is overestimated, except for the minimum film thickness by Wolf et al. [30,31]. Calculation by DIN 3996 predicts a different trend of the minimum film thickness over the meshing cycle compared to the results from this study. This shows the difficulty in applying simple analytical formulae to capture the complex contact conditions of worm gears.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Latin symbols | ||

| Oil parameter for improved Yasutomi temperature–pressure–viscosity correlation | ||

| Oil parameter for improved Yasutomi temperature–pressure–viscosity correlation | ||

| Coefficients of the oil heat capacity model | ||

| Center distance of the considered worm gear pair | ||

| Semi-major Hertzian contact length | ||

| Semi-minor Hertzian contact length | ||

| Oil parameter for improved Yasutomi temperature–pressure–viscosity correlation | ||

| Oil parameter for improved Yasutomi temperature–pressure–viscosity correlation | ||

| Compliance matrix | ||

| Specific heat capacity | ||

| Oil parameter for improved Yasutomi temperature–pressure–viscosity correlation | ||

| Oil parameter for improved Yasutomi temperature–pressure–viscosity correlation | ||

| Reference diameter | ||

| Coefficients of the oil thermal conductivity model | ||

| Oil parameter for Dowson–Higginson density model | ||

| Oil parameter for Dowson–Higginson density model | ||

| Thermal effusivity | ||

| Modulus of Elasticity | ||

| Equivalent Modulus of Elasticity | ||

| Number of interpolated meshing positions between two meshing positions | − | |

| Normal force | ||

| Dimensionless relative thermal expansivity of the free volume | ||

| Undeformed gap between rigid ellipsoid and elastic body | ||

| Carreau model parameter | ||

| Film thickness | ||

| Central film thickness | ||

| Minimum film thickness | ||

| Flank distance in the direction parallel to the meshing position (-direction) | ||

| Dimensionless film thickness | ||

| Constant parameter of the film thickness equation | ||

| Gear ratio | ||

| Ellipticity ratio | ||

| Rotational speed | ||

| Carreau model parameter | ||

| Number of the considered meshing positions | ||

| Mesh resolution in - and -direction of the contact mechanics numerical model | ||

| Hydrodynamic pressure | ||

| Dimensionless hydrodynamic pressure | ||

| Hertzian pressure | ||

| Maximum Hertzian pressure | ||

| Reduced radii of curvatures in - and -direction | m | |

| Reduced radii of curvatures in - and -direction at the contact center () | ||

| Reduced radius of curvature in the transverse direction to the meshing position(-direction) | ||

| Slide-to-roll ratio | ||

| Torque | ||

| Temperature | ||

| Oil temperature | ||

| Glass transition temperature | ||

| Reference glass transition temperature | ||

| Dimensionless temperature | ||

| Time | ||

| Dimensionless time | ||

| Meshing time of a single tooth of the worm gear | s | |

| Displacement vector | ||

| Fluid velocity in -direction | m/s | |

| Fluid velocity in -direction | m/s | |

| Velocity vector | ||

| Sliding speed in -direction | m/s | |

| Sliding speed in -direction | ||

| Entrainment speed | m/s | |

| Entrainment speed evaluated at the contact center () | ||

| Worm velocity component in -direction | ||

| Worm velocity component in -direction | m/s | |

| Wheel velocity component in -direction | ||

| Wheel velocity component in -direction | ||

| ,, | Coordinates of SNETRA | |

| ,, | Coordinates of the numerical EHL model | |

| ,, | Dimensionless coordinates of the numerical EHL model | |

| Number of teeth | ||

| Greek symbols | ||

| Pressure-viscosity coefficient | Pa−1 | |

| Elastic deflection of an equivalent body | ||

| Dimensionless elastic deflection of an equivalent body | ||

| Time step size | s | |

| Oil thermal expansivity | ||

| Oil thermal expansivity at and atmospheric pressure | ||

| Contact ratio | ||

| Fluid temperature | ||

| Maximum fluid temperature | ||

| Reference oil temperature | ||

| Temperature of worm flank surface | ||

| Temperature of wheel flank surface | ||

| Dynamic viscosity | ||

| Dimensionless dynamic viscosity | ||

| Oil dynamic viscosity at and atmospheric pressure | ||

| Thermal conductivity | ||

| Oil thermal conductivity at and atmospheric pressure | ||

| Coefficient in the thermal expansivity model | ||

| Parameter for improved Yasutomi temperature–pressure–viscosity correlation | ||

| Poisson’s ratio | ||

| Equivalent Poisson’s ratio | ||

| Kinematic viscosity at | ||

| Kinematic viscosity at | ||

| Density | ||

| Dimensionless density | ||

| Oil density at and atmospheric pressure | ||

| Oil density at and atmospheric pressure | ||

| Sum of the normal force over the meshing position | ||

| Shear stress | ||

| Dimensionless shear stress | ||

| Shear stress components in the - and -direction over the computational domain | ||

| Indices | ||

| Worm | ||

| Wheel | ||

| Fluid |

References

- Niemann, G.; Winter, H. Maschinenelemente Band 3: Schraubrad-, Kegelrad-, Schnecken-, Ketten-, Riemen-, Reibradgetriebe, Kupplungen, Bremsen, Freiläufe [Machine Elements Volume 3: Helical, Bevel, Worm, Chain, Belt, Friction Gears, Clutches, Brakes, Freewheels]; 2., völlig neu bearbeitete Auflage; Springer: Berlin/Heidelberg, Germany, 2004; ISBN 978-3-642-62101-7. [Google Scholar]

