6-DOF Bilateral Teleoperation Hybrid Control System for Power Distribution Live-Line Operation Robot

Abstract

1. Introduction

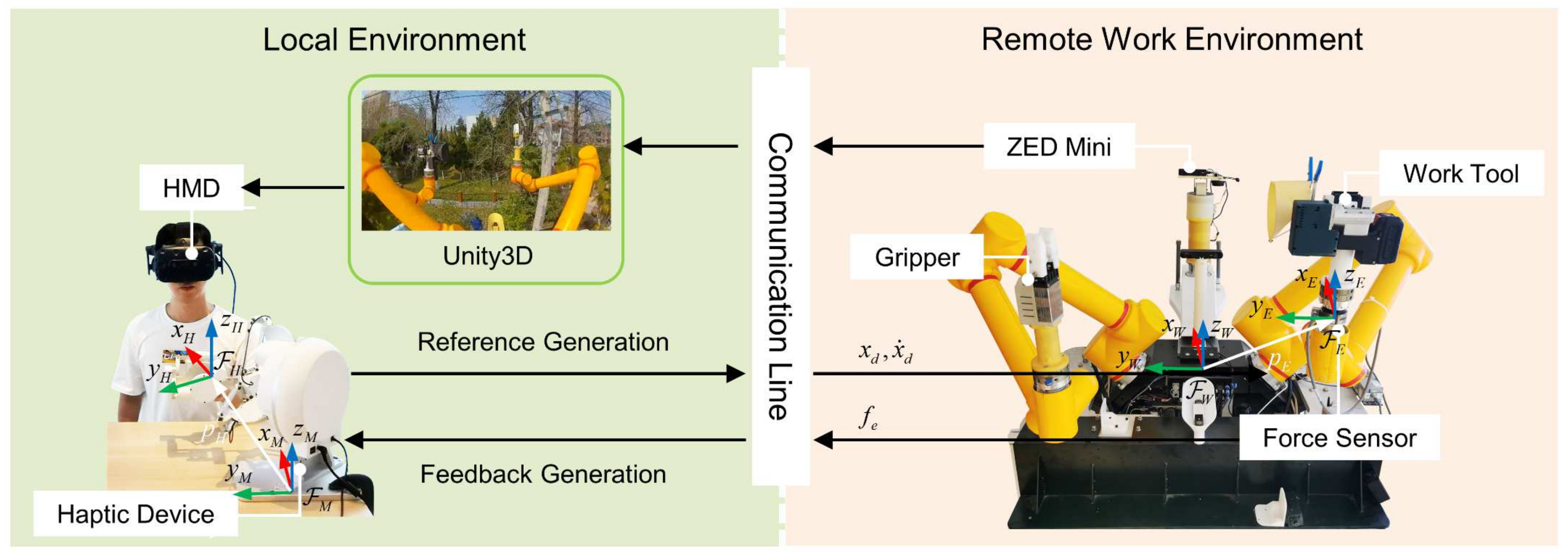

- (1)

- Mapping between the master device and the remote device. In view of the inconsistent configurations of the master device and the remote manipulator, as well as the large difference in the size of the workspaces, a hybrid control strategy is designed to switch automatically according to the current position and rotation on the end of the master device.

- (2)

- Haptic rendering of the feedback force from the end-force sensor when a tool interacts with the environment, and haptic rendering of the virtual force generated by superimposing the virtual simulation space. This feedback enables the operator to perceive interactions between the remote robot and the environment while being guided by the virtual force field.

- (3)