- Kong, S.; Sharif, K.J.; Evans, H.P.; Snidle, R.W. Elastohydrodynamics of a Worm Gear Contact. ASME J. Tribol. 2001, 123, 268–275. [Google Scholar] [CrossRef]

- Simon, V. EHD Lubrication Characteristics of a New Type of Ground Cylindrical Worm Gearing. ASME J. Mech. Des. 1997, 119, 101–107. [Google Scholar] [CrossRef]

- Yang, F.; Su, D.; Gentle, C.R. Finite element modelling and load share analysis for involute worm gears with localized tooth contact. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2001, 215, 805–816. [Google Scholar] [CrossRef]

- Sharif, K.J.; Kong, S.; Evans, H.P.; Snidle, R.W. Contact and elastohydrodynamic analysis of worm gears Part 1: Theoretical formulation. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2001, 215, 817–830. [Google Scholar] [CrossRef]

- Sharif, K.J.; Kong, S.; Evans, H.P.; Snidle, R.W. Contact and elastohydrodynamic analysis of worm gears Part 2: Results. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2001, 215, 831–846. [Google Scholar] [CrossRef]

- Sharif, K.J.; Evans, H.P.; Snidle, R.W.; Barnett, D.; Egorov, I.M. Effect of elastohydrodynamic film thickness on a wear model for worm gears. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2006, 220, 295–306. [Google Scholar] [CrossRef]

- Magyar, B. Tribo-dynamische Untersuchungen von Zylinderschneckengetrieben [Tribo-Dynamic Studies of Cylindrical Worm Gears]. Ph.D. Thesis, University of Kaiserslautern, Kaiserslautern, Germany, 2012. [Google Scholar]

- Venner, C.H. Multilevel Solution of the EHL Line and Point Contact Problems. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 1991. [Google Scholar]

- Oehler, M. Methodische Ansätze zur Optimierung des Wirkungsgrades von Schneckengetrieben [Methodical Approaches to Optimizing the Efficiency of Worm Gears]. Ph.D. Thesis, University of Kaiserslautern, Kaiserslautern, Germany, 2018. [Google Scholar]

- Habchi, W.; Bair, S. The role of the thermal conductivity of steel in quantitative elastohydrodynamic friction. Tribol. Int. 2019, 142, 105970. [Google Scholar] [CrossRef]

- Roth, P.; Sigmund, W.; Born, S.; Kadach, D.; Stahl, K. A Numerical Approach to the Calculation of the Surface Temperature Distribution of Worm Gears. In Proceedings of the ASME 2017 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Cleveland, OH, USA, 6–9 August 2017. [Google Scholar] [CrossRef]

- Roth, P.; Hein, M.; Stahl, K. Scuffing load capacity calculation of worm gears. Forsch. Ing. 2022, 86, 503–511. [Google Scholar] [CrossRef]

- Daubach, K.; Oehler, M.; Sauer, B. Wear simulation of worm gears based on an energetic approach. Forsch. Ing. 2022, 86, 367–377. [Google Scholar] [CrossRef]

- Mohammadpour, M.; Theodossiades, S.; Rahnejat, H. Transient mixed non-Newtonian thermo-elastohydrodynamics of vehicle differential hypoid gears with starved partial counter-flow inlet boundary. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2014, 228, 1159–1173. [Google Scholar] [CrossRef]

- Almqvist, A.; Pérez-Ràfols, F. Scientific Computing with Applications in Tribology: A Course Compendium. 2019. Available online: http://urn.kb.se/resolve?urn=urn:nbn:se:ltu:diva-72934 (accessed on 25 October 2022).