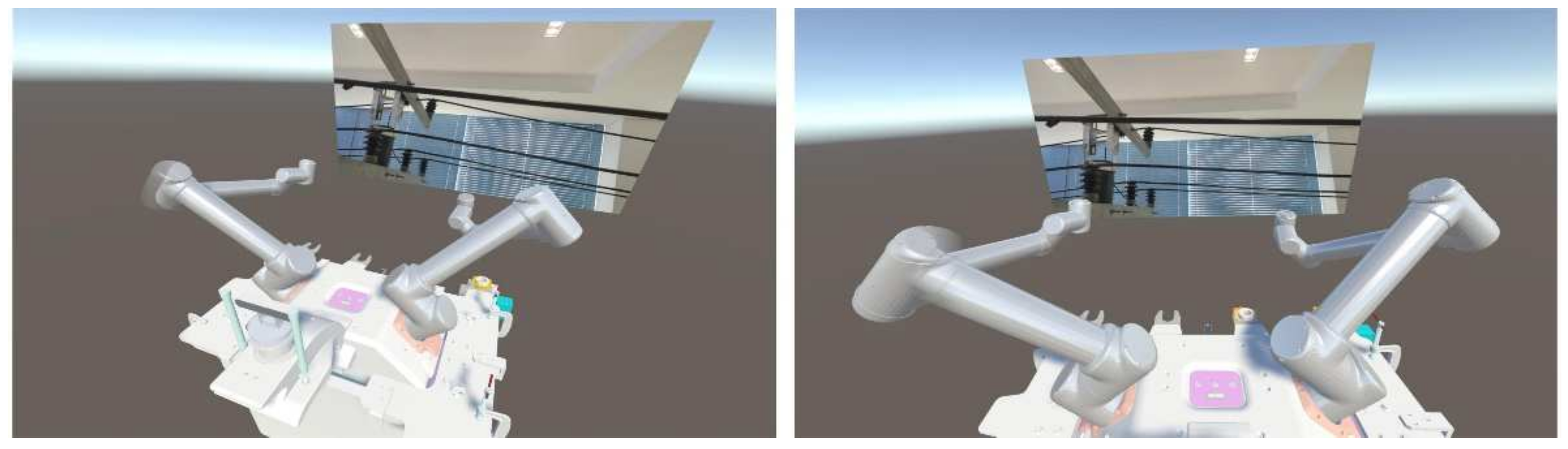

- Real-time rendering of binocular vision from the robot visual perception system of the head-mounted display (HMD). During teleoperation training, this can be switched to the visualization of a virtual simulation environment for teleoperation skill training.

- (4)

- Through the integration of the above parts, a human-centered teleoperation system that conforms to human operating habits is constructed.

2. Estimation of Contact Forces

3. Teleoperation System

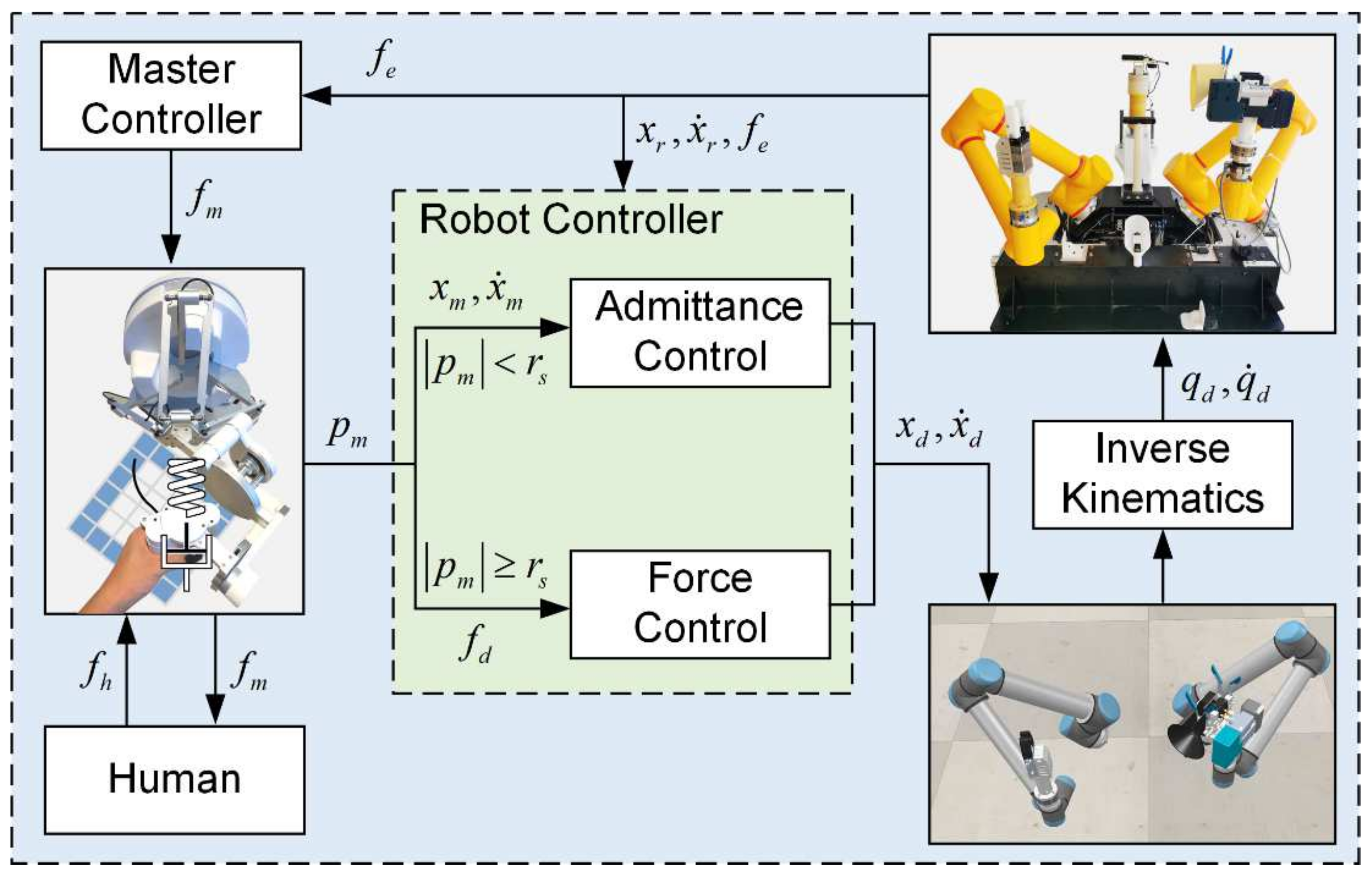

3.1. Teleoperation Control Route

3.2. Teleoperation Hybrid Control

3.2.1. Admittance Teleoperation Control Mode

3.2.2. Force-Based Speed Control Mode