- Habchi, W. Finite Element Modeling of Elastohydrodynamic Lubrication Problems; John Wiley & Sons Incorporated: Newark, NJ, USA, 2018. [Google Scholar]

- Farrenkopf, F.; Schwarz, A.; Lohner, T.; Stahl, K. Analysis of a Low-Loss Gear Geometry Using a Thermal Elastohydrodynamic Simulation including Mixed Lubrication. Lubricants 2022, 10, 200. [Google Scholar] [CrossRef]

- Bair, S.; Mary, C.; Bouscharain, N.; Vergne, P. An improved Yasutomi correlation for viscosity at high pressure. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2013, 227, 1056–1060. [Google Scholar] [CrossRef]

- Bair, S. High Pressure Rheology for Quantitative Elastohydrodynamics, 2nd ed.; Elsevier: Cambridge, MA, USA, 2019. [Google Scholar]

- Dowson, D.; Higginson, G.R. Elasto-Hydrodynamic Lubrication: The Fundamentals of Roller and Gear Lubrication, 1st ed.; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Bos, J. Frictional Heating of Tribological Contacts. Ph.D. Thesis, University of Twente, Enschede, The Netherlands, 1994. [Google Scholar]

- Larsson, E.; Andersson, O. Lubricant thermal conductivity and heat capacity under high pressure. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2000, 214, 337–342. [Google Scholar] [CrossRef]

- Ziegltrum, A.; Lohner, T.; Stahl, K. TEHL Simulation on the Influence of Lubricants on the Frictional Losses of DLC Coated Gears. Lubricants 2018, 6, 17. [Google Scholar] [CrossRef]

- Tošić, M.; Larsson, R.; Lohner, T. Thermal Effects in Slender EHL Contacts. Lubricants 2022, 10, 89. [Google Scholar] [CrossRef]

- Chittenden, R.J.; Dowson, D.; Dunn, J.F.; Taylor, C.M. A Theoretical Analysis of the Isothermal Elastohydrodynamic Lubrication of Concentrated Contacts. I. Direction of Lubricant Entrainment Coincident with the Major Axis of the Hertzian Contact Ellipse. Proc. R. Soc. Lond. 1985, 397, 245–269. [Google Scholar] [CrossRef]

- Chittenden, R.J.; Dowson, D.; Dunn, J.F.; Taylor, C.M. A Theoretical Analysis of the Isothermal Elastohydrodynamic Lubrication of Concentrated Contacts. II. General Case, with Lubricant Entrainment along Either Principal Axis of the Hertzian Contact Ellipse or at Some Intermediate Angle. Proc. R. Soc. Lond. 1985, 397, 271–294. [Google Scholar]

- Wheeler, J.D.; Fillot, N.; Vergne, P.; Philippon, D.; Morales-Espejel, G. On the crucial role of ellipticity on elastohydrodynamic film thickness and friction. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2016, 230, 1503–1515. [Google Scholar] [CrossRef]

- DIN 3996:2019; Calculation of load capacity of cylindrical worm gear pairs with rectangular crossing axis(in German). German Institute for Standardization: Berlin, Germany, 2019.

- Wolf, M.; Solovyev, S.; Fatemi, A. Film thickness in elastohydrodynamically lubricated slender elliptic contacts: Part I—Numerical studies of central film thickness. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2022, 236, 1043–1055. [Google Scholar] [CrossRef]

- Wolf, M.; Sperka, P.; Fryza, J.; Fatemi, A. Film Thickness in Elastohydrodynamically Lubricated Slender Elliptic Contacts: Part II—Experimental Validation and Minimum Film Thickness. Proc. Inst. Mech. Eng. J J. Eng. Tribol. 2022, 236, 2477–2490. [Google Scholar] [CrossRef]

- Marian, M.; Mursak, J.; Bartz, M.; Profito, F.; Rosenkrantz, A.; Wartzack, S. Predicting EHL film thickness parameters by machine learning approaches. Friction 2022. [Google Scholar] [CrossRef]

| Worm (1) | Wheel (2) | ||

|---|---|---|---|

| Worm gear geometry | |||

| Reference diameter | |||

| Number of teeth | |||

| Center distance | |||

| Gear ratio | |||

| Contact ratio | |||

| Operating conditions | |||

| Solid material properties | |||

| Material | Steel 16MnCr5 [10] | Bronze CuSn12Ni2-C [10] | |

| GPa | |||

| [11] | |||

| Oil properties of PG460 [10] | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tošić, M.; Larsson, R.; Stahl, K.; Lohner, T. Thermal Elastohydrodynamic Analysis of a Worm Gear. Machines 2023, 11, 89. https://doi.org/10.3390/machines11010089

Tošić M, Larsson R, Stahl K, Lohner T. Thermal Elastohydrodynamic Analysis of a Worm Gear. Machines. 2023; 11(1):89. https://doi.org/10.3390/machines11010089

Chicago/Turabian StyleTošić, Marko, Roland Larsson, Karsten Stahl, and Thomas Lohner. 2023. "Thermal Elastohydrodynamic Analysis of a Worm Gear" Machines 11, no. 1: 89. https://doi.org/10.3390/machines11010089

APA StyleTošić, M., Larsson, R., Stahl, K., & Lohner, T. (2023). Thermal Elastohydrodynamic Analysis of a Worm Gear. Machines, 11(1), 89. https://doi.org/10.3390/machines11010089