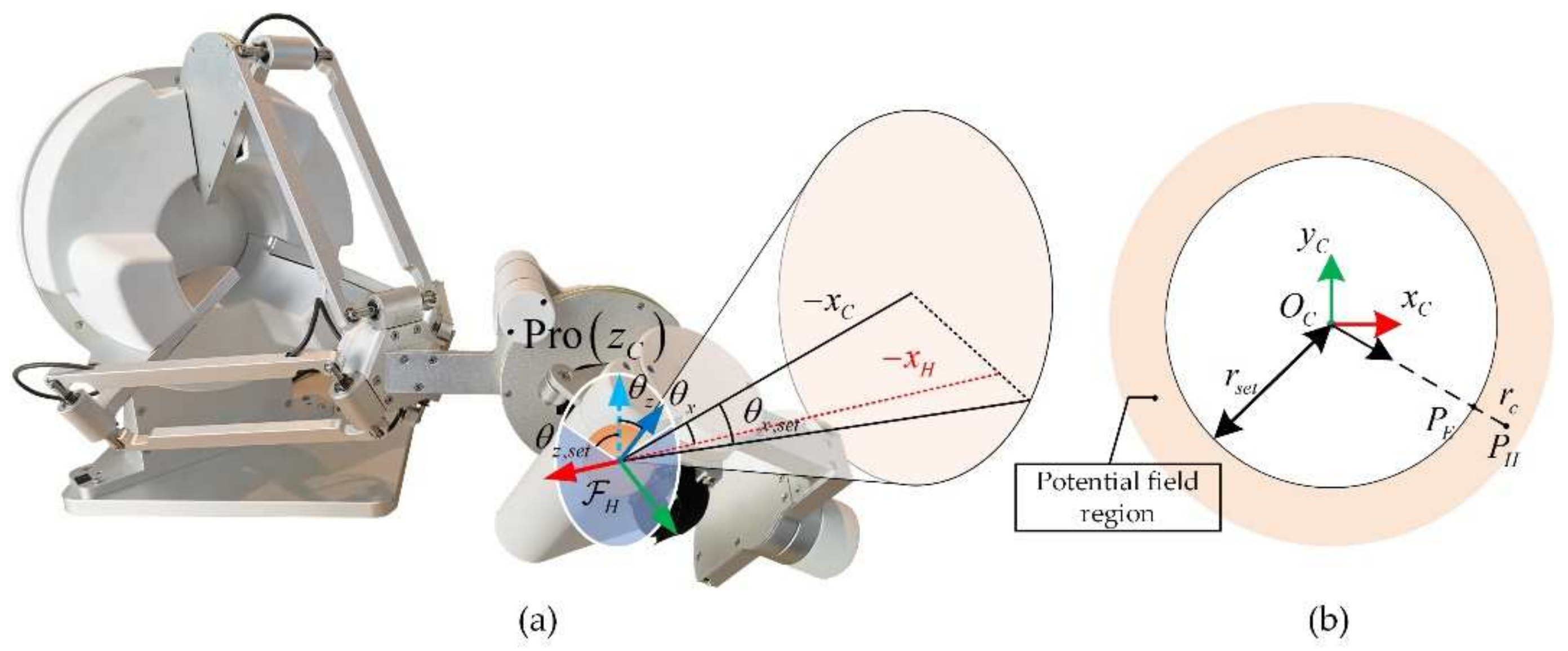

3.3. Force Feedback from Haptic Devices

3.4. Visual Feedback of Real-World and Virtual Simulation

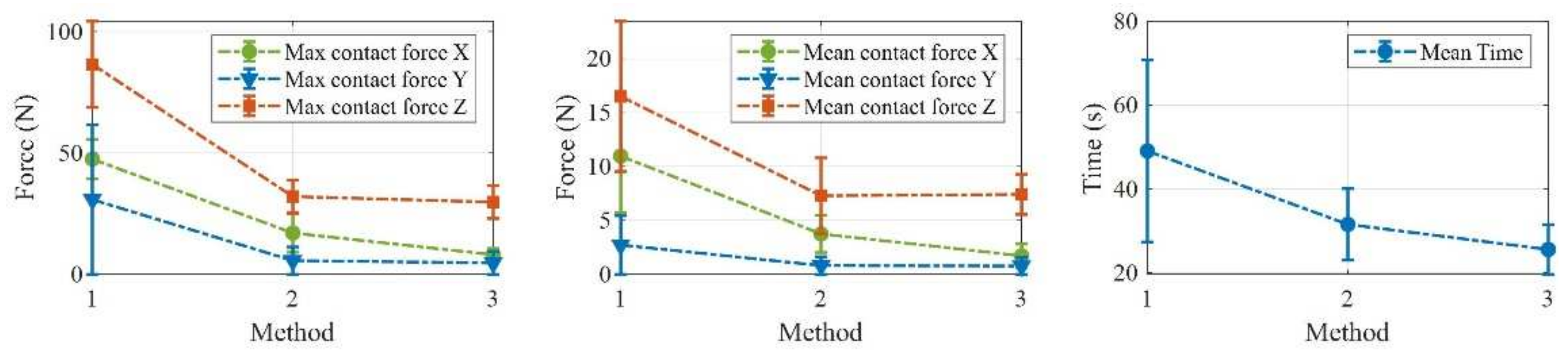

4. Experimental Evaluation

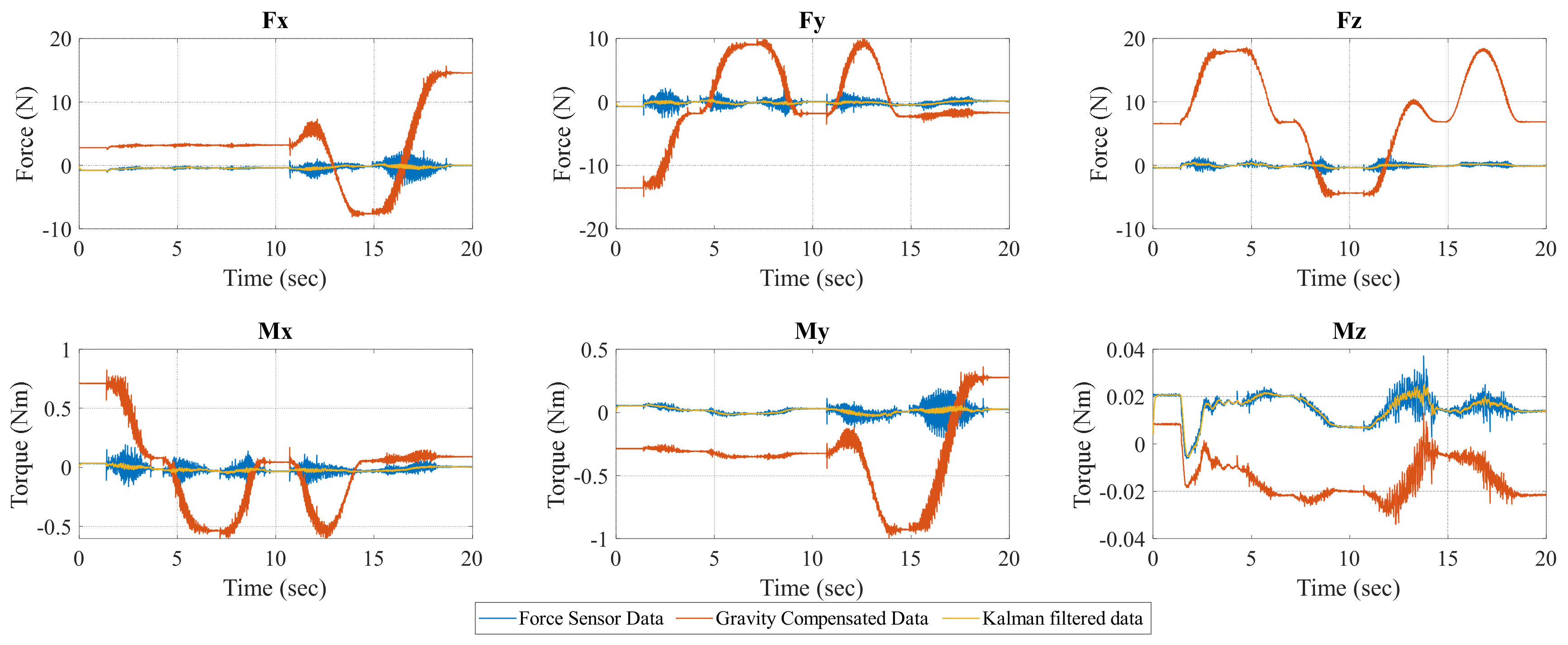

4.1. End-Load Compensation

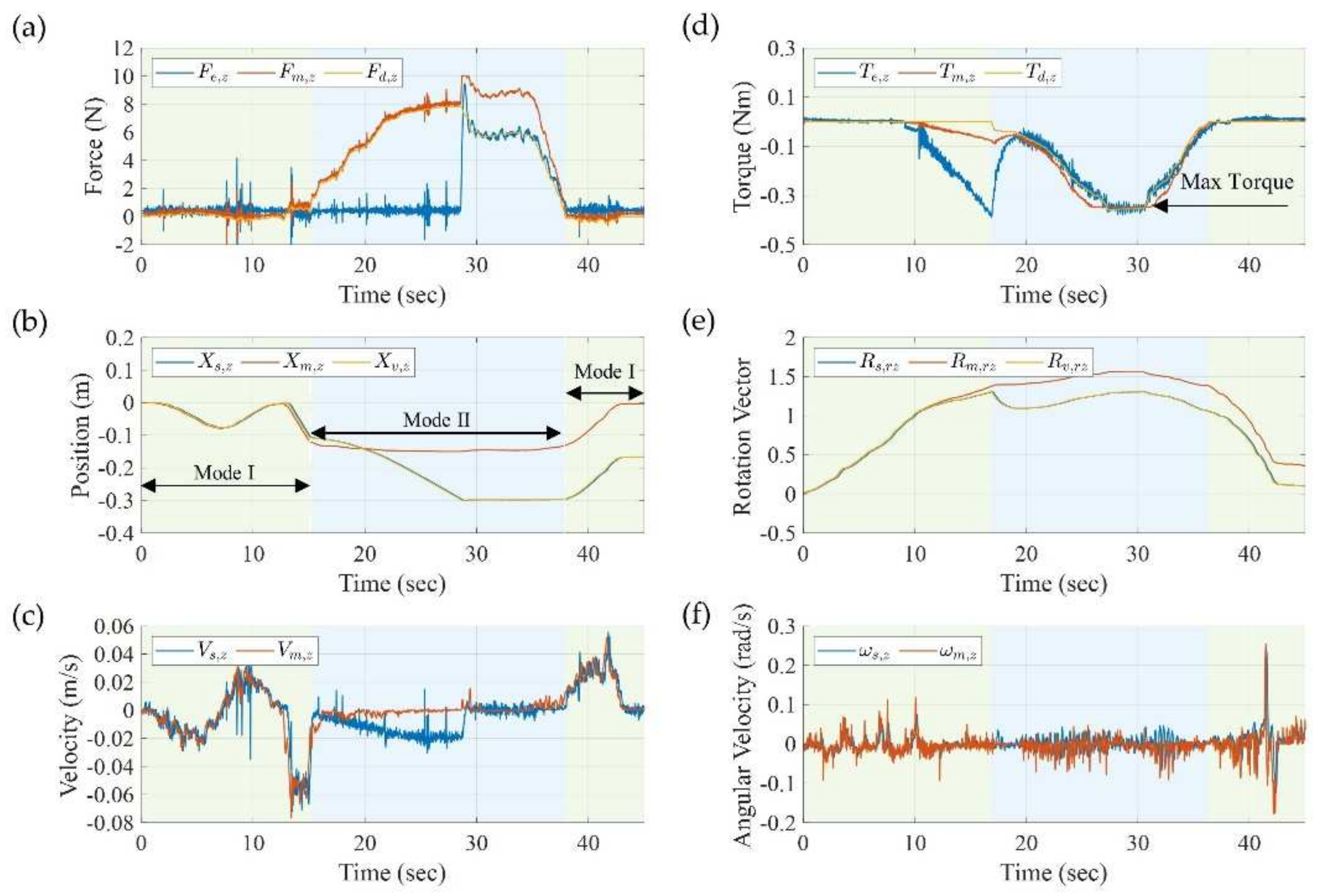

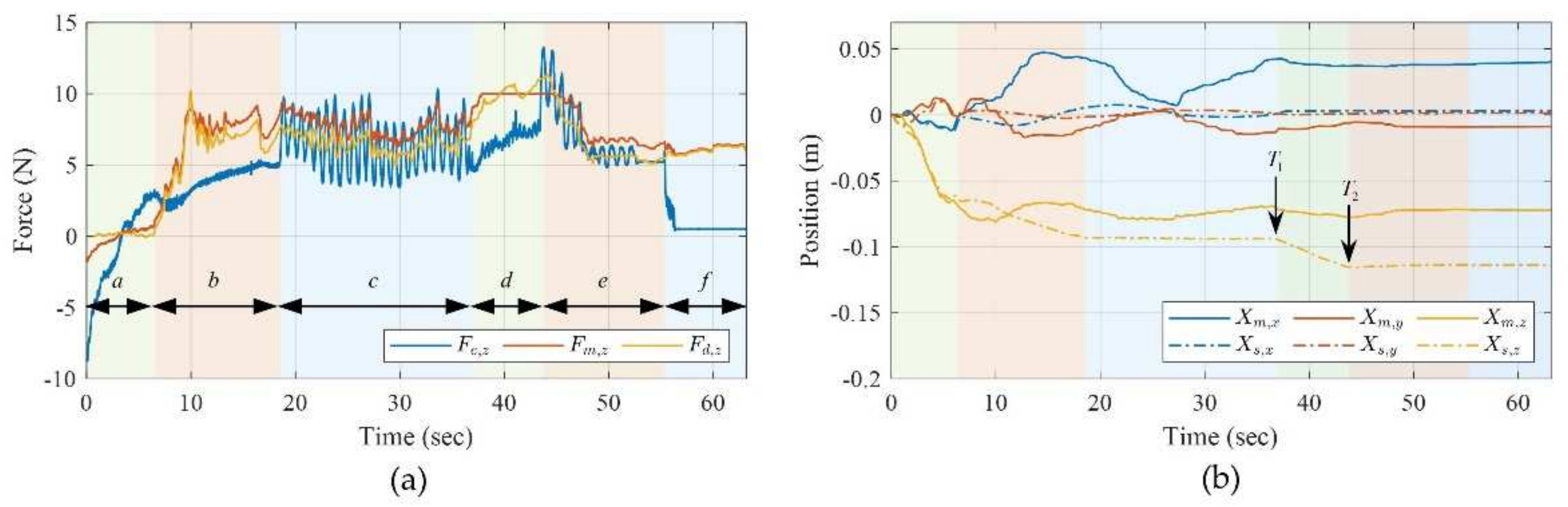

4.2. Switching of Hybrid Control

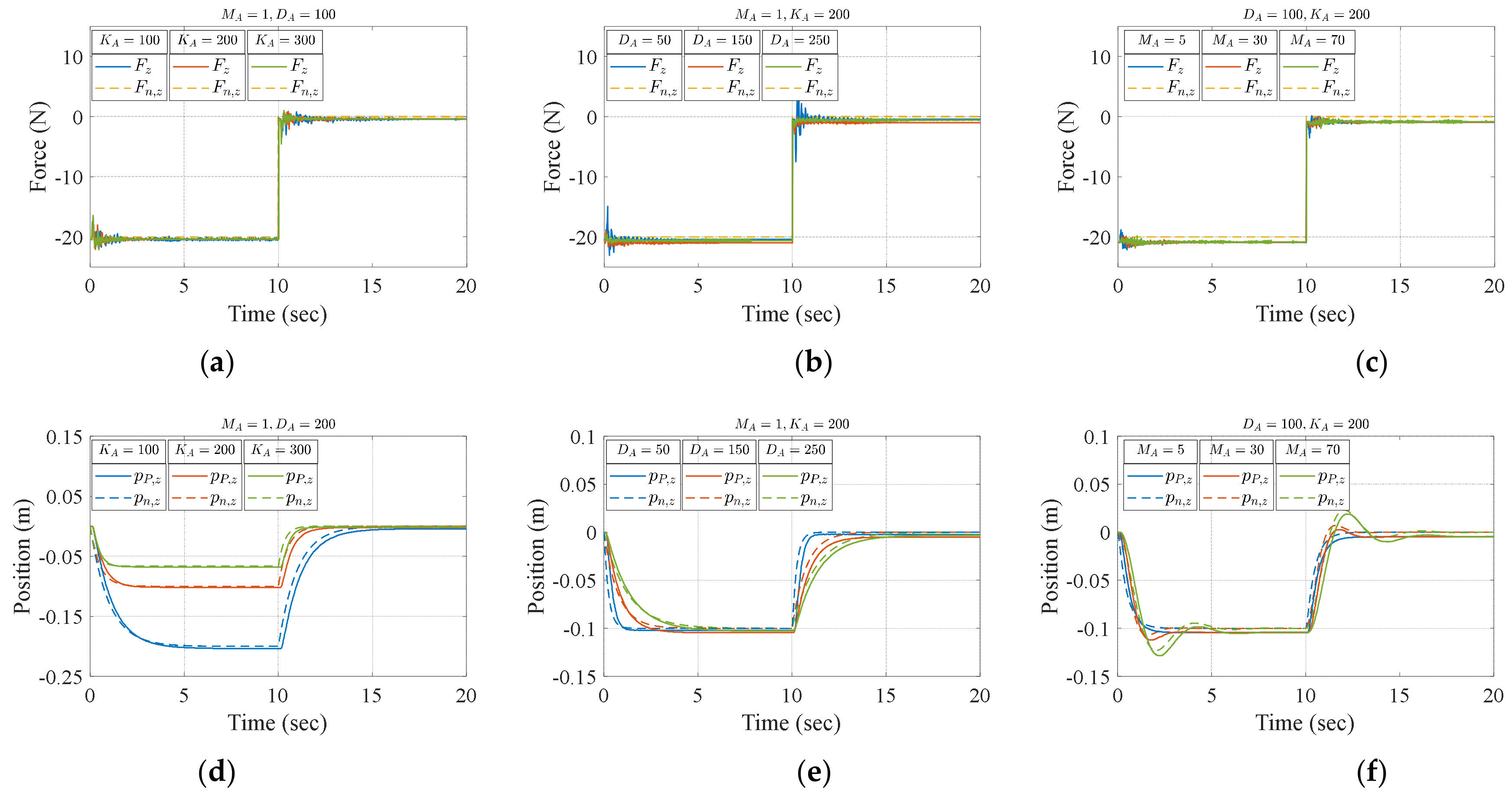

4.3. Influence of Admittance Control Parameters

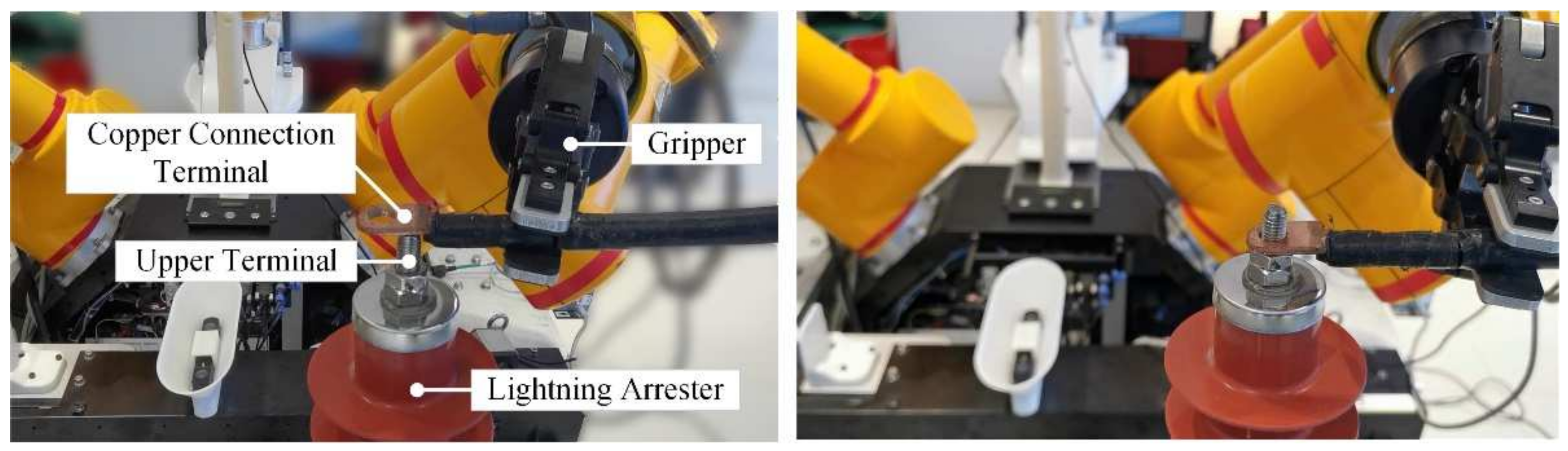

4.4. Application in PDLOR

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gu, J.; Zhang, P. Research on Safety Risk Management and Control of Live Work in Distribution Networks. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Ulaanbaatar, Mongolia, 10–13 September 2020; p. 32106. [Google Scholar]

- Zhao, H.; Wang, C.; Guo, R.; Rong, X.; Guo, J.; Yang, Q.; Yang, L.; Zhao, Y.; Li, Y. Autonomous live working robot navigation with real-time detection and motion planning system on distribution line. High Volt. 2022. [Google Scholar] [CrossRef]

- Allan, J.-F. Robotics for distribution power lines: Overview of the last decade. In Proceedings of the 2012 2nd International Conference on Applied Robotics for the Power Industry (CARPI), Zurich, Switzerland, 11–13 September 2012; pp. 96–101. [Google Scholar]

- Chen, Y.; Zhang, B.; Zhou, J.; Wang, K. Real-time 3D unstructured environment reconstruction utilizing VR and Kinect-based immersive teleoperation for agricultural field robots. Comput. Electron. Agric. 2020, 175, 105579. [Google Scholar] [CrossRef]

- Du, G.; Deng, Y.; Ng, W.W.Y.; Li, D. An Intelligent Interaction Framework for Teleoperation Based on Human-Machine Cooperation. IEEE Trans. Hum.-Mach. Syst. 2022, 52, 963–972. [Google Scholar] [CrossRef]

- Stotko, P.; Krumpen, S.; Schwarz, M.; Lenz, C.; Behnke, S.; Klein, R.; Weinmann, M. A VR System for Immersive Teleoperation and Live Exploration with a Mobile Robot. arXiv 2019, arXiv:1908.02949. [Google Scholar]

- Lipton, J.I.; Fay, A.J.; Rus, D. Baxter’s Homunculus: Virtual Reality Spaces for Teleoperation in Manufacturing. IEEE Robot. Autom. Lett. 2018, 3, 179–186. [Google Scholar] [CrossRef]

- Li, R.; Wang, H.; Liu, Z. Survey on Mapping Human Hand Motion to Robotic Hands for Teleoperation. IEEE Trans. Circuits Syst. Video Technol. 2022, 32, 2647–2665. [Google Scholar] [CrossRef]

- Ajoudani, A.; Tsagarakis, N.; Bicchi, A. Tele-impedance: Teleoperation with impedance regulation using a body–machine interface. Int. J. Robot. Res. 2012, 31, 1642–1656. [Google Scholar] [CrossRef]

- Girbes-Juan, V.; Schettino, V.; Demiris, Y.; Tornero, J. Haptic and Visual Feedback Assistance for Dual-Arm Robot Teleoperation in Surface Conditioning Tasks. IEEE Trans. Haptics 2021, 14, 44–56. [Google Scholar] [CrossRef]

- Peppoloni, L.; Brizzi, F.; Avizzano, C.A.; Ruffaldi, E. Immersive ROS-integrated framework for robot teleoperation. In Proceedings of the 2015 IEEE Symposium on 3D User Interfaces (3DUI), Arles, France, 23–24 March 2015. [Google Scholar]

- Whitney, J.P.; Chen, T.; Mars, J.; Hodgins, J.K. A hybrid hydrostatic transmission and human-safe haptic telepresence robot. In Proceedings of the International Conference on Robotics and Automation, Stockholm, Sweden, 16–21 May 2016; pp. 690–695. [Google Scholar]

- Herdocia, A.H.; Shademan, A.; Jägersand, M. Unimodal asymmetric interface for teleoperation of mobile manipulators: A user study. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; pp. 5214–5219. [Google Scholar]

- Gao, X.; Silverio, J.; Pignat, E.; Calinon, S.; Li, M.; Xiao, X. Motion Mappings for Continuous Bilateral Teleoperation. IEEE Robot. Autom. Lett. 2021, 6, 5048–5055. [Google Scholar] [CrossRef]

- Li, G.; Caponetto, F.; Del Bianco, E.; Katsageorgiou, V.; Sarakoglou, I.; Tsagarakis, N.G. Incomplete Orientation Mapping for Teleoperation With One DoF Master-Slave Asymmetry. IEEE Robot. Autom. Lett. 2020, 5, 5167–5174. [Google Scholar] [CrossRef]

- Zhou, S.; Shen, C.; Zhu, S.; Li, W.; Nie, Y.; Chen, Z. A Teleoperation Framework Based on Heterogeneous Matching for Hydraulic Manipulator. Machines 2022, 10, 536. [Google Scholar] [CrossRef]

- Liu, G.; Geng, X.; Liu, L.; Wang, Y. Haptic based teleoperation with master-slave motion mapping and haptic rendering for space exploration. Chin. J. Aeronaut 2019, 32, 723–736. [Google Scholar] [CrossRef]

- Deng, H.; Gong, D.; Yu, J.; Zuo, G. Research on Intuitive Tele-operation Motion Mapping Algorithm for Omnidirectional Mobile Heterogeneous Slave Arm System. In Proceedings of the 2020 10th Institute of Electrical and Electronics Engineers International Conference on Cyber Technology in Automation, Control, and Intelligent Systems (CYBER), Xi’an, China, 10–14 October 2020; pp. 67–72. [Google Scholar]

- Li, Z.; Zhang, E.; Zhai, B.; Li, B. Master-Slave Arm Heterogeneous Mapping With Link Pose Constraint in Teleoperation System. IEEE Access 2022, 10, 107202–107213. [Google Scholar] [CrossRef]

- Gong, D.; Wang, Y.; Yu, J.; Zuo, G. Motion mapping from a human arm to a heterogeneous excavator-like robotic arm for intuitive teleoperation. In Proceedings of the 2019 IEEE International Conference on Real-time Computing and Robotics (RCAR), Irkutsk, Russia, 4–9 August 2019; pp. 493–498. [Google Scholar]

- Yan, Y.; Jiang, W.; Zou, D.; Quan, W.; Li, H.J.; Lei, Y.; Zhou, Z.f. Research on mechanism configuration and coordinated control for power distribution network live working robot. Ind. Robot. Int. J. Robot. Res. Appl. 2020, 47, 453–462. [Google Scholar] [CrossRef]

- Wu, W.; Zhou, H.; Guo, Y.; Wu, Y.; Guo, J. Peg-in-hole assembly in live-line maintenance based on generative mapping and searching network. Robot. Auton. Syst. 2021, 143, 103797. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, W. Autonomous Live-Line Maintenance Robot for a 10 kV Overhead Line. IEEE Access 2021, 9, 61819–61831. [Google Scholar] [CrossRef]

- Islam, S.; Liu, P.X.; El Saddik, A.; Yang, Y.B. Bilateral Control of Teleoperation Systems With Time Delay. IEEE/ASME Trans. Mechatron. 2015, 20, 1–12. [Google Scholar] [CrossRef]

- Bong, J.H.; Choi, S.; Hong, J.; Park, S. Force feedback haptic interface for bilateral teleoperation of robot manipulation. Microsyst. Technol. 2022, 28, 2381–2392. [Google Scholar] [CrossRef]

- Liu, Y.-C. Task-space bilateral teleoperation systems for heterogeneous robots with time-varying delays. Robotica 2015, 33, 2065–2082. [Google Scholar] [CrossRef]

- Kim, Y.B.; Seok, D.-Y.; Lee, S.Y.; Kim, J.; Kang, G.; Kim, U.; Choi, H.R. 6-Axis Force/Torque Sensor With a Novel Autonomous Weight Compensating Capability for Robotic Applications. IEEE Robot. Autom. Lett. 2020, 5, 6686–6693. [Google Scholar] [CrossRef]

- Johansen, T.A.; Zolich, A.; Hansen, T.; Sorensen, A.J. Unmanned aerial vehicle as communication relay for autonomous underwater vehicle—Field tests. In Proceedings of the 2014 IEEE Globecom Workshops (GC Wkshps), Austin, TX, USA, 8–12 December 2014. [Google Scholar]

- Ott, C.; Mukherjee, R.; Nakamura, Y. Unified Impedance and Admittance Control. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010. [Google Scholar]

- Michel, Y.; Rahal, R.; Pacchierotti, C.; Giordano, P.R.; Lee, D. Bilateral Teleoperation With Adaptive Impedance Control for Contact Tasks. IEEE Robot. Autom. Lett. 2021, 6, 5429–5436. [Google Scholar] [CrossRef]

| 2.7014 | −2.8861 | 6.2768 | 0.0357 | −0.2755 | −0.0141 |

| 0.0007 | 0.0005 | 0.0553 | −0.0858 | 0.0313 | −10.9563 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Wang, Y.; Tang, X.; Wu, K.; Wu, S.; Guo, R.; Zhao, Y.; Dong, E. 6-DOF Bilateral Teleoperation Hybrid Control System for Power Distribution Live-Line Operation Robot. Machines 2023, 11, 2. https://doi.org/10.3390/machines11010002

Chen Y, Wang Y, Tang X, Wu K, Wu S, Guo R, Zhao Y, Dong E. 6-DOF Bilateral Teleoperation Hybrid Control System for Power Distribution Live-Line Operation Robot. Machines. 2023; 11(1):2. https://doi.org/10.3390/machines11010002

Chicago/Turabian StyleChen, Yutao, Yahao Wang, Xuming Tang, Kai Wu, Shaolei Wu, Rui Guo, Yuliang Zhao, and Erbao Dong. 2023. "6-DOF Bilateral Teleoperation Hybrid Control System for Power Distribution Live-Line Operation Robot" Machines 11, no. 1: 2. https://doi.org/10.3390/machines11010002

APA StyleChen, Y., Wang, Y., Tang, X., Wu, K., Wu, S., Guo, R., Zhao, Y., & Dong, E. (2023). 6-DOF Bilateral Teleoperation Hybrid Control System for Power Distribution Live-Line Operation Robot. Machines, 11(1), 2. https://doi.org/10.3390/machines11010002